Abstract

The spirocyclic part consisting of an α-acylated tetronic acid and a multisubstituted cyclohexene embedded in versipelostatin, a novel GRP78/Bip molecular chaperone downregulator, has been synthesized in enantiomerically pure form. The asymmetric synthesis of the targeted spiro[4.5]-1-oxa-7-decen-2,4-dione derivative was characterized by (1) stereoselective allylation at the α-carbon of methylmalonate diester, in which one carboxylic acid was esterified with a D-glucose-derived chiral template, (2) construction of the tetrasubstituted cyclohexenone substructure by high-yielding ring-closing metathesis and (3) stereoselective construction of the spirocyclic tetronic acid part starting from the cyclohexenone obtained as the ring-closing metathesis product.

Similar content being viewed by others

Introduction

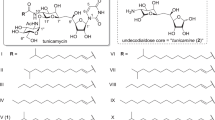

In 2002, Shin-ya et al.1 reported the isolation and structural elucidation of a macrocyclic compound of microbial origin designated as versipelostatin (1) (Figure 1). Compound 1 was isolated from the culture broth of Streptomyces versipellis 4083-SVS6 as a novel GRP78 molecular chaperone downregulator. The protein GRP78 acts as a molecular chaperone in endoplasmic reticulum (ER) by associating transiently with incipient proteins as they traverse the ER and aiding in their folding and transport. GRP78 is induced under various kind of stresses such as glucose starvation, inhibition of protein glycosylation triggered by tunicamycin, perturbation of ER function and protein movement triggered by brefeldin A and so on. The enhancement of ER stress response causes an increase in gene expression of a number of ER chaperones, thus compounds that directly down- and upregulate grp78 transcription are expected to be promising candidates as cancer chemotherapeutic agents. The structure of 1 was elucidated based on extensive NMR analyses, such as DQF-COSY and HMBC techniques. As a result, the structure of 1 was determined to consist of a novel 17-membered carbocyclic aglycon and a trisaccharide unit.2 Later, the relative and absolute stereochemistries of the aglycon in 1 were fully determined as shown in Figure 1, including an α-acylated tetronic acid that shared a spiro[5.4]-1-oxa-7-decen-2,4-dione structure with a tetrasubstituted cyclohexene.3 The cyclohexene part includes an all-carbon asymmetric quaternary carbon as C24.(Numbering of the skeletal carbon in versipelostatin is accordant with that used in reference 1.) The tetronic acid part is connected with a highly functionalized trans-fused octahydronaphthalenone (C4-C13) through a carbonyl carbon (C3). The whole 17-membered macrocyclic structure of the aglycon is formed by connecting both the spirocyclic cyclohexene and the octahydronaphthalenone parts through a 10-carbon tether (C14-C23). The C14-C23 chain, which is considered to be a polyketide array, includes an E-trisubstituted olefin and four stereogenic centers. The biosynthetic studies of 1 were also reported by Shin-ya et al.,4 which were executed by means of feeding experiments using 13C-labeled precursors such as [1-13C]acetate, [3-13C]propionate, [1-13C]butyrate and [1,2,3-13C]glycerol. Regarding the trisaccharide unit, the early papers from the Shin-ya group reported an incorrect structure for the trisaccharide unit as a β-D-digitoxosyl-(1,4)-α-D-cymarosyl-(1,4)-β-D-digitoxose.1, 2, 3, 4 Furthermore, the absolute stereochemistry of the aglycon part was determined based on the structure of the trisaccharide unit.4 In 2006, Kunst and Kirschnig5 declared the synthesis of the proposed structure of the trisaccharide unit. Recently, Tanaka et al. have reported the synthesis of the trisaccharide unit in versipelostatin and revision of its structure.6 Though their synthetic work, the structure of the trisaccharide was revised to be a β-D-digitoxosyl-(1,4)-α-L-oleandrosyl-(1,4)-β-D- digitoxose as shown in Figure 1. Since the first report of versipelostatin (1) in 2002, the Shin-ya group has further investigated the secondary metabolites isolated from S. versipellis 4083-SVS56. As a result, they reported the isolation and characterization of a novel analog of 1, designated as versipelostatin F (2) as shown in Figure 1.7 Compound 2 is an analog regarding the trisaccharide unit. Furthermore, the Shin-ya group reported additional four differently glycosylated derivatives of versipelostatin, designated as versipelostatin B-E.8 All of these analogs inhibited the expression of GRP78 induced by 2-deoxyglucose. They also suggested that the structure of the deoxysugar parts such as α- or β-configured trisaccharides or disaccharides may have an important role in downregulating GRP78 expression. Besides the synthetic studies on the trisaccharide unit, the synthesis of the 17-membered aglycon has been an interest of some groups including ours. Recently, Katsuta et al. 9 reported their synthetic effort on the enantiospecific construction of the spirocyclic part. They used a cyclic monoterpene (R)-(+)-pulegone as a starting material. In their synthetic studies, after introduction of the spirocyclic tetronate, the cyclohexane ring of pulegone was functionalized via a somewhat lengthy route, providing the spirocyclic part of versipelostatin (1) in an unnatural enantiomeric form.

Figure 1

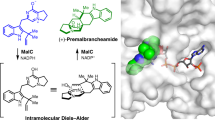

We have been involved for these several years in the total synthesis of versipelostatin (1) in natural form, especially in stereoselective synthesis of the aglycon of 1. Our grand design for synthesizing the aglycon A is shown in Figure 2. The properly protected aglycon A is divided into three segments B, C and D. These segments would be connected sequentially for constructing the 17-membered macrocyclic skeleton, through a cross metathesis between segments B and C, through a Julia–Kocienski olefination between segments C and D, and through an aldol-like bond-forming reaction between segments B and D. We have already developed stereoselective and scalable synthetic routes to segment C, a linear polyketide part (C15-C21)10 and to segment D, a highly functionalized octahydronaphthalene part (C3-C14),11 both with all the necessary stereogenic centers in correct stereochemistry. In this article, we report our synthetic efforts on efficient and enantioselective access to a compound corresponding to the spirocyclic part (segment B) sharing a tetronic acid and a highly functionalized cyclohexene. Our synthesis of the cyclohexene part of segment B was efficiently achieved though a highly stereoselective introduction of an all-carbon asymmetric quaternary center (C24) by stereoselective α-alkylation of a sugar-bound methylmalonate diester, and a ring-closing metathesis for constructing the (Z)-trisubstituted olefin (C25-C26).

Figure 2

Results and discussion

During these decades, some notable synthetic approaches toward functionalized tetronic acid and related compounds in the context of natural product synthesis have been published,12, 13, 14 and well reviewed.15 We selected spirocyclic compound 3 as a synthetic precursor of segment B. Our retrosynthetic approach to 3 is summarized in Scheme 1.16 The protected tetronic acid part in 3 would be accessible through the 1,4-addition of an oxygen nucleophile such as a methoxy anion to methylpropiolate 4, followed by transesterification (lactonization). The propiolate 4 could be obtained by a stereoselective addition of the acetylide derived from methyl propiolate to cyclohexenone 5. The 2,2,4,5-tetrasubstituted 3-cyclohexen-1-one 5 (C24-C29 in 1) would be obtained by the ring-closing metathesis of a 3,3,6,7-tetraalkylated 1,7-octadien-4-one 6, which in turn would be obtained by the Grignard coupling between aldehyde 7 and an organometallic species 8 followed by oxidation. For enantioselective synthesis of aldehyde 7, we envisioned the sugar-template-based introduction of the all-carbon asymmetric quaternary center in 7, which has been extensively developed in our group during the later half of 2000s. On the other hand, the Grignard reagent 8 would be readily accessible from commercially available methyl (R)-(–)-3-hydroxyisobutyrate (9) using a slight modification of known procedure.17 In the retrosynthetic plan, 7 would be obtainable from a 4-O-acylated D-glucopyranoside 10 by removal of the sugar moiety. In relation to this sugar derivative 10, we have developed a stereoselective quaternarization at the α-carbon of acetoacetates attached at C4 of methyl 6-deoxy-2,3-di-O-(tert-butyl)dimethylsilyl-α-D-glucopyranoside (12) or at C2 of methyl 6-deoxy-3,4-di-O-(tert-butyl)dimethylsilyl-α-D-glucopyranoside, both of which produced the corresponding α-methyl-α-allylacetoacetate highly stereoselectively.18, 19, 20 The sugar template 12, served as an efficient chiral auxiliary for asymmetric synthesis, is readily prepared in a multi-10-gram scale from methyl D-glucopyranoside,21 and its utility has been well recognized through a variety of diastereoselective carbon–carbon bond-forming reactions.22, 23, 24

With this synthetic design in mind, we embarked on the synthesis of 3. In Scheme 2, the stereoselective construction of an all-carbon asymmetric quaternary center corresponding to C24 in 3, which was achieved using the sugar-template 12, is summarized. Diethyl methylmalonate (13) was quantitatively hydrolyzed with KOH in EtOH provided 2-(ethoxycarbonyl)propionic acid (14).25 The attachment of monocarboxylic acid 14 to the chiral template 12 was achieved using dicyclohexylcarbodiimide as a dehydrating reagent, producing the 4-O-(2-ethoxycarbonyl)propionyl derivative 15 of 12, as an inseparable 1:1 diastereomeric mixture, quantitatively. For the quaternization at the α-carbon of the resulting diester 15, allyl bromide was used as an electrophile after deprotonation with NaOEt analogously to our previous reports.18, 19 As expected, the attack of allyl bromide to thus formed enolate proceeded with complete π-facial selectivity to produce the allylation product 11 as a single diastereomer in almost quantitative yield. The stereochemistry at the newly formed stereogenic center in 11 as shown was determined unambiguously by chemical transformation of 11 to an authentic specimen of our previously reported compound. (Compound 11 was converted into methyl 2,3-di-O-(tert-butyldimethylsilyl)-6-deoxy-4-O-((2R)-2-allyl-2-methyl-3-oxo-butanoyl)-α-D-glucopyranoside, compound 918, as follows: (1) Selective reduction of the ethoxycarbonyl moiety with diisobutyl aluminium hydride (Dibal-H) in toluene at −78 °C (80%); (2) tetrapropylammonium perruthenate (TPAP) oxidation of the resulting primary alcohol in the presence of N-methylmorpholine N-oxide (NMO) in CH2Cl2 and molecular sieves (MS) 4 Å (93%); (3) MeMgCl addition to the resulting aldehyde in Et2O at −78 °C (60%); (4) Dess–Martin oxidation of the resulting diastereomeric mixture of the addition products in the presence of NaHCO3 in CH2Cl2 (91%). Thus, obtained product was identical with the authentic sample in all spectral means.)

As shown in Scheme 3, ozonolysis of the vinyl group in 11 followed by reductive workup with Ph3P produced the formylmethyl derivative 16 in 90% yield. The aldehyde group in 16 was protected as a 1,3-dioxolan-2-yl form by treatment with ethylene glycol in the presence of TsOH·H2O in hot benzene. The thus obtained acetal 17 was reduced with Dibal-H and the resulting mixture of aldehyde 18 and the primary alcohol was oxidized without purification with TPAP in the presence of NMO to produce 18 in 88% yield for two steps. Wittig olefination of aldehyde 18 with methyltriphenylphosphonium bromide in the presence of n-BuLi at 0 °C provided the vinyl derivative 10. Removal of the sugar-template from 10 was best achieved by Dibal-H reduction at −18 °C, producing a neopentyl alcohol 19 in a good yield of 88%. The 3-O-silylated D-glucopyranoside 20 was also obtained in 96% yield. Under these reduction conditions, the tert-butyldimethylsilyl group at C2 in 12 was selectively removed. (Treatment of 20 with tert-buthyldimethylsilyl chloride (1.5 eq) in the presence of imidazole (3.0 eq) in DMF at room temperature (rt) for 15 h provided the sugar-template 12 selectively in 72% yield and 20 was recovered in 28% yield.)

For preparing the Grignard reagent 8 in Scheme 1, the corresponding alkyl bromide 22 was prepared as shown in Scheme 4. According to the reported procedure,17 (R)-(–)-Roche ester (9) was converted into tosylate 21 in an overall yield of 55%. Replacement of the tosyloxy group in 21 by a bromide anion provided the homoallyl bromide 22.

As shown in Scheme 5, the homoallylic alcohol 19 was converted into aldehyde 7 by Dess–Martin oxidation. The Grignard addition of the homoallylmagnesium bromide prepared from 22 to 7 produced the adduct 23 as an inseparable diastereomeric mixture (1:1) in 59% yield. The reduction product 19 was obtained in 36% yield as a result of hydride transfer from the Grignard reagent to the aldehyde 7. Despite searching more efficient Grignard reaction conditions, we could not find the reliable conditions for avoiding this reduction reaction. The diastereomeric mixture 23 was then oxidized smoothly to ketone 6 by Dess–Martin oxidation. The ring-closing metathesis of dienone 6 proceeded smoothly using 5 mol% of the Grubbs second-generation catalyst 2426 in toluene at 80 °C for 19 h to produce a tetrasubstituted 3-cyclohexen-1-one 5 in 90% yield. (The use of the Grubbs first-generation catalyst in toluene at 80 °C did not promote the ring-closing metathesis reaction, and 6 was recovered quantitatively.)

In Scheme 6, our approach to the spirocyclic segment B precursor 3 is depicted. According to some precedent reports,12, 27 we explored first the reaction between cyclohexenone 5 and methyl trans-3-methoxyacrylate for a one-step access to 3 using lithium diisopropylamide as the base at –78 °C in tetrahydrofuran (THF) in the absence or presence of CeCl3. Both cases resulted in complete recovery of 5. Next, the addition of the lithium acetylide prepared from ethyl propiolate with n-BuLi in THF at –78 °C to 5 was examined. Fortunately, the addition product 4 was obtained stereoselectively in 86% yield. The stereochemistry at the newly introduced chiral center in 4 was ascertained by the NOE experiment of 25, obtained by hemihydrogenation of acetylenic ester 4 using Lindler catalyst followed by spontaneous lactonization occurred between the resulting ethyl cis-propenoate and the tertiary hydroxyl group. Consequently, the attack of the acetylide occurred exclusively from the less hindered Re-face of the carbonyl in 5. The expected 1,4-addition of a methoxide ion from NaOMe to the β-carbon of the propiolate 4 followed by lactonization did not occur at room temperature. Only the corresponding methyl propiolate was obtained as a result of transesterification. After some experimentation, we found eventually that treatment of 4 with NaOMe in MeOH for prolonged heating at 60 °C provided the desired spirocyclic tetranote 3 in a yield of 28%. Another isolable product was the β-methoxy-α,β-unsaturated ester 26, the 1,4-addition product with Z-configuration, which was obtained in 21% yield.

In summary, we have developed the stereoselective synthesis of 3 as a synthetic equivalent to the spirocyclic part in versipelostatin. Our approach to 3 is featured by (1) exclusive construction of the desired all-carbon quaternary center (C24) using our D-glucose-derived chiral-template approach; (2) convenient synthesis of tetrasubstituted cyclohexenone by a ring-closing olefin-metathesis approach and (3) spirocyclic formation via the 1,4-addion of a methoxide ion to the propiolate 4. We are seeking a more efficient access to 3 using 5 as an advanced intermediate.

Experimental procedure

General

Specific rotations were measured in a 100-mm cell. 1H NMR spectra were recorded at 300 or 500 MHz with tetramethylsilane as an internal standard. 13C NMR spectra were recorded at 125 MHz. High-resolution mass spectra (HRMS) were measured in electron ionization (EI) mode (70 eV). Thin-layer chromatography (TLC) was performed on Merck Kieselgel 60 F254 plates. The crude reaction mixtures and extracted materials were purified by column chromatography on Silica gel 60 (Merck, Darmstadt, Germany). Unless otherwise noted, the reactions were carried out at room temperature. Combined organic extracts were dried over anhydrous Na2SO4. The solvents were removed from the reaction mixture and the combined organic extracts by concentration under reduced pressure using an evaporator with bath at 35–45 °C.

2-(Ethoxycarbonyl)propanoic acid (14). To a cooled (0 °C), stirred solution of diethyl methylmalonate (13) (2.00 ml, 11.7 mmol) in EtOH (40 ml), KOH (789 mg, 14.1 mmol) was added. After being stirred at rt for 2 hours, the mixture was diluted with H2O (60 ml) and washed with hexane/THF (2:3, 100 ml). 1 M aqueous HCl (30 ml) was added to the aqueous layer. The mixture was extracted with CH2Cl2 (20 ml × 3). The combined extracts were dried and concentrated in vacuo to provide 1.70 g (100%) of 14 as a colorless oil, which was used in the next step without further purification: TLC Rf 0.50 (EtOAc/hexane, 3:1); 1H-NMR (300 MHz, CDCl3) δ 1.28 (t, 3H, J=7.1 Hz), 1.45 (d, 3H, J=7.4 Hz), 3.47 (q, 1H, J=7.4 Hz), 4.22 (q, 2H, J=7.1 Hz); 13C-NMR (125 MHz, CDCl3) δ 13.5, 14.0, 45.9, 61.7, 169.9, 175.8.

Methyl 2,3-di-O-(tert-butyldimethylsilyl)-6-deoxy-4-O-(2-(ethoxycarbonyl)propanoyl)-α- D -glucopyranoside (15). To a stirred solution of 12 (1.90 g, 4.67 mmol) in CH2Cl2 (38 ml), DMAP (57.1 mg, 0.467 mmol), a solution of 14 (818 mg, 5.60 mmol) in CH2Cl2 (10 ml) and dicyclohexylcarbodiimide (1.16 g, 5.60 mmol) were added. The mixture was stirred at rt for 15 h, and a solution of 14 (273 mg, 1.87 mmol) in CH2Cl2 (2.4 ml) and dicyclohexylcarbodiimide (387 mg, 1.87 mmol) were added. After being stirred at rt for 3 h, the mixture was diluted with H2O (80 ml) and extracted with CH2Cl2 (20 ml × 3). The combined extracts were dried and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:40) to provide 2.44 g (98% from 12) of 15 (ca. 1:1 diastereomeric mixture) as a colorless oil: TLC Rf 0.60 (EtOAc/hexane, 1:5); IR (neat) 2931, 1757 cm−1; 1H-NMR (300 MHz, CDCl3) δ 0.05 (s, 3H), 0.07 (s, 3H), 0.10 (s, 6H), 0.83 (s, 9H × 1/2), 0.86 (s, 9H × 1/2), 0.92 (s, 9H), 1.13 (d, 3H × 1/2, J=6.6 Hz), 1.18 (d, 3H × 1/2, J=6.6 Hz), 1.27 (t, 3H × 1/2, J=7.2 Hz), 1.28 (t, 3H × 1/2, J=7.2 Hz), 1.42 (d, 3H × 1/2, J=7.2 Hz), 1.46 (d, 3H × 1/2, J=7.2 Hz), 3.36 (s, 3H × 1/2), 3.37 (s, 3H × 1/2), 3.42–3.52 (m, 1H), 3.66 (dd, 1H, J=3.5, 8.9 Hz), 3.91 (t, 1H × 1/2, J=8.9 Hz), 3.92 (t, 1H × 1/2, J=8.9 Hz), 4.19 (q, 2H, J=7.2 Hz), 4.61 (d, 1H, J=3.5 Hz), 4.69 (dd, 1H × 1/2, J=6.0, 8.9 Hz), 4.72 (dd, 1H × 1/2, J=6.0, 8.9 Hz); 13C-NMR (125 MHz, CDCl3) δ −4.5 (3/2C), −4.4 (1/2C), −3.4, −3.0 (1/2C), −2.9 (1/2C), 13.6 (1/2C), 14.0 (1/2C), 14.0 (1/2C), 14.1 (1/2C), 17.4 (1/2C), 17.6 (1/2C), 17.8 (1/2C), 17.8 (1/2C), 18.4, 25.8 (3/2C), 25.9 (3/2C), 26.1 (3C), 46.3 (1/2C), 46.3 (1/2C), 55.0 (1/2C), 55.0 (1/2C), 61.3 (1/2C), 61.5 (1/2C), 65.3 (1/2C), 65.5 (1/2C), 71.6 (1/2C), 71.7 (1/2C), 74.4, 77.6 (1/2C), 77.6 (1/2C), 100.0, 169.0 (1/2C), 169.6 (1/2C), 169.7 (1/2C), 170.2 (1/2C); HRMS (EI) calculated for C21H41O8Si2 (M+−t-C4H9) m/z 477.2340, found 477.2349.

Methyl 2,3-di-O-(tert-butyldimethylsilyl)-6-deoxy-4-O-((2 R)-2-ethoxycarbonyl-2-methylpent-4-enoyl)-α- D -glucopyranoside (11). The following reaction was carried out under Ar. To a cooled (–78 °C) stirred solution of 15 (2.44 g, 4.56 mmol) in THF (49 ml), NaOEt (1.0 m in EtOH, 4.79 ml, 4.79 mmol) was added. The mixture was stirred at –78 °C for 15 min, and allyl bromide (0.711 ml, 8.22 mmol) was added. After being stirred at –78 °C for 30 min, the mixture was warmed to 0 °C and stirred for 17 h. The mixture was quenched with saturated aqueous NH4Cl (30 ml), diluted with EtOAc (50 ml) and washed with saturated aqueous NH4Cl (50 ml × 3). The organic layer was dried and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:50) to provide 2.44 g (96%) of 11 as a colorless oil: TLC Rf 0.68 (EtOAc/hexane, 1:5); [α]27D +48.2 (c 0.880, CHCl3); IR (neat) 2956, 1735 cm−1; 1H-NMR (300 MHz, CDCl3) δ 0.08 (s, 12H), 0.85 (s, 9H), 0.93 (s, 9H), 1.17 (d, 3H, J=6.2 Hz), 1.26 (t, 3H, J=7.2 Hz), 1.43 (s, 3H), 2.47 (dd, 1H, J=7.8, 13.7 Hz), 2.84 (dd, 1H, J=6.8, 13.7 Hz), 3.37 (s, 3H), 3.69 (dd, 1H, J=3.4, 8.1 Hz), 3.75 (qd, 1H, J=6.2, 9.7 Hz), 3.92 (t, 1H, J=8.1 Hz), 4.17 (q, 2H, J=7.2 Hz), 4.62 (d, 1H, J=3.4 Hz), 4.75 (dd, 1H, J=8.1, 9.7 Hz), 5.11 (d, 1H, J=11.3 Hz), 5.12 (d, 1H, J=15.6 Hz), 5.62-5.76 (m, 1H); 13C-NMR (125 MHz, CDCl3) δ −4.3, −4.3, −3.3, −2.8, 14.0, 17.8 (2C), 18.5, 20.3, 26.0 (3C), 26.2 (3C), 40.1, 54.0, 55.0, 61.4, 65.6, 71.9, 74.3, 78.5, 99.6, 119.3, 132.6, 171.1, 171.7; HRMS (EI) calculated for C24H45O8Si2 (M+−t-C4H9) m/z 517.2653, found 517.2631.

Methyl 2,3-di-O-(tert-butyldimethylsilyl)-6-deoxy-4-O-((2 R)-2-ethoxycarbonyl-2-formylmethylpropanoyl)-α- D -glucopyranoside (16). To a cooled (–78 °C) stirred solution of 11 (1.48 g, 2.60 mmol) in CH2Cl2 (30 ml), O3 was bubbled at –78 °C for 10 min and Ph3P (810 mg, 3.09 mmol) was added. After being stirred at 0 °C for 30 min, the mixture was warmed to rt, stirred for 1 h and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:40) to provide 1.33 g (90%) of 16 as a colorless oil: TLC Rf 0.50 (EtOAc/hexane, 1:5); [α]31D+55.2 (c 1.03, CHCl3); IR (neat) 2932, 1730 cm−1; 1H-NMR (300 MHz, CDCl3) δ 0.07 (s, 12H), 0.85 (s, 9H), 0.92 (s, 9H), 1.15 (d, 3H, J=6.2 Hz), 1.26 (t, 3H, J=7.1 Hz), 1.59 (s, 3H), 2.84 (dd, 1H, J=1.2, 17.5 Hz), 3.20 (dd, 1H, J=1.2, 17.5 Hz), 3.37 (s, 3H), 3.68 (dd, 1H, J=3.4, 8.0 Hz), 3.73 (qd, 1H, J=6.2, 9.8 Hz), 3.90 (t, 1H, J=8.0 Hz), 4.21 (q, 2H, J=7.1 Hz), 4.61 (d, 1H, J=3.4 Hz), 4.74 (dd, 1H, J=8.0, 9.8 Hz), 9.73 (t, 1H, J=1.2 Hz); 13C-NMR (125 MHz, CDCl3) δ −4.2 (2C), −3.3, −2.9, 13.9, 17.7, 17.8, 18.5, 21.4, 25.9 (3C), 26.2 (3C), 48.8, 51.4, 55.0, 62.0, 65.3, 71.9, 74.3, 79.2, 99.5, 170.3, 170.4, 198.2; HRMS (EI) calculated for C26H49O8Si2 (M+−OMe) m/z 545.2965, found 545.2966.

Methyl 2,3-di-O-(tert-butyldimethylsilyl)-6-deoxy-4-O-((2R)-2-(1,3-dioxolan-2-yl)methyl-2-(ethoxycarbonyl)propanoyl)-α- D -glucopyranoside (17). To a stirred solution of 16 (1.32 g, 2.30 mmol) in benzene (26 ml), (CH2OH)2 (0.191 ml, 3.40 mmol) and TsOH·H2O (131 mg, 0.69 mmol) were added. After being stirred at 70 °C for 3 h, the mixture was quenched with saturated aqueous NaHCO3 (30 ml) at 0 °C and extracted with CH2Cl2 (20 ml × 3). The combined extracts were dried and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:20) to provide 1.20 g (84%) of 17 as a colorless oil: TLC Rf 0.38 (EtOAc/hexane, 1:5); [α]28D +45.6 (c 1.03, CHCl3); IR (neat) 2932, 1732 cm−1; 1H-NMR (300 MHz, CDCl3) δ 0.08 (s, 12 H), 0.84 (s, 9H), 0.92 (s, 9H), 1.17 (d, 3H, J=6.3 Hz), 1.25 (t, 3H, J=7.1 Hz), 1.56 (s, 3H), 2.17 (dd, 1H, J=5.0, 14.4 Hz), 2.48 (dd, 1H, J=5.0, 14.4 Hz), 3.37 (s, 3H), 3.68 (dd, 1H, J=3.4, 8.2 Hz), 3.76–3.85 (m, 3H), 3.87–3.98 (m, 2H), 3.92 (t, 1H, J=8.2 Hz), 4.18 (q, 2H, J=7.1 Hz), 4.61 (d, 1H, J=3.4 Hz), 4.73 (dd, 1H, J=8.2, 9.7 Hz), 4.94 (t, 1H, J=5.0 Hz); 13C-NMR (125 MHz, CDCl3) δ −4.3, −4.2, −3.3, −2.9, 13.9, 17.8 (2C), 18.4, 20.6, 26.0 (3C), 26.2 (3C), 39.1, 52.3, 54.9, 61.5, 64.5, 64.8, 65.6, 71.8, 74.3, 78.7, 99.6, 101.9, 171.1, 171.5; HRMS (EI) calculated for C28H53O9Si2 (M+−OMe) m/z 589.3228, found 589.3217.

Methyl 2,3-di-O-(tert-butyldimethylsilyl)-6-deoxy-4-O-((2R)-2-(1,3-dioxolan-2-yl)methyl-2-formylpropanoyl)-α- D -glucopyranoside (18). The following reaction was carried out under Ar. To a cooled (–78 °C) stirred solution of 17 (1.20 g, 1.93 mmol) in toluene (24 ml), Dibal-H (1.01 M in toluene, 4.78 ml, 4.83 mmol)was added. After being stirred at –78 °C for 30 min, the mixture was quenched with H2O (15 ml) at –78 °C and diluted with aqueous solution (20 ml) of potassium sodium (+)-tartrate tetrahydrate (4.09 g) and warmed to rt. The mixture was stirred vigorously for 2 h, and the organic layer was separated. The aqueous layer was extracted with EtOAc (20 ml × 3). The combined extracts were dried and concentrated in vacuo to provide a crude product, which was used in the next step without further purification.

The following reaction was carried out under Ar. To a stirred solution of crude product obtained above in CH2Cl2 (60 ml), MS 4 Å powder (1.80 g) and N-methylmorpholine N-oxide (113 mg, 0.965 mmol) were added. The mixture was stirred at rt for 10 min and tetrapropylammonium perruthenate (34.0 mg, 0.097 mmol) was added. After being stirred at rt for 1 h, the mixture was filtered through a pad of Celite and washed with EtOAc. The combined filtrate and washings were concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:25) to provide 973 mg (88%) of 18 as a colorless oil: TLC Rf 0.50 (EtOAc/hexane, 1:4); [α]28D +39.0 (c 1.13, CHCl3); IR (neat) 2932, 1723 cm−1; 1H-NMR (300 MHz, CDCl3) δ 0.01 (s, 3H), 0.08 (s, 3H), 0.09 (s, 6H), 0.82 (s, 9H), 0.91 (s, 9H), 1.10 (d, 3H, J=6.3 Hz), 1.43 (s, 3H), 2.22 (dd, 1H, J=4.4, 14.4 Hz), 2.37 (dd, 1H, J=5.5, 14.4 Hz), 3.35 (s, 3H), 3.66 (dd, 1H, J=3.4, 8.4 Hz), 3.73 (dd, 1H, J=6.2, 9.8 Hz), 3.77–3.82 (m, 2H), 3.87–3.98 (m, 2H), 3.91 (t, 1H, J=8.4 Hz), 4.60 (d, 1H, J=3.4 Hz), 4.75 (dd, 1H, J=8.4, 9.8 Hz), 4.98 (dd, 1H, J=4.4, 5.5 Hz), 9.70 (s,1H); 13C-NMR (125 MHz, CDCl3) δ –4.3, –4.1, –3.2, –2.8, 17.8 (3C), 18.5, 25.9 (3C), 26.2 (3C), 38.5, 55.0, 55.7, 64.8, 64.9, 65.3, 71.8, 74.5, 78.6, 99.7, 101.3, 171.3, 198.4; HRMS (EI) calculated for C26H49O8Si2 (M+–OMe) m/z 545.2966, found 545.2974.

Methyl 2,3-di-O-(tert-butyldimethylsilyl)-6-deoxy-4-O-((2 R)-2-((1,3-dioxolan-2-yl)methyl)-2-methyl-3-butenoyl)-α- D -glucopyranoside (10). The following reaction was carried out under Ar. To a cooled (–78 °C) stirred solution of methyltriphenylphosphonium bromide (1.50 g, 4.20 mmol) in THF (50 ml), n-BuLi (2.69 M in hexane, 1.26 ml, 3.39 mmol) was added. After being stirred at –78 °C for 30 min, the mixture was warmed to 0 °C and a solution of 18 (967 mg, 1.68 mmol) in THF (8.0 ml) was added at 0 °C. After being stirred at 0 °C for 1 h, the mixture was quenched with saturated aqueous NH4Cl (30 ml) at 0 °C and extracted with EtOAc (20 ml × 3). The combined extracts were dried and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:30) to provide 842 mg (87%) of 10 as a colorless oil: TLC Rf 0.59 (EtOAc/hexane, 1:4); [α]26D +39.5 (c 1.07, CHCl3); IR (neat) 2932, 1730 cm−1; 1H-NMR (300 MHz, CDCl3) δ 0.03 (s, 3H), 0.08 (s, 3H), 0.10 (s, 6H), 0.82 (s, 9H), 0.92 (s, 9H), 1.10 (d, 3H, J=6.2 Hz), 1.41 (s, 3H), 2.05 (dd, 1H, J=5.6, 14.5 Hz), 2.20 (dd, 1H, J=3.8, 14.5 Hz), 3.37 (s, 3H), 3.67 (dd, 1H, J=3.4, 8.3 Hz), 3.73 (dd, 1H, J=6.2, 9.8 Hz), 3.73-3.83 (m, 2H), 3.89-3.98 (m, 2H), 3.91 (t, 1H, J=8.3 Hz), 4.61 (d, 1H, J=3.4 Hz), 4.71 (dd, 1H, J=8.3, 9.8 Hz), 4.84 (dd, 1H, J=3.8, 5.6 Hz), 5.17 (d, 1H, J=17.3 Hz), 5.19 (d, 1H, J=10.5 Hz), 6.03 (dd, 1H, J=10.5, 17.3 Hz); 13C-NMR (125 MHz, CDCl3) δ –4.3, –4.0, –3.3, –2.7, 17.8, 17.9, 18.5, 20.3, 26.0 (3C), 26.2 (3C), 42.2, 46.9, 54.9, 64.3, 64.7, 65.6, 71.9, 74.5, 77.8, 99.7, 102.2, 115.0, 140.5, 174.4; HRMS (EI) calculated for C27H51O7Si2 (M+–OMe) m/z 543.3173, found 543.3172.

(2R)-2-((1,3-dioxolan-2-yl)methyl)-2-methylbut-3-en-1-ol (19) and methyl 3-O-(tert-butyldimethylsilyl)-6-deoxy-α- D -glucopyranoside (20). The following reaction was carried out under Ar. To a cooled (–18 °C) stirred solution of 10 (842 mg, 1.46 mmol) in CH2Cl2 (17 ml), Dibal-H (1.02 M in toluene, 5.74 ml, 5.85 mmol) was added. After being stirred at rt for 45 min, the mixture was quenched with H2O (15 ml) at –18 °C and diluted with aqueous solution (25 ml) of potassium sodium (+)-tartrate tetrahydrate (4.96 g) and warmed to rt. The mixture was stirred vigorously for 2 h, and the organic layer was separated. The aqueous layer was extracted with EtOAc (15 ml × 3). The combined extracts were dried and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:15) to provide 221 mg (88%) of 19 and 413 mg of 20 (96%). Compound 19 was obtained as a colorless oil: TLC Rf 0.16 (EtOAc/hexane, 1:3); [α]27D –2.4 (c 1.14, CHCl3); IR (neat) 3485, 3018 cm−1; 1H-NMR (300 MHz, CDCl3) δ 1.07 (s, 3H), 1.77 (dd, 1H, J=4.8, 14.5 Hz), 1.82 (dd, 1H, J=4.8, 14.5 Hz), 3.41 (d, 1H, J=11.3 Hz), 3.49 (d, 1H, J=11.3 Hz), 3.82-3.86 (m, 2H), 3.96-4.00 (m, 2H), 4.92 (t, 1H, J=4.8 Hz), 5.06 (d, 1H, J=17.5 Hz), 5.10 (d, 1H, J=11.0 Hz), 5.83 (dd, 1H, J=11.0, 17.5 Hz); 13C-NMR (125 MHz, CDCl3) δ 22.2, 40.4, 41.2, 64.7, 64.8, 69.4, 102.5, 113.4, 143.9; HRMS (EI) calcd for C9H15O3 (M+–H) m/z 171.1021, found 171.1024. Compound 20 was obtained as a colorless oil: TLC Rf 0.29 (EtOAc/hexane, 1:3); 1H-NMR (300 MHz, CDCl3) δ 0.13 (s, 3H), 0.16 (s, 3H), 0.92 (s, 9H), 1.29 (d, 3H, J=6.3 Hz), 1.93 (d, 1H, J=9.3 Hz, −OH at C-2), 2.12 (d, 1H, J=2.5 Hz, −OH at C-4), 3.12 (dt, 1H, J=2.5, 9.0 Hz), 3.41 (s, 3H), 3.45 (dt, 1H, J=3.9, 9.3 Hz), 3.61 (t, 1H, J=9.0 Hz), 3.65 (qd, 1H, J=6.3, 9.0 Hz), 4.69 (d, 1H, J=3.9 Hz).

(3S)-2,3-dimethyl-4-(p-toluenesulfonyl)oxybut-1-ene (21). The following reaction was carried out under Ar. To a cooled (0 °C) stirred solution of MeMgCl (3.0 M in Et2O, 9.96 ml, 26.9 mmol) in Et2O (30 ml), a solution of methyl (R)-(–)-3-hydroxyisobutyrate (9) (0.90 ml, 8.15 mmol) in Et2O (4.5 ml) was slowly added. After being stirred at rt for 1.5 h, the mixture was quenched with aqueous 1 M HCl (60 ml) at 0 °C and the organic layer was separated. The aqueous layer was diluted with saturated aqueous NaHCO3 (100 ml) and extracted with EtOAc (20 ml × 15). The combined extracts were washed with saturated aqueous NaHCO3 (10 ml) and saturated aqueous NaCl (10 ml). The organic layer was dried and concentrated in vacuo to provide 966 mg of dimethylated tertiary alcohol, which was used in the next step without further purification: TLC Rf 0.45 (EtOAc/hexane, 2:1).

The following reaction was carried out under Ar. To a cooled (0 °C) stirred solution of the product obtained above (966 mg) in pyridine, (8 ml) TsCl (1.90 g, 9.97 mmol) was added. After being stirred at 0 °C for 15 h, the mixture was quenched with H2O (10 ml) at 0 °C and extracted with EtOAc (10 ml × 3). The combined extracts were washed with saturated aqueous KHSO4 (10 ml), saturated aqueous NaHCO3 (10 ml) and saturated brine (10 ml). The organic layer was dried and concentrated in vacuo to provide 2.06 g of monotosylate, which was used in the next step without further purification: TLC Rf 0.63 (EtOAc/hexane, 2:1); 1H-NMR (300 MHz, CDCl3) δ 0.95 (d, 3H, J=7.2 Hz), 1.11 (s, 3H), 1.18 (s, 3H), 1.81–1.87 (m, 1H), 2.44 (s, 3H), 3.91 (dd, 1H, J=7.8, 9.5 Hz), 4.23 (dd, 1H, J=4.4, 9.5 Hz), 7.34 (d, 2H, J=8.4 Hz), 7.79 (d, 2H, J=8.4 Hz).

The following reaction was carried out under Ar. To a stirred solution of monotosylate obtained above (2.06 g) in Et2O (60 ml), MsCl (1.29 ml, 16.7 mmol) was added. Then Et3N (15.8 ml, 113 mmol) was added slowly at 0 °C. After being stirred at rt for 15 h, the mixture was quenched with aqueous 1 M HCl (60 ml) at 0 °C and extracted with EtOAc (30 ml × 3). The combined extracts were washed with aqueous 1 M HCl (30 ml), saturated aqueous NaHCO3 (30 ml) and saturated brine (30 ml). The organic layer was dried and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:15) to provide 1.15 g (56% over three steps) of 21 as a colorless oil: TLC Rf 0.60 (EtOAc/hexane, 1:4); [α]27D+7.4 (c 0.910, CHCl3); IR (neat) 2974, 1649 cm−1; 1H-NMR (300 MHz, CDCl3) δ 1.02 (d, 3H, J=6.9 Hz), 1.62 (d, 3H, J=0.6 Hz), 2.47 (m, 1H), 2.45 (s, 3H), 3.86 (dd, 1H, J=7.1, 9.5 Hz), 3.99 (dd, 1H, J=6.6, 9.5 Hz), 4.69 (m, 1H), 4.78 (m, 1H), 7.34 (d, 2H, J=8.3 Hz), 7.78 (d, 2H, J=8.3 Hz); 13C-NMR (125 MHz, CDCl3) δ 15.9, 20.1, 21.6, 40.1, 73.1, 112.0, 127.9 (2C), 129.8 (2C), 133.1, 144.6, 144.9; HRMS (EI) calculated for C13H18O3S (M+) m/z 254.0977 found 254.0981.

(3S)-4-bromo-2,3-dimethylbut-1-ene (22). The following reaction was carried out under Ar. To a stirred solution of 21 (2.60 g, 10.2 mmol) in THF (26 ml) LiBr (3.55 g g, 40.8 mmol) was added. After being stirred under reflux for 3.5 h, the mixture was cooled to rt, diluted with Et2O (50 ml), and washed with saturated aqueous NH4Cl (80 ml × 3) and saturated brine (80 ml). The organic layer was dried and concentrated by distillation to provide 1.67 g of crude 22, which was used in the next step without further purification: TLC Rf 0.78 (EtOAc/hexane, 1:10); 1H-NMR (300 MHz, CDCl3) δ 1.17 (d, 3H, J=6.9 Hz), 1.72 (s, 3H), 2.50–2.57 (m, 1H), 3.33 (dd, 1H, J=7.4, 9.8 Hz), 3.44 (dd, 1H, J=6.2, 9.8 Hz), 4.78-4.79 (m, 1H), 4.84–4.86 (m, 1H).

(2R)-2-((1,3-dioxolan-2-yl)methyl)-2-methylbut-3-enal (7). To a cooled (0 °C) stirred solution of 19 (390 mg, 2.27 mmol) in CH2Cl2 (8 ml), NaHCO3 (572 mg, 6.81 mmol) and Dess–Martin periodinane (1.44 g, 3.41 mmol) were added. After being stirred at rt for 1 h, the mixture was quenched with saturated aqueous NaHCO3/20 wt% aqueous Na2S2O3 (1:1, 20 ml) at 0 °C and extracted with CH2Cl2 (10 ml × 3). The combined extracts were dried and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:15) to provide 370 mg (96%) of 7 as a colorless oil: TLC Rf 0.71 (EtOAc/hexane, 1:1); [α]26D +6.0 (c 0.990, CHCl3); IR (neat) 3020, 1727 cm−1; 1H-NMR (300 MHz, CDCl3) δ 1.26 (s, 3H), 1.99 (dd, 1H, J=4.5, 14.4 Hz), 2.06 (dd, 1H, J=5.5, 14.4 Hz), 3.78–3.83 (m, 2H), 3.92–3.96 (m, 2H), 4.91 (dd, 1H, J=4.5, 5.5 Hz), 5.16 (d, 1H, J=17.6 Hz), 5.27 (d, 1H, J=10.8 Hz), 5.83 (dd, 1H, J=10.8, 17.6 Hz), 9.38 (s, 1H); 13C-NMR (125 MHz, CDCl3) δ 18.7, 39.9, 50.7, 64.8, 64.9, 101.9, 116.7, 138.4, 201.5; HRMS (EI) calculated for C9H14O3 (M+) m/z 170.0943, found 170.0944.

1:1 mixture of (3R,4R and S,6R)-3-[(1,3-dioxolan-2-yl)methyl]-3,6,7-trimethylocta- 1,7-dien-4-ols (23). The following reaction was carried out under Ar. To magnesium turnings (372 mg, 10.2 mmol) soaked with THF (8 ml) were added 1,2-dibromoethane (131 μl, 1.53 mmol) and a solution of crude 22 obtained above (1.67 g) in THF (2 ml). The mixture was stirred under reflux for 1 h, and a solution of 7 (370 mg, 2.17 mmol) in THF (3 ml) was added. After being stirred at rt for 1 h, the mixture was quenched with saturated aqueous NH4Cl (20 ml) at 0 °C and extracted with EtOAc (10 ml × 3). The combined extracts were washed with saturated brine (10 ml), dried and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:20) to provide 326 mg (59%) of 23 as a ca. 1:1 diastereomeric mixture and 135 mg (36%) of 19. Compound 23 was obtained as a colorless oil: TLC Rf 0.24 (EtOAc/hexane, 1:4); [α]27D –6.5 (c 1.31, CHCl3); IR (neat) 3491, 2965 cm−1; 1H-NMR (500 MHz, CDCl3) δ 1.01 (d, 3H × 1/2, J=6.9 Hz), 1.02 (d, 3H × 1/2, J=6.9 Hz), 1.04 (s, 3H × 1/2), 1.06 (s, 3H × 1/2), 1.33-1.51 (m, 2H), 1.61 (s, 3H × 1/2), 1.68–1.77 (m, 1H), 1.71 (s, 3 H × 1/2), 1.83–1.94 (m, 1H), 2.33–2.39 (m, 1H × 1/2), 2.48–2.58 (m, 1H × 1/2), 3.28 (d, 1H × 1/2, J=10.5 Hz), 3.28 (d, 1H × 1/2, J=10.5 Hz), 3.80–3.90 (m, 2H), 3.93–4.10 (m, 2H), 4.67–4.69 (m, 1H), 4.73–4.74 (m, 1H), 4.90 (dd, 1H × 1/2, J=2.7, 6.7 Hz), 4.93 (dd, 1H × 1/2, J=4.0, 5.5 Hz), 5.03 (dd, 1H × 1/2, J=1.3, 17.5 Hz), 5.07 (dd, 1H × 1/2, J=1.2, 17.0 Hz), 5.12 (dd, 1H × 1/2, J=1.3, 10.9 Hz), 5.13 (dd, 1H × 1/2, J=1.2, 11.0 Hz), 5.85 (dd, 1H × 1/2, J=10.9, 17.5 Hz), 5.87 (dd, 1H × 1/2, J=11.0, 17.0 Hz); 13C-NMR (125 MHz, CDCl3) δ 18.1 (1/2C), 18.6 (1/2C), 18.7 (1/2C), 19.4 (1/2C), 19.9 (1/2C), 20.8 (1/2C), 36.1 (1/2C), 37.1 (1/2C), 38.0 (1/2C), 38.2 (1/2C), 41.3 (1/2C), 42.6 (1/2C), 43.1 (1/2C), 43.2 (1/2C), 64.4 (1/2C), 64.6 (1/2C), 64.8 (1/2C), 65.0 (1/2C), 74.4 (1/2C), 74.6 (1/2C), 102.5 (1/2C), 102.7 (1/2C), 108.7 (1/2C), 110.6 (1/2C), 113.8, 143.7 (1/2C), 143.8 (1/2C), 149.0 (1/2C), 151.7 (1/2C); HRMS (EI) calculated for C15H26O3 (M+) m/z 254.1882, found 254.1894.

(3R,6R)-3-[(1,3-dioxolan-2-yl)methyl]-3,6,7-trimethylocta-1,7-dien-4-one (6). To a cooled (0 °C), stirred solution of the mixture 23 (326 mg, 1.28 mmol) in CH2Cl2 (6.5 ml) were added NaHCO3 (323 mg, 3.84 mmol) and Dess–Martin periodinane (815 mg, 1.92 mmol). The mixture was stirred at rt for 1 h, and then quenched with 20% aqueous Na2S2O3 (15 ml). The mixture was stirred vigorously for 1 h, and extracted with CH2Cl2 (10 ml × 4). The combined extracts were dried and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:30) to provide 281 mg (87%) of 6 as a colorless oil: TLC Rf 0.59 (EtOAc/hexane, 1:4); [α]32D–33.7 (c 0.990, CHCl3); IR (neat) 2969, 1708 cm−1; 1H-NMR (300 MHz, CDCl3) δ 0.97 (d, 3H, J=6.9 Hz), 1.30 (s, 3H), 1.69 (s, 3H), 2.06 (d, 2H, J=4.9 Hz), 2.45 (dd, 1H, J=7.6, 17.3 Hz), 2.61 (dd, 1H, J=5.1, 17.3 Hz), 2.64–2.76 (m, 1H), 3.58–3.80 (m, 2H), 3.90-3.95 (m, 2H), 4.67 (s, 2H), 4.84 (t, 1H, J=4.9 Hz), 5.18 (d, 1H, J=17.5 Hz), 5.22 (d, 1H, J=10.5 Hz), 5.92 (dd, 1H, J=10.5, 17.5 Hz); 13C-NMR (125 MHz, CDCl3) δ 19.4, 20.3, 20.4, 35.6, 41.1, 43.4, 52.3, 64.5, 64.7, 102.3, 109.0, 115.3, 141.1, 149.7, 210.4; HRMS (EI) calculated for C15H24O3 (M+) m/z 252.1726, found 252.1729.

(2R,5R)-2-((1,3-dioxolan-2-yl)methyl)-2,4,5-trimethylcycohex-3-en-1-one (5). The following reaction was carried out under Ar. To a stirred solution of 6 (305 mg, 1.21 mmol) in degassed toluene (62 ml), Grubbs 2nd generation catalyst 24 (54 mg, 0.060 mmol) was added. After being stirred at 80 °C for 18 h, the mixture was cooled to rt and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:30) to provide 245 mg (90%) of 5 and 22 mg (7%) of recovered 6. Compound 5 was obtained as a colorless oil: TLC Rf 0.36 (EtOAc/hexane, 1:4); [α]26D +103.3 (c 1.00, CHCl3); IR (neat) 2965, 1714 cm−1; 1H-NMR (300 MHz, CDCl3) δ 1.07 (d, 3H, J=7.2 Hz), 1.14 (s, 3H), 1.73 (dd, 1H, J=4.1, 14.1 Hz), 1.77 (d, 3H, J=0.6 Hz), 2.16 (dd, 1H, J=6.0, 14.1 Hz), 2.31 (dd, 1H, J=5.0, 14.0 Hz), 2.45–2.56 (m, 1H), 2.73 (dd, 1H, J=6.4, 14.0 Hz), 3.73–3.79 (m, 2H), 3.87–3.94 (m, 2H), 4.84 (dd, 1H, J=4.1, 6.0 Hz), 5.25 (br s, 1H); 13C-NMR (125 MHz, CDCl3) δ 19.6, 21.3, 26.9, 36.2, 42.4, 44.4, 46.2, 64.4, 64.6, 102.4, 128.1, 137.5, 213.8; HRMS (EI) calculated for C13H20O3 (M+) m/z 224.1413, found 224.1414.

(1S,2R,5R)-2-((1,3-Dioxolan-2-yl)methyl)-1([2-(ethoxycarbonyl)ethynyl)-2,4,5-trimethylcyclohex-3-en-1-ol (4). The following reaction was carried out under Ar. To a cooled (–78 °C) stirred solution of ethyl propiolate (0.087 ml, 0.90 mmol) in THF (0.5 ml) n-BuLi (2.69 M in hexane, 0.34 ml, 0.92 mmol) was added. The mixture was stirred at –78 °C for 1 h, and a solution of 5 (27.6 mg, 0.123 mmol) in THF (1.3 ml) was added. After being stirred at –78 °C for 1.5 h, the mixture was quenched with saturated aqueous NH4Cl (5 ml) at –78 °C and extracted with EtOAc (5 ml × 3). The combined extracts were dried and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:20) to provide 34.1 mg (86%) of 4 as a colorless oil: TLC Rf 0.39 (EtOAc/hexane, 1:2); [α]25D +7.8 (c 1.07, CHCl3); IR (neat) 3437, 3020, 2233, 1707 cm−1; 1H-NMR (300 MHz, CDCl3) δ 1.07 (d, 3H, J=7.2 Hz), 1.29 (s, 3H), 1.30 (t, 3H, J=7.1 Hz), 1.67 (s, 3H), 1.83 (dd, 1H, J=8.7, 13.2 Hz), 1.85−1.90 (m, 2H), 2.07 (dd, 1H, J=6.6, 13.2 Hz), 2.35–2.40 (m, 1H), 3.35 (br s, 1H), 3.81–3.88 (m, 2H), 3.95–4.01 (m, 2H), 4.21 (q, 2H, J=7.1 Hz), 5.00 (dd, 1H, J=4.3, 5.4 Hz), 5.07 (s, 1H); 13C-NMR (125 MHz, CDCl3) δ 14.0, 19.2, 21.0, 23.8, 33.6, 41.1, 41.6, 42.2, 61.9, 64.6, 64.9, 73.7, 76.4, 89.8, 102.6, 128.4, 136.6, 153.6; HRMS (EI) calculated for C18H26O5 (M+) m/z 322.1780, found 322.1775.

(5R,6R,9R)-6-((1,3-dioxolan-2-yl)methyl)-6,8,9-trimethyl-1-oxaspiro[4.5]deca-3,7-dien-2-one (25). To a stirred solution of 4 (4.8 mg, 0.015 mmol) in EtOAc (1 ml), Lindlar catalyst (1.0 mg) under Ar was added, and then the atmosphere was replaced to H2. The mixture was stirred for 1.5 h under H2, filtered through a pad of Celite, and washed well with EtOAc. The combined filtrate and washings were concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:20) to provide 3.1 mg (74%) of 25 as a colorless oil: TLC Rf 0.52 (EtOAc/hexane, 1:2); IR (neat) 3020, 1755 cm−1; 1H-NMR (500 MHz, CDCl3) δ 0.90 (s, 3H), 1.09 (d, 3H, J=7.2 Hz), 1.66 (dd, 1H, J=6.3, 12.8 Hz), 1.71 (s, 3H), 1.93 (dd, 1H, J=6.3, 14.3 Hz), 1.99 (dd, 1H, J=4.0, 14.3 Hz), 2.15 (dd, 1H, J=10.6, 12.8 Hz), 2.19–2.25 (m, 1H), 3.78–3.86 (m, 2H), 3.92–3.98 (m, 2H), 5.00 (dd, 1H, J=4.0, 6.3 Hz), 5.29 (s, 1H), 6.05 (d, 1H, J=5.7 Hz), 7.46 (d, 1H, J=5.7 Hz); 13C-NMR (125 MHz, CDCl3) δ 19.5, 20.9, 22.1, 34.5, 38.3, 39.4, 43.0, 64.4, 64.7, 92.9, 102.8, 121.0, 128.6, 136.3, 159.5, 172.5; HRMS (EI) calculated for C16H22O4 (M+) m/z 278.1518, found 278.1513.

(5S,6R,9R)-6-((1,3-dioxolan-2-yl)methyl)-4-methoxy-6,8,9-trimethyl-1-oxaspiro[4.5]deca-3,7-dien-2-one (3) and (1S,2R,5R)-2-((1,3-dioxolan-2-yl)methyl)-1-((Z)-1-methoxy-2-(ethoxycarbonyl)ethenyl)-2,4,5-trimethylcyclohex-3-en-1-ol (26). The following reaction was carried out under Ar. To a stirred solution of 4 (34.6 mg, 0.107 mmol) and MS 3A powder (200 mg) in MeOH (1.0 ml) was added NaOMe (1.0 M in MeOH, 0.27 ml, 0.27 mmol). After being stirred at rt for 18 h, the mixture was warmed to 60 °C. The mixture was stirred at 60 °C for 16.5 h, quenched with saturated aqueous NH4Cl (5 ml) and extracted with EtOAc (5 ml × 3). The combined extracts were dried and concentrated in vacuo. The residue was purified by column chromatography on silica gel (EtOAc/hexane, 1:10) to provide 9.2 mg (28%) of 3 and 7.5 mg of 26 (21%). Compound 3 was obtained as a colorless oil: TLC Rf 0.17 (EtOAc/hexane, 1:2); [α]26D +11.1 (c 0.465, CHCl3); IR (neat) 3020, 1745, 1627 cm−1; 1H-NMR (500 MHz, CDCl3) δ 0.97 (s, 3H), 1.05 (d, 3H, J=6.9 Hz), 1.68 (s, 3H), 1.88 (dd, 1H, J=6.5, 14.0 Hz), 1.89 (dd, 1H, J=6.2, 14.3 Hz), 1.93 (dd, 1H, J=3.8, 14.3 Hz), 2.05 (dd, 1H, J=9.7, 14.0 Hz), 2.33-2.41 (m, 1H), 3.77–3.86 (m, 2H), 3.79 (s, 3H), 3.91-3.96 (m, 2H), 5.01 (s, 1H), 5.02 (dd, 1H, J=3.8, 6.2 Hz), 5.19 (s, 1H); 13C-NMR (125 MHz, CDCl3) δ 19.5, 21.0, 21.2, 32.6, 37.4, 39.1, 43.2, 59.2, 64.3, 64.7, 88.2, 89.1, 102.8, 126.9, 136.7, 171.8, 185.8; HRMS (EI) calculated for C17H24O5 (M+) m/z 308.1624, found 308.1633. Compound 26 was obtained as a colorless oil: TLC Rf 0.59 (EtOAc/hexane, 1:2); [α]21D +33.8 (c 0.575, CHCl3); IR (neat) 3462, 3020, 1708, 1626 cm−1; 1H-NMR (500 MHz, CDCl3) δ 0.99 (s, 3H), 1.11 (d, 3H, J=7.0 Hz), 1.61 (dd, 1H, J=4.6, 13.8 Hz), 1.70 (s, 3H), 1.74 (dd, 1H, J=3.2, 14.9 Hz), 2.00 (dd, 1H, J=6.0, 14.9 Hz), 2.22 (dd, 1H, J=7.3, 13.8 Hz), 2.25–2.30 (m, 1H), 3.34 (s, 1H), 3.68 (s, 3H), 3.80–3.89 (m, 2H), 3.91 (s, 3H), 3.95–4.00 (m, 2H), 4.99 (dd, 1H, J=3.2, 6.0 Hz), 5.17 (s, 1H), 5.60 (s, 1H); 13C-NMR (125 MHz, CDCl3) δ 20.5, 21.6, 25.7, 33.0, 38.8, 41.7, 42.6, 51.0, 62.4, 64.7, 64.8, 78.0, 95.8, 103.2, 128.1, 136.3, 166.2, 176.0; HRMS (EI) calculated for C18H27O6 (M+–H) m/z 339.1808, found 339.1810.

References

Park, H.-R., Furihata, K., Hayakawa, Y. & Shin-ya, K. Versipelostatin, a novel GRP78/Bip molecular chaperone down-regulator of microbial origin. Tetrahedron Lett. 43, 6941–6845 (2002).

Shin-ya, K., Park, H.-R., Chijiwa, S., Hayakawa, Y. & Furihata, K. Studies on the inhibitor of molecular chaperon GRP78 expression, versipelostatin Abstracts of papers of the 45th symposium on natural product chemistry, page 157, Kyoto (2003).

Park, H.-R., Chijiwa, S., Furihata, K., Hayakawa, Y. & Shin-ya, K. Relative and absolute configuration of versipelostatin, a down-regulator of molecular chaperone GRP78 expression. Org. Lett. 9, 1457–1460 (2007).

Chijiwa, S. et al. Biosynthetic studies of versipelostatin, a novel 17-membered α-tetronic acid involved macrocyclic compound isolated from Streptomyces versipellis. Tetrahedron Lett. 44, 5897–5900 (2003).

Kunst, E. & Kirschning, A. Total synthesis of the trisaccharide unit of the molecular chaperone down-regulator versipelostatin. Synthesis 2397–2403 (2006).

Tanaka, H. et al. Efficient synthesis of the deoxysugar part of versipelostatin by direct and stereoselective glycosylation and revision of the structure of the trisaccharide unit. Chem. Asian J. 4, 1114–1125 (2009).

Ueda, J., Chijiwa, S., Takagi, M. & Shin-ya, K. A novel versipelostatin analogue, versipelostatin F isolated from Streptomyces versipellis 4083-SVS6. J. Antibiot. 61, 752–755 (2008).

Zhao, P. et al. New glycosylated derivatives of versipelostatin, the GRP78/Bip molecular chaperone down-regulator, from Streptomyces versipellis 4083-SVS6. Org. Biomol. Chem. 7, 1454–1460 (2009).

Katsuta, R., Arai, K., Yajima, A. & Nukada, T. Synthetic study of versipelostatin A: synthesis of the spirotetronate unit starting from pulegone. Synlett 397–400 (2012).

Samejima, S., Takao, K. & Tadano, K. Synthetic studies on the upper segment of versipelostatin The 98th symposium on organic synthesis, Japan, paper O-3, Tokyo, 5 November (2010).

Sasaki, S., Ishii, M., Takao, K. & Tadano, K. Synthetic studies on the lower segment of vesipelostatin utilizing an intramolecular Diels–Alder reaction strategy The 10th Annual meeting of the Japanese association for the pursuit of new bioactive resources, Yokohama, 10 June (2011).

Matsuda, K., Nomura, K. & Yoshii, E. Synthesis of the chiral upper fragment of tetronolide. J. Chem. Soc., Chem. Commun. 221–223 (1989).

Trullinger, T. K., Qi, J. & Roush, W. R. Studies on the synthesis of quartromicins A3 and D3: synthesis of the vertical and horizontal bis-spirotetronate fragments. J. Org. Chem. 71, 6915–6922 (2006).

Boeckman, R. K. et al. Toward the development of a general chiral auxiliary, a total synthesis of (+)-tetronolide via a tandem ketene-trapping [4+2] cycloadditon strategy. J. Am. Chem. Soc 128, 10572–10588 (2006).

Zografos, A. L. & Georgiadis, D. Synthetic strategies towards naturally occurring tetronic acids. Synthesis 3157–3188 (2009).

Anzai, K. et al. Synthetic studies of versipelostatin The 102nd symposium on organic synthesis, Japan, paper O-2, Tokyo, 8 November (2012).

Beszant, S., Giannini, E., Zanoni, G. & Vidari, G. Electrophilic cyclization of 1,6-dienes containing an allylsilane moiety – Enantioselective synthesis of cis- and trans-γ-irone. Eur. J. Org. Chem 3958–3968 (2003).

Kozawa, I. et al. Stereoselective double alkylation of the acetoacetate ester α-carbon on a D-glucose-derived template: application to the synthesis of enantiopure cycloalkenones bearing an asymmetric quaternary carbon. Synlett 399–402 (2007).

Kubo, H., Kozawa, I., Takao, K. & Tadano, K. Stereoselective synthesis of highly enantioenriched 3-methyl-2-cyclohexen-1-ones possessing an asymmetric quaternary carbon as C4 or C-6: a sugar template approach. Tetrahedron Lett. 49, 1203–1207 (2008).

Akashi, Y., Takao, K. & Tadano, K. Stereoselective α-alkylation of methyl 6-deoxy-3,4-di-O-(tert-butyldimethylsilyl)-2-O-(2-methyl-3-oxobutanoyl)-α-D-glucopyranoside. Tetrahedron Lett. 50, 1139–1142 (2009).

Munakata, R., Totani, K., Takao, K. & Tadano, K. Highly stereoselective Lewis acid mediated conjugate radical additions to methyl α-D-glucopyranoside derivatives tethering an unsaturated ester moiety at C-4. Synlett 979–982 (2000).

Totani, K., Takao, K. & Tadano, K. Sugar as a tool for asymmetric synthesis: some effective approaches. Synlett 2066–2080 (2004).

Totani, K. & Tadano, K. in Glycoscience–Chemistry and Chemical Biology 2nd edn (eds Fraser-Reid B. O., Tatsuta K., Thiem J., ) pp. 1029–1075 Springer: Verlag, Berlin-Heidelberg, (2008).

Totani, K., Takao, K. & Tadano, K. Some stereoselective carbon-carbon bond-forming reactions realized by using sugar-derived chiral templates. J. Synth. Org. Chem., Jpn. 69, 1363–1374 (2011).

Marion, F. et al. Hydroxamates: relationships between structure and plasma stability. J. Med. Chem. 52, 6790–6802 (2009).

Scholl, M., Ding, S., Lee, C. W. & Grubbs, R. H. Synthesis and activity of a new generation of ruthenium-based olefin metathesis catalysts coordinated with 1,3-dimesityl-4,5-dihydroimidazol-2-ylidene ligands. Org. Lett. 1, 953–956 (1999).

Miyata, O. & Schmidt, R. β- and α-lithiation of methyl β-methoxyacrylate: Efficient synthesis of α,γ-substituted methyl tetronates—structure of aspertetronins and gregatins. Tetrahedron Lett. 23, 1793–1796 (1982).

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper is dedicated to Professor Kuniaki Tatsuta with respect and admiration for his achievement of the total syntheses of more than 100 natural products including important antibiotics.

Rights and permissions

About this article

Cite this article

Sasaki, S., Samejima, S., Uruga, T. et al. Synthetic studies of the spirocyclic cyclohexene part of versipelostatin, a novel GRP78/Bip molecular chaperone downregulator. J Antibiot 66, 147–154 (2013). https://doi.org/10.1038/ja.2012.124

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/ja.2012.124

Keywords

This article is cited by

-

GRP78 in lung cancer

Journal of Translational Medicine (2021)