Abstract

Phytase is one of the most effective feed additives to increase the availability of phosphorus and minerals by catalyzing the hydrolysis of phytic acid. A modified appA gene (mappA) was transformed into soybean (Glycine max) under the control of a seed-specific promoter from common bean (Phaselous vulgaris). The soybean recombinant phytase showed optimal activity at pH 4.5 and 70 °C. A slight increase in enzyme activity occurred when the recombinant enzyme was pre-incubated with n-hexane. In addition, the phytase activity from our transgenic soybean does not reduce even after 2 hours of extraction with n-hexane at 55~65 °C. In conclusion, the oil extraction process using n-hexane does not inactivate the phytase expressed in the mAppA transgenic soybean, and the meal derived from the transgenic soybean processing can be used as feed supplement to livestock.

Similar content being viewed by others

Introduction

Phytate (myo-inositol 1, 2, 3, 4, 5, 6-hexakisphosphate) is the major form of phosphorus found in plant-based feeds such as cereals, legumes and oilseed crops1,2,3. Phytate phosphorus is not readily available to monogastrics4,5, thus phosphate supplementation is required for optimal animal growth6. However, release of undigested phytate through manure can lead to eutrophication in areas of intensive livestock production7,8. Phytate can chelate important cations, such as iron, zinc, magnesium, manganese, copper and calcium, and may also bind protein to form phytate-cation-protein complexes that lower the bioavailability of minerals and amino acids in feed9,10,11.

Phytase (myo-inositol hexakisphosphate phosphohydrolase) hydrolyzes phytate to less-phosphorylated myo-inositol derivates and inorganic phosphate. Exogenous phytase is supplemented in the diet of monogastrics because of the absent or limited phytase activity in their digestive tract12. In this matter, phytase can improve the dietary availability of phosphorus and minerals and has emerged as one of the most effective feed additives10,11. Phytases are broadly found in plants, animals and microorganisms8. Microbial phytases have been employed in feed industry and are commercially produced by submerged fermentation techniques (SmF)13,14. Currently, the production of phytase by solid-state fermentation techniques (SSF) has gained a fresh attention from researchers14,15,16,17,18. As compared to SmF, SSF possesses higher product concentration, better product recovery, lower catabolic repression and lower capital cost19,20. However, SSF is still under research due large scale production and enzyme purification limitations. Developing phytase transgenic crops represents another effective way to increase phosphorus availability and eliminate the need for phytase supplementation.

Soybean (Glycine max) is widely harvested worldwide to be used as food or raw material for oil and protein production. In feed industry, soybean meal is obtained after oil extraction as forage to livestock due its abundant protein content21,22. Phytase has been reported to be expressed in transgenic soybean previously. Some of the transgenic soybean was generated to express phytase to reduce phytate content of soybean itself 23,24,25,26, while other transgenic soybean was created to provide an alternative to phytase supplementation26,27. Of note, a soybean line (CAPPA) expressing an Escherichia coli appA gene driven by the soybean lectin promoter exhibited a high level of phytase expression (>1000 units g−1 seed)26, making its meal as a suitable replacement of commercial fungal phytases. The same gene was previously transformed into Arabidopsis thaliana and the transgenic seed phytase exhibited an optimum temperature of 50 °C and remained <5% of activity after incubation at 70 °C for 20 min28. It is highly desirable to develop transgenic soybean expressing a thermostable phytase to accommodate soybean processing procedures which often endure high temperature. In the present study, we generated a transgenic soybean expressing a modified thermostable phytase mAppA29. Transgenic soybean retained its high phytase activity after oil extraction by n-hexane. Soybean meal derived from mAppA transgenic soybean seeds can be used as sources of phytase as alternative to manual phytase addition after oil extraction.

Results

Generation of soybean events expressing mAppA

To create the transgenic soybean events expressing the mAppA, we constructed a T-DNA consisting of the phytase gene expression and the glyphosate resistance cassettes (Fig. 1). The mappA gene expression cassette is composed by the promoter of the common bean storage protein β-phaseolin, the codon-optimized synthetic mappA gene and a terminator. The glyphosate resistance cassette is used as the selection marker for soybean transformation. The T-DNA was transformed into the elite soybean cultivar ‘Wandou-28’ by Agrobacterium-mediated transformation.

Diagram of the T-DNA used for soybean transformation. RB and LB, right border and left border of T-DNA respectively; Pphas, promoter of the β-phaseolin gene; SS, signal peptide of the 2S2 seed storage protein gene of A. thaliana; mappA, the modified thermostable phytase gene; E9 ter, the rbcSE9 terminator of Pisum sativum; P35S, CaMV 35S promoter; G10, 5-enolpyruvylshikimate-3-phosphate synthase (EPSPS) gene; 35S ter, CaMV 35S terminator.

Expression of mAppA in seeds of transgenic soybean

Forty transgenic lines were obtained and T1 seed batches were analyzed for their phytase content. The expression levels ranged from 0.29 to 350 U/g seed. Four events with the highest phytase activity were selected for further analysis.

Crude protein extracts were prepared from seed batches of transgenic lines. The extracts were analyzed by western blot analysis using antisera against mAppA. A band of about 45 kDa was detected among different transgenic lines (Fig. 2, detailed information shown in supplementary Figure S1) showing phytase expression and its molecular weight (45.3 kDa).

Event Phs-39 expresses the highest level of phytase as suggested by activity assay. We investigated the major agronomic traits of this line. Plant height and pods per plant of Phs-39 were similar to non-transgenic soybean (Table 1). The germination rate of Phs-39 line was not reduced (data not shown). However, we observed a 4% reduction in 100-grain weight in Phs-39 compared to the non-transgenic crop (Table 1). In addition, transgenic rice seeds expressing cellulase30 and lipase31 also presented reduction in seed weight. The high level expression of xenogeneic enzymes likely has cost the seed weight.

Characterization of mAppA expressed in soybean seeds

The phytase from transgenic soybean had a pH optimum of 4.5 (Fig. 3A). Phytase exhibited more than 80% of its maximal activity at pHs between of 3.5 to 5.0. pHs above 6.5 or at pH 1.5 exerted an inhibitory effect on the enzyme.

The phytase from transgenic soybean showed a temperature optimum of 70 °C (Fig. 3B). The enzymatic activity gradually increased with the temperature up to 70 °C, while the activity decreased above 70 °C. Temperature stability assay showed the enzyme remained stable below 65 °C, and its stability declined at higher temperatures (Fig. 3B).

Kinetic parameters of the phytase

The kinetic properties of the phytase were determined by incubation with different concentrations of sodium phytate: 0.0125 mM, 0.025 mM, 0.05 mM, 0.1 mM, 0.2 mM, 0.4 mM, 0.8 mM, 1.6 mM, 3.2 mM or 6.4 mM. Our results show that the average Km value for the phytase extracted from E. Coli (purified 6 × His-fused recombinant protein) or the transgenic soybean (without purification) was 98.6 ± 19.8 μM and 103 ± 35.2 μM, respectively. Thus, the enzymatic kinetics of the protein expressed in the soybean is similar to that expressed in the bacteria.

Effect of metal ions on phytase activity

The effect of different metal ions on phytase activity was assessed by incubating the enzyme with different metal ions (K+, Mn2+, Mg2+, Cu2+, Zn2+, Ca2+ or Co2+) at different molar concentrations (1 mM or 5 mM) for 1 h at room temperature. Our results indicated that phytase activity was not significantly affected by most of ions tested (Table 2). The phytase activity was inhibited by Zn2+ and Cu2+ at 1 mM or 5 mM (Table 2).

Effect of organic solvents on phytase activity

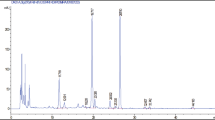

Extraction by organic solvent is the most common and efficient method for oil production. However, different polarity of organic solvents may modify the activity of phytase. We investigated whether the activity of phytase can be modified after being pretreated with different organic solvents for 1 h. The phytase activity was significantly inhibited by isopropanol (75.3% reduction) and slightly inhibited by ethanol (11.6% reduction). Of note, increased enzyme activity was observed after treatment with methanol (4.7% increase), acetone (10.0% increase) or n-hexane (21.8% increase) (Fig. 4A).

Effects of organic solvents on the enzymatic activity of the phytase produced in soybean and the tolerance of recombinant phytase in n-hexane. (A) Effects of organic solvents on the activity of recombinant phytase. Control, sample without being incubated with any solvents. (B) Effects of n-hexane-extraction on recombinant phytase activity. Control, sample without being extracted with n-hexane. The residual activity was determined using the standard assay method, and the activity of the untreated control was set to 100%. Data are showed as the mean ± SD (n = 3).

Effect of n-hexane-extraction on phytase activity

To further confirm the effects of n-hexane on phytase activity, this organic solvent was used to extract oil from the transgenic soybean at different temperatures and time points. High phytase activity, ranging from 114.0% to 128.7%, was observed when the extraction occurred within two hours (Fig. 4B). Thus, the coproduct of soybean oil production, the soybean meal, has the potential to be used as feed additive.

Discussion

Phytase is an important additive to monogastrics diet, due its ability to increase phosphorus accessibility and to reduce excessive phosphorus accumulation in manure. Phytase supplementation can also reduce rock phosphorus use and is conducive to resource preservation32. Field studies showed that the addition of 500 to 1,000 units kg−1 of phytase to feed diet is analogous to 1% dicalcium phosphate or 0.18% phosphorus supplementation5. In the present study, we report the presence of 350 units of phytase per gram of seed on our mAppA soybean, suggesting that only 2~3 kg of the transgenic soybean may be required to supplement 1 metric ton of feed. Our mAppA transgenic soybean can be used as a natural additive to feed without downstream processing.

Solvent extraction is the most common and efficient method for oil production. Therein, commercial hexane (45–90% n-hexane) is the most frequently used solvent in the industry33,34. We evaluated the effect of five organic solvents on the catalytic properties of phytase. It was noticed that phytase treated with n-hexane showed higher activity than control. Similar phenomenon has been observed when extracellular phytase from Aspergillus niger van Teighem was incubated with hexane (10% v/v)35. These results suggest that n-hexane has no deleterious effect on active site residues of phytase.

The process to extract oil from soybean using industrial settings, takes about 25 min (contact time)36, and most extractions occur at 60 °C to provide a safety margin below the solvent boiling range36. In our protocol, we found a slight increase in phytase activity after extraction using n-hexane between 55 to 65 °C along 2 hours, indicating this enzyme can sustain the oil extraction process at high temperatures. This is partially due the thermostable characteristic of the phytase expressed in our transgenic soybean. Soybean meal is the by-product of oil extraction from soy and it is the most important protein source used to feed livestock. Soybean meal represents two-thirds of the total world output of protein feedstuffs, including other major oil and fish meals21. Thus, the soybean meal derived from the mAppA transgenic soybean showed sufficient enzyme activity to serve as a feed additive.

In conclusion, the mAppA transgenic soybean can be used as a source phytase supplementation to feed livestock even after oil extraction. Its application in feed industry can decrease enzyme purification steps and production costs.

Methods

Vector construction

pCambia1300 (Cambia, Canberra, Australia) was digested with XhoI to substitute the hygromycin-resistant gene sequence with a glyphosate-tolerant G10 gene sequence37. Thus, the open reading frame was brought under control of the CaMV 35S promoter and the CaMV 35S terminator. The modified vector was named as p1300-G10, and was further used to clone the phytase expression cassette.

The phytase gene mappA with the N-terminal signal sequence of the seed storage protein 2S238 and the rbcSE9 terminator of Pisum sativum (GenBank Accession No. X00806.1) was codon-optimized and synthesized by Sangon Biotech (Shanghai) Corporation Limited. A BamHI site was introduced at the 5′ end, and a KpnI site was added to the 3′ end of the synthetic sequence. Genomic DNA of Phaselous vulgaris cv. Velour was isolated39 and used as a template in a PCR reaction. The β-phaseolin promoter (GenBank Accession No. J01263.1) was amplified using a forward primer (5′-AAGCTTATTGTACTCCCAGTATC-3′, the HindIII restriction site is underlined) and a reverse primer (5′-GGATCCGAAAGAAGTGAGTGATATTAG -3′, the BamHI restriction site is underlined). The β-phaseolin promoter fragment was digested with HindIII and BamHI, the synthetic gene fragment was digested with BamHI and KpnI, and the vector p1300-G10 was predigested with HindIII and KpnI. The promoter, gene fragment, and the vector were further ligated to generate the p1300-mappA-G10 plasmid. This construct includes two expression cassettes and the glyphosate resistance and the phytase expression cassettes.

Agrobacterium-mediated transformation

p1300-mappA-G10 plasmids were transformed into Agrobacterium tumefaciens EHA105 by electroporation. Elite soybean cultivar ‘Wandou-28’ [Glycine max (L.) Merrill] was transformed using an Agrobacterium-mediated transformation method40. Glyphosate (Sigma-Aldrich) was used as selection agent for transgenic soybean plants from cotyledon explants.

Expression and purification of his-tagged recombinant protein

Using ClonExpress®II One Step Cloning Kit (Vazyme Biotech Co., Ltd.), a full-length ORF encoding the mappA gene was cloned into the pET28a (Merck Millipore, Darmstadt, Germany) vector. The recombinant vector (pET28a-mappA) was transformed into Transetta (DE3) (TransGen Biotech). Expression mAppA and purification of 6 × His-fused recombinant protein were carried out according to the manufacturer’s protocol (Qiagen, Hilden, Germany). The purified 6 × His-fused protein was dialyzed overnight and analyzed by SDS-PAGE. Positive samples were then used as an immunogen for the preparation of polyclonal rat antisera. The purified 6 × His-fused protein was quantified against bovine serum albumin standard according to the recommendations of the manufacturer of the BioRad protein assay.

Western blot analysis

Seed samples weighting 0.1 g were milled, homogenized in 1 mL PBS buffer and centrifuged at 12396 g for 10 min at 4 °C. The supernatant was collected and the expression of mAppA in the transgenic soybean was verified by Western Blot analysis. The proteins were separated by SDS-PAGE and then transferred to a PVDF membrane (Pall, Ann Arbor, MI, USA). Primary rabbit anti-mAppA polyclonal antibodies were prepared from rabbits immunized with E. coli expressing mAppA protein. The anti-mAppA antibody was then detected by horseradish peroxidase-conjugated goat anti-rabbit IgG (Sigma-Aldrich) as the secondary antibody. TMB stabilized substrate solution for Horseradish Peroxidase (Promega catalog number W4121) was used for detection.

Phytase activity assay

Phytase activity was detected in protein extracts from mature seeds. Samples weighting 0.1 g were pulverized in a mortar and protein extracts were homogenized in 10 mL 100 mM sodium acetate buffer, pH 5.0. The resulting mixture was clarified by centrifugation (15938 g, 10 min) and the supernatant was collected and assayed for phytase activity by the ferrous sulfate-molybdenum blue method41 with slight modification: 150 µL aliquots of the protein extracts were incubated with 600 µL of 6.25 mM sodium phytate in 100 mM sodium acetate buffer pH 5.0 for 30 min at 37 °C. The reaction was stopped by adding 750 µL of a 5% (w/v) trichloroacetic acid solution. Color reagent was added to the sample solution and the production of phosphomolybdate was measured by spectrophotometer at 700 nm. One unit (U) was defined as the amount of enzyme required to release 1 μmol orthophosphate from phytic acid per minute under assay conditions.

Effect of pH on phytase activity

The pH optimum for phytase activity was determined using different solutions ranging from pH 1.5 to 7 at 37 °C: 0.2 M glycine-HCl (pH 1.5–3.5), 0.2 M sodium acetate – acetic acid (pH 4–5.5), 0.2 M MES (pH 6–6.5), and 0.2 M Tris-HCl (pH 7).

Effect of temperature on phytase activity and stability

The temperature optimum for phytase activity was measured using the standard assay at different temperatures from 35 to 80 °C. Temperature stability of phytase was determined by incubation of enzyme in 0.2 M sodium acetate buffer for 30 min at temperatures from 35 to 80 °C and assaying the residual phytase activity in accordance with the standard assay.

Effect of organic solvents and metal ions on phytase activity

To determine the effect of organic solvents on phytase activity, 45 µL of methanol, ethanol, acetone, isopropanol, n-hexane or 100 mM sodium acetate buffer, pH 5.0 (as the control), was added individually to 105 µL of properly diluted crude enzyme extracts and mixed by vortexing. After incubated at room temperature for 1 h, the enzyme activity of the mixtures was measured using the standard assay. The activity of the enzyme without organic solvents was used as control and set at 100%. All measurements were repeated three times.

To investigate the effect of different metal ions on phytase activity, the enzyme was pre-incubated with 1 mM or 5 mM of KCl, MnCl2, MgCl2, CuCl2, ZnSO4, CaCl2 or CoCl2 at room temperature for 1 h. Enzyme samples without metal ions treated were used as control. The residual activity of the enzyme was measured using the standard assay.

Effect of n-hexane-extraction on phytase activity

Mature seeds from the mAppA transgenic line were pulverized to permit passage through a 0.38 mm sieve36. The extraction mixture consisted of 1 g of collected soybean flour42 and 5 mL of n-hexane (97%, Sinopharm Chemical Reagent Co., Ltd). The ratio of solvent to beans was 5:143. Experiments were performed at 55, 60 or 65 °C44,45, with extraction time limit set to 1, 2 or 3 hs at each temperature point. All the extractions were carried out in triplicate. At the end of the contact time, the supernatants were discarded by centrifugation (15938 g, 10 min) and traces of solvent remaining were removed by evaporation. The resulting precipitation was homogenized in 10 mL of 0.2 M sodium acetate buffer (pH 5.0) for phytase extraction. The phytase in the control sample (1 g of soybean flour without n-hexane extraction) was extracted simultaneously with 10 mL of 0.2 M sodium acetate buffer (pH 5.0). After centrifugation (15938 g, 10 min), the supernatants were collected and assayed for phytase activity using the standard method. The phytase activity per gram for both non n-hexane-extracted and n-hexane extracted samples were calculated based on original pulverized soybean weight.

Characterization of the kinetic parameters of phytase

The purified 6 × His-fused phytase and unpurified soybean recombinant phytase were diluted with 50 mM sodium acetate buffer, pH 4.5, to a final concentration of 0.2 U/mL. Phytase activity was determined at 37 °C using sodium phytate as substrate at 10 different concentrations ranging from 12.5 μM to 6.4 mM in a 5 min assay (n = 3). The software Origin 8.0 was used for nonlinear regression analysis of the enzyme kinetics data.

Evaluation of major agronomic traits of the mAppA transgenic soybean

Data about plant height, pods per plant and the 100-grain weight were collected at the Experimental Station of Zhejiang University in Sanya City (Hainan Province) during December 2018 to March 2019. All accessions were planted in three-row plots in 500-cm-long rows with spacing of 50 cm between rows. The experiment was design as a randomized complete block with three replications. All plots of transgenic and non-transgenic soybean (Wandou 28) were uniformly managed to control water, fertilizer, disease and pest. At maturity, major agronomic characteristics, such as plant height, pods per plant, and the 100-grain weight, were evaluated.

References

Reddy, N.R., Sathe, S.K. & Salunkhe, D.K. In Advances in Food Research Vol. 28 (eds Chichester, C. O., Mrak, E. M. & Stewart, G. F.) 1–92 (Academic Press, 1982).

Harland, B. F. & Morris, E. R. Phytate: A good or a bad food component? Nutr. Res. 15, 733–754 (1995).

Kerovuo, J., Lauraeus, M., Nurminen, P., Kalkkinen, N. & Apajalahti, J. Isolation, characterization, molecular gene cloning, and sequencing of a novel phytase from Bacillus subtilis. Appl. Environ. Microbiol. 64, 2079–2085 (1998).

Vats, P. & Banerjee, U. C. Production studies and catalytic properties of phytases (myo-inositolhexakisphosphate phosphohydrolases): an overview. Enzyme Microb. Technol. 35, 3–14 (2004).

Lei, X. et al. Phytase, a New Life for an “Old” Enzyme. Annu. Rev. Anim. Biosci. 1, 283–309 (2013).

Chen, R. et al. Transgenic maize plants expressing a fungal phytase gene. Transgenic Res. 17, 633–643 (2008).

Volfová, O., Dvořáková, J., Hanzlíková, A. & Jandera, A. Phytase fromAspergillus niger. Folia Microbiol. 39, 481–484 (1994).

Jain, J., Sapna & Singh, B. Characteristics and biotechnological applications of bacterial phytases. Process Biochem. 51, 159–169 (2016).

Li, J. et al. Secretion of active recombinant phytase from soybean cell-suspension cultures. Plant Physiol. 114, 1103–1111 (1997).

Rao, D. E. C. S., Rao, K. V., Reddy, T. P. & Reddy, V. D. Molecular characterization, physicochemical properties, known and potential applications of phytases: An overview. Crit. Rev. Biotechnol. 29, 182–198 (2009).

Dersjant-Li, Y., Awati, A., Schulze, H. & Partridge, G. Phytase in non-ruminant animal nutrition: a critical review on phytase activities in the gastrointestinal tract and influencing factors. J. Sci. Food Agric. 95, 878–896 (2015).

Brinch-Pedersen, H., Sørensen, L. D. & Holm, P. B. Engineering crop plants: getting a handle on phosphate. Trends Plant Sci. 7, 118–125 (2002).

Pandey, A., Szakacs, G., Soccol, C. R., Rodriguez-Leon, J. A. & Soccol, V. T. Production, purification and properties of microbial phytases. Bioresour. Technol. 77, 203–214 (2001).

Buddhiwant, P., Bhavsar, K., Kumar, V. R. & Khire, J. M. Phytase production by solid-state fermentation of groundnut oil cake by Aspergillus niger: A bioprocess optimization study for animal feedstock applications. Prep. Biochem. Biotechnol. 46, 531–538 (2016).

Costa, J. A. V., Treichel, H., Kumar, V. & Pandey, A. In Current Developments in Biotechnology and Bioengineering (eds Pandey, A., Larroche, C. & Soccol, C. R.) 1–17 (Elsevier, 2018).

Rani, R. & Ghosh, S. Production of phytase under solid-state fermentation using Rhizopus oryzae: Novel strain improvement approach and studies on purification and characterization. Bioresour. Technol. 102, 10641–10649 (2011).

Madeira, J. V., Macedo, J. A. & Macedo, G. A. Detoxification of castor bean residues and the simultaneous production of tannase and phytase by solid-state fermentation using Paecilomyces variotii. Bioresour. Technol. 102, 7343–7348 (2011).

Arora, S., Dubey, M., Singh, P., Rani, R. & Ghosh, S. Effect of mixing events on the production of a thermo-tolerant and acid-stable phytase in a novel solid-state fermentation bioreactor. Process Biochem. 61, 12–23 (2017).

Krishna, C. Solid-State Fermentation Systems—An Overview. Crit. Rev. Biotechnol. 25, 1–30 (2005).

Singhania, R. R., Patel, A. K., Soccol, C. R. & Pandey, A. Recent advances in solid-state fermentation. Biochem. Eng. J. 44, 13–18 (2009).

Heuzé, V., Tran, G. & Kaushik, S. Soybean meal, https://feedipedia.org/node/674 (2017).

Pettersson, D. & Pontoppidan, K. In Soybean - Bio-Active Compounds (ed. El-Shemy, H. A.) Ch. 13, (InTech, 2013).

Chiera, J., Finer, J. & Grabau, E. Ectopic expression of a soybean phytase in developing seeds of Glycine max to improve phosphorus availability. Plant Mol. Biol. Rep. 56, 895–904 (2004).

Gao, X., Wang, G., Su, Q., Wang, Y. & An, L. Phytase expression in transgenic soybeans: stable transformation with a vector-less construct. Biotechnol. Lett. 29, 1781–1787 (2007).

Yang, S., Li, G., Li, M. & Wang, J. Transgenic soybean with low phytate content constructed by Agrobacterium transformation and pollen-tube pathway. Euphytica 177, 375–382 (2011).

Bilyeu, K. et al. Quantitative conversion of phytate to inorganic phosphorus in soybean seeds expressing a bacterial phytase. Plant Physiol. 146, 468–477 (2008).

Denbow, D. M. et al. Soybeans transformed with a fungal phytase gene improve phosphorus availability for broilers. Poultry Science 77, 878–881 (1998).

Coello, P. et al. Generation of low phytic acid Arabidopsis seeds expressing an E. coli phytase during embryo development. Seed Sci Res 11, 285–291 (2001).

Short, J. M., Gray, K. A., B.Garrett, J. & O’Donoghue, E. Phytase, nucleic acids encoding them and methods for making and using them. United States patent US7078035B2 (2003).

Zhang, Q., Zhang, W., Lin, C., Xu, X. & Shen, Z. Expression of an Acidothermus cellulolyticus endoglucanase in transgenic rice seeds. Protein Expr. Purif. 82, 279–283 (2012).

Yang, Y. et al. Transgenic rice as bioreactor for production of the Candida antarctica lipase B. Plant Biotechnol. J. 12, 963–970 (2014).

Herrmann, K. R., Ruff, A. J., Infanzón, B. & Schwaneberg, U. Engineered phytases for emerging biotechnological applications beyond animal feeding. Appl. Microbiol. Biotechnol. 103, 6435–6448 (2019).

Hammond, E. G., Johnson, L. A., Su, C., Wang, T. & White, P. J. In Bailey’s Industrial Oil and Fat Products Vol. 2 Major Reference Works (ed. Shahidi, F.) (Wiley-Interscience, 2005).

Johnson, L. A. & Lusas, E. W. Comparison of alternative solvents for oils extraction. J. Am. Oil Chem. Soc. 60, 229–242 (1983).

Vats, P. & Banerjee, U. C. Biochemical characterisation of extracellular phytase (myo-inositol hexakisphosphate phosphohydrolase) from a hyper-producing strain of Aspergillus niger van Teighem. J. Ind. Microbiol. Biotechnol. 32, 141–147 (2005).

Kemper, T. G. In Bailey’s Industrial Oil and Fat Products Vol. 5 Major Reference Works (ed. Shahidi, F.) (Wiley-Interscience, 2005).

Zhao, Q., Liu, M., Tan, M., Gao, J. & Shen, Z. Expression of Cry1Ab and Cry2Ab by a polycistronic transgene with a self-cleavage peptide in rice. Journal 9, e110006, https://doi.org/10.1371/journal.pone.0110006 (2014).

Krebbers, E. et al. Determination of the Processing Sites of an Arabidopsis 2S Albumin and Characterization of the Complete Gene Family. Plant Physiol. 87, 859–866 (1988).

Dellaporta, S. L., Wood, J. & Hicks, J. B. A plant DNA minipreparation: version II. Plant Mol. Biol. Rep. 1, 19–21 (1983).

Paz, M. M., Martinez, J. C., Kalvig, A. B., Fonger, T. M. & Wang, K. Improved cotyledonary node method using an alternative explant derived from mature seed for efficient Agrobacterium-mediated soybean transformation. Plant Cell Reports 25, 206–213 (2006).

Bae, H., Yanke, L., Cheng, K. & Selinger, L. A novel staining method for detecting phytase activity. J. Microbiol. Methods 39, 17–22 (1999).

Thiex, N., Anderson, S. & Gildemeister, B. Crude fat, hexanes extraction, in feed, cereal grain, and forage (Randall/Soxtec/submersion method): Collaborative study. J. AOAC Int. 86, 899–908 (2003).

Cheng, M. & Rosentrater, K. Economic feasibility analysis of soybean oil production by hexane extraction. Ind. Crops Prod. 108, 775–785 (2017).

Serrato, A. Extraction of oil from soybeans. J. Am. Oil Chem. Soc. 58, 157–159 (1981).

Valduga, E., Tonel, E., Tatsch, P., Silva, M. & Treichel, H. Evaluation of process parameters in the industrial scale process of soybean oil extraction using experimental design methodology. J. Food Process Eng. 34, 351–362 (2011).

Acknowledgements

This work was supported by the Grant from the Department of Agriculture of China (2016ZX08010003). We thank Dr. Ting Zheng and Dr. Qing Zhang for kindly making recommendations for experimental design and data analysis. We thank Li Jiang, Xiahui Ding, Hongying Tong, Chun Jiang, Jing Li, Hong Jiang and Mengzhen Tang for the maintenance of plants in greenhouse and in fields.

Author information

Authors and Affiliations

Contributions

Y.Z., C.X. and Z.S. designed the research plan. Y.Z. constructed the plasmids for E. coli expression and soybean transformation. Y.Z. and L.Z. performed the enzyme activity assay and studied the characterization of recombinant phytase. L.Z. performed protein identification in transgenic plants. Y.Z., C.X., C.L. and Z.S. drafted the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhao, Y., Zhu, L., Lin, C. et al. Transgenic soybean expressing a thermostable phytase as substitution for feed additive phytase. Sci Rep 9, 14390 (2019). https://doi.org/10.1038/s41598-019-51033-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-51033-y

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.