Abstract

The discovery of single-phase multiferroic materials and the understanding of coupling mechanisms between their spin and polarization is important from the point of view of next generation logic and memory devices. Herein we report the fabrication, dielectric, ferroelectric, piezo-response force microscopy, and magnetization measurements of Pd-substituted room-temperature magnetoelectric multiferroic PbPd0.3Ti0.7O3 (PbPdT) thin films. Highly oriented PbPdT thin films were deposited on {(LaAlO3)0.3(Sr2AlTaO6)0.7} (LSAT) substrates in oxygen atmosphere using pulsed laser deposition technique. X-ray diffraction studies revealed that the films had tetragonal phase with (001) orientation. Surface morphology studies using atomic force and scanning electron microscopy suggest a smooth and homogeneous distribution of grains on the film surface with roughness ~2 nm. A large dielectric constant of ~1700 and a low-loss tangent value of ~0.3 at 10 kHz were obtained at room temperature. Temperature dependent dielectric measurements carried out on Pt/PbPdT/La0.7Sr0.3MnO3 (LSMO) metal-dielectric-metal capacitors suggest a ferroelectric to paraelectric transition above 670 K. The measured polarization hysteresis loops at room temperature were attributed to its ferroelectric behavior. From a Tauc plot of (αhν)2 versus energy, the direct band gap Eg of PbPdT thin films was calculated as 3 eV. Ferroelectric piezoelectric nature of the films was confirmed from a strong domain switching response revealed from piezo-response force microscopy. A well-saturated magnetization M-H loop with remanent magnetization of 3.5 emu/cm3 was observed at room temperature, and it retains ferromagnetic ordering in the temperature range 5–395 K. Origin of the magnetization could be traced to the mixed oxidation states of Pd2+/Pd4+ dispersed in polar PbTiO3 matrix, as revealed by our x-ray photoelectron spectroscopic results. These results suggest that PbPdT thin films are multiferroic (ferroelectric-ferromagnetic) at room temperature.

Similar content being viewed by others

Introduction

Multiferroic materials with coupled electric and magnetic ordering in a single phase are of research interest due to their fascinating physics and potential for multifunctional device applications, such as speed writing and non-destructive data storage1,2,3,4. Only a limited number of single phase multiferroics are available due to the chemical incompatibility between magnetic and ferroelectric order parameters2. The most well-known examples are: BiFeO3, Pb(Fe0.5Nb0.5)O3, YMnO3, TbMnO3, GaFeO35,6,7,8,9,10,11. However, a majority of these materials exhibit multiferroicity at cryogenic temperature. Materials exhibiting multiferroicity at room temperature are important for device applications, but only a few have been discovered so far, the most celebrated examples being BiFeO310,12, epitaxial thin films of GaFeO313 and Bi2FeCrO614,15,16. During last decade, extensive studies have been carried out to investigate BiFeO310,11,12,17 that exhibits both ferroics ordering above room temperature with ferroelectric to paraelectric phase transition temperature Tc ~ 1143 K and antiferromagnetic to paramagnetic phase transition Néel temperature TN ~ 643 K, to understand the origin and mechanism of its multiferroicity. Pd-substituted PbTiO3-based oxides are new promising room temperature multiferroic materials due to coexistence of ferroelectric and magnetization ordering at and above room temperature. Lead titanate (PbTiO3) is a classical ferroelectric at room temperature, belonging to the perovskite family with the general formula ABO3 (Fig. 1). The sublattice A is occupied by non-magnetic Pb2+ (6P0, S = 0) and the B-site is occupied by non-magnetic Ti4+ (3d0, S = 0) ions. It undergoes a first-order displacive phase transition from ambient tetragonal to high temperature cubic phase at Tc ~ 763 K18. However, recent density functional theoretical (DFT) studies19 have predicted ferromagnetism in Pd-substituted PbTiO3. They revealed that the isoelectronic substitutions of Pd2+ at the A-site (Pb2+ ion) and Pd4+ cation at the B-site (Ti4+ ion) do not establish magnetic ordering. However, replacement of Pb2+ by Pd4+ ion produces magnetism in PbTiO3, and this is argued to be due to donation of two electrons by the substituted Pd4+ cation to the defect states in the band gap lying between the conduction and valence bands10,19. Remarkably, Pd cation (Pd2+, Pd4+) substitution on Pb site is complicated as the radii of these two cations are not similar and latter is oversized for Pd cations. Earlier studies suggested that Pd atom is as such non-magnetic (4d10, S = 0)20; however, under the influence of external electric field and/or strain, Pd cation can become ferromagnetic and its magnetic ordering can be electrically tunable21,22,23,24. A single phase of 30% Pd-substituted Pb(Zr0.20Ti0.80)0.70Pd0.30O3−δ (PZTP30) ceramic was successfully prepared by solid state reaction method, that is reported to be room temperature multiferroic14. It exhibited a weak ferromagnetism, improved ferroelectricity, and importantly showed strong magneto-electric (ME) coupling. Very recently, Pd-doping of up to 30% in ferroelectric PbTiO3 was realized experimentally that established its magnetoelectric multiferroicity at room temperature, superior to BiFeO325. The magnetism in the ceramic sample was ascertained from the presence of Pd4+ chemical state from x-ray photo electron spectroscopy (XPS). However, thin films fabrication of this intriguing multiferroic and investigation of their polarization and magnetization (multiferroic order parameters) are yet to be carried out. Multifunctional thin films are preferable for device applications such as in highly sensitive actuators and sensors, multistate memories, and nanoelectronics10,26,27,28,29, and they are also fascinating for their rich physics. Pulsed laser deposition technique is a sophisticated thin film growth technique often useful for the fabrication of high purity thin films with nanoscale precision30,31,32,33 and is preferable for deposition of high quality films including epitaxial films on appropriate substrates.

ABO3 type structure of PbTiO3: drawn using VESTA software47.

We report the fabrication of PbPd0.3Ti0.7O3 (PbPdT) thin films using pulsed laser deposition technique and investigations of their structural, dielectric, ferroelectric, and magnetic ordering behavior with temperature. We have fabricated Pt/PbPdT/La0.7Sr0.3MnO3(LSMO)/{(LaAlO3)0.3(Sr2AlTaO6)0.7} (LSAT) heterostructures for electrical measurements, and studied the magnetization of PbPdT thin films (of similar thickness) grown on LSAT (001) substrates in order to avoid any magnetization contribution from La0.7Sr0.3MnO3 (LSMO). These films had c-axis orientation. Study of the role of chemical substitution of Pd ions on the magnetic properties of the films revealed that the PbPdT films exhibited well defined M-H hysteresis loops up to 395 K and retained ferromagnetic ordering from 5 to 395 K, the highest temperature in the present study. X-ray photo electron spectroscopic measurements revealed mixed oxidation states of Pd2+ and Pd4+ in Pd-substituted polar PbTiO3 matrix and fulfilled the requirement to realize ferromagnetism in PbPdT films. Dielectric studies on Pt/PbPdT/LSMO metal-insulator-metal (MIM) capacitors suggest that the ferroelectric to paraelectric phase transition temperature is above 670 K. From the Tauc plot analysis of absorption spectra using (αhν)2 versus energy, the direct band gap Eg of PbPdT thin films is estimated as 3 eV. The ferroelectric piezoelectric nature of the films is evident from the strong domain switching response obtained from the piezoresponse force microscopy (PFM) studies involving color contrast phase and amplitude images. Furthermore, magnetocapacitance effect was noticed in our thin films.

Results and Discussion

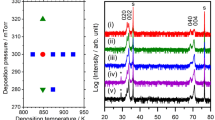

The PLD deposition parameters were optimized for the growth of PbPdT thin films as summarized in Table 1. The high-resolution x-ray diffraction pattern of one of the PbPdT thin films deposited on LSMO buffer layer coated on LSAT substrate is shown in Fig. 2. As can be seen, in the θ-2θ scan, the reflections corresponding to PbPdT, LSMO and LSAT substrate were noticed in the 2θ range from 20°–60°. In addition, absence of any impurity peaks originating from other secondary phases indicated that the grown PbPdT thin film is phase pure and stabilized in a single perovskite phase The thin films were stabilized in the tetragonal phase (P4mm), as in pristine PbTiO3 (JCPDF # 742495), and these were oriented with their (001) plane parallel to the substrate surface along with their out-of-plane lattice parameter c as 3.958 Å. Lattice mismatch between the thin film and the substrate induces a structural strain, which can be estimated using the relation33, η = (asubstrate − afilm/afilm) × 100. The LSAT and LSMO stabilized in cubic perovskite phase with their lattice parameters asubstrate = 3.868 Å34 and aLSMO = 3.871 Å34, respectively. However, the in-plane lattice parameters (a and b) of the films can not be extracted from the present diffraction result (Fig. 2). In order to obtain these lattice parameters, in-plane x-ray diffraction and/or Reciprocal Space Mapping measurements are required. In the absence of these extra experimental results, the in-plane lattice strain in the films could not be calculated. The thickness of the films, estimated using a Profilometer, was found to be ~300 nm. The presence of the constituent elements, such as Pb, Pd, Ti, and O in the films were inferred from an energy dispersive x-ray spectrum (EDS) (Fig. 3) excited using an electron beam of kinetic energy 20 keV. X-ray emission lines corresponding to O Kα1 0.53 keV, Pb Mα1 2.34 keV, Pd Lα1 2.88 keV, Pd Lβ1 3.01 keV, Ti Kα1 4.53 keV and Pb Lα1 10.58 keV exactly match with the available theoretical characteristic x-ray emission lines. The surface topography of the thin films was measured using atomic force microscopy (AFM) (Fig. 3: inset) from the surface of the thin films indicating a smooth surface of the films with its root mean square roughness (RQ) of ~2 nm. The surface morphology of the films using scanning electron microscopy (SEM) is shown in Fig. 4a. It suggests that the thin films are smooth and dense with close packed crystal grains. A homogeneous distribution of these chemical elements was ascertained via SEM-based elemental mapping profiles (Fig. 4b–f), scanned over a large surface area of the films.

As mentioned earlier, it was argued from DFT studies19 as well as other earlier experimental reports on Pd-based ceramics19,25 that the origin of magnetism in PbPdT is due to the existence of Pd4+ cationic state at Pb2+ site (A-site). Therefore, it is imperative to examine the valence state of palladium (Pd) using x-ray photoelectron spectroscopy. From the survey spectra, the presence of all constituent elements, as inferred from EDS spectra, were confirmed from their respective binding energy matching with the standard theoretical values. The high resolution XPS spectrum of Pd consists of two components due to spin-orbit coupling effect (Fig. 5). The spin-orbit doublets of Pd were found to be asymmetric with peak centers at Pd 3d5/2 = 335.65 eV and Pd 3d3/2 = 340.91 eV, suggesting the presence of Pd4+ and Pd2+ valence states. These doublets were deconvoluted using the Casa XPS software and by choosing a suitable background. The deconvolution of Pd 3d5/2 peak yielded Pd2+, and Pd4+ states at 335.56 eV, and 336.11 eV, respectively. Similarly, the Pd 3d3/2 peak can be resolved into Pd2+ state at 340.82 eV, and Pd4+ state at 341.37 eV (Fig. 5). The effective area ratio Pd4+:Pd2+ was calculated to be 0.83: 1. The smaller value of Pd4+ states can be explained by oxygen loss from the surface, that turns some Pd4+ into Pd2+ states. The observed magnetism in our PbPdT thin films is due to mixed oxidation states of Pd that essentially fulfills the requirement to realize the ferromagnetism in Pd-based perovskites19,25.

X-ray photoelectron spectroscopic analysis for the Pd element. The individual deconvoluted peaks of Pd 3d5/2 and Pd 3d3/2 doublet of Pd 3d spectrum are also shown. (CasaXPS, Version 2.3.22, http://www.casaxps.com/).

The dielectric constant (ɛ) and the loss tangent (tan δ) of PbPdT thin films were measured in the frequency range 102–106 Hz and temperature between 100–670 K (Fig. 6(a)). The room temperature dielectric constant and dielectric loss were found to be ~1700 and ~0.3, respectively, measured at 10 kHz. The dielectric constant ɛ was found to be higher than the reported values for PZTP30 (~300) and PbPdT sintered bulk samples (~500). One can notice a nominal decrease in dielectric constant and almost constant loss tangent values with increasing frequency up to 105 Hz. However, a substantial decrease in the dielectric constant and a rise in dielectric loss were observed above 105 Hz frequency. The reduction in ɛ is expected since the dielectric constant of PbPdT thin films has contributions from intrinsic factors related to the lattice, and extrinsic contributions involving grain boundary and interface. In particular, the intrinsic contribution is dependent upon the grain size, film orientation, and strain on the films. However, the interface between the PbPdT film and the bottom LSMO electrode acts as a pinning center that contributes extrinsically34 to the dielectric constant. It perturbs the domain wall motion, and consequently leads to a reduction in the dielectric constant. Such a reduction of dielectric constant at high frequencies was reported in Pb(Zr0.52Ti0.48)O3/LSMO thin films34, and it was argued to arise due to interfacial contributions. A close inspection of the dielectric behavior of the reported LSMO films35, and the present PbPdT/LSMO films at high frequencies indicate a similar decreasing trend suggesting that the dielectric response of our thin film capacitors (>105 Hz) could be mainly from the bottom layer (LSMO). The loss tangent values become larger at higher frequency which can be attributed to the semiconducting nature of the bottom layer36, and also to the presence of disorder or defects in the films37,38. The present dielectric behavior is similar to those reported in other perovskite ferroelectrics, such as Pb(Zr0.53Ti0.47)0.9Sc0.1O327, Pb(Zr0.2Ti0.8)0.3O3-δ36. At high temperatures (≥400 K), a substantial drop in the dielectric constant at high frequencies (>105 Hz) is observed due to thermal activation of hopping motion of oxygen vacancies. As in several perovskite oxides37,39, ionic conductivity in PbPdT films is expected to increase due to increase in movement of oxygen vacancies with thermal energy. The temperature dependent behavior of dielectric constant and loss tangent in the frequency range 100 Hz −1 MHz is shown in Fig. 6(b). The dielectric constant was found to be almost constant up to 400 K, followed by a drastic increase above this temperature. A sharp rise in dielectric constant above 670 K could indicate that the system is approaching the ferroelectric-paraelectric phase transition temperature. Using our temperature controller MMR K-20, the heater power allows us to reach only up to 670 K, therefore the actual dielectric maximum that is likely to be above this temperature (≥670 K), could not be observed. Indeed the ferroelectric Curie temperature Tc in PbPdT ceramics is reported to be 740 K25. Pd cation is larger in size compared to Ti cation, therefore upon substituting such a large size Pd cation at the Ti-site in PbTiO3, the unit cell volume increases. Hence the transition temperature Tc is expected to reduce compared to the pristine PbTiO3 films (Tc ~ 823 K)40. The rise of loss tangent at higher temperatures is due to space charge polarization contribution.

(a) Frequency dependencies of dielectric constant (ɛ) of PbPd0.3Ti0.7O3 thin films measured at different temperatures (Inset: dissipation factor (tan δ) with frequencies at different temperatures), (b) Temperature dependent dielectric constant (ɛ) of PbPd0.3Ti0.7O3 thin films. (Inset: dissipation factors (tan δ) with temperatures).

P-E hysteresis loops of PbPdT thin film capacitors measured at various applied fields at 10 kHz frequency at room temperature are shown in Fig. 7. With increasing electric field from 0 to ~500 kVcm−1, both the polarization maximum Pmax and the remanent polarization Pr increase and are likely to reach a saturation value at higher electric fields than the present field range. A possible reason for non-saturation of P-E loop is that the conductivity originates from oxygen vacancies and other ionic conduction processes25. In fact, several Pd-based perovskites are reported to possess large conductivity due to Pd cation effect25,41,42. The current-voltage (I-V) characteristics of thin film oxides support significant conductivity (leakage current) through the films with bias voltage (discussed later). The P-E loop of our thin films showed a maximum polarization of 92 µCcm−2 and a remanent polarization of 27 µCcm−2, larger than those measured in other Pb-based bulk counterparts19. The coercive field Ec was obtained as 55 kVcm−1, which is also larger compared to the Pd-based ceramics (6.5 kVcm−1)19. In thin films, defects such as oxygen vacancies, interface layers and several other impurities generate an internal electric field43,44. The observed discontinuity in the hysteresis loops is a result of the polarization relaxation due to this field. Such discontinuities in P-E loops were also reported in other ferroelectric materials, e.g. (Ba0.955Ca0.045)(Zr0.17Ti0.83)O345 and Pb-based ferroelectric films43,44. Since the structure has a polar axis, a definite proof of ferroelectricity is later confirmed from our piezoresponse force microscopy experiments.

Figure 8 shows the typical leakage current conduction behavior i.e. current-voltage (I-V) characteristic curve of the PbPdT thin films, measured with a voltage step of 0.1 V and elapsed time of 0.5 s at each voltage step. Two distinct regions are noticed in the I-V curve: below 0.11 MV/cm, the current increases linearly with applied electric field suggesting an Ohmic conduction behavior, and above 0.11 MV/cm, the current increases exponentially with increasing electric field, which is reminiscent of Schottky or Poole-Frankel emission type conduction processes45. A significant leakage current (>0.001 A) through the films is seen above 0.4 MV/cm, and it can be attributed to conductivity that originates from oxygen vacancies, and interface limited conduction processes25. Similar conduction behavior was observed in PLD based (Ba0.955Ca0.045)(Zr0.17Ti0.83)O3 thin film capacitors, exhibiting a large leakage current density above an applied field of 0.7 MV/cm45.

To study the ferroelectricity at nanoscale, PFM measurements were carried out on the surfaces of PbPdT films. Conducting Pt/Ir cantilever tip was used as PFM tip and it acted as the top electrode, and LSMO as the bottom electrode was grounded to obtain the piezo response images. A strong domain switching response was inferred from the amplitude and phase images (Fig. 9). A large square area of (6 × 6) µm2 and other central square area of (4 × 4) µm2 of the thin films were polled with +12 V and −12 V bias dc voltages, respectively. The domains with opposite polarization were distinguished with dark and bright contrast in the image. Two color contrast polling regions are clearly seen indicating the polar switching behavior in the PbPdT films in nanoscale, and the ferroelectric piezoelectric nature of the films is confirmed as that inferred from our dielectric and ferroelectric studies.

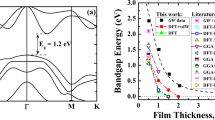

The optical absorption spectra of the thin films were measured employing a UV-2400PC spectrophotometer in the wavelength range of 300–800 nm. The substrate contribution was excluded from the spectrum by using a similar ITO-coated glass substrate as a reference. The UV-visible spectrum (Fig. 10(a)) of the PbPdT thin films show an absorption edge at 390 nm. From the Tauc plot of (αhν)2 versus energy (Fig. 10(b)), the direct band gap Eg was calculated as 3 eV, which is found to be less than that reported for PbTiO3 thin films18,46. Thus, a reduction in band gap upon Pd substitution is apparent.

Figure 11 shows the magnetization hysteresis curves for the PbPdT films at various temperatures. The films exhibited clear magnetic hysteresis loops indicating ferromagnetism in the films. At the lowest temperature of 5 K, the saturation magnetization (Ms) and the coercive field (Hc) of the films were 6 emu-cm−3 and 242.7 Oe, respectively. DFT calculations suggest that the substitution of non-isoelectric Pd4+ cation at the Pb2+ site of PbTiO3 generates two electrons, which occupy the induced defect states in the electronic band gap of PbTiO3. These electrons are believed to produce magnetism19. Our XPS studies confirmed the presence of mixed oxidation states of Pd ions (Pd2+, Pd4+) that fulfilled the condition for magnetization in the films. To experimentally demonstrate that the Pd4+ is at the A-site, experimental works providing local bonding coordination are required, which we are planning to carry out separately. The temperature dependence of the magnetization was studied by carrying out measurements of magnetization hysteresis loops (M-H curve) at different temperatures (Fig. 11). A plot of the coercive field Hc and the remanent magnetization Mr of PbPdT films as a function of temperature is inset in Fig. 11. Upon increasing temperature, Mr and Hc values of the hysteresis loops decrease. These Hc and Mr values obtained at different temperatures are presented in Table 2. The Hc value at 300 K (114 Oe) is about 2 times less than that observed at 5 K (242 Oe). Similarly, the Mr value at 300 K (3.4 emucm−3) reduces by nearly half compared to that at 5 K (6 emucm−3). The appearance of magnetic hysteresis loop in the films at 395 K indicates that the films are ferromagnetic with a Curie temperature above 395 K. The small discontinuity in hysteresis loop could be due to a few missing data points in our measurements due to the lock-in amplifier (or other electronics) changing the range of measurements in the PPMS system. To examine if there are any changes in the magnetic ordering of the films, we have investigated the temperature evolution of magnetization from 5 to 395 K. A saturation field of 2 T was applied at 5 K, and the field was turned off thereafter. In the absence of the field (H = 0), thermal evolution of magnetization was measured up to 395 K (Fig. 12). A gradual reduction of magnetization with increasing temperature is noticed. The rate of change of magnetization with temperature (dM/dT) that provides information about any changes in the magnetic ordering is inset in Fig. 12. In principle, any change in magnetic ordering would result in a significant change in the magnetization curve. Since dM/dT remains constant, it is evident that there is no change in magnetic ordering in the films up to 395 K. Thus, the films are ferromagnetic throughout the temperature range of the present studies and the magnetic Curie temperature is above 395 K.

Conclusions

(001)-oriented PbPd0.3Ti0.7O3 thin films were grown on LSAT single crystal substrates using pulsed laser deposition technique. X-ray diffraction analysis indicates that the grown thin films are phase pure and stabilized in tetragonal phase. Temperature dependent dielectric studies on Pt/PbPdT/LSMO metal-insulator-metal capacitors suggest that the ferroelectric Curie temperature is above 670 K. The polarization hysteresis loops at room temperature were attributed to its ferroelectric behavior. The P-E loop of our thin films showed a maximum of 92 µCcm−2 polarization with remanent polarization Pr of 27 µC cm−2 at an applied electric field of 500 kVcm−1. A saturated magnetization M-H loop with remanent magnetization Mr of 3.5 emu/cm3 was observed at room temperature and the film retains ferromagnetic ordering up to as high as 395 K. X-ray photoelectron spectroscopic results confirmed the mixed chemical states of the Pd 3d state with Pd4+: Pd2+ of 0.83: 1. Magnetization in the PbPdT films is due to the existence of mixed oxidation states of Pd2+/Pd4+ and this fulfills the predicted requirement to realize ferromagnetism in PbPdT films. From the Tauc plot of (αhν)2 versus energy, the direct band gap of PbPdT thin films was estimated as 3 eV. Ferroelectric piezoelectric nature of the films was confirmed from a strong domain switching response revealed from our piezoresponse force microscopy studies on the phase and amplitude contrast images. The experimental results revealed that the PbPdT thin films are multiferroic (ferroelectric-ferromagnetic) at room temperature and have potential for device applications in non-volatile memories, transducers, and actuators.

Methods

PbPdT, and PbPdT/LSMO thin films were grown on {(LaAlO3)0.3(Sr2AlTaO6)0.7} (LSAT) (001) substrates in an oxygen atmosphere using a KrF gas excimer laser operated at λ = 248 nm with a pulse repetition rate of 10 Hz using PLD technique. PbPdT target with a stochiometric molecular formula was prepared employing the solid-state reaction method following the procedure reported earlier25. The PLD deposition parameters were optimized for the growth of PbPdT thin films as summarized in Table 1. Using an XP-200 Profilometer the thickness of the films was measured to be ~300 nm. Elemental compositions and their mapping distributions were studied using Energy Dispersive X-ray Spectroscopy (EDS) employing a scanning electron microscope (JEL JSM-6480LV). Atomic Force Microscopy (AFM-Veeco) was operated in contact mode to study the surface topography of thin films and their surface roughness. The crystallographic phase and orientation of these grown thin films were confirmed from the analysis of high-resolution XRD data measured using a Smartlab x-ray diffractometer employing a Cu-Kα radiation (λ = 1.5405 Å). The chemical states of the constituent elements were studied using x-ray photo emission spectroscopy (XPS). For electrical measurements, PbPdT capacitors sandwiched between a conducting bottom LSMO layer and a top platinum (Pt) electrode were fabricated. Pt electrodes were fabricated by D.C. sputtering technique using a metal shadow mask of area 10−8 m2 followed by annealing at 620 K in an oxygen environment to recover any defects generated during sputtering. The temperature dependent dielectric properties such as capacitance and dielectric loss tangent (tan δ) were measured at several frequencies (100 Hz to 1 MHz) in the temperature range of 100–670 K by employing a programmable temperature controller (MMR K-20) with a temperature stability of ±1 K and using an impedance analyzer (HP 4294 A). Ferroelectric hysteresis loops (P-E curves) were measured at ambient temperature using a hysteresis loop tester (radiant Technologies RT6000 HVS). Magnetization measurements were carried out using a physical properties measurement system (PPMS, Quantum design), operated in the VSM module in the temperature range of 5–395 K. Piezoresponse force microscopy (PFM) studies on thin films were carried out at ambient temperature using a Multimode Nanoscope V (Veeco Instruments). The used conductive tips were coated with Pt/Ir having a resonance frequency of 140 kHz and force constant of 4.5 Nm−1. During PFM measurements, the driving applied voltages on the film surface was ±12 V to monitor the material’s polarization switching and amplitude.

Data availability

The data sets are available from the corresponding author on reasonable request.

References

Kimura, T. et al. Magnetic control of ferroelectric polarization. Nature 426, 55 (2003).

Eerenstein, W., Mathur, N. D. & Scott, J. F. Multiferroic and magnetoelectric materials. Nature 442, 759 (2006).

Tokura, Y., Seki, S. & Nagaosa, N. Multiferroics of spin origin. Rep. Prog. Phys. 77, 076501 (2014).

Scott, J. F. Data storage: Multiferroic memories. Nat. Mater. 6, 256 (2007).

Hill, N. A. Why Are There so Few Magnetic Ferroelectrics? J. Phys. Chem. B 104, 6694 (2000).

Wang, Y., Hu, J., Lin, Y. & Nan, C.-W. Multiferroic Magnetoelectric Composite Nanostructures. NPG Asia Mater. 2, 61 (2010).

Ma, J., Hu, J., Li, Z. & Nan, C.-W. Recent Progress in Multiferroic Magnetoelectric Composites: from Bulk to Thin Films. Adv. Mater. 23, 1062 (2011).

Vaz, C. A. F., Hoffman, J., Ahn, C. H. & Ramesh, R. Magnetoelectric Coupling Effects in Multiferroic Complex Oxide Composite Structures. Adv. Mater. 22, 2900 (2010).

Rao, C. N. R., Sundaresan, A. & Saha, R. Multiferroic and Magnetoelectric Oxides: The Emerging Scenario. J. Phys. Chem. Lett. 3, 2237 (2012).

Wang, J. et al. Epitaxial BiFeO3 Multiferroic Thin Film Heterostructures. Science 299, 1719 (2003).

Zhao, T. et al. Electrical control of antiferromagnetic domains in multiferroic BiFeO3 films at room temperature. Nat. Mater. 5, 823 (2006).

Lebeugle, D. et al. Room-temperature coexistence of large electric polarization and magnetic order in BiFeO3 single crystals. Phys. Rev. B 76, 024116 (2007).

Song, S. et al. Ferroelectric polarization switching with a remarkably high activation energy in orthorhombic GaFeO3 thin films. NPG Asia Materials 8, e242 (2016).

Nechache, R. et al. Coexistence of antiferromagnetic and ferromagnetic orders at remanent state in epitaxial multiferroic Bi2FeCrO6 nanostructures. J. Phys.: Condens. Matter 24, 142202 (2012).

Quattropani, A. et al. Band-Gap Tuning in Ferroelectric Bi2FeCrO6 Double Perovskite Thin Films. J. Phys. Chem. C 122, 1070 (2018).

Nechache, R. et al. Epitaxial thin films of multiferroic Bi2FeCrO6 with B-site cationic order. J. Mater. Res. 22, 2102 (2007).

Catalan, G. & Scott, J. F. Physics and Applications of Bismuth Ferrite. Adv. Mater. 21, 2463 (2009).

Mansoor, M. A. et al. Perovskite-Structured PbTiO3 Thin Films Grown from a Single-Source Precursor. Inorg. Chem. 52, 5624 (2013).

Kumari, S. et al. Palladium-based ferroelectrics and multiferroics: Theory and experiment. Phys. Rev. B 95, 214109 (2017).

Guthrie, A. N. & Copley, M. J. The Magnetic Moment of the Palladium Atom. Phys. Rev. B 38, 360 (1931).

Obinata, A. et al. Electric-field control of magnetic moment in Pd. Scientific Reports 5, 14303 (2015).

Birsan, M., Fultz, B. & Anthony, L. Magnetic properties of bcc Fe-Pd extended solid solutions. Phys. Rev. B 55, 11502 (1997).

Evans, D. M. et al. The Nature of Magnetoelectric Coupling in Pb(Zr,Ti)O3-Pb(Fe,Ta)O3. Adv. Mater. 27, 6068 (2015).

Bennett, J. W., Grinberg, I., Davies, Peter, K. & Rappe, A. M. Pb-free semiconductor ferroelectrics: A theoretical study of Pd-substituted Ba(Ti1−xCex)O3 solid solutions. Phys. Rev. B 82, 184106 (2010).

Gradauskaite, E. et al. Lead palladium titanate: A room-temperature multiferroic. Phys. Rev. B 96, 104104 (2017).

Eerenstein, W. et al. Comment on Epitaxial BiFeO3 Multiferroic Thin Film Heterostructures. Science 307, 1203 (2005).

Levstik, A. et al. Magnetoelectric relaxor. Appl. Phys. Lett. 91, 012905 (2007).

Kumar, A., Rivera, I., Katiyar, R. S. & Scott, J. F. Multiferroic Pb(Fe0.66W0.33)0.80Ti0.20O3 thin films: A room-temperature relaxor ferroelectric and weak ferromagnetic. Appl. Phys. Lett. 92, 132913 (2008).

Ortega, N., Kumar, A., Bhattacharya, P., Majumder, S. B. & Katiyar, R. S. Impedance spectroscopy of multiferroic PbZrxTi1−xO3∕CoFe2O4 layered thin films. Phys. Rev. B 77, 014111 (2008).

Schlom, D. G., Chen Long-Qing, P., Xiaoqing Schmehl, A. & Zurbuchen, M. A. J. Am. Ceram. Soc. 91, 2429–2454 (2008).

Chrisey, D. B. & Hubler, G. K. Pulsed Laser Deposition of Thin Films. 1st edn (Wiley-Interscience, 1994).

Bhattarai, M. K., Mishra, K. K., Dugu, S., Instan, A. A. & Katiyar, R. S. Ferroelectric ordering and energy storage density of thin films capacitor by doping La3+ and Sc3+ on Pb(Zr0.53Ti0.47)O3 using pulse laser deposition technique. Appl. Phys. Lett. 114, 223902 (2019).

Bhattarai, M. K., Mishra, K. K., Instana, A. A., Bastakoti, B. P. & Katiyar, R. S. Enhanced energy storage density in Sc3+ substituted Pb(Zr0.53Ti0.47)O3 nanoscale films by pulse laser deposition technique. Appl. Surf. Sci. 490, 451 (2019).

Barrionuevo, D. et al. Thickness dependent functional properties of PbZr0.52Ti0.48O3/La0.67Sr0.33MnO3 heterostructures. J. Appl. Phys. 114, 234103 (2013).

Majumdar, S., Huhtinen, H. Paturi, P. & Majumdar H. S. Effect of strain and grain boundaries on dielectric properties in La0.7Sr0.3MnO3 thin films. J. Mater Sci. 48, 2115 (2013).

Kumari, S. et al. Effect of thickness on dielectric, ferroelectric, and optical properties of Ni substituted Pb(Zr0.2Ti0.8)O3 thin films. J. Appl. Phys. 118, 184103 (2015).

Bajpai, P. K., Pastor, M. & Singh, K. N. Diffuse Phase Transition and Electrical Conductivity of Pb(Ca1/3Nb2/3)O3. J. Electron. Mater. 43, 1403 (2014).

Singh, G., Tiwari, V. S. & Gupta, P. K. Role of oxygen vacancies on relaxation and conduction behavior of KNbO3 ceramic. J. Appl. Phys. 107, 064103 (2010).

Newnham, R. E. Properties of Materials: Anisotropy, Symmetry, Structure. Kindle edn (Oxford University Press Inc., 2005).

Ryu, J. et al. Upshift of Phase Transition Temperature in Nanostructured PbTiO3 Thick Film for High Temperature Applications. ACS Appl. Mater. Interfaces 6, 11980 (2014).

Singh, U. G. et al. Pd-doped perovskite catalyst, BaCe1−xPdxO3−δ, for CO oxidation. J. Catal. 249, 349 (2007).

Zhu, Y. et al. Boosting Oxygen Reduction Reaction Activity of Palladium by Stabilizing Its Unusual Oxidation States in Perovskite. Chem. Mater. 27, 3048 (2015).

Thomas, R., Mochizuki, S., Mihara, T. & Ishida, T. Preparation of Pb(Zr,Ti)O3 thin films by RF-magnetron sputtering with single stoichiometric target: structural and electrical properties. Thin Solid Films 413, 65 (2002).

Lee, J. & Ramesh, R. Imprint of (Pb,La)(Zr,Ti)O3 thin films with various crystalline qualities. Appl. Phys. Lett. 68, 484 (1996).

Puli, V. S. et al. Nanoscale polarisation switching and leakage currents in (Ba0.955Ca0.045)(Zr0.17Ti0.83)O3 epitaxial thin films. J. Phys. D: Appl. Phys. 48, 355502 (2015).

Zametin, V. I. Absorption Edge Anomalies in Polar Semiconductors and Dielectrics at Phase Transitions. Phys. Status Solidi B 124, 625 (1984).

Momma, K. & Izumi, F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 44, 1272 (2011).

Acknowledgements

The authors acknowledge the financial support from the Department of Defense, USA (DoD Grant No. FA9550-16-1-0295). K.K.M thanks to all SPECLAB members for their help in experimental studies.

Author information

Authors and Affiliations

Contributions

K.K.M. synthesized and characterized the thin films. The data were analyzed by K.K.M. A.A.I. involved in the PFM analysis. S.K. helped with the XPS analysis. R.S.K. and J.F.S supervised this research work. Manuscript written by K.K.M. All co-authors co-wrote and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mishra, K.K., Instan, A.A., Kumari, S. et al. Lead palladium titanate: A room temperature nanoscale multiferroic thin film. Sci Rep 10, 2991 (2020). https://doi.org/10.1038/s41598-020-59961-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-59961-w

This article is cited by

-

Effect of particle size on magnetodielectric and magnetoelectric coupling effect of CoFe2O4@BaTiO3 composite fluids

Journal of Materials Science: Materials in Electronics (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.