Abstract

The key factors governing the single-phase or multi-phase structural change behaviors during the intercalation/deintercalation of guest ions have not been well studied and understood yet. Through systematic studies of orthorhombic Fe2(MoO4)3 electrode, two distinct guest ion occupation paths, namely discrete one for Li and pseudo-continuous one for Na, as well as their relationship with single-phase and two-phase modes for Na+ and Li+, respectively during the intercalation/deintercalation process have been demonstrated. For the first time, the direct atomic-scale observation of biphasic domains (discrete occupation) in partially lithiated Fe2(MoO4)3 and the one by one Na occupation (pseudo-continuous occupation) at 8d sites in partially sodiated Fe2(MoO4)3 are obtained during the discharge processes of Li/Fe2(MoO4)3 and Na/Fe2(MoO4)3 cells respectively. Our combined experimental and theoretical studies bring the new insights for the research and development of intercalation compounds as electrode materials for secondary batteries.

Similar content being viewed by others

Introduction

Intercalation compounds as energy storage materials have been extensively studied for secondary batteries1,2,3,4. All of these intercalation materials for the secondary batteries allow the guest ions to move in and out without significant damage of their host frameworks. The composition variations in intercalation compounds during the intercalation/deintercalation of guest ions are often accompanied by structural changes5,6. Most of intercalation compounds (Supplementary Table 1) fall into the single-phase solid solution mode7 or the two-phase transformation mode8 or three-phase separation mode9 as a result of the composition variations in the certain concentration range of guest ions. For example, the layered LixCoO2 (0.5 < x ≤ 0.75) deintercalates/intercalates Li+ via a single-phase process7,10, while the layered NaxCoO2 (0.5 ≤ x ≤ 1) shows various single-phase or two-phase domains depending on Na+ concentration11. The olivine-type LiFePO4 exhibits a two-phase transformation reaction (LiFePO4/FePO4) by undergoing a phase interface propagation based on steady-state results12 and some non-equilibrium single-phase solid solution processes as predicted by ab initio calculations13 and confirmed by in situ diffraction experiments14,15. The various phase transformation mechanisms of Li+ ions in LiFePO4/FePO4 are revealed to be dependent on the rate16. Understanding these structural change mechanisms during the intercalation/deintercalation process is very important for the development of high energy density and long cycle-life batteries. Here, through the systematic studies of an intercalation compound of Fe2(MoO4)3, we report the single-phase structural change behavior for Na+ intercalation/deintercalation, but two-phase reaction mode for Li+ intercalation/deintercalation. The framework structure remains unchanged in the entire concentration range of Na+ or Li+. More interestingly, such single-phase and two-phase reactions are closely related to the guest ion occupation paths during intercalation/deintercalation, as clearly demonstrated by the aberration-corrected scanning transmission electron microscopy (STEM) results. These results provide new insights into the origin of structural changes in the guest-host material systems.

Fe2(MoO4)3 is one of the most promising cathode materials for rechargeable lithium/sodium battery as an environment friendly energy storage material from the viewpoints of the inexpensive and non-toxic of iron. From X-ray diffraction studies, it is known that Fe2(MoO4)3 has two types of crystal structures: low temperature monoclinic structure and high temperature orthorhombic structure. Although there have been several reports on the monoclinic Fe2(MoO4)3 as the cathode materials for lithium (or sodium) battery, the Li+ (or Na+) intercalation/deintercalation mechanisms remain unclear or contradict with each other. For example, some of literatures17,18,19,20 indicated a two-phase reaction during the intercalation/deintercalation of both Na+ and Li+ into the monoclinic Fe2(MoO4)3, whereas single-phase solid solution reaction of NaxFe2(MoO4)3 (0 < x < 2) was also observed21. This may be due to the structural complex or thermodynamic unfavorableness of monoclinic Fe2(MoO4)3. In this work, orthorhombic Fe2(MoO4)3 was studied as the cathode material for lithium and sodium batteries. Its electrochemical properties and structural change behaviors during charge and discharge processes are investigated by synchrotron based X-ray diffraction (XRD), X-ray absorption spectroscopy (XAS), aberration-corrected scanning transmission electron microscopy (STEM) and first-principles thermodynamic calculations. The discrete Li occupation path and pseudo-continuous Na occupation path in Fe2(MO4)3 during intercalation/deintercalation process and their relationship with the two-phase and single-phase reactions are proposed.

Results

Electrochemical characterization

The intercalation/deintercalation behaviors of alkali (A = Li or Na) metal ions in the Fe2(MoO4)3 were examined in Li and Na cells in Fig. 1. As shown in Fig. 1a and b, the initial discharge capacity of 89.5 mAh g−1 can be obtained for both Li and Na cells at the current rate of C/20. This value corresponds to the intercalation number of 2.0 Li or Na per Fe2(MoO4)3 unit. The discharge/charge curves in the lithium cell (Fig. 1a) show a flat plateau at about 3.0 V vs. Li+/Li during the discharging process and a flat plateau at about 3.02 V vs. Li+/Li during the charging process in a large range. By contrast, the discharge/charge curves of Na/Fe2(MoO4)3 cell show a slope type in the voltage range of 2.5 to 2.7 V vs. Na+/Na in Fig. 1b. The capacity fades of Li/Fe2(MoO4)3 and Na/Fe2(MoO4)3 cells during the first 20 cycles are about 0.3% and 0.9% per cycle, respectively, indicating a better capacity retention of Li/Fe2(MoO4)3 cell than that of Na/Fe2(MoO4)3 cell. The discharge and charge curves of Li/Fe2(MoO4)3 cell at a current density of C/5 shown in Supplementary Fig. 1 indicates a good cyclic performance up to 400 cycles with a capacity fading less than 0.02% per cycle. The shapes of one pairs of cathodic peak and anodic peak in the cyclic voltammogram (CV) curves of Li/Fe2(MoO4)3 cell exhibit the feature of mirror-symmetry as shown in Fig. 1c. Such an appearance of the peak is related to the typical diffusion and reaction kinetics at around half-discharging and half-charging processes. For the CV curves of Na/Fe2(MoO4)3 cell, two couples of reduction/oxidation peaks at around 2.65/2.73 V and 2.54/2.62 V (Fig. 1d) are in good agreement with the discharge/charge curves.

Electrochemical performance of Fe2(MoO4)3 in lithium and sodium cells.

Galvanostatic discharge/charge curves of Fe2(MoO4)3 electrode under a current density of C/20 in (a) Li and (b) Na cells. Cyclic voltammogram curves of Fe2(MoO4)3 electrode in the initial three cycles at the scan rate of 0.01 mVs−1 in (c) lithium and (d) sodium cells.

Ex situ XRD patterns

To investigate the structural evolutions of Fe2(MoO4)3 during Li+ and Na+ intercalation/deintercalation, a series of synchrotron based XRD patterns were collected at different charge/discharge states. As shown in Fig. 2a for LixFe2(MoO4)3 (x = 0.0, 0.5, 1.0, 1.5 and 2.0) during the first discharge-charge cycle in a Li/Fe2(MoO4)3 cell. All diffraction peaks of the pristine and fully lithiated Fe2(MoO4)3 (after discharging to 2.5 V) can be well indexed to Fe2(MoO4)3 (JCPDS card No. 852278) and Li2Fe2(MoO4)3 (JCPDS card No. 841001) with the same orthorhombic structure, respectively. During the discharge process, the intensity of the major peaks (111), (211), (012), (021), (310), (212) and (231) representing Fe2(MoO4)3 decreased gradually and finally disappeared when the 2.5 V discharge limit was reached. At the meantime, a new Li2Fe2(MoO4)3 phase was formed as observed through the appearing and growing intensity of a new set of (111), (211), (012), (021), (310), (212) and (231) peaks at lower 2θ angles relative to those original ones. No peak shifts are observed for both Fe2(MoO4)3 and Li2Fe2(MoO4)3 phases in the entire discharge process. During the recharge process, the peak evolution is exactly in the opposite way to the discharge process. After the initial cycle, the Fe2(MoO4)3 phase can be fully recovered, indicating an excellent structural reversibility. The coexistence of both Fe2(MoO4)3 and Li2Fe2(MoO4)3 phases with changing ratio, demonstrates a typical two-phase reaction during the discharge and charge process in the lithium cell.

Fig. 2b shows the XRD patterns of NaxFe2(MoO4)3 (x = 0.0, 0.5, 1.0, 1.5 and 2.0) during the first discharge-charge cycle in a Na/Fe2(MoO4)3 cell. Interestingly, a completely different structural change behavior other than that in the lithium cell was observed. No new set of peaks, but only peak shifts were observed throughout the entire discharge/charge process. During the discharge process, major peaks (111), (211), (102), (021), (310), (212), (022), (130) and (231) all gradually moved toward lower 2θ angles with increasing x from 0.0 to 2.0 in NaxFe2(MoO4)3. During the recharge process, all of these peaks reversibly moved back to their original positions with decreasing x from 2.0 to 0.0. The reversible peak shifts are attributed to the continuous lattice expansion and contraction during the discharge and charge respectively. This result demonstrates a typical single-phase (solid-solution) reaction during the discharge and charge process in the sodium cell.

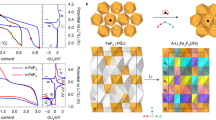

DFT simulations

It is quite interesting to note that the same Fe2(MoO4)3 orthorhombic structure shows such different structural change behaviors during Li+ and Na+ intercalation/deintercalation process. The crystal structure and thermodynamics of the orthorhombic Fe2(MoO4)3 during guest alkali ion insertion were further studied. As shown in Fig. 3a and b, the crystal structure of the orthorhombic Fe2(MoO4)3 with a space group of Pbcn is composed of MoO4 tetrahedra sharing all four corners with FeO6 octahedra and FeO6 octahedra sharing all six corners with MoO4 tetrahedra. Such an open three dimensional framework structure is suitable for guest (A = Li and Na) ions accommodation and diffusion. After the alkali ion intercalation, the crystal structure of Li2Fe2(MoO4)3 is isostructural to Na2Fe2(MoO4)3 based on ab initio calculations. A2Fe2(MoO4)3 (A = Li, Na) have the same orthorhombic structure as Fe2(MoO4)3. The eight A ions occupy the 8d tetrahedra interstitial sites in a unit cell. Their lattice parameters and unit cell volumes obtained from Le Bail fitting of the XRD patterns are listed in Supplementary Table 2. In order to understand the thermodynamic origin about the intercalation/deintercalation behaviors of A ions in the Fe2(MoO4)3, the formation energy (Ef) of AxFe2(MoO4)3 with respect to Fe2(MoO4)3 and A2Fe2(MoO4)3 via:

where three energy terms represent the total energies of per AxFe2(MoO4)3, Fe2(MoO4)3 and A2Fe2(MoO4)3 formula unit (f.u.), respectively. Here a completely random A/vacancy distribution at 8d site in AxFe2(MoO4)3 is given, the configurational entropy, Scon = kB[(x/2)ln(x/2) + (1 − x/2)ln(1 − x/2)], is included in the total energy of AxFe2(MoO4)3. To obtain the most energetically favorable configuration, all possible A occupancies were considered. There are 248 possibilities in all, namely,  , where

, where  (i = 0, 1, 2, 3, 4, 5, 6, 7, 8) stands for possible arrangements of different numbers of A in a unit cell (Z = 4). Only the calculated lowest formation energies of AxFe2(MoO4)3 at different x(x = i/Z) values are shown in Fig. 3c. It can be found that the single-phase solid solution of LixFe2(MoO4)3 is not thermodynamically favorable with the positive formation energies of 5~30 meV/f.u., which implies the phase separation of Fe2(MoO4)3 and Li2Fe2(MoO4)3. Conversely, NaxFe2(MoO4)3 exhibits the negative formation energies (−12~−40 meV/f.u.), which is representative of the single-phase solid solution instead of the two-phase separation. Dependences of calculated lattice parameters (a, b and c) on x in AxFe2(MoO4)3 are shown in Fig. 3d and e. Results indicate that the variation of the lattice parameters with x in LixFe2(MoO4)3 disobeys Vegard's law, thus invalidating the solid solution reaction for the lithium ion intercalation process. Nonetheless, the Vegard's law is true for the case of NaxFe2(MoO4)3, indicating the single phase solid solution reaction for the sodium ion intercalation process. This suggests that the first-principles thermodynamic calculations draw the identical conclusion as the ex situ XRD patterns in Figure 2.

(i = 0, 1, 2, 3, 4, 5, 6, 7, 8) stands for possible arrangements of different numbers of A in a unit cell (Z = 4). Only the calculated lowest formation energies of AxFe2(MoO4)3 at different x(x = i/Z) values are shown in Fig. 3c. It can be found that the single-phase solid solution of LixFe2(MoO4)3 is not thermodynamically favorable with the positive formation energies of 5~30 meV/f.u., which implies the phase separation of Fe2(MoO4)3 and Li2Fe2(MoO4)3. Conversely, NaxFe2(MoO4)3 exhibits the negative formation energies (−12~−40 meV/f.u.), which is representative of the single-phase solid solution instead of the two-phase separation. Dependences of calculated lattice parameters (a, b and c) on x in AxFe2(MoO4)3 are shown in Fig. 3d and e. Results indicate that the variation of the lattice parameters with x in LixFe2(MoO4)3 disobeys Vegard's law, thus invalidating the solid solution reaction for the lithium ion intercalation process. Nonetheless, the Vegard's law is true for the case of NaxFe2(MoO4)3, indicating the single phase solid solution reaction for the sodium ion intercalation process. This suggests that the first-principles thermodynamic calculations draw the identical conclusion as the ex situ XRD patterns in Figure 2.

Considering an interface between Li2Fe2(MoO4)3 and Fe2(MoO4)3 feasibly forms with the lithium ion intercalation into Fe2(MoO4)3 but no interface exists with the sodium ion intercalation into Fe2(MoO4)3, an A2Fe2(MoO4)3/Fe2(MoO4)3 interface parallel to (010) plane (Supplementary Fig. 2) was constructed and the interfacial energy was calculated22. The interfacial energy, γinterface, is defined as γinterface = (Ebulk − EA,contained − EA,free)/2S, where Ebulk is the total energy of the given interface supercell and EA,contained and EA,free are the total energies of the relaxed free A2Fe2(MoO4)3 and Fe2(MoO4)3 (010) surfaces. γinterface(Li) and γinterface(Na) were calculated to be −1.422 and −1.071 Jcm−2, respectively. It is very interesting to find that γinterface(Li) is more negative than γinterface(Na), indicating that Li2Fe2(MoO4)3/Fe2(MoO4)3 interface is more thermodynamically stable than Na2Fe2(MoO4)3/Fe2(MoO4)3 one. This result can be used for the explanation on the coexistence of two-phases and single-phase during the discharge processes of Li/Fe2(MoO4)3 and Na/Fe2(MoO4)3 cells, respectively.

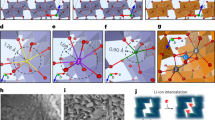

STEM imaging

To further confirm the two-phases and single-phase during the lithiation and sodiation processes of Fe2(MoO4)3, spherical aberration-corrected STEM were employed to obtain a direct observation at the atomic resolution. Considering the relative less structural stability of lithium-containing compound based on our own experience and reported works23. Here we decreased the probe current to about 20 pA and the pixel dwell time to 10 μs, to avoid the electron beam damage or phase transformation during STEM analysis. The schematic drawings for Fe2(MoO4)3 and Li2Fe2(MoO4)3 projected along the [001] direction have the ellipse-shaped unit constructions as shown in Fig. 4a. All annular-bright-field (ABF) images of partially lithiated Fe2(MoO4)3 at the 1/4, 1/2 and 3/4 discharge states were examined and the same two different regions could be observed in these ABF images. The typical ABF image of partially lithiated Fe2(MoO4)3 at the 1/2 discharge state is shown in Fig. 4b, in which one boundary is marked with a red dash line between regions 1 and 2. Unfortunately, lithium ions which are supposed to occupy both sides of the shoulder of ellipse cannot be obviously visualized because of the wide atomic number gap between Li and Mo. Therefore, line profiles (Fig. 4c) were acquired across two regions through the purple line in the ABF image (Fig. 4b) to confirm the lithium contrast with respect to oxygen. The corresponding purple lines in the Fe2(MoO4)3 and Li2Fe2(MoO4)3 unit structures are also shown in Fig. 4a. The Li and O positions are displayed as arrows in the line profile (Fig. 4c). The corresponding line profile shows two distinctly different periodic characteristics in these two regions. Region 1 shows the same featured line profiles as Li2Fe2(MoO4)3, in which O and Li can be well marked by red and black arrows, respectively (Fig. 4c) and four Li 8d sites occupy both sides of the shoulder of ellipse with symmetrical distribution close to four Mo 8d sites as shown in the unit structure of Li2Fe2(MoO4)3. In contrast, the line profiles in the region 2 are found to be the same as those of Fe2(MoO4)3 (Supplementary Fig. 3). After examining a group of line profiles (see Supplementary Fig. 4) in Fig. 4b, an interface of the two different phases can be marked with the red line in Fig. 4b. The coexistence of Li2Fe2(MoO4)3 and Fe2(MoO4)3 phases observed from the ABF image of the partially lithiated Fe2(MoO4)3 agrees very well with the XRD results in Fig. 2a.

STEM images of half lithiated Fe2(MoO4)3.

(a) Schematics of Fe2(MoO4)3 and Li2Fe2(MoO4)3 along the [001] projection. (b) ABF-STEM image of partially lithiated Fe2(MoO4)3 at the 1/2 discharge state. Atomic arrangements of Li2Fe2(MoO4)3 and Fe2(MoO4)3 are shown as the insets in the regions 1 and 2, respectively. (c) The corresponding ABF line profile acquired at the purples lines across the boundary (red dash lines) in (b). O sites and Li sites are marked by red and black arrows in the region 1 respectively and the O sites are marked by blue arrows in the region 2.

ABF images of partially sodiated Fe2(MoO4)3 at the 1/4, 1/2 and 3/4 discharged states were also carefully examined, but only one uniform region is found in all of these images. As shown in Fig. 5 a, b and c, the repeat unit can be clearly visualized (shown in the green ellipses) in these ABF images, which has the identical cage structure with Fe2(MoO4)3. In the ABF images of sodiated Fe2(MoO4)3 at the 1/4, 1/2 and 3/4 discharged states, four spots representing Mo 8d sites on the shoulder of ellipse do not exhibit the same blackness as that in the pristine Fe2(MoO4)3 (Supplementary Fig. 3). Therefore, some intriguing contrasts of four black spots representing Mo 8d sites on the shoulder of ellipse between the pristine and partially sodiated Fe2(MoO4)3 in ABF images could provide the information of Na occupancy in Fe2(MoO4)3. Interestingly, one spot marked by yellow circle on the green ellipse is the best blackness in four spots representing Mo 8d sites on the shoulder of ellipse at the 1/4 discharge states, in which other three dark spots were marked by white circles (Fig. 5a). According to the atomic occupancies of simulated ABF image of Na0.5Fe2(MoO4)3 in Fig. 5d based on the energetically most favorable configuration (Supplementary Fig. 5), one Na 8d site (shown as the red arrow in Fig. 5d) resides in the vicinity of the one of four Mo 8d sites on the shoulder of ellipse in the construction of Na0.5Fe2(MoO4)3, resulting in that one of four spots representing Mo 8d sites at every repeated unit structure exhibits more blackness than any other three spots. The Na columns as red dash lines with the periodicity and homogeneity can be clearly observed in the ABF image (Fig. 5a). After the depth of discharge to 1/2, two spots representing Mo 8d sites (yellow circles) on both sides of the shoulder of ellipses with asymmetric distribution are found to be blacker than other two spots (white circles) as shown in Fig. 5b, which perfectly coincides with simulated ABF image of NaFe2(MoO4)3 structure based on first principle calculations (Supplementary Fig. 5), in which two Na 8d site (shown as the red arrow in Fig. 5e) reside in the vicinity of the two of four Mo 8d sites with Na ordering on the shoulder of ellipse. When the Na/Fe2(MoO4)3 cell is discharged to 3/4 of the fully discharged state, the ABF image is different from one of any other ABF images for the pristine and partially sodiated Fe2(MoO4)3 at the 1/4 and 1/2 discharged states. In four spots representing Mo 8d sites on the shoulder of ellipse, three spots (yellow circles) are blacker than other one spot (white circles) in the Fig. 5c. They represent Na-occupied or Na-unoccupied in Na1.5Fe2(MoO4)3 structure based on first principle calculations (Supplementary Fig. 5) and the simulated ABF image (Fig. 5f). Na columns as red dash lines with the periodicity and homogeneity are also observed in all region of these images, indicating the feature of single domain. In the other word, ABF images at various discharge states not only characterize the solid solution mode of Na+ intercalation into Fe2(MoO4)3, but also provide the preferred occupancy patterns of Na+ in Fe2(MoO4)3 during the electrochemical intercalation process.

The STEM images of partially sodiated Fe2(MoO4)3.

(a) at the 1/4, (b) at the 1/2 and (c) at the 3/4 discharged states viewed along [001] projection and their corresponding simulated ABF images (d), (e) and (f). Repeated unit structures are labeled by green ellipse. The Na occupied sites are marked by yellow circles and the unoccupied sites are marked by white circles in (a), (b) and (c).

Discussion

The high resolution atomic images provide a direct evidence on the different atomic occupancies of Li and Na in Fe2(MoO4)3 from the repeating Fe2(MoO4)3 unit of ellipse along the [001] projection in the partially lithiated and sodiated Fe2(MoO4)3. The existence of biphasic domains and the lithium occupancy near four of the Mo 8d sites taking a discrete manor (all empty or all occupied) during the discharge process of Li/Fe2(MoO4)3 cell are confirmed. The new formed Li2Fe2(MoO4)3 phase is revealed with four Li 8d sites occupying both sides of ellipse configuration in symmetric distribution apart from the original Fe2(MoO4)3 phase. In contrast, the single-phase domains with various compositions were observed at the different discharge states of Na/Fe2(MoO4)3 cell. Four Na 8d vacancies in the ellipse configuration are occupied one by one during the discharge process. According to the structural characteristics of Fe2(MoO4)3, its unit of ellipse along the [001] projection can hold four A atoms distributed on both sides of ellipse configuration. The electrochemical intercalated Li ions capture all four sites simultaneously to form Li2Fe2(MoO4)3 at the different discharge states. This feature can be depicted as a “discrete-occupation” path (shown in Fig. 6) that defines that the Li occupation for the four available 8a sites is either all empty or all occupied, in forming the Li2Fe2(MoO4)3. The amount of Li2Fe2(MoO4)3 phase increases with increasing Li content at the expense of Fe2(MoO4)3 phase. In contrast, Na ion intercalation in Fe2(MoO4)3 can be described as a “pseudo-continuous-occupation” path, where Na ions progressively occupy four of the 8d sites in the ellipse unit of Fe2(MoO4)3 one after another. The holistic occupation of Na ions in Fe2(MoO4)3 results in the formation of a series of pseudo continued NaxFe2(MoO4)3 solid solutions in which x value increases from 0.0 to 2.0. Apparently, the different occupation behaviors of Li and Na ions in Fe2(MoO4)3 lead to two different structural change modes. Based on the ex situ XRD and electrochemical characterization results, the deintercalation of A ions from A2Fe2(MoO4)3 is reversible during the charge process.

Comparison between sodiation and lithiation process in Fe2(MoO4)3.

Schematic diagrams of “discrete occupation” and “pseudo-continuous occupation” during Li and Na ions intercalation into Fe2(MoO4)3. Solid red circles and dash green ellipses stand for Li+ (or Na+) and Fe2(MoO4)3 frameworks, respectively.

The single-phase and two-phase modes of Fe2(MoO4)3 with the intercalation/deintercalation of Li and Na ions are revealed on atomic-scale. The orthorhombic Fe2(MoO4)3 electrode is a quite interesting material for studying the key factors governing the solid-solution and two-phase reactions during the ion intercalation/deintercalation process. Based on the calculated lattice information in Supplementary Table 2, the unit-cell volume changes of Fe2(MoO4)3 after the full lithiation and sodiation are ca. 2.96% and 4.72%, respectively. These values are significantly smaller than that of the LiFePO4 (6.8%)8. In addition, the calculated diffusion constants of Li+ and Na+ are 3.45 × 10−8 and 4.94 × 10−11 cm2s−1, respectively (Supplementary Fig. 6 and Supplementary Table 3). The smaller volume change and faster ion diffusion in the Li/Fe2(MoO4)3 cell contribute to its better cycle performance as compared with that in the Na/Fe2(MoO4)3 cell. Thus, Fe2(MoO4)3 electrode is also a good example to bridge the understanding of the relationship between the electrochemical properties and the intercalation/deintercalation process.

In summary, the two-phase and single-phase mechanisms were revealed during the intercalation/deintercalation of Li and Na ions into Fe2(MoO4)3. The “discrete occupation” and “pseudo-continuous” were proposed to describe the distinctly different occupation paths of Li and Na ions into Fe2(MoO4)3. The first-principle thermodynamic calculations and direct atomic-scale observation by STEM provide further insight on the intercalation/deintercalation process. Most importantly, the discrete occupation path for Li and pseudo-continuous occupation path for Na and their relationship with two-phase reaction for Li and single-phase reaction for Na, respectively during the intercalation/deintercalation process in Fe2(MoO4)3 may very well be extended to the knowledge of other intercalation compounds. Noticeably, the present results were made at a relatively low rate of 1/20 C, which is close to the equilibrium state. The above mentioned intercalation/deintercalation reactions of of Li and Na ions into Fe2(MoO4)3 should be further investigated at the high rates which is far away from the equilibrium state in the future work. All in all, our experimental and theoretical studies could provide very valuable information for the research and development of intercalation compounds as electrode materials for secondary batteries.

Methods

Sample Preparation and Characterization

Orthorhombic Fe2(MoO4)3 microspheres were synthesized by a simple hydrothermal method24 using Fe(NO3)3·9H2O and Na2MoO4·2H2O as precursor. Scanning electron microscopy (SEM, Cambridge S-360) was employed to study the morphology and particle size of Fe2(MoO4)3 (Supplementary Fig. 7). Powder X-ray diffraction (XRD) patterns (Supplementary Fig. 8) were collected at beamline X14A of the National Synchrotron Light Source (NSLS) at Brookhaven National Laboratory using a linear position sensitive silicon detector. The wavelength used was 0.7747 Å. X-ray absorption spectroscopy (XAS) was performed at beamline X19A of the NSLS. Fe K-edge XAS was collected in transmission mode (Supplementary Fig. 9). The XAS data was processed using Athena25.

Electrochemical measurements

A slurry of 80 wt % Fe2(MoO4)3, 10 wt % carbon black and 10 wt % polyvinylidenefluoride (PVDF, Sigma-Aldrich) dispersed in N-methyl-2-pyrrolidone (NMP, Sigma-Aldrich) was prepared and cast on aluminum foil. The electrodes were dried at 120°C and were punched to small circular pieces of diameter of 14 mm. Electrochemical cells were assembled into coin cells in an Ar-filled glovebox (MBraun, Germany). Sodium pieces and lithium pieces were used as a counter electrode for sodium and lithium batteries, respectively. The electrolytes consisted of 1 M NaPF6 (Alfa-Aesar) and LiPF6 (Alfa-Aesar) in a nonaqueous solution of ethylene carbonate (EC, Alfa-Aesar) and dimethyl carbonate (DMC, Alfa-Aesar) with a volume ratio of 1:1. Galvanostatic discharge-charge measurements were carried out at room temperature with a Land CT 2001A battery test system. The current densities and capacities of electrodes were calculated based on the weight of active materials. On the basis of two electrons transfer in the Fe2(MoO4)3, 1C was calculated to correspond to about 91.00 mA g−1.

DFT simulations

All the first-principle total energy calculations were performed using a plane-wave basis set and the projector-augmented wave (PAW) method26 as implemented in the Vienna ab initio simulation package (VASP)27. Generalized gradient approximation (GGA) in the parametrization of Perdew, Burke and Ernzerhof (PBE)28 pseudopotential was used to describe the exchange−correlation potential and a Hubbard-type correction U was taken into account due to the strongly correlated nature of the Fe 3d electrons29. Referring to the DFT calculations on LiFePO4 and FePO4 materials, the effective U value was set to 4.3 eV30. A kinetic energy cutoff of 550 eV was used in all calculations. Geometry optimizations were performed by using a conjugate gradient minimization until all the forces acting on ions were less than 0.02 eV/Å per atom. (1 × 2 × 2) and (1 × 1 × 2) Monkhorst-Pack grids were used for the bulk and interface supercells. Activation energies for Na+ and Li+ ion diffusion in Fe2(MoO4)3 were calculated using the nudged-elastic-band (NEB) method31 using seven images and two endpoint structures, which is a reliable method to search the minimum-energy path (MEP) when the initial and final states are known. An interpolated chain of configurations (images) between the initial and final positions are connected by springs and relaxed simultaneously to the minimum-energy path. The structure diagrams were drawn by VESTA32.

STEM imaging

STEM samples were made by sonication of the discharged cathode films in anhydrous dimethyl carbonate inside an argon-filled glove box and sealed in airtight bottles before immediately transfer into the STEM column. A JEM-ARM200F STEM operated at 200 KV and equipped with double aberration-correctors for both probe-forming and imaging lenses was used to perform high-angle annular-dark-field (HAADF) and ABF imaging. The attainable spatial resolution of the microscope is 78 pm at the incident semi-angle of 25 mrad. To observe Li directly using ABF collection geometry, the acceptance semi-angle in this study was fixed between 12 and 25 mrad. The STEM ABF and HAADF images were taken simultaneously at the optimal defocus value of the HAADF imaging condition, which was more defocused than the optimal ABF imaging condition on this instrument. Thus, the contrast in the ABF image is reversed with the bright area corresponding to the atomic positions33.

References

Dunn, B., Kamath, H. & Tarascon, J. M. Electrical energy storage for the grid: A battery of choices. Science 334, 928–935 (2011).

Whittingham, S. M. Ultimate limits to intercalation reactions for lithium batteries. Chem. Rev. 114, 11414–11443 (2014).

Goodenough, J. B. & Kim, Y. Challenges for Rechargeable Li Batteries. Chem. Mater. 22, 587–603 (2010).

Yabuuchi, N., Kubota, K., Dahbi, M. & Komaba, S. Research development on sodium-ion batteries. Chem. Rev. 114, 11636–11682 (2014).

Meng, Y. S. & Arroyo-de Dompablo, M. E. Recent advances in first principles computational research of cathode materials for lithium-ion batteries. Accounts of Chemical Research. 46, 1171–1180 (2011).

Pan, H., Hu, Y. S. & Chen, L. Q. Room-temperature stationary sodium-ion batteries for large-scale electric energy storage. Energy Environ. Sci. 6, 2338–2360 (2013).

Mizushima, K., Jones, P. C., Wiseman, P. J. & Goodenough, J. B. LixCoO2 (0 < x ≤ 1): A new cathode material for batteries of high energy density. Mater. Res. Bull. 15, 783–789 (1980).

Padhi, A. K., Nanjundaswaswamy, K. S. & Goodenough, J. B. Phospho-olivines as positive-electrode materials for rechargeable lithium batteries. J. Electrochem. Soc. 144, 1188–1194 (1997).

Sun, Y. et al. Direct atomic-scale confirmation of three-phase storage mechanism in Li4Ti5O12 for room-temperature sodium-ion batteries. Nat. Commun. 4, 1870 (2013).

Reimers, J. N. & Dahn, J. R. Electrochemical and in situ X-Ray diffraction studies of lithium intercalation in LixCoO2 . J. Electrochem. Soc. 139, 2091–2097 (1992).

Berthelot, R., Carlier, D. & Delmas, C. Electrochemical investigation of the P2–NaxCoO2 phase diagram. Nat. Mater. 10, 74–80 (2011).

Delmas, C. et al. Lithium deintercalation in LiFePO4 nanoparticles via a domino-cascade model. Nat. Mater. 7, 665–671 (2008).

Malik, R., Zhou, F. & Ceder, G. Kinetics of non-equilibrium lithium incorporation in LiFePO4 . Nat. Mater. 10, 587–590 (2011).

Liu, H. et al. Capturing metastable structures during high-rate cycling of LiFePO4 nanoparticle electrodes. Science 344, 1480–1487 (2014).

Orikasa, Y. et al. Direct observation of a metastable crystal phase of LixFePO4 under electrochemical phase transition. J. Am. Chem. Soc. 135, 5497–5500 (2013).

Liu, Q. et al. Rate-dependent, Li-ion insertion/deinsertion behavior of LiFePO4 cathodes in commercial 18650 LiFePO4 cells. ACS Appl. Mater. Interfaces. 6, 3282–3289 (2014).

Manthiram, A. & Goodenough, J. B. Lithium insertion into Fe2(MoO4)3 frameworks: comparison of M = W with M = Mo. J. Solid State Chem. 71, 349–360 (1987).

Shirakawa, J., Nakayama, M., Wakihara, M. & Uchimoto, Y. Changes in electronic structure upon lithium insertion into Fe2(SO4)3 and Fe2(MoO4)3 investigated by X-ray absorption spectroscopy. J Phys. Chem. B 111, 1424–1430 (2007).

Sun, Q., Ren, Q. Q. & Fu, Z. W. NASICON-type Fe2(MoO4)3 thin film as cathode for rechargeable sodium ion battery. Electrochem. Commun. 23, 145–148 (2012).

Bruce, P. G. & Miln, G. Sodium intercalation into the defect garnets Fe2(MoO4)3 and Fe2(WO4)3 . J. Solid State Chem. 89, 162–166 (1990).

Nadiri, A., Delmas, C., Salmon, R. & Hagenmuller, P. Chemical and electrochemical alkali metal intercalation in the 3D-framework of Fe2(MoO4)3 . Rev. Chim. Miner. 21, 537–544 (1984).

Jung, J., Cho, M. & Zhou, M. Ab initio study of the fracture energy of LiFePO4/FePO4 interfaces. J. Power Sources 243, 706–714 (2013).

Liu, F., Markus, I. M., Doeff, M. M. & Xin, H. L. Chemical and structural stability of lithium-ion battery electrode materials under electron beam. Sci. Rep. 4, 5694 (2014).

Ding, Y., Yu, S. H., Liu, C. & Zang, Z. A. 3D architectures of iron molybdate: phase selective synthesis, growth mechanism and magnetic properties. Chem. Eur. J. 13, 746–753 (2007).

Newville, M. IFEFFIT: interactive XAFS analysis and FEFF fitting. J. Synchrotron Radiat. 8, 322–324 (2001).

Blochl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979(1994).

Kresse, G. & Furthmuller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3869 (1996).

Zhou, F., Maxisch, T. & Ceder, G. Configurational electronic entropy and phase diagram of mixed-valence oxides: the case of LixFePO4 . Phys. Rev. Lett. 97, 155704 (2006).

Zhou, F. et al. Phase separation in LixFePO4 induced by correlation effects. Phys. Rev. B 69, 201101 (2004).

Henkelman, G., Uberuaga, B. P. & Jonsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904(2000).

Momma, K. & Izumi, F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 44, 1272–1276 (2011).

Lee, S. et al. Reversible contrast in focus series of annular bright field images of a crystalline LiMn2O4 nanowire. Ultramicroscopy 125, 43–48 (2013).

Acknowledgements

This work was financially supported by the National Nature Science Foundation of China (Grant Nos. U1430104 and 51372228), 973 Program (Grant No. 2011CB933300) of China and Science& Technology Commission of Shanghai Municipality (Grant Nos. 08DZ2270500 and 11JC 1400500) and Shanghai Pujiang Program (Grant No. 14PJ1403900). The work at Brookhaven National Laboratory was supported by the U.S. Department of Energy, the Assistant Secretary for Energy Efficiency and Renewable Energy, Office of Vehicle Technologies under Contract No. DEAC02-98CH10886. Use of the National Synchrotron Light Source was supported by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences, under Contract No. DE-AC02-98CH10886. All the computations were performed on the high performance computing platform of Shanghai University.

Author information

Authors and Affiliations

Contributions

Z.-W.F. and S.-Q.S. planned the study and supervised all aspects of the research. J.-L.Y. and Z.-W.F. wrote the manuscript. J.-L.Y. and X.-Q.H. tested the electrochemical performance. J.-L.Y., J.L. and S.-Q.S. performed the DFT calculations. Y.-N.Z. and X.-Q.Y. performed the XRD and XAS measurements and analyzed the data. L.G. performed STEM observation and H.L., L.G., J.-L.Y., Z.S. and Z.-W.F. analyzed the STEM data. Z.-Z.Y. performed the STEM simulation. All the authors discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Yue, JL., Zhou, YN., Shi, SQ. et al. Discrete Li-occupation versus pseudo-continuous Na-occupation and their relationship with structural change behaviors in Fe2(MoO4)3. Sci Rep 5, 8810 (2015). https://doi.org/10.1038/srep08810

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep08810

This article is cited by

-

Temperature-dependent synthesis of SnO2 or Sn embedded in hollow porous carbon nanofibers toward customized lithium-ion batteries

Science China Materials (2023)

-

Disordered carbon coating free Li0.2375La0.5875TiO3: a superior perovskite anode material for high power long-life lithium-ion batteries

Journal of Materials Science (2022)

-

Low-temperature synthesis of Fe2(MoO4)3nanosheets: A cathode for sodium ion batteries with kinetics enhancement

Nano Research (2021)

-

Morphology-controlled synthesis and gas-sensing properties of Fe2(MoO4)3 microspheres

Journal of Materials Science: Materials in Electronics (2019)

-

Graphene oxide-decorated Fe2(MoO4)3 microflowers as a promising anode for lithium and sodium storage

Nano Research (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.