Abstract

The study aims at preparation and characterization of six organic lime putty (hydraulic Lime + fermented plant extract) using regionally available plants namely Terminalia Chebula (kadukkai), Rosa Sinensis (hibiscus), Palm jaggery (refined sugar), Xanthorrhoeaceae (aloe vera), and Indigofera Tinctoria (neelamari) as per the methods given in the ancient palm leaf of Padmanabhapuram Palace, India. Advanced analytical techniques like Gas chromatography-mass spectroscopy (GC–MS), UV-Spectrophotometer and carbon dioxide quantification were used to study the fermented plant extracts and Fourier transform-infrared spectroscopy (FT-IR), X-ray Diffraction (XRD), Field emission-scanning electron microscopy (FESEM) to study hydrated phases and microstructure of organic lime putty. GC–MS recorded the phytochemical compounds like fatty acids, traces of proteins, polysaccharides and carbohydrates. Fermented kadukkai and neelamari extracts reported as fatty acid, palm jaggery as carbohydrate, hibiscus as polysaccharide and aloevera rich in all the biomolecules. The detection limit of Quantification:0.013 and limit of detection:0.067 for polysaccharides, 0.026 and 0.088 for unsaturated fatty acids was reported through a U.V spectrophotometer for all the herbs. Aloevera and neelamari fermented extracts recorded the CO2 release around 96,000 and 90,000 ppm on 4th day of fermentation, whereas for other herbs it ranged below the recorded readings. Supply of CO2 has initiated the internal carbonation of the lime putty and precipitation of calcite in three different forms aragonite, calcite and vaterite minerals. The addition of organics resulted in high-intensity portlandite peaks and calcium carbonate polymorphs as reported in XRD graphs in agreement with FT-IR analysis. FESEM morphology validated the early formation of carbonate polymorphs, and EDX. has shown that kadukkai lime putty, jaggery lime putty and reference lime putty. mixes have calcium around 35–45%. From the overall results, 3% addition of eco-friendly biopolymers has altered the properties like setting time, water repellency and higher carbonation rate, which is the main reason behind longevity of the structure.

Similar content being viewed by others

Introduction

Since prehistoric times, India abides by the vast cultural heritage with the glorious tradition of preserving knowledge through oral and written communication. Historic structures include the temples, palaces, tombs & mosques, and the buildings, artefacts, historic precincts, and cultural landscapes1,2,3,4,5. Moreover, the ancient materials and the protected archives like literary collections, metal carvings, palm leaf manuscripts, wall paintings and stone inscriptions were the earliest historic references symbolizing the regional styles, agama shastras (religious rituals) and Chitra sutra (mural paintings) before the invention of the paper6,7,8,9. The earliest known palm-leaf manuscript belongs to the 2nd Century A.D of the Gupta regime. Writing on palm leaf continued up to 19th Century A.D, archiving the historical significance of civilization. Heritage is any tangible or intangible values passed on to us from the past. This wisdom hauls various traditional significances like economic, cultural, aesthetic, spiritual and archaeological sources that connect with past civilization and carry their advancements to modern times. Likewise, some ancient sources communicate the knowledge, ranging from the caves to copper plates and from the bark of trees to leaves of various kinds8,10,11,12.The ancient manuscripts are the sources of human history available on various media like stone, clay, tablets, palm leaves, metal leaves, barks, animal skin, cloth, paper etc. Despite all the ancient writing materials, palm leaf was used as the predominant media due to the local availability of palm trees across the Indian subcontinent10. Though many modern innovations have emerged in recent times, not all are holistic. Few recent studies underway understand the ancient structures' holistic construction practices through digital preservation, artificial intelligence, and modern analytical techniques. Starting from the Indus valley providing the evidence on the ancient town planning of Harrapan and Mohenjo-Daro depict the building culture, advanced drainage system and road systems. The construction method has transformed since 300 B.C with the whole new level of Dravidian style of gigantic towers. Long pillared halls, artistic vimanas and common structural features such as domes, slender minarets and arches were influenced from the Islamic and the Persian style of architectures. Every structure has its unique significances and architectural point of view. One such fine example of Brihadeshwara temple, Tanjore, India has the longest vimana of height 216 ft with axial and symmetrical geometry rules with fortified granite structure in the world5. The archaeological archive forum across the countries has documented some of the traditional secrets of old construction practices and preservative methods to understand the designs' scientific methods. It is estimated that there are 300 manuscript libraries all over India and 77 libraries outside India on preserving the archives. Some of the major repositories in India are national archives of India (N.A.I.), Indian national trust for art and cultural heritage (I.N.T.A.C.H.), Indira Gandhi national center for the arts (I.G.N.C.A.), Department of culture and its museum and libraries, state archives and state museums. Mostly the national archives reveal the secrets of regimes, culture, medicinal scripts, trades and civilization13. The ancient construction practices prominently utilized the binders such as clay, mud, limestone, volcanic ash and gypsum in the preparation of mortar since the ancient times, following its setting and hardening properties. Archaeological evidences has shown the usage of Lime started before the prehistoric period in Iran and China14. Romans and Egyptians were known for their use of pozzolanic elements, gypsum and quick Lime in early construction, unfortunately the plasters prolonged to set at conventional period of time. Hence the historic engineers and masons experimented with the locally available organic substances like gum Arabic, animal glue, blood of animals, figs, egg whites and yolks, casein, keratin that served as adhesives substances to enhance the weak mortars15. Francesco milizia16 reported on mixture added with oil to enhance the mortars' impermeability used in aqueducts and cisterns. The carbohydrate-based materials such as sugar, molasses, malt, drum stick gum and arabica gum were incorporated during production to quickly react to form calcium saccharate, which improved the cohesion properties and resistance against environmental forces17,18,19,20,21. The cactus (nopal juice) extracts were commonly added to mortars in ancient Mexican buildings to resist the water penetration and crack formation on the surfaces by improved mechanical properties due to the cactus' polysaccharide mucilage interaction with portlandite at early stages22. Calcium oxalates (Weddellite, whewellite) are important biominerals found in nature and are the most abundant organic minerals category identified in sediments and hydrothermal veins. The genesis of calcium oxalates has been identified in many limestone structures as layers, and they act as a barrier to reduce the deterioration of stones due to weathering action. The effective role of jaggery (unrefined sugars), kadukkai (Terminalia chebula), kulamavu (Persea Macrantha) in lime mortars have been analyzed, and it has been found that the addition of fermented organics leads to the formation of weddellite in lime mortar, it has dramatically increased physical and mechanical properties23. Protein-lime was mainly used in ancient masonry construction, clay sculptures, mural paintings, and wall paintings; it's been found that the addition of albumen can bring a series of physicochemical property changes stickiness, water repellency, air-entraining and antimicrobial etc.24,25.The sixth century C.E. sites of Ellora caves, India, reported on earthen/Lime as a binding material in addition to cannabis Sativa (Hemp). Daulatabad fort, India reported on the addition of local vegetal fibres into mortar providing the information about the hempcrete production technology during Yadava regime26. The use of organic compounds dated back to ancient times and has widely spread across the world to enhance the mortar's strength. The mortar produced with lime putty and cheese adhered extremely well to stone blocks. The most commonly used additives were oxblood, animal fat, dairy products, tree barks, linseed oil, fig juices, lard, eggs, wine, beer, casein and cactus juice etc.27. Based on the regional availability a group of herbs rich in carbohydrate, protein and fat were fermented for few days and used for lime mortars production instead of water. During fermentation, the carbon-di-oxide produced will react with Lime for faster hardening and biomineralize calcium carbonate polymorphs28. Much ancient text talks about the use of plant and animal extracts in construction. One such preserved palm-leaf manuscript from the Padmanabhapuram Palace museum (Fig. 1), Tamil nadu, India, described the locally available organic herbs into mortar during the construction practices.

The palm leaf manuscripts acknowledged the traditional usages of organics like palm jaggery (Refined sugar), Kadukkai (Terminalia Chebula), Neelamari (Indigofera Tinctoria), Aloe vera (Xanthorrhoeaceae) and eggs during construction. Recent studies have used natural organic additives to slow down and accelerate the setting time and increase the mortar's workability. Modern analytical techniques like GC–MS were highly recommended to identify organic substances like polysaccharides and fatty acids. The 4th-century Macedonian tombs (Greece) wall paintings revealed the addition of plant gums and their pigments in mural wall paintings, detected by ion chromatography29. The byzantine tombs pointed out egg white usage in the lime mortar to enhance the mortar's binding and flexural strength, investigated through the HPLC technique30. Despite the above-mentioned recent investigations, to our best knowledge, the determination of organic mineral and its effect on Lime was rarely documented, but this study proposes a multi analytical approach to determine the possible bioactive compounds present in the identified herbs as mentioned in the ancient manuscript and to understand its effective role with lime paste through the sophisticated methods like Gas chromatography and mass spectroscopy (GC–MS), X-Ray diffraction, Fourier transform-infrared spectroscopy, U.V. spectrophotometer, FE-SEM and quantitative methods like protein and fatty acid test methods. The characterized results will help Archaeology department, conservation engineers, architects and N.G.O.s working in the field of conservation to understand the traditional production technology and to produce the simulation mortar to restore the historic structures.

Experimental section

Collection of organic herbs

According to the palm leaf inscriptions and a semi-formal survey among the local people, the locally available healthy plant herbs like Kadukkai, Neelamari, Aloe vera, Hibiscus and Palm jaggery, etc. collected for the experiment, as shown in Fig. 2. The plants were washed with running tap water to remove the organic dust particles on the surface and open air-dried. Further, the dried leaves were gently crushed through pestle mortar to a fine powder. 5% by weight of each herb was soaked in the normal water for 14 days for fermentation. Later the aqueous fermented liquid is filtered through Whatman filter paper 42 for lyophilization31 (Blaško et al., 2008; Nandagopalan 2015).

Quantification of CO2 from fermented extracts

The amount of CO2 release from 0 to 14 days of fermented organics was regularly measured at an interval of 24 h using a wireless CO2 sensor operated by PASCO PS-3208. The sensing element, a pyroelectric device with a quartz reflector at one end of the probe and the other end is the I.R. band filter, absorbs the CO2 Gas in the probe. The concentration of CO2 is measured by non-dispersive infrared technology (N.D.E.R.) with an operating temperature of 0-50º C, the relative humidity of 0–95%, and the detection limit of CO2 concentration ranged between 100 and 1,00,000 ppm32.

Lyophilization of fermented samples

From supplementary Fig. 1. The filtered aqueous extract is being defrizzed at -80ºC and been lyophilized for 24 h. The aqueous sample gets modified into pellet form through the lyophilization process by vacuuming at -50 ºC to evaporate the substance's total moisture. The samples are then extracted through the ethyl acetate in the volume of 1:4 to examine the bioactive compounds through (GC–MS) gas chromatography-mass spectroscopy (Abdurahman, 2019; Degani 2015; Lluveras 2010; Nandagopalan et al., 2015).

GC–MS analysis

All the 5-ethyl acetate extracted organic samples were injected in an Agilent 7890 A GC system coupled with an MS 5975 selective detector (Agilent Technologies) with a single quadrupole mass spectrometer PTV injector at National Institute of Ocean Technology (N.I.O.T), Pallikaranai, Chennai, Tamil Nadu. The GC–MS operating conditions were set with oven temperature at 50 ºC for 2 min, then 100ºC at 10 ºC/min and finally increased to 200 ºC and been held isothermally for 10 min. The sample injected was 2µL, and the gas carrier was helium with a flow rate of 1 mL/min. All five samples are ionized by electron energy 70 eV. The GC–MS's total running time was 63 min to characterize the organic compounds through the N.I.S.T. 14.L library18,31,33,35 . The detection (L.O.D.) and the quantification (L.O.Q.) limits of fatty acids, sugars, lipids, tannins, protein (amino acids) and carboxylic acids were calculated at a significance level of 0.05 and used for the quantitative evaluation of each compounds29,33.

Process of organic lime putty

Figure 3 Laboratory scale processing of natural herbs followed by anaerobic fermentation for a period of 14 days to extract the bio precipitated solution. The extracted solution was experimented under GC–MS and classified based on its composition namely fatty acids, carbohydrate, polysaccharide and proteins. The fermented organic extract is filtered and mixed with hydraulic Lime (NHL 2.5) procured from Dhone, Andhra Pradesh, to produce the lime putty. Table 1 showed that 1:0.65 as water to Lime (W/L) ratio for reference lime putty and organic water to lime ratio at 1:0.68 (O/L) for Kadukkai, Neelamari, Aloe vera and 1:0.74 for Jaggery and Hibiscus according to flow table test as per I.S. 6932-Part (VIII)-1973 for the right consistency and the free water content of lime putty is maintained between 45 and 70% according to BS EN 459-Part 136.

UV spectrophotometer analysis

Derivatization of Total sugars

2 mg of the fermented solution is taken into a calorimetric tube, and 0.05 ml of 80% phenol is added. Further, 5 ml of concentrated sulfuric acid is added rapidly, the stream of acid being directed against the liquid surface rather than against the test tube's side to obtain good mixing. The tubes are allowed to stand for 10 min. Then they are placed in a water bath for 10 to 20 min at 25-30ºC. The absorbance of the characteristic yellow-orange colour is measured at the scanning range of 540 nm for galactose, hexoses and pentoses using ultra violet-spectrophotometer37 (Hitachi UH 5300, Japan) as shown in Supplementary Fig. 2. (Dubois 1951).

Determination of total fatty acids (Fame method)

0.25 g of each fermented extract is taken in a 50 ml round-necked volumetric flask. Add 10 ml of 0.2 N sodium methylate to methanol placed on an electric heater for 15 min to reach 100 °C. The solutions should be clear, usually lasting 10 min. The reaction is complete after 15 min, further removing the flask and the condenser from heat until the reflux stops and adding 1% of phenolphthalein solution to the methanol. Adding 1 N sulphuric acid solution to methanol until the solution is colourless, and add 1 ml more. Fit the condenser and boil for another 20 min. Remove the heat source and cool the bottle under running water. Remove the condenser, add 20 ml of saturated sodium chloride aqueous solution, stir, add 5 ml of heptane, plug the flask and shake vigorously for 15 s. Allow it to settle until the two phases have been separated. Repeat the saturated sodium chloride solution until the aqueous layer reaches the lower end of the flask neck, as shown in Supplementary Fig. 3. UV-Spectrophotometric further observes the processed solution with a concentration level (10–100 μg/ml) with an absorbance wavelength (660 nm)38.

Analytical techniques

The mineralogical phases were determined by X-Ray diffraction (XRD) using the Rigaku smart lab II diffractometer according to the diffraction powder method operating at 9 kW and 9 mA with oriented sample holders in polymethyl methacrylate or Si of diameters 25 and 20 mm depending on the amount of material (2–5 mg). The XRD patterns were obtained by scanning at the rate of 1º/minute from 5º to 90º (2 h) and steps of 0.05º (2 h)39. Fourier transform infrared spectroscopy (FT-IR) was performed using the Bruker Tensor 27IR with KBr pellets to measure the samples' energy absorption. 5 mg of finely ground < 75 µm specimen powder was homogenously mixed with 250 mg of KBr powder until the mixture had the consistency of fine flour and then pressed into a thin 15 mm diameter disc with infrared spectra obtained at 4000–400 cm − 1 range, with a resolution of 4 cm−1 32 scans respectively40,41,42,43. The samples' morphology was observed with a Carl Zeiss Supra 55 FE-SEM. The elemental analyses were performed using an X-ray dispersive spectrometer (E-DAX) resolution of 0.8 nm coupled to F.E.S.E.M. Each sample was coated with gold sputter (90 s) in a vacuum evaporating system. The sample was observed at a magnification range of 3300–10,000 × with low vacuum mode at 20 kV (Izaguirre, Lanas, & Álvarez 2010; Macwilliam & Nunes, 2019; Pradeep & Selvaraj, 2019).

Results and discussions

Liberation of CO2 & biomineralization of calcite

Fermentation was performed on the herbs to enhance the chemical reactions induced by microorganisms or the enzymes that split the complex compounds into the simplest substances in the absence of oxygen. This splitting of complex compounds is one reason for the carbonation of Lime. The fermentation periods of the organic herbs were fixed according to greater CO2 levels. The air bubbling in the airlock container will gradually slow down, becoming more and more infrequent and then stopping up altogether44 (Reddy 2018).

The amount of liberation of CO2 ranged between 10,000 and 90,000 ppm during the complete fermentation process shown in Fig. 4. Organic herbs like neelamari and aloe vera have significantly released the highest CO2 of 96,000 and 90,000 ppm on the 4th day of fermentation. Further, it slowed down its activity as the days progressed. Similarly, the palm jaggery and kadukkai have liberated the considerable amount CO2 of 36,500 and 50,000 ppm on the 4th day on signalling the rise of air bubbles from the bottom, indicates the complete ethanolic transformation activity. But the hibiscus has rapidly liberated the CO2 of 32,000 ppm on the 2nd day and moderately slowing down the emission on the 7th day, indicating the hibiscus has pyruvate into complete alcoholic transformation by splitting the complex compounds into sugars such as glucose, fructose and sucrose products. The fermentation measurements suggested, the liberation of CO2 was found high for neelamari and aloe vera, followed by kadukkai and jaggery; hence all these four organic fermented extracts can be incorporated into the lime mortar on the 4th day to activate the internal carbonation and to strengthen the mortar due to the internal reaction between the lime particles and organically induced CO2 to improve the calcite crystals. But the hibiscus herb showed high liberation on the 2nd day and gradually slowed down the activity, indicating it took 2 days to ferment and extended its transformation till 14 days.

Moreover, the fermentation days have significantly varied according to the organic herbs' phytochemical compounds; hence the number of days for fermentation was not kept constant in this study32. Liberation of CO2 is very important for setting and hardening of lime mortars in heritage buildings. In general, lime sets by carbonation by absorption of CO2 from the atmosphere to precipitate the calcium carbonate (Eq. 1).

Since the lime mortars, walls are huge and a few meters thick, the outer portion up to few centimeters gets carbonated because of atmospheric carbon dioxide. However, the internal core mortars remain un-carbonated for decades and prolong the lime mortars' hardening and resulting in slow strength gain. This main drawback of slow setting and strength gain is enhanced by fermented extract into Lime instead of water. The internal supply of CO2 results in the precipitation of calcium carbonate in bio calcite and metastable aragonite and vaterite42,43,44,45,46,47,48,49. The biomineralization of calcite from CO2 supplied from organic extract helps in fast setting and increased load-bearing capacity of heritage structures. Hence in the organically modified mortars, the hydrated phased are due to atmospheric and internal carbonation due to organics. The solubility of calcium compounds influences the degree of carbonation as the solubility of Ca(OH)2 being about 100 times higher than that of all three CaCO3 polymorphs. Therefore, self-healing will preferentially occur in partially carbonated lime mortar, where the uncarbonated part will provide Ca (OH)2 to fill thin cracks, thereby enhancing durability. Furthermore, peaks of all three different polymorphs of CaCO3, namely vaterite, aragonite and calcite, are found in the XRD pattern. This combination influences the dissolution and the subsequent recrystallization process and thereby contributes to the mortars' self-healing nature, making the mortars more durable39,49,50.

GC–MS analysis of fermented extracts

The 3% organic fermented extracts were screened under the GC–MS Agilent 7890A G.C. system with an MS 5975 selective detector; it detected the various bioactive compounds present in the five fermented extracts unsaturated fatty acids polysaccharides, carbohydrates and proteins substrates. The complete phytochemical compounds detected from the GC–MS analysis is shown in Table 2.

GC–MS unsaturated fatty acid detection

The ethyl acetate extracted fractions of organic fermented samples revealed the major bioactive compounds, interpreted through the GC–MS NIST 14. L. The representation of bioactive compounds is tabulated with peak concentration (%), retention time (R.T.), molecular formula, molecular weight and weight percentage with 100 mg/ml. Tables 3, 4, 5, 6, and 7 and supplementary method 4 fermented extracts namely kadukkai (T. Chebula) resulted in the form of unsaturated fatty acids compounds like citric acid, hexadecenoic acid, trans-octadecanoic acid, 13-octadecanoic acid and 6-octadecenoic acid with the overall unsaturated fatty acid percentage quantified around 54.1%. Neelamari (Indigofera tinctoria) chromatogram fractioned adipic acid, demecolcine, nalmefene, strychnine, cholestane-6-one, aspidodasycarpine, cyano, rhodopin, lycopene, phosphine with 80.78% in 100 mg/ml concentration34 (Nayar 1999). Palm jaggery (refined sugar) depicted the acetamide, lumicolchicine, pentadecanedioic acid, acetic acid, valine (amino acid), cyclodecasiloxane, pentamide and manopyranose content around 92.85%. The high-level acetic acid observed in palm jaggery reacts with the lime particle forming calcium acetate to promote the hydration properties due to the carboxyl groups to enhance the initial strength and internal voids the mortar46,52,53,54. Sucrose is the most common sugar, made up of α-glucose and β-glucose linked together by a glycosidic bond. The hydroxyl groups make the molecule highly water-soluble. As far as the lime traditions are concerned, the use of sugars has been documented in historic lime mortars in various countries where its interaction with C–S–H has been observed by adsorbing the Ca (OH)2 to increase the binding properties of the mortar. The addition of jaggery to Lime increases the solubility of Lime in water by 84%. Hence, instead of water jaggery extract, water can be added during slaking. It helps in more conversion of calcium oxide (Lime) into calcium hydroxide (portlandite). Jaggery contains 60–85% sucrose, 5–15% glucose and fructose, 0.4% protein and 0.6–1% of minerals9. Hibiscus (Rosa Sinensis) contained hexadecenoic acid, 14-octadecadienoate, tetracontane, fumaric acid (pigment), tritriacontane, 9-octadecene and hentriacontane ranging around 8.37%, resulting in a very low unsaturated fatty acid from the chromatogram. Table 11 Aloe vera (Xanthorrhoeaceae) recorded the pentanoic acid, tetradecanoic acid, n-hexadecenoic acid, oleic acid,9-octadecanoic acid and docosanoic acid around 47.72% from the chromatogram22,53. The reduced unsaturated fatty acid was observed due to the polysaccharide presence (starch, cellulose and glycogen) in hibiscus organic fermented extract shown in Table 1217,31. The higher unsaturated fatty acid was found in palm jaggery, followed by T. chebula and aloe vera fermented extracts, in agreement with CO2 quantified liberation observed. The role of unsaturated fatty acid compounds in the fermented extracts interacts with the lime particles to improve the water-resistance, mechanical strength and enhance the microstructure's formation. Hence the addition of unsaturated fatty acids have at least one double bond between carbon atoms, and they are thus more reactive and produces compact mortar (Zhang, & Zheng, 2014; Rampazzi et al., 2016).

GC–MS polysaccharide detection

The assessment of polysaccharides (starch, cellulose and glycogen) through GC–MS analysis of the fermented organic herbs resulted in showing the sugars and fatty acid bioactive compounds from Tables 8, 9, 10, 11, and 12 and supplementary method 4. The fermented aloe vera organic extract revealed galactitol, hexacetate and acetic acid at 13.21% in 100 mg/ml concentration. Palm jaggery recorded the presence of beta-d-galactopyranose, beta-d-mannopyranose and iditol (galactokinase) at 11.80% and fatty acids of 83.02%. Palm jaggery, which is predominantly sucrose, upon reacting with calcium oxide and silica in clay, forms strong bonds and hardens on drying. Lime mortar made with fermented jaggery extracts has decreased the segregation and bleeding properties. Sugar is a carbohydrate substance composed of carbon, oxygen, and hydrogen. It mostly binds the intermolecular compounds to strengthen the mortar from cracks and acts as a load-carrying element for the bedding mortar54. Aloe vera phytochemical analysis screened 13.21% of carbohydrate and polysaccharides, which disperses in water, often making a hydro-colloidal system and retain water. Therefore, aloe vera extract's main function is water-retention, exhibiting quick frying and prevents shrinkage crack on the render after hardening. In addition, the viscosity of the extract improves the plasticity of the mortar by applying thin layers of polished finish on the surfaces. Converting into ethanolic fermented extract reduces the specific surface area and pore distribution system on hydrated phases (Chattopadhyay, 2013). The sugars peaks were untraceable in the further analysis, which responded with active fatty acid compounds in kadukkai, neelamari and fermented hibiscus extracts. Kadukkai extracts revealed citric acid (6%), hexadecenoic acid (11.21%), octadecenoate (5.37%), 13-octadecenoic acid (10.15%) and 6-octadecenoic acid (16.71%) as shown in Table 10 with the detection percentage ranged around 54.1%. Similarly, the neelamari and hibiscus also fractioned the fatty acid peaks like cyclodecasiloxane (9.15%), methyl hexadecadienoate (10.86%), oleic acid (26.54%), octadecadienoic acid (8.96%) as shown in Table 11 with weight percentage detected around 72.53%. Hibiscus extract resulted in high fatty acid compounds like pentane dioic acid (6.47%), tridecanoic acid (5%), octadecadienoic acid (4.65%), hexadecatrienoic acid (4.99%), octadecenoate acid (4.9%), 9-octadecanoic acid (15.18%), octadecanoic acid (8.14%) with overall percentage detected around 86.34% as shown in Table 12. The unsaturated fatty acid concentration levels in three fermented extracts has indicated the role of high hydrophobicity to the lime hydrate phases on creating the air entrapment to slow down the carbonation activity and also acts as a water-repellent matrix by reducing the drying shrinkage cracks on the structures56 (Hrdlickova kuckova 2015; Rao et al., 2015).

The unsaturated fatty acids are the components that have imparted the hydrophobicity to the lime paste because it comprises the highest amount of C–C double bonds. The organics herbs with more amount of monounsaturated fatty acids (oleic acid) are more effective in imparting the hydrophobicity. The recent study on the addition of oleic acid to the lime paste has observed decreased particle size precipitates57,58,59,60. The morphology of kadukkai lime paste, aloe vera lime paste, neelamari lime paste mixes has indicated the transformation of calcium hydroxide in forming the carbonate polymorphs at 7 days of testing. The unsaturated fatty acids like citric acid, hexadecenoic acid, trans-octadecanoic acid, 13-octadecanoic acid and 6-octadecenoic acid present in fermented plant extracts have accelerated the formation of microstructure at an early stage and play a role in biological nucleation.

Moreover, it regulates the growth of calcium carbonate crystals and leads to smaller particles and a more compact structure. The lime paste subsumed with unsaturated fatty acids has better mechanical properties, water resistivity and weather resistance than common reference lime paste. (Ziyang Liu 2016).

The functions of protein in lime paste include air-entraining, decrease roughness, viscous enhancing performance and environmentally friendly admixtures for modern construction materials. The addition of amino acids (valine) has improved lime paste's performance due to the interfacial activity of the protein-peptide chains and the bio-mineralization effect. Fang et al. discussed that proteinaceous substances' addition improves the consistency, cohesiveness, durability and reduces the risk of cracking of the lime mortar. Simultaneously, it has a negative influence on the compressive strength and surface hardness of the mortar along with much more compact and slows down the carbonation progress of the lime mortar14. Yang and Zeng et.al. Revealed that the presence of carbohydrates played a crucial role in the microstructure and consolidation of lime mortars. Carbohydrates act as a template and consolidate the loose structures and result in strength improvement and durability23. Thirumalini et al., in their research work they have analyzed the influence of organically added lime mortar on mechanical and physical properties of lime mortar and revealed that the addition of organics has enhances the compressive strength of lime mortar due to the reduction of a higher amount of larger pores into micropores. The addition of organics in the form of carbohydrates and protein in the lime mortar mix would have also prolonged the reaction and retarded the initial growth to arrest the drying shrinkage cracks on the lime paste.

The similar presence of calcite and vaterite in the mortar samples with traces of calcium oxalates (weddellite) could contribute to the self-healing of lime mortar in enhancing the crystalline growth high carbonation rate42,46. From the overall results, the addition of organics has proven that phytochemicals have altered the mineralogical formation and significant advantages such as setting acceleration, water repellency, hydrophobicity, strength enhancement and carbonation rate to produce an eco-friendly bio-organic mortar.

This study's phytochemicals investigation has contributed to understanding the interaction mechanism between the lime particles and fermented organics. Although many efforts have been devoted to identifying the original components of the ancient building materials, it is not always possible to find the exact reason for the structures' survivability and longevity. This is especially true for the organic additions, either because they were incorporated in small amounts (below 5%), thus falling short on detecting the possible interaction and type of phytochemicals that have improved the required structural aspects56.

Quantification of fatty acid (Fame Method)

The fatty acid methyl esters (FAME) detected the fatty acid esters derived from the transesterification of fats in the presence of methanol and been screened with a U.V. spectrophotometer between 290 and 660 nm. The absorbance produced the concentration of three herbal extracts that was plotted through the linear regression modelling coefficient (> 0.9981) and calculated the limit of quantification (L.O.Q.) and limit of detection (L.O.D.) ranging around 0.026 and 0.088 shown in Supplementary Figs. 5 and 612,20,29,33.

Sa: Standard deviation of the response, b: slope of the calibration curve.

The fatty acid concentration of kadukkai was 32.91 µg/ml, neelamari and aloe vera around 154.43 and 383.54 µg/ml through the fatty acid methyl esters transesterification method. De architectura by Vitruvius stated that the natural oil and plant extracted fatty acids were among the most common types of water-repellent additives used in ancient mortars for coating in antiquity stucco works. It's highly reactive because it contains a high amount of Oleic acid (26.4 wt%), hexadecenoic acid (22.22 wt%) and octadecenoic, commonly called (linolenic acid) (10.86 wt %) with two and three double bonds, in agreement with the GC–MS chromatograms as shown in Tables 2, 34, and 5 and release of high carbon dioxide was similarly detected through the fermented CO2 quantification analysis shown in Table 211. The unsaturated fatty acid like tung oil, olive oil, plant extracted oil, animal glue and casein are the most promising additive for improving the repair mortar durability and hydrophobicity to the molecular structure of the mortar. The addition of fatty acid components improves the binding capacity among the grains of lime particles due to their complex fatty acid chain structure. The past reported literature stated that plants contain fatty acid molecules such as oleic acid and stearic acid. Linoleic acid and minor ester fractions have provided the impervious layer to the surfaces by preventing structure instability. The presence of an appreciable number of di-unsaturated esters of linoleic acid is prone to polymerization reaction when exposed to the outer atmosphere. Drying could be rigid the molecular structure with an increase in mechanical strength17,56,58,59,60.

UV spectrophotometer total sugar regression modelling

The Beer lambert law is a linear relationship between the absorbance and the concentration, molar absorption coefficient and optical coefficient of a solution.

A: Absorbance, ε: Molar absorption coefficient M cm-1, c: Molar concentration M, l: Optical path length cm.

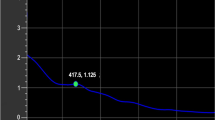

The U.V. spectrophotometric quantification analysis recorded total sugars through the phenol sulphuric reactive solution with the concentration level of (100-500 µg/ml) to evaluate the absorptivity and the wavelength detection limit ranging between (540 nm). Tables 8 and 9 indicated that total sugars were highly observed in palm jaggery kadukkai and aloe vera solutions around 6867.09 µg/ml, 424.05 µg/ml and16.46 µg/ml and with an absorbance level of 5.425. 0.335 and 0.329, respectively37. Further reagents like neelamari and hibiscus have recorded a moderate sugar concentration level due to unsaturated fatty acid in agreement with the GC–MS analysis performed on the fermented extracts. The GC–MS polysaccharide analysis detected the glycosides, monomers, monosaccharides, mannopyranose, glucopyranose and D-glucose in palm jaggery and aloe vera around 3.13 µg/ml and 11.17 µg/ml as shown in Tables 8 and 9, with > 1% sugar traced in other fermented herbs. For the realization of the calibration curve, it worked with the absorbance values obtained, the correlation coefficient (r = 0.998) and y-intercept of 0.079 × with LOQ = 0.013 and LOD = 0.067 was found to be statistically significant when performing the hypothesis testing on total sugars by UV-spectrophotometry as shown in supplementary Fig. 5 The sucrose level accelerates the lime mortar's initial hardening to significantly improve weather resistance by many folds. The addition of proteins acts as an air-entraining agent in fresh mortars and increases workability. It also acts a waterproof to mortar and controls the water movement. The basic reason for adding the proteinaceous additives is that they form a thin layer over the lime particles and slow down the hydration process. Further, calcium ion formation will increase the solubility on discouraging calcium hydroxide formation from strengthening the mortar18,37,54.

X-Ray diffraction (XRD) interpretation

After GC–MS analysis, XRD powder diffraction was performed on organic lime putty samples to evaluate their interaction with fermented herbs. Figures 5 and 6 shows mineralogical phases of the all mortar (reference and organic mortars) with crystalline polymorphs of calcium carbonate (calcite, aragonite and vaterite) and portlandite in confirmation with calcite vibration at 1409 cm−1 and portlandite peak at 3641 cm−1 in FT-IR analysis. But peaks in organic incised lime putty samples have revealed the overall formation of high portlandite peaks with low-intensity calcite peaks with traces of vaterite and aragonite peaks are observed. Minor traces of hatrurite peaks formed in insoluble silica present in the organic fermented herbs reacting with lime particle forming calcium hydrate silicates observed in K.L.P., JLP NLP organic lime putty samples validated with silicate spectral vibration observed at 420 and 478 cm−1. The organics incorporated lime putty samples modified their crystalline formation and properties like workability, water repellency, air entrapment, accelerator, and retarding effect with the interaction of biomolecules present in the fermented herbs23,28,62. Likewise, the N.L.P., K.L.P., A.L.P. and H.L.P. samples are rich in the presence of unsaturated fatty acid and fraction of sugars compounds, which has produced an internal dissociation between the lime particles by imparting hydrophobicity, making the surface more porous to increase the carbonation resulting in a gradual increase of calcite peaks with traces of fatty acid FT-IR vibration observed at 3392.1 cm−1. The unsaturated fatty acid is mostly prone to hydrophobicity. The formation of calcium oxalates (dehydrated-weddellite) peaks is observed due to oxalic acid (unsaturated acid) in the fermented organic, converting it into calcium oxalates to develop the formation of calcite slowly. The fraction of sucrose, glucose substrates present in the fermented organics tends to form strong bonds between the lime particle to develop crystalline hydrated phases to stabilize the formation of carbonate polymorphs as the days progress. J.L.P., A.L.P. and N.L.P. samples are rich in polysaccharide in agreement with GC–MS analysis. They have improved the early formation of calcite peaks, with possible break down of alcohol and CO2 converting the Ca (OH)2 to calcium alkoxide and calcium carbonate (Elert, Rodriguez-Navarro 2002). The presence of alcohol influences the metastable carbonate polymorphs phases by stabilizing them to increase the metastable vaterite and aragonite phases. The high intense portlandite peaks are similarly observed in all the organic samples. Additionally, carbohydrate FT-IR vibration peaks at 1583 cm−1 confirmed the addition of polysaccharides (starch, glucose and cellulose) would act as water reducers, water retention agents and set retarding effects to the organic incorporated samples19,21. This overall inflated transformation of portlandite peaks to calcite in reaction with internal recarbonation activity due to the organic fermented herbs will modify the amorphous phases to develop the crystallinity in forming the hydrated phases as the day's progress can be achieved with better absorbing of external CO2 through the external environment.

Infrared spectroscopy (FT-IR)

As a confirmation to the mineralogical investigation, FT-IR analysis was performed on the lime putty sample to investigate the organic, polymers and inorganic materials from the sample wavelength, as shown in Figs. 7 and 8. The reference lime putty sample revealed the presence of minor (O–H stretching) with intermolecular H-bond hydroxyl group at 3641 cm−1 and (C–H asymmetric stretching) vibration at 1409 cm−1,874.15 cm−1 (CH2 out of plane bending) show the presence of calcite peaks with traces of silicate vibration depicted at 1004 cm−1 in agreement with mineralogical investigation64. It's been evidenced that all the organically modified lime putty samples have revealed the intense characteristic peak portlandite (O–H stretching) at 3641 cm−1 and initially transformed calcite around 1400–1475 cm−1 assigned to the in-plane bending and symmetric carbonate out of plane bending vibration of calcite and aragonite. Minor peaks of vaterite have also been confirmed at 999 and 998 cm−1 around 900–1080 cm−1. The traces of silicate peaks at 420, and 480 cm−1 indicate the calcium hydrate silicate formation formed hatrurite peaks (C–S–H) in par with XRD analysis. The vaterite formation indicates the eventual transformation of amorphous conditions into calcite crystals under high CO2 pressure and the alkaline conditions of pH (8.5–10.5)65,66,67. The recent studies also have reported that vaterite formation is favored in the presence of amino acids and alcohols in addition to fermented organics (Ramadoss 2019; Ramadoss Ravi 2019). The presence of carbohydrates (C–H stretching) at 1583 cm-1 and unsaturated fatty acid peaks at 3394 and 3392 cm−1 being observed in all the modified mixes indicates the role of polysaccharides unsaturated fatty acids chains with the lime particle to transform the amorphous hydrated phases to crystalline calcite crystals. The minor stretching of hydroxyl ions at 3340–3494 cm−1 indicates ethanol, isopropanol, and calcium hydroxide observed in organically modified samples. It is observed that the reference putty (R.M.) sample has revealed well-developed calcite peaks compared to organic incorporated lime putty samples. However, the unsaturated fatty acid has created a porous surface to increase the carbonation and polysaccharides (starch, cellulose and glucose), slowing down the setting time and as waterproofing surfaces to resist the dampness from the surfaces.

Nevertheless, when the polymer is added as a dry powder, it has to dissolve first before to be able to adsorb on hydrates. Therefore, the hydrates have more time to grow, and the surface area available for adsorption is higher. It is evident that 5% of fermented organics has performed better and can further visualize the high-intensity calcite peaks with higher curing ages.

FE-SEM–EDX analysis

The morphological information of organic lime paste, provided by the field emission microscopy, helped provide valuable information about the reaction compound, allowing us to observe the nature of formation, sizes, texture and distribution system ranging between 3300 and 10,000 X in Figs. 9, 10, and 11. Reference lime paste revealed the formation of crystalline hydrated phases with E.D.X. spots indicated the more calcite formed compared to organic modified lime paste samples in agreement with XRD and FT-IR analysis. The most striking observation in all the organic lime paste was the amorphous calcite formation and major presence of portlandite peaks in observance to the XRD characterization from Fig. 4. The aloe vera lime paste sample showed the acicular shaped aragonite crystals, resulting in the paste's consistency and enhancing the compressive strength of the paste. Also, this was supported by the E.D.X. spectrum, as shown in Table 13. having the atomic weight percentage of (Ca and Mg) ranging between 35 and 45% along with carbon around 22–25% and other minor fraction of (Si, Fe, Al) around 2–4% respectively in agreement with XRD mineralogical depiction of organic lime paste samples46. The amorphous nature hindered the identification of calcite and vaterite crystals in the organic lime paste. It is observed that the surface morphology of all the organic lime paste has revealed well-developed calcite crystals and reduced pore spaces due to the enhanced carbonation in the presence of organic mineral2,60,67. The polysaccharides play a prominent role in the lime paste's microstructure and decarbonization properties. In the presence of organic additives, the initial setting has been prolonged. Hence, the cracks are not observed. It indicates that Ca (OH)2 and organics like protein and carbohydrates will increase the calcite formation and improved mechanical strength as time progresses68,69.

Ancient production technology of Organic lime mortars

Many ancient structures across the countries have documented various indigenously available organic materials during the production technology. To improve strength and durability, they included starches, flours, gums, oils, tree barks, waxes or plant resins, and animal origins such as animal fats or casein, blood, excrements and urine70,71,72. Ancient practices have incorporated the extracted oil and fats from plants and animals to waterproof the surface from the external dampness and capillary rise from the structure's ground level. Vitruvius stated that fig juice, rye dough, hogs, lard, curdled milk, blood and egg whites were employed to toughen and regulate the setting qualities. During the prehistoric periods, the moisture and dampness from the rain harm the structural wall and deteriorate the building materials. To counterbalance the problems, the historic structures were finished with permeable lime mortar to expand, contract, and flex with changes in external temperatures and moisture, hardening the structure on absorbing the CO2 from the external environment throughout its service life to increase the serviceability and longevity of the structure.

The addition of chemical additives has made the cement mortar more impervious with the nil absorption rate of CO2. The natural organic additives have activated the internal carbonation and help in carbon sequestration. Researchers reported using organic additives has improved the durability and hardness, reduced the drying shrinkage, resistance to traction, acceleration and deceleration of setting time, adhesiveness, and resistance freeze–thaw cycles, increases the plasticity and workability properties15,16. Ancient structures exposed to extreme environmental conditions have been subjected to adverse defects and chemical attacks that require repair and replication of similar traditional production technology with indigenous organics to preserve the structure and ancient wisdom.

Fermented organics like kadukkai, neelamari and palm jaggery and aloe vera are observed to be rich in unsaturated fatty acid through the GC–MS analysis. The unsaturated fatty acid compounds from plant origin have liberated maximum CO2 emission on anaerobic conditions. The overall release of CO2 confirms that the unsaturated fatty acid compounds have better carbonation with the early transformation of Ca (OH)2 into carbonate polymorphs to form the very compact structure due to hydrophobic and water repellency factors creating a waterproofing surface. Justnes et al., 2004 reported that fatty acid anions present in oils (unsaturated fatty acid) react with calcium hydroxide as follows Eqs. (5) and (6).

Calcium ions from calcium hydroxide react with the carboxyl group (C.O.O.-) of the unsaturated fatty acids to form hydrophobic salts of Ca (CXXHXXCOO)2; the dissolved CO2 salts carbonates the lime putty to improve the carbonate ions56 stated that fermented plant extracts containing more monosaturated fatty acids like oleic acid, octadec 9-enoic acid and hexadec 9-enoic acid are more effective producing the hydrophobicity to the mortar71 experimented with the effect of oleic acid on the properties of nano-calcium carbonate. They observed a decrease in the precipitates' particle size, which was also confirmed by wang et al. polysaccharides. These were identified in three herbs like kadukkai, palm jaggery and aloe vera in different percentages. The analyzed polysaccharides and proteins like acetamide, lumicolchicine, pentadecane dioic acid, valine (amino acid), cyclodecasiloxane, pentamide and manopyranose are equally classified as water reducers, set retarders and water retention agents that help to retain the moisture content in lime mortar leading to the delay in the setting time68. Polysaccharides shall contain both hydrophobic and hydrophilic segments responsible for the delay in Lime since water molecules could be attached to the parts of hydrogen bonds; being unable to escape this moisturizes the mortar mix. The major drawback of polysaccharide in lime mortar is the induced delay of hydration, and its interlocking mechanism of water molecules inside the mortar imparts slow carbonation (Poinot 2015). The addition of sugars up to 2% has water reduce the effect and reduce risk in cracks induced by dry shrinkage. However, excess addition could affect the mortar's compressive strength and water resistance. However, the usage of organics in mortar has significantly improved the properties like durability, longevity and resistance against external environmental conditions.

The ancient sustainable production technology of organic lime mortars and its capacity to sequester carbon dioxide via biomineralization provides valuable inputs to lessen greenhouse gas emissions, causing climate change and variability. Compared to cement production, Lime is substantially adopted in ancient practice because it produced at a lower temperature around 900–1200 °C, resulting in 40% less CO2 output and absorption of CO2 during its lifetime. The addition of fermented organic extracts introduces internal carbonation within the material's inner core for faster hardening and setting to resist environmental loads acting on the structure throughout its life span. The formation of additional minerals such as metastable forms of calcium carbonate aragonite and vaterite, calcium alkoxides and calcium oxalates with the supply of CO2 supports carbon capture and storage. These added organics improve various properties like carbonation, plasticity, water repellency, and the mortar's strength and durability. Bio-Mineral carbonation in organic lime mortars is a safe and novel method for permanent CO2 sequestration and offers a potential and stable carbon capture and storage (C.C.S.)72.

Conclusions

From the archival information on the ancient palm-leaf manuscript of Padmanabhapuram palace construction, the ancient production methodology has made us capitalize on the importance of the type of building materials and various organic additives like kadukkai, neelamari, hibiscus, aloe vera and palm jaggery and also its role with the binder materials that has resulted in the long-term durability to the structure.

-

The GC–MS analysis revealed various bioactive compounds such as unsaturated fatty acids, polysaccharides, carbohydrates, and proteins. The limit of quantification (LOQ) and detection limit (LOD) value was found statistically significant for sugar and fatty acid components.

-

Lime putties of Jaggery, aloevera, and kadukkai mixes have significantly improved the formation of calcite with acicular aragonite crystals in addition to polysaccharides materials such as glycosides, monomers, monosaccharides, mannopyranose, glucopyranose valine (amino acids) and D-glucose. In the presence of polysaccharides, the organic lime paste offered the hydrophobic property on offering better resistance against the absorption of the soluble substances to confront the dampness on the surfaces.

-

Hibiscus lime putty rendered the hydrophobic lining in the lime matrix pores in combined action with the effect of fatty acids and sugar monomers, such as hexadecenoic acid n-hexadecenoic acid, 14-octadecadienoate, tetracontane, fumaric acid, 9-octadecene, hentriacontane and rhodopin-glucose.

-

The phytochemicals present in the jaggery lime putty have attributed the combined chemical reaction like water repellency, retarding effect, adhesive properties that show the lime particle interaction to arrest the porosity resisting the shrinkage cracks and developing early mechanical strength with complete carbonation on the internal and external surfaces.

-

Supply of CO2 has initiated the internal carbonation of the lime putty and precipitation of calcite in three different forms aragonite, calcite and vaterite minerals. The XRD depicted the amorphous polymorphs of (calcite and vaterite) peaks, along with traces of CSH products such as hartrurite and larnite at initial stages, indicated the transformation of amorphous calcium silicate hydrate in agreement with FT-IR analysis. FESEM images revealed that the co-existence of amorphous and crystalline calcite enhances the hydration process as more free lime has been available for the reaction. The EDX results depicted the amount of carbon presence up to 24%.

-

Scientific research decodes the influence of plant extracts in the lime mortars. It provides valuable input to the State Archeology Department, conservation engineers and architects, NGO’s, and to simulate new organic mortars for repointing, rendering, stucco, and waterproof surfaces to restore and safeguard the ancient structures.

Abbreviations

- XRD:

-

X-ray diffraction

- FESEM-EDX:

-

Field emission scanning electron microscopy

- FT-IR:

-

Fourier transformation-infrared spectroscopy

- GC–MS:

-

Gas chromatography-mass spectroscopy

- K.L.P.:

-

Kadukkai lime putty

- J.L.P.:

-

Jaggery lime putty

- A.L.P.:

-

Aloe vera lime putty

- N.L.P.:

-

Neelamari lime putty

- H.L.P.:

-

Hibiscus lime putty

- L.O.Q.:

-

Limit of Quantification

- L.O.D.:

-

Limit of detection

References

Mohamed Sabri, A. A. & Suleiman, M. Z. Study of the Use of Lime Plaster on Heritage Buildings' in Malaysia: A Case Study in George Town, Penang. M.A.T.E.C. Web Conf. 17, 01005 (2014).

Zhao, C., Zhang, Y., Wang, C. C., Hou, M. & Li, A. Recent progress in instrumental techniques for architectural heritage materials. Herit. Sci. 7, (2019).

Clemente, P. Extending the life-span of cultural heritage structures. J. Civ. Struct. Heal. Monit. 8, 171–179 (2018).

Lourenço P. B. The I.C.O.M.O.S. methodology for conservation of cultural heritage buildings: Concepts, research and application to case studies. REHAB 2014 - Proc. Int. Conf. Preserv. Maint. Rehabil. Hist. Build. Struct. 945–954 (2014). doi:https://doi.org/10.14575/gl/rehab2014/095

Menon, A. Heritage Conservation in India: Challenges and New Paradigms. SAHC2014 – 9th Int. Conf. Struct. Anal. Hist. Constr. 14–17 (2014).

Pacheco-Torgal, F. & Jalali, S. Cementitious building materials reinforced with vegetable fibres: a review. Constr. Build. Mater. 25, 575–581 (2011).

Bimal, B., Adars, S., Akshay, M., Arun, K. & Betson Jose, P. R. Finite element analysis of wheel rim using abaqus software. Int. J. Eng. Res. Appl. 7, 31–34 (2017).

Thirumalini, P., Ravi, R., Sekar, S. K. & Nambirajan, M. Study on the performance enhancement of lime mortar used in ancient temples and monuments in India. Indian J. Sci. Technol. 4, 1484–1487 (2011).

Thirumalini, P. & Sekar, S. K. Review on herbs used as admixture in lime mortar used in ancient structures. Indian J. Appl. Res. 3, 295–298 (2011).

Sharma, D., Singh, M., Krist, G. & Velayudhan, N. M. Structural characterization of 18th century Indian Palm leaf manuscripts of India. Int. J. Conserv. Sci. 9, 257–264 (2018).

Blaško, J. et al. Gas chromatography/mass spectrometry of oils and oil binders in paintings. J. Sep. Sci. 31, 1067–1073 (2008).

Benzidia, B. et al. Chemical composition and antioxidant activity of tannins extract from green rind of Aloe vera (L.) Burm. F. J. King Saud. Univ. Sci. 31, 1175–1181 (2019).

Kolay, S. Cultural heritage preservation of traditional Indian art through virtual new-media. Proc. Soc. Behav. Sci. 225, 309–320 (2016).

Yang, F., Zhang, B., Pan, C. & Zeng, Y. Traditional mortar represented by sticky rice lime mortar-One of the great inventions in ancient China. Sci. China Ser. E Technol. Sci. 52, 1641–1647 (2009).

Holmström, I. Mortars, cements and grouts for conservation and repair. Some urgent needs for research. Mortars, Cem. grouts used Conserv. Hist. Build. = Mortiers, ciments coulis Util. dans la Conserv. des bâtiments Hist. Symp. 3–6.11.1981 Rome 19–24 (1982).

Rampazzi, L. et al. Technology of medieval mortars: an investigation into the use of organic additives. Archaeometry 58, 115–130 (2016).

Alara, O. R. & Abdurahman, N. H. FTIR analyses of oils from Hibiscus sabdariffa, Stigma maydis and Chromolaena odorata leaf obtained from Malaysia: Potential sources of fatty acids. Chem. Data Collect. 20, 100200 (2019).

Li, K. et al. Optimized GC-MS method to simultaneously quantify acetylated aldose, ketose, and alditol for plant tissues based on derivatization in a methyl sulfoxide/1-methylimidazole system. J. Agric. Food Chem. 61, 4011–4018 (2013).

Ravi, R., Thirumalini, S. & Taher, N. Analysis of ancient lime plasters—Reason behind longevity of the monument charminar India a study. J. Build. Eng. 20, 30–41 (2018).

Sassaki, G. L. et al. Application of acetate derivatives for gas chromatography-mass spectrometry: Novel approaches on carbohydrates, lipids and amino acids analysis. J. Chromatogr. A 1208, 215–222 (2008).

Thirumalini, S., Ravi, R. & Rajesh, M. Experimental investigation on physical and mechanical properties of lime mortar: Effect of organic addition. J. Cult. Herit. 31, 97–104 (2018).

Cardenas, A., Arguelles, W. M. & Goycoolea, F. M. On the possible role of Opuntia ficus-indica mucilage in lime mortar performance in the protection of historical buildings. J. Prof. Assoc. Cactus Dev. 3, 64–71 (1998).

Thirumalini, S., Ravi, R., Sekar, S. K. & Nambirajan, M. Knowing from the past - Ingredients and technology of ancient mortar used in Vadakumnathan temple, Tirussur, Kerala India. J. Build. Eng. 4, 101–112 (2015).

Colombini, M. P. & Modugno, F. Characterisation of proteinaceous binders in artistic paintings by chromagtographic techniques. J. Sep. Sci. 27, 147–160 (2004).

Li, S. et al. Experimental Study on Physicomechanical Properties of Sandstone under Acidic Environment. Adv. Civ. Eng. 2018, (2018).

Singh, M. & Vinodh Kumar, S. Mineralogical, chemical, and thermal characterizations of historic lime plasters of thirteenth–sixteenth-century daulatabad fort, India. Stud. Conserv. 63, 482–496 (2018).

Pecchioni, E., Fratini, F. & Cantisani, E. Le Malte Antiche e Moderne tra Tradizione ed Innovazione. 238 (2008).

Singh, M., Vinodh Kumar, S., Waghmare, S. A. & Sabale, P. D. Aragonite-vaterite-calcite: Polymorphs of CaCO3 in 7th century CE lime plasters of Alampur group of temples. India. Constr. Build. Mater. 112, 386–397 (2016).

Colombini, M. P., Andreotti, A., Bonaduce, I., Modugno, F. & Ribechini, E. Analytical strategies for characterizing organic paint media using gas chromatography/mass spectrometry. Acc. Chem. Res. 43, 715–727 (2010).

Meir, I. A., Freidin, C. & Gilead, I. Analysis of Byzantine mortars from the Negev Desert, Israel, and subsequent environmental and economic implications. J. Archaeol. Sci. 32, 767–773 (2005).

Nandagopalan, V., Gritto, M. J. & Doss, A. GC-MS analysis of bioactive components of the methanol extract of Hibiscus tiliaceus Linn.. Pelagia Res Libr. Asian J. Plant Sci. Res. 5, 6–10 (2015).

Jayasingh, S. & Selvaraj, T. Influence of organic additive on carbonation of air lime mortar–changes in mechanical and mineralogical characteristics. Eur. J. Environ. Civ. Eng. 1–16 (2019).

Lluveras, A., Bonaduce, I., Andreotti, A. & Colombini, M. P. GC/MS analytical procedure for the characterization of glycerolipids, natural waxes, terpenoid resins, proteinaceous and polysaccharide materials in the same paint microsample avoiding interferences from inorganic media. Anal. Chem. 82, 376–386 (2010).

Degani, L., Riedo, C. & Chiantore, O. Identification of natural indigo in historical textiles by GC–MS. Anal. Bioanal. Chem. 407, 1695–1704 (2015).

Singh, G. & Kumar, P. Extraction, gas chromatography-mass spectrometry analysis and screening of fruits of Terminalia chebula Retz for its antimicrobial potential. Pharmacognosy Res. 5, 162–168 (2013).

BS EN 459–1: B.S.I. Standards Publication Building lime Part 1: Definitions, specifications and conformity criteria. (2010).

Dubois, M., Gilles, K., Hamilton, J. K., Rebers, P. A. & Smith, F. A colorimetric method for the determination of sugars. Nature 168, 167 (1951).

Randall, R. J. & Lewis, A. The folin by oliver.

Moropoulou, A., Bakolas, A. & Bisbikou, K. Investigation of the technology of historic mortars. J. Cult. Herit. 1, 45–58 (2000).

Fiorentino, S., Grillini, G. C. & Vandini, M. The National Monument to Francesco Baracca in Lugo di Romagna (Ravenna, Italy): Materials, techniques and conservation aspects. Case Stud. Constr. Mater. 3, 19–32 (2015).

Corti, C. et al. Thermal analysis and archaeological chronology: The ancient mortars of the site of Baradello (Como, Italy). Thermochim. Acta 572, 71–84 (2013).

Singh, M. & Arbad, B. R. Scientific studies on decorated mud mortar of Ajanta. Case Stud. Constr. Mater. 1, 138–143 (2014).

Rao, H., Li, B., Yang, Y., Ma, Q. & Wang, C. Proteomic identification of organic additives in the mortars of ancient Chinese wooden buildings. Anal. Methods 7, 143–149 (2015).

Macwilliam, K. & Nunes, C. Structural Analysis of Historical Constructions. 18, (Springer International Publishing, 2019).

Izaguirre, A., Lanas, J. & Álvarez, J. I. Ageing of lime mortars with admixtures: durability and strength assessment. Cem. Concr. Res. 40, 1081–1095 (2010).

Pradeep, S. & Selvaraj, T. Identification of Bio-Minerals and Their Origin in Lime Mortars of Ancient Monument: Thanjavur Palace. Int. J. Archit. Herit. 0, 1–11 (2019).

Microstructure , Chemical Processes and Experimental Investigation of Lime-Based Mortars. (2012).

Reddy, M. V. S., Latha, K. A., Madhuri, M., Sasi, K. & Sagar, C. V. Effective Utilization of Herbocrete - A natural admixture in cement mortar to assess the strength properties. 3, 31–36 (2018).

Singh, M. International journal of conservation science characterization of ancient lime plasters of the historical sea characterization of ancient lime plasters of the. (2018).

Surendran, S. M., Ravi, R., Subramani, G. S. & Chattopadhyay, S. Characterization of ancient mortars of Veppathur temple. Int. J. Civ. Eng. Technol. 8, 2132–2139 (2017).

Nayar, T. S., Binu, S. & Pushpangadan, P. Uses of plants and plant products in traditional Indian mural paintings. Econ. Bot. 53, 41–50 (1999).

Artioli, G., Secco, M. & Addis, A. The vitruvian legacy: Mortars and binders before and after the Roman world. Eur. Mineral. Union Notes Mineral. 20, 151–202 (2019).

Ravi, R., Selvaraj, T. & Sekar, S. K. Characterization of hydraulic lime mortar containing opuntia ficus-indica as a bio-admixture for restoration applications. Int. J. Archit. Herit. 10, 714–725 (2016).

Fang, S. Q., Zhang, H., Zhang, B. J. & Zheng, Y. The identification of organic additives in traditional lime mortar. J. Cult. Herit. 15, 144–150 (2014).

Bag, A., Bhattacharyya, S. K. & Chattopadhyay, R. R. The development of Terminalia chebula Retz (Combretaceae) in clinical research. Asian Pac. J. Trop. Biomed. 3, 244–252 (2013).

Nunes, C., Viani, A. & Ševčík, R. Microstructural analysis of lime paste with the addition of linseed oil, stand oil, and rapeseed oil. Constr. Build. Mater. 238, (2020).

Hrdlickovakuckova, S., Schultz, J., Veiga, R., Murta, E. & Sandu, I. C. A. Proteomics tools for the contemporary identification of proteinaceous binders in gilded samples. Int. J. Conserv. Sci. 6, 507–518 (2015).

Azeman, N. H. et al. Study on the spectrophotometric detection of free fatty acids in palm oil utilizing enzymatic reactions. Molecules 20, 12328–12340 (2015).

Jeon, C. W. et al. Nonpolar surface modification using fatty acids and its effect on calcite from mineral carbonation of desulfurized gypsum. Coatings 8, (2018).

Ventol, L., Vendrell, M., Giraldez, P. & Merino, L. Traditional organic additives improve lime mortars: New old materials for restoration and building natural stone fabrics. Constr. Build. Mater. 25, 3313–3318 (2011).

Scanned by CamScanner 连 发 阉. 2016 (2016).

Ravi, R. & Thirumalini, S. Effect of natural polymers from cissus glauca roxb on the mechanical and durability properties of hydraulic lime mortar. Int. J. Archit. Herit. 13, 229–243 (2019).

Elert, K., Rodriguez-Navarro, C., Pardo, E. S., Hansen, E. & Cazalla, O. Lime mortars for the conservation of historic buildings. Stud. Conserv. 47, 62–75 (2002).

Rodriguez-Navarro, C., Vettori, I. & Ruiz-Agudo, E. Kinetics and mechanism of calcium hydroxide conversion into calcium alkoxides: implications in heritage conservation using nanolimes. Langmuir 32, 5183–5194 (2016).

Nugroho, A., Satyarno, I. & Subyakto, I. Bacteria as self-healing agent in mortar cracks. J. Eng. Technol. Sci. 47, 279–295 (2015).

Ramadoss, R., Ahamed, A. & Selvaraj, T. Alternative approach for traditional slaking and grinding of air lime mortar for restoration of heritage structures: natural polymer. J. Archit. Eng. 25, 04019017 (2019).

Ventolà, L., Vendrell, M. & Giraldez, P. Newly-designed traditional lime mortar with a phase change material as an additive. Constr. Build. Mater. 47, 1210–1216 (2013).

Peschard, A. et al. Effect of polysaccharides on the hydration of cement suspension. J. Eur. Ceram. Soc. 26, 1439–1445 (2006).

Poinot, T., Bartholin, M. C., Govin, A. & Grosseau, P. Influence of the polysaccharide addition method on the properties of fresh mortars. Cem. Concr. Res. 70, 50–59 (2015).

Eires, R., Camões, A. & Jalali, S. Ancient materials and techniques to improve the earthen building durability. Key Eng. Mater. 634, 357–366 (2015).

Zhao, P. et al. Material characteristics of ancient Chinese lime binder and experimental reproductions with organic admixtures. Constr. Build. Mater. 84, 477–488 (2015).

Kelektsoglou, K. Carbon capture and storage: A review of mineral storage of CO2 in Greece. Sustain. 10, (2018).

Acknowledgements

The National Institute of Ocean Technology (N.I.O.T.) and Vellore institute of technology has provided the facilities for conducting laboratory experiments on GC-MS and qualitative analysis on Bio-organic polymers. My sincere thanks to the N.I.O.T. staff members and English language editing by native English professor Dr Laxmi Dhar Dwivedi, School of Social Sciences and Languages, Vellore Institute of Technology, Vellore.

Author information

Authors and Affiliations

Contributions

Dr.TS designed research plan, MS conducted experimental investigation and data interpretation . MP conducted chemical and GC–MS analysis, MP and Dr TS drafted the manuscript and all authors read and approved the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shivakumar, M., Selvaraj, T. & Dhassaih, M.P. Preparation and characterization of ancient recipe of organic Lime Putty-Evaluation for its suitability in restoration of Padmanabhapuram Palace, India. Sci Rep 11, 13261 (2021). https://doi.org/10.1038/s41598-021-91680-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-91680-8

This article is cited by

-

Reinvestigating the science and engineering behind the architectural marvels of Ahom dynasty in pre-colonial Assam (1228–1826 CE)

Indian Journal of History of Science (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.