Abstract

In the present study, the Sr1−xAl2O4:Eux (x = 0.00, 0.01, 0.03, 0.05, 0.07, and 0.09) phosphor were synthesized by urea fuel combustion method at 580 °C temperature with very high brightness and long after glow. The structural studies carried out using XRD technique shows that the sample is single phased in nature and it gets crystallized into monoclinic phase with standard JCPDS 34-0379 card. The oxide formation was examined using FTIR technique. UV–Visible spectroscopy has been used to study the optical band gap of material, it’s value in the current case, Sr1−xAl2O4:Eux (x = 0.05) is 3.78 eV. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM), confirm the formation of nano particle, with average particle size around 6–25 nm. The elemental composition was confirmed by using Energy Dispersive X-ray (EDX) technique. The photo-luminescence study revealed that it gives broad emission spectra using excitation wavelength λex = 365 nm. It is observed that the Sr1−xAl2O4:Eux (x = 0.05) phosphor give maximum emission intensity and it can be regulated as green (0.23, 0.49) emission with the colour temperature 3224 K, CRI 78, and colour purity 60.69%. The spectra are intense and lie in the visible range. The green lights can regulate the circadian rhythm through melatonin, and it is also suitable for green LED and other optoelectronic devices. The Sr1−xAl2O4:Eux (x = 0.00 and 0.05) phosphor behaves like eco-materials, because nano particles of Sr1−xAl2O4:Eux (x = 0.05) does not show antimicrobial activity.

Similar content being viewed by others

Introduction

Phosphor materials are being used more widely as a durable, cost-effective source of energy on a global basis. Light-emitting diodes (LEDs) are anticipated to reduce light energy use by 15% by 2020 and 40% by 2030, totalling 3.0 quads in 2030 alone, compared to today's estimates, according to the US Department of Energy, resulting in a $26 billion energy savings1. As a result, there would be a nearly 190 million metric tonne decrease in carbon dioxide (greenhouse gas) emissions. Luminescence, which has revolutionised everything from overhead fluorescent tubes to incandescent light bulbs, may become extinct in the coming years, according to the United States Department of Energy2. Because of their inherent qualities, such as low energy consumption, long life, high chemical stability, and environmental friendliness, phosphors converted white light-emitting diodes and other light-emitting diodes are outstanding materials for solid lighting technology and could be used in future lighting devices3. Due to their outstanding luminous properties, rare earth and alkaline earth aluminates phosphorescent materials have a wide range of applications in solid-state lighting, display components, and other fields. Alkaline earth aluminates make the perfect chemical host material for enhancing luminescence in today's luminescence-based technologies. The host lattice's structure affects the luminescence, which can happen anywhere in the electromagnetic spectrum from ultraviolet to infrared. The long-lived luminescence property is demonstrated by the photoluminescence of rare-earth-doped alkaline earth aluminates, MAl2O4 (M = Ca, Sr, Ba)4. The researchers have gained interest in long afterglow characteristic of rare earth-doped alkaline earth aluminates phosphors. Luminescent paint, emergency device safety indicators, electronic instrument dial pads, vehicle dials and panels, writing and printing inks, plasma display phosphors, and many other products use phosphor ingredients5. SrAl2O4 is commonly produced using a solid state reaction method that necessitates annealing at high temperatures, usually above 1000 °C, for extended periods of time, ranging from several hours to days, in order to form crystals and produce particle sintering6,7,8. The literature has already reported on the sol–gel method, crystallisation of spray-dried amorphous precursors precipitation, flame spray pyrolysis, and other synthesis techniques9,10,11,12. The combustion method, which involves an exothermic reaction between metal nitrates and an organic fuel, is employed in this study since it is a rapid and energy-efficient process. The combustion process self-replicates once the raw material solution is heated to a low temperature and ignited to produce the required chemical4,13. The discussion serves as the inspiration for the nano-scale phosphor preparation. In the present investigation the Sr1−xAl2O4:Eux (x = 0.00, 0.01, 0.03, 0.05, 0.07, and 0.09) phosphor nanocrystalline powder were synthesized by using urea fuel combustion method. The structural, optical, morphological, and photoluminescence studies of the phosphor sample were investigated and the antibacterial property has been investigated for the first time for Sr1−xAl2O4:Eux (x = 0.00 and 0.05) phosphors. Our study puts forward an eco-friendly material which is suitable to be used as an optical coating agent for making solid state luminescent devices14,15.

Experimental

Sample preparation

To synthesize Sr1−xAl2O4:Eux (x = 0.00, 0.01, 0.03, 0.05, 0.07, and 0.09) phosphor, urea fuel combustion was employed. In the synthesis process, nitrates such as strontium nitrate [Sr(NO3)2], aluminium nitrate [Al(NO3).H2O], oxides such as europium oxide [Eu2O3], and urea [CO(NH2)2] were utilized as starting materials. The Europium oxides were converted to nitrates by dissolving them in 5 ml of concentrated HNO3.

Urea was combined with the initial components in stoichiometric ratios, and the mixture was then mashed with a mortar-pestle to create a paste. Using a vertical furnace, the paste was delivered to the crucible and burned at 580 °C16. The solution catches fire and turns into white foam (ash) in a few seconds. The entire reaction takes 5–10 min to complete. Using a mortar and pestle, the ashes left behind from burning the solution were turned into a fine nanopowder17.

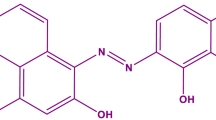

The chemical reaction of these reactants is shown in Eq. (2) which is for the Sr1−xAl2O4:Eux (SAE) phosphor synthesized with the urea fuel combustion method as shown in Fig. 1.

The samples synthesized with different molar ratios of Eu2+ ions such SrAl2O4:Eu0.00, Sr0.99Al2O4:Eu0.01, Sr0.97Al2O4:Eu0.03, Sr0.95Al2O4:Eu0.05, Sr0.93Al2O4:Eu0.07 and Sr0.91Al2O4:Eu0.09 by urea fuel combustion method and for simplicity the samples coded as SAE 0.00, SAE 0.01, SAE 0.03, SAE 0.05, SAE 0.07 and SAE 0.09 respectively.

Characterization techniques

The crystalline phase purity of Sr1−xAl2O4:Eux (x = 0.00, 0.01, 0.03, 0.05, 0.07, and 0.09) phosphors were characterized by X-ray diffraction pattern; it was obtained using Bruker D8 Advance X-ray diffractometer with CuKα (1.5406 Å) radiation. The diffraction pattern was recorded between 10° and 70° (2θ) by using step size at 0.02680 and Estimated Scan Time of 3832 s/step during the XRD measurement. The structural parameters were estimated by using Full-prof program. The surface morphology of samples was studied using a scanning electron microscope (SEM, NOVA NANOSEM 450). For the purpose of confirming the elemental composition, an energy dispersive X-ray (EDX) spectrometer (Oxford-EDX system INCA 250 EDS linked with SEM, NOVASEM 450) was employed. Images of transmission electron micrographs (TEM) were obtained by utilizing a TEM-TECNAI G2 T30 (S-TWIN) electron microscope with a voltage range of 100–400 kV, which was employed for measuring the particle crystal picture, HRTEM image, selected area electron diffraction (SAED) image, crystal structure, voids, pores, particle size defect, and other properties of Sr1−xAl2O4:Eux (x = 0.05) phosphor. Fourier transform infrared spectroscopy was used to examine the chemical bonding behavior of materials (FTIR-6300 spectrometer equipped with NRS-3300 laser, Jasco, Japan). The optical characterization was done by using UV–VISIBLE spectrophotometer (Labindia Analytical UV3092) and the photoluminescence (PL) was recorded on spectrofluorophotometer (Horiba scientific Instrument Fluoromax-4 spectrofluorometer) with a spectral slit width of 1.0 nm using a 450 W xenon arc lamp as an exciting source.

Antibacterial studies

In this investigation, gram-negative bacteria Escherichia coli (E. coli) and gram-positive bacteria Staphylococcus aureus (S. aureus) were employed as pathogenic bacterial strains. The antibacterial activity of Sr1−xAl2O4:Eux (x = 0.00 and 0.05) phosphors were evaluated using the agar well diffusion method. In sterilized Petri dishes, nutrient media was added. The each bacterial strain was disseminated separately on the agar medium and seeded into Luria–Bertani (LB) broth along with the respective clinical isolates for 24 h-incubated cultures. In each Petri plate, wells with a 6 mm diameter are created using a sterile cork borer and under aseptic circumstances. Nanoparticle concentrations of 1 mg/ml were utilized to measure the activity of the particles. Using sterile micropipettes, the nanoparticles are mixed with distilled water and added to the wells. The common antibiotic ciprofloxacin (used as a positive control) was tested against the pathogens simultaneously, after which the plates were incubated for 24 h at 37 °C. Each well's zone of inhibition was examined after the incubation period, and the results were recorded.

Results and discussion

X-ray analysis

The synthesized Sr1−xAl2O4:Eux (x = 0.00, 0.01, 0.03, 0.05, 0.07, and 0.09) phosphor’s (SAE phosphor) dominating peaks are completely matches that of the reference JCPDS Card 34-0379. The single-phase character of the synthesized sample was shown by the XRD data obtained in the angle range of 10° to 70° displayed in Fig. 2a. Additionally, it was noted that the sample had a monoclinic structure with the space group P 21/n. The sample is crystalline in nature according to the characterization peak's intensity; however the sample's broad peaks show lesser average crystalline size.

Rietveld refinement analysis

The Rietveld refinement was used to obtain the crystal structure of the synthesised phosphors with the help of the Full-Prof programme. We refined the SrAl2O4 sample using the pseudo Voigt function, as displayed in Fig. 2b. The synthesised sample's refining results and the measured and computed values match. The refinement supported the existence of the pure monoclinic structure with the P 21/n space group indicated in Fig. 2c,d. The calculated refined phase parameters are as follows: a = 8.4423 Å, b = 8.8243 Å, c = 5.1544 Å, α = 90.00°, β = 93.36°, γ = 90.00°, V = 383.3143 Å3 and χ2 = 4.8. For sample SrAl2O4 (SAE 0.00), the goodness of fit (GOF) value was determined to be 2.8. All these data are analogues to the values reported by the authors in different works of literature18,19. The refinement parameters and their values are listed in Table 1. A comparison of refinement crystallographic data for atom parameters of SrAl2O4 phosphor is listed in Table 2.

These formulas are used to compute the crystallite sizes (D), Dislocation density (δ), Micro strain (ε) and inter-planner spacing (d). The values of crystallite sizes (D), Dislocation density (δ), Microstrain (ε) and inter-planner spacing (d) for Sr1−xAl2O4:Eux (x = 0.00, 0.01, 0.03, 0.05, 0.07, and 0.09) phosphor (SAE phosphor) are given in the Table 317,20,21,22.

where D is the crystallite size, n equates to unity, resulting in the lowest possible dislocation density, λ is the X-beam wavelength, θ is the Bragg's diffraction angle, and β is the full width at half maxima (FWHM), expressed in radians23.

From the Table 3 it is shown in Fig. 3 that when we start increasing the concentration of europium in our host SrAl2O4 (SAE 0.01 to SAE 0.05) it’s average crystallite size is decreasing. This is due to their variable ionic radii; the change of Eu particles with the Sr site is lower. However, there is a slight difference in their ionic radii Sr2+ (1.13 Å) and Eu2+ (1.06 Å) substituting for the smaller Al3+ (0.53 Å) ions in the host lattice. The Eu2+ ion is incorporated into SrAl2O4 lattice rather than interstitial sites24,25. The average crystallite size is minimum for SrAl2O4:0.05Eu (SAE 0.05), due to this the luminescence property also changes abruptly Fig. 11b.

SEM analysis

The SEM images of the Sr1−xAl2O4:Eux (x = 0.00 and 0.05) phosphor (SAE0.00 and SAE 0.05 phosphor) are displayed in Fig. 4a,b and c,d, respectively. The sample's microstructure exhibits characteristics of combustion as it occurs naturally. Pores are created with the production of microscopic particles close to the pores while a gas is exiting under high pressure during combustion. Figure 4a–d illustrates the uneven and non-uniform forms of the particles.

The elemental composition and distribution of the sample can be determined from the Energy Dispersive X-ray (EDX) spectra. The EDX spectra of the SAE 0.00 and SAE 0.05 phosphor (Sr1−xAl2O4:Eux (x = 0.00, 0.05) phosphor) samples are depicted in Fig. 5a,b, respectively. The EDX spectra show that oxygen (O), strontium (Sr), aluminium (Al), europium (Eu), and these metals are the phosphor’s main constituents. Quantitative EDX analysis reveals that while the percentage contribution of the other elements remained constant, the concentration of Sr decreased as a result of the rise in dopant Eu2+. This agrees well with the theoretically calculated stoichiometry. The EDX spectra's prominent peaks serve as proof that the elements are present in the synthesized phosphor.

The typical elemental mapping images of Sr1−xAl2O4:Eux (x = 0.00, 0.05) phosphor (SAE 0.00 and SAE 0.05 phosphor) samples material are shown in Figs. 6a–d and 7a–e respectively. The elemental mappings show the homogeneous distribution of nano particles in crystal structure of synthesized phosphor.

TEM analysis

Transmission electron microscopy was used to measure the particle crystal imaging, HR image, and selected area electron diffraction (SAED) image. The specifics of defects in crystal structure, voids, pores, and particle size, etc. The TEM micrograph shows the growth of irregular shape of agglomerated nanoparticles as shown in Fig. 8a–c. The average particle size is found around 6–25 nm (Calculated by Image J software). The associated SAED pattern (Fig. 8e) makes it obvious that the diffraction pattern is from a nano phosphor assembly since it displays distinct rings. Table 4 displays the inter-planner spacing determined from the TEM SAED pattern. Using the Image J software, the fringe width of the HRTEM image was estimated. Figure 8d displays a typical HRTEM image of a phosphor sample. The homogeneous lattice fringe with estimated inter-planner spacing d = 0.22 nm by using TEM data and observed inter-planner spacing d = 0.222 nm for (231) plan from XRD result is highly matched (Supplementary Table) for Sr1−xAl2O4:Eux (x = 0.05) phosphor (SAE 0.05)26.

FTIR analysis

The Fourier transform Infra-red spectra (FTIR) for Sr1−xAl2O4:Eux (x = 0.05) phosphor (SAE 0.05 phosphor) is shown in Fig. 9. The Fourier transform Infra-red spectra were recorded in the wave number range of 400–4000 cm−1. The monoclinic crystal structure of SrAl2O4 was determined by a sequence of absorption peaks in the 400–900 cm−1 range. The Al=O, Sr=O, and Sr–O–Al bond vibrations are responsible for the bands between 350 and 1000 cm−1, which are all connected to the infrared active vibration modes of SrAl2O4 phosphor. The band at 534 cm−1 is produced by the symmetric bond of O–Al–O, but the anti-symmetric stretching bands between 588 and 845 cm−1 are produced by the vibrations of Sr–O, leading to the conclusion that the band at 842.24 cm−1 is most likely Sr–O. The inherent active IR vibration modes of strontium aluminates are commonly seen in the bands below 1000 cm−1. The anti-symmetric stretching bands of Sr–O at 642.24 cm−1, 779.45 cm−1, and 842.24 cm−1 are absorption bands27.

UV–VISIBLE analysis

The Sr1−xAl2O4:Eux (x = 0.05) was examined using a UV–VISIBLE spectrophotometer to determine its optical bandgap. The diffuse reflectance spectroscopy (DRS) is a straight forward and effective spectroscopic tool for this purpose. Diffuse reflectance spectroscopy was used to examine the UV–visible absorption spectra of the Sr1−xAl2O4:Eux (x = 0.05) phosphor that has been doped with Eu2+. The Kubelka–Munk function was used to estimate the band gap. In the parabolic band structure, the Eg and absorption coefficient are related via the Tauc relation. The statement provides the Tauc relation for a material with a direct band gap, the Tauc relation is given by the statement28.

The linear absorption coefficient is α, the light frequency is υ, and the proportionality constant is A. The power of the parenthesis, n, is taken to be 1/2 for direct band gap materials. The perfect diffuse scattering of incoming light causes the absorption coefficient K to equal 2. In this illustration, assuming the scattering coefficient S is constant with respect to wavelength, the Kubelka Munk function is proportional to the absorption coefficient. Using the above equation, we get the following relationship29:

As demonstrated in Fig. 10, the energy-band gap of the powder sample is easily determined using the (αhυ)2 vs. hυ graph. The energy axis is intersected by an extrapolated straight line along the sharp edge of the curve and the optical band gap in this case (SAE 0.05) is 3.78 eV. Because of the doping of the Eu ion in the host crystal lattice, the band gap is smaller than the band gap of host material reported in literature30.

Photoluminescence (PL) analysis

The excitation spectrum of Sr1−xAl2O4:Eux (x = 0.00, 0.01, 0.03, 0.05, 0.07, and 0.09) phosphor (SAE phosphor) synthesized via urea fuel combustion method is shown in Fig. 11a.

The emission spectra of a Sr1−xAl2O4:Eux (x = 0.00, 0.01, 0.03, 0.05, 0.07, and 0.09) phosphor (SAE phosphor) was captured is shown in Fig. 11b. The excitation wavelength 365 nm is used. It consists of a broad band and the emission peak at 514 nm and a small peak at 611 nm, which is imputed to typical \(4{\mathrm{f}}^{6} 5{\mathrm{d}}^{1}\to 4{\mathrm{f}}^{7}\) transition of Eu2+ ion16,31,32. Observed emission spectra reveal an obvious absorption from host SrAl2O4 in the 450-600 nm region, which can be attributed SrAl2O4, self absorption band as well as the f-d transition of Eu2+. When we change the concentration of activator Eu in the host SrAl2O4 the nature of emission is change according to Fig. 11b. The Sr1−xAl2O4:Eux (x = 0.05) phosphor concentration give maximum emission intensity.

In the case of Sr1−xAl2O4:Eux (x = 0.05) (SAE 0.05 phosphor), the energy band gap from photoluminescence excitation spectra was calculated with the broad emission spectra with maximum intensity is at 365 nm, and its energy band gap is 3.39 eV, which is highly matched with optical band gap, computed using UV–VISIBLE spectroscopy, 3.78 eV (Fig. 10).

For Visual understanding of the colour-tuneable emission of synthesized phosphors Fig. 12 show the Commission International de’ LEclarirage (CIE) diagram of Sr1−xAl2O4:Eux (x = 0.00, 0.01, 0.03, 0.05, 0.07, and 0.09) phosphor (SAE phosphor).

The colour purity for Sr1−xAl2O4:Eux have been calculated by using Eq. (9)

where (xs, ys) are the co-ordinates of phosphors reported in present work, (xi, yi) co-ordinates of white light which are (0.3101, 0.3162) and (xd, yd) are co-ordinates of dominant wavelength according to the national television standards committee (NTSC).

Each solid-state lighting product has a distinct CCT attribute that represents the colour temperature of white light. Additionally, it describes the source of the light and how warm or cold the light it emits is. The CCT value is high in the cool region and low in the warm region. However, it indicated the cool region if the CCT value of the light source was greater than 4000 K. The colour correlated temperature (CCT) is computed using McCamy empirical33 formula, which is given in Eq. (10)

where \(n = \frac{{(x - x_{e} )}}{{y - y_{e} }}\) is the reciprocal of slope line, (x,y) are the computed CIE coordinates of Sr1−xAl2O4:Euxand xe = 0.3320, ye = 0.1858 is the epicentre. The calculated CCT values of the synthesized phosphor are presented in Table 5; it is observed that the CCT values are lie between 3092–7526 K.

The importance of the light source's spectrum is described by the associated colour rendering index (CRI). It is an important parameter to define how well the spectrum of the light source is composed. An excellent quality light source has a CRI range from 75 to 100, a good quality source of light has CRI range from 56 to 75, a fair quality source of light has CRI range from 55 to 65, and a poor quality source of light has CRI range from 0 to 55 are observed14. In this work, we have calculated the CRI value by Eq. (11)

Ghosh et al. have already described the idea behind and method for calculating the colour rendering index (CRI)34. Calculated CRI values in this work range from 76 to 96, indicating the prepared SAE phosphor exhibits an excellent CRI range for green colour. The use of broad photo emission spectra with excellent colour index and high CCT value to obtain direct green light emitting diodes and other optoelectronic devices could be considered another possibility; the green lights can regulate the circadian rhythm through melatonin. The Table 5, lists the chromaticity coordinates, correlated colour temperature (CCT), colour rendering index (CRI) and colour purity determined from the associated emission spectrum35,36. It can be observed that the Sr1−xAl2O4:Eux (x = 0.05) phosphor can be regulated as green (0.23, 0.49) emission with the colour temperature 3224 K, CRI 78 and colour purity 60.69%.

Antibacterial property of the phosphor

The antibacterial property was investigated first time for Sr1−xAl2O4:Eux (x = 0.00 and 0.05) phosphors. In this work the antibacterial activity of Sr1−xAl2O4:Eux (x = 0.00, and 0.05) phosphor (SAE 0.00 and SAE 0.05 phosphor) is observed by adopting agar well diffusion method against Gram-positive Staphylococcus aureus (S. aureus) and Gram negative Escherichia coli (E. coil) bacteria, which are tabulated in Table 6, for observing antibacterial study we have used our synthesized phosphor (SAE 0.00 and SAE 0.05 phosphor) and initial material such as Al, Sr and Eu as control. So according to an observation from the Fig. 13a,b, we have found a small inhibition zone around 5 mm for Escherichia coli bacteria for Al control (Fig. 13a). The Gram-positive Staphylococcus aureus bacteria exhibited comparative larger inhibition zone around 20 mm for Al control (Fig. 13b). The rest phosphor material and control did not show any inhibition zone for both Gram-positive Staphylococcus aureus and Gram-negative Escherichia coli bacteria. Since there are several physical parameters that can affect the antibacterial activity of the material namely particle size, morphology, shape, stability, reactivity, and chemical properties. In the last two decades, researchers, scientists, and technologists have utilised both organic and inorganic nanoparticles as antibacterial agents due to their eco-friendliness and enhanced material durability. From our study we can conclude that the Sr1−xAl2O4:Eux (x = 0.00, and 0.05) phosphor (SAE 0.00 and SAE 0.05 phosphor) synthesized by urea fuel combustion method is eco-friendly material, because it did not release any high toxic gas during synthesis process, therefore the synthesized material is applicable as an optical coating agent for making solid state luminescent devices14,15. It is also useful in food preservation, safe cosmetics preparation, medical devices and water treatment.

Conclusion

The Sr1−xAl2O4:Eux (x = 0.00, 0.01, 0.03, 0.05, 0.07, and 0.09) phosphor was successfully synthesized via urea fuel combustion method. The kind of phase and crystal structure of the sample were confirmed using XRD data, which revealed that it was a single phase with a monoclinic structure and a space group of P 21/n. The FTIR technique was used to chemical bonding behaviour of synthesized phosphor. According to an optical band gap analysis, the sample is a broad band gap material; the value of optical band gap in the current case (SAE 0.05) is 3.78 eV. From Transmission electron microscopy (TEM), the average size found around 6–25 nm. The Image J software was used to compute the fringe width of the HRTEM image. The estimated inter-planner spacing d = 0.222 nm for (231) plan from XRD results is quite close to the observed inter-planner spacing d = 0.22 nm for HRTEM image. The PL emission spectra displayed characteristic glow peaks corresponding to Eu2+ in the visible range. When we change the concentration of activator Eu in the host SrAl2O4 the nature of emission is change accordingly. The Sr1−xAl2O4:Eux (x = 0.05) phosphor give maximum emission intensity. It can be observed that the Sr1−xAl2O4:Eux (x = 0.05) phosphor can be regulated as green (0.23, 0.49) emission with the colour temperature 3224 K, CRI 78 and colour purity 60.69%. The use of broad photo emission spectra to obtain direct green emission for green light emitting diodes and other optoelectronic devices could be considered another possibility; the green lights can regulate the circadian rhythm through melatonin. Also the Sr1−xAl2O4:Eux (x = 0.00 and 0.05) phosphor behaves like eco-materials. Because nano particles of Sr1−xAl2O4:Eux (SAE 0.05) does not show antibacterial activity. It is applicable as an optical coating agent for making solid state luminescent devices and it is also useful in food preservation, safe cosmetics, medical devices and water treatment.

Data availability

On the behalf all authors, the corresponding author state that materials described in the manuscript, including all relevant raw data will be freely available to any researcher wishing to use them for non-commercial purposes, without breaching participant confidentiality. The corresponding author also states that the information on where data supporting the results reported in the article can be found, if applicable. When and where applicable, hyperlinks to publicly archived datasets analyzed or generated during the study.

References

Neema, R., Saleem, M., Sharma, P. K. & Mittal, M. Structure, optical bandgap and luminescence studies of SrAl2O4:Eu3+, Dy3+ nanophosphor. 3rd International Conference on Condensed Matter and Applied Physics (ICC-2019) 2220, 020159 (2020).

Aoki, Y. & Bell, P. E. L. United States Patent (19) 29 (1995).

Abstracts, E. Abstracts of the XIIth international symposium on luminescence spectrometry—Detection techniques in biomedical, environmental and food analysis (ISLS 2006) determination of benzimidazole fungicides by coupling solid-phase microextraction and. Luminescence 320–386 (2006).

Qiu, Z., Zhou, Y., Lu, M., Zhang, A. & Ma, Q. Combustion synthesis of long-persistent luminescent MAl2O4:Eu2+, R3+ (M = Sr, Ba, Ca, R = Dy, Nd and La) nanoparticles and luminescence mechanism research. Acat Mater. 55, 2615–2620 (2007).

Rojas-Hernandez, R. E., Rubio-Marcos, F., Rodriguez, M. Á. & Fernandez, J. F. Long lasting phosphors: SrAl2O4:Eu, Dy as the most studied material. Renew. Sustain. Energy Rev. 81, 2759–2770 (2018).

Panse, V. R., Yerpude, A. N., Dhoble, S. J., Kokode, N. S. & Choithrani, R. Synthesis and optical characterization of CaSr2Al2O6:RE3+ (RE = Eu and Tb) phosphor for solid state lighting. J. Mater. Sci. Mater. Electron. 28, 16880–16887 (2017).

Kurmi, S., Litoriya, P. K. & Verma, A. Structural interpretation and photoluminescence properties of Sr0.90−xCa0.10Al12O19:Dyx3+ nanophosphors synthesis by combustion system. Indian J. Sci. Technol. 15(15), 649–657 (2022).

Kurmi, S. A comparative analysis on structural and photoluminescence properties of dysprosium, neodymium and europium doped strontium. Indian J. Nat. Sci. 12, 38447–38452 (2022).

Yu, Y. et al. Structural characterization and optical properties of long-lasting CaAl2O4:Eu2+, Nd3+ phosphors synthesized by microwave-assisted chemical co-precipitation. J. Rare Earths 35, 652–657 (2017).

Andre, M. Crystallisation of spray-dried amorphous precursors in the SrO-Al2O3 system: A DSC study. J. Eur. Ceram. Soc. 23, 2075–2081 (2003).

Choi, S., Kim, N., Yun, Y. & Choi, S. Photoluminescence properties of SrAl2O4 and CaAl2O4 long-phosphorescent phosphors synthesized by an oxalate coprecipitation method. J. Ceram. Process. Res. 7, 62–65 (2006).

Peng, T., Huajun, L., Yang, H. & Yan, C. Synthesis of SrAl2O4:Eu, Dy phosphor nanometer powders by sol-gel processes and its optical properties. Mater. Chem. Phys. 85, 68–72 (2004).

Litoriya, P.K. et al. Using the urea fuel combustion method, structural, morphological, and photoluminescence investigation of nanophosphor. Vidyabharati International Interdisciplinary Research Journal (Special Issue) ISSN 2319–4979. 333–342 (2021).

Verma, A. et al. Investigation of structural, luminescence, and anti- bacterial properties of novel Zn1−xEuxAl2−yO4Sry phosphor. J. Mater. Sci. Mater. Electron. 33, 15858–15878. https://doi.org/10.1007/s10854-022-08486-1 (2022).

Verma, A. & Verma, A. thermoluminescence, and antibacterial properties of SrMgAl10O17:Eu phosphor. J. Alloy. Compd. 802, 394–408 (2019).

Yu, X., Zhou, C., He, X., Peng, Z. & Yang, S. P. The influence of some processing conditions on luminescence of SrAl2O4:Eu2+ nanoparticles produced by combustion method. Mater. Lett. 58, 1087–1091 (2004).

Litoriya, P. K., Kurmi, S. & Verma, A. Structural, optical, morphological and photoluminescence properties of SrAl2O4:Dy by using urea fuel combustion method. Mater. Today Proc. https://doi.org/10.1016/j.matpr.2022.05.487 (2022).

Zhai, B. G. & Huang, Y. M. Green afterglow of undoped SrAl2O4. Nanomaterials 11, 2331 (2021).

Senaratne, C. L., Gallagher, J. D., Jiang, L., Aoki, T. & Smith, D. J. Ge1−y Sn y (y = 0.01–0.10) alloys on Ge-buffered Si: Synthesis, microstructure, and optical properties. J. Appl. Phys. 116, 133509 (2014).

Shanthraj, P. & Zikry, M. A. Dislocation density evolution and interactions in crystalline materials. Acta Mater. 59, 7695–7702 (2011).

Verma, A., Verma, A., Bramhe, G. V. & Sahu, I. P. Optical studies of the Ba1−xMgAl10O17:Eux phosphors synthesis by combustion route. J. Alloy. Compd. https://doi.org/10.1016/j.jallcom.2018.07.371 (2018).

Liu, Y., Liu, Y. & Drew, M. G. B. Clarifications of concepts concerning interplanar spacing in crystals with reference to recent publications. SN Appl. Sci. https://doi.org/10.1007/s42452-020-2498-5 (2020).

Gupta, P., Patel, P., Sujata, K. M. & Solanki, R. G. Synthesis and characterization of ZnSe nanorods by coprecipitation method. Mater. Today Proc. https://doi.org/10.1016/j.matpr.2022.05.411 (2022).

Das, T., Das, B. K., Parashar, S. K. S. & Parashar, K. Impact of divalent dopant Ca2+ on the electrical properties of ZnO by impedance spectroscopy. Bull. Mater. Sci. 40, 247–251 (2017).

Hammad, T. M., Kuhn, S., Amsha, A. A., Hejazy, N. K. & Hempelmann, R. Comprehensive study of the impact of Mg2+ doping on optical, structural, and magnetic properties of copper nanoferrites. J. Supercond. Novel Magn. 33, 3065–3075 (2020).

Finley, E., Paterson, A. S., Cobb, A., Willson, R. C. & Brgoch, J. Reducing particle size of persistent luminescent SrAl2O4:Eu2+, Dy3+ via microwave-assisted, reverse micelle synthesis. Opt. Mater. Express 7, 2597 (2017).

Calderón-Olvera, R. M. et al. Characterization of luminescent SrAl2O4 films doped with terbium and europium ions deposited by ultrasonic spray pyrolysis technique. Ceram. Int. 44, 7917–7925 (2018).

Tauc, T., Kubelka, P. & Munk, F. How to correctly determine the band gap energy of modified semiconductor photocatalysts based on UV–Vis spectra. J. Phys. Chem. Lett. 9, 6814–6817. https://doi.org/10.1021/acs.jpclett.8b02892 (2018).

Nakauchi, D., Okada, G., Koshimizu, M. & Yanagida, T. Optical and scintillation properties of Nd-doped SrAl2O4 crystals. J. Rare Earths 34, 757–762 (2016).

Litoriya, P. K., Kurmi, S. & Verma, A. Structural, optical, morphological and photoluminescence properties of Eu2+, Dy3+ co-doped Sr1−xAl2O4 phosphor by using urea fuel Combustion method. Oxid. Commun. 45(3), 514–528 (2022).

Fu, Z., Zhou, S., Yu, Y. & Zhang, S. Combustion synthesis and luminescence properties of nanocrystalline monoclinic SrAl2O4:Eu2+. Chem. Phys. Lett. 395, 285–289 (2004).

Singh, S., Tanwar, V., Simantilleke, A. P. & Singh, D. Structural and photoluminescent investigations of SrAl2O4:Eu2+, RE3+ improved nanophosphors for solar cells. Nano-Structures Nano-Objects 21, 100427 (2020).

Banjare, G. R., Bisen, D. P., Brahme, N. & Belodhiya, C. Synthesis and luminescence behavior of Ba2SiO4:Dy3+ phosphors in presence of charge compensator ions phosphors in presence of charge compensator ions. IOP Conf. Ser. Mater. Sci. Eng. https://doi.org/10.1088/1757-899X/798/1/012010 (2020).

Ghosh, A., Selvaraj, P., Sundaram, S. & Mallick, T. K. The colour rendering index and correlated colour temperature of dye-sensitized solar cell for adaptive glazing application. Sol. Energy 163, 537–544 (2018).

Li, C. et al. Accurate method for computing correlated color temperature. Opt. Express 24, 421–426 (2016).

Herna, J., Lee, R. L. & Romero, J. Calculating correlated color temperatures across the entire gamut of daylight and skylight chromaticities. Appl. Opt. 38, 5703–5709 (1999).

Acknowledgements

The characterisation facilities of the Sophisticated Instrument Centre (SIC) of the Dr. Harisingh Gour Vishwavidyalaya, Sagar (M.P.) (A Central University) have been used, and the authors thank the SIC for this. The heads of the physics departments and head of microbiology of Dr. Harisingh Gour Vishwavidyalaya Sagar (M.P.) (A Central University) are also acknowledged by the authors for their help with PL characterization and antibacterial study respectively.

Author information

Authors and Affiliations

Contributions

Material preparation, Conceptualization, Methodology, Formal analysis, Investigation, Writing and editing—original draft, data collection and analysis were performed and the first draft of the manuscript was written by P.K.L. Formal analysis of TEM was performed by S.K. Funding acquisition, Conceptualization, Supervision, Project administration, Resources was provided by A.V. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Litoriya, P.K., Kurmi, S. & Verma, A. Investigation of structural, optical, morphological, photoluminescence and antimicrobial properties of SrAl2O4:Eu2+ nanophosphor by using urea fuel combustion method. Sci Rep 13, 2188 (2023). https://doi.org/10.1038/s41598-023-29241-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-29241-4

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.