Abstract

Color is one of the most important indicators for the flue-cured tobacco quality. The color change of tobacco has a great relationship with the natural pigments in the tobacco. The relationship between color characteristics and the content of natural pigments in tobacco leaves during curing was investigated. The middle part of variety K326 tobacco was taken at each key time point during the curing process to determine the changes of color characteristics, moisture, pigment and polyphenol content. The results showed that moisture content of wet basis of tobacco gradually decreased from 72 to 18% during the curing process, the b* value increased and then decreased, and the a* value increased significantly. The lutein and β-carotene content decreased to 63.83 μg/g and 28.3 μg/g, respectively. The total polyphenols content increased to 50.19 mg/g. Meanwhile, the a* value was significantly and positively correlated with polyphenols content and negatively correlated with pigments content. Cluster analysis showed that the samples were divided into three categories: samples with the curing time of 0 h, 24–72 h, and 84–132 h. These results demonstrated that the color change of tobacco during curing process can be divided into three stages from the perspective of chemical composition, which are strongly related to the degradation of pigments and the transformation of polyphenols.

Similar content being viewed by others

Introduction

In the growth, development and maturity stage of plants, the change of color has been widely concerned by people1. The change of plant appearance color not only involves the regulation of proteins and other molecules, but also involves a series of complex biological processes such as material metabolism. The color change of tobacco curing has always been the focus of research in the tobacco industry2,3. Color change is an important index of flue-cured tobacco quality4,5. Moreover, the color of tobacco leaves is related to the sensory quality, and it is also an important factor for tobacco farmers to pick flue-cured tobacco leaves6.

Tobacco curing process from the appearance of the color change and moisture loss, reasonable tobacco curing is a process of tobacco moisture loss and yellowing coordination. The main physiological and biochemical processes include the decomposition and transformation of carbohydrates, proteins and pigments, the formation of aroma-inducing substances, and the change of polyphenol oxidase activity7,8. The color of tobacco leaves is determined by a variety of coloring substances, such as pigments. According to the chemical structure, the pigments contained in tobacco can be divided into the following four categories: pyrrole pigments represented by chlorophyll, polyene pigments represented by carotenoids, phenolic pigments represented by flavonoids, and ketone pigments represented by betaine. The color of tobacco leaves is the comprehensive expression of pigments in fresh leaves and coloring substances formed by browning reaction during curing. The plant pigments in fresh tobacco leaves are mainly composed of chlorophyll, β-carotene, neoxanthin and violaxanthin9,10.

Pigments are one of the most important influencing factors in the formation of color during tobacco curing11. After curing, the pigments inside the tobacco leaves are decomposed and transformed, which will affect the color of the tobacco leaves12. The yellowing of tobacco is a reflection of organic substance transformation, which is an enzymatic process. Moreover, the appearance of tobacco color from green to yellow indicates that the enzymatic process has been completed. Meanwhile, with the decrease of moisture content in the tobacco during curing, the enzyme activity is weakened or terminated, which will lead to the decrease of the change rate of chemical substances, and the yellow color of the tobacco is fixed13. Throughout the curing process, chlorophyll degrades completely with time, while the proportion of carotenoid in the total pigment increases gradually with curing time and develops to a dominant position10. The appearance of tobacco leaves at the end of curing is yellow. In addition, carotenoid is an important source of tobacco flavor and has a significant effect on tobacco quality. Thus, carotenoid was chosen to study the relationship between tobacco color and pigments. Furthermore, the molecular mechanism of tobacco leaf pigment metabolism was studied using isobaric tags for relative and absolute quantification (iTRAQ) proteomics approach2.

Phenolic pigments are polyphenol derivatives, also known as plant polyphenols14,15. Polyphenols have a great influence on the color change of tobacco leaves. Polyphenol oxidase (PPO) oxidizes polyphenols to quinone, which undergoes a series of reactions to produce brownish-yellow substances to realize the curing process of tobacco leaves from green to yellow. Therefore, it is necessary to effectively control the enzymatic oxidation of polyphenols during curing to improve the appearance quality of tobacco leaves. Meanwhile, the temperature and time of curing also influence the decomposition and transformation of pigments, which affects the color of tobacco leaves16,17. The previous study reported that the retention rates of Maillard reaction compounds and carotenoid degradation products decreased by 14.5% and 9.4% with raising the temperature (10 °C)18. Therefore, the parameters of curing need to be controlled to obtain the desired color and quality of tobacco.

In this study, the middle part of tobacco leaves variety K326 produced in Nanping, Fujian Province, China, were used as test materials. The aim is to characterize the relationship between color characteristics and pigments content in tobacco leaves during curing through analysis of variance (ANOVA), correlation analysis, principal component analysis (PCA) and cluster analysis, which can provide a basis for further optimization of tobacco curing process.

Materials and methods

Plant materials

Variety K326 was planted in Nanping City, Fujian Province, China. Before sampling, tobacco leaves with principally the same growth, relatively consistent leaf color and leaf size, and principally the same field quality were selected as test materials. The tobacco leaves from the middle part were taken and cured generally in the tobacco baking room with a three-stage curing process. The process was divided into three stages: yellowing stage, color fixing stage and dry tendon stage. The key temperature point parameters and tobacco change targets during the curing process are shown in Table 119.

During the curing process, tobacco samples were collected from the upper, middle and lower layers of the tobacco baking room once at 24 h, and after collecting twice, once at 12 h until the leaves were dry. A total of ten groups of tobacco samples were taken, forty pieces in each group. Ten pieces were used for color determination, and ten pieces were used for moisture determination. After removing the main vein, twenty pieces were freeze-dried using a freeze-dryer (FreeZone2.5Plus, Labconco, USA) before the determination of pigments and polyphenols.

Analysis of samples

Determination of the color

During the curing process, a portable spectrophotometer (Ci64, X-rite, USA) was used to measure the lightness value (L*), greenness/redness value (a*), blueness/yellowness value (b*), color ratio (H*), hue (H°), saturation (C*) and color difference (ΔE) of ten pieces of tobacco leaves selected from each time point. According to the previously reported method, each tobacco leaf was determined at six measurement points20.

Determination of moisture content of wet basis

Tobacco leaves were placed in an oven and the moisture content of wet basis was determined using the heated-drying method. Ten pieces of tobacco leaves were dried at 105 ± 3 °C for at least 2 h, and the moisture content of wet basis of tobacco leaves was determined. The moisture content of wet basis is derived from the difference in mass of the tobacco before and after oven drying divided by the mass before oven drying21.

Determination of pigment content

A sample (2 g) was accurately weighed into the conical flask (50 mL), mixed with 25 mL 90% acetone, and sonicated for 20 min. Next, approximately 2 mL of the mixture was removed from the flask and filtered through a 0.45 µm organic membrane, with the filtrate collected in a high-performance liquid chromatography (HPLC) vial. The content of lutein and β-carotene in the filtrate were determined using HPLC22.

Determination conditions of HPLC: pigments were separated on a reversed-phase C18 column (Particle size 4 μm, 3.9 mm i.d. × 150 mm), with a mobile phase of (A) isopropanol and (B) acetonitrile (80%) using a gradient elution at a flow rate of 1.5 mL/min. The optimum elution gradient was as follows: 0–40 min, 100% B; 40–46 min, 100% A. The column temperature was 30 °C, and the injection volume was 10 μL. The detection wave length was 448 nm.

Determination of polyphenol content

A sample (0.1 g) was accurately weighed into the conical flask (50 mL), mixed with 20 mL 50% methanol, and sonicated for 20 min. Next, approximately 2 mL of the mixture was removed from the flask and filtered through a 0.45 µm hydrophilic membrane, with the filtrate collected in a HPLC vial. The content of chlorogenic acid, neochlorogenic acid, caffequinic acid, scopoletin, rutin and kaempferol glycosides in the filtrate was determined using HPLC23,24.

Determination conditions of HPLC: polyphenols were separated on a reversed-phase C18 column (Particle size 5 μm, 4.6 mm i.d. × 250 mm), with a mobile phase of (A) water–methanol-acetic acid (10:88:2, v/v/v) and (B) water–methanol-acetic acid (88:10:2, v/v/v) using a gradient elution at a flow rate of 1 mL/min. The optimum elution gradient was as follows: 0–16.5 min, 100% A, 16.5–30 min, 80% A + 20% B, 30–40 min, 20% A + 80% B. The column temperature was 30 °C, and the injection volume was 10 μL. The detection wave length was 340 nm.

Data analysis

All experiments were carried out in triplicate according to independent replicate experiments, and the results were reported as mean value ± standard deviation. Significant difference analysis was executed by one-way ANOVA using SPSS Statistics 21.0 (SPSS Inc., Shanghai, China), Duncan’s test was used in post hoc analysis, and a probability value (P ≤ 0.05) indicated that the difference between the means was statistically significant. Origin 2021 software (OriginLab Corporation, USA) was used to operate PCA and draw correlation heatmap and hierarchical clustering heatmap.

Ethics declarations

The authors declare that the collection of plant material (tobacco leaves) and the experimental studies complied with the relevant institutional, national and international guidelines and legislation. The authors confirm that all methods were carried out in accordance with relevant guidelines in the method section. The authors comply with the IUCN Policy Statement on Research Involving Species at Risk of Extinction and the Convention on the Trade in Endangered Species of Wild Fauna and Flora.

The authors ensure that the collection of tobacco leaves samples had been licensed by the local tobacco production regulatory agency.

Results and discussion

Significance analysis

Color change of tobacco leaves

With the progress of curing in tobacco leaves, the indexes of color were significantly different before and after 24 h in Table 2. In the whole process of curing, the difference among the upper, middle and lower layers of color was not significant in tobacco baking room. With the increase of curing time, the L* value and the b* value of the tobacco leaves first increased and then decreased. The former achieved the maximum value (71.8) at 72 h and the latter (59.0) at 24 h. While the a* value of tobacco leaves progressively increased. The C* value and the H° value also increased and then decreased, both of which reached the maximum at 24 h. The H* was rising, while the ΔE value first rose and then stabilized after 24 h. The results are consistent with the drying process results of Radix Paeoniae Alba (RPA) slice25. The L* value decreased as the moisture content of wet basis decreased, while the a* value and the b* value increased with the decrease in the moisture content of wet basis. On the whole, the color of tobacco leaves changed significantly from green to yellow in the early stage (from 0 to 72 h), and the yellowness of tobacco leaves deepened in the later stage (from 72 to 132 h).

Moisture content of wet basis change of tobacco leaves

The moisture content of wet basis of the upper, middle and lower layers of tobacco leaves in tobacco baking room was significantly different in Fig. 1. From the beginning to the end of curing, the moisture content of wet basis of the tobacco leaves decreased to 15–20%. Before the curing time (72 h), the moisture content of wet basis changed little. The moisture content of wet basis decreased substantially from the curing time 72 h to 108 h. After that, the moisture content of wet basis tended to be stable. These results indicated that the water loss of tobacco leaves during the curing process was slow in the early stage (from 0 to 72 h), accelerated in the middle stage (from 72 to 96 h), and stabilized in the later stage (from 96 to 132 h). In the study of the moisture distribution and state of stemless tobacco leaves during curing, the moisture content of wet basis was about 10%. The plant material was Variety Yunyan 87, and it was planted in Luoyang City, Henan Province26. The equilibrium moisture content was lower in Luoyang tobacco and higher in Fujian27. The experimental results of Yunyan 87 were different from the results of this experiment, it might be caused by the different humidity in the two places28.

The change of lutein and β-carotene content in tobacco leaves

From the beginning to the end of tobacco curing, the difference between the upper, middle and lower layers of pigments content was significant in tobacco baking room in Fig. 2, and the lutein and β-carotene content was significantly higher in the upper and lower layers than in the middle layer. This may be caused by uneven heating of tobacco leaves at different positions in tobacco baking room29. The lutein content of the tobacco leaves decreased continuously with the increase of curing time. The content of β-carotene and lutein decreased rapidly until 48 h, while the content decreased slowly after that. The results demonstrated that the trend in β-carotene content followed that in lutein content. During the curing process, the substances of tobacco leaves were oxidized and decomposed by the action of lipoxygenase, and intermediate products such as violaxanthin, geraniol and violetone were formed11. The decrease in the content of both may be related to this reason.

The changes of plastid pigments in tobacco leaves under different curing time. Different letters indicated significant differences at different times (P ≤ 0.05). (A) The change of the lutein content in tobacco leaves under different curing time. (B) The change of the β-carotene content in tobacco leaves under different curing time.

Polyphenols changes of tobacco leaves

During the whole process of tobacco curing, the polyphenols content was not significantly different in the upper, middle and lower layers of the tobacco baking room in Table 3. With the increase of curing time, the content of chlorogenic acid, neochlorogenic acid and caffequinic acid in tobacco leaves increased continuously. The content of rutin and kaempferol glycoside in tobacco leaves first increased and then decreased, reaching the maximum value between 96 and 108 h. The content of scopoletin in tobacco leaves showed a trend of first increasing, decreasing and then increasing, reaching the great value with 48 h and 120 h, respectively. In addition, the total polyphenols content showed a trend of increasing. The changes of polyphenolic compounds were very intense during the curing period of tobacco leaves, and the total polyphenolic compounds increased significantly due to the pyrolysis and enzymatic decomposition of phenol glycosides30. Polyphenols can be pyrolyzed into dibasic phenolic and furfural derivatives. Moreover, polyphenols are easily oxidized to produce light red to dark brown quinones and their polymers under the action of peroxidase and polyphenol oxidase, resulting in the color change of tobacco leaves from yellow to orange or different degrees of brownish-brown. The polyphenolic substances and their oxidation products can also occur with amino acids, sugars and minerals enzymatic browning reaction, forming many complex pigments of different molecular weight and color, which also have a vital impact on the formation of tobacco color31.

Correlation of color, moisture content of wet basis, pigments and polyphenols of tobacco leaves

As shown in Fig. 3, the color of tobacco leaves was significantly correlated with the moisture content of wet basis, pigments and polyphenols content during curing. The moisture content of wet basis of tobacco leaves was significantly and negatively correlated with polyphenols content, and it was significantly and positively correlated with the a* value. It could be due to the decrease in the moisture content of wet basis of tobacco leaves affects the activity of PPO and the content of malondialdehyde (MDA), which causes change in polyphenols content28. Meanwhile, the moisture content of wet basis was significantly and negatively correlated with the b* value. The a* value was significantly and positively correlated with polyphenols content and negatively correlated with pigments content. It may be due to the non-enzymatic browning (Maillard reaction). Due to the acceleration of Maillard reaction at higher temperatures, the interaction between sugars and amino acids is easy to form brown compounds, resulting in darker color23. The pigments content of tobacco leaves was significantly and negatively correlated with polyphenols content. Overall, the change in apparent color of tobacco leaves during curing was closely related to the content of intrinsic pigment classes.

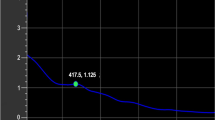

PCA

Each index with a correlation coefficient greater than 0.50 was selected for PCA analysis with each curing time point. The main data information of the samples with different curing time points between each index was extracted by PCA to show the similarity between the samples. As shown in Fig. 4, the cumulative contribution of the first two principal components in the variance reached 93.1%, which indicated that these two principal components could represent most of the information on the curing characteristics of the samples. The PC1 was negatively correlated with the first four samples with curing time (0–60 h), while it was positively correlated with the other six samples (curing time of 72–132 h). In addition, the PC2 was positively correlated with the samples (curing time of 24–72 h), while it was negatively correlated with the other samples (curing time of 0 h and 84–132 h). The results showed that the curing characteristics of the samples with curing time (0–60 h) were statistically significantly different from those with curing time (72–132 h). This may be related to the yellowing stage of tobacco curing32. The yellowing stage starts from curing and generally takes from 24 to 72 h.

Cluster analysis

Cluster analysis is one of the most important techniques for data mining and exploratory data analysis33. Each index with a correlation coefficient greater than 0.50 was selected for cluster with each curing time point.

In terms of each curing characteristic indicator, it could be divided into three categories (Fig. 5). The first category contained chromaticity and scopoletin content, the second category included the contents of chlorogenic acid, neochlorogenic acid, caffequinic acid, rutin, kaempferol glycosides and the total polyphenols, and the third category was composed of pigments content and moisture content of wet basis. Scopoletin content was not classified with other polyphenols contents, and it belonged to the coumarin class and had a different mechanism of action28. Moisture content of wet basis and pigments content were separated in one category. This was consistent with the analysis of significant differences. It showed that the results of moisture content of wet basis decrease and pigment degradation during curing were accurate and reliable.

From the samples of each curing time, they could be divided into three categories (Fig. 5). The first category contained samples with curing time (0 h), the second category included samples with curing time (24–72 h), and the third category was composed of samples with curing time (84–132 h). The results showed that tobacco curing could be divided into three stages. The color of fresh tobacco leaves changed from green to light yellow, and finally to brownish yellow. This corresponded to the yellowing stage, the color fixing stage and the dry tendon stage of tobacco curing19.

Conclusions

The content of pigmented substances affected the color change of flue-cured tobacco to a certain extent. During the curing process, the lutein content and β-carotene content decreased to 63.83 μg/g and 28.3 μg/g, respectively. The total polyphenols content increased to 50.19 mg/g. Meanwhile, the a* value was significantly and positively correlated with the content of chlorogenic acid, neochlorogenic acid, caffequinic acid, scopoletin, rutin and kaempferol glycosides. The a* values of tobacco leaves were negatively correlated with lutein and β-carotene content. The PCA showed that the curing characteristics of the samples with curing time (0–60 h) were statistically significantly different from those with curing time (72–132 h). Cluster analysis showed that the samples were divided into three categories: samples with the curing time of 0 h, 24–72 h, and 84–132 h. The degradation of pigments and transformation of polyphenolic substances had a combined effect on the color of tobacco leaves during curing, causing a change in color to a deeper golden, deep yellow and brownish yellow. Properly controlling the degradation and conversion of pigmented substances will be helpful to make flue-cured tobacco reach the desired color.

Data availability

The data presented in this study are available on request from the corresponding author.

References

Pina, F. et al. Evolution of flavylium-based color systems in plants: What physical chemistry can tell us. Int. J. Mol. Sci. 22, 3833. https://doi.org/10.3390/ijms22083833 (2021).

Wu, S. et al. Comparative proteomic analysis by iTRAQ reveals that plastid pigment metabolism contributes to leaf color changes in tobacco (Nicotiana tabacum) during curing. Int. J. Mol. Sci. 21, 2394. https://doi.org/10.3390/ijms21072394 (2020).

Condorí, M., Albesa, F., Altobelli, F., Duran, G. & Sorrentino, C. Image processing for monitoring of the cured tobacco process in a bulk-curing stove. Comput. Electron. Agric. 168, 105113. https://doi.org/10.1016/j.compag.2019.105113 (2020).

Chen, Y. et al. Dynamic changes in physiological and biochemical properties of flue-cured tobacco of different leaf ages during flue-curing and their effects on yield and quality. BMC Plant Biol. 19, 555. https://doi.org/10.1186/s12870-019-2143-x (2019).

Li, Y. et al. Metabolome of flue-cured tobacco is significantly affected by the presence of leaf stem. BMC Plant Biol. 23, 89. https://doi.org/10.1186/s12870-023-04093-2 (2023).

Zong, J. et al. Effect of two drying methods on chemical transformations in flue-cured tobacco. Drying Technol. 40, 188–196. https://doi.org/10.1080/07373937.2020.1779287 (2020).

Wang, Y. & Qin, L. Research on state prediction method of tobacco curing process based on model fusion. J. Ambient. Intell. Humaniz. Comput. 13, 2951–2961 (2021).

Liu, A. et al. Metabolomics and proteomics revealed the synthesis difference of aroma precursors in tobacco leaves at various growth stages. Plant Physiol. Biochem. 192, 308–319 (2022).

Sigurdson, G. T., Tang, P. & Giusti, M. M. Natural colorants: Food colorants from natural sources. Annu. Rev. Food Sci. Technol. 8, 261–280. https://doi.org/10.1146/annurev-food-030216-025923 (2017).

Song, Z. et al. The mechanism of carotenoid degradation in flue-cured tobacco and changes in the related enzyme activities at the leaf-drying stage during the bulk curing process. Agric. Sci. China 9, 1381–1388 (2010).

Armarego-Marriott, T. et al. Highly resolved systems biology to dissect the etioplast-to-chloroplast transition in tobacco leaves. Plant Physiol. 180, 654–681. https://doi.org/10.1104/pp.18.01432 (2019).

Wang, L. et al. Intelligent tobacco flue-curing method based on leaf texture feature analysis. Optik 150, 117–130 (2017).

Zhang, Q. et al. Microbial and enzymatic changes in cigar tobacco leaves during air-curing and fermentation. Appl. Microbiol. Biotechnol. 107, 5789–5801 (2023).

McGrath, T. E., Brown, A. P., Meruva, N. K. & Chan, W. G. W. G. Phenolic compound formation from the low temperature pyrolysis of tobacco. J. Anal. Appl. Pyrolysis 84, 170–178. https://doi.org/10.1016/j.jaap.2009.01.008 (2009).

Matheis, G. & Whitaker, J. R. Modification of proteins by polyphenol oxidase and peroxidase and their products. J. Food Biochem. 8, 137–162. https://doi.org/10.1111/j.1745-4514.1984.tb00322.x (1984).

Tang, Z. et al. Climatic factors determine the yield and quality of Honghe flue-cured tobacco. Sci. Rep. 10, 19868. https://doi.org/10.1038/s41598-020-76919-0 (2020).

Li, Y. et al. Cold stress in the harvest period: Effects on tobacco leaf quality and curing characteristics. BMC Plant Biol. 21, 131. https://doi.org/10.1186/s12870-021-02895-w (2021).

Zhu, W. K. et al. Effect of two-stage dehydration on retention of characteristic flavor components of flue-cured tobacco in rotary dryer. Drying Technol. 34, 1621–1629. https://doi.org/10.1080/07373937.2016.1138965 (2016).

Liu, H., Duan, S. & Luo, H. Design and temperature modeling simulation of the full closed hot air circulation tobacco bulk curing barn. Symmetry 14, 1300. https://doi.org/10.3390/sym14071300 (2022).

Su, H. & Lv, H. Data research on tobacco leaf image collection based on computer vision sensor. J. Sens. 1–11, 2021. https://doi.org/10.1155/2021/4920212 (2021).

Nirmaan, A. M. C., Rohitha Prasantha, B. D. & Peiris, B. L. Comparison of microwave drying and oven-drying techniques for moisture determination of three paddy (Oryza sativa L.) varieties. Chem. Biol. Technol. Agric. 7, 2394. https://doi.org/10.1186/s40538-019-0164-1 (2020).

Ligor, M. & Buszewski, B. Study of xanthophyll concentration in spinach leaves by means of HPLC coupled with UV–VIS and corona CAD detectors. Food Anal. Methods 5, 388–395. https://doi.org/10.1007/s12161-011-9256-7 (2011).

Long, M. et al. Effect of different combined moistening and redrying treatments on the physicochemical and sensory capabilities of smoking food tobacco material. Drying Technol. 36, 52–62. https://doi.org/10.1080/07373937.2017.1299752 (2017).

Ji, X., Liu, G. & Chen, H. Quantitative determination of polyphenols in tobacco leaves by HPLC. Food Agric. Environ. 11, 868–870 (2013).

Meng, Y., Song, C., ElGamal, R. & Liu, C. Relationship between heat/mass transfer and color change during drying process. J. Food Meas. Charact. 16, 4151–4160. https://doi.org/10.1007/s11694-022-01497-w (2022).

Wei, S. et al. Investigation on water distribution and state in tobacco leaves with stalks during curing by LF-NMR and MRI. Drying Technol. 36, 1515–1522. https://doi.org/10.1080/07373937.2017.1415349 (2018).

Lin, C. et al. Regulating water binding capacity and improving porous carbohydrate matrix’s humectant and moisture proof functions by mixture of sucrose ester and Polygonatum sibiricum polysaccharide. Int. J. Biol. Macromol. 147, 667–674 (2020).

Zhao, S., Wu, Z., Lai, M., Zhao, M. & Lin, B. Determination of optimum humidity for air-curing of cigar tobacco leaves during the browning period. Ind. Crops Prod. 183, 114939. https://doi.org/10.1016/j.indcrop.2022.114939 (2022).

Sun, J. et al. Simultaneous measurement of temperature-dependent thermal conductivity and heat capacity of an individual cured tobacco leaf. Int. J. Thermophysics 42, 132. https://doi.org/10.1007/s10765-021-02881-2 (2021).

He, Q. et al. Estimating the aroma glycosides in flue-cured tobacco by solid-phase extraction and gas chromatography-mass spectrometry: Changes in the bound aroma profile during leaf maturity. Flavour Fragr. J. 30, 230–237. https://doi.org/10.1002/ffj.3235 (2015).

Vhangani, L. N. & Van Wyk, J. Heated plant extracts as natural inhibitors of enzymatic browning: A case of the Maillard reaction. J. Food Biochem. 45, 24. https://doi.org/10.1111/jfbc.13611 (2021).

Rochester, M. The chemical changes that occur during the curing of tobacco leaves. Science 73, 397–399 (1931).

Zou, H. Clustering algorithm and its application in data mining. Wirel. Pers. Commun. 110, 21–30. https://doi.org/10.1007/s11277-019-06709-z (2019).

Acknowledgements

This work was supported by the Key Science and Technology Project of CNTC (Grant No. 110202101084), the Science and Technology Project of Henan tobacco company (Grant No. 2021410000240019), the University Student Innovation and Entrepreneurship Training Programs (Grant No. 202310463017), the Young Key Teachers Training Program of Henan University of Technology, and the Natural Science Innovation Fund for Science and Technology Team of Henan University of Technology (Grant No. 2020ZKCJ20).

Author information

Authors and Affiliations

Contributions

Conceptualization: Y.W., W.G.; Data curation: Y.M., Y.W.; Formal analysis: Y.M., K.L.; Funding acquisition: Y.W.; Investigation: Y.M., H.X., Y.W., Z.C.; Methodology: Y.M., Y.W., W.G.; Project administration: Y.W.; Resources: Y.W., W.G.; Software: Y.M., Y.W.; Supervision: Y.W., W.G.; Validation: A.W., Q.X., J.L., Q.Z.; Visualization: Y.M., Y.W.; Writing—original draft: Y.M.; Writing—review and editing: Y.W., W.G. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests. Weimin Guo, Zuxiao Chen, Aiguo Wang and Qiang Xu were employed by Zhengzhou Tobacco Research Institute of CNTC (Zhengzhou, China). Jianjun Liu was employed by Henan Provincial Tobacco Company (Zhengzhou, China). Qiang Zeng was employed by Nanping Branch of Fujian Provincial Tobacco Company (Nanping, China). The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Meng, Y., Wang, Y., Guo, W. et al. Analysis of the relationship between color and natural pigments of tobacco leaves during curing. Sci Rep 14, 166 (2024). https://doi.org/10.1038/s41598-023-50801-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-50801-1

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.