Abstract

Oil-immersed transformers are expensive equipment in the electrical system, and their failure would lead to widespread blackouts and catastrophic economic losses. In this work, an elaborate diagnostic approach is proposed to evaluate twenty-six different transformers in-service to determine their operative status as per the IEC 60599:2022 standard and CIGRE brochure. The approach integrates dissolved gas analysis (DGA), transformer oil integrity analysis, visual inspections, and two Back Propagation Neural Network (BPNN) algorithms to predict the loss of life (LOL) of the transformers through condition monitoring of the cellulose paper. The first BPNN algorithm proposed is based on forecasting the degree of polymerization (DP) using 2-Furaldehyde (2FAL) concentration measured from oil samples using DGA, and the second BPNN algorithm proposed is based on forecasting transformer LOL using the 2FAL and DP data obtained from the first BPNN algorithm. The first algorithm produced a correlation coefficient of 0.970 when the DP was predicted using the 2FAL measured in oil and the second algorithm produced a correlation coefficient of 0.999 when the LOL was predicted using the 2FAL and DP output data obtained from the first algorithm. The results show that the BPNN can be utilized to forecast the DP and LOL of transformers in-service. Lastly, the results are used for hazard analysis and lifespan prediction based on the health index (HI) for each transformer to predict the expected years of service.

Similar content being viewed by others

Introduction

An electrical transformer is a critical component of electricity transmission and distribution networks. An oil-immersed transformer is the most expensive equipment in the electrical system, and its failure would lead to widespread blackouts and catastrophic economic losses1,2. Therefore, it is vital to perform routine maintenance and continuous monitoring of electrical transformers, particularly those employed at critical locations. Several massive electrical transformers that have been in service in recent years have been quite ancient3. These very ancient units are still in use, owing predominately to economic constraints. Presently, mankind has become increasingly reliant on the provision of power, imposing strain on the stability, availability, and cost-effectiveness of power supply4. The trouble-free operation of electrical transformers is a crucial condition for electrical system reliability and security. However, among the primary reasons for the failure of aging transformers in5,6, the mechanical integrity of the units to withstand stress caused by short-circuit currents can deteriorate dramatically with the degrading of insulation material. As a result, it is critical to thoroughly assess the aging state of the insulation material. The withering and lifespan duration of an oil-immersed transformer is determined by the solid insulation and the level of the withering of the insulating paper7,8,9,10. Oil has a strong insulating property while also operating as a cooling medium via natural or induced circulation. The oil-impregnated paper acts as an electrical insulator between windings and a mechanical barricade between individual windings and winding layers. As a result, the paper serves a major vocation in paper-oil insulation. Poor paper integrity causes early insulation deterioration, which potentially contributes to transformer collapse following a winding short circuit, for instance11,12.

Presently, the approaches for evaluating electrical transformers are separated into two categories: online supervision and offline supervision. With the evolution of the units, online system supervision has become more prevalent. While the transformers are in operation, online supervision approaches may be utilized to inspect and assess operational efficiency, evaluation, emergency warning action, and establish effective maintenance and repair forecasts13,14. Most significantly, using analysis, these online supervision systems can estimate the residual expected lifespan. However, monitoring approaches in this discipline are relatively recent. Research and innovation studies are constantly improving, although, it is still a challenge to determine the residual life of an electrical transformer since residual-life calculations are dependent on a variety of conditions. According to present requirements, the structural lifespan of an electrical transformer is restricted to the duration of the insulation paper. Deterioration of an insulation paper can be diagnosed using the degree of polymerization (DP), Furan analysis (FA), and \({\text{CO}}_{2}\text{/CO}\) ratio analyses15,16. DP analyses measure the physical capability of paper by calculating the cellulose degree. However, DP analyses and other tests fail to predict the operational lifespan of the transformer since numerous other factors influence the insulation degradation process17,18. Accurate detection and mining of certain dissolved gases in dielectric transformer oil has become the fastest-growing procedure in the diagnosis of transformer faults. Insulation breakdown occurs over time and is affected by heat, humidity, and oxygen concentration. Sophisticated oil conservation systems can reduce humidity and oxygen impacts on insulation breakdown19,20. The main determining factor in withering is the insulation temperature. Consequently, in practice, the extent of the cellulose paper withering is influenced by the transformer’s hotspot temperature. Tensile strength and DP are measured to determine the mechanical qualities of cellulose paper21. These characteristics are employed to assess when the cellulose paper insulation reaches the end of its dependable life. The cellulose paper insulation end-of-life requirements are commonly proposed22 to have DP values of 150–250; below 150, the cellulose paper is considered to be mechanically weak. The assessment of paper insulation for its DP value requires the extraction of a few sheet strips of paper from the investigated transformers23,24. However, the process remains challenging. Oil samples are utilized as an alternative. The procedure can conveniently be carried out during transformer maintenance, service, or repairs since it is usually not practical (and often dangerous to the transformer) to obtain the cellulose paper sample from a de-energized, in-service transformer. It has been demonstrated in25,26,27,28, that the amount of 2-Furaldehlyne (2FAL) present in oil (the most important component of cellulose paper degradation) is significantly related to the DP of the cellulose paper within the transformer. The levels of 2FAL in oil correspond to the typical degradation of the cellulose paper. By measuring the quantity and types of furans present in a transformer oil sample, the cellulose paper insulation overall DP can be inferred with a high degree of confidence. The types and concentration of furans in an oil sample can also indicate abnormal stress in a transformer, whether intense, short-duration overheating or prolonged, general overheating. Therefore, estimating their residual lifespan is critical to prevent transformers from being shut down prematurely during service29,30. Table 1 illustrates the furan concentration thresholds used to grade the transformer condition. The value of DP and the amount of furan can be used to determine the condition of cellulose paper.

The furan test can simply determine furan from oil sampling on an in-service transformer. As demonstrated in Table 2, the quantity of furan concentration contained in the cellulose paper is used to calculate the transformers’ service life in years.

Several DP and loss of life (LOL) techniques for electrical transformers have been proposed recently, in33,34, however, the current standards and approaches possess limitations, such as inaccurate estimations and inconsistent results for similar oil samples. These challenges must be rectified to have an efficient lifespan prediction scheme. Computational techniques have also been utilized to address these challenges. DGA has been conducted utilizing wavelet networks (WN)35,36, expert systems (ES)37, adaptive neuro-fuzzy inference system (ANFIS)38, artificial immune networks (AIN)39, support vector machines (SVM)40, and fuzzy logic (FL)41. Although the results for LOL of transformers presented in this work are decent, it is essential to promote the proposed approach to enhance LOL prediction accuracy to provide dielectric testing facilities and transformer manufacturers with reliable alternatives to existing techniques. Table 3 presents a comparative study of the recent research works and the proposed algorithm for forecasting LOL of cellulose paper insulation.

Paper contribution

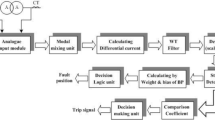

In this work, an elaborate diagnostic approach is proposed to evaluate twenty-six different transformers in-service to determine their operative status. The solid insulation evaluation process is a reliable practice to assess and forecast the DP and LOL as it provides generous information in inspecting the transformer condition. The contributions of the current research study are as follows and demonstrated in a block diagram as shown in Fig. 1.

-

DGA is utilized to obtain 2FAL data from oil samples received from all transformers under investigation.

-

A BPNN algorithm is proposed to forecast the DP using 2FAL concentration measured from oil samples using DGA.

-

A second BPNN algorithm is proposed to forecast the transformer LOL using the 2FAL and DP data obtained from the first BPNN algorithm.

-

Lastly, the results are used for hazard analysis and lifespan prediction based on the health index (HI) for each transformer to forecast the expected years of service as per the IEC 60599:2022 standard47 and CIGRE brochure48.

According to current research works, \({\text{MeOH}}\) is commonly used to analyze cellulose paper in oil transformers. The experimental investigations reported and addressed in49,50,51,52 have revealed that \({\text{MeOH}}\) is a potential degradation indicator for all cellulose-based materials and may be used in many types of mineral oil. There is a significant relationship between DP and \({\text{MeOH}}\) formation, as well as earlier diagnosis of cellulose degradation than 2FAL concentrations, supporting published works. However, at high temperatures, \({\text{MeOH}}\) concentrations tend to stabilize while only 2FAL concentrations keep on developing53. Nonetheless, it is critical to recognize that early detection \((\text{MeOH)}\) is critical for effective monitoring and mitigation measures at the appropriate time. In this work, the fact that 2FAL compounds are constantly produced, even at a later stage than \({\text{MeOH}}\), lends further weight to employing 2FAL data to forecast the transformer LOL utilizing the proposed BPNN algorithms since they can learn and train continuously growing 2FAL concentrations without experiencing overfitting. The results obtained using the proposed approach will be used to decide whether to repair, monitor, service, or scrap the transformer under investigation10,54.

The currently available capabilities and limitations of the proposed BPNN algorithm in comparison to other types of learning algorithms are presented in Table 4. The performances of the learning algorithms are evaluated according to how well they can generalize the relationship between vibration parameters, damage locations, and severities across a range of input and output variable counts55.

For future work, the authors will evaluate \({\text{MeOH}}\) and 2FAL concentrations using artificial intelligence algorithms. The conclusions about which data produces accurate results using the algorithms presented in Table 3 will be drawn from which data produces underfitting and overfitting during training59.

Paper organization

The rest of the work is structured as follows: Section “Methods used to investigate transformers” outlines the methods used to investigate transformers in-service. Section “Results and analysis” provides a discussion of the results and analysis of the investigated transformers. Section “Discussion” provides a discussion and recommendations, and the paper is concluded in section “Conclusion”.

Methods used to investigate transformers in-service

The practical diagnostic approach for estimating the current status and remaining operating lifespan of an electrical transformer in terms of expected End of Life (EOL)60 is discussed in this Section. Four different tactics for analyzing data from on-site testing and estimating using algorithms were combined to develop the diagnostic technique. Oil tests were combined for estimating dissolved gases and oil quality, DP calculations based on indirect measurements of dissolved 2FAL in transformer oil, the HI approach for processing data collected through visual inspection, history, and test results, and risk of failure calculation based on the HI61,62. These techniques were utilized to determine whether transformers should be repaired, closely monitored, maintained, or scrapped63,64. Twenty-six specific transformers utilized in distribution substations in South Africa, Mpumalanga, were exposed to the proposed diagnostics. The diagnostics were divided into five phases, which are described below25,65,66,67,68:

-

Assessment of the transformer’s current condition: involves visual inspection and all DGA and chemical tests conducted on transformer oil.

-

Gathering historical data: involves gathering information from prior faults, repairs, and maintenance. Obtaining data for the transformer’s load history and analyzing yearly test reports.

-

Algorithm analysis: the outcomes of each test are evaluated and applied to various algorithms to gather more data on the technical status of the transformers, as well as to detect hidden issues and abnormalities.

-

Application/Generalization: all data obtained through various tests and algorithms is generalized and analyzed to obtain more detailed knowledge about the transformer’s present condition. The majority of the tests usually yield comprehensive data for individual transformer parts.

-

Conclusions, predictions, and proposals: conclusions are reached and predictions are provided regarding the likelihood of failure, EOL of the transformers, and dependability according to the outcomes of diagnostic tests and procedures used. Proposals are provided to prioritize maintenance for the most degraded transformers or to discard them if the end of life has passed. Figure 2 demonstrates a block diagram of the five phases utilized in technical diagnosis.

The data gathered from the transformer’s historical events, conducted tests, as well as visual inspection is utilized to forecast imminent failures and EOL of each transformer, and according to these factors, a decision is made to prioritize transformers for repair, maintenance, or replacement if a transformer has reached its EOL69. Figure 3 demonstrates the primary descriptive framework of the approach utilized, which relies on HI calculations70,71.

The inspected transformers were manufactured throughout a variety of periods, and some of them had been in service for more than 30 years. The rated power ranged from 1250 kVA to 3.2 MVA, and the primary and secondary voltages were 11 kV, 6.6 kV, and 400 V, respectively. Transformer designs changed based on the year they were manufactured. Several transformers had undergone maintenance over their existence. The cooling system designs of transformers ranged from Oil Natural Air Natural (ONAN); Oil Natural Air Forced (ONAF); Oil Forced Air Forced (OFAF); Oil Natural Water Forced (ONWF); and Oil Forced Water Forced (OFWF)72,73. Table 5 contains technical information on the transformer group under consideration72.

A diagnosis procedure was developed to estimate the present status of all transformers. The following tests and analyses were conducted on all transformers.

Transformer oil diagnostics

-

Water content in transformer oil was measured per IEC 60814 Oil-impregnated paper and pressboard74,75.

-

The breakdown voltage of transformer oil was measured per IEC 60156 Insulating liquids76,77.

-

The level of acidity present in transformer oil was measured per IEC 6202178,79.

-

Analysis of corrosive sulfur in transformer oil content using ASTM D1275-15 standard testing procedure for corrosive sulfur in electrical insulating fluids80.

-

Estimating the water content in insulating paper using the IEC 60814 standard81,82.

-

DGA of the transformer oil using IEC 60599 standard83,84,85.

Visual inspection assessments were performed on all accessible transformer components

Analysis of the data consisted of several methods for assessment

Investigation of transformer present state about oil tests and DGA findings:

-

Chemical assessments of transformer oil were performed to establish some of its properties that are critical for the mechanical performance of the unit, which covered the following: Chemical properties: (i) water content, (ii) corrosive sulfur, and (iii) acidity number93; Electrical properties: (i) dielectric strength, (ii) specific resistance and (iii) dielectric dissipation factor (tan δ)94,95. Each of these properties influences the integrity and reliability of transformer oil and its insulating characteristics. In terms of chemical properties, high water concentration in transformer oil may result in lower dielectric strength. The presence of corrosive sulfur in transformer oil creates an acidic environment in the oil, causing accelerated degradation of the cellulose paper and also the oil to become more acidic over time96. The quantity of acid present in the transformer is a critical signature that determines transformer oil integrity97,98. Electrical properties consist of (i) transformer oil dielectric strength—which signifies the maximum test voltage that the oil will sustain as an insulation material; (ii) specific resistance—which illustrates the insulation characteristics of transformer oil; and (iii) dielectric dissipation factor (tan δ)—indicates the quality of the transformer oil as an insulation material and the level of losses when voltage is applied across it99,100,101.

-

Electrical transformers emit decomposition gasses when in service, which are primarily produced from organic insulation. The gas creation process is caused by thermal or electrical challenges, as well as the decomposition of transformer oil or cellulose. This might be due to regular transformer operation or an emergency with the unit in question. A portion of the produced gasses dissolves in the transformer oil102,103. DGA is used for evaluating different types of gases in transformer oil and then performing transformer diagnostics. This approach is effective for detecting specific defects (thermal or electrical) and assessing transformer operation104,105,106. There are several techniques for interpreting the DGA. In most cases, a combination of these techniques is utilized to identify the cause of gasses. These approaches include identifying key gases (\({\text{H}}_{2}\), \({\text{C}}{\text{H}}_{4}\), \({\text{CO}}\), CO2, C2H4, C2H2, and \({\text{C}}_{2}{{\text{H}}}_{6}\)) as well as their quantities in oil. An increase in the amount of several gases might indicate an issue in the transformer. If this is the case, the gas ratio should be established. Then, to address the issue, an interpretation technique for gas ratios provided in IEC 60599 might be applied. Alternatively, the proposed approach could potentially be utilized for interpreting the data. The values of the obtained gas ratios based on these techniques indicate a specific problem in the performance of the transformer107. In summary, the proposed approach has been employed in this work, and it is a good precise approach for transformer diagnosis. It could be utilized as well for periodic testing, with the findings compared over time to monitor the level of gas creation and gauge the actual condition of the transformer1,3,4,23.

Analysis of the condition of the transformers through BPNN algorithms

-

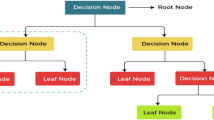

This analysis involved two BPNN algorithms for determining the LOL of transformers based on collected and measured data. The first BPNN algorithm proposed is based on forecasting the DP using 2FAL concentration measured from oil samples using DGA, and the second BPNN algorithm proposed is based on forecasting transformer LOL using the 2FAL and DP data obtained from the first BPNN algorithm. To acquire a complete understanding of the state of the transformer, the data based on the BPNN algorithm with weighting coefficients is applied, and the LOL is determined108,109,110. Figure 4 demonstrates the analysis and results of HI components.

Several studies have used the BPNN approach60,72 to anticipate numerous transformer states, such as the diagnosis of incipient defects using DGA111. In this work, BPNN algorithms are presented to forecast the remaining DP utilizing 2FAL concentration. A databank of 100 samples is utilized to construct the proposed BPNN algorithms using 2FAL as an input and DP as an output. Analysis of the data collected was changed into descriptive data ranging from A “Excellent” to E “Critical” condition112,113. DP of cellulose paper114,115 was used to estimate the remaining life of the transformer. An accurate estimate of DP to 2FAL was achieved by implementing an algorithm with a BPNN116,117. The BPNN algorithms were developed using several transformers and oil samples collected for lab testing. The algorithms were evaluated using cellulose paper samples extracted from transformers that had been removed from service for maintenance and retrofit. Since each transformer has an independent voltage level and capacity, the volume concentrations of dissolved gases in oil vary. Therefore, normalization of the input DGA data was employed to remove the discrepancy. In this work, the relative portion of the oil samples was adopted as the input vectors, which is shown in (1):

\({\text{X}}_{\text{i}}\) denotes the proportion of volume concentration of each gas contained in the oil data. Equation (2) was developed to determine DP using experimental data acquired from transformers well-insulated with standard Kraft paper:

Equation (3) was developed to determine DP using experimental data from Kraft cellulose paper as well as hermetical aging tests performed under high-temperature conditions and the degradation of a polymer main chain using (4):

Using (5), the DP can be used to forecast the remaining lifespan of the transformer at the time the oil sample was collected. This equation is based on a single variable, specifically the expected DP of cellulose paper.

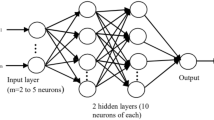

The BPNN algorithm was adopted in this study due to its capacity to self-learn, simulate non-linear issues, and provide output that is not confined to the input feed, which is important for addressing the issue of cellulose paper for transformer manufacturers118,119. Figure 5a illustrates a conceptual representation of the proposed BPNN algorithm for estimating DP. It contains an input layer, hidden layers as required, and an output layer. The system works similarly to a biological neuron, receiving stimuli, interpreting them, and responding with an output. The input layer nodes receive input data and transfer it to the hidden layer 1 nodes via interconnected connections. When data are transported from input nodes to subsequent nodes, they are multiplied with weights and sent to the relevant layer using a transfer function. Similarly, it is forwarded to the output layer, where the target vector is used to compute the error. To generate the precise weighted combination of input data for target vector prediction, weights are altered based on this error. Using an artificial BPNN algorithm has several advantages over more conventional models. It learns the complexities of nature without being explicitly translated into mathematical form. The 2-hidden layers were used for two reasons: (i) the model performs efficiently using the BPNN algorithm, despite the extremely nonlinear input, and (ii) it is unlikely to experience overfitting. The learning process of a neural network (NN) is an iterative process in which the calculations are carried out forward and backward through each layer in the network until the loss function is minimized. This is illustrated in Fig. 5b.

The proposed algorithms use the input (2FAL) and the targeted output (DP) supplied to the BPNN network to generate the network output target of a new dataset. Figure 6 shows a detailed flowchart utilized for the design of the proposed BPNN algorithms. The process of designing the BPNN algorithms is divided into three phases: training, testing, and validation120,121,122. The data is prepared using the following steps:

-

The preparation of the data ensures that it is error-free, consistent, and has no missing values before it is fed into the BPNN algorithm. These can have an impact on the performance and accuracy of the algorithm, leading to unexpected outcomes.

-

The data is modified to match inside the suitable BPNN range. The values are altered to have comparable magnitudes and distributions. This scaling allows the BPNN to learn more quickly and effectively while also avoiding numerical difficulties. To reduce noise creation, normalization, and standardization is used to rescale input and output variables before training the BPNN algorithm123,124.

-

The data is classified based on labels, classes, or categories and represented numerically using binary encoding for the BPNN to understand. Encoding also aids in reducing the dimensionality and complexity of data. After the data has been cleaned, scaled, and encoded, it is divided into separate sets using k-fold cross-validation for training, testing, and validation. This helps to analyze and enhance the BPNN algorithm while avoiding overfitting and underfitting.

-

In situations when the BPNN algorithm experiences a shortage of data, data augmentation is employed to improve the size and diversity of the data. Data augmentation involves making numerous transformations and adjustments to existing data, by creating modified copies of a dataset using existing data125,126.

-

Lastly, data visualization is employed to further study and comprehend the data. Data visualization entails producing graphical interpretations of data, such as charts, graphs, or diagrams. Data visualization aids in identifying patterns, trends, outliers, or correlations in data, as well as providing insights into the BPNN algorithm’s performance.

BPNN training

During the BPNN training stage, the network is fed data comprising the 2FAL concentrations and the transformer DP samples as the targeted output. The training stage is essential in the development of the proposed BPNN algorithm. The network dimension, training functionality, adoption learning functionality, number of layers, as well as transfer functionality, are all aspects that have the potential to affect BPNN network efficiency127. Moreover, this stage can provide several difficulties, such as overfitting and underfitting128. This happens when an algorithm is trained on a large scale of data as it begins to learn from errors and noise in the input data set. Furthermore, testing using test data that has a high variance. The algorithm then fails to appropriately classify the data due to too many details and noise, and it leads to bad performance of the network. Stopping the network early has been utilized to prevent network overfitting and underfitting129. The optimal BPNN settings with the maximum precision, which is equivalent to the correlation coefficient (R), were obtained by modifying the number of hidden layers, the number of neurons, as well as the transfer functionality108,130. In this work, a two-layer system with 10-hidden layers and a 1-output layer was adopted for both BPNN algorithms. The proposed BPNN algorithm was developed using a databank containing 100 data sets, of which 70 were utilized for training and 30 for testing and validation. While a 1-hidden layer is sufficient for nonlinear modeling, a system with 2-hidden layers outperforms systems with 1-hidden layer in terms of the number of iterations, precision, and complexity. Furthermore, the 2-layer system helps solve the challenge of slow learning rates73.

BPNN testing

During BPNN testing, an unknown dataset is added to the network to evaluate the efficiency of the trained network. At this stage, the BPNN network is evaluated using linear regression modeling. The R is determined to analyze the relationship between the BPNN network outputs and the intended output. A successful network will have an R-value close to 1, indicating that there is a notable relationship between the BPNN network output and the targeted output. The overall efficiency of the BPNN network is expressed by the value of R and the best BPNN network is identified based on its closest relationship value to 168,95. The Levenberg–Marquardt (LM) training approach64,65 was used since it is recommended as the preferable supervised algorithm in the MATLAB environment due to its fast training rate116. Figure 7a,b show the coding of the two algorithms. Figure 8 shows the modeling configuration that predicts DP using only 2FAL concentration. Figure 9 shows the Mean Square Error (MSE)94 plot of the first BPNN algorithm. The three curves represent the change in the MSE with epochs for training, validation, and testing. However, the best algorithm was reached at epoch 19 as marked by the vertical dash line. It proves that the network achieved better results during the training stage compared to the testing stage because the desired outputs of the test data are always unknown to the network. No significant overfitting occurred with this iteration. The characteristics of both the validation and test curves are similar. The remarks above indicate acceptable results for the network.

Figure 10 shows the regression analysis of the NN modeling of the training, validation, test, and complete datasets presented in this study. The training dataset consists of 100 data points (i.e. 70% of total data points for training), while the validation and test datasets have 30 data points (i.e. 15% each). It can be observed that the algorithm produces a correlation coefficient of 0.970 for the training, 0.956 for the validation, 0.944 for the testing, and an overall correlation of 0.965 when the DP is predicted using the 2FAL measured in oil. From Fig. 10, it is observed that the four linear fit lines were achieved (Eqs. 6–9) in the form \(\text{y = a.x + b}\), where x and y are observed and predicted peak ground acceleration (PGA), respectively, which are listed below:

Figure 11 shows the error histogram for our NN modeling showing most of the larger positive and negative values are near the zero-error line (shown by an orange thick line), which suggests the error distribution of the NN modeling is good. Thus, the algorithm is well trained.

Figure 12 illustrates the algorithm setup for forecasting LOL based on predicted DP and measured 2FAL. Figure 13 shows the MSE plot of the first BPNN algorithm. The network produces a substantial MSE at first, however, it decreases as the training advances to 5 epochs. As demonstrated in Fig. 13, the best validation performance of the second BPNN algorithm occurred at 5 iterations, as shown by the vertical dash line. This iteration shows a minor overfitting. The characteristics of both the validation and test curves are slightly different; however, the remarks above indicate acceptable results for the network.

Figure 14 shows the second proposed BPNN algorithm performance plot, and the regression analysis of the NN modeling for our training, validation, test, and complete datasets. The training dataset consists of 100 data points (i.e. 70% of total data points), while the validation and test datasets have 30 data points (i.e. 15% each). It can be observed that the algorithm produces a correlation coefficient of 0.999 for the training, 0.999 for the validation, 0.999 for the testing, and an overall correlation of 0.999 when the prediction of transformer LOL concerning 2FAL generated and the amount of DP present produced. From Fig. 14, it is observed that the four linear fit lines were achieved (Eqs. 10–13) in the form \(y=a.x+b\), where x and y are observed and predicted PGA, respectively, which are mentioned below:

Figure 15 shows the error histogram for our NN modeling showing most of the larger positive and negative values are near the zero error line (shown by an orange thick line), which suggests the error distribution of the NN modeling is good. Thus, the algorithm is well trained. Figure 16 is given as some results of trained neurons, and the overall amount of gas dissolved in the oil, which is the average of all gas amounts recorded.

Table 6 summarizes the analytical settings used in the proposed BPNN algorithms. The MSE, R, and computation time for the two algorithms are contrasted in Table 7. The second algorithm outperforms the first algorithm in terms of R. Due to the large quantity of data to train, the second approach takes a bit more time to compute than the first algorithm. However, because the simulation is done offline, the computation time cannot be used to determine the optimum algorithm44. Consequently, after considering all simulation data, it is proven that the second algorithm has an exceptional capacity to accurately forecast transformer LOL131.

Transformer lifespan estimates were performed using the calculated HI coefficient. The HI coefficients and grades are presented in Table 8. The integrity of the transformer was specified as its capacity to withstand minimal loads and pressures while preserving its functional specifications over time. Transformer condition reliability can be calculated using (14):

where t is the time in years, and \(\lambda = f(HI)\)

When a transformer is operating normally, without external or sudden issues that might cause failure, all parts of the equipment deteriorate at a constant rate, which is usually specified by its working years and the current condition of all the parts. To account for all of the transformer’s parts that have an impact on its condition over extended periods, and years, the HI is included in the calculation of the transformer’s durability. The formula used to determine the failure rate is given in (15):

where parameter \(A = f (t, \gamma )\). Parameter A is calculated by using (16):

where t is the years of service of the transformer; γ is coefficient 1, 2, 3, and 4 depending on the degrading curve (γ = 1 if the transformer is relatively new and it is in the zone of sudden failures; γ = 2 if the transformer is working normally but its designed working years are unknown; γ = 3 when the transformer has already exceeded its initially planned years of service; γ = 4 when the transformer is a risk); and \({\text{t}}_{\text{e}}\) is the expected working years of the transformer. All calculations were performed with \({\text{t}}_{\text{e}}\) = 61 years. Durability was used to calculate the risk of failure. Transformer durability and risk of failure statistics are shown in the estimated years that the transformers will operate reliably.

Results and analysis

The outcomes of all conducted experiments and proposed BPNN algorithms are reported for all evaluated transformers, ranging from T1 to T26. The data were collected using transformer oil sampling and DGA. Sampling was performed to predict the water concentration in cellulose paper based on chemical analysis for oil integrity. Data was obtained using visual inspections as well as the past events of the transformer, which was investigated during the testing process. The outcomes of the proposed BPNN algorithms were established on HI estimations, predicted transformer lifespan based on estimated DP via the BPNN, and durability and risk of failure estimates based on the HI. The results gathered from all conducted checks and analyses on all studied transformers were consolidated.

Transformer oil measurements and test data

DGA of the transformer oil

Table 9 illustrates a description of the investigated gases discussed in the study and Table 10 shows the measurements of dissolved gases detected and recorded in oils of the evaluated transformers.

Chemical analysis of transformer oil

Figures 17, 18, 19 and 20 illustrate the chemical and electrical properties of the evaluated oil data.

Data collected through visual inspection

Main tank

Table 11 provides an overview of the information gathered from visual inspections of the main tanks of all the transformers under investigation.

Tap changer

Table 12 provides an overview of the information gathered from visual inspections of the tap changers of all the transformers under investigation.

Oil conservator

Table 13 provides an overview of the information gathered from visual inspections of the oil conservators of all the transformers under investigation.

Breather

Table 14 provides an overview of the information gathered from visual inspections of the breathers of all the transformers under investigation.

Cooling tubes

Table 15 provides an overview of the information gathered from visual inspections of the cooling tubes of all the transformers under investigation.

Buchholz relay

Table 16 provides an overview of the information gathered from visual inspections of the Buchholz relays of all the transformers under investigation.

Results obtained through applied analysis of collected data

DGA of the transformer oil and oil analysis

Table 17 provides an overview of the conclusions drawn from the analysis of the data.

Health Index (HI)

Figure 21 illustrates the outcomes of the HI calculations that were performed using the algorithms proposed in in study.

Table 18 shows the estimated years of operation for each transformer according to the calculated HI. It was estimated that six transformers would last more than 15 years. There were no transformers discovered to have near EOL or EOL materials. Small to medium-sized defects that can be resolved to stop serious failures were discovered in every transformer. The service and maintenance of seven transformers were given priority.

Calculated degree of polymerization

Table 19 displays the compiled results for all transformers, and Figure 22 displays the estimated DP for all units using the proposed BPNN algorithms. The results demonstrate that none of the units was discovered to be approaching the end-of-life category, and all tested units meet the standard aging domain of cellulose paper132.

To improve estimation precision and diagnose defect types, diagnostic techniques must be classified based on their susceptibility and monitoring capabilities against defects and insulation deterioration. Table 20 summarizes routine and diagnostic analysis according to their capacity to discover defects. According to IEEE C57.104133, DGA alone is capable of diagnosing 70% of typical defects, however, additional evaluations are required to identify mechanical defects.

To improve dependability, significant industry regulations and improved research, such as CIGRE, IEEE, and IEC, have been applied to specific procedures for evaluating and analyzing test results. These quantitative and diagnostic procedures can assist maintenance professionals in interpreting test results and recommending key transformer characteristics that ought to be monitored. These procedures can assist utilities in preventing unforeseen breakdowns and offer a rationale for plant managers for the replacement of unreliable aging transformers through accurate forecasts. This work offers an overview of current testing as well as transformer condition assessment strategies. This is a discipline whereby a great deal of research is being conducted to better comprehend the features of various tests and to develop improved techniques for integrating test results to monitor the state of this costly and vital equipment. As the number of units of assets ages, the relevance of these strategies appears to increase even more.

Discussion

Electrical transformers are essential to the electrical system, and detecting latent defects immediately can help prevent more significant issues. This work tackled the issue of predicting and identifying electrical transformer defects using DGA data samples that result from low-occurring transformer issues. The capability to monitor equipment degradation opens up possibilities of reducing costs related to repairs and maintenance while also avoiding a variety of unexpected events. This will enable long-term studies on invested materials as well as a reduction in the initial energy required to design new units. The twenty-six electrical transformers, which were the topic of complex evaluations and inspection, were addressed and classified into different classes based on their HI, DP, DGA, and P (risk of failure). These classes involved scheduled maintenance and repair. The HI observations showed that the units had a significant amount of residual life and the technical capability of being in operation for extra years. As a consequence, none of the transformers required to undergo repair. The findings demonstrate that the transformers T1, T2, T5, T6, T7, T8, T9, T12, T13, T14, T15, T16, T17, T18, T19, T20, T21, T22, T24, and T26 are operating normally, thus no preventative action required at this stage. Methane levels in T4, T8, and T25 were approaching alert limits and were planned to undergo further diagnostics and monitoring. DGA discoveries in transformers T3, T10, T11, and T25 led to the diagnosis of an electrical fault and were planned to undergo visual inspection and testing. Transformers T3, T5, and T17 produced positive HI and DP findings, however, the DGA and R results indicate that cautious/or further diagnostics are required and the units were scheduled for moisture purification and resampling for safety and economic purposes. Table 21 summarizes the findings of the complex inspections and evaluations of the twenty-six electrical transformers surveyed, with color-coded data.

In this study, the approaches together supplied more detailed knowledge on the condition of each transformer as well as its expected lifespan. As per the 2FAL results obtained from the oil data, each transformer had minimal insulation degradation as well as a significant DP. However, their expected lifespans over the years of operation differed, and according to the HI, eighteen units performed admirably. Table 22 illustrates comparisons derived from all diagnostic techniques applied. The actions that must be implemented when utilizing DP data to assess the condition of the transformer to implement safety precautions are listed in Table 23.

Conclusion

In this work, twenty-six electrical transformers were put through diagnostic and monitoring assessments. The proposed approach integrated DGA, transformer oil integrity analysis, visual inspections, and two BPNN algorithms to predict the LOL of the transformers through condition monitoring of the cellulose paper and the HI approach for prioritizing units for repair, maintenance, or replacement. The findings of the proposed diagnostic procedures were acquired and investigated, and a list of transformers was proposed for repair, maintenance, and continuous supervision.

Based on the diagnostic approach proposed in this study, the following conclusions were attained:

-

The adoption of DGA and visual inspections on electrical transformers saves money when planning a maintenance schedule.

-

The DGA data were used as input samples into the NN for diagnosis. The experimental findings demonstrated that the first BPNN algorithm could accurately forecast transformer DP. The first algorithm produced a correlation coefficient of 0.970 when the DP was predicted using the 2FAL measured in oil. It is essential to schedule transformer maintenance in advance to prevent failure from escalating.

-

The results of the second BPNN algorithm were fed into the NN for assessment. The experimental results demonstrated that the second BPNN method was successful at forecasting transformer LOL. The second algorithm produced a correlation coefficient of 0.999 when the LOL was predicted using the 2FAL and DP output data obtained from the first algorithm.

-

The experimental results demonstrated that the BPNN algorithms can overcome the constraints of other learning algorithms based on DGA due to the limited and disorganized dispersal of transformer oil data. The BPNN algorithm offers more effective generalization performance compared to the other learning algorithms.

-

The HI findings revealed that no transformers had near-end-of-life or end-of-life materials as per the IEC 60599:2022 standard and CIGRE brochure.

Examining the condition of the cellulose paper insulation is crucial when thinking about a transformer maintenance schedule. In this instance, moving the transformer to a manufacturing station for rehabilitation would be a more economical maintenance strategy. All previous studies have demonstrated and verified that \({\text{MeOH}}\) appears to be an effective marker for detecting the start of cellulose paper degradation. \({\text{MeOH}}\) concentration increases in a “logarithmic’ trend (early diagnosis of deterioration), whereas 2FAL increases in an “exponential” trend (diagnosis when deterioration is extreme). When the cellulose insulation is exposed to low temperatures and the deterioration process is fully engaged, \({\text{MeOH}}\) content appears to stabilize. From this point on, 2FAL is considerably generated and becomes greater than \({\text{MeOH}}\). For future work, the authors will evaluate \({\text{MeOH}}\) and 2FAL concentrations using artificial intelligence algorithms. The conclusions about which data produces accurate results using the algorithms will be drawn from which data produces underfitting and overfitting during training.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Zou, D. et al. Transformer fault classification for diagnosis based on DGA and deep belief network. Energy Rep. 9, 250–256 (2023).

Gopakumar, S. & Sree Renga Raja, T. Determination of power transformer fault’s severity based on fuzzy logic model with GR, level and DGA interpretation. J. Electr. Eng. Technol. 1–22 (2023).

Lekshmi, A. K., Kumar, D. S. & Beevi, K. S. Trend prediction of power transformers from DGA data using artificial intelligence techniques. in Communication and Intelligent Systems: Proceedings of ICCIS 2021 1053–1065 (Springer, 2022).

Wajid, A. et al. Comparative performance study of dissolved gas analysis (DGA) methods for identification of faults in power transformer. Int. J. Energy Res. 2023 (2023).

Booth, C. & McDonald, J. R. The use of artificial neural networks for condition monitoring of electrical power transformers. Neurocomputing 23(1–3), 97–109 (1998).

Ghoneim, S. S., Taha, I. B. & Elkalashy, N. I. Integrated ANN-based proactive fault diagnostic scheme for power transformers using dissolved gas analysis. IEEE Trans. Dielectr. Electr. Insul. 23(3), 1838–1845 (2016).

Singh A. & Verma, P. A review of intelligent diagnostic methods for condition assessment of insulation system in power transformers. in 2008 International Conference on Condition Monitoring and Diagnosis 1354–1357 (IEEE, 2008).

Husain E., & Mohsin, M. Transformer insulation condition monitoring using artificial neural network. in ICSD’01. Proceedings of the 20001 IEEE 7th International Conference on Solid Dielectrics (Cat. No. 01CH37117) 295–298 (IEEE, 2001).

Nezami, M., Equbal, M., Khan, S. A., Sohail, S. & Ghoneim, S. S. Classification of cellulosic insulation state based on smart life prediction approach (SLPA). Processes 9(6), 981 (2021).

Sameh, W., Gad, A. H. & Eldebeikey, S. M. An intelligent classifier of electrical discharges in oil immersed power transformers. in 2019 21st International Middle East Power Systems Conference (MEPCON) 866–871 (IEEE, 2019).

Ahmad, A., Othman, M. L., Zainab, K. K. B. & Hizam, H. Adaptive ANN based differential protective relay for reliable power transformer protection operation during energisation. IAES Int. J. Artif. Intell. 8(4), 307 (2019).

Žarković, M. & Stojković, Z. Analysis of artificial intelligence expert systems for power transformer condition monitoring and diagnostics. Electr. Power Syst. Res. 149, 125–136 (2017).

Abbasi, A. R. Fault detection and diagnosis in power transformers: a comprehensive review and classification of publications and methods. Electr. Power Syst. Res. 209, 107990 (2022).

Thango, B., Moloi, K., Jordaan, J. & Nnnach, A. A further look into the service lifetime cost of solar photovoltaic energy transformers. in 2021 Southern African Universities Power Engineering Conference/Robotics and Mechatronics/Pattern Recognition Association of South Africa (SAUPEC/RobMech/PRASA) 1–7 (IEEE, 2021).

Thango, B. A., Nnachi, A. F., Dlamini, G. A. & Bokoro, P. N. A novel approach to assess power transformer winding conditions using regression analysis and frequency response measurements. Energies 15(7), 2335 (2022).

Srividhya, V. et al. Determination of breakdown voltage for transformer oil testing using ANN. in Congress on Intelligent Systems 443–452 (Springer, 2020).

de Andrade Lopes, S. M., Flauzino, R. A. & Altafim, R. A. C. Incipient fault diagnosis in power transformers by data-driven models with over-sampled dataset. Electr. Power Syst. Res. 201, 107519 (2021).

Faiz, J. & Soleimani, M. Assessment of computational intelligence and conventional dissolved gas analysis methods for transformer fault diagnosis. IEEE Trans. Dielectr. Electr. Insul. 25(5), 1798–1806 (2018).

Modi, M. M. & Patel, R. A. Intelligent approach to interpret incipient faults of power transformer from DGA database. J. Inst. Eng. (India) Ser. B 1–8 (2023).

Ekojono, Prasojo, R. A., Apriyani, M. E. & Rahmanto, A. N. Investigation on machine learning algorithms to support transformer dissolved gas analysis fault identification. Electr. Eng. 104(5), 3037–3047 (2022).

Barbosa, F. R., Almeida, O. M., Braga, A. P., Amora, M. A. & Cartaxo, S. J. Application of an artificial neural network in the use of physicochemical properties as a low cost proxy of power transformers DGA data. IEEE Trans. Dielectr. Electr. Insul. 19(1), 239–246 (2012).

Zeinoddini-Meymand, H., Kamel, S. & Khan, B. An efficient approach with application of linear and nonlinear models for evaluation of power transformer health index. IEEE Access 9, 150172–150186 (2021).

Barkas, D. A., Kaminaris, S. D., Kalkanis, K. K., Ioannidis, G. C. & Psomopoulos, C. S. Condition assessment of power transformers through DGA measurements evaluation using adaptive algorithms and deep learning. Energies 16(1), 54 (2022).

Sahoo, S., Chowdary, K. V. & Das, S. DGA and AI technique for fault diagnosis in distribution transformer. in International Conference on Emerging Trends and Advances in Electrical Engineering and Renewable Energy 35–46 (Springer, 2020).

Tightiz, L., Nasab, M. A., Yang, H. & Addeh, A. An intelligent system based on optimized ANFIS and association rules for power transformer fault diagnosis. ISA Trans. 103, 63–74 (2020).

Saroja, S., Haseena, S. & Madavan, R. Dissolved gas analysis of transformer: An approach based on ML and MCDM. IEEE Trans. Dielectr. Electr. Insul. (2023).

Hasan, A. & Singh, A. Condition Monitoring of Distribution Transformer Using Machine Learning (Galgotias University, 2020).

Meira, M., Carlucho, I., Álvarez, R., Catalano, L. & Acosta, G. DGA: A novel strategy for key gases identification in power transformers. in 2020 IEEE Electrical Insulation Conference (EIC) 290–293 (IEEE, 2020).

Thango, B. A. & Bokoro, P. N. Defining and specifying design considerations for distribution transformers in large-scale solar photovoltaic plants. Energies 15(8), 2773 (2022).

Meira, M., Ruschetti, C. R., Álvarez, R. E. & Verucchi, C. J. Power transformers monitoring based on electrical measurements: State of the art. IET Gener. Transmiss. Distrib. 12(12), 2805–2815 (2018).

Aciu, A.-M., Nicola, C.-I., Nicola, M. & Nițu, M.-C. Complementary analysis for DGA based on Duval methods and furan compounds using artificial neural networks. Energies 14(3), 588 (2021).

Raj, N., Gopinath, D., Aryanandiny, B. & Pillai, S. Fuzzy logic-based spectroscopic analysis for condition assessment of distribution transformers. IEEE Trans. Ind. Appl. (2024).

Thango, B., Akumu, A., Sikhosana, L., Nnachi, A. & Jordaan, J. Empirical based approaches to evaluating the residual life for oil-immersed transformers—A case study. in 2021 IEEE AFRICON 1–4 (IEEE, 2021).

Gockenbach, E. & Borsi, H. Condition monitoring and diagnosis of power transformers. in 2008 International Conference on Condition Monitoring and Diagnosis 894–897 (IEEE, 2008).

Chen, W., Pan, C., Yun, Y. & Liu, Y. Wavelet networks in power transformers diagnosis using dissolved gas analysis. IEEE Trans. Power Deliv. 24(1), 187–194 (2008).

Cui, Q. M., Cui, S. T., Guan, Z. Y. & Sun, W. T. Expert system based on ESTA and guide for condition evaluation of transformers. Adv. Mater. Res. 347, 306–309 (2012).

Uljayev, E., Ubaydullaev, U., Narzullayev, S. N. & Norboyev, O. Application of expert systems for measuring the humidity of bulk materials. Int. J. Mechatron. Appl. Mech. 1(9), 131–137 (2021).

Huang, W. et al. A data mining approach for transformer failure rate modeling based on daily oil chromatographic data. IEEE Access 8, 174009–174022 (2020).

Lian, L. Reactive power optimization based on adaptive multi-objective optimization artificial immune algorithm. Ain Shams Eng. J. 13(5), 101677 (2022).

Zhang, Y., Li, J., Fan, X., Liu, J. & Zhang, H. Moisture prediction of transformer oil-immersed polymer insulation by applying a support vector machine combined with a genetic algorithm. Polymers 12(7), 1579 (2020).

Malik, H., Sharma, R. & Mishra, S. Fuzzy reinforcement learning based intelligent classifier for power transformer faults. ISA Trans. 101, 390–398 (2020).

Liu, J., Zhang, H., Geng, C., Fan, X. & Zhang, Y. Aging assessment model of transformer insulation based on furfural indicator under different oil/pressboard ratios and oil change. IEEE Trans. Dielectr. Electr. Insul. 28(3), 1061–1069 (2021).

Oria, C., Méndez, C., Carrascal, I., Ortiz, A. & Ferreño, D. Impact of the use of vegetable oil on the mechanical failure of the cellulosic insulation of continuously transposed conductors in power transformers. IEEE Trans. Dielectr. Electr. Insul. 29(2), 607–613 (2022).

Chen, Q. et al. Study on aging assessment model of transformer cellulose insulation paper based on methanol in oil. IEEE Trans. Dielectr. Electr. Insul. 29(2), 591–598 (2022).

Wu, S. et al. Concentration prediction of polymer insulation aging indicator-alcohols in oil based on genetic algorithm-optimized support vector machines. Polymers 14(7), 1449 (2022).

Ngwenyama, M. & Gitau, M. N. Discernment of transformer oil stray gassing anomalies using machine learning classification techniques. Sci. Rep. 14(1), 376 (2024).

Commission, I. Mineral oil-filled electrical equipment in service–Guidance on the interpretation of dissolved and free gases analysis. IEC 60599, 2015 (2015).

Force, C. T. Ageing of cellulose in mineral-oil insulated transformers. in CIGRE: Paris, France (2007).

Nadolny, Z. Design and Optimization of Power Transformer Diagnostics. Vol 16, p 6466 (MDPI, 2023).

Elok, N., Putri, R. I. & Priyadi, A. The remaining life of distribution transformer prediction by using neuro-wavelet method. Przeglad Elektrotechniczny, 99(2) (2023).

Jin, L., Kim, D. & Abu-Siada, A. State-of-the-art review on asset management methodologies for oil-immersed power transformers. Electr. Power Syst. Res. 218, 109194 (2023).

Zhang, W. et al. Residual lifetime evaluation of power transformers based on data fusion and wiener model. IEEE Trans. Power Deliv. (2023).

Zhang, W. et al. Influence of operational defects and hotspot temperature on methanol concentration in transformer oil. IEEE Trans. Power Deliv. (2022).

Fan, J. et al. An online monitoring system for oil immersed power transformer based on SnO2 GC detector with a new quantification approach. IEEE Sens. J. 17(20), 6662–6671 (2017).

Rodriguez-Celis, E., Duchesne, S., Jalbert, J. & Ryadi, M. Understanding ethanol versus methanol formation from insulating paper in power transformers. Cellulose 22, 3225–3236 (2015).

Mi, X., Subramani, G. & Chan, M. The application of RBF neural network optimized by K-means and genetic-backpropagation in fault diagnosis of power transformer. In E3S Web of Conferences Vol. 242, p. 03002 (EDP Sciences, 2021).

Yang, X. et al. BA-PNN-based methods for power transformer fault diagnosis. Adv. Eng. Informat. 39, 178–185 (2019).

Wang, Z., Xue, Z. & Liang, Y. Application of counter propagation network in fault diagnosis of power transformer. in 2009 International Conference on Artificial Intelligence and Computational Intelligence vol. 2, pp. 490–492 (IEEE, 2009).

Bare, C. E. & Merritt, S. Y. Methanol as an ageing marker for in service transformers. in 2017 Annual Pulp, Paper And Forest Industries Technical Conference (PPFIC), 1–7 (IEEE, 2017).

Rokani, V., Kaminaris, S. D., Karaisas, P. & Kaminaris, D. Power transformer fault diagnosis using neural network optimization techniques. Mathematics 11(22), 4693 (2023).

Diefenthäler, A. T., Sausen, A. T., De Campos, M., Sausen, P. S. & Lenz, J. M. Artificial neural networks: Modeling and comparison to detect high impedance faults. IEEE Access (2023).

Chabert, A., Bakkay, M., Schweitzer, P., Weber, S. & Andrea, J. A transformer neural network for AC series arc-fault detection. Eng. Appl. Artif. Intell. 125, 106651 (2023).

Parvin, F., Faiz, J., Qi, Y., Kalhor, A. & Akin, B. A comprehensive inter-turn fault severity diagnosis method for permanent magnet synchronous motors based on transformer neural networks. IEEE Trans. Ind. Informat. (2023).

Malik, I. M., Sharma, A. & Naayagi, R. T. A comprehensive and practical method for transformer fault analysis with historical data trend using Fuzzy logic. IEEE Trans. Dielectr. Electr. Insul. (2023).

Kim, M.-S. et al. A method for fault section identification of distribution networks based on validation of fault indicators using artificial neural network. Energies 16(14), 5397 (2023).

Rao, S., Zou, G., Yang, S. & Khan, S. A. Fault diagnosis of power transformers using ANN and SMOTE algorithm. Int. J. Appl. Electromagn. Mech. 70(4), 345–355 (2022).

Bhalla, D., Bansal, R. K. & Gupta, H. O. Function analysis based rule extraction from artificial neural networks for transformer incipient fault diagnosis. Int. J. Electr. Power Energy Syst. 43(1), 1196–1203 (2012).

Alabbawi, A. A. M., Alnaib, I. I., Al, O.S.A.-D.Y. & Mohammed, K. K. Faults detection, location, and classification of the elements in the power system using intelligent algorithm. Bull. Electr. Eng. Informat. 12(2), 597–607 (2023).

Wang, L., Littler, T. & Liu, X. Dynamic incipient fault forecasting for power transformers using an LSTM model. IEEE Trans. Dielectr. Electr. Insul. (2023).

Li, S., Li, X., Cui, Y. & Li, H. Review of transformer health index from the perspective of survivability and condition assessment. Electronics 12(11), 2407 (2023).

Padmanaban, S., Khalili, M., Nasab, M. A., Zand, M., Shamim, A. G. & Khan, B. Determination of power transformers health index using parameters affecting the transformer’s life. IETE J. Res. 1–22 (2022).

Han, X. et al. A transformer condition recognition method based on dissolved gas analysis features selection and multiple models fusion. Eng. Appl. Artif. Intell. 123, 106518 (2023).

Ballal, M. S., Wath, M. G. & Suryawanshi, H. M. Measurement current transformer error compensation by ANN methodology. J. Inst. Eng. India Ser. B 101, 261–271 (2020).

Mandlik, M. & Ramu, T. Moisture aided degradation of oil impregnated paper insulation in power transformers. IEEE Trans. Dielectr. Electr. Insul. 21(1), 186–193 (2014).

Pahlavanpour, B., Eklund, M. & Sundkvist, K. Revised IEC standard for maintenance of in-service insulating oil. In Weidmann Third Annual Technical Conference (2004).

Seghir, M., Seghier, T., Zegnini, B. & Rabhi, A. Breakdown Voltage Measurement in Insulating Oil of Transformer According to IEC Standards. In Proceedings of the 2nd International Conference on Electronic Engineering and Renewable Energy Systems: ICEERE 2020, 13-15 April 2020, Saidia, Morocco 543–551. (Springer, 2021).

Tlhabologo, B. A., Samikannu, R. & Mosalaosi, M. Alternative liquid dielectrics in power transformer insulation: A review. Indones. J. Electr. Eng. Comput. Sci. 23(3), 1761–1777 (2021).

Atanasova-Höhlein, I. IEC 60296 (Ed. 5)–a standard for classification of mineral insulating oil on performance and not on the origin. Transf. Mag. 8(1), 86–91 (2021).

Safiddine, L. et al. Transformer oil reclamation by combining several strategies enhanced by the use of four adsorbents. IET Gener. Transmiss. Distrib. 11(11), 2912–2920 (2017).

da Silva, L. M., da Silva Júnior, M. M. & Galdeano, C. A. Evaluation of the corrosion potential of mineral insulating oil through ASTM D 1275 and gas chromatography with ECD based on IEC TR 62697-3 before and after proposed oil treatment process. in 2020 8th International Conference on Condition Monitoring and Diagnosis (CMD) 141–144 (IEEE, 2020).

Kanumuri, D., Sharma, V. & Rahi, O. Analysis using various approaches for residual life estimation of power transformers. Int. J. Electr. Eng. Informat. 11(2), 389–407 (2019).

Mariprasath, T., Kishore, P. & Padmavathi, M. Feasibility analysis of new green liquid dielectrics for transformers. Green Mater. 40, 1–5 (2023).

Duval, M. & DePabla, A. Interpretation of gas-in-oil analysis using new IEC publication 60599 and IEC TC 10 databases. IEEE Electr. Insul. Mag. 17(2), 31–41 (2001).

Irungu, G. K., Akumu, A. O. & Munda, J. L. Comparison of IEC 60599 gas ratios and an integrated fuzzy-evidential reasoning approach in fault identification using dissolved gas analysis. in 2016 51st International Universities Power Engineering Conference (UPEC) 1–6 (IEEE, 2016).

Miranda, V. & Castro, A. R. G. Improving the IEC table for transformer failure diagnosis with knowledge extraction from neural networks. IEEE Trans. Power Deliv. 20(4), 2509–2516 (2005).

Liu, B., Takahashi, Y., Fujiwara, K. & Imamori, S. Stray loss evaluation of power transformers using simplified air-core model with tank and frame. IEEE Trans. Magn. (2023).

Pan, Y., Han, S., Zhou, C. & Guo, X. On switching transient modeling and analysis of electronic on-load tap-changers based Sen transformer. Int. J. Electr. Power Energy Syst. 130, 107024 (2021).

Yayan, U. & Yılmaz, O. Overcoming hurdles: Challenges in testing and validating wind turbine transformers with electronic tap changers. Transf. Mag. 10(4), 92–99 (2023).

Jin, L., Kim, D., Abu-Siada, A. & Kumar, S. Oil-immersed power transformer condition monitoring methodologies: A review. Energies 15(9), 3379 (2022).

Riedmann, C., Schichler, U., Hausler, W. & Neuhold, W. Gas losses in transformers-influences and consideration. IEEE Access 11, 58654–58663 (2023).

Ch, H. B., Mariprasath, T., Kiran, S. R. & Murali, M. An experimental analysis of degradation of cellulosic insulating material immersed in natural ester oil for transformer. ECS Trans. 107(1), 18957 (2022).

Chothani, N., Raichura, M. & Patel, D. An Overview of the Protection of Power Transformers. Adv. Power Transf. Infrastruct. Digit. Protect. 27–69 (2023).

Rangel Bessa, A., Farias Fardin, J., Marques Ciarelli, P. & Frizera Encarnação, L. Conventional dissolved gases analysis in power transformers. Energies 16(21), 7219 (2023).

Sharifi, A., Kuhnke, M., Werle, P. & Akbari, A. The limitations of Arc detection using semiconductive light sensing elements inside the transformer tank. In 2023 13th International Conference on Power, Energy and Electrical Engineering (CPEEE) 88–92 (IEEE, 2023).

Chavhan, S. G. & Dongre, K. A. Fault detection using ann and wavelet transform for power transformer. EPRA Int. J. Multidiscip. Res. (IJMR) 8(2), 181–187 (2022).

Jan, B., Parveen, S. & Khan, S. A. ANN based multi-stage binary classification technique for incipient fault diagnosis of oil immersed transformer. In 2022 International Conference on Industry 4.0 Technology (I4Tech) 1–6 (IEEE, 2022).

Zhang, Y., Tang, Y., Liu, Y. & Liang, Z. Fault diagnosis of transformer using artificial intelligence: A review. Front. Energy Res. 10, 1006474 (2022).

Chavhan, S. G. & Dongre, K. A. Review on fault detection using ANN and wavelet transform for power transformer. EPRA Int. J. Multidiscip. Res. (IJMR) 8(2), 161–163 (2022).

Wani, S. A. et al. Advances in DGA based condition monitoring of transformers: A review. Renew. Sustain. Energy Rev. 149, 111347 (2021).

Taha, I. B., Ibrahim, S. & Mansour, D.-E.A. Power transformer fault diagnosis based on DGA using a convolutional neural network with noise in measurements. IEEE Access 9, 111162–111170 (2021).

Rao, U. M., Fofana, I., Rajesh, K. & Picher, P. Identification and application of machine learning algorithms for transformer dissolved gas analysis. IEEE Trans. Dielectr. Electr. Insul. 28(5), 1828–1835 (2021).

Dwiputranto, T. H., Setiawan, N. A. & Adji, T. B. DGA-based early transformer fault detection using GA-optimized ANN. In 2021 International Conference on Technology and Policy in Energy and Electric Power (ICT-PEP) 342–347 (IEEE, 2021).

Benmahamed, Y., Kherif, O., Teguar, M., Boubakeur, A. & Ghoneim, S. S. Accuracy improvement of transformer faults diagnostic based on DGA data using SVM-BA classifier. Energies 14(10), 2970 (2021).

Mohamed, S. H., Bakar, A. H. A. & Ali, M. S. Comparative study of DGA for transformer service life. Int. J. Renew. Energy Resour. 11(1), 13–26 (2021).

Wang, J., Zhang, X., Liu, L. & Wang, Z. Dissolved gas analysis in transformer oil using Ni-doped GaN monolayer: A DFT study. Superlattices Microstruct. 159, 107055 (2021).

Ali, M. S., Omar, A., Jaafar, A. S. A. & Mohamed, S. H. Conventional methods of dissolved gas analysis using oil-immersed power transformer for fault diagnosis: A review. Electr. Power Syst. Res. 216, 109064 (2023).

Buchacz, T., Buchacz, J. & Duval, M. Stray gassing of oil in HV transformers. IEEE Trans. Dielectr. Electr. Insul. 28(5), 1729–1734 (2021).

Sudrajad, G. A., Suwarno, S. & Prasojo, R. A. Health Index prediction using Artificial Neural Network (ANN) on historical data of power transformer. In 2023 IEEE 3rd International Conference in Power Engineering Applications (ICPEA) 239–242 (IEEE, 2023).

Alqudsi, A. & El-Hag, A. Application of machine learning in transformer health index prediction. Energies 12(14), 2694 (2019).

Taha, I. B. Power transformers health index enhancement based on convolutional neural network after applying imbalanced-data oversampling. Electronics 12(11), 2405 (2023).

Zeng, W. et al. Hybrid CEEMDAN-DBN-ELM for online DGA serials and transformer status forecasting. Electr. Power Syst. Res. 217, 109176 (2023).

Islam, N. et al. Power transformer health condition evaluation: A deep generative model aided intelligent framework. Electr. Power Syst. Res. 218, 109201 (2023).

Soni, R. & Mehta, B. A review on transformer condition monitoring with critical investigation of mineral oil and alternate dielectric fluids. Electr. Power Syst. Res. 214, 108954 (2023).

Adekunle, A. A., Oparanti, S. O. & Fofana, I. Performance assessment of cellulose paper impregnated in nanofluid for power transformer insulation application: A review. Energies 16(4), 2002 (2023).

Tang, C. et al. A review on the research progress and future development of nano-modified cellulose insulation paper. IET Nanodielectr. 5(2), 63–84 (2022).

Abd Aziz, A. M., Talib, M. A., Abidin, A. F. & Al Junid, S. A. M. Development of power transformer health index assessment using feedforward neural network. J. Adv. Res. Appl. Sci. Eng. Technol. 30(3), 276–289 (2023).

Kucuk, I. & Derebasi, N. Prediction of power losses in transformer cores using feed forward neural network and genetic algorithm. Measurement 39(7), 605–611 (2006).

Balaga, H., Gupta, N. & Vishwakarma, D. N. GA trained parallel hidden layered ANN based differential protection of three phase power transformer. Int. J. Electr Power Energy Syst. 67, 286–297 (2015).

Shankar, B. B., Bhat, H., Poornima, S., Bharanidharan, R., Sridharan, M. & Banik, A. Conventional protection of power transformers at distribution grid side using artificial neural network. In 2023 Second International Conference on Electronics and Renewable Systems (ICEARS) 901–906 (IEEE, 2023).

Čerkezović, E., Konjić, T., & Tešanović, M. Evaluation of losses in power transformer using artificial neural network. In Advanced Technologies, Systems, and Applications III: Proceedings of the International Symposium on Innovative and Interdisciplinary Applications of Advanced Technologies (IAT) Vol. 2, pp. 396–404 (Springer International Publishing, 2019).

Poonnoy, N., Suwanasri, C., & Suwanasri, T. Artificial neural network for STEM-ED in power transformer failure investigation based on power utility practice. In 2023 8th International STEM Education Conference (iSTEM-Ed) 1–4 (IEEE, 2023).

Li, Q. & Yu, M. Achieving sales forecasting with higher accuracy and efficiency: A new model based on modified transformer. J. Theoret. Appl. Electron. Commerce Res. 18(4), 1990–2006 (2023).

Taha, I. B. & Mansour, D. Novel power transformer fault diagnosis using optimized machine learning methods. Intell. Autom. Soft Comput. 28(3), 739–752 (2021).

Li, S. et al. Interpretation of DGA for transformer fault diagnosis with complementary SaE-ELM and arctangent transform. IEEE Trans. Dielectr. Electr. Insul. 23(1), 586–595 (2016).

Spressola, F. E., Roman, Z., Oliveira, R. G., Lagos, F. M. & Neto, E. T. W. Aging of oil-impregnated paper high voltage current transformers: Long duration test and lifespan estimation. IEEE Trans. Dielectr. Electr. Insul. (2023).

Kharezy, M., Mirzaei, H. R., Thiringer, T. & Serdyuk, Y. V. Green solution for insulation system of a medium frequency high voltage transformer for an offshore wind farm. Energies 15(6), 1998 (2022).

Patekar, K. D. & Chaudhry, B. DGA analysis of transformer using Artificial neutral network to improve reliability in power transformers. in 2019 IEEE 4th International Conference on Condition Assessment Techniques in Electrical Systems (CATCON) 1–5 (IEEE, 2019).

Mousavi, S. A., Hekmati, A., Sedighizadeh, M., Bigdeli, M. & Bazargan, A. ANN based temperature compensation for variations in polarization and depolarization current measurements in transformer. Therm. Sci. Eng. Progr. 20, 100671 (2020).

Nurcahyanto, H., Nainggolan, J. M., Ardita, I. M. & Hudaya, C. Analysis of power transformer’s lifetime using health index transformer method based on artificial neural network modelling. in 2019 International Conference on Electrical Engineering and Informatics (ICEEI) 574–579 (IEEE, 2019).

Li, Z., Jiao, Z. & He, A. Knowledge-based artificial neural network for power transformer protection. IET Gener. Transmiss. Distrib. 14(24), 5782–5791 (2020).

Aciu, A.-M., Nițu, M. C., Nicola, M. & Nicola, C.-I. Determination of the condition of solid insulation in high-power transformers based on 2-furfuraldehyde and methanol markers using neural networks. in 2021 International Conference on Electromechanical and Energy Systems (SIELMEN) 175–180 (IEEE, 2021).

Kes, M. & Christensen, B. E. Degradation of cellulosic insulation in power transformers: A SEC–MALLS study of artificially aged transformer papers. Cellulose 20, 2003–2011 (2013).

Draper, Z. H., Dukarm, J. J. & Beauchemin, C. How to Improve IEEE C57. 104–2019 DGA Fault Severity Interpretation. in 2022 IEEE/PES Transmission and Distribution Conference and Exposition (T&D) 1–5 (IEEE, 2022).

Acknowledgements

The authors would like to acknowledge the University of Pretoria for wholly supporting the study for academic purposes.

Author information

Authors and Affiliations

Contributions

Conceptualization, M.K.N.; methodology, M.K.N.; software, M.K.N.; validation, M.K.N., and M.N.G.; formal analysis, M.K.N.; investigation, M.K.N.; writing—original draft preparation, M.K.N.; writing—review and editing, M.K.N. and M.N.G.; visualization, M.K.N.; supervision, M.N.G. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ngwenyama, M.K., Gitau, M.N. Application of back propagation neural network in complex diagnostics and forecasting loss of life of cellulose paper insulation in oil-immersed transformers. Sci Rep 14, 6080 (2024). https://doi.org/10.1038/s41598-024-56598-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-56598-x

Keywords

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.