Abstract

Increased levels of nutrients and algae can cause drinking water problems in communities. Harmful algal blooms affect humans, fish, marine mammals, birds, and other animals. In the present study, we investigated the use of a combined system [Hydrodynamic Cavitation, Ozone (O3), and Hydrogen Peroxide (H2O2)] on the removal of Chlorophyll a and Organic substances in the raw water was investigated. The Effect of different operating conditions such as pH, cavitation time, pressure, distance, flow rate, ozone dose, and hydrogen peroxide concentration was studied. Utilizing the Taguchi design method, experiments were planned and optimized. The combined system treatment yielded a maximum reduction in Chlorophyll a and Total Organic Carbon (TOC) at an optimum condition of pH 5, cavitation pressure 5 bar, flow rate of 1 m3/h, a distance of 25 cm from the orifice plate, O3 3 g/h and 2 g/l of H2O2 concentrations. The most efficient factor in the degradation of TOC and Chlorophyll a, was cavitation pressure based on the percentage contributions of each parameter (38.64 percent and 35.05 percent, respectively). H2O2 was found to have the most negligible impact on degradation efficiency (4.24 percent and 4.11 percent, respectively).

Similar content being viewed by others

Introduction

Everybody of water gradually transitions toward eutrophication over time as a result of rapid population growth, the expansion of agriculture and industry, dwindling freshwater resources, forest degradation, soil erosion, climate change, and repeated droughts. An essential result of this process is a general decrease in the availability of water for use and an increase in the significance of lakes and other water basins; as a result, many resources for socioeconomic development may be seriously compromised1. Algal blooms can be triggered by a decrease in water supply, a decrease in lake and reservoir depth, an increase in stagnation, an increase in nutrients from diverse sources, and a rise in temperature2,3. Numerous issues arise from algal substances in the water, including (1) pH, alkalinity, hardness, dissolved oxygen, and organic matter, (2) The increase in coagulation dose, (3) Physical indicators of water quality, such as color, flavor, odor, and cloudiness, to deteriorate as a result, (4) Filter blockage and decreased filter run, (5) Chlorine demand is rising, and by-products of disinfection are being produced, (6) Algae also cause other issues like forming a slimy and gelatinous layer, corrosive, and interference with other purification processes, (7) On direct contact, some types of algae can irritate the skin and trigger allergic reactions; However, different algae have been known to produce harmful toxins that are deadly to people and can even result in death in some extreme cases4,5,6,7,8,9. These issues can make filtered water unappealing and detrimental; on the other hand, they can also increase the price of drinking water purification by adding more chemicals, as well as increasing the workload for treatment plant workers9.

An important indicator used to describe biomass that uses light energy and is autotrophic is the concentration of chlorophyll-a. It is a crucial parameter reflecting the nutrient status of water bodies and can be used to estimate phytoplankton biomass and productivity. Due to their small-size, high mobility, low density, and negatively charged surface, algal cells in many existing water treatment plants cannot be removed or treated5,10,12. Algae from water sources are controlled using various physical, chemical, and biological techniques. Aeration, dissolved air flotation, filtration, skimming, mixing, membrane processes, ultraviolet, ultrasonic, electrolysis, and other related techniques are used to prevent harmful algae using the physical control method. Algal population management can be accomplished through biological processes like slow sand filters or activated sludge. The main chemical processes are coagulation, copper sulfate, activated carbon, nano particles, oxidation, hydrogen peroxide, and chlorination13,14,15,16,17,18,19. Most chemicals, however, are overpriced and too general, harming aquatic organisms that aren't their intended targets. Most toxic chemical types are not species-specific, which may harm the ecological balance. The potential for environmental harm from improper chemical application is lower than that from artificial mixing. The aeration technology may have drawbacks due to the high maintenance costs (labor costs) and energy consumption needed, and it does not kill the algae. Additionally, aquatic plants add a lot of oxidizing agents, which means that the disinfection by-products they produce are above the required level. The operational cost of algae removal in the water plant using membrane filtration, air flotation, and other techniques is high when the amount of algae in the water is high. The residual Al/Fe in treated water sometimes exceeds the upper limit of water standards, which poses a serious threat to human health, even though using chemicals to remove algae causes secondary pollution. But cyanobacteria oxidation can cause cell lysis. When intracellular organic matter (IOM) is released in large quantities, the water quality can suffer10,20,21,22.

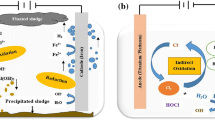

In hydrodynamic cavitation (HC) reactors, voids are created as a result of pressure fluctuations that occur in the liquid as a result of passage through the constriction (such as a throttling valve, orifice plate, venturi, etc.)23,24,25. Cavitation is the formation and immediate implosion of cavities in a liquid what is subjected to rapid changes in pressure. The fluid's kinetic energy increases as it passes through the obstruction, at the expense of the local pressure. The liquid vaporizes and forms a series of cavities when the pressure at the mechanical stenosis's neck, or vena contracta drops below the liquid's vapor pressure. The cavities finally collapse when the pressure rises downstream of the mechanical stenosis. Cavity collapse causes the development of hotspots, the release of reactive free radicals, surface cleaning or erosion, and an improvement in mass transit. It has been hypothesized that in these circumstances, water molecules split into hydroxyl (∙OH) and hydrogen (∙H) radicals, which can attack and weaken the chemical makeup of the algal cell wall to the point of disintegration. During cavitation collapse, these localized hot spots have temperatures of about 5000 k, pressures of 1000 atmospheres, and lifetimes of a few microseconds. Another inactivation mechanism involves damage to the photosynthesis pathways26,27,28,29. Hydrodynamic cavitation harms algal cells by destroying gas vacuoles and cell walls, as well as reducing photosynthetic activity. A further mechanism of the hydrodynamic cavitation process is mentioned in the literature20,30,31,32. As thermal degradation. Many studies have demonstrated that the limited rate of oxidizing radical generation makes the degree of mineralization achieved by hydrodynamic cavitation alone insufficient. Combining HC with appropriate other advanced oxidant processes (AOPs) can help to increase the process efficiency and, as a result, the current work objectives in the development of hybrid treatment approaches33,34,35,36. Algal degradation is facilitated by a dual mechanism thanks to the combined use of HC, O3, and H2O2. The compound is degraded due to hydroxyl radicals produced during the direct attack of molecules of ozone and hydrogen peroxide. Additionally, the removal of the process's mass transfer restrictions was caused by high turbulence brought on by hydrodynamic cavitation37,38,39. The use of experimental design techniques, however, can be helpful to efficiently streamline the process and decrease the number of experiments. The Taguchi design approach is a popular experimental design technique for process modeling and evaluation. The aim of this approach is to improve the response variable, which is affected by several process parameters. Additionally, it guarantees effective process design performance. In recent years, Algal eutrophication has been a common occurrence at the Sanandaj Vahdat Dam in Iran. The water was then tested for flavor and aroma. Water users have expressed their disapproval and worries about the safety and quality of the water as a result. The goal of this study is to assess the effect of a combined system of hydrodynamic cavitation, ozone, and hydrogen peroxide on the removal of chlorophyll-a and organic substances in raw water. The distance of the orifice plate from the beginning of the cavitation tube was considered in this research, while this factor was not investigated in previous studies.

Materials and methods

pilot and materials

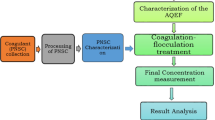

This water was used for the pilot because it had the characteristics of the incoming water to the Sanandaj water treatment plant, which are variable (Table 1). The experimental setup for using ozone and hydrogen peroxide in conjunction with hydrodynamic cavitation is shown in Fig. 1. There is a jet flow loop and a 20-L polyethylene tank in it. The cooling water circulation system controls the temperature of the water in the reactor. A centrifugal pump of 2 HP (CB210), purchased from Electrogen, was used to pump the water flowing through the cavitation device through an attached 25 mm ID steel tube. When comparing orifices with the same cross-sectional flow area, multi-hole orifices produce more cavities than single-hole orifices; therefore, a 5-hole orifice plate (1 mm) was used. The pressure was measured using two manometers (model EN837, Dragon). The required ozone concentration was produced by an ozone generator (made by Pakzhi Company). During the experiment, the tank was filled with 35 percent w/v of analytical-grade hydrogen peroxide (H2O2) that was purchased from Merck in Germany. The TOC analyzer (Analytic, Jena, Germany) was used to perform the analysis. A spectrophotometer (Hach DR 4000U) and the method's standard instructions (plankton-10200) were used to analyze chlorophyll a, respectively40.

Parameters

Seven parameters were chosen as the main parameters for the study of the hydrodynamic cavitation process, including pH (5, 7, 9), retention time (20, 60, 90 min), cavitation pressure (1, 3, 5 bar), flow rate (1, 3, 5 m3/h), the distance of the orifice from the beginning of the cavitation tube (25, 50, 75 cm), ozone concentration (0, 2, 3 g/h), and hydrogen peroxide concentration (0, 1, 2 g/l). Chlorophyll a (algae index) and TOC were chosen as the two factors.

Designation and optimization of experiment

The Taguchi method is a potent approach to problem-solving that raises productivity, yield, and process performance. Through the systematic use of the statistical design of experiments, also known as robust design, Taguchi's main goal is to reduce variability around the target value of product properties. Taguchi explained that the framework could be seen in three main components: (1) Systems Design (it may include the best fusion of materials and procedures), (2) Design of the parameters (which includes the best set of guidelines for the recognized design components), (3) Tolerance Design: Look at the factors that play a significant role in product quality41,42. The required variation in the design is then provided by tolerance limits that are then identified. By evaluating the impact of variables on removal efficiency (response), experimental results can be analyzed using the signal-to-noise ratio (S/N). A dimensionless parameter (metric) known as the signal-to-noise ratio measures the discrepancy between a response and the desired value. Three types of signal-to-noise analysis are commonly used. Lower is better (LB), nominally better (NB), and higher is better (HB), respectively. A larger S/N was chosen since the primary objective of optimization in this study was to achieve the highest removal efficiency. Thus, for the larger one, the S/N ratio is a better criterion in the Eq. (1) is:

The n represents the number of repetitions of the experiment and the EF represents the outcomes of the measurements. The removal efficiency of chlorophyll a and TOC is obtained from Eq. (2), where C1 and C2 are the initial and equilibrium concentrations of pollutants (chlorophyll a and TOC, respectively). After designing the experiment using the Taguchi method for the seven parameters, 27 proposed run steps. Tables 2 and 3 provide specifics about each experiment. Every experiment was run twice, put into the model, and then analyzed. Here, the analysis of the statistical mean value approach (ANOM) is utilized to produce ideal conditions43,44. First, the average of the S/N ratio of each factor at a given level should be calculated (Eq. 3).

where [(S/N) Factor = I] is the S/N ratio of Factor I in Level i, I is the mean S/N ratio of Factor I at Level i, nIi denotes the number of instances of Factor I in Level I, and the order of appearance in Tables 4 and 5 is the jth. Each controllable factor's.

Impact on the separation of Chlorophyll a and TOC is also examined using the statistical technique of analysis of variance (ANOVA). The percentage contribution of each factor, RF, is given by Eq. (4):

Each parameter's degree of freedom (DF) is one number less than the number of levels in the factor, which in this study are two.

The total sum of squares, SST, is given by Eq. (5)

Equation (6) is used to determine the value of EFT. Where m (27 experiments) and n (two repetitions) denote the number of experiments and number of experiments, respectively.

The sum of factor squares (SSF) is calculated using Eq. (7):

EFkF the average of the measurement results of a certain factor in the kth level.

In addition, the error variance, VEr, is given by Eq. (8):

Results and discussions

Optimization

For each test condition, the S/N ratio is calculated in Tables 2 and 3. The maximum signal-to-noise ratio among the 27 tests is indicated in bold type in these tables. According to Tables 4 and 5, the ideal conditions for removing TOC and chlorophyll a are as follows: pH = 5, retention time = 90 min, cavitation pressure = 5 bar, water flow = 1 m3/h, orifice plate distance = 25 cm, ozone value = 3 g/h, and H2O2 concentration = 2 g/l. The confirmation experiment was carried out under the aforementioned ideal circumstances, the EF of chlorophyll a and TOC were measured, and the S/N ratio was computed. Table 6 shows the efficiency difference between the optimal and test 5 conditions were about 1.7 percent for chlorophyll a, and it was about 19.75 percent for TOC. Due to the difference in the 30-min retention time and the requirement to adjust the pH, Run 5 is more cost-effective than the ideal state when it comes to the consumption of ozone and hydrogen peroxide.

Effect of studied factors

Influence of factors under investigation The production of hydroxyl radicals (Eq. 1) is the primary mechanism of pollutant degradation by the hydrodynamic cavitation process9,10,11. Hydrodynamic cavitation produces hydroxyl radicals, and the amount and rate of formation are influenced by variables and reactor conditions. The main influences on the removal of TOC and chlorophyll a are depicted in Figs. 2 and 3, respectively. According to these figures, hydrogen peroxide has the most negligible impact on cavitation pressure and a greater impact on cavitation pressure.

pH effects

The pH of the water is an important parameter in determining the extent of the degradation of the organic pollutants by the HC process. Figure 4 shows the percentage reduction in chlorophyll a and TOC of the water sample as the pH changed. It was discovered that as the pH increased from 5 to 9, the percentage reduction also started to decrease (Fig. 5). Thus, based on the findings of this study, cavitation produces the largest degradation when operating in an acidic environment, and less severe degradation when used in an alkaline environment. Algae in water sources usually have a negative charge (zeta potential), and the ideal values also depend on the specific compounds' pKa during processing. The zeta potential (ZP) of the algal cells needs to be destabilized to improve the removal of algal cells during water purification. In acidic media, the generation of %∙OH radicals is preferred and also has a higher oxidizing capacity. "Additionally, the recombination probability of the ∙OH radicals is low, resulting in a higher number of ∙OH radicals in the solution to degrade the target contaminant. With an increase in pH, the recombination of ∙OH radicals takes place, reducing their ability to degrade the target contaminant. Numerous studies support this finding, highlighting that as pH increases, the removal efficiency of parameters decreases." Several studies have supported this as the pH increases, the removal efficiency of the parameters decreases47,48,49,50,51,52.

Time effect

The cavitation flow, ozone, and hydrogen peroxide injection all increase with increasing cavitation time, which also accelerates the rate at which free radicals are produced and pollutants are broken down. The production of free radicals and the rate at which organic matter and chlorophyll decompose also rise as the cavitation time increases along with the cavitation flow, ozone injection, and hydrogen peroxide injection. The Chlorophyll a and TOC values of the cavitated liquid are likely to continue to decline as the processing time increases, but this is also likely to result in a higher energy need for the procedure. This figure illustrates the relationship between the contact time and the removal efficiency of chlorophyll a and TOC. Other studies have supported these results50,51,52,53.

Pressure effects

As the liquid passes through strictures like the orifice, the pressure at the vena contract falls below the vapor pressure of the liquid, causing the liquid to flash and produce a series of bubbles that later burst when pressure is restored downstream of the stricture. The photosynthetic system and membrane structure of algal cells can be damaged by high pressure and the hydroxyl radicals that are produced during the HC process. Thus, cavitation effectiveness and the generation of free radicals are influenced by pressure. Results for how inlet pressure affected this study's findings. Figure 6 illustrates how changes in inlet pressure result in an increase in the percentage of chlorophyll a and TOC removal. This is because more cavities are created as the inlet pressure rises, which leads to an increase in the percentage of OH radical formation and organic degradation20,54,55,56. Jadhav et al. demonstrated Imidacloprid removal using a cavitation device combined with oxidants and reported that increasing the inlet pressure from 5 to 15 bar increased the degradation efficiency of Imidacloprid57. The research's findings corroborated earlier studies that found cavitation efficiency rises with pressure up to 5 bar58,60. Increasing the cavitation pressure leads to increase in the velocity of the fluid at the orifice hole and then, more cavitation bubbles are generated and the intensity of cavitation also increases, thereby leading to the formation of more %∙OH radicals and more degradation of the organic content49.

Flow effect

The ability of hydrodynamic cavitation reactors to process contaminants more than once during a single operation is the desired benefit. Under other studies, decomposition is made simple and the number of free radicals produced per pollutant unit rises when the flow rate is reduced60,61. Figure 7 also illustrates how this study's findings adjust with those of other studies.

Distance effect

The removal efficiency of chlorophyll a and TOC increased with decreasing orifice plate distance from the cavitation tube, as shown by the study's findings (Fig. 8). This might be connected to a hole in the low-pressure region having a longer retention time. Additionally, holes and heat are produced on the orifice plate when the water that has been infused with energy and pressure from the pump strikes it. The geometry of the cavitation devices affects the hydrodynamic cavitation reactor's efficiency. So, the geometry of cavitation devices is dependent on how long the cavity remains in the low-pressure region. Thus, it is likely that the cause of the increase in algae removal efficiency at distances near the orifice plate with the primary cavitation tube is the increase in the cavitation time of a cavity in a low-pressure region. Since, over a short distance, the incident energy and pressure change are increased and the distance between the orifice plate and the cavitation tube's starting point is decreased, the cavitation intensity is probably increased. Thus, the effectiveness of hydrodynamic cavitation depends on the orifice plate's position20,59,63,64,65,66.

Ozone effect

Ozone-assisted hydrodynamic cavitation can be used to increase the oxidation intensity of pollutants while reducing ozone consumption. In hydrodynamic cavitation by ozone, it has been confirmed that the oxidation of contaminants occurs immediately after the injection of ozone. The combined operation of ozone and cavitation ensures that, in addition to being directly attacked by ozone, pollutants are also decomposed by hydroxyl radicals. Also, the local turbulence generated by cavitation contributes to the mass transfer of ozone from the gas phase to the bulk, so the rate of reaction of ozone with pollutant molecules is not very significant due to high mass transfer resistances in water. In addition to this, ozone dissociates in the presence of cavitation and generates atomic oxygen (∙O), which further reacts with water molecules to generate highly reactive ∙OH radicals. The combined effect of adding ozone and HC improved the degradation efficiency in both pH ranges (acidity and alkalinity) compared to HC treatment alone or ozone treatment alone. This is because the combined operation of ozonation and HC renders a synergistic effect52,67,68,69,70. It can be seen in Fig. 9 that the effect of ozone on removing chlorophyll is greater than that of TOC. The reason for this is probably the destruction of algal gas vacuoles by ozone. Also shown in this graph, the pollutant removal efficiency increases with the increase in ozone concentration. The reason is the increase in free radical production per pollutant, which is consistent with previous studies70,71.

Hydrogen peroxide effect

With increasing H2O2 dosages (0–2 g/l), the results are shown in Fig. 10 for the degradation of chlorophyll a and TOC. The creation and then attack of hydroxyl radicals is a critical mechanism that aids in the degradation of pollutants by HC-H2O2 (Eqs. 16–18). Because hydrogen peroxide accelerates the oxidation of chlorophyll a and TOC by producing ∙OH, the removal efficiency of chlorophyll a and TOC increases with increased hydrogen peroxide concentration. In the presence of HC and H2O2, owing to the high pressure and temperature conditions created by cavitation, the dissociation of H2O2 and water resulted in numerous hydroxyl H2O2 loading increases. H2O2 was constantly dissociated under cavitation, resulting in an enhanced formation of hydroxyl radicals. H2O2 enhances the hydroxyl radical-induced degradation process by acting as a more abundant source of these hydroxyl radicals. A similar study of the treatment of actual industrial wastewater effluent has also observed that the efficacy of hydrodynamic cavitation is enhanced appreciably by using it in combination with H2O2. It was found that the extent of TOC reduction increased with an increase in the loading of H2O2. Other related studies have supported the findings70,72,73,74,75,76.

Percentage of contribution

First, REkF is obtained and shown in Tables 7 and 8. REkF is the mean value of the measured results for the factor at the kth level. By replacing REkF and RET (Chlorophyll a: 58.45 and TOC: 41.28) into Eq. (7) the factorial sum of squares,SSF, for each factor was calculated for each factor and determined in Table 9. Using Eq. (5), the total sum of squares, SST, was calculated. By changing SSF and SST in Eq. (8), the error variance, VER, was obtained. Finally, by substituting SSF, SST, VER, and DOFF in Eq. (4) to determine the percentage contribution of each factor, RF, the results are shown in Table 9.

Conclusion

-

Hydrodynamic cavitation systems have been recognized as a new form of multiphase reactors capable of producing favorable oxidation, including localized hotspots, turbulence, and reactive free radicals within the system. In this study, chlorophyll a and TOC were removed from water using a combination of hydrodynamic cavitation, ozone, and hydrogen peroxide. The ideal conditions for removing chlorophyll a and TOC are as follows: cavitation pressure of 5 bar, retention time of 90 min, pH: 5, flow of 1 m3/h, distance from the orifice of 25 cm, ozone of 3 g/h, and hydrogen peroxide of 2 g/l. According to the percentage contributions of each factor, cavitation pressure was identified as the factor that was most effective in the degradation of TOC and chlorophyll a (38.64 percent and 35.5 percent, respectively). H2O2 was found to have the least impact on degradation efficiency (4.24 percent and 4.11 percent, respectively). The issues and future research directions that merit careful consideration are listed below in light of the study's findings.

-

The orifice plate's distance from the cavitation tube's beginning was considered in this study, but it was not in earlier ones. In this study, distances of 25, 50, and 75 cm were assessed; however, future studies may assess extra distances.

-

The addition of ozone increased the effectiveness of removing pollutants while decreasing the amount of time needed to achieve this result. The main drawback of using ozone alone in water treatment plants is mass transfer, but hydrodynamic cavitation can increase the mass transfer of ozone from a gaseous phase to water.

-

In this study, the synergistic effect of combining hydrodynamic cavitation with hydrogen peroxide and ozone oxidants was minimal. Changes in the organic load and algal input to the sewage treatment plant may be to blame for this (Table 1). This is so that the research could be done using actual raw water that entered the Sanandaj treatment facility.

-

Throughout this study, several parameters, including a load of organic matter, rainfall, the temperature of the inlet water, and the load of algae, changed, which had an impact on how effectively the algae were removed.

-

Due to its high efficiency in destroying microalgae, hydrodynamic cavitation has a lot of potential for treating nutrient-rich waters. Because it doesn't produce secondary pollution, hydrodynamic cavitation is also a sustainable abatement technique.

Data availability

Contains data required for analysis in manuscript. The corresponding author is willing to clarify the data and will provide all necessary datasets according to the request.

References

Avagyan, A. B. Water global recourse management through the use of microalgae addressed to sustainable development. Clean Technol. Environ. Policy 13(3), 431–445 (2011).

Fetahi, T. Eutrophication of Ethiopian water bodies: A serious threat to water quality, biodiversity and public health. Afr. J. Aquat. Sci. 44(4), 303–312 (2019).

Chorus, I., Fastner, J. & Welker, M. Cyanobacteria and cyanotoxins in a changing environment: Concepts, controversies, challenges. Water 13(18), 2463 (2021).

Ghernaout, D., Elboughdiri, N., Ghareba, S. & Salih, A. Coagulation process for removing algae and algal organic matter—An overview. Open Access Lib. J. 7(4), 1–21 (2020).

Jia, P., Zhou, Y., Zhang, X., Zhang, Y. & Dai, R. Cyanobacterium removal and control of algal organic matter (AOM) release by UV/H2O2 pre-oxidation enhanced Fe (II) coagulation. Water Res. 131, 122–130 (2018).

Makhlough, A., Saravi, H. N. & Ebrahimzadeh, M. The water quality of the Shahid Rajaee reservoir (Mazandaran-Iran): Based on phytoplankton community. Iran. J. Sci. Technol. Trans. A Sci. 41, 627–635 (2017).

Brooks, B. W. et al. Are harmful algal blooms becoming the greatest inland water quality threat to public health and aquatic ecosystems?. Environ. Toxicol. Chem. 35(1), 6–13 (2016).

Dehghani, M. H. Removal of cyanobacterial and algal cells from water by ultrasonic waves—A review. J. Mol. Liq. 222, 1109–1114 (2016).

Ghernaout, B., Ghernaout, D. & Saiba, A. Algae and cyanotoxins removal by coagulation/flocculation: A review. Desalin. Water Treat. 20(1–3), 133–143 (2010).

Yang, H., Tong, X. Study on the removal methods of plankton in micro-polluted reservoir water. In IOP Conference Series: Earth and Environmental Science. (IOP Publishing, 2021).

Byeon, K. D. et al. Investigation and evaluation of algae removal technologies applied in domestic rivers and lakes. J. Korean Soc. Environ. Eng. 38(7), 387–394 (2016).

Gallardo-Rodríguez, J. J., Astuya-Villalón, A., Llanos-Rivera, A., Avello-Fontalba, V. & Ulloa-Jofré, V. A critical review on control methods for harmful algal blooms. Rev. Aquac. 11(3), 661–684 (2019).

Chen, G., Ding, X. & Zhou, W. Study on ultrasonic treatment for degradation of Microcystins (MCs). Ultrason. Sonochem. 63, 104900 (2020).

Bibak, M. & Hosseini, S. A. Review ways to control harmful algal bloom (HAB). World J. Fish Mar. Sci. 5(1), 42–44 (2013).

Souza Leite, L., Hoffmann, M. T., Vicente, F. S., Santos, D. V. & Daniel, L. A. Adsorption of algal organic matter on activated carbons from alternative sources: Influence of physico-chemical parameters. J. Water Process Eng. 44, 102435 (2021).

Fuente, A. et al. Electrocoagulation/flocculation of cyanobacteria from surface waters. J. Clean. Prod. 238, 117964 (2019).

Kalbar, P. P. Hybrid treatment systems: A paradigm shift to achieve sustainable wastewater treatment and recycling in India. Clean Technol. Environ. Policy 23, 1365–1373 (2021).

Deng, E., Chen, X., Rub, D., Tran, T. N. & Lin, H. Energy-efficient membranes for microalgae dewatering: Fouling challenges and mitigation strategies. Sep. Purif. Technol. 296, 121382 (2022).

Guo, T., Yang, Y., Liu, R. & Li, X. Enhanced removal of intracellular organic matters (IOM) from Microcystic aeruginosa by aluminum coagulation. Sep. Purif. Technol. 189, 279–287 (2017).

Sun, X. et al. A review on hydrodynamic cavitation disinfection: The current state of knowledge. Sci. Total Environ. 737, 139606 (2020).

Balaji-Prasath, B. et al. Methods to control harmful algal blooms: A review. Environ. Chem. Lett. 20(5), 3133–3152 (2022).

Ren, B., Weitzel, K.A., Duan, X., Nadagouda, M.N., Dionysiou, D.D. A comprehensive review on algae removal and control by coagulation-based processes: mechanism, material, and application. Sep. Purif. Technol. 121106 (2022).

Dindar, E. An overview of the application of hydrodinamic cavitation for the intensification of wastewater treatment applications: A review. Innov. Energy Res. 5(137), 1–7 (2016).

Kurokawa, M. et al. Effect of sonication frequency on the disruption of algae. Ultrason. Sonochem. 31, 157–162 (2016).

Saharan, V. K., Rizwani, M. A., Malani, A. A. & Pandit, A. B. Effect of geometry of hydrodynamically cavitating device on degradation of orange-G. Ultrason. Sonochem. 20(1), 345–353 (2013).

Wu, X., Joyce, E. M. & Mason, T. J. Evaluation of the mechanisms of the effect of ultrasound on Microcystis aeruginosa at different ultrasonic frequencies. Water Res. 46(9), 2851–2858 (2012).

Kong, Y. et al. Removal of Microcystis aeruginosa by ultrasound: Inactivation mechanism and release of algal organic matter. Ultrason. Sonochem. 56, 447–457 (2019).

Wu, Z. et al. Removal of blue-green algae using the hybrid method of hydrodynamic cavitation and ozonation. J. Hazard. Mater. 235, 152–158 (2012).

Gao, L. et al. Hydroxyl radical-aided thermal pretreatment of algal biomass for enhanced biodegradability. Biotechnol. Biofuels 8(1), 1–11 (2015).

Lee, I., Oh, Y. K. & Han, J. I. Design optimization of hydrodynamic cavitation for effectual lipid extraction from wet microalgae. J. Environ. Chem. Eng. 7(2), 102942 (2019).

Innocenzi, V., Prisciandaro, M., Tortora, F. & Vegliò, F. Optimization of hydrodynamic cavitation process of azo dye reduction in the presence of metal ions. J. Environ. Chem. Eng. 6(6), 6787–6796 (2018).

Kim, D. et al. Selective removal of rotifers in microalgae cultivation using hydrodynamic cavitation. Algal Res. 28, 24–29 (2017).

Zupanc, M. et al. Effects of cavitation on different microorganisms: The current understanding of the mechanisms taking place behind the phenomenon. A review and proposals for further research. Ultrason. Sonochem. 57, 147–165 (2019).

Wang, X., Jia, J. & Wang, Y. Combination of photocatalysis with hydrodynamic cavitation for degradation of tetracycline. Chem. Eng. J. 315, 274–282 (2017).

Saharan, V. K., Badve, M. P. & Pandit, A. B. Degradation of Reactive Red 120 dye using hydrodynamic cavitation. Chem. Eng. J. 178, 100–107 (2011).

Thanekar, P. et al. Degradation of dimethoate using combined approaches based on hydrodynamic cavitation and advanced oxidation processes. Process Saf. Environ. Prot. 143, 222–230 (2020).

Gujar, S. K. & Gogate, P. R. Application of hybrid oxidative processes based on cavitation for the treatment of commercial dye industry effluents. Ultrason. Sonochem. 75, 105586 (2021).

Shen, Y., Xu, Q., Wei, R., Ma, J. & Wang, Y. Mechanism and dynamic study of reactive red X-3B dye degradation by ultrasonic-assisted ozone oxidation process. Ultrason. Sonochem. 38, 681–692 (2017).

Arimi, M., Kiprop, A., Ramkat, R. & Kiriamiti, H. Progress in applications of advanced oxidation processes for promotion of biohydrogen production by fermentation processes. Biomass Convers. Biorefinery. 5, 1–25 (2020).

Rice, E. W. & Bridgewater, L. Association APH (American Public Health Association, 2012).

Thébault, E., Purucker, M., Whaler, K. A., Langlais, B. & Sabaka, T. J. The magnetic field of the Earth’s lithosphere. Space Sci. Rev. 155, 95–127 (2010).

Sayed, M. A., Dawood, O. M., Elsayed, A. H. & Daoush, W. R. Application of Taguchi method in optimization of process parameters of ODS tungsten heavy alloys. Adv. Mater. Res. 6(1), 079 (2017).

Zolfaghari, G. et al. Taguchi optimization approach for Pb (II) and Hg (II) removal from aqueous solutions using modified mesoporous carbon. J. Hazard. Mater. 192(3), 1046–1055 (2011).

Dargahi, A. et al. Electrodegradation of 2, 4-dichlorophenoxyacetic acid herbicide from aqueous solution using three-dimensional electrode reactor with G/β-PbO 2 anode: Taguchi optimization and degradation mechanism determination. RSC Adv. 8(69), 39256–39268 (2018).

Bandala, E. R. & Rodriguez-Narvaez, O. M. On the nature of hydrodynamic cavitation process and its application for the removal of water pollutants. Air Soil Water Res. 12(20–40), 1 (2020).

Gągol, M., Przyjazny, A. & Boczkaj, G. Effective method of treatment of industrial effluents under basic pH conditions using acoustic cavitation—A comprehensive comparison with hydrodynamic cavitation processes. Chem. Eng. Process. Process Intensif. 128, 103–113 (2018).

Laszakovits, J. R. & MacKay, A. A. Removal of cyanotoxins by potassium permanganate: Incorporating competition from natural water constituents. Water Res. 155, 86–95 (2019).

Kalhori, E. M. et al. Effective reduction of metronidazole over the cryptomelane-type manganese oxide octahedral molecular sieve (K-OMS-2) catalyst: Facile synthesis, experimental design and modeling, statistical analysis, and identification of by-products. Environ. Sci. Pollut. Res. 25, 34164–34180 (2018).

Mukherjee, A. et al. Performance and energetic analysis of hydrodynamic cavitation and potential integration with existing advanced oxidation processes: A case study for real life greywater treatment. Ultrason. Sonochem. 66, 105116 (2020).

Saharan, V.A., Pandit, A.B., Satish Kumar, P.S., Anandan, S. Hydrodynamic cavitation as an advanced oxidation technique for the degradation of Acid Red 88 dye. Ind. Eng. Chem. Res. 1981–1989 (2012).

Randhavane, S. B. & Khambete, A. K. Hydrodynamic cavitation: An approach to degrade Chlorpyrifos pesticide from real effluent. KSCE J. Civ. Eng. 22, 2219–2225 (2018).

Thanekar, P., Panda, M. & Gogate, P. R. Degradation of carbamazepine using hydrodynamic cavitation combined with advanced oxidation processes. Ultrason. Sonochem. 40, 567–576 (2018).

Wang, B. et al. Hydrodynamic cavitation and its application in water treatment combined with ozonation: A review. J. Ind. Eng. Chem. 114, 33–51 (2022).

Joshi, R. K. & Gogate, P. R. Degradation of dichlorvos using hydrodynamic cavitation based treatment strategies. Ultrason. Sonochem. 19(3), 532–539 (2012).

Zhang, K., Dong, Z.-Y. & Yao, R.-H. Pressure characteristics of hydrodynamic cavitation reactor due to the combination of Venturi tubes with multi-orifice plates. J. Hydrodyn. 30(3), 514–521 (2018).

Calcio Gaudino, E., Canova, E., Liu, P., Wu, Z. & Cravotto, G. Degradation of antibiotics in wastewater: New advances in cavitational treatments. Molecules 26(3), 617–629 (2021).

Raut-Jadhav, S. et al. Synergetic effect of combination of AOP’s (hydrodynamic cavitation and H2O2) on the degradation of neonicotinoid class of insecticide. J. Hazard. Mater. 261, 139–147 (2013).

Lalwani, J., Gupta, A., Thatikonda, S. & Subrahmanyam, C. Oxidative treatment of crude pharmaceutical industry effluent by hydrodynamic cavitation. J. Environ. Chem. Eng. 8(5), 104281 (2020).

Saxena, S., Rajoriya, S., Saharan, V. K. & George, S. An advanced pretreatment strategy involving hydrodynamic and acoustic cavitation along with alum coagulation for the mineralization and biodegradability enhancement of tannery waste effluent. Ultrason. Sonochem. 44, 299–309 (2018).

Rajoriya, S., Bargole, S. & Saharan, V. K. Degradation of reactive blue 13 using hydrodynamic cavitation: Effect of geometrical parameters and different oxidizing additives. Ultrason. Sonochem. 37, 192–202 (2017).

Fang, Y., Hariu, D., Yamamoto, T. & Komarov, S. Acoustic cavitation assisted plasma for wastewater treatment: Degradation of Rhodamine B in aqueous solution. Ultrason. Sonochem. 52, 318–325 (2019).

Gore, M. M., Saharan, V. K., Pinjari, D. V., Chavan, P. V. & Pandit, A. B. Degradation of reactive orange 4 dye using hydrodynamic cavitation based hybrid techniques. Ultrason. Sonochem. 21(3), 1075–1082 (2014).

Shokoohi, R., Rahmani, A., Asgari, G., Ashrafi, M. & Ghahramani, E. Removal of algae using hydrodynamic cavitation, ozonation and oxygen peroxide: Taguchi optimization (case study: Raw water of sanandaj water treatment plant). Process Saf. Environ. Prot. 169, 896–908 (2023).

Saharan, V. K. Computational study of different venturi and orifice type hydrodynamic cavitating devices. J. Hydrodyn. Ser. B. 28(2), 293–305 (2016).

Bashir, T. A., Soni, A. G., Mahulkar, A. V. & Pandit, A. B. The CFD driven optimisation of a modified venturi for cavitational activity. Can. J. Chem. Eng. 89(6), 1366–1375 (2011).

Ozonek, J. Application of Hydrodynamic Cavitation in Environmental Engineering, 1st Ed. (CRC Press, 2012).

Gogate, P. & Patil, P. Ultrasonics Sonochemistry Combined treatment technology based on synergism between hydrodynamic cavitation and advanced oxidation processes. Ultrason. Sonochem. 25, 60–69 (2015).

Zhang, H., Duan, L. & Zhang, D. Decolorization of methyl orange by ozonation in combination with ultrasonic irradiation. J. Hazard. Mater. 38, 53–59 (2006).

Wu, Z. et al. Enhanced effect of suction-cavitation on the ozonation of phenol. J. Hazard. Mater. 190, 375–380 (2011).

Raut-Jadhav, S. et al. Treatment of the pesticide industry effluent using hydrodynamic cavitation and its combination with process intensifying additives (H2O2 and ozone). Chem. Eng. J. 295, 326–335 (2016).

Silva, J. P., Carneiro, L. M. & Roberto, I. C. Assessment of advanced oxidative processes based on heterogeneous catalysis as a detoxification method of rice straw hemicellulose hydrolysate and their effect on ethanol production by Pichia stipitis. Biomass Convers. Biorefinery. 4, 225–236 (2014).

Chakinala, A. G., Gogate, P. R., Burgess, A. E. & Bremner, D. H. Treatment of industrial wastewater effluents using hydrodynamic cavitation and the advanced Fenton process. Ultrason. Sonochem. 15, 49–54 (2008).

Jung, K. W., Park, D. S., Hwang, M. J. & Ahn, K. H. Decolorization of Acid Orange 7 by an electric field-assisted modified orifice plate hydrodynamic cavitation system: Optimization of operational parameters. Ultrason. Sonochem. 26, 22–29 (2015).

Barik, A. J. & Gogate, P. R. Hybrid treatment strategies for 2,4,6-trichlorophenol degradation based on combination of hydrodynamic cavitation and AOPs. Ultrason. Sonochem. 40, 383–394 (2018).

Tao, Y., Cai, J., Huai, X. & Liu, B. A novel antibiotic wastewater degradation technique combining cavitating jets impingement with multiple synergetic methods. Ultrason. Sonochem. 44, 36–44 (2018).

Kobayashi, Y. et al. Bactericidal effect of hydroxyl radicals generated from a low concentration hydrogen peroxide with ultrasound in endodontic treatment. J. Clin. Biochem. Nutr. 54(3), 161–165 (2014).

Acknowledgements

This study was taken from a Ph. D thesis at Hamadan University of Medical Sciences. The deputy of Research and Technology, Hamadan University of Medical Sciences, and the Water and Waste Water Company of Kurdistan all provided funding for the study.

Funding

The study was supported by the deputy of Research and Technology, Hamadan University of Medical Sciences (No. 140003182237), and Water and Waste Water Company of Kurdistan.

Author information

Authors and Affiliations

Contributions

Consent to Publication All agree on the manuscript date and submit the final manuscript to the Journal of Scientific Report for approved.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shokoohi, R., Rahmani, A., Asgari, G. et al. The effect of the combined system of hydrodynamic cavitation, ozone, and hydrogen peroxide on chlorophyll a and organic substances removal in the raw water. Sci Rep 13, 10102 (2023). https://doi.org/10.1038/s41598-023-37167-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-37167-0

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.