Abstract

Metal individual atoms and few-atom clusters show extraordinary catalytic properties for a variety of organic reactions, however, their implementation in total synthesis of complex organic molecules is still to be determined. Here we show a 11-step linear synthesis of the natural product (±)-Licarin B, where individual Pd atoms (Pd1) catalyze the direct aerobic oxidation of an alcohol to the carboxylic acid (steps 1 and 6), Cu2-7 clusters catalyze carbon-oxygen cross couplings (steps 3 and 8), Pd3-4 clusters catalyze a Sonogashira coupling (step 4) and Pt3-5 clusters catalyze a Markovnikov hydrosylilation of alkynes (step 5), as key reactions during the synthetic route. In addition, the new synthesis of Licarin B showcases an unexpected selective alkene hydrogenation with metal-free NaBH4 and an acid-catalyzed intermolecular carbonyl-olefin metathesis as the last step, to forge a trans-alkene group. These results, together, open new avenues in the use of metal individual atoms and clusters in organic synthesis, and confirm their exceptional catalytic activity in late stages during complex synthetic programmes.

Similar content being viewed by others

Introduction

The eruption during the last ten years of single atoms catalysts (SACs)1 and catalytic few-atom metal clusters2 with exceptional catalytic activity (thousand to millions of turnover numbers) for different reactions have brought the organic synthetic community to adopt them for a variety of transformations3,4,5,6,7,8, including biologically active compounds3,4,9, since the metal efficiency of these ultrasmall catalytic species can in many cases be higher than classical organometallic complexes9. Significant progresses have been achieved in single and few-atom metal-catalyzed hydrogenation, oxidation, hydroaddition and cross-coupling reactions, to name a few, covering also from mild click chemistry to harsh radical C–H activation reactions10. Therefore, the time has come to test these single and few metal atom catalysts in long synthetic routes, from early to late stages, in order to confirm that the extraordinary catalytic activity of these ligand-free subnanometric metal species in benchmark reactions is maintained for structurally elaborated organic substrates. It is noteworthy to remark that the SACs and few-atom metal clusters employed here as catalysts are present in solution, not supported, thus we will name the SACs as “individual metal atoms”.

Lignans and neolignans constitute a huge family of natural products11 with a plethora of well-known pharmaceutical properties, ranging from neuroprotective12,13 to antiviral14 activity. More and more structures are found each year, and only in the last decade >500 members of the (neo)lignan family have been isolated, structurally characterized and biologically determined11,15,16. Within the neolignan family, the dehydrobenzofurane-containing sub-family can be considered one of the most numerous and relevant, and Fig. 1 shows representative natural products of this kind. It can be seen that the dehydrobenzofurane core is decorated with different functional groups, to achieve an array of natural products with diverse biological functions. However, in contrast to the great interest arisen by these compounds in pharma, the number of synthesis for most of them is very limited or just non-existent.

Licarin B ( ± )-1 is a prominent member of the dehydrobenzofurane neolignan family with antibacterial17, antidiabetic18,19, antiviral20 and neuroprotective effects21. Its structure in racemic form (Fig. 1) was confirmed by total synthesis more than three decades ago (the last synthesis in 1991)21,22 employing the synthetic toolkit available at that time, i.e., non-catalytic procedures and extensive use of protecting groups, with accumulated yields as low as 2.5% after ~10 linear-steps23. As far as we know, any other synthesis of (±)-1 has not been reported since then11, and this lack of modern synthetic methodologies for (±)-1 is indeed extensible to many benzofurane (neo)lignans24,25. Therefore, the design of a general synthesis of benzofurane (neo)lignans based on modern catalytic reactions is still pending for the synthetic organic community.

Figure 2 shows the retrosynthetic approach proposed here for (±)-1, also valid for other dehydrobenzofurane (neo)lignans. The synthetic route is based on diverse single and few-atoms metal catalyzed-reactions, including dehydrogenation26, hydrosilylation27 and cross-coupling reactions28,29 with Pd, Pt and Cu single atoms and metal cluster catalysts in solution, and without any canonical ligand (phosphines, carbenes,…). It must be noticed here again that the concept “SACs” often refer to single atoms supported/embedded onto solid supports, however, we will use here these SACs (and also metal clusters) in solution, named “individual metal atoms”, since the latter allows free interaction with large molecules and avoids the inherent diffusion limitations associated to solid catalysts. However, the solid-supported counterparts for the ultrasmall catalytic metal species used here are as active as the catalysts in solution, at least for the reported reactions26,27,28, thus leaving room to also perform the reactions under heterogeneous reaction conditions. Besides, our retrosynthesis contains a recently reported intermolecular carbonyl-olefin metathesis30 as the last step of the synthesis, since this transformation affords a high trans alkene selectivity either under homogenous or heterogeneous reaction conditions. Furthermore, the intermolecular carbonyl-olefin metathesis reaction has to our knowledge been barely tested in synthetic programs, much less in a late stage synthetic step31. We will also show here that, unexpectedly, the hydrogenation of an intermediate ketone with NaBH4, without any apparent catalytic metal, will promote preferentially the hydrogenation of an alkene rather than the conjugated ketone. This reaction has somehow been reported for LiAlH432 but it is difficult to find for NaBH4, as far as we know33. We think that all these features make the synthesis of (±)-1 described here of interest for catalytic and synthetic chemists.

Results

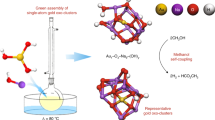

Synthesis of intermediate 14

Figure 3 shows the first part of the (±)-Licarin B 1 synthesis, going from the commercially available and relatively cheap starting materials 2 and 11 to the coupled intermediate 14 (see Supplementary Methods and Supplementary Data 1 for NMR copies of the products). First, benzyl alcohol 2 is oxidized under aerobic conditions to the corresponding benzoic acid 3 in high yield (83%), without any solvent or additive, catalyzed Pd1 individual atoms formed in-situ after mild reduction of the Pd precursor [in this case Pd(OAc)2] with 2 (a complete substrate scope for this catalyst can be found in the previous study)26. The previous characterization of the catalytic Pd1 individual atoms, including a representative aberration-corrected high-angle annular dark field scanning-transmission electron microscopy (AC-HAADF-STEM) image and X-ray absorption near-edge structure (XANES) / extended X-ray absorption fine structure (EXAFS) spectra, can be found in the Supplementary Information (Fig. S1 and Table S1)26. The used catalyst was not characterized after reaction, however, this can be found in the precedent study26 (this applies to the single atom and cluster catalysts ahead). The isolated carboxylic acid 3 can now be easily di-iodinated in both metha-positions with N-iodosuccinimide (NIS) under acid conditions, to give the tri-halogen substituted intermediate 4 in >95% yield. A selective substitution of one of the I atoms on the ring, to give 5, was accomplished with catalytic Cu clusters of 2 to 7 atoms (Cu2-7) in basic media. The characterization of the catalytic clusters here prepared was accomplished using absorption/emission ultraviolet-visible (UV-vis) spectrophotometric measurements and MALDI-TOF spectra [Fig. S2 top and Tables S2–S3, see the corresponding UV-vis and MALDI-TOF spectra of the previously reported Cu clusters in Fig. S2 bottom, for the sake of comparison, and a complete substrate scope for this catalyst can be found in the previous study]29. It is worth commenting here that the control over the mono-hydroxylation reaction, on just one single halogen site, is not easy and significant amounts of starting material 4 and di-hydroxylated compounds were concomitantly recovered after reaction. Nevertheless, a reasonable two-step yield of 6 (43%) was obtained after methylation of the two OH groups present in the molecule. The methylation of both OH groups after the Cu-catalyzed C-O cross-coupling reaction allows using inexpensive aqueous NaOH as a nucleophile and circumvents the possible degradation of a previously prepared ester group.

Metal individual atoms and few-atoms metal clusters catalysts are marked in bold. All reactions were carried out with dried solvents and under nitrogen atmosphere otherwise indicated. Yields refer to isolated yields in all cases. Reaction conditions: (a) 2 (neat, 2 mmol), Pd1 [0.3 mol%, prepared from Pd(OAc)2], O2 (4 bar), 150 °C, 16 h; (b) 3 (49.8 mmol), H2SO4(c) (0.3 M), N-iodosuccinimide (NIS, 128.3 mmol, 2.6 equiv.), room temperature, 16 h; (c) 4 (2.2 mmol), 120 mg (0.8 mmol, 0.4 equiv.), Cu2-7 (40 mol%, prepared from Cu2O), NaOH (12 mmol, 5.4 equiv.), H2O (10 ml), 85 °C, 16 h, then precipitation and treatment with K2CO3 (5.6 mmol, 2.2 equiv.), acetone (37 ml) and dimethyl sulfate (DMS, 5.5 mmol, 2.1 equiv.), 50 °C, 16 h; (d) 6 (0.4 mmol), trimethylsilylacetylene (0.8 mmol, 2 equiv.), Pd2-3 [0.1 mol%, prepared from Pd(OAc)2], KOAc (0.5 mmol, 1.25 equiv.), N-methyl pyrrolidone (NMP, 0.5 M), 150 °C, 20 h, then K2CO3 (20 mol%), MeOH (0.2 M); (e) 8 (0.16 mmol.), triethylsilane (0.19 mmol, 1.2 equiv.), Pt3-5 [0.7 mol%, prepared from Karstedt’s complex (Pt0-1,3-divinyl-1,1,3,3-tetramethyldisiloxane)], toluene (0.5 M), 110 °C, 16 h, or 8 (0.2 mmol), Pd(PPh3)2Cl2 (5 mol%), tetrabutylstannane (0.2 mmol, 1 equiv.), THF (0.5 M), 0 °C, 1.5 h; (f) As in (a); (g) 12 (1.1 mmol), SOCl2 (0.5 M), 80 °C, 3 h; (h) 10 (0.32 mmol), 13 (0.36 mmol, 1.1 equiv.), Pd(PPh3)4 (1 mol%), toluene (0.1 M), 110 °C, 16 h.

With compound 6 in hand, a Cu-free Sonogahira coupling between 6 and trimethylsilylacetylene, catalyzed by a 0.03 mol% of two- and three-atoms Pd clusters (Pd2-3), was carried out [again, the characterization of the catalytic clusters was carried out with absorption/emission UV-vis and MALDI-TOF measurements (Fig. S3 top and Tables S2, S4) and compared with the previously reported Pd clusters (Fig. S3 bottom), and a complete substrate scope for this catalyst can be found in previous studies]28,34. The Pd2-3 clusters were prepared after mild reduction of Pd(OAc)2 in aqueous (1 wt%) N-methylpyrrolidone (NMP), stored in solution and added to the reaction mixture [0.1 mol%, see absorption/emission UV-vis spectrophotometry and matrix-assisted laser desorption/ionization coupled to time-of-flight (MALDI-TOF) mass spectrometry spectra in Fig. S3]28. The corresponding Sonogashira product 7 was obtanied in low yield (17%), lower to that obtanied by a conventional procedure with PdCl2(PPh3)2 and CuI co-catalysts (>95%, see Supplementary Methods, Fig. S4). However, it is noteworthy that the amount of Pd is two orders of magnitude lower for clusters and Cu is not used (turnover number, TON = 566 for Pd2-3 vs 20 for the organometallic complex). A one-pot base-catalyzed desilylation reaction gives the terminal phenylacetylene derivative 8 in 89% yield after two steps without isolation of 7.

The C-Br bond in 8 may, in principle, allow to construct the dehydrobenzofurane core of 1 using a C-O cross-coupling reaction with Cu clusters as a catalyst and piperonyl alcohol as a nucleophile, such as in the synthesis of 5 (Fig. S5). However, the intermolecular C-O cross-coupling reaction proved fruitless, in accordance with the lower reactivity of C-Br respect to C-I bonds and the high steric hindrance around the C-Br bond. Thus, we turned our attention to piperaldehyde as an electrophile, instead of piperonyl alcohol as a nucleophile, and to activate the α-position of the terminal alkyne in 8. Under reported conditions with Et2AlH as a hydroaluminating agent and Ti(OiPr)4 as an activator of the aldehyde electrophile35, any coupled product was not observed (Fig. S6). Thus, we decided to pre-activate the alkyne α-position with a good transmetallable or leaving group, to then carry out the coupling reaction with the piperonyl moiety.

Pt clusters between 3 and 5 atoms (Pt3-5) were prepared by heating the Karstedt’s complex (Pt0-1,3-divinyl-1,1,3,3-tetramethyldisiloxane) in toluene solution, and characterized by absorption/emission UV-vis and MALDI-TOF measurements (Fig. S7 top and Tables S2, S5), comparing with the previously reported Pt clusters (Fig. S7 bottom, with a representative AC-HAADF-STEM image, the emission UV-vis spectrum and the high-resolution mass spectrum in an ORBITRAP instrument)36,37. They were applied as a catalyst for the regioselective Markovnikov hydrosilylation of the terminal alkyne in 8 (a complete substrate scope for this catalyst can be found in the previous study)27,36. However, the yield of product 9 was low (30%). Besides, the attempted coupling of 9 with piperonaldehyde, catalyzed by a phosphazene compound38, failed (Fig. S8). Thus, we tested a related Pd-catalyzed procedure with tetrabutylstannane39, to give product 10 in >95% yield, having the required Markovnikov regioselectivity. With 10 in hand, we tested different reactions to couple piperaldehyde and thus leave a free alcohol group for the later cyclization reaction (Fig. S9), however, none of the reported conditions39,40,41 worked in our hands.

At this point, we envisioned a different coupling reaction to achieve the diaryl substituted gem-conjugated ketone 14 instead of the alcohol, based on the use of acyl chloride 13 as a coupling partner. The latter was obtained in two steps, first performing the Pd1-catalyzed aerobic oxidation of piperonyl alcohol 11, under the same reaction conditions than for the starting material 2 [notice that reported Pinnick oxidation conditions from piperonal42 gave, in our hands, lower conversion than the Pd1-catalyzed aerobic oxidation (Fig. S10)] and subsequent chlorination of acid 12. Now, the synthesis of 14 from 10 and 13 was attempted by a Pd-catalyzed Stille-type coupling reaction catalyzed by Pd(PPh3)4 under reported reaction conditions43, which gave 14 in 92% yield. The use of a Pd-catalyzed reaction is an alternative methodology to the use of typical CrCl2-mediated Nozaki-Hiyama-Kishi reaction conditions44, which nevertheless failed here, after forming the corresponding vinyl iodide from 10 (Fig. S11). Unfortunately, the use of Pd2-3 clusters as a catalyst for the Stille-type coupling did not give the desired product (Fig. S12)28.

Completion of the synthesis

Figure 4 shows the completion of the synthesis (see Supplementary Methods and Supplementary Data 1 for NMR copies of the products). The coupled intermediate 14 was treated with an excess (2.4 equivalents) of NaBH4, in order to hydrogenate the ketone. However, for our surprise, the alkene functionality was also hydrogenated, even faster than the ketone, thus both the methyl and the alcohol groups were formed at once, to give 15 in 75% yield. Indeed, the ketone intermediate could be isolated and characterized (Fig. S13). Inductively coupled plasma-optical emission spectroscopy (ICP-OES) analyses showed that the metal content in the reaction mixture is extremely low for all metals analysed, except for Sn, Si and B, and, of course, Na (Table S6, sample A). In order to check if some Sn traces, remaining in reactant 14 after purification of the reaction with 10, were catalyzing the hydrogenation of the alkene with NaBH4, a new batch of 14 with higher amounts of Sn (Table S6, sample B) was tested, however, the hydrogenation of the alkene was slower than before, while the ketone was hydrogenated somewhat faster. Thus, we have to preliminary conclude here that NaBH4 is able to hydrogenate the alkene group in 14 by its own, which constitutes a practical reaction (hydrogenation of alkenes with NaBH4) with any uncatalyzed precedent, as far as we know45. This methodology adds to related synthetic strategies, such as the circumvention of carbonyl group reduction challenges under Luche reduction46. Notice here that racemic 1,2-diarylethanols can be easily converted to enantiomerically pure compounds by dynamic kinetic resolution47, thus enabling the access to the corresponding enantiomeric forms of (±)-1.

Metal individual atoms and few-atoms metal clusters catalysts are marked in bold. All reactions were carried out with dried solvents and under nitrogen atmosphere otherwise indicated. Yields refer to isolated yields in all cases. Reaction conditions: (a) 14 (0.25 mmol), NaBH4 (0.6 mmol, 2.4 equiv.), THF:MeOH 1:1 (0.1 M), room temperature, 16 h; (b) 15 (0.014 mmol), Cu2-7 (10 mol%, prepared from CuI), Cs2CO3 (0.02 mmol, 1.5 equiv.), DMF (0.05 M), 130 °C, 16 h; (c) 16 (0.05 mmol), LiAlH4 (0.20 mmol, 4 equiv.), THF (0.1 M), room temperature, 16 h; (d) 17 (0.044 mmol), activated MnO2 (0.27 mmol, 6 equiv.), DCM (0.5 M), room temperature, 16 h; (e) 18 (0.012 mmol), 19 (0.036 mmol, 3 equiv.), BF3·OEt2 (0.012 mmol, 1 equiv.), DCE (0.03 M), 70 °C, 40 h.

The C-O intramolecular coupling in 15 was then attempted with Cu2-7 clusters as catalysts, as previously carried out for intermediate 5. Despite a C-Br bond is more difficult to activate than a C-I bond48, we envisioned that the formation of a very stable dehydrobenzofuran core would entropically help to the reaction to proceed, moreover with the O-nucleophile activated by a base. In contrast to the synthesis of 5, we avoided aqueous conditions to not generate hydroxyls in the medium, thus NMP was used as the solvent. Under these reaction conditions, the Cu2-7 clusters catalyzed the reaction quantitatively, to obtain 16 in >95% yield. Hydrogenation of the ester to alcohol 17 and dehydrogenation of the latter to aldehyde 18, under classical reaction conditions (with LiAlH4 and activated MnO2, respectively) gave intermediate 18 in >60% yield after two steps.

The final step consists in the transformation of the aldehyde in 18 into a trans ethylene group. This transformation is not straightforward by classical methodologies since Wittig-type reactions either lead to the cis alkene product or require the activation of the alkene with electron withdrawing groups to have a reasonable trans selectivity. Thus, we envisioned the use of a recently reported by us30 acid-catalyzed intermolecular carbonyl-olefin metathesis reaction, with high trans selectivity and which does not require activated alkenes. For that, we prepared ketal 19 which, under the acidic reaction conditions, stays in equilibrium with the corresponding vinyl ether form, to engage with aldehyde 18 in an intermolecular carbonyl-olefin metathesis reaction and give the desired (±)-Licarin B 1 in 46% yield. The ketal without phenyl group was also prepared49 and tested (Fig. S14), however, did not show the desired reactivity of 19. To our knowledge, examples of intermolecular carbonyl-olefin metathesis during late stages of a complex organic synthesis are extremely rare31. In order to check the formation of the trans alkene isomer, we additionally performed the synthesis of (±)-1 by a Takai reaction50, which is arguably the most reliable methodology to get a trans ethylene product from an aldehyde, however, at expenses of not fulfilling any sustainable principle for modern chemistry, since employs stoichiometric amounts of anhydrous CrCl251. For that, we prepared ethyl diiodide by a recently reported zeolite-catalyzed halogen exchange reaction52, avoiding the classical hydrazine-based methodology53. The Takai reaction with 18 gave (±)-1 in very high yield (93%) and a trans/cis ratio >20:1 (Fig. S15), similar not only to the product of the carbonyl-olefin metathesis reaction but also to a commercial sample of enantiomerically pure 1. Comparison of the synthesized (±)-Licarin B 1 with a commercial sample by Fourier transform infrared spectra (FT-IR), gas chromatography (GC), UV/vis spectrophotometry, and 1H and 13C nuclear magnetic resonance (NMR) spectra (Figs. S16–S20) validate our synthetic route, and shows that the regioselectivity of the as-synthesized (±)-1 is enriched in the anti regioisomer (ca. 5:1), as in natural Licarin B 1 (pure anti regioisomer). We infer that the enrichment in the natural regioisomer occurs by a favourable conformation during the cyclization reaction. Notice that acetone and DCM solvent traces are contained in both our synthesized 1 and the commercial sample, with FT-IR peaks at 1650 and 700 cm−1, and 1H NMR signals at 5.3 and 2.17 ppm, respectively, and that the 13C NMR signal at 125.5 ppm may correspond to the small amount of cis alkene product formed during the Takai reaction.

Conclusions

The synthesis of (±)-Licarin B 1 has been accomplished in 11 linear steps with 6 of these steps catalyzed by individual metal atoms and few-atom metal clusters in solution. The overall yield is 13.1%, higher than any of the previous synthesis reported >30 years ago. The synthetic route could be easily diverted to achieve other members of the neolignan family (see Fig. 1) and also to obtain the diastereomerically pure isomers. Other remarkable features found here are a late stage intermolecular carbonyl-olefin metathesis and an apparently metal-free hydrogenation of an alkene with NaBH4, faster than the hydrogenation of a ketone. These results, overall, can open new ways in the utilization of individual and few-atoms metal catalysts for total synthesis and new synthetic pathways for the synthesis of dehydrobenzofurane neolignans.

Methods

General

Reagents and solvents were obtained from commercial sources and were used without further purification otherwise indicated. The commercial sample of enantiomerically pure Licarin B 1 shows a 97% purity grade. Glassware was dried in an oven at 175 °C before use. Reactions were performed in round-bottomed flasks or 2.0 ml vials closed with a steel cap, equipped with a magnetic stirrer and having a rubber septum part to sample out. A nitrogen atmosphere was set for all reactions, otherwise indicated. Products were characterized by gas chromatography-mass spectrometry (GC-MS), high resolution electrospray ionization-mass spectrometry (ESI-MS), 1H- and 13C- nuclear magnetic resonance NMR, and distortionless enhancement by polarization transfer (DEPT). GC analyses were performed in an instrument equipped with a 25 m capillary column of 5% phenylmethylsilicone. Nitrobenzene or N-dodecane were used as an external standard. GC-MS analyses were performed on a spectrometer equipped with the same column as the GC and operated under the same conditions. 1H, 13C and DEPT measurements were recorded in a 300 or 400 MHz instrument using CDCl3 (containing TMS as an internal standard) and DMSO-d6 as a solvent. The metal content of the catalyst solutions and of the reaction mixture with NaBH4 was determined by inductively coupled plasma-optical emission spectroscopy (ICP-OES) after disaggregation of the mixture in acidic water mixtures: typically, 0.5 ml of the mixture were treated with 5 ml of aqua regia for 5 min, diluting with 50 ml of bi-distilled water and analyzing, after quantification by comparison of the response with a calibration plot. Absorption and emission ultraviolet-visible spectroscopy measurements were performed on the same samples than that for mass determination, using an UV/Vis (UV0811M209, Varian) and a LP S-220B spectrophotometer (Photon Technology International, equipped with 75 W Xe lamp), respectively.

Microscopy measurements

Pd1 and Pt3-5 species were characterized by electron microscopy after depositing one drop of the synthesized clusters in solution (or trapped in charcoal) onto holey-carbon coated Cu grids. After their preparation, samples were conserved under vacuum conditions. Scanning-transmission electron microscopy studies, using high-angle annular dark-field (HAADF- STEM), were performed on a FEI Titan Themis 60–300 double aberration corrected microscope operated at 300 kV. To obtain images with good quality, the beam current and image acquisition time were optimized according to the stability of the sample under the beam.

X-Ray Absorption Structure (XAS) techniques

X-ray absorption near edge structure (XANES) and extended X-ray absorption fine structure (EXAFS) measurements for Pd1 were carried out on CLAESS beamline at ALBA Synchrotron Light Source, Barcelona, Spain. The synchrotron light coming from the multipole wiggler has been first vertically collimated, then monochromatized using two pairs of liquid nitrogen cooled Si(311) crystals and finally focused on the sample position down to ~500 × 500 μm2. Rh stripe coating on the two optical mirrors guarantees the higher harmonics rejection. The Pd in solution sample was prepared in a 10 ml glass vial equipped with a stirring bar, adding benzyl alcohol (1.96 mmol, 200 µl) and 0.08% mol of Pd(OAc)2 (0.4 mg). The vial was closed with a septum equipped with a manometer and charged with air. Then the mixture was placed in a pre-heated metal heating plate at 150 °C and stirred at 450 rpm for 30 min. The XAS data were obtained in fluorescence mode at the Pd K-edge (24.350 keV) for our samples and transmission mode for the standards. Energy scale was calibrated by measuring a Pd foil sample. The local structure of the sample was refined using the EXAFS signal in the k range 3:10 Å−1.

Orbitrap measurements

The mass of the Pt3-5 clusters were measured in a flow injection-HRMS consisted of an injection and pump systems and a single mass spectrometer Orbitrap Thermo Fisher Scientific (Exactive™) using an electrospray interface (ESI) (HESI-II, Thermo Fisher Scientific) in positive or negative mode. The sample (10 μl) was injected into the flow-injection solvent consisting of an aqueous solution of 0.1% formic acid and methanol (1:1). The mass spectra were acquired employing two alternating acquisition functions: full MS, ESI + , without fragmentation and all-ion fragmentation (AIF), ESI + , with fragmentation. The mass range was 150.0–1500.0 m/z.

Matrix-assisted laser desorption/ionization coupled to time-of-flight (MALDI-TOF) mass spectrometry

MALDI-TO measurements for the Pd2-3 clusters were performed on the solution in DMF or NMP, diluted in 1 ml of acetonitrile (1 μL of the final solution was spotted onto the MALDI plate). After the droplets were air-dried at room temperature, 0.5 μL of matrix (5 mg/mL CHCA (Bruker) in 0.1% TFA-ACN/H2O (7:3, v/v) was added and allowed to air-dry at room temperature. The resulting mixtures were analyzed in a 5800 MALDI TOFTOF (ABSciex) in positive reflectron mode (3000 shots every position) in a mass range of 150–1500 m/z. Previously, the plate and the acquisition method were calibrated with 1 µL the TOFTOF calibration mixture (ABSciex), in 13 positions.

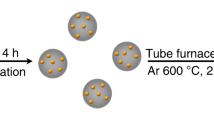

Synthesis of the individual and few-atom metal catalysts

The synthesis of Pd1 individual atoms was performed from Pd(OAc)2 following a reported procedure26. In brief, the Pd salt was heated in the benzyl alcohol under air, to in-situ form the Pd1 single atoms after mild reduction with the alcohol. The synthesis of Cu2-729, Pd2-328 and Pt3-536 clusters was also performed by reported procedures, briefly, by mild reduction in amide solvents (DMF or NMP) while heating at 120–150 °C for a few minutes. For Pd2-3 clusters, a 1 wt% of water was added to stabilize the clusters.

Reaction procedures

Synthesis of 4-bromobenzoic acid 3

In a 10-mililiter sealed reactor, 365.6 mg (1.96 mmol, 1 equiv.) of 4-bromo benzyl alcohol (2) were heated at 150 °C along with 1.32 mg (0.006 mmol, 0.003 equiv.) of Pd(OAc)2 under an O2 atmosphere of 4 atm. After 4 h, the temperature was cooled down and the reaction progress was checked by 1H NMR and GC. A distribution of three products was obtained in a proportion 1:1:1. As there was a 49% conversion, the reactor was charged with 2 atm of O2 and heated for 16 h. After that time, it was obtained full conversion, with an 83% yield of the target benzoic acid after hydrolysis of the ester formed.

Synthesis of 4-bromo-3,5-diiodobenzoic acid 4

In a one-neck round bottom flask, 9.96 g (49.75 mmol, 1 equiv.) of 3 were dissolved in 184 mL of H2SO4(c) and, then, the mixture was cooled down to 0 °C. 28.7 g (128.35 mmol, 2.6 equiv.) of N-iodosuccinimide (NIS) were added portionwise. The reaction was stirred overnight at room temperature. A mixture of 250 mL water/ice was added slowly and stirred for 30 min. Next, 7.4 g of Na2S2O3 dissolved in 74 mL of deionized water were added. After 2 h of mixing, the solid was filtered by vacuum and was treated with deionized water until fully disappearance of turbidity in the liquid phase. Compound 3 was isolated as a coral powder (22.4 g, 99% yield). 1H NMR (401 MHz, DMSO) δ 8.32 (s, 2H). 13C NMR (75 MHz, DMSO) δ 164.27, 140.52, 139.92, 132.25, 101.90. IR υ max : 2513, 1684, 1521, 1361, 1280 cm−1.

Synthesis of 4-bromo-3-hydroxy-5-iodobenzoic acid 5

In a 25-mililiter flask, 1 g (2.21 mmol, 1 equiv.) of 4, 120 mg (0.84 mmol, 0.4 equiv.) of Cu2O and 475 mg (11.88 mmol, 5.4 equiv.) of NaOH (previously prepared in 10 mL of deionized water) were mixed in a preheated oil bath at 85 °C during 16 h. Then, the pH was adjusted at 2 and the content was poured in a 10-mililiter mixture of water/ice. The solid was filtered by vacuum. 880 mg of a mixture of 5 and 4 (1:1.3) were isolated as a light brown solid. 1H NMR (401 MHz, DMSO) δ 13.55 (s, 1H), 11.05 (s, 1H), 7.84 (d, J = 1.6 Hz, 1H), 7.47 (d, J = 1.6 Hz, 1H). IR υ max : 3204, 2808, 1686, 1570, 1405, 1283, 1243, 1090 cm−1.

Synthesis of methyl 4-bromo-3-iodo-5-methoxybenzoate 6

880 mg of a mixture of 4 and 5 (1.3:1) were dissolved in a 25-mililiter flask with 37 mL of acetone along with 770 mg (5.57 mmol, 2.17 equiv.) of K2CO3. Then, 530 µL (5.53 mmol, 2.15 equiv.) of DMS (dimethyl sulfate) were added and the stirring was kept overnight at 50 °C. Next, the mixture was filtered and the acetone evaporate. The crude was re-dissolved in AcOEt and NaHCO3 (sat.) was added. Three extractions with AcOEt were carried out and the organic phase was washed with NaCl (sat), dried with MgSO4, filtered and the solvent was removed by vacuum. The crude was purify by chromatographic column, using hexane:DCM (85:15) as an eluent. 415 mg of 6 as a white powder were isolated [99% yield referred to the initial proportion of 5:4 (1:1.3)]. 1H NMR (401 MHz, CDCl3) δ 8.14 (d, J = 1.8 Hz, 1H), 7.49 (d, J = 1.8 Hz, 1H), 3.93 (s, 3H), 3.92 (s, 3H). 13C NMR (101 MHz, CDCl3) δ 165.44, 156.72, 133.13, 131.30, 125.21, 111.69, 102.88, 57.01, 52.75. IR υ max : 1703, 1556, 1390, 1280, 1241, 1190, 1123, 1055, 1021 cm-1.

Synthesis of methyl 4-bromo-3-methoxy-5-((trimethylsilyl)ethynyl)benzoate 7

Method A (Pd2-3 clusters): In a vial, 10 mg (0.027 mmol, 1 equiv.) of 6 were dissolved in 60 μL of NMP along with 8 μL (0.053 mmol, 2 equiv.) of trimethylsilylacetylene, 3.8 mg (0.039 mmol, 1.4 equiv.) of KOAc and the appropriated quantity of Pd(Ac)2 to get 300 ppm of Pd in the mixture. The mixture was stirred 20 h at 130 °C. Then, an aliquot was taken and analyzed by GC. A conversion of 45% took place, with a selectivity towards the desired product of 37% (the dehalogenated byproduct complted the mass balance). Method B [Pd(PPh3)2Cl2 and CuI]: In a 10-mililiter flask, 149 mg (0.40 mmol, 1 equiv.) of 6, 15 mg (0.081 mmol, 0.2 equiv.) of CuI, 180 μL (1.21 mmol, 3 equiv.) of NEt3 and 14 mg of Pd(PPh3)2Cl2 were dissolved in 1.8 mL of dry 1,4-dioxane under inert atmosphere. Then, 80 μL (0.53 mmol, 1.3 equiv.) of trimethylsilylacetylene were added and the mixture was stirred at 80 °C for 16 h. After cooling the reaction, 15 mL of AcOEt were added and the organic phase washed twice with HCl 0.5 M, once with NaCl (sat), dried with anhydrous MgSO4, filtered and the solvent removed by vacuum. 130 mg of 7 as a brownish powder were obtained (94% yield). 1H NMR (401 MHz, CDCl3) δ 7.78 (d, J = 1.9 Hz, 1H), 7.47 (d, J = 1.9 Hz, 1H), 3.95 (s, 3H), 3.92 (s, 3H), 0.28 (s, 9H). 13C NMR (101 MHz, CDCl3) δ 166.05, 156.49, 129.96, 127.14, 126.84, 120.85, 112.01, 102.33, 100.95, 56.80, 52.62, −0.09. HRMS: m/z calculated for C14H18BrO3Si (M + H+): 341.0208; found: 341.0187. IR υ max : 1712, 1566, 1403, 1239, 1217 cm−1.

Synthesis of methyl 4-bromo-3-ethynyl-5-methoxybenzoate 8

In a 25-mililiter flask, 130 mg (0.38 mmol, 1 equiv.) of 7 and 15 mg (0.08 mmol, 0.2 equiv.) of anhydrous K2CO3 were dissolved in 2 mL of dry MeOH. The mixture was stirred for 3 h, diluted with 5 mL of AcOEt and filtered. Then, the crude was purify by chromatographic column using hexane:AcOEt as an eluent 95:5. 101 mg of 8 were isolated as a brownish powder (99% yield). 1H NMR (300 MHz, CDCl3) δ 7.74 (d, J = 1.9 Hz, 1H), 7.44 (d, J = 1.9 Hz, 1H), 3.89 (s, 3H), 3.86 (s, 3H), 3.35 (s, 1H). 13C NMR (75 MHz, CDCl3) δ 165.76, 156.40, 130.02, 127.01, 126.02, 120.72, 112.31, 82.68, 81.24, 56.88, 56.68. HRMS: m/z calculated for C11H10BrO3 (M + H+): 268.9813; found: 268.9795. IR υ max : 3253, 1706, 1566, 1400, 1324, 1238, 1214 cm-1.

Synthesis of methyl 4-bromo-3-methoxy-5-(1-(triethylsilyl)vinyl)benzoate 9

In a vial, 42 mg (0.16 mmol, 1 equiv.) of 8 were dissolved in 210 μL of toluene along with 30 μL (0.19 mmol, 1.2 equiv.) of HSiEt3 and stirred at 110 °C. Then, 35 mg (0.001 mmol, 0.007 equiv.) of Karsdest’s catalyst were dissolved in 100 μL of toluene and added over the previous mixture. The mixture was stirred for 16 h. Next, the solvent was removed by vacuum and the crude purify by chromatographic column, using hexane:AcOEt as an eluent. 20 mg of 9 were isolated as a colorless oil (33% yield). 1H NMR (401 MHz, CDCl3) δ 7.38 (d, J = 2.0 Hz, 1H), 7.29 (d, J = 1.9 Hz, 1H), 5.77–5.72 (m, 2H), 3.96 (s, 3H), 3.95 (s, 3H), 1.04–0.81 (m, 9H), 0.71–0.60 (m, 6H).

Synthesis of methyl 4-bromo-3-methoxy-5-(1-(tributylstannyl)vinyl)benzoate 10

In a 10-mililiter flask, 52 mg (0.19 mmol, 1 equiv.) of 8 and 6.8 mg (0.01 mmol, 0.05 equiv.) of Pd(PPh3)2Cl2 were dissolved in 700 μL of dry THF under inert atmosphere. The temperature was lowered to 0 °C and 60 μL (0.20 mmol, 1.05 equiv.) of HSnBu3 were added. After 1.5 h of reaction, the crude was purify by chromatographic column, using hexane:AcOEt 98:2 as an eluent. 10 was obtained as a colorless oil (104 mg, 96% yield). 1H NMR (401 MHz, CDCl3) δ 7.36 (d, J = 1.9 Hz, 1H), 7.32 (d, J = 1.9 Hz, 1H), 5.79 (d, J = 2.6 Hz, 1H), 5.52 (d, J = 2.6, 1H), 3.95 (s, 3H), 3.91 (s, 3H), 1.51–1.38 (m, 6H), 1.26 (h, J = 7.3 Hz, 6H), 0.97–0.90 (m, 6H), 0.85 (t, J = 7.3 Hz, 9H). 13C NMR (101 MHz, CDCl3) δ 13 C NMR (101 MHz, CDCl3) δ 166.86, 156.64, 155.82, 150.34, 129.82, 128.70, 121.63, 116.45, 109.30, 56.70, 52.43, 29.84, 29.34, 29.22, 29.12, 29.02, 28.92, 27.71, 27.55, 27.42, 27.13, 14.45, 13.86, 13.77, 13.01, 12.00, 11.37, 11.35, 10.84. HRMS: m/z calculated for C23H38BrO3Sn (M + H+): 561.1026; found: 561.0995. IR υ max :2921, 2359, 1723, 1570, 1395, 1318, 1235 cm−1.

Synthesis of benzo[d][1,3]dioxole-5-carboxylic acid 12

Method A (Pd1 single atom): In a 10-mililiter sealed reactor, 298 mg (1.96 mmol, 1 equiv.) of piperonyl alcohol (11) were heated along with 1.32 mg (0.006 mmol, 0.003 equiv.) of Pd(AcO)2 at 150 °C under an O2 atmosphere of 4 atm, overnight. After that, the crude was analyzed by 1H NMR, obtaining a 4:1mixture of piperonal and 12, with a conversion of 86%. Method B (Pinnick oxidation): In a 25-mililiter flask, 298.3 mg (2 mmol, 1 equiv.) of piperonal were dissolved along with 138.3 mg (0.8 mmol, 0.4 equiv., 70 wt%) of NaH2PO4 and 2 mL of H2O2 (21.2 mmol, 10.6 equiv., 30 wt%) in 12 mL of a mixture MeCN:H2O 5:1. The temperature was lowered to 0 °C and 368 mg (4 mmol, 2 equiv.) of NaClO2 dissolved in deionized water were added dropwise. The mixture was stirring at room temperature overnight. 20 mL of HCl 2 M were added and extracted three times with AcOEt. Next, three extractions with NaOH 2 M were carried out and acidified with HCl(c), until pH 2, approximately. Finally, three additional extractions with AcOEt were done. This organic phase was washed twice with NaCl (sat), dried over anhydrous MgSO4, filtered and the solvent removed by vacuum. 220 mg of 12 were isolated as a slightly brown powder (68% yield). 1H NMR (300 MHz, DMSO) δ 12.70 (s, 1H), 7.54 (dd, J = 8.1, 1.7 Hz, 1H), 7.36 (d, J = 1.7 Hz, 1H), 7.00 (d, J = 8.1 Hz, 1H), 6.12 (s, 2H). 13C NMR (75 MHz, DMSO) δ 166.61, 151.12, 147.47, 124.96, 124.65, 108.78, 108.07, 101.93. HRMS: m/z calculated for C8H7O4 (M + H+): 167.0344; found: 167.0331. IR υ max : 2921, 2518, 1661, 1448, 1292, 1257 cm−1.

Synthesis of benzo[d][1,3]dioxole-5-carbonyl chloride 13

In a 25-mililiter flask, 183 mg (1.10 mmol, 1 equiv.) of 12 were dissolved in 2 mL of SOCl2 under inert atmosphere and refluxed for 3 h. Then, SOCl2 was removed by vacuum and the brown solid was re-dissolved in DCM and filtered through Al2O3. After evaporating the solvent, compound 13 was obtained as a light brown powder (145 mg, 71% yield). 1H NMR (401 MHz, CDCl3) δ 7.80 (dd, J = 8.3, 1.9 Hz, 1H), 7.52 (d, J = 1.9 Hz, 1H), 6.89 (d, J = 8.3 Hz, 1H), 6.11 (s, 2H). 13C NMR (75 MHz, CDCl3) δ 177.11, 154.05, 148.50, 136.36, 129.04, 110.78, 108.45, 102.71. IR υ max : 1738, 1503, 1601, 1261, cm−1.

Synthesis of methyl 3-(3-(benzo[d][1,3]dioxol-5-yl)-3-oxoprop-1-en-2-yl)-4-bromo-5-methoxybenzoate 14

Method A (Pd2-3 clusters): In two vials, 16 mg (0.03 mmol, 1 equiv.) of 10 were dissolved along with 0.38 mg (3.3·10−4 mmol, 0.01 equiv.) of Pd(PPh3)4 and 5.6 mg (0.03 mmol, 1 equiv.) of 13 in 100 µL of DMF dry. One of the vials also contained 11.7 mg (0.033 mmol, 1.1 equiv.) of Cs2CO3. The reactions were heated at 120 °C for 16 h. Then, they were quenched with deionized water and extracted thrice with AcOEt. The organic phase was washed with NaCl (sat), dried over MgSO4, filtered and the solvent removed by vacuum. The remaining mixture was analyzed by GC-MS. Method B [Pd(PPh3)4]: In a Schlenk tube, 181 mg (0.32 mmol, 1 equiv.) of 10 were dissolved along with 66 mg (0.36 mmol, 1.1 equiv.) of 13 and 4.3 mg of Pd(PPh3)4 in 4.5 mL of dry toluene under inert atmosphere. The mixture was mixed in a preheated sand bath at 110 °C for 16 h. The crude was directly purify by chromatographic column using a mixture of hexane:AcOEt from 87.5:12.5 to 75:25 as an eluent. 125 mg of 14 were isolated as a colorless oil (92% yield). 1H NMR (300 MHz, CDCl3) δ 7.68 (d, J = 1.9 Hz, 1H), 7.60 (dd, J = 8.1, 1.7 Hz, 1H), 7.55 (d, J = 1.9 Hz, 1H), 7.46 (d, J = 1.9 Hz, 1H), 6.86 (d, J = 8.1 Hz, 1H), 6.08 (d, J = 0.8 Hz, 1H), 6.06 (s, 2H), 6.00 (d, J = 0.8 Hz, 1H) 3.53 (s, 3H), 3.34 (s, 3H). 13C NMR (101 MHz, CDCl3) δ 193.16, 166.27, 156.07, 151.62, 148.46, 147.85, 141.87, 131.31, 130.32, 128.30, 126.60, 124.66, 117.80, 111.93, 109.96, 107.76, 101.85, 56.68, 52.46. HRMS: m/z calculated for C19H16BrO6 (M + H+): 419.0130; found: 419.0113. IR υ max : 2359, 2341, 1718, 1438, 1239 cm−1.

Synthesis of methyl 3-(1-(benzo[d][1,3]dioxol-5-yl)-1-hydroxypropan-2-yl)-4-bromo-5-methoxybenzoate 15

In a 10-mililiter flask, 106 mg (0.25 mmol, 1 equiv.) of 14 and 24 mg (2.4 equiv.) of NaBH4 were dissolved in a 2-mililiter mixture of dry THF:MeOH 1:1. The stirring was kept overnight at room temperature. Next, 15 mL of deionized water were added and extracted thrice with DCM. The organic phase was washed with NaCl (sat), dried with anhydrous MgSO4, filtered and the solvent was removed by vacuum. 80 mg of 15 were isolated as a white powder (75% yield). 1H NMR (401 MHz, CDCl3) δ 7.66 (dd, J = 6.3, 1.9 Hz, 1H), 7.44 (d, J = 1.8 Hz, 1H), 6.95 (t, J = 1.7 Hz, 1H), 6.01 - 5.96 (m, 2H), 4.75 (d, J = 7.0 Hz, 1H), 3.97 (d, J = 0.9 Hz, 3H), 3.94 (s, 1H), 3.85 - 3.74 (m, 1H), 1.02 (d, J = 7.0 Hz, 3H). 13C NMR (101 MHz, CDCl3) δ 166.73, 156.26, 148.03, 147.53, 145.31, 136.56, 130.14, 120.87, 110.36, 108.16, 107.27, 101.23, 56.72, 52.54, 30.78, 27.62, 13.84. HRMS: m/z calculated for C19H18BrO6 (M-H+): 421.0283; found: 421.0231. IR υ max : 2359, 2341, 1715, 1577, 1489, 1240 cm−1.

Synthesis of methyl 2-(benzo[d][1,3]dioxol-5-yl)-7-methoxy-3-methyl-2,3-dihydrobenzofuran-5-carboxylate 16

In a 10-mililiter flask, 6 mg (0.014 mmol, 1 equiv.) of 15, 0.3 mg (0.001 mmol, 0.1 equiv.) of CuI and 7 mg (0.02 mmol, 1.5 equiv.) of Cs2CO3 were dissolved in 300 μL of dry DMF under inert atmosphere. The mixture was heated at 130 °C for 16 h. Next, the crude was diluted with DCM, filtered and the solvent removed by vacuum. 5 mg of 16 were obtained as a slightly brownish powder (99% yield). 1H NMR (300 MHz, CDCl3) δ 7.59–7.43 (m, 2H), 6.92–6.84 (m, 2H), 6.79 (d, J = 7.8 Hz, 1H), 5.96 (s, 2H), 5.19 (d, J = 7.0 Hz, 1H), 3.93 (s, 3H), 3.90 (s, 3H), 3.53–3.37 (m, 1H), 1.42 (d, J = 7.0 Hz, 2H). 13C NMR (75 MHz, CDCl3) δ 167.07, 151.71, 148.17, 147.99, 144.07, 133.77, 133.06, 123.83, 120.41, 118.44, 113.35, 108.31, 106.84, 101.34, 94.41, 56.22, 52.13, 45.46, 29.84, 18.17. IR υ max : 1708, 1444, 1326, 1181 cm−1.

Synthesis of (2-(benzo[d][1,3]dioxol-5-yl)-7-methoxy-3-methyl-2,3-dihydrobenzofuran-5-yl)methanol 17

In a vial, 16 mg (0.05 mmol, 1 equiv.) of 16 and 8 mg (0.20 mmol, 4 equiv.) of LiAlH4 were dissolved in 500 μL of dry THF at 0 °C under inert atmosphere. The mixture was stirred at room temperature overnight. Then, the crude was diluted with AcOEt and 5 mL of deionized water were added. Three extractions with AcOEt were carried out and the organic phase was washed with NaCl (sat), dried over MgSO4, filtered and the solvent was removed by vacuum. 14 mg of a yellow oil were isolated as 17 (99% yield). 1H NMR (401 MHz, CDCl3) δ 6.92 (d, J = 1.7 Hz, 1H), 6.87 (dd, J = 8.0, 1.7 Hz, 1H), 6.83 (d, J = 1.6 Hz, 1H), 6.81–6.72 (m, 2H), 5.11 (d, J = 6.8 Hz, 1H), 4.63 (s, 2H), 3.89 (s, 3H), 3.56–3.35 (m, 3H), 1.38 (d, J = 6.8 Hz, 3H). 13C NMR (75 MHz, CDCl3) δ 148.07, 147.78, 147.09, 144.40, 134.69, 134.40, 133.26, 120.33, 114.98, 111.05, 108.24, 106.90, 101.26, 101.17, 93.61, 65.83, 56.17, 45.96, 29.84, 18.11. IR υ max : 3358, 1606, 1489, 1442, 1246, 1036 cm-1.

Synthesis of 2-(benzo[d][1,3]dioxol-5-yl)-7-methoxy-3-methyl-2,3-dihydrobenzofuran-5-carbaldehyde 18

In a vial, 14 mg (0.044 mmol, 1 equiv.) of 17 and 26 mg (0.27 mmol, 6 equiv.) of activated MnO2 were mixed in 200 μL of dry DCM. The mixture was stirred at room temperature for 16 h. Next, the crude was filter over silica and the solvent removed. 18 was obtained as a colorless oil (9 mg, 66% yield). 1H NMR (401 MHz, CDCl3) δ 9.84 (s, 1H), 7.37 (s, 1H), 7.33 (s, 1H), 6.91–6.84 (m, 2H), 6.80 (d, J = 7.9 Hz, 1H), 5.97 (s, 2H), 5.24 (d, J = 6.8 Hz, 1H), 3.95 (s, 3H), 3.57 - 3.44 (m, 1H), 1.44 (d, J = 6.8 Hz, 3H). 13C NMR (75 MHz, CDCl3) δ 190.76, 133.46, 131.68, 120.46, 120.22, 111.98, 108.38, 106.81, 101.40, 94.77, 56.26, 53.56, 45.22, 29.85, 18.24. IR υ max: 2921. 2851, 1731, 1681, 1445, 1321, 1251, 1133 cm-1.

Synthesis of (E)-5-(7-methoxy-3-methyl-5-(prop-1-en-1-yl)-2,3-dihydrobenzofuran-2-yl)benzo[d][1,3]dioxole (±)-1

Carbonyl-olefin metathesis: aldehyde 18 (0.012 mmol) and 2-ethyl-2-phenyl-1,3-dioxolane 1928,54 (0.036 mmol) were introduced. Afterwards, 0.3 mL of dichloroethane (DCE) and 0.012 mmol of BF3·OEt2 were added and the reaction was stirred overnight at 70 °C. Conversion was measured by GC analysis which showed an approximately 50% conversion to the desired product. Takai olefination: To a stirring suspension of anhydrous CrCl2 (0.226 mmol, 8 equiv.) in 250 µL of dry THF, 18 μL (0.226 mmol, 8 equiv.) of dry DMF were added and the reaction was stirred at room temperature for 30 min. After that, a solution of 2-(benzo[d][1,3]dioxol-5-yl)-7-methoxy-3-methyl-2,3-dihydrobenzofuran-5-carbaldehyde (0.0282 mmol, 1 equiv.) and 1,1-diiodoethane (0.056 mmol, 2 equiv.) in 100 μL of dry THF was added and the reaction was stirred at room temperature for 1 h. Then, the mixture was purified by TLC using hexane:AcOEt 9:1 as an eluent. 8.5 mg of 1 were isolated as a white powder (93% yield). 1H NMR (300 MHz, CDCl3) δ 7.02–6.85 (m, 2H), 6.85–6.65 (m, 3H), 6.42–6.30 (m, 1H), 6.19–6.02 (m, 1H), 5.17–5.02 (m, 1H), 3.53–3.30 (m, 1H), 1.92 (dd, J = 7.2, 1.9 Hz, 0.6H), 1.87 (dd, J = 6.6, 1.6 Hz, 2.4H), 1.41–1.33 (m, 3H). 13C NMR (75 MHz, CDCl3) δ 148.05, 147.75, 146.66, 144.27, 134.49, 133.24, 132.38, 131.07, 130.00, 125.20, 123.63, 120.35, 113.51, 109.46, 108.21, 106.95, 101.24, 93.56, 56.11, 53.56, 53.31, 45.93, 34.51, 29.85, 18.51, 18.06. IR υ max : 2961, 2916, 2847, 2359, 1600, 1489, 1331, 1206 cm−1.

Data availability

The datasets generated during and/or analysed during the current study are included in this published article (and its supplementary information files) or available from the corresponding author on reasonable request. Datasets could be also deposited in public repositories of the UPV and CSIC. Source data are provided with this paper. Supplementary Data 1 contains NMR copies.

References

Li, W.-H., Yang, J., Wang, D. & Li, Y. Striding the threshold of an atom era of organic synthesis by single-atom catalysis. Chem 8, 119–140 (2022).

Oliver-Meseguer, J. & Leyva-Pérez, A. Single atom and metal cluster catalysts in organic reactions: From the solvent to the solid. ChemCatChem. e202201681. https://doi.org/10.1002/cctc.202201681 (2023).

Yan, H., Su, C., He, J. & Chen, W. Single-atom catalysts and their applications in organic chemistry. J. Mater. Chem. A 6, 8793–8814 (2018).

Zhang, L., Ren, Y., Liu, W., Wang, A. & Zhang, T. Single-atom catalyst: a rising star for green synthesis of fine chemicals. Natl. Sci. Rev. 5, 653–672 (2018).

Bayram, E. et al. Is it homogeneous or heterogeneous catalysis derived from [RhCp*Cl2]2? In operando EXAFS, kinetic, and crucial kinetic poisoning evidence for subnanometer Rh4 cluster–based benzene hydrogenation catalysis. J. Am. Chem. Soc. 133, 18889–18902 (2011).

Eremin, D. B. & Ananikov, V. P. Understanding active species in catalytic transformations: From molecular catalysis to nanoparticles, leaching, “cocktails” of catalysts and dynamic systems. Coord. Chem. Rev. 346, 2–19 (2017).

Sarma, B. B. et al. One–pot cooperation of single–atom Rh and Ru solid catalysts for a selective tandem olefin isomerization–hydrosilylation process. Angew. Chem. Int. Ed. 59, 5806–5815 (2020).

Galushko, A. S., Boiko, D. A., Pentsak, E. O., Eremin, D. B. & Ananikov, ValentineP. Time-resolved formation and operation maps of pd catalysts suggest a key role of single atom centers in cross-coupling. J. Am. Chem. Soc. 145, 9092–9103 (2023).

Greco, R., Mon, M. & Leyva–Pérez, A. Supported metal single atom thermocatalysts for c—c, c—si, and c—b bond–forming (coupling) reactions and biomedical applications; in Supported Metal Single Atom Catalysis (eds Serp, P. & Minh, D. P.) 473–502 Wiley. ISBN: 978-3-527-34844-2 (2022).

Saptal, V. B., Ruta, V., Bajada, M. A. & Vilé, G. Single-atom catalysis in organic synthesis. Angew. Chem. Int. Ed. e202219306. https://doi.org/10.1002/anie.202219306 (2023).

Teponno, R. B., Kusari, S. & Spiteller, M. Recent advances in research on lignans and neolignans. Nat. Prod. Rep. 33, 1044–1092 (2016).

Lee, T. H. et al. Procyanidins and phlobatannins from the twigs of Rosa multiflora and their neuroprotective activity. J. Nat. Prod. 85, 917–926 (2022).

Zhu, S. et al. Neuroprotective potency of neolignans in Magnolia officinalis cortex against brain disorders. Front. Pharm. 13, 857449 (2022).

Xu, X.-Y., Wang, D.-Y., Li, Y.-P., Deyrup, S. T. & Zhang, H.-J. Plant-derived lignans as potential antiviral agents: a systematic review. Phytochem. Rev. 21, 239–289 (2022).

Tang, G.-H. et al. Neolignans from Aristolochia fordiana prevent oxidative stress-induced neuronal death through maintaining the Nrf2/HO‑1 pathway in HT22 cells. J. Nat. Prod. 78, 1894–1903 (2015).

Yang, C. S. et al. Two new norneolignans and other components from Strophioblachia fimbricalyx. Phytochem. Lett. 57, 87–91 (2023).

Zhang, J. et al. Licarin-B exhibits activity against the Toxoplasma gondii RH strain by damaging mitochondria and activating autophagy. Front. Cell Develop. Biol. 9, 684393 (2021).

Shyni, G. L. et al. Licarin B from Myristica fragrans improves insulin sensitivity via PPARγ and activation of GLUT4 in the IRS-1/PI3K/AKT pathway in 3T3-L1 adipocytes. RSC Adv. 6, 79859–79870 (2016).

Yoshioka, Y., Kono, R., Kuse, M., Yamashita, Y. & Ashida, H. Phenylpropanoids and neolignans isolated from Myristica fragrans enhance glucose uptake in myotubes. Food Funct. 13, 3879–3893 (2022).

Park, J.-Y. et al. Sialidase inhibitory activity of diarylnonanoid and neolignan compounds extracted from the seeds of Myristica fragrans. Bioorg. Med. Chem. Lett. 27, 3060–3064 (2017).

Engler, T. A. & Chai, W. Synthesis of (±)-licarin b and eupomatenoids-1 and -12: a general approach to 2-aryl-7-alkoxy-benzofuranoid neolignans. Tetrahedron Lett. 37, 6969–6970 (1996).

Watanabe, M., Kawanishi, K., Akiyoshi, R. & Furukawa, S. A Regioselective lithiation of ortho-cresols using the bis(dimethylamino)phosphoryl group as a directing group: general synthesis of 2,3-dihydrobenzo[b]furans including naturally occurring neolignans. Chem. Pharma. Bull. 39, 3123–3131 (1991).

Aira, C. J. & Gottlieb, O. R. Synthesis of (±)-Licarin-B. Phytochem. 14, 253–255 (1975).

Chioccara, F. et al. Regio- and Diastereo-selective synthesis of dimeric lignans using oxidative coupling. Acta Chem. Scand. 47, 610–616 (1993).

Nascimento, I. R., Lopes, L. M. X., Davin, L. B. & Lewis, N. G. Stereoselective synthesis of 8,9-licarinediols. Tetrahedron. 56, 9181–9193 (2000).

Tiburcio, E. et al. Soluble/MOF-supported palladium single atoms catalyze the ligand‑, additive‑, and solvent-free aerobic oxidation of benzyl alcohols to benzoic acids. J. Am. Chem. Soc. 143, 2581–2592 (2021).

Rivero–Crespo, M. A. et al. Cyclic metal(oid) clusters control platinum–catalysed hydrosilylation reactions: from soluble to zeolite and MOF catalysts. Chem. Sci. 11, 8113–8124 (2020).

Leyva–Pérez, A., Oliver–Meseguer, J., Rubio–Marqués, P. & Corma, A. Water–stabilized three– and four–atom palladium clusters as highly active catalytic species in ligand–free C–C cross–coupling reactions. Angew. Chem. Int. Ed. 52, 11554–11559 (2013).

Oliver-Meseguer, J. et al. Stabilized naked sub-nanometric Cu clusters within a polymeric film catalyze C−N, C−C, C−O, C−S, and C−P bond-forming reactions. J. Am. Chem. Soc. 137, 3894–3900 (2015).

Rivero-Crespo, M. Á., Tejeda-Serrano, M., Pérez-Sánchez, H., Cerón-Carrasco, J. P. & Leyva-Pérez, A. Intermolecular carbonyl–olefin metathesis with vinyl ethers catalysed by homogeneous and solid acids in flow. Angew. Chem. Int. Ed. 59, 3846–3849 (2020).

Albright, H. et al. Carbonyl–olefin metathesis. Chem. Rev. 121, 9359–9406 (2021).

Grigorjeva, L., Kinens, A. & Jirgensons, A. Unsaturated syn- and anti-1,2-amino alcohols by cyclization of allylic bis-trichloroacetimidates. stereoselectivity dependence on substrate configuration. J. Org. Chem. 80, 920–927 (2015).

Ballesteros–Soberanas, J., Mon, M. & Leyva-Perez, A. Diastereoisomeric enrichment of 1,4–enediols and H2–splitting inhibition on Pd–supported catalysts. Org. Biomol. Chem. 21, 7136–7140 (2023).

Fernández, E. et al. Base–controlled Heck, Suzuki and Sonogashira reactions catalyzed by ligand–free platinum or palladium single atom and sub–nanometer clusters. J. Am. Chem. Soc. 141, 1928–1940 (2019).

Kumar, R., Kawasaki, H. & Harada, T. Catalytic enantioselective synthesis of Α-substituted secondary allylic alcohols from terminal alkynes and aldehydes via vinylaluminum reagents. Chem. Eur. J. 19, 17707–17710 (2013).

Rivero-Crespo, M. A., Leyva-Pérez, A. & Corma, A. A ligand-free Pt3 cluster catalyzes the markovnikov hydrosilylation of alkynes with up to 106 turnover frequencies. Chem. Eur. J. 23, 1702–1708 (2017).

Rubio−Marqués, P., Rivero−Crespo, M. A., Leyva−Pérez, A. & Corma, A. Well−defined noble metal single sites in zeolites as an alternative to catalysis by insoluble metal salts. J. Am. Chem. Soc. 137, 11832–11837 (2015).

Suzawa, K., Ueno, M., Wheatley, A. E. H. & Kondo, Y. Phosphazene base-promoted functionalization of aryltrimethylsilanes. Chem. Commun. 46, 4850–4852 (2006).

Barlow, A. J., Compton, B. J. & Weavers, R. T. Synthesis of the 3-methylene-2-vinyltetrahydropyran unit; the hallmark of the sesquiterpene, Hodgsonox. J. Org. Chem. 70, 2470–2475 (2005).

Chenard, B. L. & Van Zyl, C. M. Silylstannanes in organic synthesis. scope and limitation of palladium-catalyzed reaction with acetylenes. J. Org. Chem. 51, 3561–3566 (1986).

Abid, I. et al. TBAF-triggered aldol-type addition of α-triethylsilyl-α-diazoacetone. J. Org. Chem. 80, 9980–9988 (2015).

Wang, C.-Q., Feng, C. & Loh, T.-P. Rh(III)-catalyzed hydroarylation of internal alkynes through C−H bond activation. Asian J. Org. Chem. 5, 1002–1007 (2016).

Asao, N., Liu, P. & Maruoka, K. 1,8-Bis(allylstannyl)naphthalene derivatives as neutral allylation agents: rate acceleration by chelation-induced lewis acidity. Angew. Chem. Int. Ed. 36, 2507–2509 (1997).

Takai, K., Kimura, K., Kuroda, T., Hiyama, T. & Nozaki, H. Selective Grignard-type carbonyl addition of alkenyl halides mediated by chromium(II) chloride. Tetrahedron Lett. 24, 5281–5284 (1983).

Meta, C. T. & Koide, K. Trans-selective conversions of γ-hydroxy-α,β-alkynoic esters to γ-hydroxy-α,β-alkenoic esters. Org. Lett. 6, 1785–1787 (2004).

Mallick, R. K., Vangara, S., Kommu, N., Guntreddi, T. & Sahoo, A. K. Lewis acid-driven Meyer–Schuster-type rearrangement of yne-dienone. J. Org. Chem. 86, 7059–7068 (2021).

Kim, M.-J. et al. Highly enantioselective dynamic kinetic resolution of 1,2-diarylethanols by a lipase-ruthenium couple. Org. Lett. 10, 1295–1298 (2008).

Garnes–Portolés, F. et al. Regioirregular and catalytic Mizoroki–Heck reactions. Nat. Catal. 4, 293–303 (2021).

Apana, S. M., Anderson, L. W. & Berridge, M. S. Synthesis and biodistribution of [11C]SN-38. J. Label. Compd. Radiopharm. 53, 178–182 (2010).

Francais, A., Leyva, A., Etxebarria-Jardi, G. & Ley, S. V. Total synthesis of the anti-apoptotic agents iso- and bongkrekic acids. Org. Lett. 12, 340–343 (2010).

Okazoe, T., Takai, K. & Utimoto, K. (E)-Selective olefination of aldehydes by means of gem-dichromium reagents derived by reduction of gem-diiodoalkanes with chromium(II) chloride. J. Am. Chem. Soc 109, 951–953 (1987).

Mingueza-Verdejo, P., Hernández-Garrido, J. C., Vidal-Moya, A., Oliver-Meseguer, J. & Leyva-Pérez, A. Zeolites catalyze the halogen exchange reaction of alkyl halides. Catal. Sci. Technol. 13, 2308–2316 (2023).

Friedrich, E. C., Falling, S. N. & Lyons, D. E. A convenient synthesis of ethylidene iodide. Synth. Commun. 5, 33–36 (1975).

Takakura, R. et al. Palladium on carbon–catalyzed oxidative transformation of benzylic ethers. Heterocycles 103, 494–501 (2021).

Acknowledgements

This work is part of the project PID2020-115100GB-I00 funded by MCIN/AEI/10.13039/501100011033MICIIN (Spain). Financial support by Severo Ochoa centre of excellence program (CEX2021-001230-S) is gratefully acknowledged. The work has also been funded by Generalitat Valenciana (Prometeo Grupos de Investigación de Excelencia PROMETEU/2021/054, and INNEST/2022/20 from Agència Valenciana de la Innovació). S.R.-N. thanks Agència Valenciana de la Innovació for a contract. M.-E. thanks to the Universitat de València (PROMETEU/2021/054) for the concession of a contract.

Author information

Authors and Affiliations

Contributions

S.R.-N. and M.E. designed, performed and interpreted all the experimental part. A.L.-P. designed the experiments and supervised the whole work. The manuscript has been written with contributions from all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Chemistry thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rodríguez-Nuévalos, S., Espinosa, M. & Leyva-Pérez, A. Soluble individual metal atoms and ultrasmall clusters catalyze key synthetic steps of a natural product synthesis. Commun Chem 7, 76 (2024). https://doi.org/10.1038/s42004-024-01160-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-024-01160-z

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.