Abstract

The energy balance and life cycle assessment (LCA) of ohmic heating and appertization systems for processing of chopped tomatoes with juice (CTwJ) were evaluated. The data included in the study, such as processing conditions, energy consumption, and water use, were experimentally collected. The functional unit was considered to be 1 kg of packaged CTwJ. Six LCA impact assessment methodologies were evaluated for uncertainty analysis of selection of the impact assessment methodology. The energy requirement evaluation showed the highest energy consumption for appertization (156 kWh/t of product). The energy saving of the ohmic heating line compared to the appertization line is 102 kWh/t of the product (or 65% energy saving). The energy efficiencies of the appertization and ohmic heating lines are 25% and 77%, respectively. Regarding the environmental impact, CTwJ processing and packaging by appertization were higher than those of ohmic heating systems. In other words, CTwJ production by the ohmic heating system was more environmentally efficient. The tin production phase was the environmental hotspot in packaged CTwJ production by the appertization system; however, the agricultural phase of production was the hotspot in ohmic heating processing. The uncertainty analysis results indicated that the global warming potential for appertization of 1 kg of packaged CTwJ ranges from 4.13 to 4.44 kg CO2eq. In addition, the global warming potential of the ohmic heating system ranges from 2.50 to 2.54 kg CO2eq. This study highlights that ohmic heating presents a great alternative to conventional sterilization methods due to its low environmental impact and high energy efficiency.

Similar content being viewed by others

Introduction

Life Cycle Assessment (LCA) is a recognized standardized methodology for examining environmental consequences in food systems. In recent years, this method has been applied to the environmental assessment of agricultural systems, such as apple1, peanut2, strawberry3, cacao4, kiwifruit5, canola6, tea7, peach8, apricot9, barley10, corn11, and tobacco12. However, there are few studies on the LCA of food processing systems, such as tomato-based product processing13, olive oil14, tea processing15, whole peeled canned tomato16, pasta production17, legume processing and packaging18, and apple juice19. Life cycle environmental impact assessment of food production (agricultural phase and processing) throughout its supply chain can improve the understanding of environmental impacts and determine the environmental hotspots of production systems.

In recent years, the development of an environmentally sustainable food supply chain has become important20. In this regard, LCA can also help policymakers and managers produce their products in a more environmentally friendly manner. In this regard, tomato (Lycopersicon esculentum) is the second most important vegetable crop after potato, and the total worldwide tomato production was 182 million tons in 201721. There are different tomato-based products, such as purée, paste, juice, chopped tomatoes, and peeled tomatoes in tomato juice, resulting in various processing systems.

The environmental impacts of the agricultural phase of tomato production have been widely investigated in different parts of the world, such as Australia22, Albania23, Colombia24, Iran25,26, Italy16,27, Spain28,29,30, and Canada31. More information regarding the LCA studies on the agricultural phase of tomato production systems can be found in Pineda et al.32. However, there are a few published documents related to the LCA of different tomato processing systems. Table 1 displays a summary of the relevant literature on the LCA of tomato processing systems.

Industrial food processing is the second most notable phase of the food supply chain, accounting for 28% of the total energy use33. Moreover, industrial production, together with logistics and packaging (beyond the farm gate), are responsible for approximately half of the total energy consumption in the food chain33. The EU food industry is making significant contributions to improve energy efficiency while optimizing production processes through different approaches: (i) energy and heat recovery, (ii) selection of renewable energy sources to minimize the impact of energy consumed, and (iii) development and application of new sustainable “green and innovative” techniques in food processing. In comparison to conventional food processing technologies, green and innovative food processing technologies involve less processing time, reduced solvent and energy consumption, and a lower CO2 footprint34. The most common innovative thermal and non-thermal technologies in the food industry are ohmic heating, microwave heating, radiofrequency, high-pressure processing, and pulsed electric fields. Ohmic heating provides a rapid and uniform heating, consequentially reducing thermal damage compared to conventional heating and allows manufacturers to obtain high-quality products with minimum nutritional, sensorial, and structural changes35. The conversion of electric energy into thermal energy during ohmic heating results in high energy efficiency (i.e., > 90%), which is considerably higher than those achieved by the traditional indirect heating technologies that rely on the burning of fuels, such as appertization, tubular heat exchangers, and plate heat exchangers36,37. In a study, Aganovic et al.38 investigated the energy consumption and environmental life cycle of thermal, high-pressure processing (HPP), and pulsed electric field (PEF) technologies for tomato and watermelon preservation. The results indicated that the tomato juice farm-to-gate environmental impact was higher than that of watermelon juice, and the largest energy uptake was documented for HPP, followed by PEF and traditional thermal processing.

Italy leads tomato production in the EU with a share of 36%; the amount of total tomato production was 5.6 million tons (96% for processing) in 201539. Reviewing the related relevant literature, it has been highlighted that in-depth research has not yet been conducted on the environmental impacts of chopped tomatoes with juice (CTwJ) processing by conventional processing, including appertization and innovative electro-technology such as ohmic heating. Similarly, for energy efficiency, research studies focus only on specific unit operations and not on the entire processing line to determine energy consumption. Thus, this study aimed to perform an energy efficiency comparison (global line and thermal unit operations) and LCA of ohmic heating and appertization for CTwJ processing.

Materials and methods

Tomato processing

Tomatoes (Solanum lycopersicum var. Hybrid) were grown in the Italian Puglia region. They were purchased and transported to processing plants located 160 km away and then processed at a local Italian factory. For the purpose of this study, the industrial appertization and aseptic ohmic heating units were selected as described in Figs. 1 and 2, respectively. The preparation processes (grading, washing, peeling, and dicing) were the same for both industrial lines. The tomatoes were peeled using a steam system (Cavalieri, Italy) under pressurized steam at 110 °C for 10 s, followed by mechanical separation of the peels. A linear dicer was used to cut tomatoes (Cavalieri, Italy). The tomatoes were first cut into 2 cm thick slices, and afterward to 1.7 cm-side cubes. Diced tomatoes and juice were mixed in a tank for approximately 10 min for further processing by appertization or ohmic heating. A volumetric pump was used to feed the ohmic heating and appertization units. This pump minimizes product damage and enables moving fluid–solid mixtures containing approximately 60% of diced tomatoes in 40% tomato juice. Figures 1 and 2 illustrate the system boundaries in CTwJ processing and packaging upon appertization and ohmic heating systems.

Appertization line

Diced tomatoes and juice were mixed in a tank for 10 min. They were pre-heated (ca. 60 °C) using direct steam injection before hot filling in tinplate cans. Cans sterilization was done using a tunnel sterilizer (Manzini, Italy) at 95 °C for 30 min with a production rate of 6 t/h of canned diced tomatoes with juice. The steam production system consists of firetube steam boilers (PB 100 model, Mingazzini, Parma, Italy) with a steam output of 10,000 kg/h and rated pressure of 12 bar.

Aseptic ohmic heating line

The process is based on the electrical resistance of the chopped tomato with the juice that is treated. Dissipation of the electrical energy when electric current flows through food leads to heat release (Joule effect)40. Ohmic heating was conducted in an industrial-scale unit, consisting of one stage for pre-heating the CTwJ up to 75 °C and a subsequent stage for heating them up to 102 °C. It then enters the insulated holding tubes before being cooled in tubular heat exchangers (Tetra Pak, Denmark) up to 20 °C. After cooling, the product is pumped into the aseptic storage vessel prior to aseptic packaging in multi-layer plastic pouches. The total electrical power of the ohmic system was 240 kW, and the average product flowrate was 4 t/h. The flowrate was recorded using an electromagnetic flowmeter (EMC, Auckland, New Zealand) with a precision of within 1% of the full range. The bulk temperatures were measured using platinum resistance probes (Pt 100 Ω to 0 °C with a ± 0.1 °C accuracy) placed at the inlet and outlet of each zone. Relative pressure was measured with manometers (JUMO, type 4AP30, Fulda, Germany) at the inlet and outlet of each zone with a precision of 0.1%. The power supply delivers bipolar potential pulses, and electrolysis is prevented by using a high-frequency alternating voltage41.

Energy auditing

Energy requirements were experimentally measured through energy auditing. Both processing lines were instrumented to determine thermal and electrical energy inputs and consumption.

The energy requirement for the appertization line encompasses the electricity used by conveyers, pumping systems, and line dicers; thermal energy is required for peeling, pre-heating prior to appertization, sterilization and cooling of the product.

The specific energy required for heating the cans (Ec) and their contents (Ep) was calculated using Eqs. (1) and (2), where nc is the number of cans per cycle, mc is the weight of empty cans, mp is the weight of the product per can, Cpc is the specific heat of cans, Cpp is the specific heat of the product, Tc is the temperature of the cans, Tp is the temperature of the product, and Ts is the steam temperature inside the sterilizer:

The energy input in the tunnel sterilizer (Es) was calculated using Eq. (3), with \(\dot{m}_{{vs}}\) as the steam mass flowrate, and hvs is the specific enthalpy of steam:

Ohmic heating occurs due to the electrical conductivity and ability of the electrical current to flow through it. The power clamp meter was connected to the electrical power supply to measure the given electrical power (Pg). The fraction of electrical power converted to thermal energy and dissipated in the product was calculated using Eq. (4), with \(\dot{m}_{{po}}\) as the mass flowrate of the product in the ohmic heater, Cpp is the specific heat of the product, Tpi is the inlet temperature of the product, and Tpo is the outlet temperature of the product.

The energy required for final cooling prior to aseptic packaging was calculated using Eq. (5), where \(\dot{m}_{{wc}}\) is the mass flowrate of cooling water, Cpw is the specific heat of water, Tiw is the inlet temperature water, and Tow is the outlet temperature of water in the heat exchanger:

Software

EDraw Max (ver. 9.1, 2018; Sheung Wan, Hong Kong) was used for the representation of the appertization and ohmic heating flowcharts. The LCA analysis was performed using the professional SimaPro software (ver. 8.1.0 Analyst) and adapted Ecoinvent 3.2 database.

LCA methodology

LCA is a standardized and widespread methodology to study environmental consequences associated with food42. The LCA procedure is outlined by ISO 14040 and ISO 1404443. A comprehensive LCA comprises four coherent and iterative phases (1) goal and scope definition, (2) life cycle inventory, (3) impact assessment, and (4) interpretation of the results.

Definition of the goal and scope

The objective of this study was to perform an attributional life cycle environmental assessment of CTwJ processing and packaging upon appertization and ohmic heating systems. The functional unit (FU) was considered as 1 kg of CTwJ, which is a single reference of the product, requiring 1.6 kg of fresh tomato. Mass-based FU is common in food processing LCA (see Table 1). Figures 1 and 2 illustrate the system boundaries in CTwJ processing and packaging for the appertization and ohmic heating systems.

Life cycle inventory

The inputs and outputs of the investigated system were quantified in the second phase of the LCA44. The cradle-to-grave emissions were classified into background (off-site) and foreground (on-site) emissions45. The background emissions include the emitted pollutants from the production of material inputs, for instance, the emissions released within the generation of electricity and natural gas. However, foreground emissions comprise the direct emissions from the consumption of inputs in the investigated factory, for instance, emissions released within the combustion of natural gas. The background’s emissions coefficients, such as the emissions of electricity generation and distribution, were adapted from the Ecoinvent database.

Life cycle impact assessment

In the third phase of an LCA study, impact category selection and characterization are mandatory; however, normalization and weighing are optional46. The IMPACT 2002+ methodology was applied as the baseline impact assessment methodology, given its inclusion of various impact and damage categories. It is also a combination hybrid IMPACT 2002, Eco-Indicator 99, CML, and IPCC.

Uncertainty analysis of the impact assessment

There are some sources of uncertainties affecting the LCA results, including data quality, scenarios, and mathematical models underlying the impact assessment methods44,47. As shown in Table 1, studies on the LCA of tomato processing have employed different impact assessment methodologies (see Table 1). In this study, an uncertainty analysis was performed to investigate the effect of impact assessment selection on the LCA results of the case study. For this purpose, six impact assessment methodologies, i.e., EDIP 2003, CML-IA baseline, EDP 2013, ILCD 2011 Midpoint, ReCiPe midpoint, and IMPACT 2002+ were considered to be evaluated by LCA. The analyses were conducted using SimaPro V8.0.3.14.

Research involving plants

Studies complied with local and national regulations for using plants.

Results and discussion

Energy auditing

An overview of the energy and water requirements for the aseptic ohmic heating and appertization lines is presented in Table 2.

The global specific energies for appertization and ohmic heating industrial lines for pre-processing and processing of CTwJ were 156 and 54 kWh/t, respectively. The energy requirement for the appertization line encompasses the electricity consumed by conveyers, pumping systems, and line dicers; the thermal energy required for peeling, pre-heating prior to appertization, and the energy required for sterilization, cooling, and packing of the product. Energy uptake for the ohmic heating includes the electricity used by conveyers, pumping systems, and line dicers; thermal energy required for peeling, ohmic pre-heating and ohmic sterilization; and energy consumption for cooling and aseptic packaging of the final product. The energy saving of the ohmic heating line compared to the appertization line is 102 kWh/t of the product (or 65% energy saving).

The energy efficiencies of the appertization and ohmic heating systems are 25% and 77%, respectively. For ohmic heating, the electrical energy input is converted to thermal energy by the Joule effect, where the chopped tomato with juice behaves like a resistor in an electrical circuit. Energy losses in the ohmic heating system are mainly due to the pre-processing step and the cooling of the product during the holding phase between ohmic pre-heating and ohmic heating steps of the product; this temperature gradient was around 4.5 °C. Adding thermal insulation to this holding zone will improve the energy efficiency of the ohmic heating system.

Energy losses in the appertization line are mainly due to the lack of insulation, lack of reuse of steam condensate, and non-condensation of part of the injected steam. Steam condensate could be reused to heat feedwater for the steam boiler, pre-heat utilities, or clean equipment. Another major reason is the non-synchronization of the cans flow rates between the filling and retorting levels, which induces a continuous injection of steam in the retort even with a low load of cans. This situation leads to large energy losses due to the high steam consumption. This low efficiency can be improved by installing a steam regulation in the retort, which will provide the required steam flow depending on the load of the cans.

Interpretation of LCA results

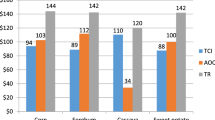

Table 3 displays the characterization indices for CTwJ production. The global warming potential, ozone layer depletion, and non-renewable energy consumption for 1 kg production of packaged CTwJ for the appertization system were determined to be 4.38 kg CO2eq, 1.34 × 10–7 kg CFC-11 eq, and 52.15 MJ, respectively. However, the aforementioned amounts for 1 kg of packaged CTwJ production upon the ohmic heating system were 2.52 kg CO2eq, 4.00 × 10–8 kg CFC-11 eq, and 24.94 MJ, respectively. The results clearly showed that the environmental impacts of CTwJ processing and packaging on appertization were higher than those of ohmic heating systems. In other words, CTwJ production by the ohmic heating system was more environmentally efficient. The global warming potential of tomato sauce production was reported to be 1.5 kg CO2eq48.

Figures 3 and 4 illustrate the share of inputs in environmental burdens of CTwJ production upon appertization and ohmic heating systems, respectively. The results indicated that the tin production phase was the hotspot in CTwJ production by the appertization system. The agricultural phase was the second main contributor to the most impacted categories. More specifically, the agricultural phase of tomato production and tin packaging accounted for 54.33% and 45.00% of the total global warming potential of CTwJ production, respectively. The results are in line with the study of Manfredi and Vignali49, which indicated that packaging was the main contributor to most impact categories for tomato purée production in a glass jar. Arnal et al.50 also highlighted that canning was the largest contributor to the total industrial-scale environmental impacts of packaged peeled tomato production systems. Packaging was reported to be responsible for the environmental impacts within all selected impact categories of tomato purée production, except for acidification and eutrophication51. Del Borghi et al.13 showed that packaging and agricultural phases had the highest adverse impacts on the environment during the production of 13 different tomato processed products. Many studies have also reported that the packaging phase is an environmental hotspot during the production of some other processed food products, such as dairy products52, and canned sardine53.

The results highlight the important contributions of the agricultural phase in the ohmic heating system in the most impacted categories. The agricultural phase accounted for 94.44% of the total global warming potential of CTwJ production by the ohmic heating system. In other words, the consumption of inputs, such as diesel fuel and chemical fertilizer cause a huge negative environmental impact during the CTwJ production supply chain.

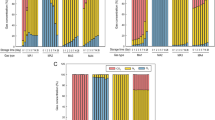

Figure 5 and 6 show the normalized damage assessment of CTwJ processing and packaging upon appertization and ohmic heating systems, respectively. The largest adverse environmental impact belonged to the human health damage category upon CTwJ production in both systems. The direct emissions of fossil fuels during the tomato production supply chain play a key role in the human health damage category. The resources damage category was placed as the second damage category with higher adverse environmental impacts in packed CTwJ production.

Figure 7 illustrates the normalized damage assessment of CTwJ processing and packaging for appertization and ohmic heating systems. The normalized damage assessment of CTwJ processing and packaging for the appertization system was higher than the ohmic heating system in all impact categories. So, the packed CTwJ for the ohmic heating system was more environmentally friendly. An LCA study on tomato processing also indicated that the application of PEF technology could mitigate environmental impacts50.

Uncertainty analysis of the impact assessment

Table 4 illustrates the indicators of CTwJ production for different impact assessment methodologies. The obtained results help to compare the results of this study with those published on LCA tomato-based products. The results showed that the global warming potential of 1 kg of packaged CTwJ ranges from 4.13 to 4.44 kg CO2eq, within the appertization line. In addition, the global warming potential of the ohmic heating system ranges from 2.50 to 2.54 kg CO2eq. The results also indicated that the ozone layer depletion for the production of 1 kg of packaged CTwJ ranges from 1.33 × 10–7 to 1.35 × 10–7 kg CFC-11 eq; however, this value for ohmic heating systems ranges from 3.99 × 10–8 to 4.03 × 10–8.

Mitigation strategies

As previously mentioned, packaging and agricultural phases were the environmental hotspots in both systems. One solution to reduce the environmental burdens of tomato product processes is related to the packaging phase; it could be weight reduction49, and transitioning to packaging materials with less environmental impacts, such as bio-based packaging13,51. Therefore, the mitigation of the environmental impacts of tomato cultivation, replacing the packaging materials with bio-based materials, and using the by-products of cultivation and processing for supplying a part of the energy requirement can be considered as the main strategy for environmental impact mitigation of the CTwJ production supply chain. In the case of agricultural phase of CTwJ supply chain, Muñoz et al.28 highlighted that the environmental impacts of 1 kg of tomato production in a greenhouse is less than that of an open field system due to the efficient use of water, fertilizers, and pesticides. A study compared three tomato farming systems (open field, greenhouse, and hydroponic) in terms of energy use patterns and concluded that the hydroponic system was the most environmentally friendly system54. Bojacá et al.24 believed that the implementation of integrated pest management programs could mitigate the environmental impacts of Colombian greenhouse tomato production. Bacenetti et al.55 compared the two scenarios of the tomato purée production supply chain. In the first scenario, tomato by-products were sent back to the farms as bio-fertilizers; in the second scenario, the by-products were used in terms of biogas generation. The results showed that the second scenario was more environmentally efficient.

Moreover, there are some measures which can be taken in to consideration in order to mitigate the environmental impacts of CTwJ processing. For instance, a study focusing on the valorization of tomato by-products (tomato seeds and peels) highlighted the potential application of whole tomato by-products for valuable compound recovery and sequential low-cost biosorbent production56. Winans et al.57 applied LCA to study the diced tomatoes and paste production systems in California over a 10-year timeframe. They showed that the introduction of renewables in the life cycle of the production systems, such as solar-powered irrigation pumps, and on-site solar energy generation for facilities can mitigate the GWP impacts by 9–10%.

Conclusions

This is the first study to compare the energy requirement and life cycle environmental impact of a novel food processing technology (ohmic heating) with a conventional method (appertization) in the tomato processing industry, considered one of the largest food processing industries worldwide. Moreover, uncertainty analysis was performed through the application of six different impact assessment methodologies.

The energy requirement evaluation showed the highest energy consumption for appertization (156 kWh/t of product). The energy saving of the ohmic heating line compared to the appertization line was 102 kWh/t of the product (or 65% energy saving). The energy efficiencies of the appertization and ohmic heating systems are 25% and 77%, respectively. There are opportunities for energy optimization of the investigated processes while maintaining the potential quality benefit. In the appertization system, a more energy-efficient process could be obtained by reducing steam non-condensation and installing a steam regulation, which will give the necessary steam flow depending on the load of the cans. In the case of ohmic heating, adding thermal insulation to the holding zone will improve the energy efficiency of the system.

From the LCA perspective, the uncertainty analysis results suggested that the global warming potential of the production of 1 kg of packaged CTwJ ranges from 4.13 to 4.44 kg CO2eq. In addition, the global warming potential of the ohmic heating system ranges from 2.54 to 2.78 kg CO2eq. Overall, CTwJ production by the ohmic heating system was more environmentally efficient than traditional retort canning.

Given this study was conducted on an industrial scale, the effect of influencing variables in the manufacture process of CTwJ production was not optimized. Therefore, further research is needed to optimize the processes in terms of energy and environmental impacts. In addition, replacing the packaging materials with bio-based materials, and using the by-products of cultivation and processing for supplying a part of the energy requirement, on the final energy and environmental impacts of CTwJ production should be further explored.

Abbreviations

- CML:

-

Institute of environmental sciences

- CO2 :

-

Carbon dioxide

- CTwJ:

-

Chopped tomatoes with juice

- Eq:

-

Equivalent

- FU:

-

Functional unit

- FU:

-

Functional units

- HPP:

-

High pressure processing

- IPCC:

-

Intergovernmental panel on climate change

- ISO:

-

International standardization organization

- kg:

-

Kilogram

- LCA:

-

Life cycle assessment

- LCI:

-

Life cycle inventory

- m3 :

-

Cubic meter

- MJ:

-

Mega joule

- PEF:

-

Pulsed electric fields

- SO2 :

-

Sulfur dioxide

- t:

-

Tonne

- Wh:

-

Watt-hour

References

Keyes, S., Tyedmers, P. & Beazley, K. Evaluating the environmental impacts of conventional and organic apple production in Nova Scotia, Canada, through life cycle assessment. J. Clean. Prod. 104, 40–51 (2015).

Nikkhah, A., Khojastehpour, M., Emadi, B., Taheri-Rad, A. & Khorramdel, S. Environmental impacts of peanut production system using life cycle assessment methodology. J. Clean. Prod. 92, 84–90 (2015).

Tabatabaie, S. M. H. & Murthy, G. S. Cradle to farm gate life cycle assessment of strawberry production in the United States. J. Clean. Prod. 127, 548–554 (2016).

Utomo, B., Prawoto, A. A., Bonnet, S., Bangviwat, A. & Gheewala, S. H. Environmental performance of cocoa production from monoculture and agroforestry systems in Indonesia. J. Clean. Prod. 134, 583–591 (2016).

Nikkhah, A. et al. Integration of life cycle assessment and Cobb–Douglas modeling for the environmental assessment of kiwifruit in Iran. J. Clean. Prod. 137, 843–849 (2016).

Mousavi-Avval, S. H. et al. Application of multi-objective genetic algorithms for optimization of energy, economics and environmental life cycle assessment in oilseed production. J. Clean. Prod. 140, 804–815 (2017).

Kouchaki-Penchah, H., Nabavi-Pelesaraei, A., O’Dwyer, J. & Sharifi, M. Environmental management of tea production using joint of life cycle assessment and data envelopment analysis approaches. Environ. Prog. Sustain. Energy 36(4), 1116–1122 (2017).

Nikkhah, A., Royan, M., Khojastehpour, M. & Bacenetti, J. Environmental impacts modeling of Iranian peach production. Renew. Sustain. Energy Rev. 75, 677–682 (2017).

Pergola, M. et al. A comprehensive Life Cycle Assessment (LCA) of three apricot orchard systems located in Metapontino area (Southern Italy). J. Clean. Prod. 142, 4059–4071 (2017).

Tricase, C., Lamonaca, E., Ingrao, C., Bacenetti, J. & Giudice, A. L. A comparative Life Cycle Assessment between organic and conventional barley cultivation for sustainable agriculture pathways. J. Clean. Prod. 172, 3747–3759 (2018).

Lee, E. K. et al. Projecting life-cycle environmental impacts of corn production in the US Midwest under future climate scenarios using a machine learning approach. Sci. Total Environ. 714, 136697 (2020).

Mirkarimi, S. R., Ardakani, Z. & Rostamian, R. Economic and environmental assessment of tobacco production in Northern Iran. Ind. Crops Prod. 161, 113171 (2021).

Del Borghi, A., Gallo, M., Strazza, C. & Del Borghi, M. An evaluation of environmental sustainability in the food industry through Life Cycle Assessment: The case study of tomato products supply chain. J. Clean. Prod. 78, 121–130 (2014).

Tsarouhas, P., Achillas, C., Aidonis, D., Folinas, D. & Maslis, V. Life Cycle Assessment of olive oil production in Greece. J. Clean. Prod. 93, 75–83 (2015).

Khanali, M., Mobli, H. & Hosseinzadeh-Bandbafha, H. Modeling of yield and environmental impact categories in tea processing units based on artificial neural networks. Environ. Sci. Pollut. Res. 24(34), 26324–26340 (2017).

Garofalo, P., D’Andrea, L., Tomaiuolo, M., Venezia, A. & Castrignanò, A. Environmental sustainability of agri-food supply chains in Italy: The case of the whole-peeled tomato production under life cycle assessment methodology. J. Food Eng. 200, 1–12 (2017).

Heidari, M. D. et al. Regionalised life cycle assessment of pasta production in Iran: Damage to terrestrial ecosystems. J. Clean. Prod. 159, 141–146 (2017).

Del Borghi, A., Strazza, C., Magrassi, F., Taramasso, A. C. & Gallo, M. Life Cycle Assessment for eco-design of product–package systems in the food industry—The case of legumes. Sustain. Prod. Consum. 13, 24–36 (2018).

Khanali, M. et al. Energy flow modeling and life cycle assessment of apple juice production: Recommendations for renewable energies implementation and climate change mitigation. J. Clean Prod. 246, 118997 (2020).

De Marco, I. & Iannone, R. Production, packaging and preservation of semi-finished apricots: A comparative Life Cycle Assessment study. J. Food Eng. 206, 106–117 (2017).

Anwar, R., Fatima, T. & Mattoo, A. Tomatoes: A model crop of solanaceous plants. In Oxford Research Encyclopedia of Environmental Science https://doi.org/10.1093/acrefore/9780199389414.013.223 (2019).

Page, G., Ridoutt, B. & Bellotti, B. Carbon and water footprint tradeoffs in fresh tomato production. J. Clean. Prod. 32, 219–226 (2012).

Canaj, K., Mehmeti, A., Cantore, V. & Todorović, M. LCA of tomato greenhouse production using spatially differentiated life cycle impact assessment indicators: An Albanian case study. Environ. Sci. Pollut. Res. 27(7), 6960–6970 (2020).

Bojacá, C. R., Wyckhuys, K. A. & Schrevens, E. Life cycle assessment of Colombian greenhouse tomato production based on farmer-level survey data. J. Clean. Prod. 69, 26–33 (2014).

Khoshnevisan, B., Rafiee, S., Omid, M., Mousazadeh, H. & Clark, S. Environmental impact assessment of tomato and cucumber cultivation in greenhouses using life cycle assessment and adaptive neuro-fuzzy inference system. J. Clean. Prod. 73, 183–192 (2014).

Pishgar-Komleh, S. H. et al. Integration of life cycle assessment, artificial neural networks, and metaheuristic optimization algorithms for optimization of tomato-based cropping systems in Iran. Int. J. Life Cycle Assess. 25(3), 620–632 (2020).

Ronga, D. et al. Carbon footprint and energetic analysis of tomato production in the organic vs the conventional cropping systems in Southern Italy. J. Clean. Prod. 220, 836–845 (2019).

Muñoz, P. et al. Comparing the environmental impacts of greenhouse versus open-field tomato production in the Mediterranean region. In International Symposium on High Technology for Greenhouse System Management: Greensys 2007, 801, 1591–1596 (2007).

Antón, A. et al. Improvement of agricultural life cycle assessment studies through spatial differentiation and new impact categories: Case study on greenhouse tomato production. Environ. Sci. Technol. 48(16), 9454–9462 (2014).

Neira, D. P., Montiel, M. S., Cabeza, M. D. & Reigada, A. Energy use and carbon footprint of the tomato production in heated multi-tunnel greenhouses in Almeria within an exporting agri-food system context. Sci. Total Environ. 628, 1627–1636 (2018).

Maham, S. G., Rahimi, A., Subramanian, S. & Smith, D. L. The environmental impacts of organic greenhouse tomato production based on the nitrogen-fixing plant (Azolla). J. Clean. Prod. 245, 118679 (2020).

Pineda, I. T., Lee, Y. D., Kim, Y. S., Lee, S. M. & Park, K. S. Review of inventory data in life cycle assessment applied in production of fresh tomato in greenhouse. J. Clean. Prod. 282, 124395 (2020).

Monforti-Ferrario, F. et al. Energy use in the EU food sector: State of play and opportunities for improvement (Publications Office of the European Union, 2015).

Misra, N. N. et al. Landmarks in the historical development of twenty first century food processing technologies. Food Res. Int. 97, 318–339 (2017).

Ghnimi, S., Delaplace, G. & Fillaudeau, L. Tubular and fluid jet units. In Ohmic Heating in Food Processing, Electro-Technologies for Food Processing Series (CRC Press (Taylor & Francis Group), 2014).

Ramaswamy, H. S., Marcotte, M., Sastry, S. & Abdelrahim, K. Ohmic heating for food processing (2016). https://doi.org/10.1201/b12112-22.

Yildiz, H. & Guven, E. Industrial applications and potential use of ohmic heating for fluid foods. Bulgar. Chem. Commun. 46, 98–102 (2014). http://bcc.bas.bg/BCC_Volumes/Volume_46_Special_B_2014/BCC-46-B-98-102.pdf.

Aganovic, K. et al. Pilot scale thermal and alternative pasteurization of tomato and watermelon juice: An energy comparison and life cycle assessment. J. Clean. Prod. 141, 514–525 (2017).

Costa, J. M. & Heuvelink, E. The global tomato industry. Tomatoes 1–26 (CABI, 2018).

Ghnimi, S., Zaid, I., Maingonnat, J. F. & Delaplace, G. Axial temperature profile of ohmically heated fluid: Analytical model and experimental validation. Chem. Eng. Sci. 64(13), 3188–3196 (2009).

Ghnimi, S., Flach-Malaspina, N., Dresh, M., Delaplace, G. & Maingonnat, J. F. Design and performance evaluation of an ohmic heating unit for thermal processing of highly viscous liquids. Chem. Eng. Res. Des. 86, 627–632 (2008).

Nikkhah, A. Life cycle assessment of the agricultural sector in Iran (2007–2014). Environ. Prog. Sustain. Energy 37(5), 1750–1757 (2018).

Collotta, M. et al. Comparative LCA of three alternative technologies for lipid extraction in biodiesel from microalgae production. Energy Procedia 113, 244–250 (2017).

Rafiee, S. et al. Sustainability evaluation of pasteurized milk production with a life cycle assessment approach: An Iranian case study. Sci. Total Environ. 562, 614–627 (2016).

Paramesh, V., Arunachalam, V., Nikkhah, A., Das, B. & Ghnimi, S. Optimization of energy consumption and environmental impacts of arecanut production through coupled data envelopment analysis and life cycle assessment. J. Clean. Prod. 203, 674–684 (2018).

Dong, Y. H. & Ng, S. T. A life cycle assessment model for evaluating the environmental impacts of building construction in Hong Kong. Build. Environ. 89, 183–191 (2015).

Nikkhah, A., Firouzi, S., Dadaei, K. & Van Haute, S. Measuring circularity in food supply chain using life cycle assessment; Refining Oil from Olive Kernel. Foods 10(3), 590 (2021).

Parajuli, R., Matlock, M. D. & Thoma, G. Cradle to grave environmental impact evaluation of the consumption of potato and tomato products. Sci. Total Environ. 758, 143662 (2021).

Manfredi, M. & Vignali, G. Life cycle assessment of a packaged tomato puree: A comparison of environmental impacts produced by different life cycle phases. J. Clean. Prod. 73, 275–284 (2014).

Arnal, Á. J. et al. Implementation of PEF treatment at real-scale tomatoes processing considering LCA methodology as an innovation strategy in the agri-food sector. Sustainability 10(4), 979 (2018).

Shahvarooghi Farahani, S. S., Soheilifard, F., Raini, M. G. N. & Kokei, D. Comparison of different tomato puree production phases from an environmental point of view. Int. J. Life Cycle Assess. 24(10), 1817–1827 (2019).

Djekic, I., Miocinovic, J., Tomasevic, I., Smigic, N. & Tomic, N. Environmental life-cycle assessment of various dairy products. J. Clean. Prod. 68, 64–72 (2014).

Almeida, C., Vaz, S. & Ziegler, F. Environmental life cycle assessment of a canned sardine product from Portugal. J. Ind. Ecol. 19(4), 607–617 (2015).

Platis, D. P. et al. Analysis of energy and carbon and blue water footprints in agriculture: A case study of tomato cultivation systems. Euro-Mediterr. J. Environ. Integr. 6(1), 1–10 (2021).

Bacenetti, J., Duca, D., Negri, M., Fusi, A. & Fiala, M. Mitigation strategies in the agro-food sector: The anaerobic digestion of tomato puree by-products. An Italian case study. Sci. Total Environ. 526, 88–97 (2015).

Azabou, S., Louati, I., Taheur, F. B., Nasri, M. & Mechichi, T. Towards sustainable management of tomato pomace through the recovery of valuable compounds and sequential production of low-cost biosorbent. Environ. Sci. Pollut. Res. 27(31), 39402–39412 (2020).

Winans, K., Brodt, S. & Kendall, A. Life cycle assessment of California processing tomato: An evaluation of the effects of evolving practices and technologies over a 10-year (2005–2015) timeframe. Int. J. Life Cycle Assess. 25(3), 538–547 (2020).

Brodt, S., Kramer, K. J., Kendall, A. & Feenstra, G. Comparing environmental impacts of regional and national-scale food supply chains: A case study of processed tomatoes. Food Policy 42, 106–114 (2013).

Fillaudeau, L. & Ghnimi, S. Energy efficiency and control of ohmic heating process. In Ohmic Heating in Food Processing, Electro-Technologies for Food Processing Series (CRC Press (Taylor & Francis Group), 2014).

Bosona, T. & Gebresenbet, G. Life cycle analysis of organic tomato production and supply in Sweden. J. Clean. Prod. 196, 635–643 (2018).

Wohner, B., Gabriel, V. H., Krenn, B., Krauter, V. & Tacker, M. Environmental and economic assessment of food-packaging systems with a focus on food waste. Case study on tomato ketchup. Sci. Total Environ. 738, 139846 (2020).

Acknowledgements

The authors would like to acknowledge the support received from Ghent University Global Campus.

Author information

Authors and Affiliations

Contributions

S.G. developed the initial concept of the research and contributed to the data collection, energy analysis, and manuscript writing and editing A.N. contributed to the development of the initial concept, LCA analysis and writing of the first draft of the manuscript. J.D. contributed to the validation of the results, manuscript writing and editing. S.V. contributed to the concept, and editing of the article.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ghnimi, S., Nikkhah, A., Dewulf, J. et al. Life cycle assessment and energy comparison of aseptic ohmic heating and appertization of chopped tomatoes with juice. Sci Rep 11, 13041 (2021). https://doi.org/10.1038/s41598-021-92211-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-92211-1

This article is cited by

-

Ohmic Heating Technology for Food Applications, From Ohmic Systems to Moderate Electric Fields and Pulsed Electric Fields

Food Engineering Reviews (2024)

-

Life cycle assessment of rose oil and rose water production: a case study in Iran

International Journal of Environmental Science and Technology (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.