Abstract

Several environmentally acceptable non-ionic gemini surfactants are synthesized in this work using natural sources, including polyethenoxy di-dodecanoate (GSC12), polyethenoxy di-hexadecanoate (GSC16), and polyethenoxy di-octadecenoate (GSC18). The produced surfactants are confirmed by spectrum studies using FT-IR, 1HNMR, and 13CNMR. It explored and examined how the length of the hydrocarbon chain affected essential properties like foaming and emulsifying abilities. Surface tension examinations are used to assess the surface activity of the examined gemini surfactants. The lower value of critical micelle concentrations (0.381 × 10−4M) is detected for GSC18. Their spontaneous character is shown by the negative values of the free energy of adsorption (ΔGads) and micellization (ΔGmic) which arranged in the order GSC18 > GSC16 > GSC12. Based on theoretical, weight loss, and electrochemical investigations, these novel surfactants were investigated for their possible use in inhibiting carbon steel from corroding in 1 M HCl. Measuring results show that GSC18 inhibits corrosion in carbon steel by 95.4%. The isotherm of adsorption evaluated for the investigated inhibitors and their behavior obeys Langmuir isotherm.

Similar content being viewed by others

Introduction

Surfactants are unique molecules that contain both lipophilic and lipophobic moieties1,2,3. These compounds have great importance in many industrial applications, such as detergents, floatation, additives, paints, paste control, and corrosion inhibitors3,4,5,6. Modern surfactants, known as gemini surfactants, comprise two typical surfactant molecules chemically bonded together using a flexible or stiff spacer7,8. Critical micelle concentrations (CMCs) of gemini surfactants are generally 10–100 times lower than those of equivalent monomeric surfactants9,10. Dimeric surfactants outperform their monomeric counterparts in terms of their ability to reduce surface tension. Gemini surfactants' peculiar characteristics are the basis for their use as emulsifiers, dispersants, coating agents, and corrosion inhibitors11.

Metal corrosion leads to many problems in the industry and exposes factories to significant losses and environmental risks such as pollution12,13,14. One of the essential substances used in the construction of pipelines for gas and oil transportation is carbon steel15,16. The primary alloying element of these iron-based materials is carbon, which makes steel alloy hard, so there are differences in strength and hardness according to the percentage of carbon in the alloy17. Hydrochloric acid (HCl) is widely used in several sectors, including the acidifying process of petroleum tanks for storage and chemical cleaning, pickling, and the purpose of descale procedures18.

Utilizing corrosion inhibitors on metal surfaces is a widespread method for reducing metal corrosion. Nitrogen, Sulphur, and oxygen atoms should be present in molecules that act as acid inhibitors19. The inhibitor molecules protect the metal from the corrosive environment by forming an adsorption coating on the metal's surface. For an inhibitor to be efficient, water needs to be extracted from the metal surface area before it can engage with the anodic and cathodic reactions20,21,22.

Gemini surfactants inhibit corrosion by adsorbing the polar group (hydrophilic head) on the metal surface, where the surfactant's non-polar group (hydrophobic tail) is directed toward the solution. The effect of the alkyl chain length of different pyridyl gemini surfactants was studied. The authors concluded that a long hydrophobic chain enhances the corrosion performance of the P110 steel in acid media23. The presence of a surfactant inhibitor drastically alters the properties of surfaces and interfaces because surfactants may combine to produce micelles24.

Deyab et al. examined newly synthesized gemini surfactants based on alkyl benzenaminium with different alkyl chain lengths25. The authors concluded that excellent inhibition efficiency ranged from 95 to 99%. In addition, the effect of spacer length for a series of cationic gemini surfactants was studied by El-Shamy and Nissem26. The results declare that the inhibition efficiency increases linearly with spacer length.

The usage of eco-friendly corrosion inhibitors is a concern27. Abdallah et al. investigate the inhibition efficiencies of different natural extracts28. The results demonstrate that the applied natural extracts acted as pitting corrosion inhibitors and the potential has shifted to great noble values.

Numerous studies claim that the inhibitor's functional groups, steric effects, electronic density of the donor atoms, the orbital character of the donating electrons, and other physical, chemical, and electronic characteristics mainly determine the inhibitory action29. Quantum chemical calculations are a potential method that supports understanding of the molecule structure, electrical structure, and reactivity of the corrosion inhibitors30. DFT has introduced a beneficial framework based on theoretical calculations. Quantum chemical parameters are calculated by Al-Fahemi et al. for different investigated inhibitors. The results proven that their action are excellent as corrosion inhibitors31.

The work involved the preparation of new, cost-effective, and eco-friendly nonionic gemini surfactants based on natural sources, the synthesized gemini surfactants characterized by FT-IR, 1HNMR, and 13CNMR spectroscopy techniques. The surface activities, foam test, and emulsification performance for the synthesized geminis are determined and discussed. The protection efficiency of these surfactants for carbon steel in 1 M HCl is investigated using electrochemical and weight loss measurements. In addition, the effect of electronic properties on the corrosion resistance of the synthesized surfactants is evaluated using quantum calculations by applying density function theory (DFT).

Experimental part

Materials

Dodecanoic, hexadecanoic, octadecanoic acid, di bromo ethane, polyethylene glycol (400), and benzene were obtained from Sigma Aldrich, and p. toluenesulfonic acid, ethyl alcohol, potassium hydroxide purchased from Al-nasr chemical company. 1.0 M hydrochloric acid was used as an aggressive corrosion medium (blank solution). In this study, the carbon-steel specimens for each test were prepared using a different range of emery sheets with sizes ranging from 400 to 2500. X-ray fluorescence (Bruker) was used to determine the composition of the working electrode. The composition (weight %) of carbon steel includes 0.36% carbon, 0.04% phosphorus, 0.09% silicon, 0.48% manganese, and the remaining element is iron.

Synthesis

Preparation of monoester

The monoesters of different hydrophobic chain lengths were prepared according to the following steps. 0.1 mol of the fatty acid (dodecenoic acid, hexadecenoic acid, and octadec-9-enoic acid) was dissolved separately in toluene and mixed with equimolar polyethylene glycol (400)32.

Dean Stark's apparatus was used, outfitted with a magnetic stirrer to facilitate the reaction. The mixture was heated until the eliminated water content in Dean Stark was 1.8 mL. The polyethylene glycol mono laurate and palmitate are colorless, viscous liquids with 94% and 93% yields (weight %). A pale yellow liquid with a high viscosity and a yield of 92% (weight %) was obtained for the synthesized mono oleate. The formed molecules of polyethylene glycol monolaurate, monopalmitate, and monooleate were characterized using FTIR and 1HNMR analyses. The deuterium solvent used in NMR analysis is dimethyl sulfoxide.

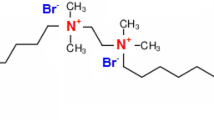

Synthesis of gemini surfactants

The synthesized mono-esters prepared geminis (GSC12, GSC16, and GSC18) by adding dibromo ethane and stirring in ethanolic KOH for 36 h at 110 °C. Then, the solvent was evaporated, and the mixture was repeatedly washed with diethyl ether to remove the unreacted material. Geminis surfactants were recrystallized using petroleum ethers to yield of 95%. IR and 1HNMR spectra proved the prepared compounds. Figure 1 shows the synthesis of the investigated gemini surfactants.

Surfactants properties measurements

Emulsification power and stability

The surfactant solution's emulsifying ability at ambient temperature was evaluated using liquid paraffin, palm, castor, and pine oils, according to the following31: 20 mL of the surfactant solution (0.1% w/v) was poured into the 100 mL cylinder. Then, paraffin, palm oil, castor oil, and pine oil, totalling 20 mL, were transferred to the measuring cylinder. The cylinder was inverted five times at a rate of once per minute. Subsequently, the cylinders were set upright. It was determined how long it would take to filter 19 mL of aqueous solution.

Foam’s strength and steadiness

The modified Ross-Miles method was used for determining the foaming power of a 0.1% aqueous surfactant solution by measuring the height of the foam five minutes after a vigorous 100 shakes at 298 K. By comparing the foam height after 5 min to the initial value, foam stabilities were calculated33.

By using the modified Ross-Miles method, the foaming power of a 0.1% aqueous solution of surfactant was determined by measuring the height of the foam five minutes after shaking vigorously 100 times at a temperature of 298 K. To calculate the foaming stability, the foam height after 5 min was compared to the initial foam height.

Surface tension

The surface tension of the geminis surfactant solution was determined using a Du-nouy Tensiometer. The device was calibrated with de-ionized water before measurements and found around 72 at 298 K34. Different concentrations of the synthesized gemini surfactants range from 1 × 10−6 to 8 × 10−3 M.

Electrochemical and chemical measurements

A glass unit (100 mL with three electrodes) was utilized for the electrochemical analysis. A platinum (Pt) plate was employed as the counter electrode, while a saturated calomel electrode (SCE) was the reference electrode. The carbon steel working electrode has a contact area of 0.266 cm2. The Gamry-reference 3000 potentiostat/galvanostat was used for all experiments. Potential current graphs were performed under specific conditions (scan rate = 0.125 mV s−1, potential region = ± 250 mV vs. open circuit potential (OCP). The polarization experiments were conducted according to ASTM G59-97(2020). The electrochemical impedance spectroscopy (EIS) was conducted at A 10 mV peak-to-peak sinusoidal wave in the 100 kHz–0.01 Hz frequency region. Impedance measurements in the lower frequency range are often used to analyze the behavior of corrosion processes that involve slow electrochemical reactions, such as the formation and dissolution of protective films, or the diffusion of ions through passive layers. In the higher frequency range, impedance measurements are useful for studying more rapid electrochemical processes, including charge transfer reactions at the metal-electrolyte interface and double-layer capacitance effects.

Evaluation of weight loss was carried out according to ASTM G 01. The following relation determines the corrosion rate of carbon steel (CR):

where W is mass loss (mg), A is the surface area of specimens (cm2) and t is the immersion time (h).

Before each experiment, the carbon steel surface was manually scraped away with increasing grit silicon carbide (SiC) sheets, then ultrasonically cleaned in ethanol, thoroughly rinsed with water, and air dried.

The surface morphology investigations were conducted using ZEISS/EVO Scanning Electron Microscope (SEM) for carbon steel samples after 24 h of immersion in 1 M HCl solution in the absence and presence of 10 × 10−3 M surfactants at 298 K.

Quantum studies

The quantum chemical calculations were performed using the HyperChem 8.010 program implemented in the core i7 laptop. Density functional Theory (DFT) was selected to evaluate the electronic properties of the investigated surfactants after complete geometry optimization. B3LYP/medium 6-31G basis set.

Results and discussion

Confirmation of surfactants structures

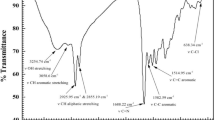

Figure 2 shows FT-IR spectra of GSC12. The absorption bands at 1735 cm−1 and 1100 cm−1, related to the stretching vibration of C=O and C–O, respectively, confirm the monolaurate molecule's formation. In addition, the bands at 2925 and 2859 cm−1 are assigned to the stretching vibration of C-H of the hydrophobic tail of the synthesized surfactants, while their stretching bending is located at 1457 cm−1 and 1349 cm−1. Similar characteristic bands (See Fig. S1a,b confirm the formation of GSC16 and GSC18.

Figure 3 shows 1H NMR spectra of the synthesized GSC12. Concerning the figure, it is clear that characteristic spectra appear as the following: δ (ppm): 0.88 (t, 3H, [CH3–CH2–]), 1.26 (S, 16H, [(CH2)8–]), 1.66 (m, 2H, [CH2CH2COO]), 2.32 (t, 2H, [CH2–COO]), 3.52 (s, 32H, 8[CH2–CH2–O]), 3.63 (t, 2H,[COO–CH2–CH2–O–]), 4.20(t, 2H, [COO–CH2–CH2–O–]). Also, the similar bands in Fig. S1a,b are related to GSC16 and GSC18.

Figure 4 shows the 13C NMR spectra of GSC12, the signal (δ) (present at 14.1 ppm) corresponds to the terminal CH3 group. The aliphatic CH2 of the long-chain hydrocarbon is located at δ of 22.70, 29.25, and 33.90 ppm. In addition, the signals at 69.9 and 70.1 ppm are assigned to the CH2 group, which is linked to the carboxylate group. The signal corresponding to the carboxyl group's carbon is detected at δ = 173.1 ppm. The similar signals are detected for GSC16 and GSC18 (Fig. S3).

In the case of GSC18, additional signals located at 27.7 and 130.6 ppm correspond to CH2 (nearest ethylene group) and CH of the ethylene group, respectively. The FT-IR, 1HNMR, and 13CNMR matched the chemical structure of the synthesized gemini surfactants (GSC12, GSC16, and GSC18).

Surface activities

Emulsification power and emulsification stability:

Detergents, petrochemicals, and cosmetics are a few significant industrial applications where emulsifying power is utilized. The chemical nature of the oil and the surfactant has an essential effect on the stability of the generated emulsion. With the help of liquid paraffin, palm, castor, and pine oil in water, the long-term stability of the emulsion between the surfactant solution and the oil can be assessed.

The produced surfactant has good emulsification stability, particularly peg oleate, which demonstrated the highest degree of emulsification power due to its high affinity for adsorption at the interface, as shown by their values for Ccmc (critical micelle concentration) and adsorption-free energy. The emulsification power and emulsification stability values are shown in Fig. 5. The figure shows the emulsifying ability of an aqueous solution of synthetic non-ionic gemini surfactants at a concentration of 0.1% (w/v) for a variety of oils.

Foam's strength and steadiness

The power and stability of the foam results are listed in Table 1. It was noted that all the prepared gemini compounds initially have good foam, but the foam level decreases as time increases. Longer hydrocarbon chains result in less foaming action, and the foaming stability becomes good, so gemini laurate has maximum foaming ability and lowest strength.

Surface tension and critical micelle concentration (CMC)

The surface tension of the gemini solutions was less than that of pure bi-distilled water. Surfactant molecules adsorb at the water–air interface, causing the hydrophobic tails to point towards the air phase while the polar head groups remain attached to the water surface. There is less surface tension because fewer hydrogen bonds are formed between water molecules in the presence of adsorbed surfactant molecules at the air-solution interface. Synthetic surfactants can be evaluated for their surface-active features by measuring their surface tension at varying concentrations. Figure 6 displays the logarithmic surfactant concentrations versus surface tension relationship at 298 K. The CMC was calculated. GSC18 revealed the lowest CMC values because more methylene groups are in the hydrophobic chains, which results in more repulsion between surfactant molecules. So, as the hydrophobic chain length increases, there is a greater tendency for the molecules to form micelles in the bulk of the solution35.

-

(a)

Effectiveness πcmc

When surface tension was reduced between bi-distilled water and prepared nonionic gemini surfactants at critical micelle concentration, it was defined as effectiveness and expressed by equation36:

$$\pi_{{{\text{cmc}}}} = \gamma_{{\text{o}}} - \gamma_{{{\text{cmc}}}}$$(2)here, γo is the surface tension of the bi-distilled water (71.8 mN/m), and γcmc is the surface tension of the surfactant solution at the CMC. The calculated effectiveness values for the geminis are listed in Table 2. GSC18 caused more significant surface reduction at CMC than GSC12 and GSC16 due to its highest hydrophobic characteristics37.

Table 2 Gemini nonionic surfactants surface and thermodynamic characteristics.

The Excess of the surface (Γmax)

Surface excess (Γmax) was determined based on the surfactant adsorption at the air/water interface. The Gibbs adsorption equation was used to calculate the Γmax37.

where R is the universal gas constant, T is absolute temperature, (dγ/d lnC) is the slope of the linear line on the surface tension graph. As the hydrophobicity increases from C12 to C18, efficient coverage of the interface surface results in a higher value of surface excess concentration (see Table 2). The previous results agree with other research37,38.

The surface area per molecule (Amin)

Adsorbed molecules require the smallest possible surface area, Amin, the amount of space one molecule occupies at the liquid/air interface in units of nm2. It was determined using the following equation38.

where NA is the Avogadro’s number, from the results (see Table 2), it was clear that (Amin) values decrease and Γmax increase by increasing the hydrophobic chain, explained by the tendency of the coiling of the long hydrophobic tails as mentioned before in different research39,40.

Since the hydrophobic part hates polar water solvents, the surfactants' tendency to form micelles increases as the hydrophobic chain length increases, and the micelles will start at lower concentrations (see Table 2). In addition, the remarkable ability of the long hydrophobic for coiling decreases their minimum surface area (Amin) and hence increases the surface excess (Γmax) concentration and, therefore, the surface tension (πcmc)41,42. In sum, the synthesized geminins possess excellent surface activities, facilitating their adsorption to the metal surface.

Thermo-dynamic properties of the synthesized gemini non-ionic surfactants

Surfactant molecules tended to adsorb at the interface or micellize in the bulk of their solution. The free energy of micellization (ΔGmic) was calculated by calculating CMC values from the micellization Gibbs equation:

where n is the number of counter ions in the case of ionic surfactant n = 0 for nonionic surfactants.

Free energy of adsorption ΔGads were calculated by the following equation:

where ΔGmic is micellization-free energy in KJ mole−1n, πcmc is effectiveness in mN/m and (Amin). The smallest area of surface per adsorbed molecule in nm238. Since the values in micellization-free energy and surfactant adsorption are always negative, the process happened spontaneously. Gads have a lower value than Gmic, which is a more negative value. Thus, the produced surfactant was more likely to adsorb at the air/water interface than to form micelles in most of its solutions. Adsorption and micellization-free energy increase negatively by increasing hydrophobic chain length for surfactants36.

Anti-corrosion characteristics of gemini surfactants

Electrochemical and weight loss studies

The kinetic behaviors of steel corrosion reactions in 1.0 M HCl solution with GSC12, GSC16, and GSC18 gemini surfactants were investigated using electrochemical study results. The polarization graph for the GSC18 is shown, for example, in Fig. 7. The plot is shaped like a Tafel. Table 3 shows the potential for corrosion (Ecorr), Tafel slopes (βa and βc), and corrosion current density (jcorr) as polarization parameters. The following relationship is utilized to calculate the efficiency of protection (Pj%)43,44.

The corrosion current density in a blank acid solution is given by jcorr(0).

Table 3 includes the following details:

-

(1)

By incorporating GSC12, GSC16, and GSC18, jcorr values are significantly reduced to very low levels44.

-

(2)

Ecorr changes are insignificant (less than 85 mV) in the control sample. This demonstrates that all of the GSC12, GSC16, and GSC18 are of mixed nature45,46,47.

-

(3)

Ecorr started to shift anodically concerning the blank at all gemini surfactant concentrations. This implies that these additives are mixed inhibitors with predominant anodic activity48,49.

-

(4)

Significant percentage inhibition efficiencies were achieved with low quantities of gemini surfactant (i.e., 10 × 10−3 M). This is attributed to their ability to form protective films on metal surfaces, which act as a barrier against corrosive species. The inhibition efficiency has also improved with increasing gemini surfactant concentration.

-

(5)

The results show that the inhibition efficiency values for GSC12, GSC16, and GSC18 differ markedly, where the inhibition efficiency of gemini surfactants is shown in the following order: GSC12 < GSC16 < GSC18.

-

(6)

At the highest concentration of GSC18 (10 × 10−3 M), the optimal performance (95.4%) was observed.

The fundamental cause of the gradual reduction in corrosion of C-steel specimens in 1.0 M HCl is the ability of novel gemini surfactants GSC12, GSC16, and GSC18 to adsorb on steel surface50,51,52. Gemini surfactants work together to block cathodic and anodic reactions.

Given that the C-steel has been positively charged by either an inhibited or uninhibited 1.0 M HCl solution, the gemini surfactant molecules are always able to adsorb on the Fe/solution interface in at least one form53,54,55:

(1) Back–forward interactions occur among the bi-e’s and vacant 3d of the metal surface56. (2) Free oxygen pairs of e’s and 3d of carbon steel57. (3) interaction between positively charged cloud located over carbonyl groups and 3d.

The inhibition effectiveness improves with the length of the terminal chain (i.e., GSC12 < GSC16 < GSC18). This is clarified by implying that increasing the length of the terminal chain tends to increase the extent of surface coverage and the average area surrounded by each adsorbed molecule.

At 298 K, carbon steel was subjected to electrochemical impedance spectroscopy after exposure to 1.0 M HCl. The Nyquist graphs for increasing amounts of GSC12 (as an example) are shown in Fig. 8. The diameter of semi-circles grows with the addition of newly synthesized surfactants. This is frequently related to a charge transfer mechanism and an improvement in the surface resistivity of carbon steel. The comparable equivalent circuit with a charge transfer resistance (Rct), a constant phase element (CPE), and solution resistance (Rs) is depicted in Fig. 8 (insert image).

Table 4 shows the numerical values of the several EIS parameters (Rct and CPE) as well as the inhibition efficiency (ηR%). The ηR% from EIS data is given by43:

where Rcto = charge transfer resistances in absence of new surfactants.

The Rct increases significantly when GSC12, GSC16, and GSC18 concentrations increase, but the CPE drops considerably. This significant drop could be caused by a growth in the thickness of the electrical double layer (due to surfactant compounds surface adsorption) and/or a reduction in the local dielectric constant48. EIS demonstrates the inhibitory effectiveness of gemini surfactants to follow the same patterns as polarization (see Tables 3 and 4).

Table 5 shows the carbon steel corrosion rate (the result obtained from weight loss studies) after 24 h immersion in 1.0 M HCl solution in the absence and presence of 10 × 10−3 M surfactants at 298 K and 328 K. The presence of newly synthesized surfactants in a 1.0 M HCl solution decreases the corrosion rate of carbon steel CR, demonstrating that they have corrosion inhibiting properties. The corrosion-inhibition effectiveness of surfactants (ƞw%) is determined from weight loss data employing a given formula20:

CR0 = corrosion rate without surfactants.

Table 5 shows that the inhibiting corrosion efficacy of surfactants based on weight loss data follows the same patterns as electrochemical investigations.

Furthermore, the inhibitory efficacy diminishes slowly as temperature rises (Table 5), indicating a physisorption mechanism28.

The morphological inspection (SEM) of the carbon steel in 1.0 M HCl solution in the absence and presence of 10 × 10−3 M of surfactants at 298 K are presented in Fig. 9. In the blank solution (micrograph a), the surface morphology of carbon steel exhibited structural damage and intense roughness on top. In the presence of 10 × 10−3 M of surfactants (micrograph b, c, and d), the carbon steel has a clean surface and is corrosion-free.

Quantum studies

The highest occupied molecule orbital energy, EHOMO, and the lowest vacant molecular orbital energy, ELUMO, were calculated and then employed in the following equation to derive other essential quantum parameters for the gemini surfactants31,54,55,58.

An inhibitor's efficiency might be affected by its electrical and geometric molecular structure. The frontier orbital theory states that the HOMO and LUMO orbitals of the reactants were the primary sites of reaction, and an interaction between their frontier orbitals causes a transition state to arise. To explore the inhibitory mechanism, looking into the distribution of HOMO and LUMO was crucial. Figure 10, Figs. S4, and Fig. S5 show the optimized structure, HOMO, LUMO, and molecular electrostatic potential for the synthesized surfactants.

The molecular structure and ability to donate and receive electrons are determined by the EHOMO and ELUMO values, respectively (see Table 6). In addition, it was reported that lower energy gap (ΔEg) values would result in excellent inhibition efficiency since the molecule needs little energy to remove an electron from the final occupied orbital59. The values of ΔEg of the investigated gemini surfactants are arranged in the following order: GSC12 ≈ GSC16 > GSC18.

GSC18 possesses the lowest ΔEg and highest EHOMO values, indicating strong adsorption ability onto the steel surface via donation and back-donation interaction60. In addition, the global hardness (η) of the investigated inhibitors was calculated, and GSC18 possesses the lowest value. It is known that a hard molecule has less tendency to adsorption61. In contrast to hard molecules, soft molecules can more easily supply electrons to the metal surface, also due to their low energy gap value ΔEg values. Consequently, the molecule's reactive site may be absorbed, where has the maximum value62. Furthermore, all the investigated molecule possesses similar (≈ 1.454 eV) and lower back donation energy, indicating the remarkable ability of these molecules to not only donate electrons to the vacant d orbital of carbon steel but also accept an electron from metals to give a stable, protective layer59. The previous electronic parameter recommended all the investigated geminis as corrosion inhibitors and GSC18 is the most efficient.

Adsorption studies

Electrochemical studies are carried out to assess the surface coverage (ɵ) at various gemini surfactant concentrations (Cinh), and several isotherms are used to identify the best fit that characterizes the inhibitor molecules' behavior. The Langmuir isotherm is being proven to be the best at representing the adsorption process. Monolayer surface coverage is predicted by the Langmuir-adsorption model to follow an asymptotic procedure.

The following relationships reflect this isotherm and the Gibbs free energy change (ΔG0ads)61:

R = 8.314 J mol−1 K−1, T = the thermodynamic temperature in Kelvin. Kads = adsorption constant. Figure 11 shows the Langmuir adsorption isotherm for the adsorption of GSC12, GSC16, and GSC18 on the carbon steel surface. Linear regression coefficients R2 are approximate to one (R2 = 0.996). The values of Kads are 3.3 × 103, 5 × 103, 5.6 × 103 M−1 for GSC12, GSC16, and GSC18, respectively. The value of ΔG0ads for GSC12, GSC16 and GSC18 were found to be -29.97, -31.0, and -31.28 kJ mol−1. ΔG0ad is negative, indicating that the GSC12, GSC16, and GSC18 molecules have a high inclination to be adsorbed onto the steel surface and that the film produced is steady62. The absolute values of ΔG0ads, falling within the range of -20 into − 40 kJ mol−1, suggest that GSC12, GSC16, and GSC18 adsorption involves physisorption and chemisorption62.

Conclusion

Three nonionic gemini surfactants with different hydrophobic chain lengths (GSC12, GSC16, and GSC18) were prepared, and their emulsifying and foaming power were investigated. Surface tension measurements are used to determine the surface activities of the synthesized surfactant solutions. The data show that increasing the hydrophobic characters decreases the CMC value and other surface parameters (πcmc, Γmax, and Amin). In addition, from thermodynamic studies, GSC18 has the highest ability for both micellization and adsorption. The corrosion inhibition efficiency was examined using electrochemical and weight loss measurements and the results declare efficient inhibition for all surfactants in the following order: GSC18 > GSC16 > GSC12. Moreover, DFT is applied to relate the electronic properties of the synthesized gemini surfactants by calculating different quantum descriptors as energy gaps using practical data. Both theoretical and experimental studies demonstrate the high efficacy of all gemini surfactants.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Catarino Centeno, R. et al. Surfactant chain length and concentration influence on the interfacial tension of two immiscible model liquids: A coarse-grained approach. J. Mol. Model. 23, 306 (2017).

Dettmer, T., Ibbotson, S., Öhlschläger, G., Herrmann, C. & Kara, S. Technical applications of Jatropha oil—Environmental effectiveness of renewable resources. Int. J. Life Cycle Assess. 20, 1376–1386 (2015).

Shalaby, M. N. & El-Shamy, O. A. A. Performance of some surfactants as wetting agents. Tenside Surfactants Deterg. 42, 373–378 (2005).

Al-Jabri, M. & Rodgers, T. The effect of changing the molecular structure of the surfactant on the dissolution of lamellar phases. J. Colloid Interface Sci. 643, 9–16 (2023).

Prinsen, P., Warren, P. & Michels, M. Mesoscale simulations of surfactant dissolution and mesophase formation. Phys. Rev. Lett. 89(14), 148302 (2002).

Dhakal, S. & Sureshkumar, R. Anomalous diffusion and stress relaxation in surfactant micelles. Phys. Rev. E. 96(1), 012605 (2017).

Tehrani-Bagha, A. R. & Holmberg, K. Cationic ester-containing gemini surfactants: Physical–chemical properties. Langmuir. 26, 9276–9282 (2010).

Myers, D. Surfactant Science and Technology 3rd edn. (Wiley, 2006).

J. Yang, B. Guan, Y. Lu, W. Cui, X. Qiu, Z. Yang, W. Qin, Viscoelastic evaluation of gemini surfactant gel for hydraulic fracturing, in: SPE Eur. Form. Damage Conf. Exhib., SPE, 2013: p. SPE-165177.

Kamal, M. S. A review of gemini surfactants: Potential application in enhanced oil recovery. J. Surfactants Deterg. 19, 223–236 (2016).

Deyab, M. A. & Mohsen, Q. Inhibitory influence of cationic Gemini surfactant on the dissolution rate of N80 carbon steel in 15% HCl solution. Sci. Rep. 11, 10521 (2021).

Deyab, M. A., Abd El-Rehim, S. S., Hassan, H. H. & Shaltot, A. M. Impact of rare earth compounds on corrosion of aluminum alloy (AA6061) in the marine water environment. J. Alloys Compounds. 820, 153428 (2020).

Kalaiselvi, P., Chellammal, S., Palanichamy, S. & Subramanian, G. Artemisia pallens as corrosion inhibitor for mild steel in HCl medium. Mater. Chem. Phys. 120, 643–648 (2010).

Abdel-Karim, A. M. et al. Green synthesis of novel bis structure of (Carbamothioyl) oxalamide derivatives as corrosion inhibitors for copper in 3.5% NaCl; experimental and theoretical investigation. J. Mol. Struct. 1295, 136597 (2024).

Deyab, M. A. & AbdEl-Rehim, S. S. Effect of succinic acid on carbon steel corrosion in produced water of crude oil. J. Taiwan Inst. Chem. Eng. 45, 1065–1072 (2014).

Usher, K. M., Kaksonen, A. H., Cole, I. & Marney, D. Critical review: Microbially influenced corrosion of buried carbon steel pipes. Int. Biodeterior. Biodegradation. 93, 84–106 (2014).

Deyab, M. A. Sulfonium-based ionic liquid as an anticorrosive agent for thermal desalination units. J. Mol. Liquids 296, 111742 (2019).

Mahgoub, F. M. et al. Inhibition of corrosion of steel in produced water of Western Desert crude oil. J. Appl. Electrochem. 32, 775–781 (2002).

Deyab, M. A. Enhancement of corrosion resistance in MSF desalination plants during acid cleaning operation by cationic surfactant. Desalination 456, 32–37 (2019).

Ali, S. A., Saeed, M. T. & Rahman, S. U. The isoxazolidines: A new class of corrosion inhibitors of mild steel in acidic medium. Corros. Sci. 45, 253–266 (2003).

Deyab, M. A. & Guibal, E. Enhancement of corrosion resistance of the cooling systems in desalination plants by green inhibitor. Sci. Rep. 10, 4812 (2020).

Deyab, M. A. & Mele, G. Polyaniline/Zn-phthalocyanines nanocomposite for protecting zinc electrode in Zn-air battery. J. Power Sources 443, 227264 (2019).

Han, T., Guo, J., Zhao, Q., Wu, Y. & Zhang, Y. Enhanced corrosion inhibition of carbon steel by pyridyl gemini surfactants with different alkyl chains. Mater. Chem. Phys. 240, 122156 (2020).

El-Katori, E. E., Nessim, M. I., Deyab, M. A. & Shalabi, K. Electrochemical, XPS and theoretical examination on the corrosion inhibition efficacy of stainless steel via novel imidazolium ionic liquids in acidic solution. J. Mol. Liq. 337, 116467 (2021).

Deyab, M. A., Ashmawy, A. M., Nessim, M. I. & Mohsen, Q. New Gemini surfactants based on alkyl benzenaminium: Synthesis and links to application of corrosion protection. J. Mol. Liq. 332, 115855 (2021).

El-Shamy, O. A. A. & Nessim, M. I. Surface activities and quantum chemical calculations for different synthesized cationic gemini surfactants. Tenside Surfactants Deterg. 54, 443–447 (2017).

Abdallah, M., Altass, H. M., Al Jahdaly, B. A. & Salem, M. M. Some natural aqueous extracts of plants as green inhibitor for carbon steel corrosion in 0.5 M sulfuric acid. Green Chem. Lett. Rev. 11, 189–196 (2018).

Abdallah, M. et al. Natural nutmeg oil as a green corrosion inhibitor for carbon steel in 1.0 M HCl solution: Chemical, electrochemical, and computational methods. J. Mol. Liquids. 323, 115036 (2021).

El-Shamy, O. A. A. Semiempirical theoretical studies of 1,3-benzodioxole derivatives as corrosion inhibitors. Int. J. Corros. https://doi.org/10.1155/2017/8915967 (2017).

Ju, H., Ding, L., Sun, C. & Chen, J. Quantum chemical study on the corrosion inhibition of some oxadiazoles. Adv. Mater. Sci. Eng. 2015, 519606. https://doi.org/10.1155/2015/519606 (2015).

Al-Fahemi, J. H., Abdallah, M., Gad, E. A. M. & Jahdaly, B. A. A. L. Experimental and theoretical approach studies for melatonin drug as safely corrosion inhibitors for carbon steel using DFT. J. Mol. Liquids. 222, 1157–1163 (2016).

Abdullah, F. Z., Maamor, A., Daud, N. A. & Hamid, S. B. A. Selective synthesis of peg-monoester using cesium heteropoly acid as heterogeneous catalyst. Quim. Nova. 40, 506–512 (2017).

X. Li, J. Li, X. Wang, L. Yang, H. Xu, J. Dong, Novel Branched-Chain Sulfonate Surfactants Based on Α-Olefins from Fischer–Tropsch Synthesis, Available SSRN 4229832. (n.d.).

Lee, B.-B., Chan, E.-S., Ravindra, P. & Khan, T. A. Surface tension of viscous biopolymer solutions measured using the du Nouy ring method and the drop weight methods. Polym. Bull. 69, 471–489 (2012).

El Feky, A. A., Shalaby, M. N., El-Shamy, O. A. & Suzy, A. Surface activity and adsorption of some surfactants at aqueous/air interface at different temperatures. Int. J. Sci. Technol. Res. 5, 179–184 (2016).

Lin, L.-H. & Lai, Y.-C. Synthesis and physicochemical properties of nonionic Gemini surfactants with a sulfonate spacer. Colloids Surfaces A Physicochem. Eng. Asp. 386, 65–70 (2011).

El-Shamy, O. A. A., Habib, A. O., Mohamed, D. E. & Badawi, A. M. Synthesis, characterization, surface, and thermodynamic studies of alkyl tetrachloroferrates: Performance evaluation of their nanostructures as biocides. J. Surfactants Deterg. 23, 215–223 (2020).

Bhadra, P. & Siu, S. W. I. Effect of concentration, chain length, hydrophobicity, and an external electric field on the growth of mixed alkanethiol self-assembled monolayers: A molecular dynamics study. Langmuir. 37, 1913–1924 (2021).

Bao, Y. et al. Cationic silicon-based gemini surfactants: Effect of hydrophobic chains on surface activity, physic-chemical properties and aggregation behaviors. J. Ind. Eng. Chem. 53, 51–61 (2017).

Feng, D. et al. Synthesis and surface activities of amidobetaine surfactants with ultra-long unsaturated hydrophobic chains. J. Surfactants Deterg. 15, 657–661 (2012).

Rosen, M. J. & Liu, L. Surface activity and premicellar aggregation of some novel diquaternary gemini surfactants. J. Am. Oil Chem. Soc. 73, 885–890 (1996).

Reeve, J. R., Thomas, R. K. & Penfold, J. Surface activity of ethoxylate surfactants with different hydrophobic architectures: The effect of layer substructure on surface tension and adsorption. Langmuir. 37, 9269–9280 (2021).

El-Rehim, S. S. A., Hassan, H. H., Deyab, M. A. M. & Moneim, A. A. E. Experimental and theoretical investigations of adsorption and inhibitive properties of Tween 80 on corrosion of aluminum alloy (A5754) in alkaline media. Zeitschrift Für Phys. Chemie. 230, 67–78 (2016).

Deyab, M. A., Keera, S. T. & El Sabag, S. M. Chlorhexidine digluconate as corrosion inhibitor for carbon steel dissolution in emulsified diesel fuel. Corrosion Sci. J. 53, 2592–2597 (2011).

Lebrini, M., Robert, F., Vezin, H. & Roos, C. Electrochemical and quantum chemical studies of some indole derivatives as corrosion inhibitors for C38 steel in molar hydrochloric acid. Corros. Sci. 52, 3367–3376 (2010).

Zhao, J., Duan, H. & Jiang, R. Synergistic corrosion inhibition effect of quinoline quaternary ammonium salt and Gemini surfactant in H2S and CO2 saturated brine solution. Corros. Sci. 91, 108–119 (2015).

Nessim, M. I., Zaky, M. T. & Deyab, M. A. Three new gemini ionic liquids: Synthesis, characterizations and anticorrosion applications. J. Mol. Liq. 266, 703–710 (2018).

Boudalia, M. et al. Experimental and theoretical tests on the corrosion protection of mild steel in hydrochloric acid environment by the use of pyrazole derivative. Materials (Basel). 16, 678 (2023).

Deyab, M. A. & Mele, G. Stainless steel bipolar plate coated with polyaniline/Zn-Porphyrin composites coatings for proton exchange membrane fuel cell. Sci. Rep. 10, 3277 (2020).

Deyab, M. A. Understanding the anti-corrosion mechanism and performance of ionic liquids in desalination, petroleum, pickling, de-scaling, and acid cleaning applications. J. Mol. Liq. 309, 113107 (2020).

Deyab, M. A., Fouda, A. S., Osman, M. M. & Abdel-Fattah, S. Mitigation of acid corrosion on carbon steel by novel pyrazolone derivatives. RSC Adv. 7, 45232–45240 (2017).

Deyab, M. A. & Awadallah, A. E. Advanced anticorrosive coatings based on epoxy/functionalized multiwall carbon nanotubes composites. Progress Org. Coatings 139, 105423 (2020).

Deyab, M. A. et al. NaNi(H2PO3)3.H2O as a novel corrosion inhibitor for X70-steel in saline produced water. J. Mol. Liq. 216, 636–640 (2016).

Deyab, M. A. et al. Synthesis and characteristics of alkyd resin/M-Porphyrins nanocomposite for corrosion protection application. Prog. Org. Coatings. 105, 286–290 (2017).

Deyab, M. A. & El-Rehim, S. S. A. On surfactant–polymer association and its effect on the corrosion behavior of carbon steel in cyclohexane propionic acid. Corros. Sci. 65, 309–316 (2012).

Bentiss, F., Lagrenee, M., Traisnel, M. & Hornez, J. C. The corrosion inhibition of mild steel in acidic media by a new triazole derivative. Corros. Sci. 41, 789–803 (1999).

Hanza, A. P., Naderi, R., Kowsari, E. & Sayebani, M. Corrosion behavior of mild steel in H2SO4 solution with 1, 4-di [1′-methylene-3′-methyl imidazolium bromide]-benzene as an ionic liquid. Corros. Sci. 107, 96–106 (2016).

Mrani, S. A. et al. DFT and electrochemical investigations on the corrosion inhibition of mild steel by novel Schiff’s base derivatives in 1 M HCl solution. Arab. J. Sci. Eng. 46, 5691–5707. https://doi.org/10.1007/s13369-020-05229-4 (2021).

H. Hussien, S. Shahen, A.M. Abdel-karim, I.M. Ghayad, O.A.A. El-Shamy, N. Mostfa, N. E.-D. Ahmed (2023) Experimental and theoretical evaluations: green synthesis of new organic compound bis ethanethioyl oxalamide as corrosion inhibitor for copper in 3.5% NaCl, Egypt. J. Chem. 66: 189–196. https://doi.org/10.21608/ejchem.2023.182301.7364.

Abdel-karim, A. M., Shahen, S., Elsisi, D. M., Hyba, A. M. & El-Shamy, O. A. A. Experimental and theoretical studies of corrosion resistance enhancement of carbon steel in 1 M HCl by quinoxalinosulfonamide hybrid-bearing theophylline moiety. J. Bio- Tribo-Corrosion. 8, 70. https://doi.org/10.1007/s40735-022-00666-0 (2022).

Gece, G. & Bilgiç, S. Molecular-level understanding of the inhibition efficiency of some inhibitors of zinc corrosion by quantum chemical approach. Ind. Eng. Chem. Res. 51, 14115–14120. https://doi.org/10.1021/ie302324b (2012).

H. Elmsellem, H. Nacer, F. Halaimia, A. Aouniti, I. Lakehal, A. Chetouani, S.S. Al-Deyab, I. Warad, R. Touzani, B. Hammouti, Anti-corrosive Properties and Quantum Chemical Study of ( E )-4-Methoxy-N-( Methoxybenzylidene ) Aniline and ( E )-N-( 4-Methoxybenzylidene )-4-Nitroaniline Coating on Mild Steel in Molar Hydrochloric, in: 2014.

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through small group Research Project under Grant number (RGP. 1/336/44).

Author information

Authors and Affiliations

Contributions

M. A. Deyab, Ibrahim Z. Ibrahim, Omnia A. A. El-Shamy, Khalil A. Khalil, Abdelhamid F. Awad, Majed M. Alghamdi, Adel A. El-Zahhar and Mohammed A. Abo-Riya. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Deyab, M.A., Ibrahim, I.Z., El-Shamy, O.A.A. et al. Synthesis, surface activity, and corrosion inhibition capabilities of new non-ionic gemini surfactants. Sci Rep 14, 8040 (2024). https://doi.org/10.1038/s41598-024-57853-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-57853-x

Keywords

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.