Abstract

Nanomaterials with particular nanostructures which usually possess special properties always attract considerable attention. A novel bimetallic Pt/Cu hexapod nanostructure was prepared by a facile one-pot strategy. The formation mechanism was investigated by the time sequential evolution experiments and the hexapod concave nanostructures originated from the Pt/Cu rhombic dodecahedron. Further electrochemical measurements indicated the bimetallic Pt/Cu hexapod concave nanocrystals showed enhanced catalytic activities. It is believed that these novel nanostuctures would open up new opportunities for catalytic applications.

Similar content being viewed by others

Introduction

Nanocrystals with special structures usually possess special properties. Nanomaterials with particular nanostructures such as hollow and concave structure emerge with superior optical, electronic and catalytic properties which attract considerable attention for the past few years1,2,3. Recently, the concave noble-metal nanocrystals with high-index facets and higher specific surface area are subject to intense concern due to their excellent performance in catalysis4,5,6,7,8. The concave noble-metal nanocrystals were prepared mainly through seed-mediated method and chemical etching process9,10. So far, it is still not easy to synthesize these concave nanocrystals . Exploiting new strategy for their facile and direct synthesis remains a challenge.

Platinum based nanomaterials, as one kind of important noble-metal catalysts, are of great interest because of their many applications in electrocatalysis, fuel cells and petrochemical industry11,12,13. Lately, noble-metal based bimetallic alloy and intermetallic nanocrystals receive comprehensive concern by the researchers14,15. Bimetallic alloy and intermetallic nanocrystals can effectively reduce the consumption of noble metal. Besides, introducing the non-noble metal usually enhances catalytic activity compared with the single component noble-metal nanomaterials. For example, in Xia' work, bimetallic PtPd could highly increase the oxygen reduction catalytic activity16. More recently, Yan and his co-workers reported that the as-prepared Pt-Cu concave nanocubes enclosed by several concave {hk0} high-index steps and facets showed superior electrocatalytic activity17. However, preparing concave bimetallic nanocrystals is still rarely reported by other researchers.

Herein, we exploited an effective one-pot strategy to synthesize single-crystalline bimetallic Pt/Cu nanocrystals with uniform concave nanostructures. Subsequently, this possible formation mechanism of the bimetallic concave nanocrystals was speculated upon batches of contrast experiments. The different influencing factors to the bimetallic concave nanocrystals were also discussed in this work. At last, the catalytic activity of as-prepared Pt/Cu concave nanocrystals was evaluated by methanol oxidation reaction in an electrochemical measurement system and compared with as-prepared solid Pt/Cu nanoparticles and commercial Pt black. It was found that the Pt/Cu concave nanocrystals exhibited best catalytic activity among the three kinds of catalysts. By using the facile one-pot synthesis method, the uniform bimetallic Pt/Cu concave nanocrystals were fabricated and showed superior catalytic activity.

Results

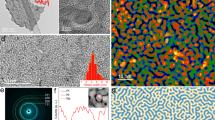

Bimetallic Pt/Cu concave nanocrystals were typically synthesized by stirring a mixture of octadecene (ODE), oleylamine (OAm), oleic acid (OA), [Pt(acac)2] (acac = acetylacetonate), [Cu(acac)2] and didodecyldimethyl-ammonium bromide (DDAB) at room temperature in air, heating it in a teflon-lined, stainless autoclave at 200°C for 2 h and allowing it to cool slowly to ambient temperature. The products were collected by filtration, washed with ethanol to remove any possible organic remnants and were then dissolved in cyclohexane. The representative electron microscopic images of the as-prepared bimetallic Pt/Cu concave nanocrystals were shown in Figure 1a and Figure S1. These nanocrystals were flower-like in shape with six arms, which is most like a hexapod concave nanostructure. The average diameter of these uniform Pt/Cu nanocrystals was ~18 nm. The further HRTEM image of Pt/Cu nanocrystals was shown in Figure 1b. The X-ray Diffraction pattern shown in Figure S2 illustrated that the as-obtained bimetallic Pt/Cu concave nanocrystals were indexed to Pt/Cu alloy whose peaks were near by the peaks of CuPt alloy compound. To further confirm the structure of the Pt/Cu hexapod concave nanocrystals, the high-angle annular dark-field scanning TEM (HAADF-STEM) image (Figure 1c) showed distinct hexapod nanostructures. The energy-dispersive X-ray spectroscopy (EDS) mapping profile shown in Figure 1d and 1e obviously indicated that bimetallic Pt/Cu nanocrystals contained both platinum and copper with homogenous distribution. The EDS results (Figure S3) also indicated the as-prepared Pt/Cu hexapod concave nanocrystals were bimetallic nanocrystals composed of both Platinum and Copper.

Nanostuctures observed by TEM, HRTEM and STEM.

(a), TEM image of Pt/Cu hexapod concave nanocrystals. (b), HRTEM image of Pt/Cu hexapod concave nanocrystals. (c), HAADF-STEM images of Pt/Cu hexapod concave nanocrystals. (d), EDS mapping of bimetallic Pt/Cu hexapod concave nanocrystals. (e), EDS mapping of bimetallic Pt/Cu hexapod concave nanocrystals.

A further detailed analysis by an FEI Titan 80–300 transmission electron microscope equipped with a spherical aberration (Cs) corrector for the objective lens was also shown in Figure 2. From these HRTEM images, it was obvious that these as-obtained Pt/Cu hexapod concave nanocrystals presented fine single crystalline nature. Continuous lattice fringes and the selected area fast Fourier transform (FFT) pattern displayed below the Figure 2a, b and c also showed that the single structure of Pt/Cu hexapod nanocrystals. Different TEM analysis results were observed from different crystal axis by tilting the TEM samples. In the Figure 2a, 2b and 2c, the images were the projection along the [111], [112] and [110] crystal axis, respectively. The relevant atomic models were also given as a schematic diagram. According to the HRTEM images and atomic models, more atomic steps and defects were found which indicated that the Pt/Cu hexapod concave nanocrystals could present good catalytic activity.

Discussion

Unlike some previous reports, these bimetallic Pt/Cu concave nanocrystals were directly synthesized through a one-pot strategy which did not need undergo complex process9. To investigate the formation mechanism of the bimetallic Pt/Cu concave nanocrystals, TEM and XRD data were collected at different stages during the reaction. The whole reaction lasted for 120 minutes and we collected samples at 80 minutes, 100 minutes and 120 minutes, respectively. The products collected at 80 minutes were shown in Figure 3a. The as-obtained Pt/Cu nanocrystals revealed distinct uniform rhombic dodecahedron in shape compared with the hexapod concave nanostructures. More details of the as-prepared Pt/Cu rhombic dodecahedron nanocrystals were shown in Figure S418,19,20,21. As the reaction proceeded, the products were collected at 100 minutes. From the Figure 3b and Figure S5, some as-collected Pt/Cu nanoparticles mainly kept the rhombic dodecahedron in shape as the samples collected at 80 minutes and some Pt/Cu nanoparticles became the polyhedral nanoparticles which even included some concave nanostructures. However, the surface of the Pt/Cu nanocaystals appeared some small holes through careful observation. At the end of the reaction, namely at 120 minutes, the TEM images in Figure 3c showed hexapod concave nanostructure totally different from the samples collected at 80 minutes and 100 minutes. The sketch diagrams of the three kinds of samples were shown in Figure 3d, f, h and the amplifying TEM images were shown in Figure 3e, g, i. According to the TEM analysis results, a possible formation mechanism proposed: the as-synthesized rhombic dodecahedron Pt/Cu nanocrystals were etched at the apex with three seamed edge and the crystal facets were further etched, then the remainder of the Pt/Cu rhombic dodecahedron showed the hexapod concave nanostructure. To further elucidate the mechanism involved in the formation of bimetallic Pt/Cu hexapod concave nanostructures, the XRD analysis was conducted. The XRD patterns collected at 80 minutes and 120 minutes were showed in Figure 3j. The diffraction peak positions for the products with rhombic dodecahedron shape were near the standard reference of Cu3Pt (JCPDS Card No.: 65-3247) and the diffraction peak positions for hexapod concave nanocrystals was near the standard reference of CuPt (JCPDS Card No.: 48-1549). The XRD patterns revealed that the structures and components of the samples were approximatively changed from Cu3Pt to CuPt, which implied the main result of copper reduction in this process. To further confirm these results, the ICP-AES analysis was carried out. The composition (Pt:Cu) of Pt/Cu nanocrystals collected at 100 minutes were 52.1:47.9 (mass ratio) and Pt/Cu nanocrystals collected at 120 minutes were 56.8:43.2 which indicated the tendency of decrease of copper. In Yan's previous work, the Pt/Cu concave nanocubes were also prepared by the one-pot hydrothermal synthesis. And they mentioned that the as-reduced Cu0 could be further oxidized by these [PtBr4]2− species and then dissolved into the solution17. As the reaction proceed, the Pt:Cu ratio increased which implied that the Pt was further reduced. Considering the DDAB added in the solution, the [PtBr4]2− species should also exist in this system. And the Cu0 reduced before were oxidized by the [PtBr4]2− species, which resulted in the decrease of the content of Cu in Pt/Cu alloy. After the fast etching process, the Cu and Pt reached the balance and form the final nanostructure and composition. According to the evolution TEM images, XRD patterns and ICP analysis, we further confirmed the proposed formation mechanism of the hexapod concave bimetallic Pt/Cu nanocrystals.

Time sequential evolution experiments of Pt/Cu nanostructures.

(a), (e), TEM images of Pt/Cu samples collected at 80 minutes. (b), (g), TEM images of Pt/Cu samples collected at 100 minutes. (c), (i), TEM images of Pt/Cu samples collected at 120 minutes. (e), (f), (h), sketch maps of Pt/Cu samples collected at 80 minutes, 100 minutes, 120 minutes. (j), XRD patterns of Pt/Cu rhpmbic dodecahedron and hexapod concave nanocrystals.

To further investigate the influencing factors for formation of the hexapod concave Pt/Cu nanostructure, some contrast experiments were conducted. Different samples were prepared by adjusting the amount of DDAB added in the reaction solution. The samples prepared without DDAB shown in Figure 4a exhibited polyhedral-like nanoparticles. While the samples prepared with three times DDAB shown in Figure 4b showed completely different shape which was hexagon with six short arms. The structure was more or less like the hexapod concave nanostructure. Further XRD analysis shown in Figure S6 indicated that the products prepared without DDAB contained more copper than the products prepared with three times DDAB. The ICP-AES analysis was also carried out to confirm the result. The composition (Pt:Cu) of Pt/Cu nanocrystals without DDAB were 44.5:55.5 and Pt/Cu nanocrystals with three times DDAB were 51.8:48.2. As the DDAB increased, the more [PtBr4]2− species oxidized copper atoms on the surface of the nanocrystals, which resulted in less copper in the Pt/Cu alloy17. From the above contrast experiments, we believed that the DDAB played a very important role in preparing the hexapod concave nanostructures. In Zheng and co-workers' work, the Br− was proposed as the key to form the concave nanostructures10. Some other bromide salts such as CTAB and TOAB were used to instead of DDAB, the as-prepared nanocrystals were shown in Figure S7 which did not show the hexapod concave nanostructure. The influence of OA was also investigated in this work. The TEM images shown in Figure S8 revealed these nanoparticles synthesized without OA agglomerated and possessed nonuniform sizes. When there was no DDAB nor OA in this synthetic system simultaneously, the samples shown in Figure S9 showed small nanoparticles without special shapes. To sum up, the formation process of the hexapod concave nanostructures was very complex which needed three kinds of surfactants at the same time. Here, the OAm was mainly employed as the reductant and surfactant22,23. The OA as a synergetic surfactant also played important role in this process.

Since the bimetallic Pt/Cu hexapod concave nanocrystals had special nanostructure, the enhanced catalytic properties were expected. The methanol oxidation reaction was evaluated in an electrochemical measurement system as the probe reaction. Commercial Pt black and Pt/Cu nanoparticles (See the Figure S10) were used as the comparison. The cyclic voltammetry (CV) curves were tested on a silver chloride electrode and current densities were normalized to the electrochemically active surface area (ECSA) estimated from hydrogen-adsorption desorption charges. The redundant surfactants of these as-prepared catalysts were removed by using the acetic acid for 12 hours24,25,26. From the TEM image shown in Figure S11, the as-prepared Pt/Cu hexapod concave nanocrystals were evenly dispersed on the active carbon without obvious change after acetic acid treatment. The ICP analysis indicated the composition (Pt:Cu) of Pt/Cu nanocrystals is 57.8:42.2 which is similar with the Pt/Cu hexapod nanocrystals (56.8:43.2) before the treatment. Figure 5a presented voltammetry curves of the catalysts in 0.5 M H2SO4. The current density in the hydrogen adsorption/desorption of the Pt/Cu hexapod concave nanocrystals were normalized to the electrochemically active surface area (ECSA) estimated from the hydrogen-adsorption desorption charges. To be specific, Pt/Cu hexapod concave nanocrystals had an ECSA of 45.8 m2 g−1 and it was higher than that of Pt/Cu nanocrystals with an ECSA of 36.5 m2 g−1 and Pt black with an ECSA of 41.9 m2 g−1. From the Figure 5b, it was obvious that the Pt/Cu hexapod concave nanocrystals had the best electrocatalytic activity which was almost 2.5 times than the commercial Pt black did. Forward peak current densities were in the order of elongated Pt Black < Pt/Cu NPs < Pt/Cu hexapod concave nanocrystals. And the mass activity (calculated in Pt) for the three catalysts were also shown in Figure S12 which indicated that the Pt/Cu hexapod concave nanocrystals possessed best catalytic activity. The result indicated that the catalytic activity of hexapod concave Pt/Cu nanocrystal was higher than the other two catalysts and was aslo higher than our previous Pt/Cu hollow nanocatalysts24. In Wang's work, the Pt nanocrystals with high-index facets and large density of atomic steps showed superior electro-oxidation activity27. According to HRTEM analysis, the as-prepared Pt/Cu hexapod concave nanocrystals with {112} facets which also belonged to the high-index facets. Besides, because of the hexapod concave nanostructures, the eletrocatalytic activity was promoted compared with the Pt/Cu nanoparticles. Moreover, the enhanced catalytic activity was also proposed to come out of the bimetallic composition17,24.

In summary, this work presented a successful synthesis of bimetallic Pt/Cu hexapod concave nanocrystals via a facile one-pot chemical reaction. Through the time sequential evolution experiments, the possible formation mechanism was investigated. The as-prepared hexapod concave nanostructures originated from uniform Pt/Cu nanocrystals with rhombic dodecahedron in shape through reduction process by the Cu0 reduced in advance. Further electrochemical measurements indicated the bimetallic Pt/Cu hexapod concave nanocrystals showed enhanced catalytic activities than the commercial Pt balck and Pt/Cu nanoparticles because of the special nanostructures. More studies are still required in order to investigate the novel nanostructures. The catalytic properties of the bimetallic Pt/Cu hexapod concave nanocrystals also need further study. It is believed that these novel nanostructures alloys would open up new opportunities for catalytic applications.

Methods

Chemicals

The reagents used in this work, including ethanol and cyclohexane were of analytical grade from the Beijing Chemical Factory of China, Cu(acac)2, Pt(acac)2, OAm, ODE, OA, CTAB, TOAB and DDAB were purchased from Alfa Aesar. All the reagents were used without further purification.

Synthesis

In a typical synthesis of bimetallic hexpod concave Pt/Cu nanoparticles, 0.025 mmol of Pt(acac)2 (acac = acetylacetonate) and 0.025 mmol of Cu(acac)2 were added into the solution with 5 ml of octadecene (ODE), 4 ml oleylamine (OAm) and 2.5 ml oleic acid(OA). Then, 0.025 mmol didodecyldimethyl-ammonium bromide (DDAB) was added into the as-prepared solution with vigorous stirring. After 15 minutes, the mixture was transferred to the teflon-lined, stainless autoclave. The reaction lasted for two hours at 200°C. Two hours later, the autoclave was taken out to cool down slowly at the ambient temperature. The products were collected and washed with ethanol several times. The as-obtained Pt/Cu hexapod concave nanocrystals were dispersed in 5 ml of cyclohexane.

Characterization

The powder XRD patterns were recorded with a Bruker D8-advance X-ray powder diffractometer with CuKα radiation (λ = 1.5406 Å). The composition of the product was measured by the inductively coupled plasma-mass spectrometry (ICP-MS). The size and morphology of as-synthesized samples were determined by using Hitachi model H-800 transmission electron microscope and JEOL-2010F high-resolution transmission electron microscope. High-resolution transmission electron microscopy observations were performed by using a FEI Titan 80–300 transmission electron microscope equipped with a spherical aberration (Cs) corrector for the objective lens.

Electrochemical studies

Electrochemical measurements were conducted in an electrochemical cell with a three-electrode configuration at room temperature. The Pt/Cu nanocrystals were mixed with the active carbon to prepare the catalysts. The weight loading of active carbon supported precursor catalyst was 20 wt%. The catalyst was prepared by ultrasonic processing of Pt/Cu nanocrystals and active carbon. Then, the samples were added with 20 mL of acetic acid and heated for 12 hours at 70°C. The catalysts were separated by centrifugation and re-dispersed in de-ionized water to form a 1 mg/mL suspension. All cyclic voltammograms were recorded after 500 potential cycles and no change in voltammetric features was observed before and after electrochemical characterization.

References

Yin, Y. D., Rioux, R. M., Erdonmez, C. K., Hughes, S., Somorjai, G. A. & Alivisatos, A. P. Formation of hollow nanocrystals through the nanoscale Kirkendall effect. Science, 304, 711–714 (2004).

Zhang, H., Jin, M. S. & Xia, Y. N. Noble-metal nanocrystals with concave surfaces: synthesis and applications. Angew. Chem. Int. Ed 51, 2–20 (2012).

Zhang, J., Langille, M. R., Personick, M. L., Zhang, K., Li, S. Y. & Mirkin, C. A. Concave cubic gold nanocrystals with high-index facets. J. Am. Chem. Soc. 132, 14012–14014 (2010).

Huang, X. Q., Zhao, Z. P., Fan, J. M., Tan, Y. M. & Zheng, N. F. Amine-assisted synthesis of concave polyhedral platinum nanocrystals having {411} high-index facets. J. Am. Chem. Soc. 133, 4718–4721 (2011).

Huang, X. Q., Tang, S. H., Zhang, H. H., Zhou, Z. Y. & Zheng, N. F. controlled formation of concave tetrahedral/trigonal bipyramidal palladium nanocrystals. J. Am. Chem. Soc. 131, 13916–13917 (2009).

Zhang, H. et al. synthesis of Pd-Pt bimetallic nanocrystals with a concave structure through a bromide-induced galvanic replacement reaction. J. Am. Chem. Soc. 133, 6078–6089 (2011).

Yu, T., Kim, D. Y., Zhang, H. & Xia, Y. N. Platinum concave nanocubes with high-index facets and their enhanced activity for oxygen reduction reaction. Angew. Chem. Int. Ed. 50, 2773–2777 (2011).

Hong, J. W., Lee, S. U., Lee, Y. W. & Han, S. W. Hexoctahedral Au nanocrystals with high-index facets and their optical and surface-enhanced raman scattering properties. J. Am. Chem. Soc. 134, 4565–4568 (2012).

DeSantis, C. J., Sue, A. C., Bower, M. M. & Skrabalak, S. E. Seed-mediated co-reduction: A versatile route to architecturally controlled bimetallic nanostructures. ACS Nano 6, 2617–2628 (2012).

Jin, M. S., Zhang, H., Xie, Z. X. & Xia, Y. N. Palladium concave nanocubes with high-index facets and their enhanced catalytic properties. Angew. Chem. Int. Ed. 50, 7850–7854 (2011).

Stamenkovic, V. R. et al. Trends in electrocatalysis on extended and nanoscale Pt-bimetallic alloy surfaces. Nat. Mater. 6, 241–247 (2007).

Liu, Z. L., Ling, X. Y., Su, X. D. & Lee, J. Y. Carbon-supported Pt and PtRu nanoparticles as catalysts for a direct methanol fuel cell. J. Phys. Chem. B. 108, 8234–8240 (2004).

Solymosi, F., Kutsan, G. & Erdohelyi, A. Catalytic reaction of CH4 with CO2 over alumina-supported Pt metals. Catal. Lett. 11, 149–156 (1991).

Wang, D. S., Peng, Q. & Li, Y. D. Nanocrystalline intermetallics and alloys. Nano. Res. 3, 574–580 (2010).

Knudsen, J. et al. A Cu/Pt near-surface alloy for water-gas shift catalysis. J. Am. Chem. Soc. 129, 6485–6490 (2007).

Lim, B. et al. Pd-Pt bimetallic nanodendrites with high activity for oxygen reduction. Science 324,1302–1305 (2009).

Yin, A. X., Min, X. Q., Zhu, W., Liu, W. C., Zhang, Y. W. & Yan, C. H. Pt-Cu and Pt-Pd-Cu concave nanocubes with high-index facets and superior electrocatalytic activity. Chem. Eur. J. 18, 777–782 (2012).

Niu, W. X., Zhang, L. & Xu, G. B. Shape-controlled synthesis of single-crystalline palladium nanocrystals. ACS Nano. 4, 1987–1996 (2010).

Jeong, G. H. et al. Polyhedral Au nanocrystals exclusively bound by {110} facets: the rhombic dodecahedron. J. Am. Chem. Soc. 131, 1672–1673 (2009).

Personick, M. L., Langille, M. R., Zhang, J., Harris, N., Schatz, G. C. & Mirkin, C. A. Synthesis and isolation of {110}-Faceted gold bipyramids and rhombic dodecahedra. J. Am. Chem. Soc. 133, 6170–6173 (2011).

Lee, Y. W., Kim, M., Kang, S. K. & Han, S. W. Polyhedral bimetallic alloy nanocrystals exclusively bound by {110} facets: Au-Pd rhombic dodecahedra. Angew. Chem. Int. Ed. 50, 3466–3470 (2011).

Wang, D. S. & Li, Y. D. One-pot protocol for Au-based hybrid magnetic nanostructures via a noble-metal-induced reduction process. J. Am. Chem. Soc. 132, 6280–6281 (2010).

Liu, X. W. et al. Palladium/tin bimetallic single-crystalline hollow nanospheres. Chem. Commun. 48, 1683–1685 (2012).

Yu, X. F., Wang, D. S., Peng, Q. & Li, Y. D. High performance electrocatalyst: Pt–Cu hollow nanocrystals. Chem. Commun. 47, 8094–8096 (2011).

Wang, D. S., Zhao, P. & Li, Y. D. General preparation for Pt-based alloy nanoporous nanoparticles as potential nanocatalysts. Sci. Rep. 1, 00037 (2011).

Snyder, J., McCue, I., Livi, K. & Erlebacher, J. Structure/processing/properties relationships in nanoporous nanoparticles as applied to catalysis of the cathodic oxygen reduction reaction. J. Am. Chem. Soc. 134, 8633–8645 (2012).

Tian, N., Zhou, Z. Y., Sun, S. G., Ding, Y. & Wang, Z. L. Science 316, 732–735 (2007).

Acknowledgements

This work was supported by the State Key Project of Fundamental Research for Nanoscience and Nanotechnology (2011CB932401, 2011CBA00500) and the Foundation for Innovative Research Groups of the National Natural Science Foundation of China (Grant No. 20921001).

Author information

Authors and Affiliations

Contributions

X.L. performed the most of experiments, collected and analyzed the data and wrote the paper; W.W. and L.L. performed the electrochemical measurements; R.Y. performed the HRTEM experiments; H.L., G.Z. and D.W. helped with data analysis; Y.L. conceived the experiments, analyzed results and wrote the paper.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

SUPPLEMENTARY INFO

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Liu, X., Wang, W., Li, H. et al. One-Pot Protocol for Bimetallic Pt/Cu Hexapod Concave Nanocrystals with Enhanced Electrocatalytic Activity. Sci Rep 3, 1404 (2013). https://doi.org/10.1038/srep01404

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep01404

This article is cited by

-

Intermetallic PtBi core/ultrathin Pt shell nanoplates for efficient and stable methanol and ethanol electro-oxidization

Nano Research (2019)

-

Simultaneous formation of trimetallic Pt-Ni-Cu excavated rhombic dodecahedrons with enhanced catalytic performance for the methanol oxidation reaction

Nano Research (2018)

-

Synthesis and Electrocatalytic Properties of Pt–Cu Worm-like Nanowires

Catalysis Letters (2017)

-

Shape-Controlled Synthesis of Pt Nanopeanuts

Scientific Reports (2016)

-

Dendritic platinum–copper bimetallic nanoassemblies with tunable composition and structure: Arginine-driven self-assembly and enhanced electrocatalytic activity

Nano Research (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.