Abstract

In the present research, response parameters such as specific energy consumption (SEC), thermal efficiency (TE), energy efficiency (EF), drying time (DT), greenhouse gas (GHG) emission (such as CO2 and NOx), and quality features (color variation and shrinkage) were modeled by response surface methodology (RSM) for apple slices dried in a microwave dryer under ultrasonication (30 ℃—10 min) and blanching (80 °C—2 min) pretreatments. Also, RSM was applied to optimize two independent parameters including microwave power and sample thickness in the levels 100, 200, and 300 W and 2, 4, and 6 mm, respectively. The results indicated the significant influence (P < 0.01) of the independent parameters on the response parameters. The vales of SEC, DT, GHG emission, shrinkage, and color difference were linearly decreased with the declining sample thickness and increasing microwave power, while the energy and thermal efficiencies were increased by a quadratic equation. The use of ultrasonication and blanching pretreatments decreased the SEC, GHG emissions, and DT; while improving the quality of the samples as compared to the non-treated slices. The optimization results showed the optimal drying times (31.55, 82.19, and 50.55 min), SEC (3.42, 10.07, and 4.37 MJ/kg), CO2 with natural gas (1539.75, 1518.75, and 4585 g), CO2 with gas oil (3662.53, 2099.25, 2721.25 g), NOx with natural gas (10.094, 9.956, and 12.906 g), and NOx with gas oil (12.934, 12.758, and 16.538 g) at a microwave power of 300 W and sample thickness of 2 mm with desirability of 0.921, 0.935, and 0.916 for control samples, ultrasonicated, and blanched, respectively.

Similar content being viewed by others

Introduction

The apple has a wide application in the food industry and has consistently been in the focus of the consumers. The annual apple production amounted to 86,442,716 tons from 4,622,366 ha of the orchards in 20201. Therefore, regarding the high annual production amounts of this product, storage of apple is of crucial significance. The apple can be eaten fresh or as dried chips. The storage life of this product can be significantly prolonged with preserved quality by decreasing its moisture content (MC) through the drying processes2,3,4. Despite the remarkable advantages of drying in the processing and storage of food and agricultural products, the use of inappropriate methods under undesirable conditions can decrease the quality value of the final product along with a high energy consumption and increased production costs5,6. Quality characteristics such as color and shrinkage of food and agricultural products are among the most popular and influential factors that determine consumers' acceptance of them7. The protection of product quality with minimum specific energy consumption (SEC) is the most important challenge in the drying industries8. Therefore, the SEC of the drying process and the final quality of the samples have to be evaluated to achieve optimal drying conditions9 To solve these problems, a microwave dryer was applied to dry apple slices. Currently, there is an emerging trend of using new drying methods, such as microwave drying, which significantly increases the drying rate and product quality, and reduces energy consumption and greenhouse gas (GHG) emissions10. In contrast with other conventional thermal methods, heat is spread throughout the product in the microwave drying method because of the penetration of microwaves into the food11. Microwave drying results in desirable quality of the dried products such as larger water resorption, lower shrinkage, and higher porosity. Furthermore, this drying method can save SEC because of the shortening of the process time12. Other drying processes are accompanied by high SEC, accounting for 12–20% of global energy consumption13. Several reports describe emerging dryers (including microwave dryers) on energy indices such as energy efficiency (EF), thermal efficiency (TE), SEC, and drying efficiency (DE) for various crops such as garlic in a microwave vacuum14, gala apple in a microwave dryer with blanching, electric field and freezing pretreatment15, and Rosmarinus officinalis L in a convective and hybrid vacuum microwave16.

One of the most common non-thermal techniques to maintain the quality properties of food used as a pretreatment or in combination with different drying methods is ultrasound (US)17. In recent years, ultrasound pretreatment has become one of the most common mechanical pretreatments among various pretreatments (blanching, cold plasma, radio frequency, ethanol, Citric acid, potassium metabisulphite, ohmic heating) and has shown acceptable results in terms of increasing the drying properties of fruits and vegetables and reducing energy consumption18. In food processing, ultrasound causes changes in textural, rheological, physical, chemical and functional properties19. Several studies have also dried various food products using ultrasound pretreatment for Inula viscosa (L.)17, pumpkin seeds20, longan21, apple22, celery23, carrot24, and kiwifruit25. The results showed that pretreatments with different drying methods can be applied to decrease and increase the DT and the efficiency, respectively while preserving the final sample quality.

Today, due to the increase in population, the reduction of arable land and the improvement of the standard of living, the amount of energy consumption in the agricultural sector has increased26. In order to provide food for the growing population, intensive use of agricultural machines, electrical energy, and natural resources is needed. But because fossil resources are limited, and need to be preserved for future human generations, it is necessary to use them correctly and with high efficiency27. On the other hand, the increasingly intensive use of energy resources causes environmental problems28. During the last decades, the concentration of greenhouse gases has increased rapidly in the earth's atmosphere. In dry fruit production, drying has a large share of greenhouse gas emissions, hence strategies should be adopted to optimize energy consumption in the drying sector. Karimi et al.29 showed that using temperature from 40 to 60 °C and increasing Heat Carrier Particle (HCP) to seeds from 0 to 0.5 for drying Canola seeds in a fluidized bed dryer reduces GHG emission. Kaveh et al.30 compared different drying methods (hot air, hot air-infrared, hot air-microwave, hot air-solar, continuous conveyor) to reduce the GHG emissions of Pistacia Atlantica drying and reported that the combined microwave-hot air method produces the lowest amount of greenhouse gas. In another study, Miraei Ashtiani et al.31 stated that the use of cold plasma pretreatment before drying goldenberry in an ultrasound-assisted convective dryer leads to the reduction of GHG emissions. Motevali et al.32 suggested the microwave-hot air method for drying Aloe vera in different ways to reduce the amount of GHG emissions. Seyfi et al.33 from the comparison between three types of hot air, refractance window, and solar assisted refractance window based on the photovoltaic-thermal system dryers in drying Aloe vera gel, came to the conclusion that increasing the temperature and decreasing the thickness causes the reduction of GHG emissions.

Optimization means improving the performance of a system, process or production method in order to achieve maximum benefit from them. RSM includes a series of statistical and mathematical techniques to describe the relationships between the independent and response variables by mathematical equations and optimization of these responses34. The purpose of applying this method is to find the best set of operating levels to achieve some specific and desired characteristics and also to optimize various processes. Kaveh et al.35 optimized the qualitative (color and shrinkage) and quantitative (drying time, effective moisture diffusivity, and specific energy consumption) properties of the kiwifruit with sample thicknesses, microwave powers, and ultrasound pretreatment times with the response surface method. They showed that thickness of 4 mm, power of 257.2 W, and ultrasound time of 30 min is the optimum point for drying kiwi. In another study, Liu et al.36 optimized the different properties of purple cabbage drying in combined microwave/hot air dryers using the response surface method (Box–Behnken design). Their results showed that microwave density of 2.35 W/g, moisture content of conversion point at 4.0 g/g, and hot air temperature at 55 °C were chosen as the optimum points.

Literature review has shown that no research has reported the application of RSM to optimize the drying variables and model the thermal and quality properties of dried apple slices in a microwave dryer under different pretreatments. Therefore, the scope of this research is to optimize and model the dependent (color variation, shrinkage, EF, SEC, GHG emissions, TE, DT, and dryer efficiency) and independent (microwave power and sample thickness) variables of drying apple slices by a microwave dryer using ultrasonication and blanching pretreatments with the help of RSM.

Materials and methods

The Golden delicious variety of apples was harvested from the identified orchards in Moghan college, Ardabil province, Iran in November 2021. The collection of apple samples and the performance of experimental research on such fruits complied with all the relevant Moghan college guidelines and legislation. Also, the use of fruits in the present study complies with national guidelines of Iran National Standards Organization37. The apples were first sorted uniformly according to the ripeness degree. Then the fruits were kept in the refrigerator at 4 to 6 °C to prevent rotting. Samples were placed at ambient temperature for 2 h before the tests22. The apples were washed and peeled then cut into slices of 2, 4, and 6 mm thickness with a knife. The initial MC of the fresh apple was obtained by an oven (Memmert Company, UFB500, Schwabach, Germany) at 103 \(^\circ{\rm C}\) for 24 h in triplicate. Based on the results, it was 83.2 ± 1% (w.b.).

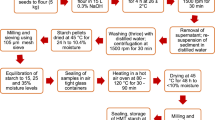

Ultrasonication and blanching pretreatments

An ultrasonic bath (Parsonic, model 7500S, Iran) at 28 kHz frequency was applied for ultrasonication. The sliced fruits were subjected to ultrasound waves at air temperature of 30 °C for 10 min in a distilled water38. The ratio of the distilled water to the sample was 4:1, such that all the samples uniformly received the ultrasound waves39. For blanching, the apples slices were subjected to the vapor of distilled water at the constant temperature of 80 °C for 2 min40. After pretreatment and removing the surface water with a towel tissue, the samples were placed in a glass cylinder-shaped container (in a thin layer) and dried with a microwave dryer until they reached a constant weight.

Microwave dryer

According to Fig. 1, a commercial domestic microwave (Sharp company, model R-861SLM) was applied to dry the apple slices with three thicknesses of 2, 4, and 6 mm at three microwave power of 100, 200, and 300 W. Samples of 80 g of apple slices were prepared for each test. A layer of the pretreated and control (untreated) samples was placed in the microwave container. The tray with the slices was on a digital balance (from the AND company, model GF-6000, made in Japan) to measure the weight of the apple slices in regular two-minute intervals. This process was performed until reaching the final MC of 11 \(\pm\) 1% (w.b.).

Moisture ratio

The moisture ratio of the apple slices was calculated accordingly to Eq. (1)41,42:

In which, MR shows the relative moisture (dimensionless); while Mfinal, Meq., and Mfirst denote the MC at time of t (d.b.), equilibrium moisture of the samples (d.b.), and initial MC of the slices (d.b.), respectively.

Specific energy consumption (SEC)

SEC of the drying process of the samples using the microwave method with ultrasonication and blanching pretreatment was calculated from the energy consumption of microwave method (SEC1), ultrasonication (SEC2), and blanching (SEC3). The SEC of the microwave drying can be obtained using Eq. (2)5,43:

In which, PM reveals the microwave power consumed (kW) and t represents the time of microwave use (s), While MW shows the weight of the eliminated water (kg).

The SEC of the drying with ultrasonication pretreatment can be obtained by Eq. (3)44:

In the above equation, W shows the ultrasonic power (W/L), while V (L) and t (s), respectively, represent the volume of water and time of ultrasonication. MW denotes the weight of the eliminated water (kg).

The consumption of energy of the blanching pretreatment is equal to the heat energy Q required to increase the water temperature from the ambient temperature to 80 °C which can be determined from Eq. (4). The SEC corresponding to this energy can be determined by Eq. (5):

Finally, the total energy consumption can be written as the sum of the SEC of ultrasonication and blanching pretreatments and microwave dryer.

The energy and thermal efficiencies (TE) can be determined by Eqs. (8) and (9)45:

In the above equation, Eeva: shows the required energy for moisture evaporation (kJ/kg), D: is the amount of product in the system (kg/m2), hfg: is the latent heat of evaporation (kJ/kg), A denotes the area of the dryer chamber (m2), and Z: is the heating capacity utilization (kW). In Eq. (9) for calculation of the thermal efficiency, the initial MC of apple (Mi), and the mean final moisture (Mo) of the apple were 83.2 ± \(1\)%, and 11\(\hspace{0.17em}\pm \hspace{0.17em}1\)% (w.b.), respectively.

Equation (10) shows the required energy for the evaporation of moisture from the apple and the elevation of the temperature of the samples46:

GHG emission

Due to the production of oil and oil products—which includes the major part of exports and gross national income—Iran indirectly has a major contribution to the production of pollutants such as carbon dioxide and methane at the global level. That is because there are various types of thermal power plants (steam, gas, and combined-cycle) in Iran that cause GHG emission (NOx and CO2). Result of other researches showed that combined cycle power plants are more efficient than other power plants47, thus in this research this type of power plant with different fuels (natural gas and gas oil) was investigated. GHG emission of combined cycle power plants using natural gas and gas oil for the production of 1 kWh energy was determined by coefficient of 450 and 622 g/kWh for CO2 and 2.95 and 3.78 g/kWh for NOx, respectively48.

Color variation

To assess the color difference of the slices, the samples were imaged starting and finalizing the drying process by a colorimeter instrument (Portable colorimeter, model HP 200, China) to extract a*, L*, and b* parameters. These parameters represent the brightness (0–100), green to red, and blue to yellow, respectively49. "a" shows red-green and "b" shows yellow-blue colors. If these values are (+); "a" is red, "b" is yellow. If these values are (−); "a" is green, and "b" is blue50. The color variations can be determined by Eq. (11)51,52,53:

In which, a1*, b1*, and L1* are the color values of the dried slices with various pretreatments under various conditions. Also a2*, b2*, and L2* are the color amounts of the initial samples.

Shrinkage

The shrinkage Sv (%) was obtained by the measurement of the initial volume of the slices before drying Vi (cm3) and after drying V (cm3) by a pycnometer in the presence of toluene38. Then, the shrinkage was V (cm3) according to Eq. (12). The shrinkage can be defiend as the volume variations of the processed samples compared to the raw sampels54:

RSM

The Design Expert ver. 10 software was applied to optimize and model the drying process by a microwave dryer and ultrasonication and blanching pretreatments in terms of the thermal and quality features. To this end, RSM with “historical data” design was used to assess the effects of two independent variables of sample thickness (2, 4, and 6 mm) and microwave power (100, 200, and 300 W), and various pretreatments (control sample, 10 min of ultrasonication and blanching at 80 °C) on the dependent parameters (such as color, shrinkage, TE, DT, SEC, and EF). Independent and mutual effects on the responses were evaluated using a quadratic equation (Eq. 13)55:

In this equation, Y shows the predicted response; while β0, βi, βjj, and βij, respectively, denote a constant, linear coefficient, quadratic coefficient, and mutual coefficient. Xi and Xj are independent parameters. A three-dimensional response surface diagram was applied to assess the relationship between the independent and dependent parameters. Table 1 shows the coded surfaces of the independent parameters.

Among the proposed treatments of the software, the minimum DT, lowest total SEC, and lower color variation and shrinkage as well as the highest EF and TE were selected for the optimization.

Results and discussions

Drying time

The results of ANOVA and modeling for the assessment of the effect of the sample thickness and microwave power on the thermal and quality properties of the dried slices in a microwave dryer with different pretreatment (blanching and ultrasonication) as compared to control samples are presented in Table 2.

According to Figs. 2, 3, 4, 5, 6, 7 and Table 2, the proposed model is linear, quadratic, and quadratic for the untreated sample, ultrasonicated and blanched samples, respectively. As the values of Adj R2, R2, Pred R2 are all above 0.99, RSM managed to fit the best mathematical model to predict the DT (experimental) in the control and pretreated samples. Based on Table 2, the influences of the sample thickness and microwave power were significant for the untreated samples (P < 0.0001) while the mutual effects and their second order were not significant. However, for ultrasonicated samples, the effects of the independent parameters, as well as the second order sample thickness, were significant (P < 0.0001). Finally, for samples pretreated with blanching, the effects of all independent parameters, their mutual effects, and their second order were significant (P < 0.0001) on the DT.

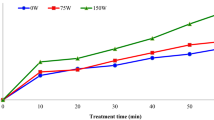

Figure 2 shows the effect of sample thicknesses and microwave power on DT for different pretreatments. According to Fig. 2a, the shortest (55 min) and longest (160 min) DT were for the control sample dried at microwave power of 300 and 100 W with the thickness of 2 and 6 mm, respectively. For ultrasonic pretreatment, Fig. 2b, the longest (145 min) and shortest (40 min) drying times were for microwave power of 100 and 300 W and thicknesses of 6 and 2 mm, respectively. Based on Fig. 2c for blanching pretreatment, the minimum (35 min) and maximum (135 min) drying times were for MP and ST of 300 W—2 mm and 100 W—6 mm, respectively.

The DT reduced by increasing the microwave power due to faster mass transfer in the apple slices at a higher microwave power as a result of more heat generation and a large vapor pressure difference between the center and the surface of the product56. The DT also decreases by reducing the sample thicknesses as the exit of moisture will become easier, accelerating the moisture movement from the texture of the material to the sample surface57. Thus, drying speed increases incrementally at low thicknesses4. Similarly, Nagvanshi et al.41 and Darvishi et al.42 reported that microwave power and sample thickness has a significant effect on drying time.

The DT of ultrasonicated apple samples decreases as compared to control samples due to the formation of more microscopic channels resulting from the cavitation phenomenon60. The findings of this research are in agreement with the reports published by other researchers for drying potatoes61, carrot24, and Tremella fuciformis62 under microwave drying with ultrasound pretreatment.

Comparison of the results revealed that the use of blanching pretreatment led to a greater decrease in DT as compared to the use of ultrasound pretreatment and non-pretreated samples. In this case, blanched samples leads to the enzyme inactivation, oxygen removal from intercellular spaces and, therefore, a higher mass transfer63. Similar reports were published by other researchers for drying of different agricultural products, including white cabbage64, apple slices65, and blackberries66.

SEC

Table 2 presents the results of the ANOVA used to investigate the effect of different drying parameters (sample thicknesses and microwave power) on the SEC of all microwave dried apple samples with ultrasonic pretreatment and blanching. For the control samples, the effect of the ST and the microwave power, the interactive effect of sample thicknesses-microwave power, the quadratic effects of the sample thicknesses and the microwave power on the total SEC were significant; while for both pretreated samples, the effect of the sample thicknesses and the microwave power of the samples, the interactive effect of microwave power-sample thicknesses on the total SEC were significant (P < 0.0001).

As shown in Fig. 3, the energy consumption decreased for all three treatments by raising the microwave power and decreasing the sample thicknesses. Total SEC depends on different factors, such as air temperature, latent heat of water evaporation, specific heat of air, air speed, and input air temperature67. At higher microwave power, the free water of the product evaporates faster and the DT is significantly (P < 0.0001) declined, therefore, decreasing the total energy consumption68,69. The SEC was lower in the pretreated samples as ultrasonication leads to more destruction (creating microscopic channels) in the apple tissue, preventing the formation of the hard layer during the drying process of the pretreated samples, thus, the product dries faster and the energy consumption is reduced70. Other researchers reported similar results for drying layers of Aloe vera32, potato61 and onion71. They showed that the application of various pretreatments will facilitate the exit of moisture and reduce the SEC.

The reason for the increase in the SEC with the increase in the sample thicknesses can be assigned to the longer times required by the thicker layers to transfer their moisture from the inside to their surface for the final evaporation. This can enhance the DT and, in turn, the SEC72. The results of this research are compatible with the reports of other researchers for sweet potato73,74, kiwi59, and onion5.

According to Fig. 3, the application of blanching pretreatment decreased the SEC as compared to the ultrasonication because the blanching pretreatment had a direct effect on the drying speed, as it caused several cracks in the outer layer of the apple through a temperature shock66. As a result, the drying speed increases, therefore, less energy is required to remove moisture from the apple. Abbaspour-Gilandeh et al.75 used hot air and infrared methods and different pretreatments for drying terebinth; they showed that the use of blanching pretreatment requires lower SEC compared to the ultrasound pretreatment. Another research on drying blackberries by various dryers (infrared, hot air, and infrared—hot air) and different pretreatments concluded that the SEC will further reduce by using of blanching pretreatment in all three dryers as compared to ultrasound pretreatment66.

Energy efficiency

Based on Table 2, the independent effects of the sample thicknesses and the microwave power as well as the second order of the microwave power are significant for the samples without pretreatment. Independent effects of the sample thicknesses and microwave power are significant for ultrasonic pretreatment; while independent effects of the sample thicknesses and the microwave power are significant for the ultrasonic pretreatment; while the independent effects of the sample thicknesses and the microwave power, as well as the second order of the sample thicknesses had significant influence on EF in the blanching pretreatment (P < 0.0001). The interactive effect of the sample thicknesses—microwave power was not significant on the EF in any of the pretreatments.

Figure 4a–c, respectively, show the interactive effect of sample thicknesses—microwave power on the EF of apple drying for control samples, ultrasound pretreatment, and blanching. The highest EF (57.69%) was obtained with a microwave power of 300 W and thickness of 2 mm with a blanching pretreatment, respectively. The lowest EF (25.69%) was for the microwave power of 100 W and thickness of 6 mm in the controlled sample, respectively. The EF increases by enhancing the microwave power and decreasing the sample thicknesses as they raise the value of moisture removal from the product and accelerate the evaporation of free water, hence, decreasing the DT. Total SEC also decreases due to the reduction in DT69. Maftoonazad et al.71 represented that using microwave/hot air hybrid drying of onion slices, the overall energy efficiency changes from about 4% to 79%. Darvishi et al.68 obtained the energy efficiency from 33.70 to 0.66% for soybean seeds in a microwave dryer under different powers.

The use of blanching and ultrasonication pretreatments will increase the changes in the texture of the apple and prevent the formation of the hard layer during the process of drying; therefore, the sample will be dried quicker, which will decrease the SEC and increase the EF60.

Namjoo et al.76 studied convective drying with ultrasonication pretreatment of cumin seeds and found that the EF varied from 0.689 and 1.542% for 30 ºC without pretreatment and 40 ºC with us pretreatment, respectively. Abbaspour-Gilandeh et al.75 showed that the maximum EF for infrared and convective drying of terebinth was obtained using ultrasonication pretreatments and blanching. Motevali et al.77 showed that the energy efficiency for drying apples increases by using ultrasonication and blanching.

Thermal efficiency

Table 2 shows the significance of the independent effects of sample thicknesses and microwave power, as well as the interactive effects of the sample thicknesses-microwave power and second order of the microwave power on the TE of the untreated and ultrasonicated samples. Furthermore, the independent effect of the sample thicknesses and microwave power and second order of microwave power had a significant (P < 0.0001) effect on the TE of the blanched sample. Additionally, R2 values were 0.9707, 0.9710, and 0.9705 for the untreated, ultrasonicated, and blanched slices, respectively, showing the suitability of the models for predicting the TE.

Figure 5 depicts the interactive effects of sample thicknesses-microwave power on the TE for microwave drying with various pretreatments. Consequently, the highest TE (49.68%) was for the microwave power of 300 W and sample thicknesses of 2 mm in the blanched samples; while the lowest TE was obtained in the microwave power of 100 W and sample thicknesses of 6 mm, respectively, in the control samples. A rise in the microwave power and the application of pretreatments increased the TE as they accelerate the evaporation of the free water and enhance the mass transfer (due to the increase in the internal pressure and concentration gradient), therefore, the DT will be significantly shorter77. The TE showed a decline by enhancing the sample thicknesses. Since the TE is the ratio of the latent heat to the required energy for moisture evaporation, the rise in the product thickness is caused to decline the moisture evaporation rate, such that the input energy cannot effectively overcome the energy barrier of the sample for internal distribution of water, therefore, the TE will decrease. Other researchers also reported an enhancement in the energy and dryer efficiencies for thinner okra72 and kiwi60.

Color

Table 2 lists the AVOVA results of color variation. The linear effect of the sample thicknesses and microwave power was significant on the color variations (∆E) of the apple pretreated with ultrasonication and blanching (P < 0.0001). The independent effects (sample thicknesses and microwave power) and the interactive effects microwave power-sample thicknesses were also significant on the color variation of the untreated apple (P < 0.00001).

Figure 6a–c show the effect of the sample thicknesses and microwave power on the color variation of apples with different pretreatments. The lowest and highest color variations were 18.24 and 36.67, respectively. The lowest changes were obtained for a microwave power of 100 W in ultrasonicated slices with a thickness of 2 mm. As shown in Fig. 6, by increasing the microwave power, the product is exposed to intense heat until it reaches a safe MC level. Therefore, a rise in the microwave power led to further increase in the color variations (∆E) between dry and fresh apples, such that a higher microwave power darkened the apples. The reason could be the formation of brown pigment through the Maillard reaction. Moreover, the increase in microwave power promoted enzymatic and non-enzymatic browning reactions, burning, and surface blackening of the samples, leading to higher color variations65. Other researchers reported similar results in drying garlic12 and mushrooms9 by microwave dryer and stated an incremental increase in color variations by raising the microwave power. Also, the use of pretreatment affected the color variations. The use of ultrasounds reduced the color variations as the deformation and destruction of cells and reduction of enzyme oxidation reaction occurred with the increase of ultrasound waves. These results are consistent with reports from other researchers published for kiwi78 and terebinth75. As shown in Fig. 6, a rise in the sample thickness enhanced the color variations as in thicker slices, moisture must travel a longer distance to reach the surface of the sample. This will increase the color variations of the samples75.

Shrinkage

Table 2 presents the ANOVA results for shrinkage in different pretreatments. Consequently, the effect of the ST and the microwave power was significant (P < 0.0001) on the shrinkage of the samples. While the interaction effect of sample thicknesses—microwave power and the second order of microwave power were significant (P < 0.0001) on the shrinkage of the control and ultrasonicated samples, respectively.

Figure 7 shows the effect of the sample thicknesses and microwave power on the shrinkage of untreated, ultrasonicated, and blanched samples. The shrinkage ranged from 53.59% (for microwave power of 100 W and thickness of 2 mm, respectively, in ultrasonic pretreatment) to 73.69% (at microwave power of 300 W and thickness of 6 mm, respectively, in untreated samples).

According to the results, the simultaneous increase of the sample thicknesses and the microwave power enhanced the shrinkage. The higher shrinkage at high microwave power can be assigned to the shortening of the drying process and the application of more intense heat and humidity stresses. The shrinkage starts from the product surface and gradually reaches the inner layers by continuing the drying process68. Other researchers reported similar results for apple70 and chrysanthemum78.

Drying the thicker products involves the evaporation of more liquid phase (water), leading to more empty spaces inside the product, which causes a greater volume change. The other possible reason for the increase in shrinkage with the increase of the thickness can be the formation of a more porous structure with weaker bonds during the drying process due to thermal and humidity stresses which will cause more volume changes in the products60.

According to Fig. 7, the lowest shrinkage was related to the ultrasonicated sample. As water removal from the cell increases the stress from the liquid on the cell wall during the drying process, as a result, it will lead to the shrinkage of the material. The ultrasound pretreatment, however, will reduce the stress on the apple tissue, hence, decreasing the shrinkage24.

GHG emission

The results of GHG modeling (CO2 and NOx) for a combined cycle power plant, as well as different pretreatments using electricity with various fuels are presented in Table 3. The R2 values were above 0.96. Also, the influence of the independent parameters (microwave power and sample thickness) was linearly significant (P < 0.0001) on the GHG emission (CO2 and NOx) for all treatments. Figures 8, 9, and 10 represent the interaction influences of microwave power and sample thickness on the CO2 and NOx emissions based on the response surface diagrams for control, ultrasonication, and blanched samples, respectively. The highest GHG emission (CO2 = 20,121.6 and NOx = 72.576 g) was observed in the control samples with thickness of 6 mm at the microwave power of 100 W. However, the lowest CO2 (1417.5 g) and NOx (9.2925 g) were obtained for the drying of the blanched samples with the thickness of 2 mm at the microwave power of 300 W with natural gas fuel. According to Figs. 8, 9, and 10, it can be seen that the more the microwave power increases in fixed thicknesses, the more GHG emission decreases. Motevali and Koloor80, Motevali et al.32 and Kaveh et al.81 stated that the process of reducing GHG emission with increasing microwave power was due to the reduction in energy consumption and drying time of the samples. While the increase in thickness in constant powers caused an increase in GHG emission. Seyfi et al.33 showed that increasing the thickness of Aloe vera gel increases GHG emission for different drying methods due to the increase in drying time. Taghinezhad et al.24 and Kaveh et al.81 also obtained similar results for drying carrots and pear in different thicknesses, respectively.

Optimization

RSM is one of the most important mathematical methods for optimizing agricultural dried samples as it straightly affects the selection of the best drying parameters82. The optimization results for samples dried in a microwave dryer under different pretreatments are shown in Table 4 with desirability. The response variables included color, shrinkage, total SEC, EF, DT, TE, CO2, and NOx. Accordingly, optimal drying conditions involve the microwave power of 300 W and ST of 2 mm for all treatments, respectively. The optimization findings show the positive effect of microwave power on the response variables as they grew with the enhancement of microwave power. Therefore, the optimal microwave power was considered to be 300 W. The thickness was also suggested at its minimum level to decrease the DT and due to its positive effect on the response variables.

Conclusions

This research addressed the optimization of the thermal properties and quality of apples dried in a microwave dryer under ultrasonication and blanching pretreatments with the help of RSM. Independent parameters included sample thickness and microwave power while response variables included SEC, drying time, energy efficiency, thermal efficiency, color, shrinkage, GHG emission. The results revealed a significant effect of independent parameters on all response variables in all pretreatments (P < 0.0001). The optimal values of independent variables involved microwave power of 300 W and sample thickness of 2 mm, respectively. Additionally, the desirability index was 0.921, 0.935, and 0.916 for untreated, ultrasonicated, and blanched samples, respectively. Analysis of variance was carried out to check the accuracy of the model fit. The variation analysis and surface graphs showed the effect of factors on the responses where the increase of microwave power and the use of different pretreatments had a positive effect on reducing SEC, GHG emissions, and drying time while increasing the energy and thermal efficiency of the drying. Moreover, the use of thinner apple slices was especially useful for reducing the shrinkage and color changes. Today, the development of post-harvest quality inspection approaches, especially, with the aim of optimization and using novel techniques to reduce processing time as well as GHG emissions can decrease the wastes and achieve standardization.

Data availability

All data generated or analyzed during this study are included in the article. All authors read and approved the final manuscript.

Abbreviations

- A :

-

Area of the dryer chamber (m2)

- C m :

-

Specific heat of the samples (kJ/kg K)

- D :

-

Sample’s density of loading (kg/m2)

- DT :

-

Drying time (min)

- E eva :

-

The required energy for moisture evaporation (kJ)

- EF :

-

Energy efficiency (%)

- E heating :

-

Energy required for elevating the temperature of the product (kJ)

- h fg :

-

Latent heat of evaporation (kJ/kg)

- MC :

-

Moisture content (%)

- M eq. :

-

Equilibrium moisture of the samples (d.b.)

- M final :

-

Moisture content at time of t (d.b.)

- M first :

-

Initial moisture content of the samples (d.b.)

- M i :

-

Initial mc of apple

- M o :

-

Final moisture of the apple

- MP :

-

Microwave power (W)

- M W :

-

Weight of eliminated water (kg)

- M W :

-

Amount of the evaporated moisture (kg)

- P M :

-

Microwave power consumed (kW)

- RSM :

-

Response surface methodology

- SEC :

-

Specific energy consumption (kJ/kg)

- ST :

-

Sample thickness (mm)

- S v :

-

Shrinkage (%)

- t :

-

Time (s)

- T 1 :

-

Temperature of the samples before drying (K)

- T 2 :

-

Temperature of the samples during drying (K)

- TE :

-

Thermal efficiency (%)

- V :

-

Water volume (L)

- Vi :

-

Sample volume before and after drying (cm3)

- W :

-

Ultrasonic power (kJ/L)

- W d :

-

Weight of the dry matter (kg)

- Y :

-

Response variable

- Z :

-

Heat transfer rate (kW)

- ε :

-

Error

- \(\Delta E\) :

-

Colour variation

References

FAO. https://www.fao.org/faostat/en/#data/QCL. Accessed December 2022 (2022).

Bai, J. W. et al. Effects of different pretreatment methods on drying kinetics, three-dimensional deformation, quality characteristics and microstructure of dried apple slices. Innov. Food Sci. Emerg. Technol. 83, 103216 (2023).

Mohammadi, I., Tabatabaekoloor, R. & Motevali, A. Effect of air recirculation and heat pump on mass transfer and energy parameters in drying of kiwifruit slices. Energy 170, 149–158 (2019).

Pandiselvam, R. et al. Advanced osmotic dehydration techniques combined with emerging drying methods for sustainable food production: Impact on bioactive components, texture, color, and sensory properties of food. J. Text. Stud. 53(6), 737–762 (2022).

Beigi, M. & Torki, M. Experimental and ANN modeling study on microwave dried onion slices. Heat Mass Transf. 57, 787–796 (2021).

Delfiya, D. A. et al. Drying kinetics of food materials in infrared radiation drying: A review. J. Food Process Eng. 45(6), e13810 (2022).

Kutlu, N. et al. Impact of ultrasonication applications on color profile of foods. Ultrason. Sonochem. 89, 106109 (2022).

Ai, Z. et al. Improving drying efficiency and product quality of Stevia rebaudiana leaves using innovative medium-and short-wave infrared drying (MSWID). Innov. Food Sci Emerg. Technol. 81, 103154 (2022).

Omari, A., Behroozi-Khazaei, N. & Sharifian, F. Drying kinetic and artificial neural network modeling of mushroom drying process in microwave-hot air dryer. J. Food Process Eng. 41, e12849 (2018).

Jeevarathinam, G. et al. Infrared assisted hot air dryer for turmeric slices: Effect on drying rate and quality parameters. LWT 144, 111258 (2021).

Caputo, L. et al. Impact of drying methods on the yield and chemistry of Origanum vulgare L. essential oil. Sci. Rep. 12(1), 3845 (2022).

İlter, I. et al. Microwave and hot air drying of garlic puree: drying kinetics and quality characteristics. Heat Mass Transf. 54, 2101–2112 (2018).

Menon, A., Stojceska, V. & Tassou, S. A. A systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends Food Sci. Technol. 100, 67–76 (2020).

Liu, J. et al. Drying characteristics, quality changes, parameters optimization and flavor analysis for microwave vacuum drying of garlic (Allium sativum L.) slices. LWT 173, 114372 (2023).

Kriaa, K. & Nassar, A. F. Comparative study of pretreatment on microwave drying of Gala apples (Malus pumila): Effect of blanching, electric field and freezing. LWT 165, 113693 (2022).

Ali, A. et al. Volatile and polyphenol composition, anti-oxidant, anti-diabetic and anti-aging properties, and drying kinetics as affected by convective and hybrid vacuum microwave drying of Rosmarinus officinalis L. Ind. Crops Prod. 151, 112463 (2020).

Aydar, A. Y. et al. Investigation on the influence of ultrasonic pretreatment on color, quality and antioxidant attributes of microwave dried Inula viscosa (L.). Ultrason. Sonochem. 90, 106184 (2022).

Pandiselvam, R. et al. Individual and interactive effect of ultrasound pre-treatment on drying kinetics and biochemical qualities of food: A critical review. Ultrason. Sonochem. 92, 106261 (2023).

Aslam, R. et al. Understanding the effects of ultrasound processng on texture and rheological properties of food. J. Text. Stud. 53(6), 775–799 (2022).

Barros, S. L. et al. Physical–chemical, functional and antioxidant properties of dehydrated pumpkin seeds: Effects of ultrasound time and amplitude and drying temperature. Waste Biomass Valorization https://doi.org/10.1007/s12649-023-02235-z (2023).

Deng, Y. et al. Effects of pretreatment methods on the physicochemical properties of dried longan (Dimocarpus longan Lour.) pulps. J. Food Sci. 88(8), 3474–3493 (2023).

Wiktor, A. et al. Selected quality parameters of air-dried apples pretreated by high pressure, ultrasounds and pulsed electric field—A comparison study. Foods 10(8), 1943 (2021).

Chen, Y., Song, C., Li, Z., Chen, H. & Jin, G. Effects of hot air and combined microwave and hot air drying on the quality attributes of celery stalk slices. J. Food Process. Preserv. 44, e14310 (2020).

Taghinezhad, E., Kaveh, M., Szumny, A. & Figiel, A. Quantifying of the best model for prediction of greenhouse gas emission, quality, and thermal property values during drying using RSM (Case Study: Carrot). Appl. Sci. 13(15), 8904 (2023).

Salehi, F., Cheraghi, R. & Rasouli, M. Mass transfer analysis and kinetic modeling of ultrasound-assisted osmotic dehydration of kiwifruit slices. Sci. Rep. 13(1), 11859 (2023).

Iranshahi, K. et al. Electrohydrodynamic drying versus conventional drying methods: A comparison of key performance indicators. Energy Convers. Manag. 279, 116661 (2023).

Zalazar-Garcia, D. et al. Exergy, energy, and sustainability assessments applied to RSM optimization of integrated convective air-drying with pretreatments to improve the nutritional quality of pumpkin seeds. Sustain. Energy Technol. Assess. 49, 101763 (2022).

Pérez-Won, M. et al. Pulsed electric fields as pretreatment for different drying methods in Chilean abalone (Concholepas concholepas) mollusk: Effects on product physical properties and drying methods sustainability. Food Bioprocess Technol. https://doi.org/10.1007/s11947-023-03102-4 (2023).

Karimi, M., Moradi, M., Niakousari, M. & Karparvarfard, S. H. Application of heat carrier particles in a fluidized bed dryer: Dimensionless modeling and GHG emissions. J. Food Process Eng. 45, e14071 (2022).

Kaveh, M., Chayjan, R. A., Taghinezhad, E., Sharabiani, V. R. & Motevali, A. Evaluation of specific energy consumption and GHG emissions for different drying methods (Case study: Pistacia Atlantica). J. Clean. Prod. 259, 120963 (2020).

Miraei Ashtiani, S.-H., Rafiee, M., Mohebi Morad, M. & Martynenko, A. Cold plasma pretreatment improves the quality and nutritional value of ultrasound-assisted convective drying: The case of goldenberry. Dry. Technol. 40, 1639–1657 (2022).

Motevali, A. et al. Comparison of environmental pollution and social cost analyses in different drying technologies. Int. J. Glob. Warm. 22, 1–29 (2020).

Seyfi, A., Asl, A. R. & Motevali, A. Comparison of the energy and pollution parameters in solar refractance window (photovoltaic-thermal), conventional refractance window, and hot air dryer. Solar Energy 229, 162–173 (2021).

Sadeghi, E., Movagharnejad, K. & Haghighi Asl, A. Parameters optimization and quality evaluation of mechanical properties of infrared radiation thin layer drying of pumpkin samples. J. Food Process Eng. 43, e13309 (2020).

Kaveh, M. et al. Use of ultrasound pre-treatment before microwave drying of kiwifruits—An optimization approach with response surface methodology. J. Food Process. Preserv. 46, e16714 (2022).

Liu, J. et al. Optimization of combined microwave and hot air drying technology for purple cabbage by Response Surface Methodology (RSM). Food Sci. Nutr. 9, 4568–4577 (2021).

Rasooli Sharabiani, V., Kaveh, M., Abdi, R., Szymanek, M. & Tanaś, W. Estimation of moisture ratio for apple drying by convective and microwave methods using artificial neural network modeling. Sci. Rep. 11, 1–12 (2021).

Mirzaei-Baktash, H., Hamdami, N., Torabi, P., Fallah-Joshaqani, S. & Dalvi-Isfahan, M. Impact of different pretreatments on drying kinetics and quality of button mushroom slices dried by hot-air or electrohydrodynamic drying. LWT 155, 112894 (2022).

Rybak, K. et al. Energy and quality aspects of freeze-drying preceded by traditional and novel pre-treatment methods as exemplified by red bell pepper. Sustainability 13, 2035 (2021).

Tepe, T. K. & Kadakal, Ç. Determination of drying characteristics, rehydration properties, and shrinkage ratio of convective dried melon slice with some pretreatments. J. Food Process. Preserv. 46, e16544 (2022).

El-Mesery, H. S., Tolba, N. M. & Kamel, R. M. Mathematical modelling and performance analysis of airflow distribution systems inside convection hot-air dryers. Alex. Eng. J. 62, 237–256 (2023).

Manikantan, M. R. et al. Investigation on thin-layer drying kinetics of sprouted wheat in a tray dryer. Qual. Assur. Saf. Crops Foods 14(SP1), 12–24 (2022).

Hazervazifeh, A., Nikbakht, A. M., Moghaddam, P. A. & Sharifian, F. Energy economy and kinetic investigation of sugar cube dehydration using microwave supplemented with thermal imaging. J. Food Process. Preserv. 42(2), e13504 (2018).

Rojas, M. L., Silveira, I. & Augusto, P. E. D. Ultrasound and ethanol pre-treatments to improve convective drying: Drying, rehydration and carotenoid content of pumpkin. Food Bioprod. Process. 119, 20–30 (2020).

Çetin, N. Comparative assessment of energy analysis, drying kinetics, and biochemical composition of tomato waste under different drying conditions. Sci. Horticult. 305, 111405 (2022).

Jafari, H., Kalantari, D. & Azadbakht, M. Energy consumption and qualitative evaluation of a continuous band microwave dryer for rice paddy drying. Energy 142, 647–654 (2018).

Sojoodi, S., Dastmalchi, L. & Neshat, H. Efficiency ranking of different types of power plants in Iran using super efficiency method. Energy 233, 121104 (2021).

Nazari, S. et al. Experimental determination and analysis of CO2, SO2 and NOx emission factors in Iran’s thermal power plants. Energy 35, 2992–2998 (2010).

Sharifian, F., Gharkhloo, Z. R., Yamchi, A. A. & Kaveh, M. Infrared and hot drying of saffron petal (Crocus sativus L.): Effect on drying, energy, color, and rehydration. J. Food Process Eng. 46(7), e14342 (2023).

Kaya Dursun, S., Aksüt, B., Nuri Öcalan, O. & Taşova, M. Oven, temperature-controlled microwave, and shade drying effects on drying kinetics, bioactive compounds and antioxidant activity of knotweed (Polygonum cognatum Meissn.). Chem. Biodivers. 20(5), e202201196 (2023).

Rostami Gharkhloo, Z., Sharifian, F., Rahimi, A. & Akhoundzadeh Yamchi, A. Influence of high wave sound pretreatment on drying quality parameters of Echinacea root with infrared drying. J. Sci. Food. Agric. 102(5), 2153–2164 (2022).

Naseri, M., Movagharnejad, K. & Nanvakenari, S. Comparison of the dried properties of Ganoderma lucidum produced by the convective dryer and infrared dryer. Sci. Rep. 13, 12636 (2023).

Srinivas, Y., Mathew, S. M., Kothakota, A., Sagarika, N. & Pandiselvam, R. Microwave assisted fluidized bed drying of nutmeg mace for essential oil enriched extracts: An assessment of drying kinetics, process optimization and quality. Innov. Food Sci. Emerg. Technol. 66, 102541 (2020).

Feng, Y. et al. Improving the hot air drying of garlic slices by perforation synergistic alcohol pretreatment. Dry. Technol. https://doi.org/10.1080/07373937.2023.2217252 (2023).

Yılmaz, F. M., Görgüç, A., Uygun, Ö. & Bircan, C. Steviol glycosides and polyphenols extraction from Stevia rebaudiana Bertoni leaves using maceration, microwave-, and ultrasound-assisted techniques. Sep. Sci. Technol. 56, 936–948 (2021).

Tepe, F. B. Impact of pretreatments and hybrid microwave assisting on drying characteristics and bioactive properties of apple slices. J. Food Process. Preserv. 46(10), e17067 (2022).

Demiray, E. et al. The effect of drying temperature and thickness on the drying kinetic, antioxidant activity, phenolic compounds, and color values of apple slices. J. Food Qual. https://doi.org/10.1155/2023/7426793 (2023).

Nagvanshi, S., Venkata, S. K. & Goswami, T. Study of color kinetics of banana (Musa cavendish) under microwave drying by application of image analysis. Food Sci. Technol. Int. 27, 660–673 (2021).

Darvishi, H., Zarein, M. & Farhudi, Z. Energetic and exergetic performance analysis and modeling of drying kinetics of kiwi slices. J. Food Sci. Technol. 53, 2317–2333 (2016).

Taghinezhad, E., Kaveh, M. & Szumny, A. Thermodynamic and quality performance studies for drying kiwi in hybrid hot air-infrared drying with ultrasound pretreatment. Appl. Sci. 11, 1297 (2021).

Dehghannya, J., Kadkhodaei, S., Heshmati, M. K. & Ghanbarzadeh, B. Ultrasound-assisted intensification of a hybrid intermittent microwave-hot air drying process of potato: Quality aspects and energy consumption. Ultrasonics 96, 104–122 (2019).

Xu, J. et al. Effects of combined ultrasonic and microwave vacuum drying on drying characteristics and physicochemical properties of Tremella fuciformis. Ultrason. Sonochem. 84, 105963 (2022).

Sledz, M., Wiktor, A., Rybak, K., Nowacka, M. & Witrowa-Rajchert, D. The impact of ultrasound and steam blanching pre-treatments on the drying kinetics, energy consumption and selected properties of parsley leaves. Appl. Acoust. 103, 148–156 (2016).

Tao, Y. et al. Applications of water blanching, surface contacting ultrasound-assisted air drying, and their combination for dehydration of white cabbage: Drying mechanism, bioactive profile, color and rehydration property. Ultrason. Sonochem. 53, 92–201 (2019).

Wang, Y., Zhao, H., Deng, H., Song, X., Zhang, W., Wu, S. & Wang, J. Influence of pretreatments on microwave vacuum drying kinetics, physicochemical properties and sensory quality of apple slices. Pol. J. Food Nutr. Sci. 69(3) (2019).

Adabi, E. M., Motevali, A., Nikbakht, A. M. & Khoshtaghaza, H. M. Investigation of some pretreatments on energy and specific energy consumption drying of black mulberry. Chem. Ind. Chem. Eng. Q. CICEQ 19, 89–105 (2013).

Jeevarathinam, G. et al. Design, development, and drying kinetics of infrared-assisted hot air dryer for turmeric slices. J. Food Process Eng. 45(6), e13876 (2022).

Darvishi, H. Quality, performance analysis, mass transfer parameters and modeling of drying kinetics of soybean. Braz. J. Chem. Eng. 34, 143–158 (2017).

Motevali, A., Minaei, S., Banakar, A., Ghobadian, B. & Khoshtaghaza, M. H. Comparison of energy parameters in various dryers. Energy Convers. Manag. 87, 711–725 (2014).

Dehghannya, J., Aghazade-Khoie, E., Khakbaz Heshmati, M. & Ghanbarzadeh, B. Influence of ultrasound intensification on the continuous and pulsed microwave during convective drying of apple. Int. J. Fruit Sci. 20, S1751–S1764 (2020).

Maftoonazad, N., Dehghani, M. R. & Ramaswamy, H. S. Hybrid microwave-hot air tunnel drying of onion slices: Drying kinetics, energy efficiency, product rehydration, color, and flavor characteristics. Dry. Technol. 40, 966–986 (2022).

Nwakuba, N., Chukwuezie, O., Asonye, G. & Asoegwu, S. Energy analysis and optimization of thin layer drying conditions of okra. Arid Zone J. Eng. Technol. Environ. 14, 129–148 (2018).

Onwude, D. I., Hashim, N., Abdan, K., Janius, R. & Chen, G. Investigating the influence of novel drying methods on sweet potato (Ipomoea batatas L.): Kinetics, energy consumption, color, and microstructure. J. Food Process Eng. 41, e12686 (2018).

Onwude, D. I., Hashim, N., Abdan, K., Janius, R. & Chen, G. Modelling the mid-infrared drying of sweet potato: Kinetics, mass and heat transfer parameters, and energy consumption. Heat Mass Transf. 54, 2917–2933 (2018).

Abbaspour-Gilandeh, Y. et al. Effect of pretreatments on convective and infrared drying kinetics, energy consumption and quality of terebinth. Appl. Sci. 11, 7672 (2021).

Namjoo, M., Moradi, M. & Niakousari, M. Evaluation of the effect of high-power ultrasound waves on conventional air drying of cumin seeds. Sustain. Energy Technol. Assess. 52, 102262 (2022).

Motevali, A., Hashemi, S. J. & Taghinejad, E. Investigation of energy parameters, environment and social costs for drying process (case study: Apple slices). Agric. Mech. Syst. Res. 20, 37–54 (2019).

Nowacka, M., Tylewicz, U., Romani, S., Dalla Rosa, M. & Witrowa-Rajchert, D. Influence of ultrasound-assisted osmotic dehydration on the main quality parameters of kiwifruit. Innov. Food Sci. Emerg. Technol. 41, 71–78 (2017).

Wang, Y. et al. Effects of hot air and microwave-assisted drying on drying kinetics, physicochemical properties, and energy consumption of chrysanthemum. Chem. Eng. Process. Process Intensif. 129, 84–94 (2018).

Motevali, A. & Koloor, R. T. A comparison between pollutants and greenhouse gas emissions from operation of different dryers based on energy consumption of power plants. J. Clean. Prod. 154, 445–461 (2017).

Kaveh, M., Çetin, N., Abbaspour-Gilandeh, Y., Sharifian, F. & Szymanek, M. Comparative evaluation of greenhouse gas emissions and specific energy consumption of different drying techniques in pear slices. Eur. Food Res. Technol. https://doi.org/10.1007/s00217-023-04346-2 (2023).

Ghasemi, A. & Chayjan, R. A. Optimization of pelleting and infrared-convection drying processes of food and agricultural waste using response surface methodology (RSM). Waste Biomass Valorization 10, 1711–1729 (2019).

Acknowledgements

The authors are deeply thankful to the Department of Agricultural Technology Engineering and office of vice chancellor for research at University of Mohaghegh Ardabili, Ardabil, Iran for providing facilities to conduct this research work, and also, thankful to NAWA—Polish National Agency for providing facilities to complete this research work and write this report at UPWr.

Funding

This research was funded by the office of vice chancellor for research at Mohaghegh Ardabili University (by a research project with Number: 1400.d.9.8779 and date 2021.07.24), and also this project was financed by the NAWA—Polish National Agency for Academic Exchange under the Ulam NAWA Program (Project No. BPN/ULM/2021/1/00231) at Wroclaw University of Environmental and Life Science (UPWr) in Poland.

Author information

Authors and Affiliations

Contributions

Conceptualization, E.T. and M.K.; methodology, E.T. and M.K.; validation, E.T. and M. K.; formal analysis, E.T.; investigation, E.T. and M.K.; resources, E.T. and A.S.; data curation, E.T. and M. K.; writing—original draft preparation, E.T. and A.S.; writing—review and editing, E.T., A.S., A.F., M. K., and J. B.; visualization, E.T., A.S., and J. B.; funding acquisition, E.T., A.S. A.F., and J. B.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Taghinezhad, E., Kaveh, M., Szumny, A. et al. Qualitative, energy and environmental aspects of microwave drying of pre-treated apple slices. Sci Rep 13, 16152 (2023). https://doi.org/10.1038/s41598-023-43358-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-43358-6

This article is cited by

-

Ultrasound Technology for Enhancing Drying Efficiency and Quality of Fruits and Vegetables: A Review

Food and Bioprocess Technology (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.