Abstract

The magnetic flux pinning capabilities of YBa2Cu3O7-x (YBCO) coated conductors vary strongly across different regions of the magnetic field–temperature phase diagram and with the orientation of the magnetic field θ. Here, we determine the optimal pinning landscape for a given region of the phase diagram by investigating the critical current density Jc(H,θ,T) in the 5–77 K temperature range, from self-field to high magnetic fields of 35 T. Our systematic analysis reveals promising routes for artificially engineering YBCO coated conductors in any region of interest of the phase diagram. In solution-derived nanocomposites, we identify the relevance of coexisting high amounts of short stacking faults, Cu-O vacancy clusters, and segmentation of twin boundaries, in combination with nanoparticles, for enhanced pinning performance at high magnetic fields and low temperatures. Moreover, we demonstrate that twin boundaries preserve a high pinning energy in thick YBCO films, which is beneficial for the pinning performance at high magnetic fields and high temperatures.

Similar content being viewed by others

Introduction

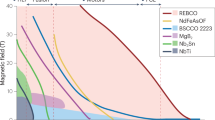

The successful development of suitable methods to grow epitaxial REBa2Cu3O7−x (REBCO, RE = Rare Earth) films on top of bi-axially textured substrates following a multi-layered architecture (i.e., coated conductors), opened the way to promote practical and scalable conductors for power applications at high magnetic fields and temperatures1,2,3,4,5,6. Among investigated superconductors, the REBCO superconductors do not exhibit either the highest critical temperature Tc or upper critical magnetic field Hc2. However, they do provide the highest irreversibility line Hirr (see Fig. S1 in the supplementary information for YBCO). Therefore, besides being suitable for power cables and fault current limiters at low magnetic fields and high temperatures7, REBCO coated conductors have been included in the design and fabrication of new coil architectures for high magnetic field applications such as research magnets8,9,10,11,12, NMR/MRI magnets13, magnets for fusion energy14,15,16, and high energy physics accelerator magnets17. They are excellent candidates not only for superconducting large currents in high field magnets at very low temperatures, but also in the intermediate magnetic fields generated in rotating machines18 or superconducting magnetic energy storage systems19,20 at temperatures in the range of 20–50 K, which can be effectively driven by cryocoolers21.

At present, the magnetic field–temperature (H–T) ranges attainable with REBCO coated conductors are much wider than the ones obtained using any other existing superconducting material. However, the intrinsic limit of the dissipation-free current, i.e., the critical current density Jc, shows a strong variation in different regions of the H–T diagram and with the orientation of the magnetic field θ. Such variations are determined by the different vortex pinning contributions that arise in each microstructure and lead to different phases of the vortex lattice22,23,24,25. A quest for an adequate microstructure that favours vortex pinning and enhances Jc has been ongoing for the last decades, motivating the search for new nanoengineering approaches aimed at tuning the REBCO defect landscape with additional pinning centres4,5,26,27,28,29,30,31,32.

Vortex pinning investigations based on the correlation between the electrical transport and microstructural visualization techniques enabled the evaluation of how each type of defect affects Jc enhancement. Nanoparticles16,27,33,34,35,36 improved the in-field Jc at all magnetic field orientations at any temperature and in some cases self-field (sf) Jc. The presence of random point defects37,38 also improved the in-field Jc, especially at temperatures below 40 K. Secondary phase nanorods/nanocolumns29,39,40 or irradiated columnar defects26,31 enhanced Jc mainly when H is parallel to the c-axis (H | | c), especially at high magnetic fields and high temperatures; the same occured for natural defects such as twin boundaries41,42 and dislocations43,44. Lately, hybrid nanostructures combining various defects45,46,47,48,49,50 have also been investigated, with the aim of merging gains. However, only a few studies cover large magnetic field and temperature ranges6,51,52,53.

In this article, we offer a broad study so as to determine the optimal microstructure for specific H–T conditions. We aim to identify relevant vortex pinning contributions in the widest possible range of the H–T diagram of YBCO, with special focus on very high magnetic fields. To do so, we analyse films that display a manifold microstructure, which we achieved with the versatile chemical solution deposition (CSD) technique used to grow nanostructured superconducting nanocomposites. Our analysis involves a thorough evaluation of Jc(H,θ,T) over a very broad range of temperatures (5–77 K) and applied magnetic fields (0-35 T), combined with detailed microstructural investigations by scanning transmission electron microscopy (STEM) and x-ray diffraction (XRD).

Results

The epitaxial solution-deposited YBCO films we study in this work are ranging in thickness from 100 nm to 1 μm. These have been grown by CSD with various precursor solutions: pristine YBCO, YBCO with additives for spontaneous segregation of nanoparticles (ss-nanocomposites), and YBCO with preformed nanoparticles (pn-nanocomposites). We grew samples with distinctive amounts of nanoparticles (0–12% mol) and diverse processing conditions (i.e., film deposition, heating ramp), yielding to very different defect landscapes54,55,56; all films have an oxygen doping state close to optimal doping, deduced from the temperature evaluation of the normalized resistivity57.

Here, we consider the identification of defect contributions according to angular pinning performance and the associated pinning strength, as described previously58. As explained in detail in Supplementary Fig. S2, in CSD YBCO we find, typically, isotropic defects (0D and 3D) such as copper-oxygen vacancy clusters38,59, small nanoparticles, or nanostrain generated in partial dislocations surrounding the stacking faults35. On the other hand, we observe planar anisotropic defects such as stacking faults parallel to the a–b planes60,61 (also named YBa2Cu3O8 intergrowths) or twin boundaries parallel to the c-axis61,62.

Regarding the associated pinning strength, the ratio between the pinning energy UP = (μ0/2)Hc2vp and the thermal energy kBT, where μ0 is the vacuum permeability, Hc is the thermodynamic critical field, (μ0/2)Hc2 is the condensation energy, vp is the volume of the pinned vortex core and kB is the Boltzmann constant, determines the thermal activation processes occurring for each kind of defect28. On one hand, point defects (i.e., oxygen and copper vacancies) have sizes below the order of magnitude of the superconducting coherence length ξ leading to a vp further below ξ3. As a consequence, UP/kBT << 1 and they are considered weak pinning centres. On the other hand, nanoparticles (with a pinned vortex length LP of ~1–5ξ), nanostrain (LP ~ 1–5ξ), stacking faults (LP~10-103ξ) and twin boundaries (LP ~ 10-103ξ) possess UP/kBT ≈ 1–103, and for this reason are considered strong pinning centres. Additionally, strong anisotropic intrinsic pinning63 (LP > 102ξ), originated in the layered structure of the YBCO itself, coexists with stacking fault pinning for H parallel to the a–b planes (H | | ab)64,65.

We present our results in three subsections: in subsection “Pinning regimes up to 9 T in the H–T phase diagram”, we evaluate the pinning performance in the H–T region 0–9 T and 5–77 K for pristine YBCO and a large batch of YBCO nanocomposites listed in table S1, distinguishing different pinning regimes for H | | c and H | | ab; in subsections “Density, strength and energy scale of vortex pinning centres up to 9 T” and “Density, strength and energy scale of vortex pinning centres up to 35 T” we evaluate for H | | c the density, strength and energy scale of the pinning centres up to 9 T and to 35 T, respectively, in a group of samples possessing very disparate microstructures.

Pinning regimes up to 9 T in the H–T phase diagram

We obtained accurate surfaces of Jc(H,T) for the main orientations of the magnetic field H | | c and H | | ab for pristine and nanocomposite films, as shown in Fig. 1. This was achieved by measuring Jc(H) curves at 5, 20, 50, 65 and 77 K, linearly interpolating, and subsequently fitting the curves as a function of temperature considering both the weak and strong pinning contributions of Jc(T) (i.e., Jcwk(T) and Jcstr(T), respectively). Whereas weak pinning centres yield a fast temperature decay of the Jc in the collective pinning model66, strong pinning centres account for a smoother temperature decay in the Bose glass model24. In a first approximation, we can describe Jc(T) by the direct sum28:

where Jc(0)wk and Jc(0)str refer to contributions at 0 K, whereas T0 and T* refer to temperatures associated to the characteristic vortex pinning energy of weak and strong defects, respectively. The final temperature interpolation is explained in detail in Supplementary Fig. S3.

It is worth stressing that the linear sum of contributions used in Eq. (1) and in Eq. (2) (in subsection “Density, strength and energy scale of vortex pinning centres up to 9 T”) is an approximation and does not take into account interaction between defects. The validity of the fitting parameters is strongly accurate when one pinning contribution dominates, otherwise the parameters are illustrative of tendencies. However, this model has demonstrated to be very successful in fitting the temperature dependence of Jc except in the high temperature and high magnetic field range (T > 60 K, μ0H > 2 T) and correlates very well with the microstructural modifications of YBCO28,54,58,67,68,69.

For the nanocomposite, the 3D Jc(H,T) representation in Fig. 1 illustrates an enlargement of the (reddish) high critical current density region (>1 MA cm−2) at low temperatures and low magnetic fields; the appealing region for high-current applications. On the other hand, at high temperatures and high magnetic fields, a rapid decay of Jc is visible at lower H–T values for H | | c, but not for H | | ab.

The enlargement of the reddish high Jc(H,T) region is concurrent with the shift to larger magnetic fields of the μ0H*(T) curve, where H* is the accommodation magnetic field, which sets the limit between the single vortex pinning regime—where vortices interact weakly with each other but strongly with defects70,71—and the vortex-vortex interaction regime. Therefore, H* is related to the density of defects. Here, it is defined as in other works58,72 by the equation Jc(μ0H*) = 0.9Jc(sf), where sf stands for self-field. Figure 2 shows a comparison between μ0H*(T) curves for several nanocomposites and a pristine sample, for both H | | c and H | | ab, highlighting the presence of the two regimes in the H–T diagram. In comparison to the pristine YBCO, all nanocomposites share the capability of enlarging the single vortex pinning regime up to high fields; this was observed for both magnetic field orientations, suggesting that the origin of this enlargement is effective at any orientation and, therefore, is isotropic.

Temperature dependence of μ0H* for (a) H | | c and (b) H | | ab for pristine and ss-nanocomposites (sample details are indicated in supplementary table S1). μ0H*(T) separates single vortex pinning from vortex-vortex interactions regimes in the H–T diagram. Error bars are determined by the standard deviation of μ0H* for iterative measurements.

In order to separate the isotropic (Jciso) and anisotropic (Jcaniso) contributions of the Jc(H) curves shown in Fig. 1 we applied the Blatter scaling approach28,73 to angular Jc(θ) measurements at temperatures of 5, 20, 50, 65 and 77 K, and applied magnetic fields of 0.1, 0.3, 0.5, 1, 3, 5, 7 and 9 T. Subsequently, we fitted their temperature dependence through the procedure explained in the Supplementary information (fig. S3), aiming to establish the weight of each contribution within the full range of the H–T diagram.

We, thus, obtained the colour maps presented in Fig. 3, which show the ratio Jciso/Jc in the H–T diagram (equivalent to 1- Jcaniso/Jc by assuming a no interaction approximation), identifying regions of pinning dominance. For H | | c, we observe that the dominance of isotropic pinning is enhanced for the nanocomposite in both temperature and magnetic field, leaving the region dominated by anisotropic pinning close to the irreversibility line. For H | | ab, the dominance of isotropic pinning is also shifted to larger magnetic fields of the order of 1 T, especially at low temperatures.

μ0H–T colour map of the ratios Jciso/Jc and Jcaniso/Jc for (a, c) a pristine and (b, d) a nanocomposite for (a, b) H | | c and (c, d) H | | ab. Solid lines with circles and triangles mark the μ0Hirr(T) and μ0H*(T) curves, respectively. Error bars are determined by the standard deviation of μ0H* for iterative measurements.

It is worth noting that the μ0H*(T) curves fall inside the region mostly dominated by isotropic pinning, in agreement with an increase of H* related to the increase of isotropic pinning centres in nanocomposites. In contrast, we observe a slight decrease of Hirr(T) for the nanocomposite, especially at H | | c, which can be associated to a lower pinning performance of the anisotropic defects (mainly twin boundaries42).

To elucidate the origin of the variation between the isotropic and anisotropic pinning contributions, let us consider the correlation between the increase of H* and the isotropic nanostrain; the nanostrain arises in the region surrounding the partial dislocations that envelope the stacking faults (Supplementary Fig. S2c, d), and it has been signalled as a characteristic defect emerging in large quantities in nanocomposites35. Hence, we macroscopically measured the nanostrain (ε) for each sample by XRD analysis, following the Williamson-Hall method74.

Figure 4a–f shows the above-mentioned correlation between the H* accomodation magnetic field (measured at 5, 50 and 77 K for both H | | c and H | | ab) and nanostrain for a very broad variety of samples (listed in the supplementary table S1). Although the results do not fall exactly on a single curve, we observe a common trend of the exponential increase of H* when ε increases; this is clear at all temperatures and orientations of the magnetic field considered. This correlation explains the importance of the isotropic nanostrain but, based on the deviations from the trend, it also reveals that this cannot be strictly distinguished as the unique cause of the enlargement of H*. Small nanoparticles able to pin vortices by themselves might well be an additional contribution of this enlargement.

For (black) pristine, (red) ss-nanocomposites and (blue) pn-nanocomposites: μ0H* at (a, b) 77 K, (c, d) 50 K and (e, f) 5 K for (a, c, e) H* | | c and (b, d, f) H* | | ab versus nanostrain and θT at 9 T as a function of μ0H* at (g) 77 K, (h) 50 K and (i) 5 K for H* | | c (closed symbols) and H* | | ab (open symbols). Dashed lines are guides to the eye. Error bars are determined by the standard deviation of iterative measurements for μ0H* and θT and by the standard error of the fitting of the Williamson-Hall method74 in the case of ε.

Further, we analysed the widening of the Jcaniso(θ) ab-peak; we approximated its half width-half-maximum with the trapping angle θT that limits the vortex staircase regime64,75 (θT calculation presented in Supplementary Fig. S4), which in this case can be interpreted as an additional capability of accommodating vortices parallel to the ab-planes due to a higher presence of stacking faults. Figure 4g–i presents θT versus μ0H* at temperatures of 77, 50 and 5 K for Jc(θ) curves measured at a field of 9 T and for Jc(H) curves measured for both H | | c and H | | ab. The linear trend of the θT(H*) combined with the exponential trend of H*(ε) indicates that the introduction of stacking faults leads to a vortex trapping widening and an increase of isotropic pinning centres by means of nanostrain. Some deviations from the θT(H*) trend are observed when H* | | ab, which can be associated with H* enhancement provided by stacking faults themselves, additional to the pinning of small nanoparticles already commented in the previous paragraph.

Density, strength and energy scale of vortex pinning centres up to 9 T

To separate the characteristics of different vortex pinning centres, we combined Jc(T) curves obtained for a wide range of magnetic fields with Jc(θ) curves obtained at specific temperatures, and applied the Blatter scaling approach28,73. Thus, we determined the Jciso(T) and Jcaniso(T) components.

We determined curves up to 35 T for a broad variety of samples that are representative of different microstructures, consisting of pristine and nanocomposite films with Ba2YTaO6 (BYTO), BaZrO3 (BZO), Y2O3 (YO), or BaHfO3 (BHO) nanoparticles (note that in this subsection we present only the results obtained up to 9 T; the results up to 35 T are summarized in the next subsection).

In Table 1 are shown the thickness (t), nanostrain (ε), nanoparticle (NP) average diameter (< ØNP > ) and density (σNP), stacking fault (SF) average length (< dSF > ) and density (λSF) and main electrical transport properties—Tc, ΔTc (transition width), Jcsf,77 K and HirrH||c,77 K—of each of the samples we analysed. All samples display Tc > 88 K, ΔTc < 6 K, and Jcsf,77 K ≈ 2–4.5 MA cm−2. We evaluated HirrH||c,77 K from Jc(H) measurements fulfiling the relation Jc(Hirr) = 10−4Jc(sf).

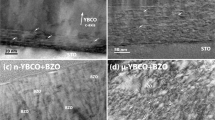

We inferred the NP and SF average densities from the high-angle annular dark field (HAADF) STEM images shown in Supplementary Fig. S5 using the formulae \({\sigma }_{{{{{{\rm{NP}}}}}}}={n}_{{{{{{\rm{NP}}}}}}}/{A}_{{{{{{\rm{YBCO}}}}}}}\) and \({\lambda }_{{{{{{\rm{SF}}}}}}}=\sum {d}_{{{{{{\rm{SF}}}}}}}/{A}_{{{{{{\rm{YBCO}}}}}}}\), where nNP is the number of nanoparticles and AYBCO is the area of the image corresponding to the analysed YBCO film. The identification of nanoparticles, stacking faults and the area AYBCO needed for these calculations are illustrated in Supplementary Fig. S6.

From Table 1, one observes that pristine films display a larger irreversibility magnetic field than nanocomposite films (except for pn-nc-thick); this indicates a significant change of the dominating pinning defect at high magnetic fields. Further, all nanocomposites exhibit a medium or high density of nanoparticles and stacking faults. However, each sample displays significant changes of the distribution and sizes of these defects. The ss-nc-thin-2 and pn-nc-thin films show signficantly shorter stacking faults than the rest of the films; this indicates a larger presence of partial dislocations. Furthermore, the pn-nc-thin film is characterized by very small nanoparticles with diameters very close to ξ (2 or 3 times) at the measured temperature.

Anisotropic defects act only as strong pinning centres, whereas isotropic defects can be either point or nanosized defects, promoting both weak and strong pinning. Therefore, the total Jc(T) can be described by the linear sum of three contributions:

where the Jcstr contribution from Eq. (1) is substituted now by the sum of the isotropic-strong (iso-str) contribution Jciso-str and the anisotropic-strong (aniso-str) contribution Jcaniso-str (corresponding directly to Jcaniso); the isotropic-weak (iso-wk) contribution Jciso-wk corresponds to the overall Jcwk contribution.

For the films that were studied in this work, we considered that iso-wk is generally associated to atom/cluster vacancies, iso-str to nanostrained regions and nanoparticles, and aniso-str to twin boundaries for H | | c. Regarding the nanoparticles, they become effective pinning centres when their diameter is sufficiently small (below 8 nm)36,56,76. By fitting Eq. (2) to the experimental results obtained at different magnetic fields, we determined the field dependence of the fitting parameters; these are the characteristic temperatures T0, T*iso-str, and T*aniso-str, and the contributions at 0 K Jc(0)iso-wk, Jc(0)iso-str, and Jc(0)aniso-str. T0, T*iso-str and T*aniso-str are associated with the characteristic pinning energy of the defects, they account for the effectiveness of their pinning potential in relation with the thermal energy kBT. Instead, Jc(0)iso-wk, Jc(0)iso-str, and Jc(0)aniso-str are the Jc values at 0 K of each pinning contribution in the absence of creep; thus, they are proportional to the density and strength of pinning centres. On the other hand, the accommodation magnetic field μ0H*(0 K) obtained in Jc(0) vs. magnetic field curves is exclusively associated to the density of pinning centres.

In Fig. 5a are shown the characteristic temperatures vs. the applied magnetic field. Coloured bands highlight the dispersion range of the characteristic temperatures obtained for different samples (i.e., T0 = 5–20 K, T*iso-str = 50–90 K and T*aniso-str = 70–130 K).

Applied magnetic field dependence of characteristic temperatures (a) T0 (solid lines, green region), T*iso-str (solid lines, blue region) and T*aniso-str (dashed lines, red region), and Jc contributions at 0 K (b) Jc(0)aniso-str, (c) Jc(0)iso-str and (d) Jc(0)iso-wk for pr-thin-1, ss-nc-thin-1, ss-nc-thin-2 and pn-nc-thin samples for H | | c. Error bars are determined by the standard error of the parameters from the fitting of Eq. (2).

We note that the characteristic temperatures for each contribution are characterized by similar ranges regardless of the sample type, indicating that the same type of defects contribute in different samples. However, differences in size and/or precise morphology of the defects induce significant changes. The larger dispersion in the pinning energy values was obtained for T*aniso-str. In this case, much lower values are found for all nanocomposites (T*aniso-str ≈ 70–80 K at high fields) as compared with the pristine, which we associate to the segmentation of twin boundaries due to a large density of stacking faults42,62 (Supplementary Fig. S2e, f). This segmentation provokes a decrease of LP which yields to less anisotropic pinning at high temperatures and a reduction of the irreversibility line Hirr24. In contrast, the pristine sample shows the highest T*aniso-str values and largest Hirr (9.4 T at 77 K, Table 1), indicative of coherent long twin boundaries24. Another remarkable difference is the one obtained for T*iso-str, which also shows lower values for nanocomposites than for the pristine, suggesting a change in the nature of isotropic-strong pinning centres, in agreement with the introduction of nanoparticles and the abundant pinning provided by nanostrain in nanocomposites.

Regarding the 0 K contributions of Jc, we also observe remarkable differences between nanocomposites and the pristine sample. In the case of iso-wk (Fig. 5d), we observe that nanocomposites show an enhanced μ0H*iso-wk(0 K), specially the pn-nc-thin, which is ascribed to a high density of Cu-O vacancy clusters hosted in the stacking faults38,59. The best Jc(0)iso-wk contribution is found for ss-nc-thin-2, in agreement with a large number of Cu-O vacancies which are stronger in this sample (see T0 in Fig. 5a). In the case of iso-str pinning in Fig. 5c, nanocomposites exhibit altogether a distinguishable behaviour with respect to the pristine film due to the nanostrain already mentioned in the previous subsection, resulting in enhanced Jc(0)iso-str at any magnetic field. In addition, nanoparticles that are sufficiently small will also contribute to enhance iso-str pinning. Last, the aniso-str pinning in Fig. 6b, mainly attributed to the pinning performance of twin boundaries, shows that pn-nc-thin and ss-nc-thin-2 films excel at exhibiting the largest Jcaniso-str values along the entire studied range, which is certainly related to a very high density of twin boundaries due to their segmentation and therefore multiplication provoked by the presence of a high density of short stacking faults as observed in these films (Supplementary Fig. S5d, e, g, h). Therefore, this evidences that a high density of short stacking faults coexists with a high density of twin boundaries, which however, produce a lower T*aniso-str due to the lack of vertical defect coherence.

Density, strength and energy scale of vortex pinning centres up to 35 T

Nanocomposites improve Jc primarily in magnetic field regions where the isotropic pinning contribution is enhanced. However, studies up to very high magnetic fields highlight that a crossover may occur, resulting in lower Jc of nanocomposites in comparison to pristine films, especially at high temperatures due to the high T*aniso-str values developed by pristine films. The Jc(H,T) surfaces of pr-thin-2 and pn-nc-thin are compared in Fig. 6a, b at 5-60 K and 10-35 T. It is recognized that the pn-nanocomposite displays larger critical current densities in a large H–T region, especially at low temperatures and intermediate fields. In contrast, at high temperatures and large magnetic fields, the nanocomposite presents a more prominent decay of Jc associated with its lower irreversibility field.

We observe in Fig. 6c that although the pn-nc-thin sample exhibits a fast Jc(H) decay at 30 K with lower Jc values at very high fields, it shows the best performance at 4.2 K at the entire analysed magnetic field range. A crossover between the Jc values from pn-nc-thin and pr-thin-2 is expected to take place at a magnetic field higher than 35 T. Such a crossover is on the other hand observed at 25 T between pn-nc-thick and pr-thick.

At 30 K, a desirable temperature for superconducting rotating machinery applications18 refrigerated with cryocooler technology21, nanocomposites also offer substantially larger Jc values than pristine films in the magnetic field region of 5–20 T, strengthening the fact that nanocomposites are very appropriate for the development of coated conductors for in-field applications. On the other hand, as depicted in Fig. 6d, thick films offer at 4.2 K higher total critical current Ic values in comparison with the pristine thin film up to 35 T, despite of their lower Jc values. This reinforces the need to further understand and optimize the growth of thick films (using inkjet printing in this case77). Our study on CSD films suggests that the selection of thick nanocomposite films is especially beneficial for the design of coated conductors operating at the range of 5–10 T offering 6 and 2.5 times larger Ic values than the thin and thick pristine films respectively.

Additionally, in the high magnetic field facilities, we have been able to analyse the isothermal magnetic field dependent current-voltage characteristics for four different samples: pr-thin-2, pr-thick, pn-nc-thin and pn-nc-thick, whose pinning force density Fp(H) curves are plotted in Supplementary Fig. S7. In these plots, we focus at three H–T conditions: [50 K,15 T], [50 K,35 T] and [4.2 K,35 T], summarized in Table 2. Notice that different samples provide the best Fp-value at each condition: the thick pn-nanocomposite provides 45 GN m−3 at [50 K,15 T], the pristine thick film 4 GN m−3 at [50 K,35 T] and the thin pn-nanocomposite 0.55 TN m−3 at [4.2 K,35 T]. In order to understand the responsible pinning contributions at the different H–T conditions, we have extended the study from the previous subsection to magnetic fields up to 35 T, obtaining the magnetic field dependence of the characteristic temperatures T0, T*iso-str and T*aniso-str and the Jc contributions at 0 K, Jc(0)iso-wk, Jc(0)iso-str and Jc(0)aniso-str, in Fig. 7. Interestingly, Fig. 7a shows that T0 tends to slightly increase, whereas both T*iso-str and T*aniso-str tend to decrease with increasing magnetic field. The increase of T0 can be related to a shrinking of the vortex core size with increasing magnetic field78,79 and the outbreak of other sources of weak pinning promoted by atomic defects of the order of Å. The performance at 30-50 K at very high magnetic fields is therefore very much influenced by the pinning characteristic temperatures.

Magnetic field dependence of characteristic temperatures (a) T0 (solid lines), T*iso-str (solid lines) and T*aniso-str (dashed lines), and Jc contributions at 0 K (b) Jcaniso-str, (c) Jciso-str and (d) Jciso-wk for pr-thin-1, pr-thin-2, pr-thick, pn-nc-thin and pn-nc-thick samples for H | | c at very high magnetic fields. Error bars are determined by the standard error of the parameters from the fitting of Eq. (2).

The analysis of the pinning contributions extrapolated to 0 K shows in general larger Jc(0) for pn-nanocomposites than for pristine samples (Fig. 7b–d), which makes nanocomposites very appealing for the application of superconducting films at helium temperature. The pn-nc-thin sample exhibits the largest values of iso-weak pinning due to the already mentioned Cu-O vacancies, and very large iso-str pinning up to 25 T due to the large density of nanostrained regions surrounding the short stacking faults and very likely due to the small BHO nanoparticles, and also a large aniso-str pinning due to the high density of segmented twin boundaries. Altogether, it makes pn-nc-thin the best sample to afford a pinning force density of 0.55 TN m−3 at [4.2 K,35 T]. However, the low T*iso-str and especially the low T*aniso-str possessed by this thin pn-nanocomposite plotted in Fig. 7a cause a strong Jc(H) decay at higher temperatures, as already observed in Fig. 6.

On the other hand, the thick pn-nanocomposite exhibits higher T*iso-str and T*aniso-str (Fig. 7a) than the thin pn-nanocomposite and ss-nanocomposites (Fig. 5a). Actually, this T*iso-str coincides with that for pristine samples (note that the different thin pristine samples display in general very similar results), indicating that nanoparticles and nanostrained regions have not effectively modified the typology of pinning centres in the thick pn-nanocomposite, also manifested by the similar Jc(0)iso-str(H) dependence in Fig. 7c. T*aniso-str in this sample is also closer to the one of pristine samples, indicating a regain in vertical coherence length of twin boundaries in comparison to thin nanocomposites. If we also consider the high T*aniso-str obtained by the thick pristine, which is the highest at 35 T, all the signs are that larger thickness favours twin boundary coherence (and therefore longer LP) and yields to a higher value of T*aniso-str. The longer twin boundary coherence can be given by any of two reasons: i) large thickness promotes more regions in the microstructure which are less faulted (regions away from the surface and from the substrate interface) so that twin boundaries are less broken, ii) with large thickness it is easier to sum twin boundary segments which coincide vertically and contribute to a final longer LP. For this enhanced T*aniso-str, pr-thick and pn-nc-thick exhibit the best pinning force densities at [50 K,35 T] and [50 K,15 T] respectively. Moreover, given the larger Ic in thicker films (Fig. 6d), the total pinning force strongly improves and therefore it is strongly recommended to take steps forward in the direction of gaining thickness.

The study of current–voltage curves at very high magnetic fields has been extended at magnetic orientations different to H | | c at the temperature of 20 K, covering an angular range of 180° centred at H | | ab for the magnetic fields of 15, 25 and 35 T. Results are plotted in Supplementary Fig. S8a for pr-thin-2, pn-nc-thin and pn-nc-thick. It is observed that the ab-peak is widened for nanocomposites, in agreement with a larger θT to accommodate vortices by stacking faults. Below the crossover magnetic field of about 20 T, where Jc values of nanocomposites fall below the ones of pristine films (in Fig. 6c at 30 K), nanocomposites offer higher performance throughout the angular range. In contrast, above 20 T, the pristine film starts to exhibit larger Jc than nanocomposites in the vicinity of H | | c, where an intricate competition takes place between the three contributions (iso-wk, iso-str and aniso-str) since T0, T*iso-str and T*aniso-str get closer at very high magnetic fields (Fig. 7a). Notice that collapses of Jciso (Supplementary Fig. S8b) are obtained for effective anisotropies (γeff) of 6, 2.5 and 2 for pr-thin-2, pn-nc-thin and pn-nc-thick respectively, which are the same values that were obtained at lower magnetic fields. Thus, confirming that γeff remains constant at very high magnetic fields and that the effective anisotropy of the nanocomposite films is certainly approaching very low values, making them very appealing for high field magnets where the isotropic characteristics of CC are a strong demand.

Discussion

The thorough study undertaken at wide temperature and magnetic field ranges up to 35 T has demonstrated that the performance of solution-derived nanocomposites is excellent at very high magnetic fields and very low temperatures. However, at temperatures above 20 K, there is a crossover of Jc values in nanocomposites with respect to the pristine films. This suggests that additional pinning centres should be induced at these conditions to overcome the existing performances of pristine CSD films, as for example promoting longer defect coherence or by a reinforcement of the density of small nanoparticles which can act as pinning centres themselves. The pinning characteristics observed in CSD films are specially ascribed to the shape, density and length of the most extended defect in these films, i.e. the stacking fault. In particular, from the analysis elaborated here we conclude that stacking faults in solution-derived YBCO nanocomposites have a triple effect in the pinning contributions for H | | c:

-

They increase the isotropic-strong contribution by means of increasing Jc(0)iso-str due to the generation of isotropic nanosized strain regions located at the partial dislocations surrounding the stacking faults. This increase is very effective at low-intermediate magnetic fields and intermediate temperatures and is responsible for the general enlargement of the single vortex pinning regime defined by the increase of μ0H*.

-

They increase the isotropic-weak contribution by means of increasing Jc(0)iso-wk due to the formation of Cu-O vacancy clusters among stacking faults. This increase is very effective at low temperatures.

-

They increase the anisotropic-strong contribution by means of increasing Jc(0)aniso-str due to the multiplication of twin boundaries given by the segmentation provoked by the appearance of stacking faults. The increase of Jc(0)aniso-str is very effective at low temperatures up to very high magnetic fields. However, the segmentation of twin boundaries causes in parallel a breaking of their vertical coherence, which yields a reduction of the pinning energy T*aniso-str and therefore a decrease of the irreversibility line μ0Hirr(T), which can be recovered in the case of thick nanocomposites.

Therefore, the intensity of each change in any of the pinning contributions will strongly depend on the precise distribution and size of the stacking faults present in each sample. To summarize, we propose general optimized defect landscapes to enhance pinning at distinctive H–T regions for H | | c, depicted in Fig. 8:

-

At low T and from low to very high H: a large density of isotropic defects (e.g., Cu-O vacancies, nanostrain and small nanoparticles) and anisotropic defects (e.g., segmented twin boundaries), no matter their length in defect coherence. Therefore, a landscape possessing large density of short stacking faults and small nanoparticles is very appropriate.

-

At intermediate T and intermediate H: a large density of strong isotropic and anisotropic defects, the latter with a long vertical coherence (e.g., nanoparticles, nanostrain and twin boundaries or a mixed landscape of long nanorods combined with nanoparticles and nanostrain).

-

At intermediate T and high H: a high density of anisotropic-strong defects with a very long vertical coherence (like long twin boundaries in thick nanocomposites or elongated nanorods), if possible combined with other auxiliary strong or weak isotropic defects in order to sum pinning gains and avoid vortex creep excitations in parallel correlated defects36,45,80.

Conclusions

Overall, the analysis presented here demonstrates the capacity to artificially modify the pinning landscape with solution-derived nanocomposites due to the benefits of adding small nanoparticles and the relevance of stacking faults and their secondary effects (generation of strained nanoregions, generation of Cu-O vacancy clusters and segmentation of twin boundaries). Furthermore, this study urges the manufacturers to fabricate customized coated conductors for different applications depending on their magnetic field and temperature operation range. Whereas the generation of a mixed landscape with plentiful kinds of defects of short length is desirable for enhancing pinning at low temperatures, the presence of strong elongated defects with long defect coherence in combination with other auxiliary defects is preferable for pinning at higher temperatures, and defects with even longer defect coherence in the case of very high magnetic fields.

Methods

YBCO film growth

Epitaxial c-axis oriented YBCO films were grown by chemical solution deposition from metal organic decomposition of trifluoroacetate salts in solution following previous works81,82,83. The solution was deposited on 5 × 5 mm LaAlO3 single crystal substrates whether by spin coating for thin films (150-250 nm) or by inkjet printing for thick films (>600 nm)84,85. Subsequently, films were pyrolized and thermal treated at high temperatures. All films in Table 1 have been grown following a conventional thermal annealing (25 °C min−1 heating ramp)83, except the pn-nc-thin sample, which followed a flash heating process (1200 °C min−1 heating ramp)86. Nanocomposites were obtained by promoting the formation of nanoparticles in the YBCO matrix, whether by including the salts directly to the solution leading to spontaneous segregation during growth (ss-nanocomposites)28,35 or by the mixing of a previously stabilized colloidal solution containing preformed nanoparticles with the trifluoroacetate precursor solution (pn-nanocomposites)55,56,87,88. Nanoparticle concentrations are expressed by the percentage of the molar concentration of nanoparticles with respect to the YBCO molar concentration. For example, for YBCO + 8%BYTO there are 8 mols of BYTO for 100 mols of YBCO.

Electric transport measurements

Current-voltage curves were obtained using the standard four-point method. Silver contacts were sputtered on YBCO with a TSST sputtering system and were post-annealed, ensuring contact resistivities below 10 μΩ·cm2. Samples were trimmed into 10–100 μm narrow bridges with lengths of 200-400 μm by standard lithography with a Micro-Writer from Durham Magneto Optics LTD and wet etching in H3PO4. The current was applied parallel to the a–b plane, always perpendicularly to the magnetic field which was rotated with the angle θ from the c-axis (0°) to the ab-plane (90°), ensuring maximum Lorentz force configuration. Critical currents were determined for a 10 μV cm−1 electric field. The current-voltage characteristics up to 9 T were conducted in a Quantum Design PPMS 9 T system, whereas the experiments carried out up to 35 T were conducted in a cryostat inside of a 35 T DC resistive magnet (32 mm bore) using a tight-vacuum probe provided with a rotating sample holder (Fig. S9 in the supplementary information) and a temperature control system operating in the 4.2-60 K range.

Microstructural characterisation

Nanostrain (ε) was quantified along the c-axis by analysing the symmetric (00 l) 2θ Bragg XRD integral breadth acquired in a Siemens D5000 diffractometer using Cu Kα radiation. Following the Williamson-Hall method74, ε was obtained following the equation: \({\beta }^{2}{co}{{s}}^{2}(\vartheta )=\frac{{\lambda }_{\alpha 1}}{{L}_{\perp }}+16{\varepsilon }^{2}{si}{{n}}^{2}(\vartheta )\), where β and θ are respectively the integrated breadth and the position of the (00 l) YBCO Bragg peaks after the subtraction of the contribution from the instrument. λα1 is the wavelength of the Cu Kα1 radiation and L⊥ is the coherent volume size perpendicular to the scattering vector. The scanning transmission electron microscopy observations were performed using an FEI Titan 60-300 kV microscope operated in STEM mode at 300 kV, which is equipped with an X-FEG gun, a CESCOR Cs-probe corrector, a Gatan energy filter TRIDIEM 866 ERS and a monochromator.

Data availability

The data that support the findings of this study are available from the corresponding authors on reasonable request.

References

Paranthaman, M. P. & Izumi, T. High-performance YBCO-coated superconductor wires. MRS Bull. 29, 533–541 (2004).

Larbalestier, D., Gurevich, A., Feldmann, D. M. & Polyanskii, A. High-Tc superconducting materials for electric power applications. Nature 414, 368–377 (2001).

Shiohara, Y., Yoshizumi, M., Takagi, Y. & Izumi, T. Future prospects of high Tc superconductors-coated conductors and their applications. Phys. C Supercond. 484, 1–5 (2013).

Selvamanickam, V. et al. Enhanced critical currents in (Gd,Y)Ba2Cu3OxBa superconducting tapes with high levels of Zr addition. Supercond. Sci. Technol. 26, 035006 (2013).

Obradors, X. & Puig, T. Coated conductors for power applications: materials challenges. Supercond. Sci. Technol. 27, 044003 (2014).

MacManus-Driscoll, J. L. & Wimbush, S. C. Processing and application of high-temperature superconducting coated conductors. Nat. Rev. Mater. 6, 587–604 (2021).

Malozemoff, A. P. Second-generation high-temperature superconductor wires for the electric power grid. Annu. Rev. Mater. Res. 42, 373–397 (2012).

Weijers, H. W. et al. High field magnets with HTS conductors. IEEE Trans. Appl. Supercond. 20, 576–582 (2010).

Weijers, H. W. et al. Progress in the development and construction of a 32-T superconducting magnet. IEEE Trans. Appl. Supercond. 26, 1–7 (2016).

Iwasa, Y. & Hahn, S. First-cut design of an all-superconducting 100-T direct current magnet. Appl. Phys. Lett. 103, 253507 (2013).

Liu, J. et al. World record 32.35 tesla direct-current magnetic field generated with an all-superconducting magnet. Supercond. Sci. Technol. 33, 03LT01 (2020).

Trociewitz, U. P. et al. 35.4 T field generated using a layer-wound superconducting coil made of (RE)Ba2Cu3O7−x (RE = rare earth) coated conductor. Appl. Phys. Lett. 99, 202506 (2011).

Song, J. B. et al. Review of core technologies for development of 2G HTS NMR/MRI magnet: a status report of progress in Korea University. Results Phys. 7, 3264–3276 (2017).

Creely, A. J. et al. Overview of the SPARC tokamak. J. Plasma Phys. 86, 865860502 (2020).

Greenwald, M. Status of the SPARC physics basis. J. Plasma Phys. 86, 861860501 (2020).

Molodyk, A. et al. Development and large volume production of extremely high current density YBa2Cu3O7 superconducting wires for fusion. Sci. Rep. 11, 2084 (2021).

Rossi, L. & Senatore, C. HTS accelerator magnet and conductor development in Europe. Instruments 5, 8 (2021).

Haran, K. S. et al. High power density superconducting rotating machines—development status and technology roadmap. Supercond. Sci. Technol. 30, 123002 (2017).

Shikimachi, K. et al. System coordination of 2 GJ class YBCO SMES for power system control. IEEE Trans. Appl. Supercond. 19, 2012–2018 (2009).

Zimmermann, A. W. & Sharkh, S. M. Design of a 1 MJ/100 kW high temperature superconducting magnet for energy storage. Energy Rep. 6, 180–188 (2020).

Radebaugh, R. Cryocoolers: the state of the art and recent developments. J. Phys. Condens. Matter 21, 164219 (2009).

Fisher, D. S., Fisher, M. P. A. & Huse, D. A. Thermal fluctuations, quenched disorder, phase transitions, and transport in type-II superconductors. Phys. Rev. B 43, 130–159 (1991).

Dekker, C., Eidelloth, W. & Koch, R. H. Measurement of the exponent μ in the low-temperature phase of YBa2Cu3O7−δ films in a magnetic field: direct evidence for a Vortex-Glass phase. Phys. Rev. Lett. 68, 3347–3350 (1992).

Nelson, D. R. & Vinokur, V. M. Boson localization and correlated pinning of superconducting vortex arrays. Phys. Rev. B 48, 13060–13097 (1993).

Jiang, W. et al. Evidence of a Bose-glass transition in superconducting YBa2Cu3O7 single crystals with columnar defects. Phys. Rev. Lett. 72, 550–553 (1994).

Civale, L. et al. Vortex confinement by columnar defects in YBa2Cu3O7 crystals: enhanced pinning at high fields and temperatures. Phys. Rev. Lett. 67, 648–651 (1991).

Foltyn, S. R. et al. Materials science challenges for high-temperature superconducting wire. Nat. Mater. 6, 631–642 (2007).

Puig, T. et al. Vortex pinning in chemical solution nanostructured YBCO films. Supercond. Sci. Technol. 21, 034008 (2008).

Matsumoto, K. & Mele, P. Artificial pinning center technology to enhance vortex pinning in YBCO coated conductors. Supercond. Sci. Technol. 23, 014001 (2010).

Obradors, X. et al. Nanostructured Superconductors with Efficient Vortex Pinning. Comprehensive Nanoscience and Technology Vol. 3 (eds Andrews, D. L. et al.) 303–349 (Amsterdam: Elsevier, 2011).

Kwok, W.-K. et al. Vortices in high-performance high-temperature superconductors. Rep. Prog. Phys. 79, 116501 (2016).

Majkic, G. et al. Engineering current density over 5 kAmm−2 at 4.2 K, 14 T in thick film REBCO tapes. Supercond. Sci. Technol. 31, 10LT01 (2018).

Haugan, T., Barnes, P. N., Wheeler, R., Meisenkothen, F. & Sumption, M. Addition of nanoparticle dispersions to enhance flux pinning of the YBa2Cu3O7-x superconductor. Nature 430, 867–870 (2004).

Wang, H. et al. Microstructure and transport properties of Y-rich YBa2Cu3O7−δ thin films. J. Appl. Phys. 100, 053904 (2006).

Llordés, A. et al. Nanoscale strain-induced pair suppression as a vortex-pinning mechanism in high-temperature superconductors. Nat. Mater. 11, 329–336 (2012).

Miura, M. et al. Tuning nanoparticle size for enhanced functionality in perovskite thin films deposited by metal organic deposition. NPG Asia Mater. 9, e447 (2017).

Haberkorn, N., Kim, J., Suárez, S., Lee, J.-H. & Moon, S. H. Influence of random point defects introduced by proton irradiation on the flux creep rates and magnetic field dependence of the critical current density Jc of co-evaporated GdBa2Cu3O7− δ coated conductors. Supercond. Sci. Technol. 28, 125007 (2015).

Gazquez, J. et al. Emerging diluted ferromagnetism in high-Tc superconductors driven by point defect clusters. Adv. Sci. 3, 1500295 (2016).

Goyal, A. et al. Irradiation-free, columnar defects comprised of self-assembled nanodots and nanorods resulting in strongly enhanced flux-pinning in YBa2Cu3O7−δ films. Supercond. Sci. Technol. 18, 1533 (2005).

Opherden, L. et al. Large pinning forces and matching effects in YBa2Cu3O7-δ thin films with Ba2Y(Nb/Ta)O6 nano-precipitates. Sci. Rep. 6, 21188 (2016).

Palau, A. et al. Crossover between channeling and pinning at twin boundaries in YBa2Cu3O7 thin films. Phys. Rev. Lett. 97, 257002 (2006).

Rouco, V. et al. Role of twin boundaries on vortex pinning of CSD YBCO nanocomposites. Supercond. Sci. Technol. 27, 125009 (2014).

Dam, B. et al. Origin of high critical currents in YBa2Cu3O7−δ superconducting thin films. Nature 399, 439–442 (1999).

MacManus-Driscoll, J. L. et al. Strongly enhanced current densities in superconducting coated conductors of YBa2Cu3O7–x + BaZrO3. Nat. Mater. 3, 439–443 (2004).

Maiorov, B. et al. Synergetic combination of different types of defect to optimize pinning landscape using BaZrO3-doped YBa2Cu3O7. Nat. Mater. 8, 398–404 (2009).

Matsumoto, K. et al. Irreversibility fields and critical current densities in strongly pinned YBa2Cu3O7-x films with artificial pinning centers. IEEE Trans. Appl. Supercond. 25, 1–6 (2015).

Sieger, M. et al. BaHfO3-doped thick YBa2Cu3O7−δ films on highly alloyed textured Ni-W tapes. IEEE Trans. Appl. Supercond. 25, 1–4 (2015).

Majkic, G., Pratap, R., Xu, A., Galstyan, E. & Selvamanickam, V. Over 15 MA/cm2 of critical current density in 4.8 µm thick, Zr-doped (Gd,Y)Ba2Cu3Ox superconductor at 30 K, 3T. Sci. Rep. 8, 6982 (2018).

Usoskin, A. et al. Double-disordered HTS-coated conductors and their assemblies aimed for ultra-high fields: large area tapes. IEEE Trans. Appl. Supercond. 28, 1–6 (2018).

Kihlstrom, K. J. et al. Large enhancement of the in-field critical current density of YBCO coated conductors due to composite pinning landscape. Supercond. Sci. Technol. 34, 015011 (2021).

Tsuchiya, Y. et al. Flux pinning landscape up to 25T in SmBa2Cu3Oy films with BaHfO3 nanorods fabricated by low-temperature growth technique. Supercond. Sci. Technol. 30, 104004 (2017).

Feighan, J. P. F., Kursumovic, A. & MacManus-Driscoll, J. L. Materials design for artificial pinning centres in superconductor PLD coated conductors. Supercond. Sci. Technol. 30, 123001 (2017).

Xu, A. et al. Strongly enhanced vortex pinning from 4 to 77 K in magnetic fields up to 31 T in 15 mol.% Zr-added (Gd, Y)-Ba-Cu-O superconducting tapes. APL Mater. 2, 046111 (2014).

Gutiérrez, J. et al. Strong isotropic flux pinning in solution-derived YBa2Cu3O7−x nanocomposite superconductor films. Nat. Mater. 6, 367–373 (2007).

Cayado, P. et al. Epitaxial YBa2Cu3O7−x nanocomposite thin films from colloidal solutions. Supercond. Sci. Technol. 28, 124007 (2015).

Li, Z. et al. Control of nanostructure and pinning properties in solution deposited YBa2Cu3O7−x nanocomposites with preformed perovskite nanoparticles. Sci. Rep. 9, 5828 (2019).

Stangl, A., Palau, A., Deutscher, G., Obradors, X. & Puig, T. Ultra-high critical current densities of superconducting YBa2Cu3O7-δ thin films in the overdoped state. Sci. Rep. 11, 8176 (2021).

Palau, A. et al. Disentangling vortex pinning landscape in chemical solution deposited superconducting YBa2Cu3O7−x films and nanocomposites. Supercond. Sci. Technol. 31, 034004 (2018).

Bartolomé, E. et al. Embedded magnetism in YBa2Cu3O7 associated with Cu–O vacancies within nanoscale intergrowths: implications for superconducting current performance. ACS Appl. Nano Mater. 3, 3050–3059 (2020).

Guzman, R. et al. Probing localized strain in solution-derived YBa2Cu3O7−δ nanocomposite thin films. Phys. Rev. Mater. 1, 024801 (2017).

Gazquez, J. et al. Structural defects in trifluoroacetate derived YBa2Cu3O7 thin films. Supercond. Sci. Technol. 25, 065009 (2012).

Guzman, R. et al. Strain-driven broken twin boundary coherence in YBa2Cu3O7−δ nanocomposite thin films. Appl. Phys. Lett. 102, 081906 (2013).

Tachiki, M. & Takahashi, S. Intrinsic pinning in cuprate superconductors. Appl. Supercond. 2, 305–313 (1994).

Civale, L. et al. Identification of intrinsic ab-plane pinning in YBa2Cu3O7 thin films and coated conductors. IEEE Trans. Appiled Supercond. 15, 2808–2811 (2005).

Vallès, F. et al. Angular flux creep contributions in YBa2Cu3O7−δ nanocomposites from electrical transport measurements. Sci. Rep. 8, 5924 (2018).

Blatter, G., Feigel’man, M. V., Geshkenbein, V. B., Larkin, A. I. & Vinokur, V. M. Vortices in high-temperature superconductors. Rev. Mod. Phys. 66, 1125–1388 (1994).

Plain, J., Puig, T., Sandiumenge, F., Obradors, X. & Rabier, J. Microstructural influence on critical currents and irreversibility line in melt-textured YBa2Cu3O7-x reannealed at high oxygen pressure. Phys. Rev. B 65, 104526 (2002).

Polat, O. et al. Thickness dependence of magnetic relaxation and E- J characteristics in superconducting (Gd-Y)-Ba-Cu-O films with strong vortex pinning. Phys. Rev. B 84, 024519 (2011).

Xu, A., Braccini, V., Jaroszynski, J., Xin, Y. & Larbalestier, D. C. Role of weak uncorrelated pinning introduced by BaZrO3 nanorods at low-temperature in (Y,Gd)Ba2Cu3Ox thin films. Phys. Rev. B 86, 115416 (2012).

Krusin-Elbaum, L. et al. Bose-glass melting in YBaCuO crystals with correlated disorder. Phys. Rev. Lett. 72, 1914–1917 (1994).

Braccini, V. et al. Properties of recent IBAD–MOCVD coated conductors relevant to their high field, low temperature magnet use. Supercond. Sci. Technol. 24, 035001 (2011).

Mezzetti, E. et al. Control of the critical current density in YBa2Cu3O7−δ films by means of intergrain and intragrain correlated defects. Phys. Rev. B 60, 7623–7630 (1999).

Blatter, G., Geshkenbein, V. B. & Larkin, A. I. From isotropic to anisotropic superconductors: a scaling approach. Phys. Rev. Lett. 68, 875–878 (1992).

Williamson, G. K. & Hall, W. H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1, 22–31 (1953).

Civale, L. et al. Angular-dependent vortex pinning mechanisms in YBa2Cu3O7 coated conductors and thin films. Appl. Phys. Lett. 84, 2121–2123 (2004).

Soler, L. et al. Ultrafast transient liquid assisted growth of high current density superconducting films. Nat. Commun. 11, 344 (2020).

Villarejo, B. et al. Pyrolysis study of solution-derived superconducting YBa2Cu3O7 films: disentangling the physico-chemical transformations. J. Mater. Chem. C 8, 10266–10282 (2020).

Kogan, V. G. & Zhelezina, N. V. Field dependence of the vortex core size. Phys. Rev. B 71, 134505 (2005).

Sonier, J. E. Muon spin rotation studies of electronic excitations and magnetism in the vortex cores of superconductors. Rep. Prog. Phys. 70, 1717–1755 (2007).

Rouco, V. et al. Vortex creep in TFA–YBCO nanocomposite films. Supercond. Sci. Technol. 27, 115008 (2014).

Roma, N. et al. Acid anhydrides: a simple route to highly pure organometallic solutions for superconducting films. Supercond. Sci. Technol. 19, 521–527 (2006).

Llordés, A. et al. Evolution of metal-trifluoroacetate precursors in the thermal decomposition toward high-performance YBa2Cu3O7 superconducting films. Chem. Mater. 22, 1686–1694 (2010).

Obradors, X. et al. Growth, nanostructure and vortex pinning in superconducting YBa2Cu3O7 thin films based on trifluoroacetate solutions. Supercond. Sci. Technol. 25, 123001 (2012).

Pop, C. et al. Growth of all-chemical high critical current YBa2Cu3O7−δ thick films and coated conductors. Supercond. Sci. Technol. 32, 015004 (2019).

Villarejo, B. et al. High performance of superconducting YBa2Cu3O7 thick films prepared by single-deposition inkjet printing. ACS Appl. Electron. Mater. 3, 3948–3961 (2021).

Li, Z. et al. Accelerated growth by flash heating of high critical current trifluoroacetate solution derived epitaxial superconducting YBa2Cu3O7 films. J. Mater. Chem. C 7, 4748–4759 (2019).

Chamorro, N. et al. Hybrid approach to obtain high-quality BaMO3 perovskite nanocrystals. RSC Adv. 10, 28872–28878 (2020).

De Keukeleere, K. et al. Superconducting YBa2Cu3O7−δ nanocomposites using preformed ZrO2 nanocrystals: growth mechanisms and vortex pinning properties. Adv. Electron. Mater. 2, 1600161 (2016).

Acknowledgements

The authors acknowledge financial support from Spanish Ministry of Economy and Competitiveness through the “Severo Ochoa” Programme for Centres of Excellence in R&D (Grant No. SEV-2015-0496), ULTRASUPERTAPE (ERC-2014-ADG-669504), EUROTAPES project (FP7-NMP-Large-2011-280432), the CONSOLIDER Excellence Network (Grant No. MAT2015-68994-REDC), COACHSUPENERGY project (Grant No. MAT2014-56063-C2-1- R and SuMaTe RTI2018-095853-B-C21, co-financed by the European Regional Development Fund), and from the Catalan Government with Grant No. 2014-SGR-753 and 2017-SGR-1519. Authors also thank the network collaboration of EU COST action NANOCOHYBRI CA16218. We also acknowledge the Scientific Services at ICMAB and Z. Li and P. Cayado for the growth of the studied samples. A portion of this work was performed at the National High Magnetic Field Laboratory, which is supported by the National Science Foundation Cooperative Agreement No. DMR-1644779 and the State of Florida.

Author information

Authors and Affiliations

Contributions

F.V., A.P. and T.P. designed the experimental study. F.V. performed the main experimental work and analysed the data. D.A., A-M.C., J.J. and F.V. prepared the experimental setup and performed the measurements at very high magnetic fields. B.M. performed and analysed the STEM observations. F.V. and T.P. prepared the manuscript with contributions from co-authors. X.O., D.L., T.P., A.P., B.M., J.J., A-M.C, D.A. and F.V. contributed to the scientific discussion.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks the anonymous reviewers for their contribution to the peer review of this work. Primary Handling Editors: Nicola Poccia and Aldo Isidori. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Vallès, F., Palau, A., Abraimov, D. et al. Optimizing vortex pinning in YBa2Cu3O7-x superconducting films up to high magnetic fields. Commun Mater 3, 45 (2022). https://doi.org/10.1038/s43246-022-00266-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43246-022-00266-y

This article is cited by

-

Impact of high growth rates on the microstructure and vortex pinning of high-temperature superconducting coated conductors

Nature Reviews Physics (2023)

-

Nd:YAG infrared laser as a viable alternative to excimer laser: YBCO case study

Scientific Reports (2023)

-

Insulating nanoparticle induced pinning in YBCO superconductor: crossover from collective to strong pinning regimes

Applied Physics A (2023)

-

In-field Performance Comparison and Vortex Pinning Analysis in Depth of Pristine and BaHfO3-Doped Y0.5Gd0.5Ba2Cu3O7-δ Films in Different Temperature Regions

Journal of Superconductivity and Novel Magnetism (2022)