Abstract

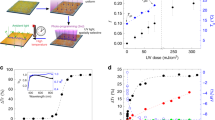

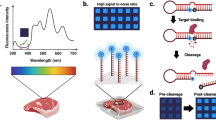

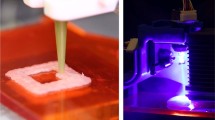

Sustainability, humidity sensing and product origin are important features of food packaging. While waste generated from labelling and packaging causes environmental destruction, humidity can result in food spoilage during delivery and counterfeit-prone labelling undermines consumer trust. Here we introduce a food label based on a water-soluble nanocomposite ink with a high refractive index that addresses these issues. By patterning the nanocomposite ink using nanoimprint lithography, the resultant metasurface shows bright and vivid structural colours. This method makes it possible to quickly and inexpensively create patterns on large surfaces. A QR code is also developed that can provide up-to-date information on food products. Microprinting hidden in the QR code protects against counterfeiting, cannot be physically detached or replicated and may be used as a humidity indicator. Our proposed food label can reduce waste while ensuring customers receive accurate product information.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request.

References

Schwartz, D., Loewenstein, G. & Agüero-Gaete, L. Encouraging pro-environmental behaviour through green identity labelling. Nat. Sustain. 3, 746–752 (2020).

Grunert, K. G., Hieke, S. & Wills, J. Sustainability labels on food products: consumer motivation, understanding and use. Food Policy 44, 177–189 (2014).

Kim, J. H. et al. Nanoscale physical unclonable function labels based on block copolymer self-assembly. Nat. Electron. 5, 433–442 (2022).

Gu, Y. et al. Gap-enhanced Raman tags for physically unclonable anticounterfeiting labels. Nat. Commun. 11, 516 (2020).

Mustafa, F. & Andreescu, S. Nanotechnology-based approaches for food sensing and packaging applications. RSC Adv. 10, 19309–19336 (2020).

Jones, K. Plastic fruit and vegetable labels to stick around after ban. Stuff (27 June 2023); https://www.stuff.co.nz/nelson-mail/news/132367540/plastic-fruit-and-vegetable-labels-to-stick-around-after-ban

Xia, Q. et al. A strong, biodegradable and recyclable lignocellulosic bioplastic. Nat. Sustain. 4, 627–635 (2021).

Rosenboom, J.-G., Langer, R. & Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 7, 117–137 (2022).

Moshood, T. D. et al. Sustainability of biodegradable plastics: new problem or solution to solve the global plastic pollution? Curr. Res. Green Sustain. Chem. 5, 100273 (2022).

Bradford, H., McKernan, C., Elliott, C. & Dean, M. Consumer purchase intention towards a quick response (QR) code for antibiotic information: an exploratory study. npj Sci. Food 6, 23 (2022).

OECD/EUIPO Trends in Trade in Counterfeit and Pirated Goods (OCED, 2019); https://doi.org/10.1787/g2g9f533-en

Badloe, T. et al. Liquid crystal-powered Mie resonators for electrically tunable photorealistic color gradients and dark blacks. Light Sci. Appl. 11, 118 (2022).

Joo, W.-J. et al. Metasurface-driven OLED displays beyond 10,000 pixels per inch. Science 370, 459–463 (2020).

Dong, Z. et al. Printing beyond sRGB color gamut by mimicking silicon nanostructures in free-space. Nano Lett. 17, 7620–7628 (2017).

Vynck, K. et al. The visual appearances of disordered optical metasurfaces. Nat. Mater. 21, 1035–1041 (2022).

Cencillo-Abad, P., Franklin, D., Mastranzo-Ortega, P., Sanchez-Mondragon, J. & Chanda, D. Ultralight plasmonic structural color paint. Sci. Adv. 9, eadf7207 (2023).

Song, M. et al. Versatile full-colour nanopainting enabled by a pixelated plasmonic metasurface. Nat. Nanotechnol. 18, 71–78 (2023).

Kim, I. et al. Metasurfaces-driven hyperspectral imaging via multiplexed plasmonic resonance energy transfer. Adv. Mater. 35, 2300229 (2023).

Dong, Z. et al. Schrödinger’s red pixel by quasi-bound-states-in-the-continuum. Sci. Adv. 8, eabm4512 (2022).

Yang, W. et al. All-dielectric metasurface for high-performance structural color. Nat. Commun. 11, 1864 (2020).

Jung, C. et al. Metasurface-driven optically variable devices. Chem. Rev. 121, 13013–13050 (2021).

So, S., Mun, J., Park, J. & Rho, J. Revisiting the design strategies for metasurfaces: fundamental physics, optimization, and beyond. Adv. Mater. 35, 2206399 (2023).

Ko, B. et al. Tunable metasurfaces via the humidity responsive swelling of single-step imprinted polyvinyl alcohol nanostructures. Nat. Commun. 13, 6256 (2022).

Espinha, A. et al. Hydroxypropyl cellulose photonic architectures by soft nanoimprinting lithography. Nat. Photon. 12, 343–348 (2018).

Code of Federal Regulations Title 21: Food and Drugs Section 177.1670 (FDA, 2011); https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=177.1670

Kumar, K. et al. Printing colour at the optical diffraction limit. Nat. Nanotechnol. 7, 557–561 (2012).

McClements, D. J. & Xiao, H. Is nano safe in foods? Establishing the factors impacting the gastrointestinal fate and toxicity of organic and inorganic food-grade nanoparticles. npj Sci. Food 1, 6 (2017).

Geppert, M. et al. Interactions of TiO2 nanoparticles with ingredients from modern lifestyle products and their effects on human skin cells. Chem. Res. Toxicol. 33, 1215–1225 (2020).

Horie, M. et al. Does photocatalytic activity of TiO2 nanoparticles correspond to photo-cytotoxicity? Cellular uptake of TiO2 nanoparticles is important in their photo-cytotoxicity. Toxicol. Mech. Methods 26, 284–294 (2016).

Zhang, L. W. & Monteiro-Riviere, N. A. Toxicity assessment of six titanium dioxide nanoparticles in human epidermal keratinocytes. Cutan. Ocul. Toxicol. 38, 66–80 (2019).

Code of Federal Regulations Title 21: Food and Drugs Section 73.575 (FDA, 2011); https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?fr=73.575

Jang, J. et al. Spectral modulation through the hybridization of Mie-scatterers and quasi-guided mode resonances: realizing full and gradients of structural color. ACS Nano 14, 15317–15326 (2020).

Yang, J.-H. et al. Structural colors enabled by lattice resonance on silicon nitride metasurfaces. ACS Nano 14, 5678–5685 (2020).

Kim, J. et al. Photonic encryption platform via dual-band vectorial metaholograms in the ultraviolet and visible. ACS Nano 16, 3546–3553 (2022).

Khorasaninejad, M. et al. Metalenses at visible wavelengths: diffraction-limited focusing and subwavelength resolution imaging. Science 352, 1190–1194 (2016).

Chen, W. T. et al. A broadband achromatic metalens for focusing and imaging in the visible. Nat. Nanotechnol. 13, 220–226 (2018).

Kim, J. et al. Metasurface holography reaching the highest efficiency limit in the visible via one-step nanoparticle-embedded-resin printing. Laser Photonics Rev. 16, 2200098 (2022).

Kim, J. et al. One-step printable platform for high-efficiency metasurfaces down to the deep-ultraviolet region. Light Sci. Appl. 12, 68 (2023).

Mendoza-Carreño, J. et al. Nanoimprinted 2D-chiral perovskite nanocrystal metasurfaces for circularly polarized photoluminescence. Adv. Mater. 35, 2210477 (2023).

So, S. et al. Multicolor and 3D holography generated by inverse-designed single-cell metasurfaces. Adv. Mater. 35, 2208520 (2023).

Choi, H. et al. Realization of high aspect ratio metalenses by facile nanoimprint lithography using water-soluble stamps. PhotoniX 4, 18 (2023).

Kim, J. et al. Scalable manufacturing of high-index atomic layer–polymer hybrid metasurfaces for metaphotonics in the visible. Nat. Mater. 22, 474–481 (2023).

Acknowledgements

This work was financially supported by the Samsung Research Funding & Incubation Center for Future Technology grant (SRFC-IT1901-52) funded by Samsung Electronics, the POSCO-POSTECH-RIST Convergence Research Center program funded by POSCO, the National Research Foundation (NRF) grants (NRF-2022M3C1A3081312, NRF-2022M3H4A1A02074314, NRF-2019R1A5A8080290, RS-2023-00283667, RS-2023-00302586) funded by the Ministry of Science and ICT of the Korean government, and the Korea Evaluation Institute of Industrial Technology grant (no. 1415179744/20019169, Alchemist project) funded by the Ministry of Trade, Industry and Energy of the Korean government. J.K. and H. Kim acknowledge the Asan Foundation Biomedical Science fellowships. J.K. and H. Kim acknowledge the POSTECH Alchemist fellowships. J.C., Y.C. and J.R. acknowledge the Catalyst: Strategic New Zealand–Republic of Korea Joint Research Partnerships programme (C11X2107) funded by the Ministry of Business, Innovation and Employment of the New Zealand government, and the NRF grant (NRF-2021K1A3A1A17086079) funded by the Ministry of Science and ICT of the Korean government. We thank T. Badloe (POSTECH) for English proofreading and fruitful discussion. We thank G. Jeon, K.-I. Lee and D. H. Yoon (RIST) for the technical support of nanoimprint lithography.

Author information

Authors and Affiliations

Contributions

J.R. conceived the idea and initiated the project. J.K. and J.R. designed the experiments. H. Kim performed the theoretical and numerical simulations. J.K. fabricated the nanopatterns and devices. H. Kang and W.K. performed the nanoimprinting and replication of the devices. J.C. and Y.C. performed the nano-ink analysis. J.K., H. Kang and H. Kim performed the experimental characterizations and data analysis. J.K., H. Kim and H. Kang mainly wrote the manuscript. All authors confirmed the final manuscript. J.R., J.C. and H.L. guided the entire work.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Food thanks Cheng-Wei Qiu, Jia Zhu and Senentxu Lanceros-Méndez for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Reflected colour at oblique viewing angles.

Calculated reflectance spectra (left side) and measured colours (right side) at the incident angle θi from 0° to 60° for the metasurface with (a) P = 305 nm, (b) P = 350 nm, and (c) P = 410 nm.

Extended Data Fig. 2 Preparation for QR code label.

(a) Photograph of a master stamp for a QR code fabricated by high-speed electron-beam lithography. (b) Photograph of a replica mould for the QR code fabricated by spin-coating and curing a h-PDMS/PDMS bilayer. (c) OM image of microprinting in the master stamp.

Extended Data Fig. 3 Effect to label under various light conditions.

Photograph of the printed QR codes under various lighting conditions. (a) Yellow light condition. (b) White light condition. (c,d) Natural light condition. The printed QR codes are recognized well regardless of light conditions, and they all reflect green colour with only slight variations in hue.

Extended Data Fig. 4 Reversible colour variation under different humidity.

OM images illustrating reversible colour variations under different humidity conditions from RH 55% to 80%. Brief exposure to high humidity (RH 75% and above) for around 20 seconds causes size adjustments in nanostructures, resulting in noticeable colour shifts. Once humidity exposure stops, the colour returns to its original state. These colour variations in the labels serve as a simple and effective humidity sensing mechanism.

Extended Data Fig. 5 Humidity stability test.

Humidity stability of the QR codes in a humidity-controlled chamber for 3 days. Even with long-term exposure to humidity conditions below RH 75%, the printed QR codes show no changes in colour or shape, ensuring reliable QR code recognition. This demonstrates the stability of the labels during product transportation.

Extended Data Fig. 6 Thermal stability test.

Thermal stability of the QR codes on a hotplate for 3 days. Below 70 degrees Celsius, the printed QR codes consistently reflect a green colour without shape deformations. This confirms the thermal stability of the labels in high-temperature environments.

Extended Data Fig. 7 Mechanical stability test.

Mechanical stability of the QR codes printed on a flexible PET film under bent condition: (a) tensile and (b) compressive bending. The QR codes printed on a flexible film endure both tensile and compressive bending with the 3 cm curvature radius. This demonstrates the high stability of labels under bending stress, showing their applicability for curved packaging.

Supplementary information

Supplementary Information

Supplementary Notes 1–8.

Supplementary Video 1

Water-solubility test of the fabricated full-colour label.

Supplementary Video 2

Scanning fabricated QR code for product information.

Supplementary Video 3

Humidity sensing with red pixel colour variation.

Supplementary Video 4

Reversible colour changes based on various humidity levels.

Supplementary Video 5

Scanning QR code after humidity and thermal stability test.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kim, J., Kim, H., Kang, H. et al. A water-soluble label for food products prevents packaging waste and counterfeiting. Nat Food 5, 293–300 (2024). https://doi.org/10.1038/s43016-024-00957-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s43016-024-00957-4

This article is cited by

-

A sustainable metasurface for smart food labelling

Nature Food (2024)