Abstract

Spraying of defoliant can promote centralized defoliation of cotton and advance maturity to facilitate harvesting. Modern pesticide application equipment includes plant protection unmanned aerial vehicles (UAVs), which are used widely for spraying defoliants. However, commonly used defoliant formulations are mainly suspension concentrates and water-dispersible granules, which need to be diluted with water when used. These are not suitable for plant protection UAVs with limited load capacity, especially in arid areas such as Xinjiang, China. Therefore, we prepared a thidiazuron·diuron ultra-low-volume (ULV) spray, which can be used directly without dilution in water. We found that ULV sprays had better wettability than the commercially available suspension concentrate, could quickly wet cotton leaves and spread fully. The volatilization rate was lower. ULV sprays also showed better atomization performance and more uniform droplet distribution than the commercially available suspension concentrate. At a dosage of 4.50–9.00 L/ha, the coverage rate on cotton leaves was 0.85–4.15% and droplet deposition densities were 15.63–42.57 pcs/cm2; defoliation rate and spitting rate were also greater than those of the reference product. This study could be contributed to the development of special pesticide formulations suitable for UAVs.

Similar content being viewed by others

Introduction

Cotton is an important economic crop. As the main raw material of the textile industry, it plays a crucial role in China's national economy1,2,3. Xinjiang is a prominent planting base for cotton in China. For a long time, farmers relied on manual harvesting of cotton; however, the huge labor expenditure seriously reduced the income of the cotton farmers4. Therefore, machine-picking has become an inevitable choice for cotton harvesting because it reduces labor and planting costs5. However, application and popularization of mechanical picking in China is far from sufficient. The main problem is that cotton bolls do not open uniformly at harvest time, and the leaves do not fall off completely, leading to a high content of impurities in mechanically picked cotton. Therefore, spraying defoliant to make leaves fall off and promote earlier and uniform opening of cotton bolls is an important step in accelerating the process of mechanized cotton picking and improving the quality of cotton seeds6,7,8.

Thidiazuron is a urea plant growth regulator that promotes the production of ethylene and abscisic acid in cotton and inhibits the transport of auxin. A separation layer forms between the leaf and the petiole to promote leaf shedding9,10. Combined use of thidiazuron and diuron produces better defoliation effects than thidiazuron alone, with diuron enhancing defoliation activity especially in low-temperature environments11. Ethylene is a gaseous hormone that promotes fruit ripening and shedding of old leaves and other organs12,13. Defoliation of cotton plants is closely related to the ripening and opening of cotton bolls, and a combination of defoliant and ethephon improves the effect of defoliation. Ethephon is a type of ethylene precursor; after being absorbed by cotton, it promotes the biosynthesis of ethylene, resulting in ripening and cracking of cotton bolls14. Therefore, chemical defoliation and ripening are essential for machine picking of cotton. Defoliation stimulates cotton bolls to open relatively early and uniformly, reduces impurities in seed cotton, avoids pollution of cotton wool with dead leaf debris, and improves the quality and yield of cotton, thereby increasing the planting efficiency of cotton.

The method used for spraying defoliants plays an important role in the efficiency of cotton defoliation. Defoliants are generally used during the boll-opening stage15,16,17. Improving the coverage of defoliants on cotton plants is key to improving the efficacy of defoliants. Currently, cotton growers in China’s Xinjiang region mainly use boom-type sprayers to spray pesticides. Compared with knapsack sprayers, these have wide spray width, large capacity, and high efficiency, leading to savings in labor costs and time. However, the terrain can restrict boom-type sprayers, which can damage plants, spraying can be uneven, and their efficacy is not excellent18. In addition, given the large application volumes, the effective utilization rate of pesticides is low, potentially causing pollution19.

Therefore, in recent years, cotton growers in China’s Xinjiang region have begun to spray defoliants using plant protection unmanned aerial vehicles (UAVs)20. Compared with traditional mechanical and artificial pesticide application, use of UAVs is labor and time-saving, with the same significant effect on defoliation and ripening of cotton, but no significant effect on yield and quality21. With the introduction of UAVs, cotton cultivation has become more mechanized and technological. Pesticides sprayed by plant protection UAVs show high levels of safety and cause little harm to the human body. The UAVs produce a low-altitude and low-volume flight spray. The airflow generated by the propeller causes the pesticide mist to flow through the cotton plant from top to bottom with strong penetration, less drift, and uniform spray22,23,24. Therefore, the coverage rate of pesticide formulations is higher and more efficient than that using more traditional methods25. At the same time, UAVs can reduce land pollution caused by pesticides and improve pesticide utilization rates. The spray efficiency and effectiveness of plant protection UAVs are significantly better than those of boom-type sprayers, but there are few pesticide formulations suitable for plant protection UAVs. The low-altitude, small-volume spray produced by plant protection UAVs imposes stricter requirements on pesticide formulations26,27,28,29. Defoliants currently registered in China are mainly suspension concentrates, water-dispersible granules and wettable powders, which are not suitable for spraying using plant protection UAVs. This lack of pesticide formulations suitable for UAVs is the biggest obstacle in the development of UAV application. Ultra-low-volume pesticide sprays, with high-boiling-point oil solvent as carrier, have low volatility and strong adhesion. Compared with conventional pesticide formulations, they provide special advantages, such as high levels of coverage and better efficacy, making them ideal for plant protection UAVs30.

In this study, we prepared a thidiazuron·diuron ultra-low-volume spray suitable for use with plant protection UAVs. The wettability, atomization, and deposition performance of the ultra-low-volume spray on cotton leaves and its defoliation and ripening effects were studied.

Experimental

Materials

Unless otherwise noted, all chemicals were purchased from commercial suppliers and were used without further purification: Thidiazuron (95%), diuron (97%), chlorinated paraffin, and methyl oleate (Aladdin BioChem Technology Co., Ltd, China); Anionic adjuvant and nonionic adjuvant (BASF SE, Germany, 99%); Thidiazuron and diuron suspension concentrate (540 g/L) (Jiangsu Changqing agrochemical Co., Ltd., China).

Screening of solvents

Different organic solvents were added to 0.2 g thidiazuron and 0.1 g diuron. After shaking uniformly, samples were heated in a water bath and subjected to ultrasonic oscillation to dissolve them. Since heating increases the volatilization of organic solvents, the temperature of the water bath did not exceed 35 °C, and the time of ultrasonic oscillation did not exceed 20 min. After this time, the dissolution state of the original pesticide was observed and the dissolution effects of different solvent combinations were compared.

Screening of adjuvant

Adjuvants in the ultra-low-volume spray can improve the physical and chemical properties of the formulation and enhance its wetting and spreading properties31. Based on solvent screening, anionic and nonionic adjuvants were selected to build a stable pesticide loading system. The ultra-low-volume spray used a high-boiling-point oily solvent as a low-volatility carrier to facilitate the deposition of small droplets32. Methyl oleate is a methylated vegetable oil adjuvant with good biodegradability and low toxicity, and this was added as the oily solvent. Characteristics of an ultra-low-volume spray are low dosage and high concentration33. Droplets produced by spraying are extremely fine and easily drift, causing phytotoxicity to non-target organisms. It is necessary to add fillers to increase the viscosity and density of the formulation, reducing the risk of drift and phytotoxicity. Therefore, chlorinated paraffin was used as the filler at a proportion of 25%.

Preparation of the ultra-low-volume spray oil concentrate

Thidiazuron and diuron were placed into a 250 mL beaker, then different organic solvents were added and stirred at 200 rpm for 20 min. After dissolving completely, the anionic adjuvant was added and stirred until the system was clear. Next, the nonionic adjuvant was added and stirred. After mixing to uniformity, chlorinated paraffin and methyl oleate were added sequentially, followed by stirring at 250 rpm for 25 min. The resulting pale yellow, single transparent, homogeneous liquid containing thidiazuron and diuron was used as an ultra-low-volume spray.

Wettability measurement

The surface tension of each sample was measured using a SFZL-A1 surface tensiometer using the platinum plate method34,35. The contact angle of each sample on cotton leaves was measured using a JC2000D contact angle meter36,37. The viscosity of the ultra-low-volume sprays was measured using a NDJ-5S rotary viscometer. The reference product was 540 g/L thidiazuron·diuron suspension concentrate, which was recorded as 6. One gram of the reference product was diluted to 540 mL with water for subsequent experiments.

Volatilization rate measurement

The volatilization rate of samples was determined using the filter paper suspension method38,39. The filter paper was weighed and recorded as m1. Approximately 1.0 mL of each sample was distributed evenly onto separate filter paper circles, and the weight was recorded as m2. Subsequently, the filter paper was suspended in a drying oven at 25 °C for 20 min. The filter paper was reweighed and recorded as m3. The volatilization rate was calculated according to Eq. (1):

Atomization performance measurement

An indoor spraying device was used to simulate field application using the plant protection UAV. A spray particle size analyzer was used to test the atomization performance of the thidiazuron·diuron ultra-low-volume (ULV) spray and to analyze the effect of viscosity on droplet size and particle size distribution.

The indoor spraying device consisted of a DC voltage stabilized power supply, a peristaltic pump, and a rotary atomizer. The current of the DC voltage stabilized power supply was set to 1.00 A, and the voltage was adjusted to the range of 12–24 V. A laser tachometer was used to test the rotation speed of the rotary atomizer at various voltages. To analyze the stability of the rotary atomizer, a linear fitting of voltage and rotation speed was performed. The discharge of the peristaltic pump was set to 100 mL/min, and water was used as a spray. A spray particle size analyzer was used to test the size and distribution of the droplets ejected by the rotary atomizer at high-speed rotation. By analyzing the relationship between droplet size and the rotation speed of the rotary atomizer, the conditions for producing uniformly distributed droplets were found. Samples were sprayed according to the optimized conditions. Cumulative volume diameter and distribution information were collected to analyze the effect of formulation viscosity on atomization performance. The droplet size distribution (Rs) was calculated according to Eq. (2):

Efficacy trial

In September 2017, an efficacy trial of the thidiazuron·diuron ultra-low-volume spray was carried out at the cotton planting base of Xinjiang Agricultural University in Shawan County (44° 19′ 31.92″ E, 85°37′ 0.88″ N), Xinjiang Uygur Autonomous Region, China. The deposition effect of the droplets, defoliation rate, and cotton boll opening rate were tested under different application dosages. The height of cotton plants was approximately 1 m. On the day of the test, the temperature was 13–27 °C and the wind force was ≤ 3.

The application equipment used in the efficacy trial was a XAG P-20 plant protection UAV (XPLANT Co., Ltd., China). Five treatments were set up. Treatments 1–4 were nebulized thidiazuron·diuron ultra-low-volume spray prepared in this study, corresponding application dosages were 4.50, 6.00, 7.50, and 9.00 L/ha. Treatment 5 was 54% thidiazuron·diuron suspension concentrate. The area of each trial was 9 × 100 m2.

Deposition measurement

A droplet test card (oil-sensitive paper/water-sensitive paper, 2.6 cm × 7.6 cm) was used to test the effect of droplet deposition in the field when the formulation was sprayed by the plant protection UAV. The width of each measurement area was 9 m, which was suitable for the UAV to fly across three times. Three points were randomly selected from each of the three flight paths, and nine sampling points were investigated. A test card was fixed using a paper clip to the cotton plant canopy at each sampling point to collect droplets. At the end of the experiment, the droplet test cards were scanned using a scanner. Image-pro Plus software was used to analyze droplet size, droplet coverage and droplet deposition density on the test cards, and droplet distribution uniformity was calculated.

Defoliation rate and boll opening rate measurement

The effect of different treatments was tested by investigating the defoliation rate and boll opening rate of cotton plants in each treatment plot. For each plot, five sampling points in the shape of an "X" were randomly selected; at each point, five cotton plants were randomly selected as survey points. The total number of leaves, bolls, and opening bolls of cotton plants were counted before and 15 days after spraying the pesticide. The defoliation rate and boll opening rate were calculated according to Eqs. (3) and (4):

M1 and M2 are the number of cotton leaves before and after application; N1 is the total number of bolls of cotton plants, N2 is the number of opening bolls.

Ethics approval

Ethics approval is not required for this paper.

Results and discussions

Screening of solvent and adjuvant

The results of solvent screening are shown in Table 1. The original pesticide could not be completely dissolved using a single solvent. However, 5% N-methyl-2-pyrrolidone + 10% cyclohexanone could completely dissolve the original pesticide. There was no solid precipitation at room temperature, so the formulation could be used for the subsequent experiment. According to Table 2, a mixture of sulfonate adjuvants (70b) and fatty alcohol polyoxyethylene ether adjuvants (AEO-4, -5, -7, -9, 992) could stabilize the system in a single, transparent, homogeneous phase. Therefore, sulfonate adjuvant (70b) was selected and mixed with five adjuvants of the AEO series to prepare thidiazuron·diuron ultra-low-volume sprays, numbered 1–5 (as shown in Table 3).

Surface tension measurement

The critical surface tension of cotton leaves is 63.30–71.81 mN/m. Figure 1 shows that the surface tension of each sample was 31.67–33.37 mN/m, which was much lower than the critical surface tension of the leaf, indicating the agent was able to completely wet the leaf and be fully distributed on the leaf surface. The maximum surface tension of the reference product was 38.90 mN/m. Under the same dosage of adjuvant, sample 5 with adjuvant 992 had the smallest surface tension of 31.67 mN/m.

Surface tensions of different samples. Different letters (a–d) indicate significant differences between means. Means followed by the same letter are not significant at the 5% significance level by the LSD test (LSD = 0.05). Vertical bars indicate a standard deviation of the mean. The detailed data of the histogram is shown in Supplementary Table S1.

Contact angle measurement

According to Young's equation, the smaller the surface tension, the smaller the contact angle40,41. Figure 2 shows the contact angle of different samples on cotton leaves and the change in contact angle over time. The contact angles of oil agents containing the adjuvant 992, AEO-7 and AEO-9 were smaller than that of the reference product, and the spreading effect was superior to that of the reference product. In the surface tension test, sample 5 had the smallest surface tension of 31.67 mN/m; this sample showed the minimum initial contact angle (39°) and a static contact angle (22°). The surface tension of the reference product was 38.90 mN/m., with the maximum initial contact angle (65.5°). Therefore, the relationship between surface tension and contact angle conformed to Young's equation.

Contact angles of different samples on cotton leaves in 0–10 s. The detailed data of drawing the contact Angle curve is shown in Supplementary Table S2.

Volatilization rate measurement

As shown in Fig. 3, the volatilization rate of the oil agent was much lower than that of the reference product. The volatilization rate of the five treatments was 5.80–8.74%, while the volatilization rate of the reference product was 22.97%. The volatilization rate of the oil agent met the quality requirements of an ultra-low-volume spray (≤ 30%). A low volatilization rate helps with spraying defoliants in hot and dry areas such as Xinjiang, effectively preventing evaporation of the droplets and increasing deposition.

Volatilization of different samples on filter paper. Different letters (a–e) indicate significant differences between means. Means followed by the same letter are not significant at the 5% significance level by the LSD test (LSD = 0.05). Vertical bars indicate a standard deviation of the mean. The detailed data of the histogram is shown in Supplementary Table S3.

Viscosity measurement

Viscosity is an important factor affecting the atomization performance of a formulation42. Figure 4 shows that the viscosity of the five oil agents ranged from 12.9 to 18.3 mPa s, meeting the quality requirements of an ultra-low-volume spray (< 2 Pa s). The addition of chlorinated paraffin effectively increased the viscosity, facilitating analysis of the relationship between deposition and the viscosity of droplets in the subsequent experiment. This part of the work is described below under atomization performance.

Viscosity of each sample. Different letters (a–f) indicate significant differences between means. Means followed by the same letter are not significant at the 5% significance level by the LSD test (LSD = 0.05). Vertical bars indicate a standard deviation of the mean. The detailed data of the histogram is shown in Supplementary Table S4.

Screening for the best working conditions for the centrifugal spray atomizer

As shown in Fig. 5, the linear equation fitted to voltage and rotation speed was y = 79.2418x + 400.2857, and the correlation coefficient was 0.9998. This indicated a good linear relationship and that the working state of the rotary atomizer was stable, and met the requirements of the next experiment.

Relationship between voltage and rotation speed of the centrifugal spray atomizer. The detailed data of drawing the curve is shown in Supplementary Table S5.

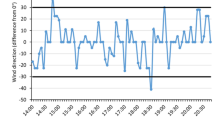

The relationship between droplet size and the rotation speed of the rotary atomizer are shown in Fig. 6. The rotation speed of the rotary atomizer and the cumulative volume diameter had a binomial distribution. The equation fitted to D10 was y = 1E−05x2 − 0.2496x + 1440.4, with a correlation coefficient of 0.9947; the equation fitted to D50 was y = 8E−06x2 – 0.1672x + 934.73, with a correlation coefficient of 0.9791; the equation fitted to D90 was y = 5E−06x2 – 0.0983x + 539.55, with a correlation coefficient of 0.9005. The correlation between the cumulative volume diameter and the rotation speed was very high, and the cumulative volume diameter became smaller as the rotation speed increased. When the rotation speed exceeded 9600 rpm (voltage 20 V), the cumulative volume diameter hardly changed. As shown in Fig. 7, when the rotation speed was 6400–7600 rpm (voltage 10–15 V), the spectral width of droplets increased with increasing rotation speed, and the distribution of droplets became more uneven. When the rotation speed was 7600–9600 rpm (voltage 15–20 V), the spectral width of droplets decreased with increasing rotation speed, and the distribution of droplets became more uniform. The minimum droplet size distribution appeared at 9600 rpm (voltage 15–20 V). When the rotation speed surpassed 9600 rpm (voltage > 20 V), the droplet size distribution tended to be stable. This coincided with data shown in Fig. 6, where the inflection point appeared when rotation speed was 9600 rpm (voltage = 20 V).

Relationship between the rotation speed of the centrifugal spray atomizer and droplet size. D10: 10% cumulative volume diameter, D50: 50% cumulative volume diameter, D90: 90% cumulative volume diameter. The detailed data of drawing the curve is shown in Supplementary Table S6.

Relationship between the rotation speed of the centrifugal spray atomizer and the fog droplet spectrum. The detailed data of drawing the curve is shown in Supplementary Table S6.

Therefore, we determined that the optimal working conditions for the rotary atomizer were achieved by setting the DC voltage stabilized power supply current to 1.00 A and voltage to 20 V, which were used for subsequent experiments.

Atomization performance

The relationship between viscosity and droplet spectrum are shown in Table 4 and Fig. 8. The cumulative volume diameter for the five treatments was less than 150 μm meeting the requirements of the ULV spray32. The cumulative volume diameter for the five treatments was larger than that for the reference product, the width of the droplet spectrum was narrower, and the droplet distribution was more uniform. Droplet size affects the drift of droplets43. The D10 of the reference product was 25.62 μm under these working conditions. This droplet size was highly susceptible to drift and deposition on non-target organisms. Water suspension was not suitable for this application at low dosage.

Relationship between formulation viscosity and droplet spectrum. The detailed data of drawing the figure is shown in Supplementary Table S7.

As presented in Table 4, droplet size increased with increasing viscosity, which influenced the droplet spectrum. The results in Fig. 8 show that the span of droplet size decreased with the increase of viscosity, indicating that droplets with more uniform distribution could be obtained by increasing the viscosity of the formulation41.

Droplet deposition effect

We tested the efficacy of the ULV spray formulation by spraying cotton plants using an UAV. The test results in Table 5 indicate that increasing the dosage of application would increase droplet size, coverage, and deposition density. At the same application dosage, the droplet size of the ultra-low-volume spray was slightly larger than that of the reference product, and the coverage and deposition density were greater than those of the reference product. The droplet spectral width (Rs) of the five treatments was less than 1, and the coefficient of variation was less than 7%, indicating that the droplet distribution was relatively uniform. Among treatments, T2 had the narrowest Rs and coefficient of variation (CV), where the droplet size distribution was the most uniform. For the ultra-low-volume spray, at the application dosage of 4.5–9.0 L/ha, the droplet coverage gradually increased from 0.85 to 4.15%; the droplet deposition densities were 15.63, 17.24, 28.45, and 42.57 pcs/cm2, which were larger than requirements suggested in the literature. The droplet coverage of the reference product (T5) was 0.73%, and the deposition density was only 11.32 pcs/cm2.

Efficacy trials

The efficacy of cotton defoliant is reflected in the defoliation rate and boll opening rate of cotton after application. Therefore, we surveyed the defoliation rate and boll opening rate of cotton in the test area 3–15 days after application. The results are shown in Figs. 9 and 10.

Defoliation rate 3–15 days after treatment. The detailed data of drawing the curve is shown in Supplementary Table S8.

Boll opening rate 3–15 days after treatment. The detailed data of drawing the curve is shown in Supplementary Table S9.

Figure 9 indicates that the defoliation rates of the five treatments 15 days after the pesticide treatment were 59.82%, 63.96%, 71.40%, 77.84%, and 54.58%, respectively. The defoliation rates of T1, T2, and T5 were less than 70%.

Application of the ultra-low-volume spray at 4.50 L/ha or 6.00 L/ha and the reference product at 6.00 L/ha had a poor defoliation effect. T4 (9.00 L/ha) was superior to the others, and the defoliation rate reached 77.84% 15 days after application. As shown in Fig. 10, the boll opening rates of the five treatments were 58.54%, 67.74%, 95.35%, 100%, and 44.68% 15 days after application. Similarly, the boll opening rates of T1, T2, and T5 were poor, with the boll opening rate of the control T5 only 44.68%. We analyzed significant differences between the defoliation rates and boll opening rates of the five treatments. The results showed that the defoliation rate and boll opening rate associated with the thidiazuron·diuron ultra-low-volume spray on cotton plants were significantly different from those of the reference product.

Overall, the defoliation rate and boll opening rate produced by the ultra-low-volume spray were superior to those produced by the reference product. This result was consistent with data shown in Table 5. The higher the droplet coverage rate, the higher the droplet deposition density and the higher the defoliation rate and boll opening rate. T1, T2 and T5 had poor deposition effect on cotton plants, and the effective pesticide utilization rate was low, resulting in dissatisfactory defoliation rates and boll opening rates. Both the droplet coverage rate and the droplet deposition density of T3 and T4 were large. Therefore, droplets of pesticide solution could deposit more easily and uniformly on cotton leaves, allowing the plants to defoliate and open their bolls easily.

Conclusions

We prepared a thidiazuron·diuron ultra-low-volume spray that met the quality requirements of an ultra-low-volume spray. We evaluated the application of thidiazuron·diuron ultra-low-volume spray compared with the reference product, 54% tidiazuron·diuron suspension concentrate. The surface tension of the oil agent was lower, the initial contact angle and the static contact angle on cotton leaves were smaller, and the spreading speed was faster than those of the reference product, indicating that the oil agent had good wetting and spreading performance. At the same time, the volatilization rate of ultra-low-volume sprays was much lower than that of the reference product, which was beneficial to use in hot and dry areas such as Xinjiang.

We determined the optimal working conditions of the rotary atomizer and tested the atomization performance of the formulations using an indoor spraying device. The cumulative volume particle size of the ultra-low-volume spray was larger than that of the reference product, and the droplet size distribution was more uniform. In addition, droplet size increased with increase in viscosity while droplet size spectrum decreased with increase in viscosity, indicating that droplets with more uniform distribution can be obtained by increasing the viscosity of the formulation.

We examined the deposition effect of the formulation, as well as the defoliation rate and boll opening rate of cotton, in an efficacy trial. Droplet size, coverage rate, and deposition density increased with increased dosage. Under the same dosage, the droplet size of the ultra-low-volume spray was slightly larger than that of the reference product, and the coverage rate and deposition density were greater than those of the reference product. The ultra-low-volume spray at 9.00 L/ha showed the best defoliation effect at 15 days after application, with a defoliation rate of 77.84% and boll opening rate of 100%. The defoliation rate of the reference product was 54.58%, and the boll opening rate was only 44.68%. Therefore, ultra-low-volume spray could be considered as an ideal pesticide formulation suitable for plant protection UAV. It had the characteristics of low dosage, high efficiency and environmentally friendly.

Data availability

Data is contained within the article or Supplementary Information.

References

Sunilkumar, G., Campbell, L., Puckhaber, L., Stipanovic, R. & Rathore, K. Engineering cottonseed for use in human nutrition by tissue-specific reduction of toxic gossypol. Proc. Natl. Acad. Sci. USA 103, 18054–18059 (2006).

Du, Y. Z. Future of China's textile industry. Textile Asia XXXVII, 46–49 (2007).

Yu, S. X., Zhang, L. & Feng, W. J. Study on strategy of large scale, mechanization, informationization, intelligence and social services for cotton production. Eng. Sci. 18, 137–148 (2016).

Wu, J. & Chen, X. Present situation, problems and countermeasures of cotton production mechanization development in Xinjiang Production and Construction Corps. Trans. Chin. Soc. Agric. Eng. 31, 5–10 (2015).

Singh, K. & Rathore, P. Effect of different defoliants and their rate and time of application on American cotton cultivars under semi-arid conditions of north-western India. Res. Crop. 16, 258 (2015).

Siebert, J. D. & Stewart, A. M. Correlation of defoliation timing methods to optimize cotton yield, quality, and revenue. J. Cotton Sci. 10, 146–154 (2006).

He, X. K., Bonds, J., Herbst, A. & Langenakens, J. Recent development of unmanned aerial vehicle for plant protection in East Asia. Int. J. Agric. Biol. Eng. 10, 18–30 (2017).

Gwathmey, C. O. & Hayes, R. M. Harvest-aid interactions under different temperature regimes in field-grown cotton. J. Cotton Sci. 1, 1–28 (1997).

Suttle, J. Involvement of ethylene in the action of the cotton defoliant thidiazuron. Plant Physiol. 78, 272–276 (1985).

Mondino, M. H. P. & De Dios, C. Efecto de la aplicación de diferentes productos químicos en el mejoramiento de las condiciones de cosecha en el cultivo de algodón (Gossypium hirsutum L.). Rev. De Investig. Agropecu. 33, 27–39 (2004).

Du, M. W. et al. Evaluation of harvest aid chemicals for the cotton-winter wheat double cropping system. J. Integr. Agric. 12, 273–282 (2013).

Barry, C. S. & Giovannoni, J. J. Ethylene and fruit ripening. Physiol. Plant. 26, 143 (1997).

Finkelstein, R. R. & Rock, C. D. Abscisic acid biosynthesis and response. Arabidopsis Book 1, e0058 (2002).

Stewart, A. M., Edmisten, K. L. & Wells, R. Boll openers in cotton: Effectiveness and environmental influences. Field Crops Res. 67, 83–90 (2000).

Uk, S. & Courshee, R. J. Distribution and likely effectiveness of spray deposits within a cotton canopy from fine ultralow-volume spray applied by aircraft. Pestic. Sci. 13, 529–536 (1982).

Xiao, Q. G. et al. Effect of aviation spray adjuvants on defoliant droplet deposition and cotton defoliation efficacy sprayed by unmanned aerial vehicles. Agronomy-Basel 9, 217–232 (2019).

Xin, F. et al. Effects of dosage and spraying volume on cotton defoliants efficacy: A case study based on application of unmanned aerial vehicles. Agronomy-Basel 8, 278–292 (2018).

Yang, S. L., Yang, X. B. & Mo, J. Y. The application of unmanned aircraft systems to plant protection in China. Precis. Agric. 19, 278–292 (2018).

Qin, W. C. et al. Optimization and test for spraying parameters of cotton defoliant sprayer. Int. J. Agric. Biol. Eng. 9, 63–72 (2016).

Huang, Y. B., Thomson, S. J., Hoffmann, W. C., Lan, Y. B. & Fritz, B. K. Development and prospect of unmanned aerial vehicle technologies for agricultural production management. Int. J. Agric. Biol. Eng. 6, 1–10 (2013).

Zhang, J. et al. Influence of spraying parameters of unmanned aircraft on droplets deposition. Trans. Chin. Soc. Agric. Mach. 43, 94–96 (2012).

Lan, Y. B., Thomson, S. J., Huang, Y. B., Hoffmann, W. C. & Zhang, H. H. Current status and future directions of precision aerial application for site-specific crop management in the USA. Comput. Electron. Agric. 74, 34–38 (2010).

Wang, J. et al. Meteorological and flight altitude effects on deposition, penetration, and drift in pineapple aerial spraying. Asia-Pac. J. Chem. Eng. 15, 1–14 (2020).

Xue, X. Y., Tu, K., Qin, W. C., Lan, Y. B. & Zhang, H. H. Drift and deposition of ultra-low altitude and low volume application in paddy field. Int. J. Agric. Biol. Eng. 7, 23–28 (2014).

Wang, M. et al. Deposition distribution of pesticide droplets over the tea canopy and control efficiency against Empoasca flavescens sprayed by unmanned aerial vehicle (UAV). Plant Protect. 45, 62–68 (2019).

De Schampheleire, M. et al. Effects on pesticide spray drift of the physicochemical properties of the spray liquid. Precis. Agric. 10, 409–420 (2009).

Ferguson, J. C. et al. Determining the uniformity and consistency of droplet size across spray drift reducing nozzles in a wind tunnel. Crop. Prot. 76, 1–6 (2015).

Yarpuz-Bozdogan, N. & Bozdogan, A. M. Comparison of field and model percentage drift using different types of hydraulic nozzles in pesticide applications. Int. J. Environ. Sci. Technol. 6, 191–196 (2009).

De Cock, N., Massinon, M., Salah, S. O. T. & Lebeau, F. Investigation on optimal spray properties for ground based agricultural applications using deposition and retention models. Biosyst. Eng. 162, 99–111 (2017).

Stonehouse, J. M. Studies of the distribution of ultra low volume spray applied within a crop canopy. J. Agric. Eng. Res. 54, 201–210 (1993).

Mohammadi, R., Wassink, J. & Amirfazli, A. Effect of surfactants on wetting of super-hydrophobic surfaces. Langmuir 20, 9657–9662 (2004).

Self, L. S., Ree, H. I., Lofgren, C. S., Shim, J. C. & Kim, K. H. Aerial applications of ultra-low-volume insecticides to control the vector of Japanese encephalitis in Korea. Bull. World Health Organ. 49, 353–357 (1973).

Huang, Y., Hoffmann, C. W., Lan, Y., Wu, W. & Fritz, K. B. Development of a spray system for an unmanned aerial vehicle platform. Appl. Eng. Agric. 25, 803–809 (2009).

Zhou, Z. L. et al. Evaporation kinetics of surfactant solution droplets on rice (Oryza sativa) leaves. PLoS ONE 12, e0176870 (2017).

Huang, X., Liu, H., Shang, S., Cai, Z. & Song, J. The equilibrium and dynamic surface tension of polymeric surfactants based on epoxidized soybean oil grafted hydroxyethyl cellulose. RSC Adv. 6, 64121–64128 (2016).

Krainer, S. & Hirn, U. Short timescale wetting and penetration on porous sheets measured with ultrasound, direct absorption and contact angle. RSC Adv. 8, 12861–21286 (2018).

Vuckovac, M., Latikka, M., Liu, K., Huhtamäki, T. & Ras, R. Uncertainties in contact angle goniometry. Soft Matter 15, 7089–7096 (2019).

Sundaram, A. A gravimetric method for determining the relative volatilities of non-aqueous pesticide formulations and spray diluents. Pestic. Sci. 16, 397–403 (1985).

Wei, K., Xu, W. M., Liu, Q., Yang, L. Y. & Chen, Z. Preparation of a chlorantraniliprole-thiamethoxam ultralow-volume spray and application in the control of Spodoptera frugiperda. ACS Omega 5, 19293–21930 (2020).

Chen, L. et al. Magnetic thermosensitive core/shell microspheres: Synthesis, characterization and performance in hyperthermia and drug delivery. RSC Adv. 4, 46806–46812 (2014).

Stalder, A. et al. Low-bond axisymmetric drop shape analysis for surface tension and contact angle measurements of sessile drops. Colloid Surface A 364, 72–81 (2010).

Wang, S., He, X., Song, J., Wang, S. & Ling, Y. Effects of xanthan gum on atomization and deposition characteristics in water and Silwet 408 aqueous solution. Int. J. Agric. Biol. Eng. 11, 29–34 (2018).

Wang, X. N. et al. Spray drift characteristics of fuel powered single-rotor UAV for plant protection. Trans. Chin. Soc. Agric. Eng. 33, 117–123 (2017).

Acknowledgements

The authors gratefully acknowledge the financial support of the National Nature Science Foundation of China (Nos. 31760532 and 21262009) and the Support Project of Excellent Scientific and Technological Innovation Talents of Colleges and Universities in Guizhou Province (No. 2013137).

Author information

Authors and Affiliations

Contributions

Q.L. and K.W. participated in each part of the experiment, analyzed the data by IBM SPSS Statistics 20 and Origin 2019b 64Bit, and wrote the manuscript. L.Y.Y. participated in the acquisition of part of the data and critically revised the manuscript. W.M.X. and W.X. participated in the design of the study, helped draft the manuscript, and critically revised the manuscript. Q.L. and K.W. contributed equally to this work, they should be regarded as co-first authors. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, Q., Wei, K., Yang, L. et al. Preparation and application of a thidiazuron·diuron ultra-low-volume spray suitable for plant protection unmanned aerial vehicles. Sci Rep 11, 4998 (2021). https://doi.org/10.1038/s41598-021-84459-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-84459-4

This article is cited by

-

Valorization of Grape Pomace-Derived Bio-Pesticide via Yeast Capsules- Nano Carriers with Entomotoxic Potential

Waste and Biomass Valorization (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.