Abstract

A series of Y3+-absent/doped NaLuF4:Yb3+, Tm3+ nano/micro-crystals were prepared via a hydrothermal process with the assistance of citric acid. Cubic nanospheres, hexagonal microdisks, and hexagonal microprisms can be achieved by simply adjusting the reaction temperature. The effect of Y3+ doping on the morphology and upconversion (UC) emission of the as-prepared samples were systematically investigated. Compared to their Y3+-free counterpart, the integrated spectral intensities in the range of 445–495 nm from α-, β-, and α/β-mixed NaLuF4:Yb3+, Tm3+ crystals with 40 mol% Y3+ doping are increased by 9.7, 4.4, and 24.3 times, respectively; red UC luminescence intensities in the range of 630–725 nm are enhanced by 4.6, 2.4, and 24.9 times, respectively. It is proposed that the increased UC emission intensity is mainly ascribed to the deformation of crystal lattice, due to the electron cloud distortion in host lattice after Y3+ doping. This paper provides a facile route to achieve nano/micro-structures with intense UC luminescence, which may have potential applications in optoelectronic devices.

Similar content being viewed by others

Introduction

Optical upconversion (UC) is an anti-Stokes process that two or more low-energy photons can be converted into a single high-energy photon1. Rare-earth (RE) doped UC materials show many advantages, including high photochemical stability, low toxicity and long luminescence lifetimes2,3,4,5,6, which may have great potential applications in fields such as biological imaging, multi-dimensional displays, optical temperature sensors and solar cells7,8,9,10. However, compared to downconversion materials, the main shortcoming of UC materials is their low luminescence efficiency. Thus, an effective strategy to enhance the UC luminescence intensity is urgently needed. In recent years, many kinds of methods have been used to achieve efficient UC luminescence. For instance, Zhao et al. reported the enhanced red UC emission in Mn2+ doped NaYF4: Yb/Er nanoparticles, due to the efficient energy transfer between Er3+ and Mn2+ 11. Tan et al. demonstrated NaYbF4:Tm3+ and NaYbF4:Er3+ nanocrystals with the enhanced red UC luminescence, which is attributed to the cross relaxation effect among the activators at high activator content12. As is known, the UC emission of RE doped materials is remarkably affected by the crystal field symmetry around activators13, and the asymmetric environment of activators can result in the emission enhancement. For instance, Zhao’s group reported Li+ doped GdF3:Yb3+, Er3+ nanocrystals with the enhanced red UC luminescence, which was caused by the decrease of local crystal field symmetry around activators after Li+ doping14. Rai et al. demonstrated the enhanced green UC emission in Li+ doped Y2O3:Yb3+/Er3+ nanocrystals15. Yin et al. reported Mo3+ doped NaYF4: Yb/Er nanocrystals with 6 and 8 times enhancement of green and red UC emissions, due to the lattice distortion after Mo3+ doping16. In order to obtain efficient UC emission, the selection of excellent host material is essential. With the similar crystalline plane, NaYF4 and NaLuF4 have been considered as the outstanding host matrix for UC processes, due to their high thermal stability, low phonon energy and high refractive index17,18,19,20,21. As is known, the ionic radius of Y3+ (0.89 Å) is larger than that of Lu3+ (0.85 Å), thus Y3+ doping may cause the expansion of NaLuF4 host lattice, leading to the distortion of local symmetry around activators. Consequently, Y3+ doping is an effective approach for enhancing the UC emission intensity in NaLuF4-based system. In addition, due to the small difference in ionic radius between Y3+ and Lu3+, the phase transformation does not occur during introducing Y3+ in NaLuF4 crystals, which would be favorable to maintain the stability of crystal structure. However, there is no report on the increase of UC luminescence intensity in NaLuF4-based system via Y3+ doping.

In this paper, in order to obtain different structures of NaLuF4 nano/micro-crystals before Y3+ doping, the influence of reaction temperature on the phase of Y3+-absent NaLuF4 crystals is studied. It is found that cubic nanospheres, hexagonal microdisks and hexagonal microprisms can be achieved with the higher temperature. α-, β-, and α/β-mixed NaLuF4:Yb3+, Tm3+ crystals with Y3+ doping show the significant enhancement of UC emissions relative to Y3+-absent samples under 980 nm excitation at room temperature. The proposed mechanisms of UC emission enhancement and shape evolution through introducing Y3+ are presented.

Results and Discussion

Phase and morphology

First, in order to obtain diverse structures of NaLuF4 nano/micro-crystals before Y3+ doping, the influence of reaction temperature on the crystal structure of Y3+-absent NaLuF4 crystals is studied. The XRD patterns and the corresponding SEM images of Y3+-absent NaLuF4:Yb3+, Tm3+ nano/micro-crystals prepared at different reaction temperatures for 12 h are displayed in Figs 1 and 2, respectively. As can be seen from Fig. 1, pure α-NaLuF4 (JCPDS 27-0725) is formed at 110 °C. The related SEM image (Fig. 2a) shows that the sample is composed of a large number of small cubic nanospheres with an average diameter of 17 nm. At higher reaction temperature of 130 °C, α/β-mixed NaLuF4 appears in the XRD pattern, indicating that the crystals partially change from α to β phase. Correspondingly, the SEM image of Fig. 2b exhibits two obvious particle morphologies containing small α-NaLuF4 nanospheres and large β-NaLuF4 microdisks with a mean diameter of 7.63 μm. After being treated at 150 °C, the corresponding XRD result demonstrates that pure β-NaLuF4 (JCPDS 27-0726) can be obtained. The corresponding sample is composed of a large amount of hexagonal microdisks with regularity and smooth surfaces, and the small cubic nanoparticles completely disappear, as presented in Fig. 2c. The average length and diameter of the disks are 0.51 μm and 4.80 μm, respectively. When the reaction temperature further increases to 180 °C and 200 °C, there still only exists hexagonal phase in the XRD patterns. The corresponding SEM images (Fig. 2d and e) show the homogeneous short hexagonal microprisms with an average size of 4.36 μm and 6.06 μm in length; 12.46 μm and 10.51 μm in diameter, respectively. The ratios of length to diameter (L/D ratios) are calculated to be about 0.11 (150 °C), 0.35 (180 °C), and 0.58 (200 °C). From the above analysis, it can be concluded that higher reaction temperature favors the formation of NaLuF4 crystals with hexagonal phase, which is ascribed to the fact that higher temperature favors the nucleation and the crystal growth25. The L/D ratio of β-NaLuF4 microcrystals is enhanced as the temperature increases from 150 °C to 200 °C. As is known, β-NaLuF4 has a high anisotropic structure26. The growth rate along [10ī0] direction is lower than that along [0001] direction at higher temperature due to Cit3− absorbs onto the {\(10\bar{{\bf{1}}}0\)} facets more strongly than the {0001} facets, thus results in the increase of L/D ratio and the shape evolution from disks to prisms.

In order to reveal the effect of Y3+ doping on the morphology and UC emission of NaLuF4 crystals, a series of Y3+ doped α-, β- and α/β-mixed NaLuF4:Yb3+, Tm3+ nano/micro-crystals were synthesized.

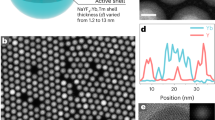

Figure 3(a and b) show the XRD patterns of α-NaLuF4:Yb3+, Tm3+ nanocrystals and β-NaLuF4:Yb3+, Tm3+ microcrystals introduced with different Y3+ contents prepared at 110 °C and 200 °C for 12 h, respectively. As can be seen, pure cubic phase (Fig. 3a) and pure hexagonal phase (Fig. 3b) can be obtained even Y3+ content increases up to 79 mol% (the Y3+-free samples have been shown in Fig. 1). No extra peaks can be observed, which indicates that Y3+ doping has no influence on the crystal structure of cubic-phase nanocrystals and hexagonal-phase microcrystals. As demonstrated in the insets of Fig. 3(a and b), with the Y3+ content increases from 0 to 79 mol%, the main diffraction peaks of α and β phases move to lower angles. According to Bragg’s law 2d sinθ = nλ, where d represents the interplanar distance, θ represents the diffraction angle, and λ represents the diffraction wavelength. When Y3+ doped into the lattice, Lu3+ can be substituted by the relatively large Y3+, resulting in the expansion of NaLuF4 host lattice (Fig. 3c), thus the interplanar distance increases and diffraction angle decreases. The values of the lattice constants and unit-cell volumes of α-NaLuF4:20%Yb3+, 1%Tm3+ doped with different concentrations of Y3+ calculated according to XRD results are shown in Table 1, the higher unit-cell volumes are caused by the larger ionic radius of Y3+ substituting Lu3+. Importantly, the lattice expansion may cause the distortion of local symmetry around Tm3+, which would break the forbidden transition of Tm3+, and consequently enhancing the UC emission intensity27. The above XRD results are well consistent with the corresponding SEM images.

XRD patterns (a and b) of different Y3+ doped α-NaLuF4:Yb3+, Tm3+ nanocrystals and β-NaLuF4:Yb3+, Tm3+ microcrystals prepared at 110 °C and 200 °C for 12 h; and possible change in the NaLuF4 crystal lattice after Y3+ doping (c). The insets of (a and b) are their main diffraction peaks. The vertical red lines are the standard profiles of α-NaLuF4 (JCPDS 27-0725) and β-NaLuF4 (JCPDS 27-0726), respectively.

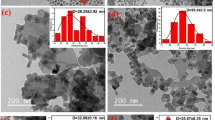

As shown in Fig. 4(a–f), the Y3+ doped α-NaLuF4 nanoparticles are composed of a great deal of small cubic nanospheres (the Y3+- absent sample has been shown in Fig. 2a). The full width at half maximum (FWHM) was gradually narrowed with the Y3+ concentration increases up to 79 mol%, as presented in Fig. 5. The average crystalline sizes can be calculated based on Scherrer’s equation: D = 0.89λ/(βcosθ), where D is the crystallite size, λ represents the wavelength of the X-ray, β stands for the corrected half width of the diffraction peak, and θ is the diffraction angle. The factor 0.89 is the characteristic of a spherical particle. Thus, the mean diameters (Table 2) of the spheres were calculated to be about 17 nm, 17 nm, 18 nm, 19 nm, 22 nm, and 24 nm, respectively. From the above results, it can be seen that the replacement of Lu3+ by larger Y3+ may lead to the increasing size of cubic-phase nanospheres.

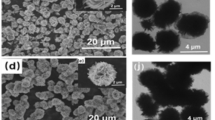

The SEM images of Y3+ doped β-NaLuF4 microparticles are displayed in Fig. 6(a–f). As exhibited in Fig. 6a, the Y3+-free sample has been shown in Fig. 2e. As the Y3+ concentration increases from 10 to 20 mol%, short hexagonal microprisms with regularity and uniformity are obtained, as presented in Fig. 6(b and c). On average, the prisms have a length of 3.01 μm and 4.81 μm; a diameter of 6.72 μm and 7.42 μm, respectively. When the Y3+ concentration increases to 40 mol%, irregular hexagonal microprisms with coarse surfaces are shown in Fig. 6d. The average length of the prisms is 14.08 μm, and the average diameter is 11.02 μm. With the Y3+ content further increases to 60 and 79 mol% [Fig. 6(e and f)], the corresponding samples consist of hexagonal microprisms with scrappy ends and concave centers on the top/bottom surfaces. The prisms have a mean size of 7.78 μm and 7.71 μm in length; 5.98 μm and 5.10 μm in diameter, respectively. The L/D ratios are calculated to be about 0.45, 0.65, 1.28, 1.30, and 1.51 when the Y3+ content is 10, 20, 40, 60, and 79 mol%. Thus, the L/D ratio of hexagonal microprisms is increased as the Y3+ content increases from 10 to 79 mol%. Under our experimental condition, the chelated Lu3+-Cit3− complex and Y3+-Cit3− complex were formed. As is known, both β-NaLuF4 and β-NaYF4 have high anisotropic structures. From Fig. 6a (Lu3+ = 79 mol%, Y3+ = 0 mol%) and Fig. 6f (Lu3+ = 0 mol%, Y3+ = 79 mol%), it can be clearly seen that the L/D ratio of β-NaYF4 is larger than that of β-NaLuF4. Thus, the v 1 /v 2 ratio of β-NaYF4 is higher than that of β-NaLuF4 under the same experimental conditions (v 1 is the growth rate along [0001] direction, v 2 is the growth rate along [\(10\bar{{\bf{1}}}0\)] direction), leading to the enhancement of L/D ratio and the morphology evolution from short hexagonal microprisms to long hexagonal microprisms when the Y3+ concentration increases from 10 to 79 mol%. According to Liu et al.’s report about the density functional theory calculation on Gd3+ doped NaYF4:Yb3+, Er3+ nanoparticles, the electron charge density in host lattice changes after Y3+ is substituted by Gd3+ in the crystal lattice28. Under our synthesis conditions, the replacement of Lu3+ by larger Y3+ is similar to the substitution of Y3+ by larger Gd3+. Thus, it is creditable that Y3+ doped into NaLuF4 host lattice may change the electron charge density, leading to the electron cloud distortion in crystal lattice, which would cause the deformation of crystal lattice. The change in crystal lattice may result in the formation of irregular and distorted hexagonal microprisms with coarse surfaces when the Y3+ content is 40 mol%.

Figure 7 shows the XRD patterns (a) and the main diffraction peak (b) of different Y3+ doped α/β-mixed NaLuF4:Yb3+, Tm3+ nano/micro-crystals prepared at 130 °C for 12 h. As shown in Fig. 7a, all samples are composed of a mixture of cubic and hexagonal phases (the Y3+-free sample has been shown in Fig. 1). Figure 7b displays the main diffraction peak of cubic phase shifts towards lower angles as the Y3+ content increases from 0 to 79 mol%, which is mainly attributed to the expansion of crystal lattice after Lu3+ is replaced by the relatively large Y3+. The shifting peak reveals that Y3+ can be doped into the host lattice. The corresponding SEM images [Fig. 8(a–f)] present two distinct particle morphologies including large microdisks (hexagonal phase) and small nanoparticles (cubic phase). It can be obviously seen that numerous spherical nanoparticles are attached on the surfaces of microdisks. The corresponding diameters of the disks are 7.63 μm, 5.64 μm, 4.79 μm, 3.50 μm, 2.66 μm, and 2.33 μm, respectively. The reduced diameter of the disks can be ascribed to the fact that β-NaYF4 has higher v 1 /v 2 ratio than β-NaLuF4 under the same experimental conditions.

The above results demonstrate that reaction temperature has a significant effect on the crystal structure of the products, and Y3+ doping may cause the size-tuning and shape evolution of the crystals. Figure 9 summarizes the formation processes of Y3+-absent/doped NaLuF4:Yb3+, Tm3+ nano/micro-crystals synthesized under different experimental conditions.

UC photoluminescence properties

Figure 10(a–c) show the UC luminescence spectra (under 980 nm excitation at room temperature) of different Y3+ doped α-, β- and α/β-mixed NaLuF4:20%Yb3+, 1%Tm3+ nano/micro-crystals prepared at 110 °C, 200 °C and 130 °C for 12 h, respectively. Blue emissions centered at 450 nm and 477 nm are generated from the 1D2 → 3F4 and 1G4 → 3H6 transitions of Tm3+, respectively. Red emissions at approximately 649 nm and 696 nm correspond to the 1G4 → 3F4 and 3F3 → 3H6 transitions of Tm3+, respectively. The energy-level diagram of UC mechanisms for blue and red emissions between Yb3+ and Tm3+ is presented in Fig. 11. For 450 nm emission, the Tm3+1D2 level is populated by the ET1+ET2+CR processes (ET = energy transfer, CR = cross relaxation). For 477 nm and 649 nm emissions, the Tm3+ 1G4 level is populated by the ET1+ET2+ET3 processes. For 696 nm emission, the Tm3+3F3 level is populated by the ET1+ET2 processes. As can be seen from Fig. 10(a–c), the blue and red UC emission intensities are distinctly enhanced as the Y3+ content increases from 0 to 40 mol%, and then declined at the content of 40–79 mol%. Thus, the strongest UC luminescence intensities are observed in the samples with 40 mol% Y3+ doping. Compared to their Y3+-free samples, the integrated spectral intensities in the range of 445–495 nm from α-, β-, and α/β-mixed NaLuF4:20%Yb3+, 1%Tm3+ crystals with 40 mol% Y3+ doping are increased by 9.7, 4.4, and 24.3 times, respectively; red UC luminescence intensities in the range of 630–725 nm are enhanced by 4.6, 2.4, and 24.9 times, respectively. Under our experimental condition, the substitution of Lu3+ by the relatively large Y3+ distorts the electron charge density in host lattice, causing the lattice expansion. The deformation of crystal lattice may decrease the symmetry of the local crystal field around Tm3+, breaking the forbidden transition of Tm3+, finally favors the fast energy transfer from Yb3+ to Tm3+ 29. Thus, the asymmetric surrounding environment around Tm3+ may result in the sharp increase of UC emission intensity. Y3+ doping only changes the lattice constants, and the phase transformation does not occur during introducing Y3+ in NaLuF4 host lattice, due to the small difference in ionic radius between Y3+ and Lu3+. When the Y3+ concentration is 0 mol% (Lu3+ = 79 mol%) and 79 mol% (Lu3+ = 0 mol%), pure NaLuF4:20%Yb3+, 1%Tm3+ nano/micro-crystals and pure NaYF4:20%Yb3+, 1%Tm3+ nano/micro-crystals are formed, respectively. Consequently, the samples doped with 0 mol% Y3+ (Lu3+ = 79 mol%) and 79 mol% Y3+ (Lu3+ = 0 mol%) have the highest crystal field symmetry around Tm3+, and the samples doped with 40 mol% Y3+ (Lu3+ = 39 mol%) have the lowest crystal field symmetry around Tm3+. Due to the most asymmetric environment of Tm3+, α-, β- and α/β-mixed NaLuF4:20%Yb3+, 1%Tm3+ nano/micro-crystals with 40 mol% Y3+ doping have the maximum UC luminescence intensity. This phenomenon is similar to Kong et al.’s report about the enhanced UC emissions in Li+ doped NaYF4:Yb3+, Tm3+ nanoparticles30. According to the results of the experiments performed by Kong et al.30, when the Li+ content is below 7 mol%, Li+ substitutes Na+, causing the shrinking of host lattice; however, as the Li+ content increases from 7 to 15 mol%, Li+ begins to occupy interstitial site, leading to the expansion of crystal lattice; thus the sample with 7 mol% Li+ doping has the highest UC emission intensity, owing to the lowest crystal field symmetry around activators. Besides, Y3+ doping causes the electron cloud distortion in host lattice, resulting in the tunable size of the as-prepared samples. As is known, as for larger-size crystals, the nonradiative energy transfer processes of Tm3+ would decrease due to their fewer surface quenching sites28, which is in favor of UC emission. Thus, as for Y3+ doped β-NaLuF4:20%Yb3+, 1%Tm3+ microcrystals, the larger-size (relative to Y3+-absent samples) of the samples with 40 mol% Y3+ doping may have a small contribution to the enhancement of UC luminescence intensity.

Figure 12 presents the decay curves of (a) 1G4 → 3H6 and (b) 1G4 → 3F4 transitions of Tm3+ in α-NaLuF4:20%Yb3+, 1%Tm3+ nanocrystals doped with 0, 40 and 79 mol% Y3+. Based on the function: τ = ∫I(t)dt/I max , where I(t) represents the emission intensity at time t, and Imax represents the peak intensity in the decay curve. The calculation results (Table 3) show that τ1 (0, 40 and 79 mol%/477 nm) = 0.391, 0.330 and 0.541 ms. τ2 (0, 40 and 79 mol%/649 nm) = 0.354, 0.250 and 0.353 ms. As can be seen, the sample with 40 mol% Y3+ doping has the lowest luminescence lifetime of 1G4 state of Tm3+. It is well known that the inverse of lifetime (1/τ) is equal to the sum (Ar+nr = Ar + Anr) of radiative (Ar) and nonradiative (Anr) transition probability. Thus, the lowest luminescence lifetime in the sample with 40 mol% Y3+ doping is mainly caused by the maximum emission intensity.

Conclusion

In summary, cubic nanospheres, hexagonal microdisks, and hexagonal microprisms can be achieved by simply adjusting the reaction temperature. It is found that higher temperature favors the nucleation and the crystal growth. The effect of Y3+ doping on the morphology and UC emission of the as-prepared samples were systematically investigated. The results demonstrate that Y3+ doping may cause the size-tuning and shape evolution of the crystals. Compared to their Y3+-free samples, the integrated spectral intensities in the range of 445–495 nm from α-, β-, and α/β-mixed NaLuF4:20%Yb3+, 1%Tm3+ crystals with 40 mol% Y3+ doping are increased by 9.7, 4.4, and 24.3 times, respectively; red UC luminescence intensities in the range of 630–725 nm are enhanced by 4.6, 2.4, and 24.9 times, respectively. It is proposed that the increased UC emission intensity is mainly ascribed to the deformation of crystal lattice, due to the electron cloud distortion in host lattice after Y3+ doping. Besides, as for Y3+ doped β-NaLuF4:20%Yb3+, 1%Tm3+ microcrystals, the larger-size (relative to Y3+-absent samples) of the samples with 40 mol% Y3+ doping may have a small contribution to the enhancement of UC luminescence intensity. As a result of their intense UC emission, these phosphors may be suitable for optoelectronic devices.

Methods

Chemicals

All of the chemicals are of analytical grade and used as received without further purification. 1 M of Lu(NO3)3, 1 M of Y(NO3)3, 0.5 M of Yb(NO3)3, and 0.1 M of Tm(NO3)3 stock solutions were prepared by dissolving the corresponding rare earth oxide (99.99%) in dilute nitric acid (30%) at elevated temperature.

Preparation

All samples were prepared based on our previously reported procedures22,23,24. As for the synthesis of Y3+-absent α-NaLuF4:20%Yb3+, 1%Tm3+ nanocrystals, 3 mmol of citric acid (2 M, 1.5 mL), 5 mmol of NaOH (4 M, 1.25 mL) and 10 mL of deionized water were mixed and stirred for 10 min. Then 1 mmol of RE(NO3)3 (0.79 mmol of Lu(NO3)3 (1M, 0.79 mL), 0.2 mmol of Yb(NO3)3 (0.5 M, 0.4 mL), and 0.01 mmol of Tm(NO3)3 (0.1 M, 0.1 mL)) were added to above mixture and then stirred for 30 min to form the RE-Cit3− complex. Subsequently, 16 mL of aqueous solution containing 9 mmol of NaF (1 M, 9 mL) and 7 mL of deionized water were added into the chelated RE-Cit3− complex to form a colloidal suspension and kept stirring for another 30 min. Finally, the suspension was transferred into a 50 ml-Teflon vessel, sealed in autoclave and maintained at 110 °C for 12 h. After the autoclave was cooled to room temperature naturally, the final products separated by centrifugation, washed with ethanol and deionized water several times, and then dried in air at 60 °C for 12 h. Other samples were prepared by a similar process only by tuning the reaction temperature (110–200 °C) and Y3+ content (0–79 mol%).

Characterization

The crystal structure of the as-prepared samples was confirmed by powder X-ray diffraction (XRD) patterns using the D-Max 2200VPC XRD from Rigaku Company (Cu-Kα radiation, λ = 1.5418 Å). The morphology was observed by Oxford Quanta 400 F Thermal Field Emission environmental Scanning Electronic Microscope (SEM). UC photoluminescence spectra were carried out on an Edinburgh Instrument Company FLS980 combined fluorescence lifetime and steady-state fluorescence spectrometer equipped with a 1 W 980 nm laser diode.

References

Wu, M. F. et al. Solid-state infrared-to-visible upconversion sensitized by colloidal nanocrystals. Nature Photon 10, 31–34 (2016).

Zhang, F. et al. Fabrication of Ag@SiO2@Y2O3:Er nanostructures for bioimaging: tuning of the upconversion fluorescence with silver nanoparticles. J. Am. Chem. Soc. 132, 2850–2851 (2010).

Zhang, F. & Wong, S. S. Ambient large-Scale template-mediated synthesis of high-aspect ratio single-crystalline, chemically doped rare-earth phosphate nanowires for bioimaging. ACS Nano 4, 99–112 (2010).

Li, Z. Q. & Zhang, Y. Monodisperse silica-coated polyvinylpyrrolidone/NaYF4 nanocrystals with multicolor upconversion fluorescence emission. Angew. Chem. Int. Ed. 45, 7732–7735 (2006).

Cheng, L. et al. Facile preparation of multifunctional upconversion nanoprobes for multimodal imaging and dual-targeted photothermal therapy. Angew. Chem. 123, 7523–7528 (2011).

Yi, G. S. & Chow, G. M. Water-Soluble NaYF4:Yb,Er(Tm)/NaYF4/polymer core/shell/shell nanoparticles with significant enhancement of upconversion fluorescence. Chem. Mater. 19, 341–343 (2007).

Zhou, J., Liu, Q., Feng, W., Sun, Y. & Li, F. Y. Upconversion luminescent materials: advances and applications. Chem. Rev. 115, 395–465 (2015).

Li, Y. Y., Guo, J. J., Liu, X. H., Aidilibike, T. & Qin, W. P. White upconversion luminescence in CaF2:Yb3+/Eu3+powders via the incorporation of Y3+ ions. Phys. Chem. Chem. Phys. 18, 16094–16097 (2016).

Liao, J. et al. Preparation and upconversion emission modification of crystalline colloidal arrays and rare earth fluoride microcrystal composites. Sci. Rep. 5, 7636, https://doi.org/10.1038/srep07636 (2015).

Ding, M. et al. Simultaneous morphology manipulation and upconversion luminescence enhancement of β-NaYF4:Yb3+/Er3+ microcrystals by simply tuning the KF dosage. Sci. Rep. 5, 12745, https://doi.org/10.1038/srep12745 (2015).

Tian, G. et al. Mn2+ dopant-controlled synthesis of NaYF4: Yb/Er upconversion nanoparticles for in vivo imaging and drug delivery. Adv. Mater. 24, 1226–1231 (2012).

Wei, W. et al. Cross relaxation induced pure red upconversion in activator- and sensitizer-rich lanthanide nanoparticles. Chem. Mater. 26, 5183–5186 (2014).

Huang, Q. M., Yu, J. C., Ma, E. & Lin, K. M. Synthesis and characterization of highly efficient near-infrared upconversion Sc3+/Er3+/Yb3+ tridoped NaYF4. J. Phys. Chem. C 114, 4719–4724 (2010).

Yin, W. Y. et al. Enhanced red emission from GdF3:Yb3+, Er3+ upconversion nanocrystals by Li+ doping and their application for bioimaging. Chem. Eur. J. 18, 9239–9245 (2012).

Mishra, K., Singh, S. K., Singh, A. K. & Rai, S. B. Frequency upconversion in Er3+ doped Y2O3 nanophosphor: Yb3+ sensitization and tailoring effect of Li+ ion. Mater. Res. Bull. 48, 4307–4313 (2013).

Yin, D. G. et al. Enhancing upconversion luminescence of NaYF4: Yb/Er nanocrystals by Mo3+ doping and their application in bioimaging. Dalton Trans. 43, 12037–12043 (2014).

Krämer, K. W. et al. Hexagonal sodium yttrium fluoride based green and blue emitting upconversion phosphors. Chem. Mater. 16, 1244–1251 (2004).

Wang, L. L. et al. Enhanced deep-ultraviolet upconversion emission of Gd3+ sensitized by Yb3+ and Ho3+ in β-NaLuF4microcrystals under 980 nm excitation. J. Mater. Chem. C 1, 2485–2490 (2013).

Li, W. B., Tan, C. B. & Zhang, Y. T. Simultaneous phase and shape control of monodisperse NaLuF4: Yb, Er microcrystals and greatly enhanced upconversion luminescence from their superstructures. Opt. Commun. 295, 140–144 (2013).

Desiraju, G. R. Polymorphism: the same and not quite the same. Cryst. Growth Des. 8, 3–5 (2008).

Chen, Z. H. et al. Upconversion NaLuF4 fluorescent nanoprobes for jellyfish cell imaging and irritation assessment of organic dyes. J. Mater. Chem. C 3, 6067–6076 (2015).

Lin, H. et al. Tuning of structure and enhancement of upconversion luminescence in NaLuF4:Yb3+, Ho3+ crystals. Phys. Chem. Chem. Phys. 17, 19515–19526 (2015).

Lin, H. et al. Simultaneous realization of structure manipulation and emission enhancement in NaLuF4 upconversion crystals. J. Mater. Chem. C 3, 11754–11765 (2015).

Lin, H. et al. Enhanced red upconversion emission and its mechanism in Yb3+–Er3+ codoped α-NaLuF4 nanoparticles. New J. Chem. 41, 1193–1201 (2017).

Wang, Y., Gai, S. L., Niu, N., He, F. & Yang, P. P. Synthesis of NaYF4 microcrystals with different morphologies and enhanced up-conversion luminescence properties. Phys. Chem. Chem. Phys. 15, 16795–16805 (2013).

Niu, N. et al. Tunable multicolor and bright white emission of one-dimensional NaLuF4:Yb3+, Ln3+ (Ln = Er, Tm, Ho, Er/Tm, Tm/Ho) microstructures. J. Mater. Chem. 22, 10889–10899 (2012).

Chen, G. Y., Liu, H. C., Liang, H. J., Somesfalean, G. & Zhang, Z. G. Upconversion emission enhancement in Yb3+/Er3+-codoped Y2O3 nanocrystals by tridoping with Li+ ions. J. Phys. Chem. C 112, 12030–12036 (2008).

Wang, F. et al. Simultaneous phase and size control of upconversion nanocrystals through lanthanide doping. Nature 463, 1061–1065 (2010).

Chen, X. Q., Liu, Z. K., Sun, Q., Ye, M. & Wang, F. P. Upconversion emission enhancement in Er3+/Yb3+-codoped BaTiO3 nanocrystals by tridoping with Li+ ions. Opt. Commun. 284, 2046–2049 (2011).

Zhao, C. Z. et al. Li+ ion doping: an approach for improving the crystallinity and upconversion emissions of NaYF4:Yb3+, Tm3+ nanoparticles. Nanoscale 5, 8084–8089 (2013).

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grant No. 11474365, 61176010 and 61172027, Guangdong Natural Science Foundation under Grant No. 2014A030311049, Science and Technology Planning Project of Guangdong Province (2017B010xxxxxx).

Author information

Authors and Affiliations

Contributions

H.L. performed the experiments and wrote the manuscript; H.L. carried out the optical and structural characterizations of the as-synthesized samples; D.K.X. and Y.L.Z. participated in experiment design and helpful recommendations; D.K.X., A.M.L., L.Y., Z.R.Q., S.H.Y. and Y.L.Z. participated in the analysis of experimental data; All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lin, H., Xu, D., Li, A. et al. Facile synthesis and emission enhancement in NaLuF4 upconversion nano/micro-crystals via Y3+ doping. Sci Rep 7, 13762 (2017). https://doi.org/10.1038/s41598-017-14228-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-14228-9

This article is cited by

-

Structural and electrical properties of Ca2+-substituted barium magnesium niobate ceramics

Journal of Materials Science: Materials in Electronics (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.