Abstract

A novel adsorbent (Fe3O4/HCO) was prepared via co-precipitation from a mix of ferriferrous oxide and a Ce-rich waste industrial sludge recovered from an optical polishing activity. The effect of system parameters including reaction time, pH, dose, temperature as well as initial concentration on the adsorption of Sb(III) were investigated by sequential batch tests. The Sb(III)/Fe3O4/HCO system quickly reached adsorption equilibrium within 2 h, was effective over a wide pH (3–7) and demonstrated excellent removal at a 60 mg/L Sb(III) concentration. Three isothermal adsorption models were assessed to describe the equilibrium data for Sb(III) with Fe3O4/HCO. Compared to the Freundlich and dubinin-radushkevich, the Langmuir isotherm model showed the best fit, with a maximum adsorption capacity of 22.853 mg/g, which exceeds many comparable absorbents. Four kinetic models, Pseudo-first-order, Pseudo-second-order, Elovich and Intra-particle, were used to fit the adsorption process. The analysis showed that the mechanism was pseudo-second-order and chemical adsorption played a dominant role in the adsorption of Sb(III) by Fe3O4/HCO (correlation coefficient R2 = 0.993). Thermodynamic calculations suggest that adsorption of Sb(III) ions was endothermic, spontaneous and a thermodynamically feasible process. The mechanism of the adsorption of Sb(III) on Fe3O4/HCO could be described by the synergistic adsorption of Sb (III) on Fe3O4, FeCe2O4 and hydrous ceric oxide. The Fe3O4/HCO sorbent appears to be an efficient and environment-friendly material for the removal of Sb(III) from wastewater.

Similar content being viewed by others

Introduction

Antimony(Sb) has the properties of both metallic and non-metallic elements1,2, and mainly occurs in the form of Sb(III) and Sb(V) oxides in water1. However, the lower oxidation state of Sb is highly toxic, for example the toxicity of Sb (III) is 10 times that of Sb (V)1. The long-term intake of excess antimony is a serious health risk which could include direct liver and lung damage, damaged the immune system as well as induced cancer. It has subsequently been ranked as one of the high-priority pollutants by USEPA (the US Environmental Protection Agency). The European Union as well as China set 5 μg/L as the maximum allowable concentration of Sb in drinking water, and the USEPA a value of 6 μg/L3,4. However, Sb is also important raw material used for example in flame retardants, alloys, ceramics, and glassware. The wide application of Sb in various industries has resulted in an increase in concentration of Sb in the aquatic environment2,5. In addition, pollution associated with its extraction and refining is excessive and needs to be addressed in some mining areas2,5,6.

Many techniques have been explored for removal of antimony from aqueous systems, including coagulation and precipitation7, solidification8,9, ion-exchange10, membrane separation technology11, and electrochemical deposition12. Among these adsorption technology had received the greatest attention because of a number of advantages, such as relatively low-cost, high-efficiency, simplicity and eco-friendly2,13. Recently, many single adsorbents have been evaluated8,14,15,16. However, there are a number of shortcomings with their application, such as low adsorption capacity and difficulty in separating materials from the aqueous solution when they are saturated2,5,6. As frequently used as adsorbents, iron-based materials combine adsorption properties with useful magnetic properties. This makes the separation of solids from liquid phases straightforward using an external magnetic field and allows for recovery and reuse after regeneration17,18. The advantage of magnetic separation of adsorbents is a more effective approach to solid-liquid separation than normal separation methods such as sedimentation and filtration19,20. Also, magnetic separation is particularly useful when the aqueous solution contains nonmagnetic solid residues as would be found in complex waste water systems19,21,22.

The Fe3O4 adsorbent system has previously been systematically studied as an excellent magnetic material23. However, it has a significant limitation in its lower sorption capacity restricting effective application17. Synthesis of iron-containing bimetal oxides can greatly enhance adsorbent performance by increasing the amount of surface pores, hydroxyl groups, and tunable surface charge2,17,18. Also, earlier studies have found that a Cerium-doped Fe3O4 magnetic adsorbent tends to have high affinity surface hydroxyl groups and very promising adsorption capacity17,24,25,26. And is considered to be an excellent adsorbent for antimony removal17,27. However, cerium is a rare metal widely used in modern devices and is expensive, limiting its application in adsorption systems. The polishing sludge identified, is particularly rich in condensed Cerium (Ce), mostly as hydrous ceric oxide (HCO: CeO2·nH2O, also known as cerium hydroxide), and is a common component in chemical mechanical polishing (CMP) process wastewaters treatment by product, appearing also as a residue from the liquid crystal display (LCD) industry. China produces more than 5.0 × 104 tons a year according to incomplete statistics. The preparation of the sorbent using Fe3O4 and the Ce-rich waste, whilst adding additional synthesis steps, uses lower amount of Ce than Cerium-doped Fe3O4 magnetic adsorbent reported in previous research17,28. In addition the sludge is stable and can be produced in a range of particle sizes29. The preparation of a successful sorbent based on Fe3O4/HCO also contributes to the aims of the “2030 Agenda for Sustainable Development”, by reducing the generation of waste residues through recycling and the efficient use of secondary resources2. Additionally, the preparation and optimization of Fe3O4/polishing sludge adsorbent seem to be a key-role to control the removal efficiency of antimony by adsorption. To the best of our knowledge, the mechanism for antimony adsorption by Cerium-doped Fe3O4 magnetic adsorbent is unclear17,27.

In this work, we focus on: (1) synthesis of Fe3O4/HCO by a modified coprecipitation method, and subsequent detailed characterization; (2) sorption of aqueous Sb(III) by Fe3O4/HCO and evaluation of capacity and the effects of pH, reaction time, the amount of adsorbent, reaction temperature and initial concentration; (3) tests of models of isothermal adsorption, reaction kinetics and thermodynamics leading to proposals for the mechanism for the adsorption of Sb(III) on Fe3O4/HCO. We believe this is the first report of the successful preparation of iron-based adsorbents with polishing sludge and its initial application addressing a pressing environmental issue of Sb(III) contamination.

Experimental

Synthesis and characterization of Fe3O4/HCO adsorbent

Polishing sludge material was collected from the wastewater treatment plant of Lansi Technology (Hunan) Co., Ltd. The air-dried bulk analysis (w/w) was: moisture content of sludge is 80.5%, and the other main components are cerium oxide (7.8%), silicon dioxide (4.5%), aluminium oxide (3.8%), calcium oxide (2.8%) and other material (0.6%).

The Fe3O4/HCO adsorbent was prepared using the following modified coprecipitation method17,30. Firstly, a 1000-ml three-necked flask was purged with nitrogen for 10 min and 10 g air dried polishing sludge was added followed by 50 ml of an aqueous solution containing 5.56 g FeSO4·7H2O and 50 ml of an aqueous solution with 10.8 g FeCl3. Secondly, the flask was placed in a water bath at 60 °C and 200 ml 7% aqueous ammonia solution slowly added whilst being agitated at 350 rpm. Thirdly, after continuous stirring for 2 h under the nitrogen atmosphere, the resulting slurry was separated by rapid centrifugation, decanted and washed with deionized water and ethanol followed by drying at 80 °C for 24 h. Finally, the dry mixture was ground into fine powder with a mortar and pestle to pass a 100-mesh sieve, and then used for Sb(III) removal studies.

Particle morphology and crystallinity of Fe3O4/HCO were characterized using scanning electron microscope (SEM, JSM-6380LV, JEOL Ltd.) and X-ray diffraction (XRD) patterns (D8 Advance, Brook AXS Ltd., Germany). Elements on the surface of Fe3O4/HCO were analyzed using Energy Dispersive Spectrometer (EDS) (Bruker XFlash 5010, Germany). The XRD was used to identify compounds present in the solid sorbent before and after adsorption of Sb(III). X-ray photo-electron spectroscopy (XPS) spectra focused on Ce, Fe and Sb sorbed onto the Fe3O4/HCO using a PHI 5000 Versa probe system (Thermo Scientific: Esala 250Xi). All the binding energies were associated with the C 1s peak at 285.1 eV and XPS peak fit version 4.1 was used to analyze the spectral data. N2 adsorption-desorption isotherms were used to test the surface area and the pore structures of Fe3O4/HCO. The specific surface area, pore volume as well as pore diameter of Fe3O4/HCO were measured by N2 adsorption at 77 K using a QuadraSorb Station 1 Instruments (Anton Paar GmbH).

Adsorption experiments

The influence of experimental variables on the adsorption isotherm and kinetics were assessed using a sequential batch test. Aliquots of concentrated Sb(III) solution and diluted with deionized water were added to a 500-ml Erlenmeyer flask to a total volume of 200 ml and 0.80 g Fe3O4/HCO was then added to the mixture and pH was adjusted using either 0.1 mol/L HCl or 0.1 mol/L NaOH solution. Adsorption was conducted at 150 rpm at temperature of 25 °C. After the reaction reached equilibrium, samples were filtered (0.45μm filter), and the concentration of Sb(III) determined in solution using hydride generation atomic fluorescence spectrometry (see below). All experiments were completed in triplicate and the adsorption tests were performed in the dark31. The effects of variation in pH (2–9), adsorbent dose (2.0–12.0 g/L), reaction time (2–24 h) as well as temperature (20, 25 and 30 °C) on Sb(III) removal were investigated.

For sorption isotherm experiments, 0.4 g of Fe3O4/HCO adsorbent was added to 100 mL Sb(III) solution (concentration range 10 to 200 mg/L). The initial pH of Sb(III) solution was 7.0 ± 0.1. After shaking at 150 rpm for 4 h, the residual Sb concentration in water was mensurated as above. All experiments were completed in triplicate at three temperatures (20 °C, 25 °C and 30 °C). Langmuir, Freundlich as well as Dubinin-Radushkevich (D-R) model (Eqs (S1–S5)) were used to fit to the Sb(III) adsorption data.

For the sorption kinetics experiments, 0.4 g portions of Fe3O4/HCO were added to 100 mL of 10, 50 100 mg/L Sb(III) solution. The initial pH of Sb(III) solution was 7.0 ± 0.1. The mixtures were shaken at 150 rpm at temperature of 25 °C. Subsequently 4 ml samples were taken at the following time intervals (10, 20, 30, 40, 50, 60, 90, 120, 150, 240, and 360 min) and the residual Sb concentration in solution determined. The method for the calculation of adsorption capacity is shown in Eq. (1).

In which q (mg/g) is the adsorption capacity; ci (mg/L) and ce (mg/L) are the ion concentrations of the solution before and after the reaction, respectively; V (mL) is the volume of the solution; M (g) is the adsorbent mass used during the reaction process. In order to analyse the adsorption mechanism, four classic kinetic models, named as the Pseudo-first-order model, Pseudo-second-order model, Elovich model and Intra-particle diffusion model30,32,33 (Eqs (S6–S9)), were used to test fit to the experimental data.

Reagents and analytical methods

A quantity of antimony potassium tartrate was weighed and dissolved in deionized water to prepare antimony standard bulk solution of 1.0 g/L Sb (III). Experimental Sb solutions were obtained by appropriate dilution. The reagents used in the experiment are analytical or superior grade reagents, and the experimental water was deionized water.

Hydride generation atomic fluorescence spectrometry was utilized to determine the concentrations of antimony (III), following the method of Leuz A et al.34. The detection limit of this method was 1 μg/L. All samples were measured within 24 h after the adsorption experiment, and deionized water was used for the blank. The Sb(III) recovery using this test was over 90.0% and analytical error on Sb determination was <1%.

Results and Discussion

Characterization of Fe3O4/HCO

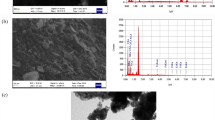

The SEM-EDS characterization of Fe3O4/HCO shows that the surface was rough and irregular shapes from spherical (Fig. 1a). This suggested that amorphous substances were precipitated on the surface and the doping of the polishing sludge hampered the precipitation during the synthesis and changed the form of the desired products17. As shown in the Fig. 1b, the chemical composition of the Fe3O4/HCO adsorbent from EDS were O (35.32%), Fe (23.01%), Ce (14.55%), Si (15.24%), Al (8.44%) and Cl (3.44%), suggesting that the main components of the adsorbent are Fe and Ce oxides. In our study, the Ce/(Fe + Ce) molar ratio of Fe3O4/HCO was only about 0.20, which influences the surface area (SBET) and adsorption performance of Fe3O4/HCO17,26. This is slightly lower than the theoretical value (0.26) and the average reported values (about 0.23) by Qi et al.17 and Zhang et al.26. Further work is needed to evaluate the potential to synthese Fe3O4/HCO with higher Ce/(Fe + Ce) molar ratio.

The detailed XRD characterization of the sorbent is given in the supplementary data (Fig. S1). Ce and Fe and mixed oxide phases are identified. The peaks were observed at 2θ = 26.62°, 28.06°, 33.11°, 47.49°, and 56.40°, represent reflections from the (220), (311), (400), (511), and (440) planes, is different from other studies17. Qi17 et al. found that the doping CeIII does not modify the original spinel structure of Fe3O4. The most probable reason for the deviation here is that the raw materials we used (particularly the sludge derived HCO) are different. The Fe3O4/HCO product contains discrete phases of Fe3O4, HCO and FeCe2O4, indicating a complex reaction between Fe3O4 and HCO occurred during the preparation. According to the structural characteristics of Fe3O4 and HCO, we speculated that FeCe2O4 could be synthesized from Fe3O4 and HCO by a double decomposition reaction (Fe3O4 + HCO + OH− → FeCe2O4 + H2O) under the alkaline conditions during the preparation of the adsorbent. The synthesis of FeCe2O4 might play a major role in the adsorption of Sb(III) and its identification is an important innovation in this study.

The specific surface area (SBET) and pore volume of the Fe3O4/HCO was found to be 83.496 m2/g and 0.098 cm3/g, respectively. It was three times greater than the original Fe3O4 (SBET 28.0 m2/g) and was much larger than hydrated ferric oxides supported by polymeric anion exchange35, indicating that the new sorbent has a significantly higher accessible surface area for adsorption of Sb(III).

Effect of pH, react time, amount of adsorbent, temperature and initial concentration

The pH and point of zero charge (pHpzc) are the most important parameters affecting Sb removal efficiency in adsorption technology6,29. As shown in Fig. 2, the removal of Sb(III) by Fe3O4/HCO varies with pH. The rate of Sb(III) removal initially increased in our experiment before decreasing as pH increased from 2 to 9, but only slightly changed (90.00–91.98%) over the pH 3 to 7 range. This was identified as optimal pH for Fe3O4/HCO to adsorb Sb(III). The measured zeta potentials of the Fe3O4/HCO suspensions was about 6.8, which was consistent with the literature results17. When the pH is 2, Sb(III) exists in the form of Sb(OH)2+ 1, competing with H+ and Sb(OH)2+ 29 which reduced the removal efficiency Sb(III). Across a pH range from 2 to 9, Sb(III) is predominantly in the form of [H3SbO3] or Sb(OH)3 1 which can result in the precipitation of Fe-Sb(III)36 and CeSbO3 37 with Fe3O4/HCO to enable a higher rate of Sb(III) removal. It was obvious that pH is close to the pHpzc and makes the adsorbent surface uncharged and attracts the neutral Sb(OH)3. When pH > 9, oxidation of Sb(III) is enhanced34, and the increase in pH can inhibit the production of iron oxyhydroxide and the solubility of iron ions18, resulting in a decrease in the removal efficiency for Sb(III). These findings are consistent with those of Fan et al.29. Compared with other iron-based adsorbents38,39 (shown in Table 1), the adsorption of Sb(III) onto Fe3O4/HCO can occur over a wide pH, which introduces versatility and enhances potential application.

The effect of reaction time on Sb(III) removal from water (Fig. 3a) suggests a two steps process: a fast stage from 0 to 2 h and a slow stage after 2 h. The reason for this is likely to be that initially surface adsorption takes place between 0–2 h. As the adsorption continues the binding sites on the adsorbent surface are saturated, therefore subsequent adsorption is by internal diffusion stage40 which reduced the rate of adsorption. The adsorption equilibrium time (2 h) of Fe3O4/HCO for removal Sb(III) is much less than that of many iron-loaded adsorbents, such as hematite coated magnetic nanoparticles41, iron (III) loaded orange peel residue42, and quartz sand loaded iron oxide21. The reaction equilibrium time of the subsequent experiments in this study was set to 2 h43.

Results for the effect of Fe3O4/HCO loading on Sb(III) removal (Fig. 3b) showed removal rates to increase from 89.68% to 92.75% with Fe3O4/HCO dosing from 2 g/L to 4 g/L. As the dose of Fe3O4/HCO rose to 12 g/L, the removal of Sb(III) slowly increased to 94.64%. This result indicates that Fe3O4/HCO loading has only a slight impact on the removal of Sb(III) when the addition of Fe3O4/HCO exceeds 4.0 g/L, a finding consistent with previous results of Sun,et al.32,44. As the adsorbent dosage increases, its surface can provide more functional groups and adsorption sites to enhance removal rate of Sb(III)18, while Sb(III) removal would not be improved when the adsorption equilibrium was reached. This indicates that an optimal dosage can be determined when other conditions remain stable18. Therefore, considering the cost of the adsorbent and the removal efficiency of Sb(III), the optimum loading of Fe3O4/HCO in our study was 4.0 g/L, this being less than that of iron (III) loaded orange peel residue (5 g/L)42, iron (III) and zirconium (IV) loaded orange peel residue (5 g/L)42 and composite material of biomorphic Fe2O3/Fe3O4/C with eucalyptus(10 g/L)45. This has positive practical application.

The effect of temperature shows a modest increase in sorption with increasing temperature. As shown in Fig. 3c, the removal of Sb(III) by Fe3O4/HCO adsorbent was 92.18%, 93.41% and 94.32% at 20 °C, 25 °C and 30 °C, respectively. The finding is consistent with studies of Sb(III) removal using ferric salts or ferric salt modified adsorbents18,32. Due to an endothermic reaction occurring when metal ions were adsorbed by the iron matrix, adsorption and removal efficiency, adsorption capacity and adsorption rate of most iron-based inorganic adsorbents will improve with an increase in temperature35. By taking operating costs into account, the optimal reaction temperature for this study was 25 °C.

As shown in Fig. 3d, an initial increase in concentration of Sb(III) from 10 mg/L to 60 mg/L resulted in a decrease in the removal of Sb(III) from 95.08% to 91.39%. When concentration increased to 200 mg/L, a significant decreased of Sb(III) removal to 51.10% was observed. This identifies good operating conditions at Sb(III) concentrations less than 60 mg/L. In addition, when the initial concentration of Sb(III) ranged from 150 mg/L to 200 mg/L, the adsorption sites on the Fe3O4/HCO sorbent were saturated when the initial concentration of Sb(III) was 200 mg/L29.

A comparison of the adsorption capacity of different iron-loaded composites for Sb(III) from water is shown in Table 1. The adsorption capacity of Fe3O4/HCO synthesized in this study is lower than the values of some adsorbents, such as Ce-doped(0.5)17, hematite coated magnetic nanoparticles41, iron (III) loaded orange peel residue42, and iron (III) and zirconium (IV) loaded orange peel residue42. However, it is significantly higher than a number of other adsorbents, for instance, ferric chloride modified sand21 and iron oxide loaded carbon nanotubes46. Also, the equilibrium time for Sb(III) adsorption Fe3O4/HCO for was only 2 h, considerably shorter than many other adsorbents.

Adsorption isotherms

Model definition and accuracy of fit for the isothermal adsorption model is related to the type of adsorbent, the valence state of the Sb ion, the initial concentration, pH, and a number of other factors18,29,32. The results for the fit to Langmuir, Freundlich and D-R model are shown in the Fig. 4. The parameters of the three adsorption isotherm models are listed in the Table 2.

As shown in Fig. 4a, the linear relationship between Ce/qe and Ce at 20 °C, 25 °C and 30 °C indicates that the Langmuir model has strong fit at each temperature (R2 > 0.99). The maximum adsorption capacity and b value for Sb(III) at 25 °C were 23.171 mg/g and 0.209 L/mg, respectively.

As shown in Fig. 4b, a linear relationship between lg(Ce) and lg(qe) for the Freundlich model at 20 °C, 25 °C and 30 °C was a slightly poorer fit (R2 > 0.82). The values of Kf as well as 1⁄n are related to the adsorbent, adsorption mechanism and reaction temperature, which can be calculated by the relationship between lg(Ce) and lg(qe). The isothermal adsorption form can be determined according to the value of 1⁄n31. At 25 °C the Kf and 1⁄n was 5.108 and 0.387, respectively. As the value of 1⁄n was less than 0.5, which indicated that Sb(III) was easily adsorbed by Fe3O4/HCO32. This is also illustrated that Fe3O4/HCO is an excellent adsorbent for adsorbing antimony.

The linear relationship between qe and ε2 of the D-R model at 20 °C, 25 °C and 30 °C are shown in Fig. 4c. The value of qs and β values at 25 °C was 80.743 mg/g and 3.335E−9 mol2/KJ2, respectively. In addition the average adsorption energy E (kJ/mol), which could be determined from the D-R model, is the free energy change as one mole of ions transfers from the solution to the sorbent surface47. Using Eq. (S4), E ranged from 113.283 to 138.145 kJ/mol at 20–30 °C. According to the scale of the force and the E value between the adsorbed substance and the adsorbent, the adsorption process can be classified as physical adsorption (1 kJ/mol ≤ E ≤ 8 kJ/mol), ion exchange (9 kJ/mol ≤ E ≤ 16 kJ/mol) as well as chemical adsorption (E > 16 kJ/mol)48. Therefore, the adsorption of Sb(III) to Fe3O4/HCO was a chemisorption process29, which is also consistent with the conclusions by Deng et al. for adsorption of Sb(III) using Fe(III)-modified humus sludge32.

In summary, the Langmuir model has the best fit (R2 > 0.99) for the removal of Sb(III) by Fe3O4/HCO. This is consistent with the adsorption of Sb(III) by iron-based matrices18,29,30,32. We conclude that sorption reactions take place on the surface of iron-based adsorbents, as monolayer adsorption29. The Langmuir model obtained the maximum adsorption capacity of Fe3O4/HCO for removing Sb(III) (up to 23.171 mg/g at 25 °C), higher than many iron-based adsorptive substrates21,46. All of the 1/n values was determined using the Freundlich model were less than 0.5, indicating that Sb(III) in an aqueous solution is readily adsorbed by Fe3O4/HCO32. Results for the D-R model further indicate that Sb(III) adsorption by Fe3O4/HCO is a chemisorption process41.

Adsorption kinetics

The adsorption kinetics model can describe the potential rate of control and adsorption mechanism of material transfer and chemical reactions during the adsorption process. Adsorption kinetics are dominated by the physical as well as chemical properties of the adsorbent in the adsorption process of the adsorbent11. In this study, Pseudo-first-order, Pseudo-second-order, Elovich and Intra-particle diffusion models are used to analyze the kinetic characteristics of Fe3O4/HCO adsorption to remove Sb(III)30,32,33. As shown in Fig. 5a and Table 3, although a high correlation coefficient (R2 = 0.971) was recorded for the Pseudo-first-order model curve, the fitting of the curve tail was poor, indicating that the Pseudo-first-order model is not an appropriate simulation for Sb(III) adsorption onto Fe3O4/HCO. However, the Pseudo-second-order model showed the strongest fit with the experimental data (R2 = 0.993) in all adsorption kinetics. In addition, there is little difference between the theoretical value of qe(23.145 mg/g) and the experimental value (21.396 mg/g). Therefore, it is proposed that the kinetics of adsorption of Sb(III) by Fe3O4/HCO can be more accurately described by the Pseudo-second-order model32.

In addition, results for the fit to the curve between qt and lnt (Fig. 5a) and the calculated parameters (Table 3) highlight that Elovich model also has a good fit with the experimental data (R2 = 0.992)31.

The intra-particle diffusion model describes the diffusion relationship between the adsorbate and the pores of the adsorbent29,49. As shown in Fig. 5b, the fit of the plots of qt and t0.5 can be divided into two steps, including a fast initial and slow later adsorption stages. The difference between the slopes of the first and second phases, indicate that a gradual phase exists in which the surface adsorption process is controlled by thickness of the boundary layer. The two intercepts (α1, α2) represent the thickness of the theoretical boundary layer of the two stages. As shown in Table 3, the significant difference between α1(−0.139) and α2(10.176) demonstrates that the pore diffusion rate is not a unique control process. Therefore, the adsorption rate of Sb(III) by Fe3O4/HCO is determined by the boundary layer effect and the external mass transfer effect29,31.

Thermodynamic studies

Gibbs free energy ΔG° (kJ/mol), standard enthalpy change ΔH° (kJ/mol) as well as standard entropy change ΔS° (J/(mol.k)) are the main parameter of adsorption thermodynamics. In the study, Eqs (2) and (3) were used to calculate the ΔG°, ΔH0 and ΔS0 for Sb(III) adsorption onto Fe3O4/HCO at 20 °C, 25 °C as well as 30 °C (Table 4). Adsorption properties were also investigated, as well as its spontaneity.

In which R is the molar constant, 8.314 J/(mol.k); T is the absolute temperature, K; K0 is the equilibrium constant of adsorption thermodynamics. K0 can acquire according to the method stated by Zheng47 and the Freundlich equation was used to fit the parameters to calculate K0, namely, K0 = Kf.

As shown in Table 4, the value of K0 increased (from 4.062 to 5.183) as temperature increased (from 293.15 K to 303.15 K), suggesting that the adsorption process of Sb(III) on Fe3O4/HCO was an endothermic reaction50. The values of ΔG0 at 293.15 K, 298.15 K and 303.15 K were −3.183 kJ/mol, −3.704 kJ/mol and −3.736 kJ/mol, respectively. All ΔG0 less than 0 indicates that adsorption of Sb(III) on Fe3O4/HCO was a spontaneous process50. Furthermore, the decrease of ΔG0 with temperature increasing implied that the degree of spontaneous adsorption could be enhanced with increasing temperature. The values of ΔH0 and ΔS0 were 33.427 kJ/mol and 11.75 J/(mol.k), respectively. ΔH0 > 0 further indicates that the adsorption process is endothermic. ΔS0 > 0 demonstrates which adsorption occurred on the surface of the Fe3O4/HCO adsorbent as a process of random improvement on the solid-liquid surface, and the arrangement of the adsorbed Sb(III) on the surface of Fe3O4/HCO was chaotic, probably owing to the release of water molecules from hydrated Sb(III)33.

Desorption

In this study, desorption of the adsorbed Sb(III) ions from sorbent was also studied in a series of batch experiments. The efficiencies of the different eluents are shown in Table 5. Compared with HCl and NaOH, the repetitive adsorption rate of Fe3O4/HCO to Sb(III) ions after EDTA and water repeatedly desorption was very low. In a 2 cycle adsorption-desorption process, after desorption by EDTA and pure water, the removal rate of Fe3O4/HCO to Sb(III) ions decreased to less than 80%(65.27% and 78.21%). After 3 and 4 cycles of adsorption-desorption process with HCl and NaOH desorption, the removal of Sb(III) ions by Fe3O4/HCO is still close to 80%(79.91% and 79.22%). Compared to HCl, NaOH is cheaper and safer. Thus NaOH solution was used as a desorption agent. Sb(III) ions desorption from Fe3O4/HCO created the removal process economical both adsorbent and Sb(III) ions were regenerated and recycled effectively.

Adsorption mechanism

From the characterization of before and after the adsorption of Sb on the Fe3O4/HCO, the mechanisms proposed for the Sb(III) adsorption on Fe3O4/HCO are illustrated in Fig. 6. The possible reactions in the adsorption process are speculated as Eqs (4)~(8). And the preferred adsorption mechanisms between Sb(III) and Fe3O4/HCO was concluded as following:

-

1.

Adsorption of Sb by Fe3O4. Firstly, the Fe3O4/HCO may hydrolyze iron octahedron, inner sphere complexes and other spherical complexes36. Subsequently, Sb(III) can preferentially interact with the A-type hydroxyl group of iron octahedron in Fe3O4 to form a monodentate mononuclear, monodentate dinuclear or bidentate dinuclear ligand via the aforementioned ligand-exchange reaction20,51 (Fig. 6a). In addition, Sb(III) may be adsorbed by the inner sphere complex of Fe3O4 and other spherical complexes36 (Eq. (4)).

-

2.

Adsorption of Sb by HCO. When the pH of aqueous solution is 6.7, HCO is a hydrated metal oxide with zero surface charge. The XRD diffraction pattern (Fig. S2) confirms that the compound CeSbO3 exists in the residual precipitate after adsorption. Therefore, the second reaction mechanism of Fe3O4/HCO adsorbing Sb(III) is speculated as shown in Fig. 6b. CeSbO3 was synthesized by the reaction of HCO with H3SbO3(HCO + H3SbO3 → CeSbO3↓ + H2O), and the main mechanism of HCO adsorbing anions in water is the exchange reaction of anionic ligands37 (Eq. (5)).

-

3.

FeCe2O4 was used to hydrolyze HCO and FeOOH, and then they reacted with Sb (III). In the preparation of Fe3O4/HCO, two Ce3+ ion replaced Fe3+ at octahedral sites in a lattice structure (Fe3O4 + HCO + OH− = FeCe2O4 + H2O). FeCe2O4 was hydrolyzed in aqueous solution, and electron and ion was transferred occurred between phase interface and aqueous solution, forming a double-electron layer structure. This results in the in situ formation of an amorphous hydrated iron oxide which has a larger specific surface area19. Ligand exchange as well as adsorption of Sb (III) occurred on the iron oxide film (Eqs (6)~(7)).

-

4.

From other studies, it can be concluded that Ce(IV) itself being a good oxidizing agent (Ce4+/Ce3+ = 1.72) in acidic medium27. As shown in the Fig. S4, Ce(IV) can oxidizes the surface sorbed Sb(III) to Sb (V) (Eq. (8)), It is basically consistent with the Sb 3d XPS Spectra. And Ce(IV) itself getting reduced to Ce3+ according to the underlying redox reaction.

Conclusion

Results from our study indicate that Fe3O4/HCO is a novel efficient and environment-friendly sorbent for removal the Sb(III) from wastewater. The pH, adsorbent loading, temperature and initial concentration of the Sb(III) solution all effect the adsorbent ability of Fe3O4/HCO. When pH was between 3–7, Sb(III) was readily removed from the solution. The maximum adsorption capacity for Fe3O4/HCO adsorbing Sb(III) was 22.8534 mg/g. Compared with the Freundlich as well as D-R models, the Langmuir model had a highest fitting accuracy for Sb(III) adsorption to Fe3O4/HCO. After fitting the adsorption data with different kinetic models, the Pseudo second-order model is most suitable. The ΔG0 and ΔH0 values indicate that the adsorption of Sb(III) by Fe3O4/HCO is a spontaneous endothermic process. The ΔS0 > 0 indicates an increase in entropy during adsorption. The mechanism of the adsorption of Sb(III) on Fe3O4/HCO can be defined by synergistic adsorption onto discrete Fe3O4, FeCe2O4 and HCO phases.

References

Filella, M., Belzile, N. & Chen, Y. Antimony in the Environment: A Review Focused On Natural Waters: II. Relevant Solution Chemistry. Earth-Sci. Rev. 59, 265–285 (2002).

Ungureanu, G., Santos, S., Boaventura, R. & Botelho, C. Arsenic and Antimony in Water and Wastewater: Overview of Removal Techniques with Special Reference to Latest Advances in Adsorption. J. Environ. Manage. 151, 326–342 (2015).

Communities, C. O. T. E. Council Directive Relating to the Quality of Water Intended for Human Consumption. J European Communities. 229 (1980).

Kang, M., Kamei, T. & Magara, Y. Comparing Polyaluminum Chloride and Ferric Chloride for Antimony Removal. Water Res. 37, 4171–4179 (2003).

He, M., Wang, X., Wu, F. & Fu, Z. Antimony Pollution in China. Sci. Total Environ. 421–422, 41–50 (2012).

Li, J. et al. Antimony Contamination, Consequences and Removal Techniques: A Review. Ecotox. Environ. Safe. 156, 125–134 (2018).

Nakashima, S., Sturgeon, R. E., Willie, S. N. & Berman, S. S. Determination of Trace Elements in Sea Water by Graphite-Furnace Atomic Absorption Spectrometry After Preconcentration by Tetrahydroborate Reductive Precipitation. Anal. Chim. Acta. 207, 291–299 (1988).

Mendil, D., Bardak, H., Tuzen, M. & Soylak, M. Selective Speciation of Inorganic Antimony On Tetraethylenepentamine Bonded Silica Gel Column and its Determination by Graphite Furnace Atomic Absorption Spectrometry. Talanta. 107, 162–166 (2013).

Yang, R. et al. Characteristics of Fulvic Acid During Coprecipitation and Adsorption to Iron Oxides-Copper Aqueous System. J. Mol. Liq. 274, 664–672 (2019).

Wu, F., Sun, F., Wu, S., Yan, Y. & Xing, B. Removal of antimony(III) From Aqueous Solution by Freshwater Cyanobacteria Microcystis Biomass. Chem. Eng. J. 183, 172–179 (2012).

Naiya, T. K., Bhattacharya, A. K. & Das, S. K. Adsorption of Cd(II) and Pb(II) From Aqueous Solutions On Activated Alumina. J. Colloid Interf. Sci. 333, 14–26 (2009).

Bergmann, M. E. H. & Koparal, A. S. Electrochemical Antimony Removal From Accumulator Acid: Results From Removal Trials in Laboratory Cells. J. Hazard. Mater. 196, 59–65 (2011).

Tang, C. et al. New Insights Into the Interaction Between Heavy Metals and Struvite: Struvite as Platform for Heterogeneous Nucleation of Heavy Metal Hydroxide. Chem. Eng. J. 365, 60–69 (2019).

Huang, M. et al. Application Potential of Biochar in Environment: Insight From Degradation of Biochar-Derived DOM and Complexation of DOM with Heavy Metals. Sci. Total Environ. 646, 220–228 (2019).

Navarro, P. & Alguacil, F. J. Adsorption of Antimony and Arsenic From a Copper Electrorefining Solution Onto Activated Carbon. Hydrometallurgy. 66, 101–105 (2002).

Xu, W., Wang, H., Liu, R., Zhao, X. & Qu, J. The Mechanism of antimony(III) Removal and its Reactions On the Surfaces of Fe-Mn Binary Oxide. J. Colloid Interf. Sci. 363, 320–326 (2011).

Qi, Z., Joshi, T. P., Liu, R., Liu, H. & Qu, J. Synthesis of Ce(III)-doped Fe3O4 Magnetic Particles for Efficient Removal of Antimony From Aqueous Solution. J. Hazard. Mater. 329, 193–204 (2017).

Deng, R. J., Jin, C. S., Ren, B. Z. & Hou, B. L. The Potential for the Treatment of Antimony-Containing Wastewater by Iron-Based Adsorbents. Water-Sui. 9, 794 (2017).

Sheng, T. Adsorption Activity of Low Concentration Arsenic On Amended Honeycomb cinder/Fe3O4 Composite: Zhe Jiang University (2014).

Mittal, V. K., Bera, S., Narasimhan, S. V. & Velmurugan, S. Adsorption Behavior of antimony(III) Oxyanions On Magnetite Surface in Aqueous Organic Acid Environment. Appl. Surf. Sci. 266, 272–279 (2013).

Xu, G., Shi, Z. & Deng, J. Removal of Antmony From Water by Iron-Oxide Coated Sand. Environ. Chem. 481–484 (2006).

Chmielewská, E. et al. Structure Investigation of nano-FeO(OH) Modified Clinoptilolite Tuff for Antimony Removal. Micropor. Mesopor. Mat. 248, 222–233 (2017).

Wang, H. et al. Highly-Dispersed Fe2O3@C Electrode Materials for Pb2+ Removal by Capacitive Deionization. Carbon. 153, 12–20 (2019).

Zhang, Y., Yang, M., Dou, X., He, H. & Wang, D. Arsenate Adsorption On an Fe-Ce Bimetal Oxide Adsorbent: Role of Surface Properties. Environ. Sci. Technol. 39, 7246–7253 (2005).

Chen, B., Zhu, Z., Guo, Y., Qiu, Y. & Zhao, J. Facile Synthesis of Mesoporous Ce-Fe Bimetal Oxide and its Enhanced Adsorption of Arsenate From Aqueous Solutions. J. Colloid Interf. Sci. 398, 142–151 (2013).

Zhang, Y. et al. Removal of Arsenic by a Granular Fe-Ce Oxide Adsorbent: Fabrication Conditions and Performance. Chem. Eng. J. 162, 164–170 (2010).

Wang, L. et al. Synthesis of Ce-doped Magnetic Biochar for Effective Sb(V) Removal: Performance and Mechanism. Powder Technol. 345, 501–508 (2019).

Deng, Q. et al. Co-Exposure to Metals and Polycyclic Aromatic Hydrocarbons, microRNA Expression, and Early Health Damage in Coke Oven Workers. Environ. Int. 122, 369–380 (2019).

Fan, H. et al. Adsorption of antimony(III) From Aqueous Solution by Mercapto-Functionalized Silica-Supported Organic-Inorganic Hybrid Sorbent: Mechanism Insights. Chem. Eng. J. 286, 128–138 (2016).

Li, Y., Geng, B. & Hu, X. Preparation and Characterization of Iron-Copper Binary Oxide and its Effective Removal of antimony(III) From Aqueous Solution. Water Science & Technology. 74, 393–401 (2016).

Zhao, Z., Wang, X., Zhao, C., Zhu, X. & Du, S. Adsorption and Desorption of Antimony Acetate On Sodium Montmorillonite. Journal of Colloid & Interface Science. 345, 154–159 (2010).

Deng, R. et al. Adsorption of Antimony(III) onto Fe(III)-Treated Humus Sludge Adsorbent: Behaviorand Mechanism Insights. Pol. J. Environ. Stud (2018).

Markovski, J. S. et al. Arsenate Adsorption On Waste Eggshell Modified by Goethite, α-MnO2 and goethite/α-MnO2. Chem. Eng. J. 237, 430–442 (2014).

Leuz, A., Mönch, H. & Johnson, C. A. Sorption of Sb(III) and Sb(V) to Goethite: Influence on Sb(III) Oxidation and Mobilization†. Environ. Sci. Technol. 40, 7277–7282 (2006).

Miao, Y. et al. Antimony(V) Removal From Water by Hydrated Ferric Oxides Supported by Calcite Sand and Polymeric Anion Exchanger. J. Environ. Sci.-China. 26, 307–314 (2014).

Farquhar, M. L., Charnock, J. M., Livens, F. R. & Vaughan, D. J. Mechanisms of Arsenic Uptake From Aqueous Solution by Interaction with Goethite, Lepidocrocite, Mackinawite, and Pyrite: An X-ray Absorption Spectroscopy Study. Environ. Sci. Technol. 36, 1757 (2002).

Hayes, K. F., Papelis, C. & Leckie, J. O. Modeling Ionic Strength Effects On Anion Adsorption at Hydrous Oxide/Solution Interfaces. Journal of Colloid & Interface Science. 115, 564–572 (1987).

Yang, X. Study On Adsorption of Antimony (III) From Aqueous Solution Using Graphene Oxide and It’S Magnetite Composites: Hunan University (2015).

Xiaohui, W., Tingchao, Y. & Cong, L. The Adsorption of Sb(iii) in Aqueous by KMnO4-modified Activated Carbon. Journal of Zhejiang University (Engineering Science). 2028–2034 (2012).

Babu, B. V. & Gupta, S. Adsorption of Cr(VI) Using Activated Neem Leaves: Kinetic Studies. Adsorption. 14, 85–92 (2008).

Shan, C., Ma, Z. & Tong, M. Efficient Removal of Trace antimony(III) through Adsorption by Hematite Modified Magnetic Nanoparticles. J. Hazard. Mater. 268, 229–236 (2014).

Biswas, B. K., Inoue, J., Kawakita, H., Ohto, K. & Inoue, K. Effective Removal and Recovery of Antimony Using Metal-Loaded Saponified Orange Waste. J. Hazard. Mater. 172, 721–728 (2009).

Saleh, T. A. Isotherm, Kinetic, and Thermodynamic Studies On Hg(II) Adsorption From Aqueous Solution by Silica- Multiwall Carbon Nanotubes. Environmental Science & Pollution Research International. 22, 16721–16731 (2015).

Sun, X. et al. Sorption and Detoxification of chromium(VI) by Aerobic Granules Functionalized with Polyethylenimine. Water Res. 44, 2517–2524 (2010).

Wei, W., Zhu, Z., Zhu, Y., Qing, H. & Liang, N. Adsorption of Sb(III) From Aqueous Solution by the Porous Biomorph-Genetic Composite of Fe2O3-Fe3O4/C Prepared with Eucalyptus Wood Template. Technology of Water Treatment. 69–72 (2013).

Zeng, C., Yu, T. & Wang, X. Adsorption of Sb(iii) in Aqueous by MnO2-modified Carbon Nanotubes. Journal of Zhejiang University(Engineering Science). 1951–1957 (2013).

Zheng, H. et al. Equilibrium, Kinetic and Thermodynamic Studies On the Sorption of 4-Hydroxyphenol On Cr-bentonite. Chem. Eng. J. 143, 117–123 (2008).

Vasiliu, S., Bunia, I., Racovita, S. & Neagu, V. Adsorption of Cefotaxime Sodium Salt On Polymer Coated Ion Exchange Resin Microparticles: Kinetics, Equilibrium and Thermodynamic Studies. Carbohyd. Polym. 85, 376–387 (2011).

Liu, W., Zhang, J., Jin, Y., Zhao, X. & Cai, Z. Adsorption of Pb(II), Cd(II) and Zn(II) by Extracellular Polymeric Substances Extracted From Aerobic Granular Sludge: Efficiency of Protein. Journal of Environmental Chemical Engineering. 3, 1223–1232 (2015).

Naiya, T. K., Bhattacharya, A. K., Mandal, S. & Das, S. K. The Sorption of lead(II) Ions On Rice Husk Ash. J. Hazard. Mater. 163, 1254–1264 (2009).

Sun, X. & Doner, H. E. An Investigation of Arsenate and Arsenite Bonding Structures On Goethite by Ftir. Soil Sci. 161, 865–872 (1996).

Li, S. The Adsorption Study of Antimony On Iron Modified Sepiolite: Xiangtan University (2009).

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (No. 41672350), the scientific research project of the Hunan Provincial Education Department (No. 18A184) and Chinese Postdoctoral Science Foundation (No. 2018M632961).

Author information

Authors and Affiliations

Contributions

Ren-jian Deng and Jun Zhang conceived and designed the study. Bo-zhi Ren and Baolin Houn analyzed the data. Ren-jian Deng and Jun Zhang wrote the paper. Andrew Hursthouse assessed data, reviewed the manuscript. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, J., Deng, Rj., Ren, Bz. et al. Preparation of a novel Fe3O4/HCO composite adsorbent and the mechanism for the removal of antimony (III) from aqueous solution. Sci Rep 9, 13021 (2019). https://doi.org/10.1038/s41598-019-49679-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-49679-9

This article is cited by

-

Enhancing Photocatalyst Performance of Magnetic Surfaces Covered by Carbon Clouds for Textile Dye Degradation

Arabian Journal for Science and Engineering (2023)

-

Recovery and reuse of floc sludge for high-performance capacitors

Frontiers of Environmental Science & Engineering (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.