Abstract

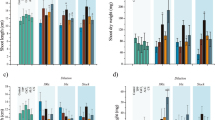

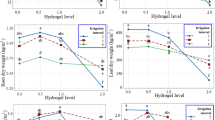

In semi-arid regions, water stress during seed germination and early seedling growth is the highest cause of crop loss. In nature, some seeds (for example, chia and basil) produce a mucilage-based hydrogel that creates a germination-promoting microenvironment by retaining water, regulating nutrient entry and facilitating interactions with beneficial microorganisms. Inspired by this strategy, a two-layered biopolymer-based seed coating has been developed to increase germination and water-stress tolerance in semi-arid, sandy soils. Seeds are coated with a silk/trehalose inner layer containing rhizobacteria and a pectin/carboxymethylcellulose outer layer that reswells upon sowing and acts as a water jacket. Using Phaseolus vulgaris (common bean) cultured under water-stress conditions in an experimental farm in Ben Guerir, Morocco, the proposed seed coating effectively delivered rhizobacteria to form root nodules, resulted in plants with better health and mitigated water stress in drought-prone marginal lands. A programmable seed coating technology has the potential to increase seed germination and water-stress tolerance in semi-arid, sandy soils.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All relevant data are included in the article, Supplementary Information and in the Source Data files. All the other raw data are available from the authors upon request. Source data are provided with this paper.

References

Status of the World’s Soil Resources (FAO, 2015).

Ricciardi, V. et al. A scoping review of research funding for small-scale farmers in water scarce regions. Nat. Sustain. 3, 836–844 (2020).

The State of Food Security and Nutrition in the World 2019 (FAO, IFAD, UNICEF, WFP and WHO, 2019).

Behera, S. & Mahanwar, P. A. Superabsorbent polymers in agriculture and other applications: a review. Polym. Technol. Mater. 59, 341–356 (2020).

Stahl, J. D., Cameron, M. D., Haselbach, J. & Aust, S. D. Biodegradation of superabsorbent polymers in soil. Environ. Sci. Pollut. Res. 7, 83–88 (2000).

Niu, X., Song, L., Xiao, Y. & Ge, W. Drought-tolerant plant growth-promoting rhizobacteria associated with foxtail millet in a semi-arid agroecosystem and their potential in alleviating drought stress. Front. Microbiol. 8, 2580 (2018).

Kuypers, M. M. M., Marchant, H. K. & Kartal, B. The microbial nitrogen-cycling network. Nat. Rev. Microbiol. 16, 263–276 (2018).

Enebe, M. C. & Babalola, O. O. The influence of plant growth-promoting rhizobacteria in plant tolerance to abiotic stress: a survival strategy. Appl. Microbiol. Biotechnol. 102, 7821–7835 (2018).

Soumare, A. et al. Exploiting biological nitrogen fixation: a route towards a sustainable agriculture. Plants 9, 1011 (2020).

McIntyre, H. J. et al. Trehalose biosynthesis in Rhizobium leguminosarum bv. trifolii and its role in desiccation tolerance. Appl. Environ. Microbiol. 73, 3984–3992 (2007).

Vriezen, J. A., de Bruijn, F. J. & Nüsslein, K. R. Desiccation induces viable but non-culturable cells in Sinorhizobium meliloti 1021. AMB Express 2, 6 (2012).

Geetha, S. J. & Joshi, S. J. Engineering rhizobial bioinoculants: a strategy to improve iron nutrition. Sci. World J. https://doi.org/10.1155/2013/315890 (2013).

Molina-Romero, D. et al. Compatible bacterial mixture, tolerant to desiccation, improves maize plant growth. PLoS ONE 12, e0187913 (2017).

Teixeira, A., Iannetta, P., Binnie, K., Valentine, T. A. & Toorop, P. Myxospermous seed-mucilage quantity correlates with environmental gradients indicative of water-deficit stress: Plantago species as a model. Plant Soil 446, 343–356 (2020).

Western, T. L. The sticky tale of seed coat mucilages: production, genetics and role in seed germination and dispersal. Seed Sci. Res. 22, 1–25 (2012).

Kreitschitz, A. & Gorb, S. N. The micro- and nanoscale spatial architecture of the seed mucilage–comparative study of selected plant species. PLoS ONE 13, e0200522 (2018).

Phan, J. L. & Burton, R. A. New insights into the composition and structure of seed mucilage. Annu. Plant Rev. Online https://doi.org/10.1002/9781119312994.apr0606 (2018).

Sun, H. & Marelli, B. Growing silk fibroin in advanced materials for food security. MRS Commun. https://doi.org/10.1557/s43579-020-00003-x (2021).

Zhou, Z. et al. Engineering the future of silk materials through advanced manufacturing. Adv. Mater. 30, 1706983 (2018).

Rockwood, D. N. et al. Materials fabrication from Bombyx mori silk fibroin. Nat. Protoc. 6, 1612–1631 (2011).

Marelli, B., Brenckle, M. A., Kaplan, D. L. & Omenetto, F. G. Silk fibroin as edible coating for perishable food preservation. Sci. Rep. 6, 25263 (2016).

Marelli, B. et al. Programming function into mechanical forms by directed assembly of silk bulk materials. Proc. Natl Acad. Sci. USA 114, 451–456 (2017).

Kim, D. et al. A microneedle technology for sampling and sensing bacteria in the food supply chain. Adv. Funct. Mater. 31, 2005370 (2021).

Cao, Y., Lim, E., Xu, M., Weng, J. K. & Marelli, B. Precision delivery of multiscale payloads to tissue-specific targets in plants. Adv. Sci. 7, 1903551 (2020).

Sun, H. & Marelli, B. Polypeptide templating for designer hierarchical materials. Nat. Commun. 11, 351 (2020).

Pritchard, E. M. & Kaplan, D. L. Silk fibroin biomaterials for controlled release drug delivery. Expert Opin. Drug Deliv. 8, 797–811 (2011).

Crowe, J. H., Carpenter, J. F. & Crowe, L. M. The role of vitrification in anhydrobiosis. Annu. Rev. Physiol. 60, 73–103 (1998).

Boothby, T. C. et al. Tardigrades use intrinsically disordered proteins to survive desiccation. Mol. Cell 65, 975–984.e5 (2017).

Zvinavashe, A. T., Lim, E., Sun, H. & Marelli, B. A bioinspired approach to engineer seed microenvironment to boost germination and mitigate soil salinity. Proc. Natl Acad. Sci. USA 116, 25555–25561 (2019).

Vílchez, S., Tunnacliffe, A. & Manzanera, M. Tolerance of plastic-encapsulated Pseudomonas putida KT2440 to chemical stress. Extremophiles 12, 297–299 (2008).

Cao, Y. & Mezzenga, R. Design principles of food gels. Nat. Food 1, 106–118 (2020).

Redondo-Nieto, M., Wilmot, A. R., El-Hamdaoui, A., Bonilla, I. & Bolaños, L. Relationship between boron and calcium in the N2-fixing legume–rhizobia symbiosis. Plant. Cell Environ. 26, 1905–1915 (2003).

Yoshimura, T., Sengoku, K. & Fujioka, R. Pectin-based superabsorbent hydrogels crosslinked by some chemicals: synthesis and characterization. Polym. Bull. 55, 123–129 (2005).

Pathak, V. & Ambrose, R. P. K. Starch‐based biodegradable hydrogel as seed coating for corn to improve early growth under water shortage. J. Appl. Polym. Sci. 137, 48523 (2020).

Ahn, S. & Lee, S. J. Nano/micro natural patterns of hydrogels against water loss. ACS Appl. Bio Mater. 3, 1293–1304 (2020).

Bakholdin, B. V. & Chashchikhina, L. P. Determination of the compression modulus of soils from compression-test data for calculation of pile-foundation settlements. Soil Mech. Found. Eng. 36, 9–12 (1999).

Nataraj, M. S. & McManis, K. L. Strength and deformation properties of soils reinforced with fibrillated fibers. Geosynth. Int. 4, 65–79 (1997).

Taylor, A. G. et al. Seed enhancements. Seed Sci. Res. 8, 245–256 (1998).

Li, J. & Mooney, D. J. Designing hydrogels for controlled drug delivery. Nat. Rev. Mater. 1, 16071 (2016).

Samateh, M. et al. Unravelling the secret of seed-based gels in water: the nanoscale 3D network formation. Sci. Rep. 8, 7315 (2018).

Nanjareddy, K. et al. Nitrate regulates rhizobial and mycorrhizal symbiosis in common bean (Phaseolus vulgaris L.). J. Integr. Plant Biol. 56, 281–298 (2014).

Yin, N. et al. Bacterial cellulose as a substrate for microbial cell culture. Appl. Environ. Microbiol. 80, 1926–1932 (2014).

Kandemir, N., Vollmer, W., Jakubovics, N. S. & Chen, J. Mechanical interactions between bacteria and hydrogels. Sci. Rep. 8, 10893 (2018).

Lichter, J. A. et al. Substrata mechanical stiffness can regulate adhesion of viable bacteria. Biomacromolecules 9, 1571–1578 (2008).

Restricting the Use of Intentionally Added Microplastic Particles to Consumer or Professional Use Products of Any Kind Annex XV Restriction Report (ECHA, 2019).

Mansori, M. et al. Seaweed extract effect on water deficit and antioxidative mechanisms in bean plants (Phaseolus vulgaris L.). J. Appl. Phycol. 27, 1689–1698 (2015).

Beebe, S. E., Rao, I. M., Blair, M. W. & Acosta-Gallegos, J. A. Phenotyping common beans for adaptation to drought. Front. Physiol. 4, 35 (2013).

Trevors, J. T. Sterilisation and inhibition of microbial activity in soil. J. Microbiol. Methods 26, 53–59 (1996).

Deaker, R., Roughley, R. J. & Kennedy, I. R. Legume seed inoculation technology—a review. Soil Biol. Biochem. 36, 1275–1288 (2004).

Mukhtar, S., Shahid, I., Mehnaz, S. & Malik, K. A. Assessment of two carrier materials for phosphate solubilising biofertilizers and their effect on growth of wheat (Triticum aestivum L.). Microbiol. Res. 205, 107–117 (2017).

Acknowledgements

We acknowledge M. Lara for R. tropici CIAT 899-GFP from Universidad Nacional Autonoma de Mexico, OCP S.A. and the Université Mohammed VI Polytechnique–MIT Research Program. This work was partially supported by the Office of Naval Research (Award No. N000141812258), the National Science Foundation (Award No. CMMI‐1752172) and the MIT Paul M. Cook Career Development Professorship. Schematics in Fig. 1a,b were created with BioRender.com.

Author information

Authors and Affiliations

Contributions

A.T.Z., J.L., M.M., B.M. and L.K. designed the study. A.T.Z., J.L., M.M., H.S., S.M., D.K. and H.M.E.F. collected and analysed the data. All authors contributed to the discussion and interpretation of the results. The manuscript was drafted by A.T.Z., J.L., H.S., M.M, L.K and B.M. and reviewed and approved by the other authors.

Corresponding author

Ethics declarations

Competing interests

B.M. and A.T.Z. are co-inventors in a patent application (US Patent application no. 63/036,088) that describes the coating technology reported in this study. B.M. is co-founder of Mori, Inc., a company that develops silk-based edible coatings to extend the shelf life of food. All other authors have no competing interests.

Additional information

Peer review information Nature Food thanks David Britt, Haihua Xiao and Maximino Manzanera for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–7, Table 1 and Methods.

Source data

Source Data Fig. 1

Statistical Source Data.

Source Data Fig. 2

Statistical Source Data.

Source Data Fig. 3

Statistical Source Data.

Source Data Fig. 4

Statistical Source Data.

Rights and permissions

About this article

Cite this article

Zvinavashe, A.T., Laurent, J., Mhada, M. et al. Programmable design of seed coating function induces water-stress tolerance in semi-arid regions. Nat Food 2, 485–493 (2021). https://doi.org/10.1038/s43016-021-00315-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s43016-021-00315-8

This article is cited by

-

Effect of selenium nanoparticles on biological and morphofunctional parameters of barley seeds (Hordéum vulgáre L.)

Scientific Reports (2023)

-

Recent Advances in Seed Coating Treatment Using Nanoparticles and Nanofibers for Enhanced Seed Germination and Protection

Journal of Plant Growth Regulation (2023)

-

Hydrogels in Agriculture: Prospects and Challenges

Journal of Polymers and the Environment (2023)

-

Plug-and-play bioinspired seed coatings

Nature Food (2021)