Abstract

Photovoltaic conversion of solar energy into electricity is an alternative way to use renewable energy for sustainable energy production. The great demand of low-cost and efficient solar cells inspires research on solution-processable light-harvesting materials. Antimony trisulfide (Sb2S3) is a promising light-harvester for photovoltaic purposes. Here we report on the in situ grown monolayer of preferentially oriented, large Sb2S3 single-crystalline cuboids on a polycrystalline titania (TiO2) nanoparticle film. A facile, oriented seed-assisted solution-processing method is used, providing the Sb2S3/TiO2-based bulk/nano-planar heterojunction with a preferred structure for efficient planar solar cells. An orientation-competing-epitaxial nucleation/growth mechanism is proposed for understanding the growth of the Sb2S3 single-crystalline cuboids. With an organic hole transporting material, the stable solar cell of the heterojunction yields a power conversion efficiency of 5.15% (certified as 5.12%). It is found that the [221]-oriented Sb2S3 cuboids provide highly effective charge transport channels inside the Sb2S3 layer.

Similar content being viewed by others

Introduction

The demand of efficient and low-cost solar cells inspires the researches on light-harvesting materials for photovoltaic purposes. Nowadays, most of the efficient, stable, and practically potential solar cells are mainly based on inorganic planar heterojunctions (PHJs), thanks to the high charge mobility and good structural stability of inorganic semiconductors. The PHJ based on a bulk semiconductor layer of large grains and a crystalline layer of nanostructures can be referred to as bulk/nano-planar heterojunction (BnPHJ) in the material structure point of view. The BnPHJs consisting of an inorganic bulk p-type semiconductor layer of grain sizes comparable to layer thickness and an inorganic n-type nanoparticle film are preferred in efficient PHJ solar cells1,2,3, because the bulk p-type layers as light-harvesting materials can offer a highly effective charge generation and transportation as the results of reducing the deficiencies related to small size (e.g., high exciton binding energy4, low carrier concentration and high defects trap density5, and poor electronic contact because of surface capping agents6) and the energy loss due to charge recombination at grain boundary. The solution-processing method, which mainly involves a film matrix formation by simple technologies (e.g., spin-coating, doctor blading, screen printing, injet printing) and a followed post-annealing at low temperatures (normally ≤ 500 oC), has been demonstrated to be an effective strategy to fabricate low-cost and efficient solar cells, for which a representative is hybrid perovskite solar cells that have reached the efficiency up to 22%7,8. However, the solution-processing methods for preparing the inorganic bulk p-type layers for efficient solar cells are still challenging3 and rarely reported9,10,11,12.

Crystalline Sb2S3 consists of non-toxic and earth-abundant elements and is a promising photon-harvesting material for solar cells13, due to its suitable direct band gap (∼1.4–1.8 eV)14, high absorption coefficient (∼105 cm−1) in the visible spectrum15, high electron (μe ≈ 10 cm2 V−1 s−1)16 and hole (μh ≈ 2.6 cm2 V−1 s−1)17 mobilities, and easy availability by many synthesis scenarios at low temperature (<400 oC). Theoretically, the single-junction solar cells based Sb2S3 absorber are expected to achieve the power conversion efficiency (η) of 27–33% according to Shockley–Queisser limit18. The highest efficiency of η = 7.5% was obtained in the bulk heterojunction solar cells based on the Sb2S3-sensitized mesoporous TiO2 films19. Up to now, only the BnPHJs of large Sb2S3 grain layers over polycrystalline CdS nanoparticle films (i.e. Sb2S3/CdS-BnPHJs) were prepared by rapid thermal evaporation and yielded the PHJ solar cells with a best device efficiency of η = 3.5%20,21.

Here, a simple repetition of spin-coating and annealing (RSCA) solution-processing method for the in situ grown monolayer of preferentially oriented large Sb2S3 single-crystalline cuboids on the polycrystalline TiO2 film surface is developed, offering a novel Sb2S3/TiO2-BnPHJ that is of application potential to efficient solar cells. Since the presence of preferentially oriented Sb2S3 crystalline seeds formed on the TiO2 film surface before carrying out the RSCA procedure is an essential prerequisite for the growth of Sb2S3 cuboids, our approach is therefore referred to as an oriented seed-assisted RSCA method. Based on scanning electron microscopy (SEM), X-ray diffraction (XRD), transmission electron microscopy (TEM) and high-resolution TEM (HRTEM) observations, a new epitaxial nucleation/growth mechanism is proposed for the in situ growth of the large single-crystals on polycrystalline surface. Furthermore, the solar cell with a considerable efficiency of η = 5.15% (certified as 5.12%) is obtained by spin-coating an organic hole transporting layer over the Sb2S3/TiO2-BnPHJ surface.

Results

Heterojunction formation and characterization

The oriented seed-assisted RSCA approach to prepare the Sb2S3/TiO2-BnPHJ in this experiment is schematically illustrated in Fig. 1a. SbCl3 and thiourea reactants were sequentially dissolved at room temperature in a mixture solvent of DMF and glycerin (DMF/glycerin = 4/1 in volume), resulting in a transparent and yellow Sb2S3 precursor solution that is stable for weeks. The SbCl3 solution in the mixture solvent was colorless, but it rapidly became yellow after adding thiourea. The color change indicates the formation of an SbCl3–thiourea complex22,23. As shown in the Supplementary Information (Supplementary Fig. 1 and Supplementary Note 1), our Fourier transform infrared (FT-IR) results confirmed the SbCl3–thiourea complex formation with a highly polar structure of thiourea molecules (Fig. 1a, inset), and also revealed that glycerin remained inactive during the complex formation. The dense polycrystalline TiO2 nanoparticle film is prepared on the clean FTO substrate by the procedure described elsewhere24. We first use a thin Sb2S3 precursor film to generate the oriented Sb2S3 crystalline seeds on TiO2 film surface (Method). Afterwards, a thicker Sb2S3 precursor film is spin-coated onto the Sb2S3 seed-decorated TiO2 film and then annealed in N2 atmosphere at 330 oC for ca. 10 min, which is referred to as one RSCA cycle; the multiple iterations of the spin-coating/annealing with a certain RSCA cycle number (n) result in the Sb2S3/TiO2-BnPHJ with a monolayer of Sb2S3 cuboids over polycrystalline TiO2 film.

Preparation and characterization of Sb2S3/TiO2-BnPHJ. a Schematic illustration showing the oriented seed-assisted RSCA method for preparing Sb2S3/TiO2-BnPHJ; n is the RSCA cycle number, and the inset shows the photography of the stable Sb2S3 precursor solution in which a Sb2S3–thiourea complex is formed. b Bird-view (right: magnified image of the marked area) and (c) cross-sectional SEM images of as-prepared Sb2S3/TiO2-BnPHJ on FTO substrate. d The XRD patterns of the Sb2S3/TiO2-BnPHJ and TiO2 film on FTO substrates, in which the standard XRD pattern for Sb2S3 (JCPDS no. 42-1393) is included for reference. Shown by the inset to d, the angle between a specific Sb2S3 crystal plane and substrate is derived from the angle between the crystal plane and the Sb2S3 [221] direction that is normal to substrate plane. The arrows on c indicate the presence of small Sb2S3 grains. The Sb2S3 cuboids in (b–d) were prepared with n = 4 and their number density is about 2.7/μm2. b Scale bars 10 μm (low magnification) and 2 μm (high magnification. c Scale bar 1 μm

SEM image (Fig. 1b) shows that an Sb2S3 layer consisting of truncated and closely packed cuboids is in situ grown on the TiO2 film surface in a large area without cracks, offering a large area Sb2S3/TiO2-BnPHJ. The Sb2S3 cuboids stem from the TiO2 film (90 nm thick) and have a number density (defined as the number of the cuboids of different sizes per unit area) of about 2.7/μm2. Most of the cuboids have a height equal to the film thickness (600 nm) (Fig. 1c), indicating that the Sb2S3 layer is actually a monolayer of Sb2S3 cuboids. In particular, the lateral sizes of the cuboids distribute broadly from 200 nm to 1.1 μm and are much larger than the size of TiO2 nanoparticles in the TiO2 film (10−20 nm) (Supplementary Fig. 2a and Supplementary Note 2). The Sb2S3 cuboids display the XRD peaks of orthorhombic Sb2S3 (stibnite) with a Pbnm space group (JCPDS no. 42-1393) and no secondary phases are observed (Fig. 1d). For simplicity, we refer to the crystal growth along the direction out of substrate plane as out-of-plane growth and that along the direction in substrate plane as in-plane growth. Interestingly, the Sb2S3 cuboids are preferentially oriented with the [221] direction normal to substrate plane, indicating that most cuboids have the out-of-plane growths along the [001], [010] and [100] directions with the (001) and (100)/(010) planes tilting the average angles of ca. 44o and 61o on substrate, respectively (Fig. 1d, inset), where a- and b-axes are closely parallel to the lateral directions and the c-axis is closely parallel to the height direction. However, the TiO2 film only exhibits the XRD pattern of FTO substrate. The reason for the undetectable TiO2 component in the TiO2 film and Sb2S3/TiO2-BnPHJ by XRD is because the diffraction of such thin TiO2 film is too weak. As shown previously24, when we used a thicker TiO2 film (e.g., 150 nm thick) on FTO substrate, the XRD peak for the (101) plane of anatase TiO2 became observable (Supplementary Fig. 2b and Supplementary Note 2), confirming the exposure of (101) crystal plane on film surface25,26,27.

TEM was used to further characterize the Sb2S3 cuboids. The TEM sample was prepared by cross-sectioning the film using the focused ion beam technique. The cross-sectional TEM image (Fig. 2a) shows two densely packed Sb2S3 cuboids almost vertically stemming from the TiO2 film surface and that the TiO2 film (90 nm thick) consists of 10−20 nm nanoparticles. The body of an individual Sb2S3 cuboid (i.e., Cuboid I) was imaged by HRTEM at different locations (Fig. 2b−d). The same lattice fringes are observed in the different locations with the lattice spacings of 0.363 nm, 0.384 nm, and 0.562 nm corresponding to the (101)/(ī01), (001) and (200) planes of orthorhombic Sb2S3, confirming the single-crystalline nature of the cuboid that has a continuous out-of-plane growth of (001) planes from stem to top. Moreover, the selected area electron diffraction (SAED) pattern of another Sb2S3 cuboid (i.e., Cuboid II) also confirms its single-crystalline nature with an out-of-plane growth along the [001] direction (Fig. 2f). The single-crystalline nature was further supported by the TEM and HETEM images of more Sb2S3 cuboids (Supplementary Fig. 3).

TEM and HRTEM characterizations of the Sb2S3/TiO2-BnPHJ. a Cross-sectional TEM image. b–e HRTEM images and (f) SAED pattern at the locations cycle-marked on image (a). On image (e), the dashed straight lines identify the Sb2S3 growth transition zone adjacent to TiO2 surface, while the dashed and curve line represents the grain boundary between two differently oriented TiO2 nanoparticles. The Sb2S3 cuboids were prepared with n = 4 and the arrow on (a) indicates the presence of small Sb2S3 grains. a Scale bar 200 nm. b–e Scale bars 2 nm

In order to get insights into the Sb2S3 cuboid growth, the Sb2S3/TiO2 interface was studied by HRTEM (Fig. 2e). The HRTEM image resolves the lattice fringes of both Sb2S3 and TiO2 regions at the interface. In the TiO2 region, two differently oriented particles (TiO2-A and TiO2-B) got imaged, where TiO2-A particle exhibits the lattice spacings of 0.352 nm and 0.268 nm, respectively, corresponding to the (101)/(011) and (110) planes, but TiO2-B particle only displays (101) planes. In the Sb2S3 region, the upper part exhibits the same lattice fringes to the main body of Cuboid I (Fig. 2b–d), and a clear Sb2S3 growth transition zone of 3–6 nm in width adjacent to the TiO2 film surface is observed. Normally, a sharp interface is observed in the epitaxially grown single-crystalline/single-crystalline heterojunctions even with lattice-misfits28,29,30,31,32,33. The appearance of the Sb2S3 growth transition zone indicates more epitaxial strains during the heterogeneous nucleation/growth of Sb2S3 crystals are present in comparison to the cases of single-crystalline/single-crystalline systems30,31. In the Sb2S3 growth transition zone, two sets of the Sb2S3 lattice fringes were observed over the two TiO2 nanoparticles. Since the anatase TiO2 film has the (101) planes exposing on film surface (Supplementary Fig. 2 and Supplementary Note 2) and the theoretical lattice mismatch (ca. 3%) between orthorhombic Sb2S3 (101) and anatase TiO2 (101) planes is quite small (Supplementary Table 1), it is expected that the epitaxial relationship for the growth of orthorhombic Sb2S3 crystals on anatase TiO2 film surface should be Sb2S3 (101)//TiO2 (101)27. As experimentally observed (Fig. 2e), the Sb2S3 (002) plane is almost parallel to TiO2 (110) plane for TiO2-A particle, while the Sb2S3 (101) plane is parallel to TiO2 (101) plane for TiO2-B particle. Interestingly, when changing the TiO2 nanoparticle orientation with Sb2S3 (002)//TiO2 (110) for TiO2-A particle to that with Sb2S3 (101)//TiO2 (101) for TiO2-B particle, the width of the Sb2S3 growth transition zone is found to get reduced. Given the Sb2S3 (002)//TiO2 (110) relationship, an angle of ca. 30o between orthorhombic Sb2S3 (101) plane and anatase TiO2 (101) plane at TiO2-A particle is theoretically derived from the difference between the angles of ca. 19o formed by orthorhombic Sb2S3 (002) and (101) planes and ca. 49o formed by anatase TiO2 (110) and (101) planes (Supplementary Table 2), which indicates that there is a larger orientation-mismatch at TiO2-A particle in respect of the Sb2S3 (101)//TiO2 (101) epitaxial relationship. Therefore, the change in the width of the Sb2S3 growth transition zone with TiO2 (101) orientation demonstrates experimentally that the epitaxial relationship of Sb2S3 (101)//TiO2 (101) is actually present for orthorhombic Sb2S3 cuboid growth on polycrystalline anatase TiO2 film surface, and the orientation-mismatch causes more epitaxial strains at the interface of heterojunction.

The growth of cuboids is highly reproducible, and the RSCA cycle number n for film growth mainly controls the Sb2S3 layer thickness/cuboid height. For example, the thinner monolayer of the Sb2S3 cuboids with a number density of ca. 3.1/μm2, a preferential [221]-orientation, a height of ca. 400 nm and a lateral size of 120 nm to 1.1 μm was obtained in a large area without cracks for n = 2 (Supplementary Fig. 4). Moreover, our results show the TiO2 surface is crucially important to the preferential [221]-orientation of Sb2S3 cuboids; for example, only irregular Sb2S3 grains preferentially oriented with the [301] direction normal to substrate plane were produced when the TiO2 film was replaced with pure FTO substrate (Supplementary Fig. 5 and Supplementary Note 3). Furthermore, when without glycerin in the precursor solution, the preferentially [221]-oriented Sb2S3 cuboids of serious rough growth surface34 were rendered (Supplementary Fig. 6 and Supplementary Note 4), demonstrating that the glycerin does not imposes evident effects on the cuboid orientation, but maintains the smoothness of cuboid growth surfaces by providing the chemical species to inhibit the strain-driven surface roughening28.

In particular, we found that the preferentially oriented Sb2S3 crystalline seeds formed on TiO2 nanoparticle film surface before carrying out the RSCA procedure are indispensable to the growth of the [221]-oriented Sb2S3 cuboids. When without Sb2S3 crystalline seeds, only the irregular and much larger Sb2S3 grains with no preferential orientation were generated on the TiO2 film surface (Supplementary Fig. 7 and Supplementary Note 5). The Sb2S3 crystalline seeds feature the irregular shapes but a preferential orientation with the [221] direction normal to substrate plane and are only rendered in thin Sb2S3 precursor film (e.g., <100 nm) (Supplementary Fig. 8 and Supplementary Note 6). Moreover, the Sb2S3 cuboids in the first RSCA cycle (i.e., n = 1) predominantly grow from the Sb2S3 seed crystals and follows the crystal plane orientation in the Sb2S3 seed crystals (Supplementary Fig. 9 and Supplementary Note 7), where the growth rate in the c-axis direction is slower than in a- and b-axes directions similar to the formation of Sb2S3 crystalline seeds.

From the comparisons amongst the number densities of the Sb2S3 cuboids (i.e., about 3.5/μm2 for n = 1, 3.1/μm2 for n = 2, and 2.7/μm2 for n = 4) and the corresponding cuboid dimensions, it is clearly known that the increase in the RSCA cycle number when n > 1 mainly leads to the growth of Sb2S3 cuboids in the c-axis direction and the merge of some small cuboids into large ones; moreover, from the unchanged [221]-orientation of Sb2S3 crystals in the seeds and the resulting cuboids at n = 1–4, particularly, the unchanged cuboid shape with increasing n value, it is known that the self-nucleated crystal growth takes place from the first seed through the resulting cuboid (Supplementary Note 8).

Heterojunction growth mechanism

The growths of Sb2S3 nanoparticles on TiO2 nanoparticles19,22 and TiO2 nanoparticle film23, large single-crystalline Sb2S3 grains on CdS nanoparticle film20,21, large single-crystalline Sb2Se3 grains on CdS35,36 and ZnO37 nanoparticle films, and perovskite CH3NH3PbI3 cuboids on PEDOT:PSS38 and condensed nanostructured TiO239,40,41 films have been reported. Very recently, the epitaxial films of inorganic semiconductor (e.g., CsPbBr3, PbI2, and ZnO) crystals were deposited onto single-crystal and single-crystal-like substrates by simply spin-coating either the materials or the material precursors42, where the out-of-plane and in-plane orientations of the films were determined by the substrate and it was assumed that the thin stagnant layer of supersaturated solution produced during spin-coating promoted heterogeneous nucleation on the substrate over homogeneous nucleation in the bulk solution. However, the nucleation/growth mechanisms of the large single-crystalline grains on polycrystalline film surfaces are so far not clear yet.

Orthorhombic Sb2S3 consists of (Sb4S6)n ribbons that grow along the [001] direction via strong covalent Sb–S bonds and are packed together along [100] and [010] directions by van der Waals forces (Fig. 3a)13,27. Experimentally, the main growth features of the Sb2S3 cuboids are: (i) the orientation of Sb2S3 cuboids is exclusively governed by the beneath TiO2 nanoparticle film; (ii) one single-crystalline Sb2S3 cuboid is grown over many TiO2 nanoparticles and the Sb2S3 cuboids mainly have the out-of-plane growths along the [001], [100] and [010] directions; (iii) the heterogeneously nucleation follows the epitaxial relationship of Sb2S3 (101)//TiO2 (101) between orthorhombic Sb2S3 and anatase TiO2, where the spatial distance of Ti–O (4.71 nm) on TiO2 (101) plane actually matches that of S–Sb (4.79 nm) on Sb2S3 (101) plane for a good coordination (Fig. 3b). Here we propose an orientation-competing-epitaxial (OCE) nucleation/growth mechanism for the in situ growth of the preferentially oriented Sb2S3 single-crystalline cuboids on polycrystalline TiO2 nanoparticle film, as illustrated in Fig. 3c.

Crystal structure and epitaxial growth model. a Orthorhombic Sb2S3 consists of (Sb4S6)n ribbons stacked parallel to [001] direction. b Atomic configuration at the Sb2S3/TiO2 interface epitaxially grown between the (101) planes of orthorhombic Sb2S3 and anatase TiO2 crystals. c Schematic illustration of the OCE nucleation/growth model for the growth of Sb2S3 single-crystalline cuboids on polycrystalline TiO2 nanoparticle film, where the most competitive TiO2 nanoparticle orientation for the Sb2S3 single-crystals to nucleate/grow features its (101) plane tilting an angle (α) on substrate plane close to α = 33o (Particle 2), but the nucleation/growth at other sites around (e.g., particle 1 of α = 0o and Particle 3 of α = 62o) is relatively much slower or suppressed due to their unfavorable TiO2 (101) plane orientations

In the OCE mechanism, the capability of a surface TiO2 nanoparticle to act as an effective site for the heterogeneously epitaxial nucleation of Sb2S3 crystal according to the epitaxial relationship of Sb2S3 (101)//TiO2 (101) strongly depends on its orientation, and only those orientated with (101) planes tilting favorable angles (α) on substrate plane are competitive during the heterogeneously epitaxial nucleation/growth of orthorhombic Sb2S3 cuboids. Known from the calculated possible angles between the crystalline planes and substrate plane for anatase TiO2 and epitaxially grown stibnite Sb2S3 crystals as the results of TiO2 (101) plane orientations (Supplementary Table 3, Supplementary Fig. 10 and Supplementary Note 9), the surface TiO2 nanoparticle orientation with the (101) plane tilting an angle of 0o ≤ α < 62o on substrate plane is theoretically necessary for heterogeneously epitaxial nucleation/growth of orthorhombic Sb2S3 single-crystalline cuboids, because it allows the easier out-of-plane growths of Sb2S3 crystals along the [001], [100], and [010] directions as experimentally observed. In view of the fact that the Sb2S3 cuboids normally have the (001) planes tilting an angle of ca. 44o on substrate plane (Fig. 1d, inset), one gets to know that the most competitive TiO2 nanoparticle orientation for the heterogeneously epitaxial nucleation/growth of the Sb2S3 single-crystalline cuboids features the tilting angle close to α ≈ 33o (Supplementary Table 3, Supplementary Fig. 10 and Supplementary Note 9).

As shown in Fig. 3c, during the OCE nucleation/growth process, the heterogeneously epitaxial nucleations of orthorhombic Sb2S3 crystals on the TiO2 nanoparticles with favorable orientations take place, when the orientations of Sb2S3 crystals are governed by the TiO2 (101) plane orientations; after nucleation, the Sb2S3 nuclei take a self-nucleated growth into the Sb2S3 crystalline seeds that maintain the orientations of their nuclei (Supplementary Fig. 8c); finally, the Sb2S3 crystalline seeds further take a self-nucleated growth into larger Sb2S3 cuboids by the followed RSCA cycles, where the growth rate in the c-axes direction turns to be larger than in a- and b-axes directions when n > 1 (Fig. 1b,c; Supplementary Figs. 4, 8b and 9b), the orientations of Sb2S3 crystal planes in their seed crystals are not changed (Fig. 1d; Supplementary Figs. 8c and 9c), and the chemical species provided by the glycerin maintains the smoothness of growing cuboid surfaces by inhibiting the strain-driven surface roughening28,34 (Fig. 1b,c; Supplementary Figs. 4 and 6). Since the self-nucleated growth of Sb2S3 cuboids takes place from stem to top, no interfaces are introduced into the cuboid body with increasing n for the cuboid growth, which is clearly indicated by the HRTEM images at different locations showing the single-crystalline nature of the cuboids (Fig. 2b–d). With the faster nucleation/growth at a site with the most/more competitive TiO2 (101) plane orientation (e.g., Particle 2), the nucleation/growth at around sites with less-competitive/unfavorable TiO2 (101) plane orientation (e.g., Particles 1 and 3) becomes much slower or suppressed, resulting in one large Sb2S3 seed crystal/cuboid over many TiO2 nanoparticles.

Moreover, the epitaxial strains caused by lattice-misfit and orientation-mismatch in the heterogeneous nucleation must get eventually released during the growth of Sb2S3 crystals, which leads to the presence of the Sb2S3 growth transition region in the vicinity to Sb2S3/TiO2 interface30,31,33. In particular, the faster Sb2S3 growth will merge the slower growth starting from the neighborhood nucleation sites with a comparable TiO2 (101) orientation, when more strains for the epitaxial growth due to the difference in the TiO2 (101) orientation inevitably lead to the widening of the Sb2S3 growth transition region (Fig. 2e). Furthermore, since the TiO2 (101) crystal planes are randomly and two-dimensionally orientated in substrate plane, the resulting Sb2S3 cuboids inevitably orient with the c-axis titling different angles on the substrate plane and pointing randomly to out-of-plane directions (Fig. 1b, c; Supplementary Figs. 4a,b and 9b). Obviously, the lateral size of Sb2S3 cuboids eventually depends on the number density of the TiO2 nanoparticles with the most/more competitive orientation. Note, we got the TEM images of the cuboids with the [001] direction closely vertical to substrate plane by a chance (Fig. 2; Supplementary Fig. 3), suggesting that those cuboids are grown from the heterogeneously epitaxial nucleations on the TiO2 nanoparticles with the (101) plane orientation of α ≈ 0o (Supplementary Table 3 and Supplementary Fig. 10).

Solar cells

The as-prepared Sb2S3 cuboids layer in Sb2S3/TiO2-BnPHJ exhibits an absorption edge at ca. 750 nm corresponding to the band gap (Eg) of Sb2S3 layer (i.e., Eg = 1.65 eV) and has an absorption coefficient (α) of ca. 105 cm−1 in the range of 350–650 nm (Fig. 4a). The Sb2S3/TiO2-BnPHJ solar cell was fabricated by spin-coating 2,2′,7,7′-tetrakis-(N,N-di-p-methoxyphenyl-amine)-9,9′-spirobifluorene (Spiro-OMeTAD) as hole transporting material over the Sb2S3/TiO2-BnPHJ, followed by depositing Au counter electrode via thermal evaporation, as shown in Fig. 4b, where SEM image clearly shows that the Spiro-OMeTAD layer tightly covers the surface of Sb2S3 cuboids. Using the energy-dependence of the measured α, the Sb2S3 layer thickness required to absorb 90% incident photons (I0) of a specific wavelength is evaluated according to Beer-Lambert law I = I0exp(−αx)43. Clearly, the Sb2S3 cuboids layer with a thickness of ca. 700 nm is required for absorbing 90% incident photons of 350–700 nm. However, the solar cells with the Sb2S3 layer of ca. 600 nm in thickness (i.e., n = 4) have a poorer performance than those with ca. 400-nm-thick Sb2S3 layer (i.e., n = 2) (Supplementary Table 4). With the diffusion coefficients (D) of 0.25 cm2 s−1 for electrons11 and 0.07 cm2 s−1 for holes17 in crystalline Sb2S3, the diffusion lengths (LD) of electrons and holes in Sb2S3 layer are respectively calculated to be 340 nm and 180 nm, according to the relation LD2 = Dτ, where τ = 4.6 ns is the lifetime of charge carriers17. The thickness-dependence of device performance inevitably correlates to the limited LD of charge carriers inside the Sb2S3 layer.

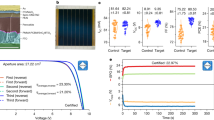

Optical property and orientation-dependent device performance. a Absorption coefficient of the Sb2S3 layer in Sb2S3/TiO2-BnPHJ and the corresponding Sb2S3 layer thickness required to absorb 90% incident photons of a specific wavelength. b Sb2S3/TiO2-BnPHJ device structure (right: cross-sectional SEM characterization). c J–V curves and (d) IPCE spectra of the solar cells based on Sb2S3/TiO2-BnPHJ and ref-Sb2S3/TiO2-BnPHJ (n = 2 for both). e The spatial arrangement of the (Sb4S6)n ribbons tilting 46o on substrate resulting from the [221]-orientation of Sb2S3 cuboids, where the electron transportation along [001] direction is easiest. b Scale bar 400 nm for SEM image

In the Sb2S3/TiO2-BnPHJ solar cell of ca. 400-nm-thick Sb2S3 layer, we obtained the considerable efficiency of η = 5.15 % under AM 1.5 illumination (100 mW/cm2) resulting from the open-circuit voltage (Voc) of 0.66 V, short-circuit current (Jsc) of 13.12 mA/cm2 and fill factor (FF) for 59.46% (Fig. 4c), for which a certified efficiency of η = 5.12 % was obtained from the National Institute of Metrology (NIM), China to confirm the reliability of the efficiency (Supplementary Fig. 11). The efficiency is much higher than that (i.e., η = 3.5%) of the devices based on the Sb2S3/CdS-BnPHJ prepared by thermal evaporation20,21, mainly due to the much higher Jsc. The observed device performance is of a high reproducibility and the averaged efficiency of six independent devices reaches 5.10% (Supplementary Table 4). The incident photon-to-current conversion efficiency (IPCE) spectrum shows that the solar cell has a broad spectral response in the wavelength range of 300–750 nm (Fig. 5d), in a good agreement with the absorption feature of the Sb2S3 layer (Fig. 4a). Our devices exhibit a good long-term stability, for example, the Sb2S3/TiO2-BnPHJ solar cell still retains over 91% of the initial efficiency after the storage in N2 atmosphere for 30 days (Supplementary Fig. 12).

In order to investigate the influence of Sb2S3 grain orientation on solar cell performance, we prepared the ref-Sb2S3/TiO2-BnPHJ solar cell with n = 2 (ca. 450-nm-thick Sb2S3 layer) for comparison. The large Sb2S3 grains in the ref-Sb2S3/TiO2-BnPHJ display the XRD pattern same to the polycrystalline powder sample (Supplementary Fig. 7), indicating no preferential orientation of Sb2S3 grains therein but actually suggesting that the Sb2S3 grains in ref-Sb2S3/TiO2-BnPHJ are oriented with [130]/[310] direction normal to substrate plane (Supplementary Note 5). However, the ref-Sb2S3/TiO2-BnPHJ solar cell exhibits a much poorer efficiency of η = 3.62% with Voc = 0.66 V, Jsc = 11.52 mA/cm2 and FF = 47.87% (Fig. 4c; Supplementary Table 4). The lower Jsc in the ref-Sb2S3/TiO2-BnPHJ device is related to the reduced contribution of the charge carriers generated in the whole Sb2S3 layer to photocurrent generation, as shown by the IPCE spectra in Fig. 4d. Our intensity modulated photocurrent spectroscopy (IMPS) results show that the transit time (τD) for photogenerated electrons to reach the collection electrode in the Sb2S3/TiO2-BnPHJ solar cell (τD = 19.55 μs) was much smaller than that in the ref-Sb2S3/TiO2-BnPHJ device (τD = 30.84 μs) (Supplementary Fig. 13). The τD values demonstrate that the electron density injected into TiO2 layer from the [221]-oriented Sb2S3 cuboids is much higher and the preferential [221]-orientation of the Sb2S3 cuboids provides a much easier transportation of the photogenerated electrons in Sb2S3 absorbing layer toward TiO2 film and further collection electrode (Supplementary Note 10). Moreover, the smaller series resistance (Rs) and larger shunt resistance (Rsh) in the Sb2S3/TiO2-BnPHJ device also suggest an easier charge transportation process therein (Supplementary Table 4).

The observed device performances of the two solar cells can be understood by the orientation of Sb2S3 grains. In a single-crystalline Sb2S3 grain, the easiest carrier transportation is in the [001] direction along the covalently bounded (Sb4S6)n ribbons35. The [221]-orientation results in eventually the (Sb4S6)n ribbons titling an angle of 46o on substrate plane, which facilitates the photogenerated charge carrier transportation toward collection electrode in the Sb2S3/TiO2-BnPHJ device (Fig. 4e); however, the (Sb4S6)n ribbons in the ref-Sb2S3/TiO2-BnPHJ with [130]/[310]-orientation of Sb2S3 grains are actually parallel to the substrate plane (Supplementary Fig. 14), leading to a lower effective transportation of photogenerated charge carriers toward the collection electrode because it needs the charge hopping between the (Sb4S6)n ribbons packed together by van der Waals forces35. Therefore, the [221]-orientation of the Sb2S3 cuboids provides the easier collection and weaker recombination of photogenerated charge carriers in the solar cells. It should be noted that the efficiency of the present solar cell is not high enough yet. We envision that, for a better device performance, it is necessary to reduce the surface roughness of the Sb2S3 layer, which may cause serious shorting risk44 and charge recombination11,45 to reduce Voc and FF values, to improve the charge collection efficiency in the device.

Discussion

In summary, an oriented seed-assisted RSCA solution-processing method is developed for the in situ growth of the monolayer of closely packed and preferentially [221]-oriented large orthorhombic Sb2S3 single-crystalline cuboids on polycrystalline anatase TiO2 nanoparticle film, offering a novel Sb2S3/TiO2-BnPHJ with the Sb2S3 cuboids having the typical growth features of the out-of-plane growth along the [001] direction with (001) planes tilting ca. 44o on substrate plane and the size much larger than TiO2 nanoparticles. It is found that the orientation of the Sb2S3 cuboids is exclusively correlated with the beneath TiO2 surface and the preferentially oriented Sb2S3 crystalline seeds formed on the TiO2 film are indispensable to cuboid growth; while glycerin remains inactive during the formation of SbCl3–thiourea complex in the precursor solution, its presence provides chemical species to maintain the smoothness of growing surfaces of cuboids by inhibiting the strain-driven surface roughening.

An OCE nucleation/growth mechanism is suggested for the in situ growth of the preferentially oriented Sb2S3 single-crystalline cuboids on polycrystalline TiO2 nanoparticle film, in which the heterogeneously epitaxial nucleation/growth of Sb2S3 crystals follows the epitaxial relationship of Sb2S3 (101)//TiO2 (101) and the surface TiO2 nanoparticle orientation with the (101) plane tilting an angle of ca. 33o on film plane is most competitive for the nucleation/growth of Sb2S3 cuboids. During the OCE nucleation/growth process, the heterogeneously epitaxial nucleations of orthorhombic Sb2S3 crystals on the anatase TiO2 nanoparticles with favorable TiO2 (101) plane orientations take place, followed by the self-nucleated growth of Sb2S3 nuclei into larger Sb2S3 crystalline seeds, when the orientations of Sb2S3 crystals are governed by the TiO2 (101) plane orientations; then the seeds from different nuclei further take a self-nucleated growth during the latter RSCA cycles into much larger Sb2S3 cuboids without the changes in Sb2S3 crystal orientations. With the faster nucleation/growth at a site with the most/more competitive TiO2 (101) plane orientation, the nucleation/growth at around sites with less-favorable/unfavorable TiO2 (101) plane orientation becomes much slower or suppressed, resulting in one large Sb2S3 seed crystal/cuboid over many TiO2 nanoparticles. When the RSCA cycle number n is >1, increasing n mainly leads to the growth of Sb2S3 cuboids in the c-axis direction and the merge of some small cuboids into large ones, but introduces no evident interfaces into the cuboid body.

The Sb2S3 cuboids layer in the Sb2S3/TiO2-BnPHJ has a band gap of Eg = 1.65 eV and an absorption coefficient of α ≈ 105 cm−1 in the range of 350–650 nm. In combination with Spiro-OMeTAD as hole transporting material, the novel solar cell with a high long-term stability is derived from the Sb2S3/TiO2-BnPHJ. In this experiment, the Sb2S3 layer thickness/cuboid height of ca. 400 nm produces the best efficiency of η = 5.15% (certified as 5.12%), as the result of the limited LD of charge carriers inside Sb2S3 layer. The Sb2S3/TiO2-BnPHJ possesses the following distinctive advantages: it is of the preferred structure for efficient planar solar cells1,2,3 and a high absorption coefficient; it is very stable and easily solution-processed on a large scale; moreover, the [221]-oriented single-crystalline Sb2S3 cuboids therein provide the highly effective charge transport channels formed the covalently bounded (Sb4S6)n ribbons tilting ca. 46o on substrate for the photogenerated charge carriers inside the Sb2S3 layer to reach collection electrode. Those make the Sb2S3/TiO2-BnPHJ have good application potentials to efficient solar cells. Our results provide a facile solution-processing method to prepare the high-quality Sb2S3/TiO2 PHJs for photovoltaic and other optoelectronic applications, and also offer a new understanding of the heterogeneously epitaxial growth of large single-crystals on polycrystalline surface.

Methods

Sb2S3 precursor solution

1.2 mmol of SbCl3 (≥99.0%, Alfa Aesar) and 2.16 mmol of thiourea (≥99.0 %, Alfa Aesar) were sequentially dissolved in 1 ml of a mixture solvent of N,N-dimethylformamide (DMF) and glycerol (DMF/glycerol = 4/1 in volume) under stirring at room temperature, resulting in a transparent and light-yellow Sb2S3 precursor solution with 1.2 M SbCl3 and a molar ratio of SbCl3:thiourea = 1:1.8. The precursor solution is stable in ambient conditions for weeks.

Sb2S3/TiO2-BnPHJ preparation

FTO (SnO2:F) coated glass sheet (14 Ω/square, 400 nm FTO in thickness, Nippon Sheet Glass Co.) (15 × 20 mm2) was patterned into one stripe (20 × 4 mm2) in the middle part of the substrate by laser, commercially obtained from the Advanced Election Technology Co. Ltd., Liaoning Province, China. The patterned FTO sheet was first washed with acetone, isopropanol, and deionized water, respectively; then it was further cleaned with UV-Ozone for 15 min and washed with ethanol before use. A compact and polycrystalline TiO2 nanoparticle film (90 nm thick) was prepared on the patterned FTO sheet by the method described elsewhere24.

Sb2S3/TiO2-BnPHJ was prepared by an oriented seed-assisted-RSCA method. The Sb2S3 precursor solution was spin-coated four times onto a seed-decorated TiO2 film to get a transparent and light-yellow Sb2S3 precursor film on the TiO2 film surface, and then the Sb2S3 precursor film dried at 60 oC for 15 min in vacuum in advance was subjected to the thermal annealing at 330 oC for 10 min on a hot-stage in N2 atmosphere, which is referred to as one RSCA cycle; after the TiO2 film had been subjected to several RSCA cycle numbers (n), the Sb2S3/TiO2-BnPHJ was in situ formed. Before carring out the RSCA process, a dilute Sb2S3 precursor solution (0.4 M SbCl3) was first spin-coated onto the bare TiO2 film, followed by the same drying and thermal annealing processes as the RSCA procedure, resulting in the oriented Sb2S3 crystalline seeds on TiO2 film surface. The Sb2S3 layer thickness/cuboid height was controlled by the n value for film growth.

In order to reveal the substrate effects on the growth of Sb2S3 cuboids, the Sb2S3 layer was directly deposited onto native FTO substrate by the seed-assisted-RSCA method same to that for preparing Sb2S3/TiO2-BnPHJ. Moreover, in order to find out the glycerin effects on the growth of Sb2S3 cuboids, the Sb2S3 layer was deposited onto TiO2 film by the seed-assisted-RSCA method same to that for preparing Sb2S3/TiO2-BnPHJ, but without glycerin in the Sb2S3 precursor solutions. Furthermore, for comparison, the reference Sb2S3/TiO2-BnPHJ (i.e., ref-Sb2S3/TiO2-BnPHJ) was prepared by the RSCA process same to that for Sb2S3/TiO2-BnPHJ but without Sb2S3 crystalline seeds.

Solar cell fabrication

First, a film of Spiro-OMeTAD (Xi’an Polymer Light Technology Corp.) was spin-coated (2500 rpm, 60 s) over the Sb2S3/TiO2-BnPHJ or ref-Sb2S3/TiO2-BnPHJ, followed by an annealing at 100 oC for 10 min in N2 atmosphere. Spiro-OMeTAD was doped in advance with lithium bis(trifluoro-methylsulphonyl)imide (Li-TFSI, 99.95%, Sigma-Aldrich) as described previously24. Then, an Au electrode (100 nm thick) was thermally evaporated onto the Spiro-OMeTAD layer. Finally, the devices were encapsulated in a glovebox under N2 atmosphere (O2 < 1 ppm, H2O < 1 ppm).

Instruments and characterization

XRD data were collected on a Philips X’Pert Pro MPD diffractometer with monochromated Cu Kα radiation (λ = 1.54056 Å). SEM measurements were performed on a field-emission scanning electron microscope (FESEM, FEI-Sirion 200). TEM and HRTEM studies were carried out on a JEOL-2010 microscopy under an acceleration voltage of 200 kV, and the samples for TEM and HRTEM analyses were prepared by a focused ion beam (FIB) process on SCIOS DualBeam FIB (FEI, USA). UV–vis absorption spectra were recorded on a Shimadzu UV-2550 spectrophotometer. The absorption coefficient of Sb2S3 layer in Sb2S3/TiO2 heterojunction film was calculated from the reflectance and transmission spectra between 240 nm and 1200 nm recorded at a scan speed of 240 nm/min on a Solid Spec-3700 UV–vis spectrometer with a resolution of 1 nm. FT-IR spectra of the solid samples of thiourea in KBr pellet and the liquid samples were respectively recorded on a Nicolet Magna-IR™ 750 spectrometer with a maximum resolution of 0.1 cm−1. The J–V curves of solar cells were measured with forward scan under AM1.5 illumination (100 mW/cm2) from a 94023 A Oriel® Sol3A solar simulator (Newport), and the light intensity from a 450 W xenon lamp was calibrated with a standard crystalline silicon solar cell. The J–V curves were collected with an Oriel® I-V test station (PVIV-1A, Keithley 2400 Source Meter, Labview 2009 SP1 GUI Software, Newport). IMPS spectra were measured on a controlled intensity modulated photo spectroscopy (CIMPS, Zahner Co., Germany; Thales 4.15 Software) in ambient conditions. During IMPS measurements45, the solar cells was illuminated with a modulated illumination (I) formed by a dc component of a steady-state background light I0 and an ac component of a small sinusoidal perturbation Iac = I0δeiωt, that is, I = I0(1 + δeiωt), where the background light intensity I0 of 10 mW/cm2 was provided by a blue light-emitting diode (BLL01, λmax = 470 nm, spectral half-width = 25 nm, Zahner Co.) driven by a frequency response analyzer and the perturbation was applied in the frequency range from 1 Hz to 100 kHz with a modulation depth of δ = 0.10. During the J–V and IMPS measurements, the illumination area of each device was limited by a mask with an aperture (2 × 2 mm2), which actually defined the effective area for getting photovoltaic parameters of the device. The IPCE spectra of the solar cells were measured with a QE/IPCE Measurement Kit (Newport) that was automatically controlled by Oriel® Tracq Basic V6.5 software with a light from a 300 W xenon lamp focusing through a monochromator (74125 Oriel Cornerstone 260 1/4 m) onto the solar cells. The light intensity and photocurrent generated were measured with a 2936-R dual channel power/current meter and an 818-UVcalibrated silicon-UV photodetector.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information files. Extra data are available from the corresponding author upon reasonable request.

References

Burst, J. M. et al. CdTe solar cells with open-circuit voltage breaking the 1 V barrier. Nat. Energy 1, 16015 (2016).

Zhao, Y. et al. Monocrystalline CdTe solar cells with open-circuit voltage over 1 V and efficiency of 17%. Nat. Energy 1, 16067 (2016).

Polman, A., Knight, M., Garnett, E. C., Ehrler, B. & Sinke, W. C. Photovoltaic materials: present efficiencies and future challenges. Science 352, aad4424 (2016).

Brus, L. E. Electron–electron and electron–hole interactions in small semiconductor crystallites: the size dependence of the lowest excited electronic state. J. Chem. Phys. 80, 4403–1409 (1984).

Ginger, D. S. & Greenham, N. C. Charge injection and transport in films of CdSe nanocrystals. J. Appl. Phys. 87, 1361–1368 (2000).

Jasieniak, J., MacDonald, B. I., Watkins, S. E. & Mulvaney, P. Solution-processed sintered nanocrystal solar cells via layer-by-layer assembly. Nano Lett. 11, 2856–2864 (2011).

Yang, W. S. et al. Iodide management in formamidinium-lead-halide–based perovskite layers for efficient solar cells. Science 356, 1376–1379 (2017).

Correa-Baena, J.-P. et al. Promises and challenges of perovskite solar cells. Science 358, 739–744 (2017).

Luo, Y. et al. Electrochemically deposited Cu2O on TiO2 nanorod arrays for photovoltaic application. Electrochem. Solid-State Lett. 15, H34–H36 (2012).

Todorov, T. K. et al. Beyond 11% efficiency: characteristics of state-of-the-art Cu2ZnSn(S,Se)4 solar cells. Adv. Energy Mater. 3, 34–38 (2013).

Qiu, Z. et al. Solution-processed solar cells based on inorganic bulk heterojunctions with evident hole contribution to photocurrent generation. Phys. Chem. Chem. Phys. 17, 12328–12339 (2015).

Wang, W. et al. Device characteristics of CZTSSe thin-film solar cells with 12.6% efficiency. Adv. Energy Mater. 4, 1301465 (2014).

Kondrotas, R., Chen, C. & Tang, J. Sb2S3 solar cells. Joule 2, 857–878 (2018).

Filip, M. R., Patrick, C. E. & Giustino, F. GW quasiparticle band structures of stibnite, antimonselite, bismuthinite, and guanajuatite. Phys. Rev. 87, 205125 (2013).

Versavel, M. Y. & Haber, J. A. Structural and optical properties of amorphous and crystalline antimony sulfide thin-films. Thin Solid Films 515, 7171–7176 (2007).

Savadogo, O. & Mandal, K. C. Studies on new chemically deposited photoconducting antimony trisulphide thin films. Sol. Energy Mater. Sol. Cells 26, 117–136 (1992).

Christians, J. A., Leighton, D. T. Jr & Kamat, P. V. Rate limiting interfacial hole transfer in Sb2S3 solid-state solar cells. Energy Environ. Sci. 7, 1148–1158 (2014).

Rühle, S. Tabulated values of the shockley–queisser limit for single junction solar cells. Sol. Energy 130, 139–147 (2016).

Choi, Y. C., Lee, D. U., Noh, J. H., Kim, E. K. & Seok, S. I. Highly improved Sb2S3 sensitized-inorganic–organic heterojunction solar cells and quantification of traps by deep-level transient spectroscopy. Adv. Funct. Mater. 24, 3587–3592 (2014).

Yuan, S. et al. Efficient planar antimony sulfide thin film photovoltaics with large grain and preferential growth. Sol. Energy Mater. Sol. Cells 157, 887–893 (2016).

Yuan, S. et al. Postsurface selenization for high performance Sb2S3 planar thin film solar cells. ACS Photonics 4, 2862–2870 (2017).

Choi, Y. C. & Seok, S. I. Efficient Sb2S3 -sensitized solar cells via single-step deposition of Sb2S3 using S/Sb-ratio-controlled SbCl3 -thiourea complex solution. Adv. Funct. Mater. 25, 2892–2898 (2015).

Zheng, Q. et al. Annealing temperature impact on Sb2S3 solar cells prepared by spin-coating method. Mater. Lett. 243, 104–107 (2019).

Chen, J. et al. Growth of compact CH3NH3PbI3 thin films governed by the crystallization in PbI2 matrix for efficient planar perovskite solar cells. ACS Appl. Mater. Interfaces 10, 8649–8658 (2018).

Gao, Y. & Elder, S. A. TEM study of TiO2 nanocrystals with different particle size and shape. Mater. Lett. 44, 228–232 (2000).

Lazzeri, M., Vittadini, A. & Selloni, A. Structure and energetics of stoichiometric TiO2 anatase surfaces. Phys. Rev. B 63, 155409 (2001).

Patrick, C. E. & Giustino, F. Structural and electronic properties of semiconductor-sensitized solar-cell interfaces. Adv. Funct. Mater. 21, 4663–4667 (2011).

Goldthorpe, I. A., Marshall, A. F. & McIntyre, P. C. Inhibiting strain-induced surface roughening: dislocation-free Ge/Si and Ge/SiGe core–shell nanowires. Nano Lett. 9, 3715–3719 (2009).

Fang, Z. et al. Epitaxial growth of CdS nanoparticle on Bi2S3 nanowire and photocatalytic application of the heterostructure. J. Phys. Chem. C. 115, 13968–13976 (2011).

Zhu, G. & Xu, Z. Controllable growth of semiconductor heterostructures mediated by bifunctional Ag2S nanocrystals as catalyst or source-host. J. Am. Chem. Soc. 133, 148–157 (2011).

Dayeh, S. A. et al. Growth, defect formation, and morphology control of germanium−silicon semiconductor nanowire heterostructures. Nano Lett. 11, 4200–4206 (2011).

Li, M.-Y. et al. Epitaxial growth of a monolayer WSe2-MoS2 lateral p-n junction with an atomically sharp interface. Science 349, 524–528 (2015).

Dai, R. et al. Epitaxial growth of lattice-mismatched core–shell TiO2@MoS2 for enhanced lithium-ion storage. Small 12, 2792–2799 (2016).

Gao, H. & Nix, W. D. Surface roughening of heteroepitaxial thin films. Annu. Rev. Mater. Sci. 29, 173–209 (1999).

Zhou, Y. et al. Thin-film Sb2Se3 photovoltaics with oriented one-dimensional ribbons and benign grain boundaries. Nat. Photon 9, 409–415 (2015).

Wen, X. et al. Vapor transport deposition of antimony selenide thin film solar cells with 7.6% efficiency. Nat. Commun. 9, 2179 (2018).

Wang, L. et al. Stable 6%-efficient Sb2Se3 solar cells with a ZnO buffer layer. Nature. Energy 2, 17046 (2017).

Guo, Y. et al. Citric acid modulated growth of oriented lead perovskite crystals for efficient solar cells. J. Am. Chem. Soc. 139, 9598–9604 (2017).

Im, J.-H., Jang, I.-H., Pellet, N., Grätzel, M. & Park, N.-G. Growth of CH3NH3PbI3 cuboids with controlled size for high-efficiency perovskite solar cells. Nat. Nanotech. 9, 927–932 (2014).

Ko, H.-S., Lee, J.-W. & Park, N.-G. 15.76% efficiency perovskite solar cells prepared under high relative humidity: importance of PbI2 morphology in two-step deposition of CH3NH3PbI3. J. Mater. Chem. A 3, 8808–8815 (2015).

Zhao, J. et al. Single crystalline CH3NH3PbI3 self-grown on FTO/TiO2 substrate for high efficiency perovskite solar cells. Sci. Bull. 62, 1173–1176 (2017).

Kelso, M. V., Mahenderkar, N. K., Chen, Q., Tubbesing, J. Z. & Switzer, J. A. Spin coating epitaxial films. Science 364, 166–169 (2019).

Musselman, K. P. et al. Strong efficiency improvements in ultra-low-cost inorganic nanowire solar cells. Adv. Mater. 22, E254–E258 (2010).

Uhl, A. R. et al. Solution-processed low-bandgap CuIn(S,Se)2 absorbers for high-efficiency single-junction and monolithic chalcopyrite-perovskite tandem solar cells. Adv. Energy Mater. 8, 1801254 (2018).

Wu, F. et al. Dynamic characterization of hybrid solar cells based on polymer and aligned ZnO nanorods by intensity modulated photocurrent spectroscopy. J. Phys. Chem. C. 114, 20225–20235 (2010).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (grant nos. 11274307, 91333121, 11474286, 51572254, U1532156), the Science and Technology Project of Auhui Province (grant no. 1604a0902148), the National Key Research and Development Program of China (grant no. 2017YFA0402800), and the Major/Innovative Program of Development Foundation of Hefei Center for Physical Science and Technology (grant no. 2016FXZY003). The authors thank Mr. Zengli Huang in Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences for helps in preparing the TEM/HRTEM samples by FIB technique.

Author information

Authors and Affiliations

Contributions

J.C. designed and performed heterojunction synthesis, solar cell fabrication and sample characterizations. J.Q. and R.L. helped with the synthesis and characterization of heterojunctions. X.Z. conducted TEM/HRTEM measurements. Z.W. contributed to the analysis of solar cell data. Q.Z. contributed to SEM measurements. S.T. contributed to the analysis of crystal structures. C.D., G.Y.A., W.C., R.P., and X.T. contributed to the fabrication and characterization of solar cells. F.Z. and S.Y. helped with solar cell characterization. M.W. conceived the study and supervised the project. M.W. and J.C. analyzed the data, interpreted the results and prepared the manuscript. All authors commented and edited the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, J., Qi, J., Liu, R. et al. Preferentially oriented large antimony trisulfide single-crystalline cuboids grown on polycrystalline titania film for solar cells. Commun Chem 2, 121 (2019). https://doi.org/10.1038/s42004-019-0225-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-019-0225-1

This article is cited by

-

Impact of compact TiO2 interface modification on the crystallinity of perovskite solar cells

Scientific Reports (2023)

-

Study of the growth mechanism of a self-assembled and ordered multi-dimensional heterojunction at atomic resolution

Frontiers of Optoelectronics (2023)

-

Effect of Ruthenium doping in tailoring structure, optical and electrical properties of Sb2S3 thin film synthesized via electrodeposition technique

Journal of Materials Science: Materials in Electronics (2023)

-

Nanoarray heterojunction and its efficient solar cells without negative impact of photogenerated electric field

Communications Physics (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.