Abstract

Epitaxial PbZr0.52Ti0.48O3 (PZT) layers were integrated on Si(001) with single PZT {001} orientation, mosaïcity below 1° and a majority of a-oriented ferroelectric domains (∼65%). Ferroelectric and pyroelectric properties are determined along both the out-of-plane and in-plane directions through parallel-plate capacitor and coplanar interdigital capacitor along the <100>PZT direction. A large anisotropy in these properties is observed. The in-plane remnant polarization (21.5 µC.cm−2) is almost twice larger than that measured along the out-of-plane direction (13.5 µC.cm−2), in agreement with the domain orientation. Oppositely, the in-plane pyroelectric coefficient (−285 µC.m−2.K−1) is much lower than that measured out-of-plane (−480 µC.m−2.K−1). The pyroelectric anisotropy is explicated in term of degree of structural freedom with temperature. In particular, the low in-plane pyroelectric coefficient is explained by a two-dimensional clamping of the layers on the substrate which induces tensile stress (from thermal expansion), competing with the decreasing tetragonality of a-domains (shortening of the polar c-axis lattice parameter). Temperature-dependent XRD measurements have revealed an increased fraction of a-domains with temperature, attesting the occurrence of a partial two-dimensional clamping. These observed properties are of critical importance for integrated pyroelectric devices.

Similar content being viewed by others

Introduction

Some of the most prominent features offered by perovskite oxides are ferroelectricity, piezoelectricity, pyroelectricity and ferromagnetism, which are exploited in a wide range of applications1,2,3. Particularly, all ferroelectric oxides simultaneously present pyroelectric and piezoelectric properties that can be exploited in various devices, such as non-volatile memories, sensors, actuators and energy harvesters4,5,6. These functional properties strongly depend on the oxide’s structure, especially on its tetragonality, and on its ferroelectric domain structure which determines the distribution of polarization axis orientations. In most applications, these functional oxides must be integrated as thin films. However, their resulting properties can strongly differ from that of bulk material given that thin film growth alters the material texture. In particular, epitaxial thin film growth could be leveraged to control and enhance ferroelectric properties through the fabrication of single crystal materials with controlled ferroelectric domain structure7.

Yet, these benefits have not been clearly demonstrated experimentally, as it requires a careful and complex assessment of the impact of epitaxy on potentially anisotropic physical properties. Attempts to investigate such a “functional” anisotropy have been proposed, for instance by varying the substrate orientation8,9,10, or by tailoring the epitaxial strain using different substrates11,12,13, but so far, no clear anisotropy measurements (probed along different crystallographic axes on the same oriented film) have been reported at the macroscale.

Studies of ferroelectric oxide thin films are usually focused on out-of-plane characterizations using parallel plate capacitors; in-plane investigations being so far very limited. Some dielectric and ferroelectric in-plane studies were conducted using interdigital capacitors (IDCs) for a variety of technological applications such as microwave integrated circuits14, surface acoustic wave (SAW) devices15 and chemical sensors16. In-plane dielectric properties have thus been reported for polycrystalline barium strontium titanates (BST)17,18 and epitaxial PMN-PT films19, and in-plane ferroelectric properties have been reported for epitaxial BST films on different oxide substrates20,21,22. However, these reports do not include out-of-plane characterizations and do not contain enough experimental details for parameters extraction to evidence a possible anisotropy. Furthermore, they do not include measurements of the in-plane pyroelectric response.

Although less studied than dielectric, ferroelectric and piezoelectric properties, pyroelectric properties, coupling a polarization variation with temperature, can lead to a broad range of applications, most notably thermal/IR sensing, imaging and thermal energy harvesting5,23. Pb(Zr,Ti)O3 (PZT) is a prototypical ferroelectric oxide that exhibits the largest reported polarizations, piezoelectric and pyroelectric coefficients4,5. Indeed, it has been used for instance to fabricate ferroelectric random access memories (FRAM)4,24, piezoelectric actuators25, mechanical energy harvesters6, pyroelectric nanogenerators for driving wireless sensor networks (WSNs)26, and enhanced nanogenerators based on coupled properties27. Moreover, thanks to its perovskite structure, PZT can be monolithically integrated on Si by epitaxy, via a SrTiO3 (STO) buffer layer13,28,29. Noticeably, a recent report has shown that epitaxial PZT layers grown on STO/Si templates lead to a gain of two orders of magnitude in pyroelectric energy conversion with respect to their polycrystalline counterparts30.

In this paper, we report both out-of-plane and in-plane ferroelectric and pyroelectric measurements of PZT films, epitaxially integrated on silicon, and demonstrate a large anisotropy in these functional properties, correlated with their structural properties.

Results and Discussion

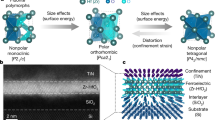

Five hundred nanometers thick epitaxial PZT (52:48) layers were grown by sol-gel process on silicon (001) substrate buffered with ∼10 nm thick epitaxial STO layers grown by oxide molecular beam epitaxy (MBE)31. Two different architectures were investigated: i) PZT layers grown on top of a 30 nm thick SrRuO3 (SRO) bottom electrode layer grown by radio frequency (rf) magnetron sputtering on top of STO/Si for out-of-plane (OOP) characterizations [Fig. 1(a)], and ii) PZT layers directly grown on top of the STO/Si pseudo-substrate for in-plane (IP) characterizations [Fig. 1(b,c)]. More details on the growth process can be found in the Method section and in previous reports13,30. Two configurations of platinum top electrodes were elaborated by rf magnetron sputtering at room temperature, UV-lithography and lift-off process for further electrical OOP and IP characterizations, and are sketched in Fig. 1 (For the out-of-plane (OOP) measurement in a metal-ferroelectric-metal (MFM) structure, the electric field lines pass across the PZT layer vertically toward the bottom electrode, the properties thus obtained, such as Pr, Ec, p etc, are those of the layer in the direction perpendicular to the surface. For in-plane (IP) measurement, two successive fingers belong to two different combs inversely polarized. Due to the absence of the lower conductive layer, the field lines pass through the PZT layer horizontally from one finger to the next. Properties thus extracted are those of the layer in the direction parallel to the surface. We consider that one of the two combs is the equivalent of the upper electrode of a plate capacitor and the second is the equivalent of the lower electrode, so the distance between two successive fingers is equivalent to the thickness of the layer between the electrodes. The total area of the capacitor is considered as the number of fingers in a comb multiplied by the surface of a finger). Square-shaped Pt top-contacts form the parallel plate electrodes on top of the PZT/SRO/STO/Si (001) heterostructure for OOP measurements [Fig. 1(a)]. Interdigital Pt top electrodes form the coplanar IDCs on the top of PZT/STO/Si (001) heterostructure along the <100>PZT direction for the IP measurements [Fig. 1(b,c)]. The pattern includes 50 fingers, with two successive fingers belonging to two different combs inversely polarized. The finger length and width is of 100 µm and 2 µm, respectively, and inter-finger gap is 2 µm [Fig. 1(d,e)].

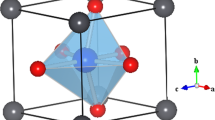

The XRD θ/2θ scans recorded before the deposition of the top electrodes on both samples shown in Fig. 2(a,c) attest to similar crystalline orientations and structures of the PZT layers. Bragg diffraction peaks corresponding to {00 l} reflection only of PZT, SRO, STO and Si are observed, indicating fully {00 l}-oriented heterostructures. The same peak positions are observed on both samples, indicating the same structure and global strain state. Pseudo-tetragonal a- and c-oriented domains of the PZT layer can be discriminated by fitting the {002} Bragg peak of PZT using two contributions. The PZT layer is mainly a-oriented (∼65%) here due to thermal expansion mismatch with respect to the Si substrate, as explained elsewhere13. The corresponding OOP and IP cell parameters are 4.05 Å and 4.12 Å for the a-oriented domains, and 4.11 Å and 4.10 Å for the c-oriented domains, respectively13. The structural details can be found elsewhere13. The domain size is expected to be in the range of hundred nanometers from the Landau-Lifshitz-Kittel scaling32. The epitaxial relationship between the oxide layers and the silicon substrate was previously measured as [100]PZT(001)//[100]SRO(001)//[100]STO(001)//[110]Si(001)13,33. The out-of-plane mosaicity of the PZT layers measured on the (002) Bragg reflection is below 1°, and slightly better for the PZT/STO/Si heterostructure (∼0.6°) compared to the PZT/SRO/STO/Si heterostructure [Fig. 2(b,d)]. The small difference could be due to the difference between the STO/Si templates quality or to the presence of additional SRO layer in the second heterostructure.

The ferroelectric hysteresis loops (P-E) measured macroscopically along both the OOP and IP directions with the positive-up negative-down (PUND) pulse train method are presented in Fig. 3. In the configuration of coplanar electrodes, the electric field can penetrate into the substrate and thus could affect the results. Here, the low dielectric constant of the Si substrate (11.68), compared to those of high-k oxides such as PZT, reduces the electric field penetration in the substrate. It is worth noting that the coercive field characterizing the switching of ferroelectric domains is the same measured in the IP and OOP configurations, which gives us confidence in our measurements. The remnant polarization (Pr) measured along the IP direction (21.5 μC.cm−2) is much larger than that measured along the OOP direction (13.5 μC.cm−2), by a factor of almost 2. These results are in agreement with the ferroelectric domain structure of the PZT layers, dominated here by a-oriented domains on Si(001)13. The IP over OOP polarization ratio roughly matches a-oriented over c-oriented ferroelectric domains concentration estimated from X-ray diffracted intensities.

Pyroelectric coefficients (p), which link a change of the remnant polarization with a temperature variation5,23, were extracted from PUND ferroelectric hysteresis loops recorded in both configurations at different stabilized temperatures ranging here from 80 K to 300 K [Fig. 4(a,b)]. As expected, the remnant polarization decreases when the temperature increases in both cases5. The variation of Pr as a function of temperature, shown in Fig. 4(c) for both configurations, is linear in this temperature range. It is worth noting that the same linear slope is observed at least up to 400 K along the OOP direction13, that means a constant pyroelectric coefficient in this whole temperature range (80 K–400 K), which is consistent with the fact that we are working far from the Curie temperature Tc (polarization vs. temperature plot exhibits a quasi-linear behavior). A possible monoclinic to tetragonal phase transition occurring around room temperature in bulk material at this PZT composition34, is shifted at higher temperatures than 500 K in epitaxial films on Si33, and would be barely measurable electrically because of slight structural difference of less than 0.5° in the c-axis orientation with respect to the normal of the a-b plane34. The decrease of Pr with temperature is much lower along the IP direction than along the OOP direction, despite a large IP polarization and tetragonality. The resulted IP and OOP pyroelectric coefficients extracted from these indirect measurements (p = ΔPr/ΔT) are −285 and −480 μC m−2 K−1, respectively. These measurements exclude the extrinsic pyroelectric effect due to domain wall motion with temperature12,30. Although these coefficients are of the same order of magnitude than those reported in previous studies,13,30 they differ from each other by a factor of almost 2. They differ from a factor of almost 3 if they are normalized with respect to their remnant polarization at room temperature (p/Pr). The remnant polarizations (Pr) and the pyroelectric coefficients (p) measured along both directions are compared in Fig. 4(d).

(a–b) Ferroelectric hysteresis loops (Polarization versus electric field by PUND method) of the PZT epitaxial layers measured at various stabilized temperatures from 80 K to 300 K (a) along the out-of-plane (OOP) direction, and (b) along the in-plane (IP) 〈100〉 direction. (c) Variation of the corresponding remnant polarization as a function of temperature. (d) Summary of the remnant polarization and the pyroelectric coefficient measured both along the OOP and IP directions.

The primary pyroelectric effect (polarization variation with temperature) is coupled with the secondary pyroelectric effect (crystal deformation via piezoelectric effect)23. The secondary pyroelectric effect is important in PZT since its piezoelectric coefficient is high6. The reduction of tetragonality with temperature by shortening the lattice parameter of the polar c-axis [Fig. 5(a)] leads to the decrease of remnant polarization [Fig. 5(b)]29, which is responsible for the pyroelectricity5,23. The variation of the polarization with temperature should be larger along the main polarization and the largest tetragonality [Fig. 5(c)]12,29. Even if both the main polarization (c-axis) and the largest tetragonality lie in-plane here, the OOP pyroelectric response is much larger than the IP pyroelectric response. This can be explained structurally by a two-dimensional clamping of the epitaxial layers to the substrate which tends to impose its thermal expansion (tensile stress) [Fig. 5(d)]13,29,33, competing with the reduction of tetragonality (decrease of c-axis lattice parameter of a-domains)29,34. The thermal expansion coefficient of the Si substrate is around 3 × 10−6 K−113,29, whereas the variation of the c-axis parameter with temperature (Δc/c) in the tetragonal phase far from Tc is negative in the range of −4 × 10−5 K−1 in bulk PZT34. The IP structural conflict with temperature here is so great that the clamping seems to be only partial. In case of pure clamping, the IP pyroelectric coefficient would be of positive sign (increase of tetragonality and consequent increase of Pr along the IP direction). And, in case of absence of clamping, the IP pyroelectric coefficient would be larger (in absolute value) than that OOP.

Some sketched basic features of ferroelectric materials, in bulk form (a,b) and epitaxial films (c,d), to take into account for ferroelectric and pyroelectric anisotropy. (a) Variation of the lattice parameters with temperature. (b) Consequent variation of remnant electric polarization with temperature, leading to pyroelectricity. (c) The main orientations of the tetragonal domains, leading to different polydomain structures. (d) Thermal expansion of the substrate.

In order to assess the hypothesis of partial clamping effect, temperature-dependent XRD measurements were carried out on both samples. Both a- and c-oriented domains are measured [Fig. 6(a)]. The evolution of the cell parameters with temperature are in agreement with previous reports on epitaxial PZT layers on STO and Si (001) substrates [Fig. 6(b)]29,33,35. More interestingly, the evolution of the normalized diffracted intensity of these two peaks with temperature well below Tc shows that the a-oriented domains fraction increases at the expense of c-oriented domains with the temperature [Fig. 6(c)]. This observation evidences the existence of the partial clamping effect occurring to the PZT layers. The thermal expansion of the Si substrate forces the c-domains, having low tetragonality (close OOP and IP parameters), to become a-domains by IP tension with temperature, in agreement with theoretical results36. The variation of the domain fraction is not a prerequisite to obtain a lower IP pyroelectric coefficient than that OOP, but is a proof of the occurrence of a clamping effect, explaining the pyroelectric anisotropy here. The variation of the domain fraction seems to be monotone close to room temperature and enhanced with temperature within the error bars. That would mean that the two-dimensional clamping effect is enhanced with temperature, probably because of better matching of the PZT lattice with the thermal expansion of the Si substrate at higher temperature. More generally, this can be due to different temperature-dependant variations of the cell parameters and to complex equilibrium in the polydomain PZT epitaxial layer considering strain, domain structure and elastic energy36,37,38. This observation signals that the IP pyroelectric coefficient can be smaller (in absolute value) above 400 K or even of positive sign, enhancing even more the pyroelectric anisotropy. It is worth noting that this phenomenon is reversible (or purely elastic), meaning that the PZT layer and structure is not affected by the measurement at relatively high temperature [Fig. 6(d)].

(a) XRD θ/2θ scan of {002} Bragg peak of PZT at room temperature and fits corresponding to a-oriented and c-oriented domains components. (b) Out-of-plane plane lattice cell parameters as a function of temperature. (c) Normalized diffracted intensity of a-oriented and c-oriented ferroelectric domains as a function of temperature. (d) XRD θ/2θ scan of {002} Bragg peak of PZT at room temperature before the measurement at temperature, at 800 K, and at room temperature after cooling.

To summarize, along the IP direction, two opposite forces occur when increasing the temperature, namely i) a shortening of the polar c-axis lattice parameter of a-domains which decreases the polarization by lowering the tetragonality, and ii) an extension induced by the thermal expansion of the substrate which can increase the a-domains over c-domains fraction36. These two main counterbalanced phenomena tend to minimize the variation of the polarization and thus the global IP pyroelectric coefficient. The degree of structural freedom along the OOP direction is larger than that IP, yielding a larger pyroelectric coefficient, inducing the pyroelectric anisotropy observed here. This shows that epitaxial effects strongly affect the pyroelectric response of the thin layers. More generally, the present study highlights the complex links between epitaxy and the resulting functional properties of oxide layers, and may be generalized to many cases where the functional properties depend on the ferroelectric domain structure, as the case of electro-optical properties for instance39. These results are essential to further tailor the pyroelectric properties of integrated films and to optimize the design of ferroelectric and pyroelectric nanodevices.

Conclusion

To conclude, the large anisotropy of the ferroelectric and pyroelectric properties of epitaxial PZT layers integrated on silicon was demonstrated. In-plane remnant polarization is about 21.5 μC.cm−2 compared to 13.5 μC.cm−2 measured along the out-of-plane direction, in very good agreement with structural properties (65% of a-oriented domains). In-plane pyroelectric coefficient along the <100> direction is found lower than that measured out-of-plane (−285 µC.m−2.K−1 and −480 µC.m−2.K−1, respectively) oppositely to the main polar axis orientation. The pyroelectric anisotropy has been explained by the degree of structural freedom: two opposite in-plane forces occur with temperature (reduction of tetragonality of a-domains and thermal expansion imposed by the substrate) which minimizes the pyroelectric effect along the in-plane direction. These properties can be exploited in other ferroelectric/pyroelectric heterostructures for which the functional properties depend on their domain structure.

Methods

Elaboration

Single-crystalline SrTiO3/Si pseudo-substrates were fabricated by molecular beam epitaxy (MBE) at ∼400 °C under P(O2) ∼5 10−8 Torr31. SrRuO3 bottom electrode was deposited by rf magnetron sputtering at ∼620 °C under P(O2) ∼3.7 mTorr in a Ar/O2 (10/1) mixture. PZT was deposited by spin-coating from a sol-gel process and crystallized by annealing under oxygen flux at 650 °C13,30. Pt top electrodes were deposited by rf magnetron sputtering at room temperature.

Structural characterization

A high-brilliance X-ray diffractometer with high-resolution (Rigaku SmartLab) equipped with a copper rotating anode and a Ge(220) monochromator with λCuKα1 = 1.54056 Å was used to investigate the structure and the crystalline orientation of the layers. Temperature-dependent diffraction was performed in air using an Anton Paar heater with a graphite dome.

Ferroelectric characterization

The ferroelectric properties were analyzed along both OOP (in top-bottom configuration) and IP directions by measuring the electric polarization versus electric field (P-E) at room temperature. PUND (Positive Up Negative Down) excitation pulse trains have been used, allowing to discriminate the polarization current from dielectric displacement and leakage currents.

Pyroelectric characterization

The pyroelectric properties were determined by measuring the remnant polarization (Pr), from the ferroelectric hysteresis loops (P-E) using PUND method, at different temperatures ranging from 80 K to 300 K, along both the OOP and IP directions.

Change history

22 June 2018

A correction to this article has been published and is linked from the HTML and PDF versions of this paper. The error has been fixed in the paper.

References

Scott, J. F. & Dearaujo, C. Ferroelectric memories. Science 246, 1400–1405 (1989).

Polar Oxides: Properties, Characterization, and Imaging, eds. Waser, R., Böttger, U. & Tiedke, S. Wiley-VCH Verlag GmbH & Co., KGaA, Weinheim, 2005.

Thin Films and Heterostructures for Oxide Electronics, ed. S. B. Ogale, Springer, New York, 2005.

Auciello, O., Scott, J. F. & Ramesh, R. The physics of ferroelectric memories. Phys Today 51, 22–27 (1998).

Bowen, C. R. et al. Pyroelectric materials and devices for energy harvesting applications. Energy Env. Sci. 7, 3836–3856 (2014).

Kim, S.-G., Priya, S. & Kanno, I. Piezoelectric MEMS for energy harvesting. MRS Bulletin 37, 1039–1050 (2012).

Schwarzkopf, J. & Fornari, R. Epitaxial growth of ferroelectric oxide films. Prog. Cryst. Growth and Charact. Mater. 52, 159–212 (2006).

Zhu, M., Du, Z., Jing, L., Tok, A. L. Y. & Teo, E. H. T. Optical and electro-optic anisotropy of epitaxial PZT thin films. Appl. Phys. Lett. 107, 031907 (2015).

Oikawa, T., Aratani, M., Funakubo, H., Saito, K. & Mizuhira, M. Composition and orientation dependence of electrical properties of epitaxial Pb(ZrxTi1−x)O3 thin films grown using metalorganic chemical vapor deposition. J. Appl. Phys. 95, 3111–3115 (2004).

Nagashima, K., Aratani, M. & Funakubo, H. Orientation dependence of ferroelectricity of epitaxially grown Pb(ZrxTi1−x)O3 thin films prepared by metalorganic chemical vapor deposition. J. Appl. Phys. 89, 4517–4522 (2001).

Nagarajan, V. et al. Role of substrate on the dielectric and piezoelectric behavior of epitaxial lead magnesium niobate-lead titanate relaxor thin films. Appl. Phys. Lett. 77, 438 (2000).

Karthik, J., Agar, J. C., Damodaran, R. & Martin, L. W. Effect of 90° domain walls and thermal expansion mismatch on the pyroelectric properties of epitaxial PbZr0.2Ti0.8O3 thin films. Phys. Rev. Lett. 109, 257602 (2012).

Moalla, R. et al. Dramatic effect of thermal expansion mismatch on the structural, dielectric, ferroelectric and pyroelectric properties of low-cost epitaxial PZT films on SrTiO3 and Si. CrystEngComm 18, 1887–1891 (2016).

Alley, G. D. Interdigital capacitors and their application to lumped-element microwave integrated circuits. IEEE Trans. Microw. Theory Tech. 18, 1028–1033 (1970).

Alzuaga, S. et al. Tunable and high quality factor SrTiO3 surface acoustic wave resonator. Appl. Phys. Lett. 105, 062901 (2014).

Zhou, R., Hierlemann, A., Weimar, U. & Göpel, W. Gravimetric, dielectric and calorimetric methods for the detection of organic solvent vapours using poly(ether urethane) coatings. Sensors Actuators B Chem. 34, 356–360 (1996).

Cheng, Y. L., Wang, Y., Chan, H. L. W. & Choy, C. L. Preparation and characterization of (Ba,Sr)TiO3 thin films using interdigital electrodes. Microelectron. Eng. 66, 872–879 (2003).

Zhang, X. Y., Wang, P., Sheng, S., Xu, F. & Ong, C. K. Ferroelectric BaxSr1−xTiO3 thin-film varactors with parallel plate and interdigital electrodes for microwaves applications. J. Appl. Phys. 104, 124110 (2008).

Wang, Y. et al. In-plane dielectric properties of epitaxial 0.65Pb(Mg1/3Nb2/3)O3 – 0.35PbTiO3 thin films in a very wide frequency range. Appl. Phys. Lett. 85, 1580 (2004).

Zhou, X. Y. et al. Thickness dependence of in-plane dielectric and ferroelectric properties of Ba0.7Sr0.3TiO3 thin films epitaxially grown on LaAlO3. Appl. Phys. Lett. 90, 132902 (2007).

Zhou, X. Y. et al. Microstructure and enhanced in-plane ferroelectricity of Ba0.7Sr0.3TiO3 thin films grown on MgAl2O4 (001) single-crystal substrate. Appl. Phys. Lett. 89, 232906 (2006).

Wang, D. Y., Wang, Y., Zhou, X. Y., Chan, H. L. W. & Choy, C. L. Enhanced in-plane ferroelectricity in Ba0.7Sr0.3TiO3 thin films grown on MgO (001) single-crystal substrate. Appl. Phys. Lett. 86, 212904 (2005).

Lang, S. B. Pyroelectricity: from ancient curiosity to modern imaging tool. Phys. Today 58, 31–36 (2005).

Scott, J. F. Applications of modern ferroelectrics. Science 315, 954–959 (2007).

Setter, N. et al. Ferroelectric thin films: Review of materials, properties, and applications. J. Appl. Phys. 100, 051606 (2006).

Yang, Y., Wang, S., Zhang, Y. & Wang, Z. L. Pyroelectric nanogenerators for driving wireless sensors. Nano Letters 12, 6408–6413 (2012).

Zhang, K., Wang, S. & Yang, Y. A one-structure-based piezo-tribo-photoelectric effects coupled nanogenerator for simultaneously scavenging mechanical, thermal, and solar energies. Adv. Energy Mater. 7, 1601852 (2017).

Kim, D. M. et al. Thickness dependence of structural and piezoelectric properties of epitaxial Pb(Zr0.52Ti0.48)O3 films on Si and SrTiO3 substrate. Appl. Phys. Lett. 88, 142904 (2006).

Sambri, A. et al. Enhanced critical temperature in epitaxial ferroelectric Pb(Zr0.2Ti0.8)O3 thin films on silicon. Appl. Phys. Lett. 98, 012903 (2011).

Moalla, R. et al. Huge gain in pyroelectric energy conversion through epitaxy for integrated self-powered nanodevices. Nano Energy 41, 43–48 (2017).

Saint-Girons, G. et al. Epitaxy of SrTiO3 on silicon: the knitting machine strategy. Chem. Mater. 28, 5347–5355 (2016).

Catalan, G. et al. Fractal dimension and size scaling of domains in thin films of multiferroic BiFeO3. Phys. Rev. Lett. 100, 027602 (2008).

Shi, Y. et al. Phase transitions in [001]-oriented morphotropic PbZr0.52Ti0.48O3 thin film deposited onto SrTiO3-buffered Si substrate. J. Appl. Phys. 115, 214108 (2014).

Noheda, B. et al. Tetragonal-to-monoclinic phase transition in a ferroelectric perovskite: the structure of PbZr0.52Ti0.48O3. Phys. Rev. B 61, 8687 (2000).

Gariglio, S., Stucki, N., Triscone, J.-M. & Triscone, G. Strain relaxation and critical temperature in epitaxial ferroelectric Pb(Zr0.20Ti0.80)O3 thin films. Appl. Phys. Lett. 90, 202905 (2007).

Karthik, J. & Martin, L. W. Pyroelectric properties of polydomain epitaxial Pb(Zr1−x,Tix)O3 thin films. Phys. Rev. B 84, 024102 (2011).

Koukhar, V. G., Pertsev, N. A. & Waser, R. Thermodynamic theory of epitaxial ferroelectric thin films with dense domain structures. Phys. Rev. B 64, 214103 (2001).

Pertsev, N. A., Kukhar, V. G., Kohlstedt, H. & Waser, R. Phase diagrams and physical properties of single-domain epitaxial Pb(Zr1−xTix)O3 thin films. Phys. Rev. B 67, 054107 (2003).

Castera, P. et al. Electro-optical modulation based on pockels effect in BaTiO3 with multi-domain structure. IEEE Photonics Technol. Lett. 28, 990 (2016).

Acknowledgements

The European commission, the national French research agency (ANR), the French government and STMicroelectronics (S. Monfray, Crolles) are gratefully acknowledged for financial supports through the projects SITOGA (FP7-ICT-2013-11-619456), TIPS (H2020-ICT-02-2014-1-644453), ANR HIRIS, ANR DIAMWAFEL, and Nano2017. The authors also acknowledge the region Rhône-Alpes for the doctoral fellowship of R. Moalla, the “Cellule Energie” of the Centre National de la Recherche Scientifique (CNRS-INSIS) for the financial support of the exploratory project PEPS “PYROS”, and the Ecole Centrale de Lyon (ECL) for the funding of emergent thematic and transversal projects. Finally, INL authors acknowledge P. Regreny, C. Botella, and J.-B. Goure for technical assistance on the Nanolyon technological platform.

Author information

Authors and Affiliations

Contributions

R.M., N.B. and R.B. conceived the experiments, and R.M. performed it. S.C. contributed to the fabrication of IDCs top electrodes. J.P. contributed to the temperature-dependent XRD measurements. B.V. contributed to the growth of SrRuO3 and PZT. G.S.-G. contributed to the growth of STO on Si. R.M., N.B. and R.B. analysed the results. R.M. and R.B. wrote the original manuscript, and N.B., S.C., J.P. and G.S.-G. commented and provided some modifications.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Moalla, R., Cueff, S., Penuelas, J. et al. Large anisotropy of ferroelectric and pyroelectric properties in heteroepitaxial oxide layers. Sci Rep 8, 4332 (2018). https://doi.org/10.1038/s41598-018-22349-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-22349-y

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.