Abstract

The photogalvanic cells (PG) are the promising and renewable electrochemical energy devices capable of doing the simultaneous solar power generation and storage. To realize the aim of the practical application of the PG cells in daily life, the electrical output of these cells has to be further enhanced to a level at least comparable to that of the photovoltaic cells. The present study of the PG cells based on so far unexplored Congo red dye-formaldehyde as a photosensitizer-reductant couple along with efficiency enhancer surfactant reagent (sodium lauryl sulfate) in the sodium hydroxide alkaline medium has shown greatly enhanced cell performance over published results. The present study has shown electrical cell performance of the PG cell as Ppp 782 μW, isc 3200 μA, Voc 1074 mV, and CE 11.02% at artificial and low illumination intensity. The storage capacity (t0.5) of the PG cell has been observed in the present study as 120 min in the dark. The study of variation of the different cell fabrication parameters has shown optimum cell performance at an optimal value of these cell fabrication parameters. The most plausible mechanism of the photo-generation of the current in PG cells is also proposed on the basis of observed potential values and published literature.

Similar content being viewed by others

Introduction

The solar energy coming from the sun is an everlasting renewable source of the energy. Solar power has the potential to become a reliable energy source as a supplement and substitute to the limited and polluting fossils’ fuels. The solar techniques like photovoltaic cells (PV), photogalvanic cells (PG)1, DSSCs2,3,4, etc., have ability to convert the solar energy directly into the solar electrical energy. The PG cells are quite different from the other solar cell techniques cells like PV cells. The PG cells are only solar cells which have inherent solar power storage capacity with stored power retrievable in the dark5. The PG cell works on the principle of the photogalvanic effect in which the photochemical changes occurring in the solution causing photopotential generation on illumination. Rideal and Williams were the first scientists to observe the photogalvanic effect6, and the Rabinowitch was the first researcher who not only systematically investigated this effect, but also gave the idea that this effect can be used for the solar energy conversion and storage7,8. To exploit this idea of the Rabinowitch, the PG cells have been extensively studied for solar energy conversion and storage by using two electrodes (anode and cathode) dipped in the solution having photosensitizer, reductant, NaOH, and surfactant (surfactant in some cases)9,10,11,12. The electrical performance (current, power, potential, efficiency, etc.) of the PG cells have been reported as dependent on the cell fabrication parameters like concentrations, diffusion length, temperature, electrode nature, Pt electrode size, illumination intensity, etc. Therefore, the various researchers have focused mainly on these cell fabrication parameters for updating and enhancing the electrical performance of PG cell technology. Various dye sensitizers, organic reductants, and micelles have been studied to increase the electrical performance of the PG cells. The chemical combination of the sensitizer-reductant-surfactant-NaOH may be labeled as a photogalvanic chemical system. The various photogalvanic chemical systems like the azur A (a dye photosensitizer)-glycerol (organic reductant)-sodium lauryl sulphate (NaLS, an anionic surfactant)-NaOH (as alkaline medium)13; azur C (a dye photosensitizer)-glycerol (organic reductant)-Triton X 100 (a nonionic surfactant)-NaOH (as alkaline medium)14; the azur A (a dye photosensitizer)- ethylenediaminetetraacetic acid (EDTA, an organic reductant)-NaLS (an anionic surfactant)-NaOH (as alkaline medium)15; the brilliant cresyl (a dye photosensitizer)-oxalic acid (an organic reductant)-NaOH (as alkaline medium)16; the congo red (a dye photosensitizer)- D-Xylose (an organic reductant)- cetyl pyridinium chloride (CPC, a cationic surfactant)-NaOH (as alkaline medium)17, the safranine O (a dye photosensitizer)-EDTA (an organic reductant)- NaLS (an anionic surfactant)-NaOH (as alkaline medium)18, the Sudan I (a dye photosensitizer)-Fructose (an organic reductant)-NaLS (an anionic surfactant)-NaOH (as alkaline medium)19, the Fast Green FCF (a dye photosensitizer)-Fructose (an organic reductant)- NaLS (an anionic surfactant)-NaOH (as alkaline medium)20, etc. have been studied in PG cells for the simultaneous solar energy conversion and storage. The photogalvanic chemical system based on mixed dyes photosensitizer (Brilliant Cresylblue + Toluidine Blue)-ethylene glycol (an organic reductant)- NaLS (an anionic surfactant) has also been exploited for enhanced photogalvanics21. The studied so far described have focused mainly on the use of reference saturated calomel electrode (SCE) and large size anodic Pt electrode (1 cm × 1 cm) leading to the relatively low electrical cell performance of the PG cell. The PG cells are the diffusion controlled cells depending on the diffusion of the ions in the bulk of the electrolytic solution. Therefore, the diffusion and sensitivity of the electrodes is one of the main determinants of their efficiency. So to ensure good diffusion and sensitivity, the small size Pt electrode (which creates less hindrance to the mobility of the ions) with more sensitive combination electrode (only SCE terminal used) has attracted the attention of the researchers to successfully improve the PG cell performance to a high level as 649.6 μW power (Ppp), 2250 μA current (isc), 1048 mV potential (Voc), 8.12% conversion efficiency (CE), and 59 min power storage capacity (as half change time, t0.5) at artificial and low illumination intensity. To realize the aim of practical application of the PG cells in daily life, the electrical output of these cells has to be further enhanced to a level at least comparable to that of the PV cells. The literature survey reveals that the dye aggregation retards the dye diffusion leading to the reduced PG cell performance. The dye decay is also reported as an adverse factor for dye sensitizer based PG cells. Both these factors (dye aggregation and dye decay) are reported to be tackled by the use of micelles (anionic micelles like NaLS more effective), and high pH alkaline medium. The Congo red dye is also reported to show decreased aggregation at high pH, and this property of Congo red makes it fit for good photogalvanics. The formaldehyde has two hydrogen atoms attached to the carbonyl group, and this peculiar position makes its hydrogen atoms easily oxidisable making it (formaldehyde) a good candidate as a reducing agent (standard reduction potential 0.237 V vs SHE). So in totality, the position emerges out of the literature survey is that the use of small size Pt electrode, combination electrode, high pH range and NaLS surfactant in alkaline medium with so far unexplored congo red dye-formaldehyde system could be a route for further updating and enhancing the electrical performance of the PG cells, and therefore, the present study was undertaken.

The present study of the PG cells based on so far unexplored Congo red dye-formaldehyde as photosensitizer-reductant couple along with efficiency enhancer surfactant reagent (sodium lauryl sulphate) in sodium hydroxide alkaline medium has shown greatly enhanced cell performance over published results. The present study has shown electrical performance of the PG cell as Ppp 782 μW, isc 3200 μA, Voc 1074 mV, and CE 11.02% at artificial and low illumination intensity. The storage capacity (t0.5) of the PG cell has been observed in present study as 120 min in the dark. The study of variation of the different cell fabrication parameters has shown optimum cell performance at an optimal value of these cell fabrication parameters. The most plausible mechanism of the photo-generation of the current in PG cells is also proposed on the basis of observed potential values and published literature. The novelty and originality of the present work lies in the fact that the use of unexplored Congo red dye photosensitizer-formaldehyde reductant couple has shown abruptly enhanced results over published work.

Materials and methods

Materials used

The chemicals like Congo red dye, Sodium Lauryl Sulfate, Formaldehyde, Sodium Hydroxide, Oxalic acid, Phenolphthalein, and singly distilled water have been used as photosensitizer, surfactant, reductant, alkaline medium, standard reagent for standardization of alkali NaOH, indicator, and solvent for preparing solutions, respectively. All solutions were stored in the amber colored vessels with the aim of protecting them from the sunlight induced decay (see Section 1 of Supplementary Information-SI).

Method

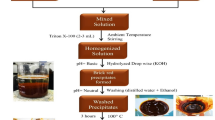

The stock solutions of all chemicals were prepared at different concentrations in the singly distilled water and kept away from the sun. The known amount of the solutions of the Congo red dye photosensitizer, formaldehyde reductant, sodium lauryl sulfate surfactant, and standardized alkali sodium hydroxide was filled in the H-shaped glass tube (diffusion length, 7.5 cm). The total volume of the solution was kept 68 ml making up by the singly distilled water. The H-shaped glass tube was externally blackened leaving a small illuminating window in a limb (called illuminated chamber). Then platinum electrode of size (0.5 cm × 0.3 cm) was dipped in the illuminated limb and combination electrode was immersed in another limb of the H-cell. The terminals of the electrodes were connected to a digital pH meter, micro ammeter, carbon pot (log 470 K), and a key to make a complete circuit. The H-cell was put in the dark to attain a stable potential (called dark potential-Vdark). Then, through the illuminating window, the solution near the platinum electrode was illuminated with the artificial sunlight coming from the incandescent Tungsten lamp of 200 Wattage. The photo potential and photo current were measured with help of digital pH meter and micro ammeter, respectively. During the experiment, variables i (current) and V (voltage) were observed. The plot i vs V gave information about efficiency of the storage of energy and conversion of stored solar energy into electrical energy. The experimental setup of photogalvanic cell is given in Fig. 19,22.

Photogalvanic experimental setup (A, Micro-ammeter; K, Key; R, A typical single-turn potentiometer (acts as a variable resistor or rheostat); V, digital pH meter; e−, electron; i, current; E, electrolytic solution having dye sensitizer, surfactant, reductant, NaOH; Pt as working electrode; Saturated Calomel electrode as counter electrode).

In literature, various formulas are reported for the calculation of the solar energy conversion efficiency of the photogalvanic cells. Potter and Thaller23 have defined the power efficiency as [(½ E0c Ic)/(ϵN)] , where E0c is zero current voltage, Ic is the short circuit current, Є is the energy per absorbed photon and N is the number of photons absorbed per second. Clark and Eckert24 have defined Sunlight Engineering Efficiency as [(maximum Power × 100)/(incident sunlight power)]. Murthy et al.25 have defined conversion efficiency as [(Voc × isc × fill factor × 100)/(cross sectional area of electrode × Incident Sunlight Power)]. A review paper on photogalvanic cells have reported calculation of conversion efficiency as [(electrical power output (in watts) at its maximum power point × 100)/(input light in Wm−2 × electrode area of the photogalvanic cell in m2)]26. The fill factor of photogalvanic cells is disproportionately low in comparison to conversion efficiency. Both the parameters (fill factor and efficiency) are indicator of solar energy conversion capacity of the photogalvanic cells. Therefore, the solar efficiency of cell as without linked to fill factor and linked to fill factor has also been defined as [(power at power point in m Wm−2 × 100%)/(illuminating intensity in m Wm−2 × Pt working electrode area in cm2)], and [(power at power point in m Wm−2 × fill factor × 100%)/(illuminating intensity in m Wm−2 × Pt working electrode area in cm2)], respectively9,11. In present research work, the cell efficiency has been calculated as [(power at power point in m Wm−2 × fill factor × 100%)/(illuminating intensity in m Wm−2 × Pt working electrode area in cm2)]. The justification of using this formula is explained as follows. The size of the open window has not been used for calculating the efficiency as—(1) the sunlight strike at illuminating window of the cell. The sunlight being of wave nature has phenomenon of scattering as well the diffraction at hole/barrier. The photogalvanic cells use very dilute solution of dye/pigments. The light diffraction effect and edge effect effectively illuminate the larger solution area, (2) the PG cell is diffusion controlled, and therefore, only those dye molecules which are nearer to Pt anodic electrode shall be able to reach the electrode within their excited life time. It means that the number of such dye molecules shall be determinable with respect to Pt area, but not the illuminating area of the cell window size; (3) the illuminating natural sunlight is free and available naturally leading to no change in cost and environmental pollution on account of illumination of the small or large area of the cell. The Pt size matters for the economic and ecological cost as use of its small size will be less costly and more eco-friendly; (4) The Pt anode area (instead of cell illumination area) for calculation of the efficiency is also supported by Murthy et al.25, who have used cross sectional area of the anode for the calculation of solar engineering efficiency; and (5) The photogalvanic cells can also be charged at low illuminating efficiency9.Therefore, the small or large sized illuminating window hardly matters for charging of the cell. The surface area of the window used to illuminate the cell is 1 cm × 1 cm.

Mechanism of photocurrent, photo-potential generation and storage capacity

The photogalvanic cell has two chambers. One is illuminated chamber having platinum electrode (anode) and other is dark chamber having saturated calomel electrode (cathode).

Illumination chamber The dye molecules get excited and excited dye molecules accept an electron from the reductant and get converted into its semi or leuco form-

At platinum electrode The semi or leuco form of the dye molecules loses an electron and gets converted into original molecules.

Dark chamber At Saturated Calomel Electrode, the dye molecules accept an electron and get converted into semi form.

Finally, semi form of dye and oxidized form of reductant combine to give original dye and reductant molecule in dark chamber. The cycle continues goes on in cell.

Here Dye, Dye*, Dye–, R and R+ are the ground state dye, excited form of dye, semi or leuco form of dye, reductant and its oxidized form, respectively.

Results and discussion

Study of the Congo red dye photosensitizer in photogalvanic system with formaldehyde as reductant

The present study of the use of Congo red dye as photo sensitizer, Formaldehyde as Reductant, Sodium lauryl sulphate as surfactant, Sodium hydroxide as alkaline medium and small Pt electrode (0.5 cm × 0.3 cm) at an artificial light has been done in H-shape glass tube vessel for further improvement in the electrical output of the cell. The cell showed the results as open circuit-potential, short circuit current, conversion efficiency, fill factor, and power at power points as 1074 mV, 3200 µA, 11.02%, 0.22, and 782 µW, respectively. The storage capacity of the photogalvanic cell was obtained 120 min. in the dark. The effect of different parameters on the electrical output of the cell was observed as described below.

Effect of the variation of the dye (Congo red) concentration in Congo red-formaldehyde photogalvanic system

The effect of variation of the dye sensitizer concentration on Congo red-Formaldehyde system has been studied by fabricating the five photogalvanic cells. The concentrations of the formaldehyde reductant, SLS surfactant, NaOH alkali (i.e. pH), diffusion length, Pt electrode size and SCE are same for all the five cells, but the concentration of Congo red dye sensitizer is different in different cells (See sec. 2 of SI).

Table 1 shows the highest electrical output for the [dye] = 1.0 × 10–4 M. Therefore, the 1.0 × 10–4 M dye concentration is the optimal dye concentration for this photogalvanic system. The optimal cell performance is Voc = 1074 mV, imax = 6000 µA, isc = 3200 µA, Ppp = 782 μW, FF = 0.22, CE = 11.02%, and charging time ‘t’ = 35 min.

On increasing the concentration of the Congo red dye photo-sensitizer, there is an increase in the photocurrent, and the optimum cell performance is observed at 1.0 × 10–4 M concentration of the Congo red dye (Table 1). This pattern of the change of photocurrent with the Congo red dye photo-sensitizer may be attributed to the fact that at a lower concentration range of the Congo red dye photo-sensitizer there will be limited numbers of the photo-sensitizer molecules to absorb the photons and to donate the electrons to the Pt electrode in the cell. The higher concentration of the Congo red dye photo-sensitizer will not permit the desired light intensity to reach the dye photo-sensitizer molecules near the electrode and hence there will be a corresponding fall in the power of the cell.

Effect of the variation of the reductant (formaldehyde) concentration on Congo red-formaldehyde photogalvanic system

The effect of variation of formaldehyde reductant concentration on Congo red-Formaldehyde photogalvanic system has been studied by fabricating the five photogalvanic cells. The concentrations of Congo red dye photo-sensitizer, SLS surfactant, NaOH alkali (i.e. pH), diffusion length, Pt electrode size and SCE are same for all five cells, but the Formaldehyde concentration is different in different cells (see sec. 3 of SI).

Table 2 shows the highest electrical output of the cell for [Formaldehyde] = 1.4 × 10–4 M. Therefore, the 1.4 × 10–4 M formaldehyde concentration is the optimal Formaldehyde concentration for this photogalvanic system. The optimal cell performance is Voc = 1074 mV, imax = 6000 µA, isc = 3200 µA, Ppp = 782 μW, FF = 0.22, CE = 11.02%, and charging time ‘t’ = 35 min.

On increasing the concentration of the Formaldehyde reductant at the constant value of other cell fabrication variables, the electrical output of the PG cell is found to increase to reach a maximum and optimum value, and thereafter, it is found to decrease. The optimum cell performance is observed at 1.4 × 10–3 M concentration of the Formaldehyde reductant (Table 2). The electrical output is low at a lower concentration range of the Formaldehyde reductant as there will be its lesser number of the molecules to donate electrons to the excited molecules of the Congo red dye photo-sensitizer. The higher concentration of the formaldehyde reductant may hinder the movement of the Congo red dye molecules towards the electrodes in the desired time limit, and may also promote back electron transfer from the Congo red dye molecule to Formaldehyde reductant molecule.

Effect of the variation of NaOH concentration (pH) on the Congo red-formaldehyde photogalvanic system

The effect of variation of the NaOH concentration (i.e., pH) on Congo red-Formaldehyde photogalvanic system has been studied by fabricating the five photogalvanic cells. The concentrations (of Formaldehyde reductant, Congo red dye sensitizer, and SLS surfactant), diffusion length, Pt electrode size and SCE are same for all five cells, but the NaOH (i.e. pH) concentration is different in different cells (See sec.4 of SI).

Table 3 shows the highest electrical output of the cell for pH = 13.82. Therefore, the 13.82 is the optimum pH for this photogalvanic system. The optimal cell performance is Voc = 1074 mV, imax = 6000 µA, isc = 3200 µA, Ppp = 782 μW, FF = 0.22, CE = 11.02%, and charging time ‘t’ = 35 min.

It is observed that the PG cell system works effectively in the strong alkaline medium. The photocurrent of the cell is high in higher pH range. The maximum photocurrent and power at power point has been observed at an optimum pH 13.82 (Table 3). On further increasing the pH, there is a decrease in the photocurrent, and it may be due to the fact that at the very high concentration of the OH− (i.e., pH), the OH− may combine with the oxidized state the formic acid reductant inhibiting regeneration of its original state.

Effect of the variation of the surfactant (SLS) on Congo red-formaldehyde photogalvanic system

The effect of the variation of SLS surfactant concentration on the Congo red-Formaldehyde photogalvanic system has been studied by fabricating the five photogalvanic cells. The concentrations [of the Congo red dye sensitizer, HCHO, NaOH (i.e. pH)], diffusion length, Pt electrode size and SCE are same for all five cells, but the SLS surfactant concentration is different in different cells (See sec. 5 of SI).

Table 4 shows the highest electrical output of the cell for [SLS] = 1.0 × 10–2 M. Therefore, the [SLS] = 1.0 × 10−2 M is the optimum concentration of SLS for this photogalvanic system. The optimal cell performance is Voc = 1074 mV, imax = 6000 µA, isc = 3200 µA, Ppp = 782 μW, FF = 0.22, CE = 11.02%, and charging time ‘t’ = 35 min.

On increasing the concentration of SLS at the constant value of all other cell fabrication variables, the electrical output of the PG cell is found to increase to reach a maximum and optimum value. The optimum cell performance is observed at 1.0 × 10–2 M concentration of the SLS surfactant (Table 4). At SLS surfactant concentration lower than the 1.0 × 10–2 M concentration, the lower value of the electrical output may be attributed to the lesser number of SLS surfactant molecules available for the electron transfer and the solubility of the Congo red dye photo-sensitizer molecules. The higher concentration of the SLS surfactant may be hindering the motion of Congo red dye photo-sensitizer molecules toward the electrodes leading to the corresponding fall in the power of the PG cell. Further, the SLS surfactant also is able to give electrons to the dye by the charge transfer process enhancing the cell performance. The SLS also reduces the back electron transfer reaction by making surrounding micelles structure about the sensitizer molecule leading to the enhanced cell performance.

Variation of the potential, current, and power with the Platinum electrode area in the Congo red-formaldehyde system based photogalvanic cell

Photogalvanic cells uses Pt electrode as working electrode. An exploratory study has shown dependence of the photo-generated current, potential and power on the Pt electrode size (See sec.6 of SI). For electrodes of area larger than this, the cell parameters were found decreasing with increase in electrode area (Table 5). For the observed effect of electrode area, the better cell parameters were found for small electrodes owing to relatively less hindrance to diffusion of ions as the Photogalvanic cells are based on ion diffusion mechanism. This observation is in agreement with the other dye sensitizer (other than Congo red) also9. The efficiency calculation is based on Pt electrode size. The main electrical parameter of the cell is the power generated to decide the number of solar panels (solar cells) to be used for establishing the solar plant capacity (KW, or MW or GW) for meeting energy needs of a locality. As far as the power generated is concerned, the electrode area 0.50 cm × 0.30 cm has shown highest power in the experimental conditions. Under the observed effect of electrode area, the imax, isc, and Ppp were found highest for electrode area 0.50 cm × 0.30 cm. It is the reason that the whole study in present research has been done with Pt of electrode area 0.50 cm × 0.30 cm. It is an optimized area under the research conditions. Below this area, the Pt area will be small and so it will provide surface for lesser number of electron rich sensitizer molecules for dye-Pt interaction leading to reduce current and power generation.

Variation of the potential, current, and power in the Congo red-formaldehyde system based photogalvanic cell

The variation of the potential during charging of the cell is shown in Table S1, and Fig. S1. This Fig. S1 shows the maximum potential Vmax = 1080 mV, and open-circuit potential Voc = 1074 mV. The change in the potential and current was observed during the charging of the cells. On illuminating each photogalvanic cell, the potential increases regularly and reaches to a highest value (Vmax), which then decrease and becomes quite constant (Voc) after some time (Table S1, and Fig. S1).

With the help of the digital pH meter and micro ammeter, we observed the short circuit current (isc) and open circuit voltage (Voc) respectively of the cell. The current and potential values in between these two extreme values were recorded with the help of carbon plot connected in the circuit of micro ammeter, through which an external load was applied. The current–voltage (i–V) characteristics of the cell were reported in Table S2 and graphically represented in the Fig. 2 (variation of the potential and power with current). The storage capacity of the photo galvanic cell system containing the Congo red was determined by applying the desired external load with keeping the cell at the power point stage in dark and noted down the time required in fall of power output to its half value. The storage capacity of the photo galvanic cell system was denoted by t1/2 (half change time), which was the measure of the performance of the cell. It was observed that the cell could be used in dark for 120 min (Table 6, Fig. 3).

The i–V characteristic of the cell is shown in the Table S2, and Fig. 2. The Fig. 2 shows that potential increases with decreases in the current. The current and power data and curve is also shown in Table S2, and Fig. 2. The maxima of this curve show the power at power point of the cell and in this system it is 782 µW. And, the current at power point (ipp) and potential at power point (Vpp) for this photogalvanic system is 1400 µA and 559 mV, respectively.

The cell performance in the dark is recorded in the Table 6, and Fig. 3. It is clear from the Fig. 3 that the power decreases with time in dark during retrieval of the stored power from the cell. Initially, the power is Ppp (782 µW), and after 120 min the power is 391 µW. This duration of the 120 min is half change time (t0.5) of this photogalvanic system. The half change time is defined as the time in which the power reduces in dark during retrieval of the stored power to half of its initial value.

The optimum cell performance at values of the cell variable is summarized as dark potential (Vdark) 692 mV; maximum potential (Vmax) 1080 mV; open-circuit potential (Voc) 1074 mV; photo potential (∆V) 388 mV; charging time (t) 35 min; maximum current (imax) 6000 µA; short-circuit current (isc) 3200 µA; power at power point (Ppp) 782 µW; potential at power point (vpp) 559 mV; current at power point (ipp) 1400 µA; t0.5 120 min, potential at t0.5 (V0.5) 276 mV; current at t0.5 (isc) 1400 µA; conversion efficiency (CE) 11.02%; fill factor (FF) 0.22.

The results in present work are impressive and an improvement in the field of photogalvanics. This is explicit from the recently published work on Congo red dye. The isc 110.0 µA, Ppp 45.0 µW, FF 0.74, CE 0.66%, and t0.5 40 min were reported for Congo red dye-Glycerol system (with Pt 1.0 cm × 1.0 cm)22. The isc 470 µA, Ppp 119.6 µW, FF 0.2356, CE 1.1500%, and t0.5 130 min were reported for Congo red dye-D-Xylose-Cetyl pyridinium chloride system (with Pt 1.0 cm × 1.0 cm)27. The isc 180 µA, Ppp 32.46 µW, CE 1.04%, and t0.5 120 min were reported for Congo red dye-EDTA system (with Pt 1.0 cm × 1.0 cm)28. The isc 972 µA, Ppp 244.02 µW, CE 7.58%, and t0.5 3.6 h were reported for Fast Green FCF dye with Fructose as reductant in NaOH as alkaline medium (with Pt 1.0 cm × 1.0 cm)29. The isc 45 µA, Ppp 14.75 µW, CE 0.14%, and t0.5 40 min were reported for Azur B dye-EDTA reductant-Tergitol-7 surfactant system (with Pt 1.0 cm × 1.0 cm)30. The latest published work has reported electrical output of these cells as high as Ppp 649.6 μW, isc 2250 μA, Voc 1048 mV, CE 8.12%, and t0.5 59 min at artificial and low illumination intensity.

The literature survey reveals that the dye aggregation retards the dye diffusion leading to the reduced PG cell performance. The dye decay is also reported as an adverse factor for dye sensitizer based PG cells. Both these factors (dye aggregation and dye decay) are reported to be tackled by the use of micelles (anionic micelles like NaLS, which is more effective), and high pH alkaline medium. The Congo red dye is also reported to show decreased aggregation at high pH and low concentration (dye)31, and this property of Congo red makes it fit for good photogalvanics. The formaldehyde has two hydrogen atoms attached to the carbonyl group, and this peculiar position makes its hydrogen atoms easily oxidisable making it (formaldehyde) a good candidate as a reducing agent (standard reduction potential 0.237 V vs SHE). Thus, the advancement in results in the present work may be attributed to factors like the use of anionic surfactant, higher pH, small Pt electrode, combination electrode, formaldehyde reductant, Congo red dye sensitizer, very low concentration of Congo red dye, etc. Present Congo red-Formaldehyde-NaLS systems have used anionic surfactant (i.e., NaLS) as micelles. Congo red-Glycerol system22 has not used any surfactant, and Congo red dye-D-Xylose-Cetyl pyridinium chloride system27 has not used anionic, but cationic surfactant.In previous works, the size of Pt electrode was large (1.0 cm × 1.0 cm), but no one used small size Pt electrode and combination electrode. Present work has used both small size Pt (0.5 cm × 0.3 cm) electrode and combination electrode. Both (anionic surfactant and small Pt electrode) help in enhancing the diffusion due to which cell performance also increases. Small Pt electrode creates less hindrance for ion diffusion in the cell. Thus, the dye Congo red coupled with small Pt electrode gives more current and power. Similarly, the anionic surfactant provides for good solubility and electron injection capacity of the dye. It facilitates and increases rate of transfer of electron to Pt electrode, which in turn gives more current and power.

The increase in solubility of cationic Congo red dye in the presence of surfactants is also supported from the published work. Shahir et al. have reported the detection of formation of dye-surfactant ion pairs, their small mixed aggregates (below the critical micelle concentration (CMC) of these surfactants) and surfactant micelles using the conductometry, spectroscopy, tensionmetry, and pulsed field gradient NMR (PFG-NMR) technology. Above the CMC, the dye is reported to be reverted to its monomeric state and solubilized in the micelles. A hydrophobic interaction as well as electrostatics is reported to contribute to the dye/surfactant interactions32.

The present research of photogalvanics based on Congo red dye photosensitier-formaldehyde reductant- surfactant reagent (sodium lauryl sulfate) has yielded promising results in terms of the power and efficiency. This photogalvanics of Congo red dye is prone to face similar challenges as are faced by the other dye based photogalvanics. Malviya and Solanki have listed some challenges as back thermal reactions (electron goes back from anodic electrode to leuco/semi form of dye), photochemical side reactions (the photo-chemical degradation competes with photogalvanics), electrode aging (electrode corrosion diminishes the activity of electrodes), low conversion efficiency, etc.26.

For future research, the use of various measures is suggested to overcome these limitations. The dye solubility, diffusion and electrode selectivity with fast electron transfer kinetics is the key factors affecting the cell efficiency and dye-anodic electrode interaction. Higher the diffusion will favor this interaction and in turn photogalvanics over photo-chemical reactions of excited dye molecules. A Vertical Architecture provides for increasing the efficiency of the photogalvanic solar cell. In vertical illumination, light enters the cell to move through the area between two electrodes, that is different from the conventional approach in which the cell is illuminated through the electrode. The vertical illumination causes spreading of the light absorption and electron generation through the depth of the device ensuring absorption of all the incoming photons even with low dye solubility. In effect, the spreading of electron generation facilitates increased solar energy conversion even at slow electrode kinetics33.

Highly efficient novel scandium supported TiO2 HOMBIKAT UV 100 (Sc/TiO2) working electrode34 and ZnO nanostructure working electrode are suggested for overcoming electrode related limitations of the photogalvanics35.

The surfactant plays a key role in the solubility and stability of the dye molecules. Regarding this, the choice for a most suitable surfactant chemical may be made from the work of Tiwari et al.36. The surfactant for which the dye-surfactant interaction affects critical micellar concentration more effectively can be most suitable micelles for enhancing the overall electrical performance of the photogalvanic cells36.

Conclusion

Sensitizer-reductant couple is one of the main determinants for deciding the performance of the photogalvanic cells. The decreased aggregation of the dye coupled with good reductant favour the efficiency of these cells. The Congo red dye is reported to show decreased aggregation at high pH, and this property of Congo red makes it fit for good photogalvanics. The formaldehyde has two hydrogen atoms attached to the carbonyl group, and this peculiar position makes its hydrogen atoms easily oxidisable making it (formaldehyde) a good candidate as a reducing agent (standard reduction potential 0.237 V vs SHE). So in totality, the hypothesis emerged out was that the use of so far unexplored congo red dye-formaldehyde system along with small size Pt electrode, combination electrode, high pH range and NaLS surfactant in alkaline medium could be a route for further updating and enhancing the electrical performance of the PG cells. The present study has shown greatly enhanced cell performance over published results. The present study has shown electrical performance of the PG cell as Ppp 782 μW, isc 3200 μA, Voc 1074 mV, and CE 11.02% at artificial and low illumination intensity. The storage capacity (t0.5) of the PG cell has been observed in present study as 120 min in the dark. The study of variation of the different cell fabrication parameters has shown optimum cell performance at an optimal value of these cell fabrication parameters.

Data availability

The data that supports the findings of this study are available within the article.

References

Koli, P. Photogalvanic cells: comparative study of various synthetic dye and nature photo sensitizer present in spinach extract. RSC Adv. 4, 46194–46202 (2014).

Guo, J., Shi, Y., Chu, Y. & Ma, T. Highly efficient telluride electro-catalysts for use as Pt-free counter electrodes in dye-sensitized solar cells. Chem. Commun. 49, 10157 (2013).

Yu, J., Fan, J. & Zhao, L. Dye-sensitized solar cells based on hollow anatase TiO2 spheres prepared by self-transformation method. Electrochim. Acta. 55, 597–602 (2010).

Zhang, S. et al. Improvement of spectral response by co-sensitizers for high efficiency dye—sensitized solar cells. J. Mater. Chem. A 1, 4812–4819 (2013).

Koli, P. Solar energy conversion and storage using naphthol green B dye photo sensitizer in photo galvanic cells. Appl. Solar Energy. 50, 63–67 (2014).

Rideal, E. K. & Williams, D. C. The action of light on the ferrous iodine iodide equilibrium. J. Chem. Soc. 127, 258–269 (1925).

Rabinowitch, E. The photogalvanic effect I: the photgalvanic properties of thionine-iron system. J. Chem. Phys. 8, 551–559 (1940).

Rabinowitch, E. The photogalvanic effect II: the photgalvanic properties of thionine-iron system. J. Chem. Phys. 8, 560–566 (1940).

Koli, P., Sharma, U. & Gongotri, K. M. Solar energy conversion and storage: rhodamine B-fructose photogalvanic cell. Renew. Energy 37, 250–258 (2012).

Meena, R. C., Kumar, V. & Singh, G. Use of dye in photogalvanic cell for solar energy conversation and storage: thymol blue and ascorbic acid system. Int. J. Chem. Sci. 6, 1438–1448 (2008).

Koli, P. & Sharma, U. Photochemical solar power and storage through photogalvanic cell: comparing performance of the dye materials. Energy Sources Part A 39, 555–561 (2017).

Koli, P. & Sharma, U. Energy conversion in electrolyte under artificial light: fast green FCF-fructose-surfactant-small Pt electrode photogalvanic cell. Appl. Solar Energy 52, 76–83 (2016).

Gongotri, K. M., Gunsaria, R. K. & Meena, R. C. Use of surfactant in photogalvanic cell foe solar energy conversion and storage: NALS-Glycerol-Azur A. Afinidad 60, 13–20 (2003).

Gunsaria, R. K. & Hussain, J. Use of surfactant in photogalvanic cell foe solar energy conversion and storage: Tx-100-Glycerol-Azur-C system. Asian J. Chem. 16, 375–384 (2004).

Gunsaria, R. K. & Hussain, J. Role of reductant, photosensitizer and surfactant for solar energy conversion and storage: EDTA-Azure A-NaLS System. Asian J. Chem. 16, 385–392 (2004).

Gunsaria, R. K., Sindal, R. S., Chandra, M. & Meena, R. C. Role of reductant and photosensitizers in solar energy conversion and storage: oxalic acid-brilliant cresyl system. Arab. J. Sci. Eng. 31, 177–183 (2005).

Gunsaria, R. K., Nadeem, S. S. & Meena, R. N. Studies of cationic micelles effect on photogalvanic cells for solar energy conversion and storage in Congo red-D-Xylose-Cetyl pyridinium chloride system. Int. J. Basic Appl. Chem. Sci. 2, 77–83 (2012).

Gangotri, P. & Koli, P. Study of the enhancement on photogalvanics: solar energy conversion and storage in EDTA-Safranine O-NaLS system. Sustain. Energy Fuels 1, 882–890 (2017).

Koli, P. Surfactant and natural sunlight enhanced photogalvanic effect of Sudan I dye. Arab. J. Chem. 10, 1077–1083 (2017).

Koli, P. Enhancing efficiency of Fast Green FCF-Fructose photogalvanic solar cell by using surfactant in natural sunlight. Int. J. Ambient Energy. 40, 868–874 (2019).

Gongotri, K. M. & Mahawar, A. K. Comparative study on effect of mixed photosensitizer system for solar energy conversion and storage: brilliant cresylblue + toluidine blue-ethylene glycol-NALS system. Environ. Prog. Sustain. Energy 31, 474–480 (2012).

Meena, R. C., Verma, N. & Kumari, M. Studies on conversion and storage of solar energy in photogalvanic cells: Congo red and glycerol system. Int. J. Chem. Pharm. Sci. 2, 612–616 (2014).

Potter, A. E. & Thaller, L. H. Efficiency of some iron–thionine photogalvanic cells. Sol. Energy 3, 1–7 (1959).

Clark, W. D. K. & Eckert, J. A. Photogalvanic cells. Sol. Energy 17, 147–160 (1975).

Murthy, A. S. N., Dak, H. C. & Reddy, K. S. Photogalvanic effect in riboflavin–ethylenediaminetetraacetic acid system. Int. J. Energy Res. 4, 339–343 (1980).

Malviya, A. & Solanki, P. P. Photogalvanics: a sustainable and promising device for solar energy conversion and storage. Renew. Sustain. Energy Rev. 59, 662–691 (2016).

Gunsaria, R. K. & Meena, R. N. Study of cationic micelles effect on photogalvanic cell for solar conversion and storage in Congo red-D Xylose- Cetyl Pyridinium Cholide system. Int. J. Basic Appl. Chem. Sci. 2, 77–83 (2012).

Kumari, M., Pachwarya, R. B. & Meena, R. C. Studies of dye sensitization for solar energy conversion into electrical energy in Congo red EDTA system. Energy Sources Part A 31, 1081–1088 (2009).

Koli, P. Solar energy conversion and storage: fast green FCF-fructose photogalvanic cell. Appl. Energy 118, 231–237 (2014).

Gongotri, K. M., Aseri, P. & Bhimwal, M. K. The use of tergitol-7 in photogalvanic cells for solar conversion and storage: an EDTA-Azur B system. Energy Sources Part A 35, 312–320 (2013).

https://en.wikipedia.org/wiki/Congo_red. Accessed 31 March 2020.

Shahir, A. A. et al. Molecular interaction of Congo red with conventional and cationic gemini surfactants. Fluid Phase Equilib. 305, 219–226 (2011).

Mahmoudzadeh, M. A. & Madden, J. D. W. A vertical architecture for increasing photogalvanic solar cell efficiency: theory and modeling. Electrochim. Acta 143, 98–105 (2014).

Mahmoud, S. A., Atia, H. & Bendary, S. H. Synthesis of a high efficiency novel working electrode scandium/HOMBIKAT in dye-sensitized solar cells. Sol. Energy 134, 452–460 (2016).

Mahmoud, S. A. & Fouad, O. A. Synthesis and application of zinc/tin oxide nanostructures in photocatalysis and dye sensitized solar cells. Sol. Energy Mater. Sol. Cells 136, 38–43 (2015).

Tiwari, S., Mall, C. & Solanki, P. P. CMC studies of CTAB, SLS & tween 80 by spectral and conductivity methodology to explore its potential in photogalvanic cell. Surf. Interfaces 18, 100427 (2020).

Acknowledgements

Authors are thankful to the Department of the Chemistry, Jai Narain Vyas University, Jodhpur (Rajasthan) India, for providing necessary laboratory facilities. Author, Yashodhara Dayma, is also grateful to the Union Ministry of Social and Justice Empowerment, Govt. of India, New Delhi, and University Grants Commission (UGC), New Delhi (India), for providing fellowship to her under the Rajiv Gandhi National Fellowship Scheme.

Author information

Authors and Affiliations

Contributions

Authors P.K. and Y.D. have contributed in every aspect of this research work including the conception, design of the work, the acquisition, analysis, interpretation of data, its revision, etc. Authors R.K.P. and M.J. have contributed in the design of work, participated in experiments, interpretation of data, review of manuscript, English and language checking, etc. Additionally, the author P.K. has also contributed as corresponding author, mentor and supervisor of the research work. All authors have approved the submitted version (including the revised version).

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Koli, P., Dayma, Y., Pareek, R.K. et al. Use of Congo red dye-formaldehyde as a new sensitizer-reductant couple for enhanced simultaneous solar energy conversion and storage by photogalvanic cells at the low and artificial sun intensity. Sci Rep 10, 19264 (2020). https://doi.org/10.1038/s41598-020-76388-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-76388-5

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.