Abstract

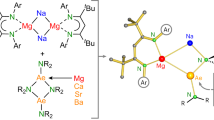

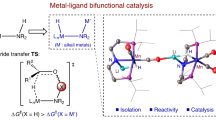

Hydrogenation of unsaturated bonds is dominated by transition metal catalysis. Compared with transition metals, the use of other metals is less explored, especially so for the s-block elements despite their ready availability and low cost. Here, we show that group 2 metal amides (M[N(SiMe3)2]2, M = Mg, Ca, Sr, Ba) unexpectedly catalyse the hydrogenation of aldimines with H2 at 80 °C and a remarkably low H2 pressure of 1–6 bar. Conversion rates increase with metal size: Mg < Ca < Sr < Ba (for Ba, quantitative conversion is reached within 15 min). The key to this catalysis is the unanticipated formation of metal hydride species by deprotonation of H2 (pK a ≈ 49) with a weak base M[N(SiMe3)2]2 (HN(SiMe3)2: pK a ≈ 25.8). Density functional theory calculations suggest that the most favourable pathway indeed involves metal hydride intermediates. The efficient alkaline earth metal-catalysed hydrogenation of imines with molecular hydrogen at remarkably low pressure provides an attractive alternative to transition metal catalysis.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

de Vries, J. G. & Elsevier, C. J. Handbook of Homogeneous Hydrogenation: 3 Volumes (Wiley-VCH, Weinheim, 2007).

Albrecht, M., Bedford, R. & Plietker, B. Catalytic and organometallic chemistry of earth-abundant metals. Organometallics 33, 5619–5621 (2014).

Schafer, L. L., Mountford, P. & Piers, W. E. Earth abundant element compounds in homogeneous catalysis. Dalton Trans. 44, 12027–12028 (2015).

Harder, S. From limestone to catalysis: application of calcium compounds as homogeneous catalysts. Chem. Rev. 110, 3852–3876 (2010).

Hill, M. S., Liptrot, D. J. & Weetman, C. Alkaline earths as main group reagents in molecular catalysis. Chem. Soc. Rev. 45, 972–988 (2016).

Berben, L. A. Catalysis by aluminum(III) complexes of non-innocent ligands. Chem. Eur. J. 21, 2734–2742 (2015).

Spielmann, J., Buch, F. & Harder, S. Early main-group metal catalysts for the hydrogenation of alkenes with H2. Angew. Chem. Int. Ed. 47, 9434–9438 (2008).

Greb, L. et al. Metal-free catalytic olefin hydrogenation: low-temperature H2 activation by frustrated Lewis pairs. Angew. Chem. Int. Ed. 51, 10164–10168 (2012).

Stephan, D. W. The broadening reach of frustrated Lewis pair chemistry. Science 354, 1248–1256 (2016).

Stephan, D. W. & Erker, G. Frustrated Lewis pair chemistry: development and perspectives. Angew. Chem. Int. Ed. 54, 6400–6441 (2015).

Stephan, D. W. Frustrated Lewis pairs: from concept to catalysis. Acc. Chem. Res. 48, 306–316 (2015).

Schuhknecht, D., Lhotzky, C., Spaniol, T. P., Maron, L. & Okuda, J. Calcium hydride cation [CaH]+ stabilized by an NNNN-type macrocyclic ligand: a selective catalyst for olefin hydrogenation. Angew. Chem. Int. Ed. 56, 12367–12371 (2017).

Harder, S. & Brettar, J. Rational design of a well-defined soluble calcium hydride complex. Angew. Chem. Int. Ed. 45, 3474–3478 (2006).

Jochmann, P., Davin, J. P., Spaniol, T. P., Maron, L. & Okuda, J. A cationic calcium hydride cluster stabilized by cyclen-derived macrocyclic N,N,N,N ligands. Angew. Chem. Int. Ed. 51, 4452–4455 (2012).

Leich, V., Spaniol, T. P., Maron, L. & Okuda, J. Molecular calcium hydride: dicalcium trihydride cation stabilized by a neutral NNNN-type macrocyclic ligand. Angew. Chem. Int. Ed. 55, 4794–4797 (2016).

Causero, A. et al. Stabilization of calcium hydride complexes by fine tuning of amidinate ligands. Organometallics 35, 3350–3360 (2016).

Causero, A. et al. β-Diketiminate calcium hydride complexes: the importance of solvent effects. Dalton Trans. 46, 1822–1831 (2017).

Penafiel, J., Maron, L. & Harder, S. Early main group metal catalysis: how important is the metal? Angew. Chem. Int. Ed. 54, 201–206 (2015).

Harder, S., Feil, F. & Knoll, K. Novel calcium half-sandwich complexes for the living and stereoselective polymerization of styrene. Angew. Chem. Int. Ed. 40, 4261–4264 (2001).

Abdur-Rashid, K. et al. An acidity scale for phosphorus-containing compounds including metal hydrides and dihydrogen complexes: toward the unification of acidity scales. J. Am. Chem. Soc. 122, 9155–9171 (2000).

Zeng, G. & Li, S. Mechanistic insight on the hydrogenation of conjugated alkenes with H2 catalyzed by early main-group metal catalysts. Inorg. Chem. 49, 3361–3369 (2010).

Fabrello, A., Bachelier, A., UrrutigoÏty, M. & Kalck, P. Mechanistic analysis of the transition metal-catalyzed hydrogenation of imines and functionalized enamines. Coord. Chem. Rev. 254, 273–287 (2010).

Blaser, H.-U. et al. Selective hydrogenation for fine chemicals: recent trends and new developments. Adv. Synth. Catal. 345, 103–151 (2003).

Wang, C., Villa-Marcos, B. & Xiao, J. Hydrogenation of imino bonds with half-sandwich metal catalysts. Chem. Commun. 47, 9773–9785 (2011).

Willoughby, C. A. & Buchwald, S. L. Catalytic asymmetric hydrogenation of imines with a chiral titanocene catalyst: kinetic and mechanistic investigations. J. Am. Chem. Soc. 116, 11703–11714 (1994).

Obora, Y., Ohta, T., Stern, C. L. & Marks, T. J. Organolanthanide-catalyzed imine hydrogenation. Scope, selectivity, mechanistic observations, and unusual byproducts. J. Am. Chem. Soc. 119, 3745–3755 (1997).

Hatnean, J. A., Thomson, J. W., Chase, P. A. & Stephan, D. W. Imine hydrogenation by alkylaluminum catalysts. Chem. Commun. 50, 301–303 (2014).

Jochmann, P. & Stephan, D. W. H2 cleavage, hydride formation, and catalytic hydrogenation of imines with zinc complexes of C5Me5 and N-heterocyclic carbenes. Angew. Chem. Int. Ed. 52, 9831–9835 (2013).

Jochmann, P. & Stephan, D. W. Zincocene and dizincocene N-heterocyclic carbene complexes and catalytic hydrogenation of imines and ketones. Chem. Eur. J. 20, 8370–8378 (2014).

Rueping, M., Azap, C., Sugiono, E. & Theissmann, T. Brønsted acid catalysis: organocatalytic hydrogenation of imines. Synlett 15, 2367–2369 (2005).

Rueping, M., Sugiono, E., Azap, C., Theissmann, T. & Bolte, M. Enantioselective Brønsted acid catalyzed transfer hydrogenation: organocatalytic reduction of imines. Org. Lett. 7, 3781–3783 (2005).

Hoffmann, S., Seayad, A. M. & List, B. A powerful Brønsted acid catalyst for the organocatalytic asymmetric transfer hydrogenation of imines. Angew. Chem. Int. Ed. 44, 7424–7427 (2005).

de Vries, J. G. & Mršić, N. Organocatalytic asymmetric transfer hydrogenation of imines. Catal. Sci. Technol. 1, 727–735 (2011).

Zhou, S., Fleischer, S., Junge, K. & Beller, M. Cooperative transition-metal and chiral Brønsted acid catalysis: enantioselective hydrogenation of imines to form amines. Angew. Chem. Int. Ed. 50, 5120–5124 (2011).

Tang, W. et al. Cooperative catalysis: combining an achiral metal catalyst with a chiral Brønsted acid enables highly enantioselective hydrogenation of imines. Chem. Eur. J. 19, 14187–14193 (2013).

Samec, J. S. M. & Bäckvall, J.-E. Ruthenium-catalyzed transfer hydrogenation of imines by propan-2-ol in benzene. Chem. Eur. J. 8, 2955–2961 (2002).

Chase, P. A., Welch, G. C., Jurca, T. & Stephan, D. W. Metal-free catalytic hydrogenation. Angew. Chem. Int. Ed. 46, 8050–8053 (2007).

Chase, P. A., Jurca, T. & Stephan, D. W. Lewis acid-catalyzed hydrogenation: B(C6F5)3-mediated reduction of imines and nitriles with H2. Chem. Commun. 1701–1703 (2008).

Paradies, J. Frustrated Lewis pair catalyzed hydrogenations. Synlett 24, 777–780 (2013).

Oestreich, M., Hermeke, J. & Mohr, J. A unified survey of Si–H and H–H bond activation catalysed by electron-deficient boranes. Chem. Soc. Rev. 44, 2202–2220 (2015).

Brady, E. D., Hanusa, T. P., Pink, M. & Young, V. G. Jr The first noncoordinated phosphonium diylide, [Me2P(C13H8)2], and its ylidic and cationic counterparts: synthesis, structural characterization, and interaction with the heavy group 2 metals. Inorg. Chem. 39, 6028–6037 (2000).

Westerhausen, M. Synthesis and spectroscopic properties of bis(trimethylsilyl)amides of the alkaline-earth metals magnesium, calcium, strontium, and barium. Inorg. Chem. 30, 96–101 (1991).

Liu, B., Roisnel, T., Carpentier, J.-F. & Sarazin, Y. When bigger is better: intermolecular hydrofunctionalizations of activated alkenes catalyzed by heteroleptic alkaline earth complexes. Angew. Chem. Int. Ed. 51, 4943–4946 (2012).

Reichardt, C. Solvents and Solvent Effects in Organic Chemistry 3rd edn (Wiley-VCH, Weinheim, 2003).

Harder, S., Feil, F. & Weeber, A. Structure of a benzylcalcium diastereomer: an initiator for the anionic polymerization of styrene. Organometallics 20, 1044–1046 (2001).

Fraser, R. R., Mansour, T. S. & Savard, S. Acidity measurements on pyridines in tetrahydrofuran using lithiated silylamines. J. Org. Chem. 50, 3232–3234 (1985).

Maitland, B. et al. A simple route to calcium and strontium hydride clusters. Angew. Chem. Int. Ed. 56, 11880–11884 (2017).

Zhao, Y. & Truhlar, D. G. The M06 suite of density functionals for main group thermochemistry, thermochemical kinetics, noncovalent interactions, excited states, and transition elements: two new functionals and systematic testing of four M06-class functionals and 12 other functionals. Theor. Chem. Acc. 120, 215–241 (2008).

Marenich, A. V., Cramer, C. J. & Truhlar, D. G. Universal solvation model based on solute electron density and on a continuum model of the solvent defined by the bulk dielectric constant and atomic surface tensions. J. Phys. Chem. B 113, 6378–6396 (2009).

Berkessel, A., Schubert, T. J. S. & Müller, T. N. Hydrogenation without a transition-metal catalyst: on the mechanism of the base-catalyzed hydrogenation of ketones. J. Am. Chem. Soc. 124, 8693–8698 (2002).

Yamakawa, M., Ito, H. & Noyori, R. The metal-ligand bifunctional catalysis: a theoretical study on the ruthenium(II)-catalyzed hydrogen transfer between alcohols and carbonyl compounds. J. Am. Chem. Soc. 122, 1466–1478 (2000).

Dub, P. A., Henson, N. J., Martin, R. L. & Gordon, J. C. Unravelling the mechanism of the asymmetric hydrogenation of acetophenone by [RuX2(diphosphine)(1,2-diamine)] catalysts. J. Am. Chem. Soc. 136, 3505–3521 (2014).

Kozuch, S. & Shaik, S. How to conceptualize catalytic cycles? The energetic span model. Acc. Chem. Res. 44, 101–110 (2011).

Acknowledgements

M.A. thanks the Fund for Scientific Research–Flanders (FWO-12F4416N) for a postdoctoral fellowship and the Free University of Brussels (VUB) for financial support. F.D.P. acknowledges the Research Foundation Flanders (FWO) and Strategic Research Program funding of the VUB. He also acknowledges the Francqui foundation for a position as ‘Francqui research professor’. S.H. acknowledges the Deutsche Forschungsgemeinschaft for financial support (HA 3218/7-1).

Author information

Authors and Affiliations

Contributions

H.B., H.E., C.F. and A.C. are responsible for the experimental work. J.P. and G.B. measured and determined the crystal structures. M.A. and F.D.P. conducted theoretical calculations. S.H. supervised the experimental work and prepared the manuscript with feedback from the other authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Methods, Supplementary Figures 1–11, Supplementary Tables 1–4, Supplementary References

Supplementary Data 1

Calculated coordinates

Rights and permissions

About this article

Cite this article

Bauer, H., Alonso, M., Färber, C. et al. Imine hydrogenation with simple alkaline earth metal catalysts. Nat Catal 1, 40–47 (2018). https://doi.org/10.1038/s41929-017-0006-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-017-0006-0

This article is cited by

-

Understanding catalytic synergy in dinuclear polymerization catalysts for sustainable polymers

Nature Communications (2023)

-

Teaming up main group metals with metallic iron to boost hydrogenation catalysis

Nature Communications (2022)

-

Uncovering the Activity of Alkaline Earth Metal Hydrogenation Catalysis Through Molecular Volcano Plots

Topics in Catalysis (2022)

-

Dogma-breaking catalysis

Nature (2018)

-

The enduring relevance and academic fascination of catalysis

Nature Catalysis (2018)