Abstract

High mobility thin-film transistor (TFT) is crucial for future high resolution and fast response flexible display. Remarkably high performance TFT, made at room temperature on flexible substrate, is achieved with record high field-effect mobility (μ FE ) of 345 cm2/Vs, small sub-threshold slope (SS) of 103 mV/dec, high on-current/off-current (I ON /I OFF ) of 7 × 106, and a low drain-voltage (VD) of 2 V for low power operation. The achieved mobility is the best reported data among flexible electronic devices, which is reached by novel HfLaO passivation material on nano-crystalline zinc-oxide (ZnO) TFT to improve both I ON and I OFF . From X-ray photoelectron spectroscopy (XPS) analysis, the non-passivated device has high OH-bonding intensity in nano-crystalline ZnO, which damage the crystallinity, create charged scattering centers, and form potential barriers to degrade mobility.

Similar content being viewed by others

Introduction

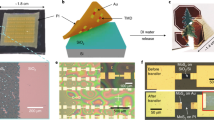

The flexible electronics is the key technology for bendable light weight display1,2,3,4,5,6,7. Similar to traditional rigid displays, the higher mobility TFT1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24 is demanded for next generation higher density, faster speed, and lower power flexible display6. The amorphous InZnGaO (IGZO) TFT5,6,7,8,9,10 is a potential candidate for flexible electronics due to the low off-current (I OFF ) from its large energy bandgap and high mobility of overlapped s-orbitals. However, the major issue for IGZO TFT is the rare Indium quantity in Earth’s crust and its high price. Alternatively, crystallized ZnO TFT is another candidate due to its better crystallinity than amorphous structure, similar with the much higher mobility of poly-Si than amorphous-Si TFTs. However, no high mobility poly-ZnO TFT was reported to date. In this paper, we demonstrate a high performance nano-crystallized ZnO TFT on low-cost Polyethylene naphthalate (PEN) flexible substrate processed at room temperature. Remarkably high μ FE of 345 cm2/Vs was achieved in nano-crystalline ZnO TFT on flexible substrate with a high dielectric constant (high-κ) gate oxide25,26,27,28,29. This μ FE value is even higher than IGZO and ZnON TFTs made on rigid glass22, 23 that is also the record highest value for devices on flexible substrate1,2,3,4,5,6,7. The high mobility is further supported by the low interface trap density from the small SS of only 103 mV/dec. Besides, high I ON /I OFF of 7 × 106 and a low VD of 2 V were measured to reach low switching power of \({C}_{G}{V}_{D}^{2}f / 2\), where C G and f are the gate capacitance and operation frequency, respectively. This remarkably high mobility TFT is achieved using novel HfLaO passivation on nano-crystalline ZnO. For comparison, the control non-passivated device has a μ FE of 43 cm2/Vs. To understand such large mobility improvement, the X-ray photoelectron spectroscopy (XPS) was performed. The non-passivated ZnO showed a strong OH bonding signal. The formed HO-Zn-OH compound via moisture absorption will break the Zn-O bonding in ZnO crystal to form dangling bonds and charged scattering centers to lower the mobility strongly. In contrast to other passivation methods14,15,16,17,18,19,20,21, the LaO-based dielectric has important advantage of moisture absorption to lower the OH bonding formation as evident from the XPS data25,26,27,28,29. The remarkably high μ FE HfLaO/ZnO TFT suggests the excellent opportunity for both flexible and rigid display applications.

Results

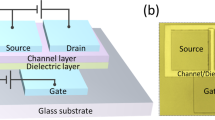

The fabricated devices on flexible PEN substrate is shown in the photo of Fig. 1. Figure S1(a,b) show the capacitance-voltage (C-V) and current-voltage (J-V) characteristics of Al/high-κ metal-gate capacitor fabricated on the same flexible PEN substrate, respectively. A high capacitance density of 0.35 μF/cm2 was measured that lead to an equivalent-oxide-thickness (EOT) of 9.9 nm. A still low leakage current of 1.4 × 10−5 A/cm2 was measured at 1.5 V, even processed at room temperature. This is due to the merit of high-κ dielectrics, especially the higher κ TiO2 dielectric. The TiO2 has higher κ value for low voltage operation. To improve the interface30, extra SiO2 dielectric was inserted between ZnO and TiO2. To improve the leakage current via the low conduction band offset (ΔEC) of TiO2, stacked TiO2/HfO2 were applied31.

Figure 2(a–c) show the transistor’s drain-source current versus drain-source voltage (I DS -V DS ) and I DS versus gate-source voltage (I DS -V GS ) characteristics of ZnO/high-κ/metal-gate TFTs with and without HfLaO passivation. The ZnO TFTs without passivation show reasonable performance of I ON /I OFF of 2 × 105, SS of 112 mV/dec, and a VT of 0.78 V. Here the gate leakage current is lower than I OFF due to the thick stacked gate dielectric. The ZnO TFTs after HfLaO passivation shows more than one order of magnitude higher I ON and 4 times lower I OFF , with large I ON /I OFF of 7 × 106, small SS of 103 mV/dec, and a low VT of 0.13 V. These good device integrities were achieved at a low VD of 2 V that is crucial to lower the switching power by orders of magnitude than existing TFT devices. Besides, the steep SS can also turn on the transistor faster for a lower voltage and power operation.

The μ EF -V GS characteristics is plotted in Fig. 3 from the measured I DS -V GS characteristics. For control non-passivated devices, an acceptable peak μ FE of 43 cm2/Vs is obtained for room-temperature-processed ZnO TFT. The TFT devices after HfLaO passivation has remarkably high μ FE of 345 cm2/Vs; this is the highest value for TFT on flexible substrate1,2,3,4,5,6,7 and is even higher than the reported IGZO and ZnON TFTs fabricated on rigid substrate22, 23. The much improved μ FE for HfLaO-passivated device is owing to the higher I ON and the lower I OFF . It is important to notice that the μ FE decreases monotonically with decreasing gate length32, 33:

where RSD is the source/drain series resistance, μFE is the apparent field-effect mobility and μ0 is the true field effect mobility. At long gate length, the μFE is approaching to μ0; thus, the long 48 μm gate length device was used.

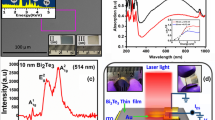

To understand the mechanism of such large mobility improvement, material and structure analysis were performed. Figure 4(a) shows the secondary ion mass spectrometry (SIMS) depth profile, where a ZnO channel, HfO2, TiO2, and thin SiO2 gate dielectric stack were recognized. The device structure of Al contact, ZnO channel, high-κ gate dielectric stack, and TaN metal-gate were also observable from the cross-sectional transmission electron microscopy (TEM) image shown in Fig. 4(b). The ZnO active layer forms columnar nano-crystalline structure with a size of ~10–20 nm. The formed crystalline structure is further evidenced from the X-ray diffraction (XRD) spectra shown in Fig. 4(c). Highly oriented phases of XRD peaks were measured, even though the ZnO was deposited by sputtering at room temperature. The full-width at half-maximum (FWHM) of XRD spectra are comparable with the data of ZnO published in literature34, 35, while the IGZO has an amorphous structure36.

Figure 5(a,b) show the XPS spectra without and with HfLaO passivation, respectively. The atomic composition of nano-crystalline structure is identified to be Zn2+-O2−, as measured from the XPS spectra. It is important to notice that significant amount of OH bonding signal was also measured for non-passivated device. The OH bonding in nano-crystalline ZnO was originated from the moisture absorption of ambient air, even though dry process steps were used to fabricate the devices. Similar strong moisture absorption is well known in IGZO to cause degradation.

The chemical reaction of ZnO and H2O is expressed as:

In addition to surface, the tiny H2O molecule can also react with grain boundaries through the thin 20-nm ZnO. Here the grain boundaries are highly reactive due to their high defect density. Once the Zn(OH)2 was formed, it damaged the Zn-O bonded nano-crystal and created dangling bonds that further form charged states in the ZnO bandgap. The decreased XPS OH signal and related charged defects are also supported from the high positive charge density (ΔQp) of 2 × 1012 cm−2, which was obtained from the VT shift (ΔVT) between HfLaO-passivated and non-passivated ZnO devices shown in Fig. 3(b), from the ΔQp = CG × ΔVT. Such positive charges and dangling bonds also found in the interim SiOx region between SiO2 and Si body, the origin of positive fixed oxide charges in SiO2/Si metal-oxide-semiconductor field-effect transistor (MOSFET) shown in text book. On the other hand, the OH bonding signal in XPS spectra of Fig. 5(b) is much lowered for HfLaO passivated ZnO device. It is well known the high-κ gate dielectric will absorb the moisture25,26,27,28,29, especially the La2O3, which in turn reduce the Zn(OH)2 formation.

The high-density positive ΔQp further causes Fermi-level closer to valance band, increases the ZnO depletion region, and lower the n-type ZnO conduction, as shown in the schematic diagrams of Fig. 6. The electron wave-function in a MOSFET typically distributes over 20 nm30; therefore the high-density ΔQp will also increase electron scattering rate and decrease mobility. However, the passivation does not affect the gate EOT, because the EOT of a TFT only counts the dielectric next to the gate. Because proper passivation blocks the reaction between H2O and ZnO, the OH bonding in HfLaO/ZnO is much reduced to lower ΔQp and potential barriers at grain boundaries. This in succession leads to much higher mobility, because the ZnO has overlapped s-orbitals for conduction.

Table 1 compares the device performance of various materials on flexible and rigid substrates. The mobility of HfLaO-passivated ZnO TFT is higher than the IGZO and ZnON TFTs on rigid substrate22, 23 that is also the record highest value for TFTs on flexible substrate1,2,3,4,5,6,7. This is possible because the poly-crystalline material always has better material quality and higher mobility than amorphous structure, and the mobility improvement can be as large as ~100 times for poly-Si versus amorphous-Si TFTs. The very high mobility ZnO TFT with excellent SS, large I ON /I OFF and low VD are vital for both DC and AC power saving. The simple process and low material cost of nano-crystalline ZnO device should have strong impact on next generation display, as long as OH bonding related charge traps and grain boundary potential barriers are improved by proper passivation. The achieved high mobility on amorphous material is also the enabling technology for high-speed 3D brain-mimicking chip24.

In conclusion, very high mobility, excellent SS, large I ON /I OFF , low VD, and low power operation were achieved in ZnO TFT device that is crucial for display and 3D IC. The excellent device integrity is due to the novel passivation scheme with simple process.

Methods

The bottom-gate ZnO/high-κ/metal-gate TFTs were made on flexible polyethylene naphthalate (PEN) substrate. In addition to its low cost, the PEN substrate has good properties of a low linear thermal expansion coefficient, surface smoothness, and optical clarity. A 300-nm smoothing SiO2 layer was first deposited on PEN substrate. Then the 60-nm TaN gate metal, tri-layer gate dielectrics of 50-nm HfO2, 40-nm TiO2 and 4-nm-SiO2, and a 20-nm ZnO active layer were deposited by physical vapor deposition (PVD). Then the Al source/drain (S/D) electrodes was formed. Finally, the device was passivated by 20 nm thick HfLaO dielectric with opened S/D probing window. The TaN gate electrode was deposited by sputtering at a power of 800 W, Ar/N2 of 100/10 sccm, and a pressure of 3 × 10−3 torr. The gate dielectric stacks were deposited by electron-gun evaporation at 5 KV, and the deposition rates were 0.24/0.2/0.1 Å/sec, respectively. The ZnO channel were deposited by sputtering at a power of 100 W, Ar/O2 of 20/5 sccm, and 1 Å/sec deposition rate. The Al source-drain was deposited by thermal evaporation deposition. The HfLaO was deposited by electron-gun evaporation at a deposition rate of 0.15 Å/sec. Before deposition, the chambers were pumped down to 3 × 10−6 torr. The low deposition rate is important to reach good quality. No post-deposition annealing was used that is the merit of this work. The gate size of fabricated TFT is 48-μm × 505-μm. To investigate the large mobility improvement, X-ray diffraction (XRD), secondary ion mass spectrometry (SIMS), cross-sectional transmission electron microscopy (TEM), and X-ray photoelectron spectroscopy (XPS) were used to analyze the material property. Very low etching rate of 0.2 Å/sec was used in the XPS measurement due to the thin 20 nm HfLaO passivation layer.

References

Li, H. U. et al. ZnO thin film transistors for more than just displays. IEDM Tech. Dig. 523 (2015).

Petrone, N., Cui, X., Hone, J., Chari, T. & Shepard, K. Flexible 2D FETs using hBN dielectrics. IEDM Tech. Dig. 534 (2015).

Kao, H. L. et al. Strain-induced very low noise RF MOSFETs on flexible plastic substrate. Symp. on VLSI Tech. Dig. 160 (2005).

Lin, Y. Y. et al. Stable and high-performance flexible ZnO thin-film transistors by atomic layer deposition. ACS Appl. Mater. Interfaces 7, 22610 (2015).

Nomura, K. et al. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 432, 488, doi:10.1038/nature03090 (2004).

Kamiya, T., Nomura, K. & Hosono, H. Present status of amorphous In–Ga–Zn–O thin-film-transistors. Sci. Technol. Adv. Mater. 11, 044305, doi:10.1088/1468-6996/11/4/044305 (2010).

Su, N. C. et al. Low-voltage-driven flexible InGaZnO thin-film transistor with small subthreshold swing. IEEE Electron Device Lett. 31, 680, doi:10.1109/LED.2010.2047232 (2010).

Zan, H. W., Yeh, C. C., Meng, H. F., Tsai, C. C. & Chen, L. H. Achieving high field-effect mobility in amorphous indium-gallium-zinc oxide by capping a strong reduction layer. Adv. Mater. 24, 3509, doi:10.1002/adma.201200683 (2012).

Iwasaki, T. et al. Combinatorial approach to thin-film transistors using multicomponent semiconductor channels: An application to amorphous oxide semiconductors in In–Ga–Zn–O system. Appl. Phys. Lett. 90, 242114, doi:10.1063/1.2749177 (2007).

Bak, J. Y. et al. Origin of degradation phenomenon under drain bias stress for oxide thin film transistors using IGZO and IGO channel layers. Scientific Reports 5, 7884, doi:10.1038/srep07884 (2015).

Yang, C. et al. Solution-processed flexible ZnO transparent thin-film transistors with a polymer gate dielectric fabricated by microwave heating. Nanotchnology 20, 465201, doi:10.1088/0957-4484/20/46/465201 (2009).

Park, J. S. et al. Flexible full color organic light-emitting diode display on polyimide plastic substrate driven by amorphous indium gallium zinc oxide thin-film transistors. Appl. Phys. Lett. 95, 013503, doi:10.1063/1.3159832 (2009).

Lim, W. et al. Low-temperature-fabricated InGaZnO4 thin film transistors on polyimide clean-room tape. Appl. Phys. Lett. 93, 252103, doi:10.1063/1.3054167 (2008).

Jeong, J. K., Yang, H. W., Jeong, J. H., Mo, Y. G. & Kim, H. D. Origin of threshold voltage instability in indium-gallium-zinc oxide thin film transistors. Appl. Phys. Lett. 93, 123508, doi:10.1063/1.2990657 (2008).

Park, J. et al. The influence of SiOx and SiNx passivation on the negative bias stability of Hf–In–Zn–O thin film transistors under illumination. Appl. Phys. Lett. 96, 262109, doi:10.1063/1.3435482 (2010).

Yang, S. et al. Improvement in the photon-induced bias stability of Al–Sn–Zn–In–O thin film transistors by adopting AlOx passivation layer. Appl. Phys. Lett. 96, 213511, doi:10.1063/1.3432445 (2010).

Cho, D. et al. Transparent Al–Zn–Sn–O thin film transistors prepared at low temperature. Appl. Phys. Lett. 93, 142111, doi:10.1063/1.2998612 (2008).

Lee, K. et al. ZnO-based low voltage inverter with low-k/high-k double polymer dielectric layer. Appl. Phys. Lett. 93, 193514, doi:10.1063/1.3028093 (2008).

Liu, S. E. et al. Influence of passivation layers on characteristics of a-InGaZnO thin-film transistors. IEEE Electron Device Lett. 32, 2 (2011).

Fortunato, E., Barquinha, P. & Martins, R. Oxide semiconductor thin-film transistors: A review of recent advances. Adv. Mater. 24, 2945, doi:10.1002/adma.v24.22 (2012).

Lee, S. W., Suh, D., Lee, S. Y. & Lee, Y. H. Passivation effect on gate-bias stress instability of carbon nanotube thin film transistors. Appl. Phys. Lett. 104, 163506, doi:10.1063/1.4873316 (2014).

Kim, S. I. et al. High performance oxide thin film transistors with double active layers. IEDM Tech. Dig. 73 (2008).

Kim, T. S. et al. High performance gallium-zinc oxynitride thin film transistors for next-generation display applications. IEDM Tech. Dig. 660 (2013).

Shih, C. W., Chin, A., Lub, C. F. & Yi, S. H. Extremely high mobility ultra-thin metal-oxide with ns2np2 configuration. IEDM Tech. Dig. 145 (2015).

Wu, Y. H., Yang, M. Y., Chin, A. & Chen, W. J. Electrical characteristics of high quality La2O3 dielectric with equivalent oxide thickness of 5 Å. IEEE Electron Device Lett. 21, 341, doi:10.1109/55.847374 (2000).

Wang, X. P. et al. Dual metal gates with band-edge work functions on novel HfLaO high-κ gate dielectric. Symp. on VLSI Tech. Dig. 9 (2006).

Cheng, C. F. et al. Very low Vt [Ir-Hf]/HfLaO CMOS using novel self-aligned low temperature shallow junctions. IEDM Tech. Dig. 333 (2007).

Wang, X. P. et al. Wide Vfb and Vth tunability for metal gated MOS devices with HfLaO gate dielectrics. IEEE Electron Device Lett. 28, 258, doi:10.1109/LED.2007.891757 (2007).

Lin, S. H., Liu, S. L., Yeh, F. S. & Chin, A. Low Vt TaN/HfLaO n-MOSFETs using low temperature formed source-drain junctions. IEEE Electron Device Lett. 30, 75, doi:10.1109/LED.2008.2009011 (2009).

Liao, C. C. et al. Metal-gate/high-κ/Ge nMOS at small CET with higher mobility than SiO2/Si at wide range carrier densities. IEEE Electron Device Lett. 34, 163, doi:10.1109/LED.2012.2230241 (2013).

Lin, S. H. et al. High density and low leakage current MIM capacitor using stacked TiO2/ZrO2 insulators. IEEE Electron Device Lett. 30, 715, doi:10.1109/LED.2009.2022775 (2009).

Chen, K. Y. et al. Influence of contact effect on the performance of microcrystalline siliconthin-film transistors. Appl. Phys. Lett. 89, 203509, doi:10.1063/1.2390634 (2006).

Chen, R. et al. Self-aligned top-gate InGaZnO thin film transistors using SiO2/Al2O3 stack gate dielectric. Thin Solid Films 548, 572, doi:10.1016/j.tsf.2013.09.020 (2013).

Im, S., Jin, B. J. & Yi, S. Ultraviolet emission and microstructural evolution in pulsed-laser-deposited ZnO films. J. Appl. Phys. 87, 9 (2000).

Lin, S. S. & Huang, J. L. Effect of thickness on the structural and optical properties of ZnO films by r.f. magnetron sputtering. Surf. Coat. Technol. 185, 222, doi:10.1016/j.surfcoat.2003.11.014 (2004).

Kim, W. K. et al. Stable high conductive amorphous InGaZnO driven by hydrogenation using hot isostatic pressing. Appl. Phys. Lett. 98, 122109, doi:10.1063/1.3567635 (2011).

Acknowledgements

This paper’s publication was supported in part by Ministry of Science and Technology of Taiwan.

Author information

Authors and Affiliations

Contributions

C.W. Shih did the experiments; Albert Chin wrote the main manuscript text. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

The results of this research have important financial interests for both Display, ultra-low power 3D IC and CTFT.

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shih, C.W., Chin, A. Remarkably High Mobility Thin-Film Transistor on Flexible Substrate by Novel Passivation Material. Sci Rep 7, 1147 (2017). https://doi.org/10.1038/s41598-017-01231-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-01231-3

This article is cited by

-

CMOS backend-of-line compatible memory array and logic circuitries enabled by high performance atomic layer deposited ZnO thin-film transistor

Nature Communications (2023)

-

Grain boundary passivation via balancing feedback of hole barrier modulation in HfO2-x for nanoscale flexible electronics

Nano Convergence (2022)

-

A phased array based on large-area electronics that operates at gigahertz frequency

Nature Electronics (2021)

-

Development of optical MEMS-based micromirror arrays on flexible substrate for curvilinear surfaces

Optical and Quantum Electronics (2021)

-

Remarkably High Hole Mobility Metal-Oxide Thin-Film Transistors

Scientific Reports (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.