Abstract

In fact, bonding of zirconia restorations is still a big challenge in clinical situations and many bonding protocols discussed in literature might be still controversial. The aim of this was to study assess the bond strength of zirconia after alumina and glass-bead pre-treatments with two different primers in combination with conventional resin cement and 10-methacryloyloxydecyl dihydrogen phosphate (MDP) containing self-adhesive resin cement without priming. Fully sintered high translucent zirconia samples (n = 160) were assigned into 2 groups of pre-treatments (n = 80): Alumina-sandblasting (AB) and Glass-bead (GB). Then, each group was divided into 4 sub-groups according to priming and cement used (n = 20 each): conventional self-adhesive resin cement, MDP-silane Primer, MDP primer both with conventional self-adhesive resin cement, and MDP contained cement. Shear bond strength (SBS) was measured after thermocycling. Failure mode was analyzed using stereomicroscope. Contact angle and surface topography were investigated using other fully sintered samples (n = 30) constructed for that sole purpose, divided into control (no pre-treatment [unmodified], alumina-, and glass-bead sandblasted groups). Two-way ANOVA was performed for SBS and failure mode was analyzed. The use of Alumina-sandblasting showed higher SBS compared to Glass-bead pre-treatment for MDP-silane primer (p = 0.034) and MDP primer (p < 0.001). While MDP contained cement showed higher but insignificant SBS when pre-treated with glass-beads. Alumina-sandblasting and glass-bead pre-treatments improve bond strength of zirconia combined using primers before cementation with conventional resin cement. Also, self-adhesive MDP contained cement along with surface pre-treatment showed the highest achievable bond strength. It was concluded that both alumina-sandblasting and glass-bead blasting improved SBS combined with MDP containing self-adhesive resin cement reducing the required clinical steps during cementation of zirconia restorations.

Similar content being viewed by others

Introduction

Nowadays, the demand for highly esthetic restorations is increasing in everyday dental practice owing to the fast-paced evolvement and innovation in digital dentistry. Dental zirconia is considered one of the most commonly used restorative materials due to its high mechanical properties compared to glass ceramics1. That leads to increase the range of indications in the field of fixed prosthodontics and indirect restorations, but earlier zirconia generations suffered from lower translucency, higher opacity and hence, less superior esthetics as it is composed of dense polycrystalline structure with no glass matrix when compared to glass ceramics limiting its use to posterior region2. To improve the optical properties, increasing the yttria content to 5 mol% yttria-stabilized tetragonal zirconia polycrystals (5Y-TZP) resulting in 50% cubic phase compared to conventional 3 mol% yttria stabilized tetragonal zirconia3,4,5 thus improving the overall aesthetics and resulted in the introduction of new class of ultra-translucent zirconia.

The bonding of zirconia to tooth tissues or other synthetic materials is controversial when compared to silica-based ceramic material due to its chemical inertness and resistance to aggressive chemical agents (strong acid, alkalis, organic and inorganic dissolving agents6. The incidence of loss of retention for zirconia restorations was 4.7% over the 5-year observation period7, and it is the directly caused by the deboning between the various adhesive interfaces within that structure8.

There are many ways for increasing the bond strength between zirconia ceramic and resin cement had been investigated in literature, either mechanical, chemical, and/or chemico-mechanical surface pre-treatment methods9,10,11. Two published meta-analyses have confirmed the importance of the combined mechano-chemical surface treatment for improving the bond strength of zirconia with resin cements12, 13. Mechanically, air-borne-particle abrasion, tribochemical airborne-particle abrasion, low-fusion porcelain application, hot chemical etching solutions, selective infiltration etching, laser irradiation, plasma spraying, and zirconia ceramic powder coating were proposed, while zirconia primers with 10-Methacryloyloxydecyl dihydrogen phosphate (10-MDP) molecule and its salt were proposed to alter the zirconia surface chemistry9, 14,15,16,17.

The air abrasion method with alumina particles showed the highest bond strength in comparison with other surface conditioning methods18. However, that alumina air abrasion produces surface defects such as flaws, plastic deformation, embedded abrasive alumina, and microcracks, which can compromise the mechanical properties of zirconia and decrease fracture strength19. To decrease the defect to zirconia surface, the use of glass beads as a softer material than sharp and hard alumina was suggested by Khanlar et al., in 2022, followed by 10-MDP & silane primer which reported a desirable bonding performance without creating surface microcracks on zirconia20.

There are scarce reports on the effect of glass-beads blasting as a mechanical bonding method either alone or combined chemically with different zirconia primers. Hence, this in vitro study was conducted to evaluate the effect of alumina-sandblasting and glass-bead blasting on bond strength of high translucent (5Y-TZP) zirconia solely or combined with different formulations of zirconia primers and MDP contained self-adhesive resin cement without subsequent priming. The null hypotheses tested were that 1. sandblasted zirconia either with alumina- and/or glass-beads will show similar bond strength, 2. different MDP-primers will not affect the bond strength to zirconia 3. MDP containing self-adhesive resin cement will show a similar result to other MDP-primers tested.

Materials and methods

Materials

The tested substrate is a high translucent yttria-stabilized tetragonal zirconia polycrystals specimens (5Y-PSZ; Liaoning Upcera Co., Ltd. Liaoning, China). An MDP-Silane primer (Visalys retoration primer, Kettenbach GmbH & Co. KG, Eschenburg, Germany) and an MDP-BPDM primer (Z-prim, Bisco Inc., IL, USA) were used. For cementation, conventional resin cement (Visalys CemCore, Kettenbach GmbH & Co. KG) and self-adhesive resin cement (Z-prim, Bisco Inc.) were used in the current study. The full compositions of used materials are listed in Table 1.

Samples preparation and grouping

A total of 160 squares samples of 5Y-PSZ (10 × 10 × 3 mm before sintering) using a low-speed precision saw machine (Isomet 4000, Buehler, Lake Bluff, IL, USA) in a dry condition without water coolant. Another 160 disc shaped samples of a 4 mm dimeter and 3 mm thickness were used to be cemented to each other for shear bond strength evaluation. For surface roughness and contact angle measurements, another 30 square samples with previously mentioned dimensions were utilized. All samples were sintered utilizing a 7-stages cycle at 1450℃ following the manufacturer instruction in zirconia furnace (Lindberg/Blue M, Asheville, NC, USA). Sintering process parameters are listed in Table 2.

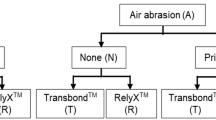

For shear bond strength analysis, the fully sintered samples [both square and disc shaped (n = 160 each)] were divided equally into two groups according to the pre-treatment protocol (n = 80 each); Alumina-sandblasting (AB) and Glass-beads (GB) groups. Each group was further sub-divided into 4 sub-groups according to the cementation protocol (n = 20 each); 1. no priming + conventional resin cement, 2. MDP-silane primer + conventional resin cement, 3. MDP-BPDM primer + conventional resin cement and 4. MDP containing resin cement without subsequent priming. A graphical presentation of the methodology is presented in Fig. 1.

Schematic represntation of the methdology implanted in the curunt reserch. (A – F) represnets the steps for shear bond strength testing. A: 160 Square and 160 disc shaped samples prepared. B:Sinitring was done according to Table 2. C: Pre-treatment with Alumina-sandblasting (AB) and Glass-beads (GB). D: Each group was sub-divided into 4 sub-groups according to the cementation protocol (n = 20 each); 1. no priming + conventional resin cement, 2. MDP-silane primer + conventional resin cement, 3. MDP-BPDM primer + conventional resin cement and 4. MDP containing resin cement without subsequent priming. E: After cementation, thermocycling for 10,000 cycle. F.Samples attached to universial testiong machine accodring to schamtic illustartion for Shear bond strentght. (G – J) represnts the surface parmater and contact angle measurments. G:30 square samples were prepaperd and sintered according to Table 2 steps. H: Samples were dividedinto three groups; control (no pre-treatment), Alumina-sandblasting (AB), and Glass-beads (GB). I: Sample were tested using 3D-CLSM for surface roughness parmaters. J: Sample were tested using contact angle measuring device.

Bonding protocols

A 600-grit silicon carbide paper was used to polish all samples before cementation. AB and GB groups were blasted with 50 µm Al2O3 (Kulzer, GmbH, Germany) and 75 µm Glass-beads particles respectively. The blasting time for both groups were 20 s at a pressure of 25 psi at a 10 mm distance and 90° angle using a sandblasting device (Microetcher IIA, Danville Materials, SanRamon, CA, USA). Afterwards, all samples were cleaned using ultrasonic cleaner (Easyclean MD, Renfert, GmbH, Germany) filled with distilled water for two minutes and then completely dried with oil-free air.

Each large square-shaped sample was bonded to the smaller disc-shaped sample. For the conventional resin cement groups, a dual cured resin cement (Visalys Cem-Core, Kettenbach GmbH & Co. KG, Eschenburg, Germany) was applied after alumina & glass-beads sandblasting respective to each group with no prior priming. For MDP-silane primer group: MDP-Silane primer (Visalys Restorative Primer, Kettenbach GmbH & Co. KG, Eschenburg, Germany) was applied by a micro-brush and left to dry for 60 s and air dried, then conventional resin cement was applied. For MDP-BPDM primer groups, samples were primed with 2 coats of MDP-BPDM primer (Z-Prime Plus, BISCO Inc., IL, USA) for 5 s then gentle air jet was applied followed by conventional resin cement. For MDP-containing self-adhesive resin cement group, all samples were cemented with dual-cured MDP-containing self-adhesive resin cement (TheraCem, Bisco Inc., IL, USA) with no prior priming. A static standard load of 5 kg was applied to all samples during cementation with the aid of a loading device12 and cement curing were initiated using LED light with a curing intensity of 1500 mW /cm2 (Eighteen CuringPen, Sifary medical technologies, Jiangsu Province, China) for 40 s.

Shear Bond Strength (SBS) testing and failure mode analysis

All samples were aged by the aid of a thermocycler (SD Mechatronik, Germany) to induce hydro-thermal stresses within the tested material and the cement interface. The bonded samples were subjected to 10,000 cycles by immersing in distilled water bath of 5 °C and 55 °C with a dwell time of 20 s and a lag time of 10 s simulating one year of clinical service in the oral cavity13. A universal testing machine (Instron, model 3345, England) was used to measure and record the shear bond strength values with a crosshead speed of 1 mm/min. For the mode of failure analysis, a stereomicroscope (Olympus, Tokyo, Japan) was used at a magnification of 20 × to examine the de-bonded interface and failure was categorized as; adhesive failure “A”, cohesive failure “C” and mixed failure “M”.

Surface topography parameters

For surface roughness, 30 square fully sintered samples were divided into 3 groups according to type of pre-treatment (n = 10 each), into control group (no alumina or glass beads sandblasting), Alumina-sandblasting (AB) and Glass-beads (GB).The samples were analyzed using a 3D confocal laser scanning microscope (CLSM, Keyence VK-X100, Keyence, Japan) with a 50 × magnification (scanning area 205 × 273.3 μm) and a MultiFile Analyzer software (V.1.3.1.120, Keyence) was used to analyze obtained scans. Arithmetical mean height (Sa), developed interfacial area ratio (Sdr) and texture aspect ratio (Str) values were recorded and analyzed.

Contact angle measurements

After measuring surface roughness parameters, the same samples were used to measure the surface wettability adopting sessile drop method using deionized water by the aid of a contact angle measuring device (DSA25B, Krüss GmbH, Germany). For each sample, 3 readings were recorded for 3 different drops and the average value was considered the mean reading for every tested sample. All mean values were reported for statistical analysis.

Statistical analysis

Sample size was calculated based on data extracted from Khanlar et. al. 202220. A minimum of 20 samples in each group will be sufficient to detect a power of 95% when α = 0.05. The mean for control was 9.2 and for AB was 11.7 with a standard deviation equals to 2 resulted in an effect size (d) of 1.2. Sample size was calculated using G*Power version 3.1.9. Data explored for normality using Shapiro–Wilk test. Two-way ANOVA used to compare between tested pre-treatment and primer/cement followed by Tukey’s HSD test for pairwise comparison. Additional, shear bond strength data were analyzed using Weibull analysis (R4, R Foundation for Statistical Computing, Vienna, Austria). Weibull parameters were calculated using Wald estimation, and 95% confidence intervals were calculated with Monte Carlo simulations. The different groups were compared at the characteristic strength (63.2% and 10% probability of failure). For surface roughness parameters and contact angle measurements, one-way ANOVA used to compare between tested groups followed by Tukey’s HSD test for pairwise comparison. (α = 0.05). Statistical analysis was performed with IBM SPSS Statistics for Windows, Version 26.0. Armonk, NY: IBM Corp.

Results

Shear bond strength (SBS)

Pre-treatment and primer/cement groups resulted in significant effect on shear bond strength at p = 0.003 and p < 0.001, respectively. The interaction between both variables resulted in a significant effect on shear bond strength at p = 0.002 as shown in Table 3. Results of pairwise comparison showed that, alumina sandblasting (AB) showed higher shear bond strength compared to glass beads (GB) for MDP-silane (p = 0.034) and MDP-BPDM (p < 0.001) groups. While for both conventional resin cement groups and MDP containing self-adhesive resin cement showed insignificant difference when pre-treated with AB and GB. For AB pre-treated groups, conventional resin cement showed the lowest significant shear bond strength compared to all other groups and insignificant difference resulted between MDP-silane primer, MDP-BPDM primer, and MDP containing cement. For GB pre-treated groups, conventional resin cement showed the lowest significant shear bond strength and MDP containing resin cement showed the highest shear bond strength compared to all other groups. Insignificant difference between MDP-silane primer and MDP-BPDM primer. Shear bond strength values for different tested groups are presented in Table 4.

Weibull analysis results presented in Table 5 and Fig. 2. The Weibull characteristic strength for conventional resin cement was significantly lower than all other groups primer/cement with AB and GB within insignificant difference between each other’s. For AB pre-treatment, an insignificant difference between MDP-Silane + Conventional cement, MDP-BPDM + Conventional cement, and MDP containing resin cement resulted for the Weibull characteristic strength. For GB pre-treatment, MDP containing resin cement showed the significantly highest Weibull characteristic strength compared to all other groups. AB + MDP-BPDM + Conventional cement and GB + MDP containing resin cement showed the highest Weibull modulus. Both ANOVA and Weibull analysis showed a similar results except that AB and GB were not signifcantley different in case of MDP-Silane Primer + conventional cement in case of Weibull analysis.

TThe Weibull survival graphs of the shear bond strength (MPa) of the tested groups. A horizontal dashed line at 63.2% probability of failure helps to compare the characteristic strengths. Vertical reference dashed line at 20 MPa and 40 MPa for comparing survival curves of the tested groups. MDP containing resin cement showed the highest characteristic strength compared to all other primers/cement protocol.

Failure mode

For glass beads (GB) pre-treatment, all the tested groups showed 100% adhesive failure. While for alumina sandblasting (AB) pre-treatment, all groups showed both mixed failure and adhesive failure. No group showed cohesive failure for both GB and AB. The mode of failure analysis is represented in Fig. 3 and a representative image for failure mode are presented in supplementary file.

Surface roughness parameters and contact angle (CA)

Results of surface roughness parameters and contact angle are presented in Fig. 4. For Sa, Control group (0.82 ± 0.04) and GB (0.84 ± 0.07) showed the lowest significant Sa values compared AB (0.97 ± 0.05) at p < 0.001. While for Sdr, Control group (1.20 ± 0.11) and AB (1.36 ± 0.70) showed the highest significant Sdr values compared GB (0.74 ± 0.14) at p < 0.001. For Str, Control group (0.85 ± 0.03) showed the lowest significant str values compared AB (0.77 ± 0.10) at p = 0.044. GB (0.79 ± 0.07) showed insignificant difference with both control and AB for Str values. Contact angle measurements showed that control group (50.53 ± 4.29) had the highest significant values compared AB (44.94 ± 2.12) at p = 0.038. GB (47.60 ± 2.34) showed insignificant difference with both control and AB for contact angle measurement.

Discussion

Over the last decades zirconia was introduced in dentistry to be used as a stronger alternative replacing weaker silica-based ceramics and increasing the range of its indications as a restorative alternative. However, bonding to zirconia has always been a major problem even with the development of more translucent monolithic alternatives since most of bonding protocols are based upon bonding to the glass matrix that can be eroded by the effect of a strong acid which is not the case with zirconia as it lacks the presence of the glassy matrix due to its polycrystalline nature.

This study investigated the bond strength to zirconia after alumina and glass-bead blasting with two different MDP-primers in combination with conventional resin cement, in addition to an MDP containing self-adhesive resin cement without priming. The tested null hypotheses were rejected as alumina- and glass-beads sandblasting combined with priming before cementation and MDP contained cement used solely showed higher bond strength when compared to sandblasted groups that were cemented with conventional resin cement with no priming.

The bond strength created between zirconia and the adhesive cement plays a major role in the success and longevity of dental restorations. A weak adhesion might be a major cause in crack formation in the restorative material that may reach the cement interface causing failure of a restoration21.

The results of this study revealed that alumina or glass-beads sandblasting combined with chemical surface treatments (primer) resulted in a significant increase in shear bond strength of 5Y-PSZ zirconia. In previous studies, it was found that air abrasion with alumina particles is the most preferred and reliable surface treatment method for high strength ceramics as it increases surface roughness resulting in an in-creased surface energy, improving wettability, and may decontaminate bonding surfaces22, 23. As for glass-beads the increase of bond strength may be attributed to the incorporation of silica to the bonded surface resulting in stable chemical bonds between the hydroxyl groups (OH) of the silica of the glass surface and the primer/resin cement24. Another study evaluated the effect of different silicatization protocols (Glass-beads and tribochemical coating) with various silane treatment methods on bond strength of translucent zirconia and they found that both alumina and glass-beads air blasting improved bond strength. Their finding was supported by Energy Dispersive Spectroscopy (EDS) and X-ray Photoelectron Spectroscopy (XPS)analysis which confirmed the deposition high silica content at the surface of cemented samples even that was not washed out by ethanol or ultrasonic cleaning10.

Surface roughness of the cemented zirconia may play a role in the adhesion as it may increase surface area of the cemented substrate. The surface roughness after alumina-blasting was higher compared to glass-beads blasted surface. The findings of this study were in agreement with Khanlar et al.20, who revealed that air abrasion with alumina particles had an effect of increasing the surface roughness while glass-beads had no effect. Moreover, their SEM/EDS investigations found that alumina created grooves and surface flowers while glass-beads resulted in the deposition of silica particles without affecting the surface roughness20. On the other hand, Mehari et al.25, found that alumina increased the bond strength while glass-beads and no treatment showed almost the same results for three different types of zirconia which may be attributed to the increased surface roughness to alumina blasted surface.

Alumina sandblasting showed the lowest significant contact angle and the highest surface roughness when compared to glass-beads and control group, both factors that led to high bond strength as per outcomes of our study. Translucent zirconia has larger grains size resulting in grains being pulled out readily during the alumina sandblasting causing surface defects and in succession increased zirconia surface roughness26. Moreover, alumina sandblasting led to formation of micro-mechanical means in terms of increased roughness enhancing surface energy and more resin flow in those micro-retentive features resulting in higher bond strength27. In previous studies, it was suggested that sandblasting may be responsible for generating hydroxyl groups on the zirconia surfaces, leading to the increase of zirconia reactivity with phosphate monomers in MDP affecting bond strength28, 29. This was not the situation with glass-beads, as the low hardness nature of glass-bead cannot alter surface roughness of zirconia. Instead, its effect was limited embedding the surface of zirconia with silica particles resulting in decreased contact angle and enhanced surface energy which improve the bonding10, 20.

The results of this study regardless of the pre-treatment method showed that MDP containing self-adhesive resin cement had the highest bond strength regardless of the pre-treatment method utilized followed by MDP-BPDM primer followed by MDP-silane primer for alumina air abrasion. As for groups with glass-beads pre-treatment, MDP-silane and MDP-BPDM containing primers had a similar bond strength value. Pure MDP results in better bonding performance to zirconia surface and addition of silane in one-bottle with MDP can decrease the bonding16. However, Pure-MDP primers are not available in the market and the commercially available primers combine more than one primer for universal application and compatibility with various substrates.

The phosphate easter groups in the MDP molecule in theory react with one or two zirconium atoms, forming two bonding configurations either “double coordinate” or “single coordinate”30. MDP containing primers has a hydrophobic phosphoric group that reacts with the hydroxyl groups on the surface of the translucent zirconia enhancing bond strength31. Additionally, MDP prevents the penetration of water between the hydrophobic phosphate layer and the oxide layer of zirconia by the action of decyl group in MDP32.

According to the literature, the presence of MDP in the resin luting agent forms a stable bond to airborne pre-treated zirconia even after thermocycling33. This may be attributed to the fact that MDP contains both a polymerizable methacrylate terminal end that adheres to resin and a hydrophilic phosphate terminal end that chemically adheres to zirconia enhancing the bond strength21.

The use of MDP-silane containing primer increased the bond strength between resin cement and zirconia ceramics as per findings in previous studies15, 34, 35. Also, with GB group the higher bond strength values are justified by chemical interaction between the silane and silica from the glass beads remaining on the zirconia surface20. However, the bond strength was lower than that of MDP containing self-adhesive resin cement. This may be attributed to silanols in the MDP-silane containing primer, which may result in that decrease in bond strength between MDP and zirconia surface11, 36.

In previous studies, it was found that MDP-BPDM containing primer had a positive effect on bond strength of cemented zirconia37,38,39. A previous study disagreed with our study finding, attributing the reason to the presence of carboxylic acid monomer in BPDM that may have a determinantal effect on the connection between this primer and self-adhesive resin cement methacrylate40.

Thus, based on that study the use of alumina air abrasion was always considered as the golden standard for bonding to zirconia, it worthy to mention that glass-beads can offer a promising alternative to enhance bonding to zirconia both in conjunction with a primer or MDP cement contained. From the limitations of this study, masticatory forces and anatomical fixed partial denture designs should be valuated to mimic the oral condition rather than the simplified design implanted in the current work. Additionally, further in-vivo studies are required to evaluate the efficacy of the proposed bonding protocols.

Conclusion

Within the limitations of the current study and based on the findings, the following can be concluded:

1. Alumina-sandblasting and glass-bead pre-treatments improve bond strength of zirconia using MDP-primers or with MDP containing self-adhesive resin cement solely without prior priming.

2. MDP containing self-adhesive resin with no prior priming can be used as a successful cementation protocol with less clinical steps for successful zirconia cementation.

3. Sandblasting should be combined with a proper chemical treatment strategy to enhance bond strength to zirconia.

Data availability

Dataset used and analyzed data can be available form corresponding author on reasonable request.

References

Zarone, F., Russo, S. & Sorrentino, R. From porcelain-fused-to-metal to zirconia: clinical and experimental considerations. Dent. Mater. 27, 83–96. https://doi.org/10.1016/j.dental.2010.10.024 (2011).

Rinke, S. & Fischer, C. Range of indications for translucent zirconia modifications: clinical and technical aspects. Quintessence Int. 44, 557–566. https://doi.org/10.3290/j.qi.a29937 (2013).

Güth, J.-F., Stawarczyk, B., Edelhoff, D. & Liebermann, A. Zirconia and its novel compositions: what do clinicians need to know?. Quintessence Int. 50, 512–520. https://doi.org/10.3290/j.qi.a42653 (2019).

Jerman, E. et al. Evaluation of translucency, Marten’s hardness, biaxial flexural strength and fracture toughness of 3Y-TZP, 4Y-TZP and 5Y-TZP materials. Dent Mater. 37, 212–222. https://doi.org/10.1016/j.dental.2020.11.007 (2021).

Spies, B. C., Zhang, F., Wesemann, C., Li, M. & Rosentritt, M. Reliability and aging behavior of three different zirconia grades used for monolithic four-unit fixed dental prostheses. Dent Mater. 36, e329–e339. https://doi.org/10.1016/j.dental.2020.08.002 (2020).

Obradovic-Djuricic, K. et al. Dilemmas in zirconia bonding: a review. Srp Arh Celok Lek. 141, 395–401. https://doi.org/10.2298/SARH1306395O (2013).

Pjetursson, B. E., Thoma, D., Jung, R., Zwahlen, M. & Zembic, A. A systematic review of the survival and complication rates of implant-supported fixed dental prostheses (FDPs) after a mean observation period of at least 5 years. Clin Oral Implants Res. 23, 22–38. https://doi.org/10.1111/j.1600-0501.2012.02546.x (2012).

Bottino, M. et al. Bonding of Y-TZP to dentin: effects of Y-TZP surface conditioning, resin cement type, and aging. Oper Dent. 39, 291–300. https://doi.org/10.2341/12-235-L (2014).

Papia, E., Larsson, C., du Toit, M. & Vult von Steyern, P. Bonding between oxide ceramics and adhesive cement systems: a systematic review. J. Biomed. Mater. Res. B Appl. Biomater. 102, 395–413. https://doi.org/10.1002/jbm.b.33013 (2014).

Khanlar, L. N. et al. The effects of different silicatization and silanization protocols on the bond durability of resin cements to new high-translucent zirconia. Clin. Oral Investig. 26, 3547–3561. https://doi.org/10.1007/s00784-021-04323-7 (2022).

Koko, M. et al. Effects of the ratio of silane to 10-methacryloyloxydecyl dihydrogenphosphate (MDP) in primer on bonding performance of silica-based and zirconia ceramics. J Mech Behav Biomed Mater. 112, 104026. https://doi.org/10.1016/j.jmbbm.2020.104026 (2020).

Inokoshi, M., De Munck, J., Minakuchi, S. & Van Meerbeek, B. Meta-analysis of bonding effectiveness to Zirconia Ceramics. J Dent Res. 93, 329–334. https://doi.org/10.1177/0022034514524228 (2014).

Özcan, M. & Bernasconi, M. Adhesion to zirconia used for dental restorations: a systematic review and meta-analysis. J Adhes Dent. 17, 7–26. https://doi.org/10.3290/j.jad.a33525 (2015).

Komine, F., Blatz, M. B. & Matsumura, H. Current status of zirconia-based fixed restorations. J Oral Sci. 52, 531–539. https://doi.org/10.2334/josnusd.52.531 (2010).

Bielen, V. et al. Bonding Effectiveness to Differently Sandblasted Dental Zirconia. J. Adhes Dent. 17(235), 42. https://doi.org/10.3290/j.jad.a34401 (2015).

Koko, M., Takagaki, T., Abd El-Sattar, N. E. A., Tagami, J. & Abdou, A. MDP salts: a new bonding strategy for Zirconia. J Dent Res. 101, 769–776. https://doi.org/10.1177/00220345211070758 (2022).

Koko, M. et al. Influence of 10-methacryloyloxydecyl dihydrogen phosphate (MDP) incorporated experimental cleaners on the bonding performance of saliva-contaminated zirconia ceramic. Clin Oral Investig. 26, 1785–1795. https://doi.org/10.1007/s00784-021-04153-7 (2022).

Wolfart, M., Lehmann, F., Wolfart, S. & Kern, M. Durability of the resin bond strength to zirconia ceramic after using different surface conditioning methods. Dental Mater. 23, 45–50. https://doi.org/10.1016/j.dental.2005.11.040 (2007).

Hallmann, L. et al. Effect of surface treatments on the properties and morphological change of dental zirconia. J Prosthet Dent. 115, 341–349. https://doi.org/10.1016/j.prosdent.2015.09.007 (2016).

Khanlar, L. N. et al. Effect of air-particle abrasion protocol and primer on the topography and bond strength of a high-translucent zirconia ceramic. J. Prosthodontics. 31, 228–238. https://doi.org/10.1111/jopr.13372 (2022).

Qeblawi, D. M., Muñoz, C. A., Brewer, J. D. & Monaco, E. A. The effect of zirconia surface treatment on flexural strength and shear bond strength to a resin cement. J. Prosthet. Dent. 103, 210–220. https://doi.org/10.1016/S0022-3913(10)60033-9 (2010).

Casucci, A. et al. Influence of different surface treatments on surface zirconia frameworks. J Dent. 37, 891–897. https://doi.org/10.1016/j.jdent.2009.06.013 (2009).

Zandparsa, R., Talua, N. A., Finkelman, M. D. & Schaus, S. E. An in vitro comparison of shear bond strength of zirconia to enamel using different surface treatments. J. Prosthodont. 23, 117–123. https://doi.org/10.1111/jopr.12075 (2014).

Martins, A. R. M., Gotti, V. B., Shimani, M. M., Borges, G. A. & Gonçalves, L. S. Improving adhesion between luting cement and zirconia-based ceramic with an alternative surface treatment. Braz Oral Res. 29, 1–7 (2015).

Mehari, K., Parke, A. S., Gallardo, F. F. & Vandewalle, K. S. Assessing the effects of air abrasion with aluminum oxide or glass beads to zirconia on the bond strength of cement. J. Contemp. Dent. Pract. 21, 713–717 (2020).

Pereira, G. K. R. et al. Mechanical reliability, fatigue strength and survival analysis of new polycrystalline translucent zirconia ceramics for monolithic restora-tions. J. Mech. Behav. Biomed. Mater. 85, 57–65. https://doi.org/10.1016/j.jmbbm.2018.05.029 (2018).

Yue, X., Hou, X., Gao, J., Bao, P. & Shen, J. Effects of MDP based primers on shear bond strength between resin cement and zirconia. Exp. Ther. Med. 17, 3564–3572. https://doi.org/10.3892/etm.2019.7382 (2019).

Kim, J.-E., Kim, J.-H., Shim, J.-S., Roh, B.-D. & Shin, Y. Effect of surface treatment on shear bond strength between resin cement and Ce-TZP/Al 2 O 3. Biomed Res Int https://doi.org/10.1155/2016/7576942 (2016).

Shin, Y.-J. et al. Evaluation of the shear bond strength of resin cement to Y-TZP ceramic after different surface treatments. Scanning 36, 479–486. https://doi.org/10.1002/sca.21142 (2014).

Xie, H. et al. Coupling of 10-methacryloyloxydecyldihydrogenphosphate to tetragonal zirconia: effect of pH reaction conditions on coordinate bonding. Dent Mater. 31, e218–e225. https://doi.org/10.1016/j.dental.2015.06.014 (2015).

Nagaoka, N. et al. Chemical interaction mechanism of 10-MDP with zirconia. Sci Rep. 7, 45563. https://doi.org/10.1038/srep45563 (2017).

Feitosa, V. P. et al. Impact of hydrophilicity and length of spacer chains on the bonding of functional monomers. Dental Mater. 30, e317–e323. https://doi.org/10.1016/j.dental.2014.06.006 (2014).

de Oyagüe, R. C. et al. Influence of surface treatments and resin cement selection on bonding to densely-sintered zirconium-oxide ceramic. Dental Mater. 25, 172–179. https://doi.org/10.1016/j.dental.2008.05.012 (2009).

Amaral, M. et al. The potential of novel primers and universal adhesives to bond to zirconia. J Dent. 42, 90–98. https://doi.org/10.1016/j.jdent.2013.11.004 (2014).

Tanış, M. Ç., Akay, C. & Karakış, D. Resin cementation of zirconia ceramics with different bonding agents. Biotechnol. Biotechnol. Equip. 29, 363–367. https://doi.org/10.1080/13102818.2014.996606 (2015).

Lima, R. B. W. et al. Effect of silane and MDP-based primers on physico-chemical properties of zirconia and its bond strength to resin cement. Dent Mater. 35, 1557–1567. https://doi.org/10.1016/j.dental.2019.07.008 (2019).

Afrasiabi, A., Mostajir, E. & Golbari, N. The effect of Z-primer on the shear bond strength of zirconia ceramic to dentin: in vitro. J. Clin. Exp. Dent. https://doi.org/10.4317/jced.54619 (2018).

Barragan, G., Chasqueira, F., Arantes-Oliveira, S. & Portugal, J. Ceramic repair: influence of chemical and mechanical surface conditioning on adhesion to zirconia. Oral Health Dent. Manag. 13, 155–158 (2014).

Go, E., Shin, Y. & Park, J. Evaluation of the Microshear Bond strength of MDP-containing and Non–MDP-containing Self-adhesive resin cement on Zirconia restoration. Oper Dent. 44, 379–385. https://doi.org/10.2341/18-132-L (2019).

Maeda, F. A., Bello-Silva, M. S., de Paula Eduardo, C., Miranda Junior, W. G. & Cesar, P. F. Association of different primers and resin cements for adhesive bonding to zirconia ceramics. J Adhes Dent. 16, 261–265. https://doi.org/10.3290/j.jad.a31938 (2014).

Acknowledgements

We thank Liaoning Upcera Co. for providing the zirconia substrate.

Author information

Authors and Affiliations

Contributions

Conceptualization, A.A.; methodology, A.A.,C.K. and A.R.; software, A.A.; validation, A.R.,C.K., N.H. and E.A.; formal analysis, A.A; investigation, A.A., N.H. and E.A.; resources, N.H., C.K. and E.A; data curation, A.A.; writing—original draft preparation, A.R.; writing—review and editing, A.A. and C.K.; visualization, A.A.; project administration, C.K. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abdou, A., Hussein, N., Kusumasari, C. et al. Alumina and glass-bead blasting effect on bond strength of zirconia using 10-methacryloyloxydecyl dihydrogen phosphate (MDP) containing self-adhesive resin cement and primers. Sci Rep 13, 19127 (2023). https://doi.org/10.1038/s41598-023-46548-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-46548-4

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.