Abstract

Silicon solar cells are a mainstay of commercialized photovoltaics, and further improving the power conversion efficiency of large-area and flexible cells remains an important research objective1,2. Here we report a combined approach to improving the power conversion efficiency of silicon heterojunction solar cells, while at the same time rendering them flexible. We use low-damage continuous-plasma chemical vapour deposition to prevent epitaxy, self-restoring nanocrystalline sowing and vertical growth to develop doped contacts, and contact-free laser transfer printing to deposit low-shading grid lines. High-performance cells of various thicknesses (55–130 μm) are fabricated, with certified efficiencies of 26.06% (57 μm), 26.19% (74 μm), 26.50% (84 μm), 26.56% (106 μm) and 26.81% (125 μm). The wafer thinning not only lowers the weight and cost, but also facilitates the charge migration and separation. It is found that the 57-μm flexible and thin solar cell shows the highest power-to-weight ratio (1.9 W g−1) and open-circuit voltage (761 mV) compared to the thick ones. All of the solar cells characterized have an area of 274.4 cm2, and the cell components ensure reliability in potential-induced degradation and light-induced degradation ageing tests. This technological progress provides a practical basis for the commercialization of flexible, lightweight, low-cost and highly efficient solar cells, and the ability to bend or roll up crystalline silicon solar cells for travel is anticipated.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in the paper and its extended data files.

References

Ballif, C., Haug, F.-J., Boccard, M., Verlinden, P. J. & Hahn, G. Status and perspectives of crystalline silicon photovoltaics in research and industry. Nat. Rev. Mater. 7, 597–616 (2022).

Razzaq, A., Allen, T. G., Liu, W., Liu, Z. & De Wolf, S. Silicon heterojunction solar cells: techno-economic assessment and opportunities. Joule 6, 514–542 (2022).

Saga, T. Advances in crystalline silicon solar cell technology for industrial mass production. NPG Asia Mater. 2, 96–102 (2010).

Solar PV. IEA https://www.iea.org/reports/solar-pv (2022).

Liu, R., Wang, Z. L., Fukuda, K. & Someya, T. Flexible self-charging power sources. Nat. Rev. Mater. 7, 870–886 (2022).

Massiot, I., Cattoni, A. & Collin, S. Progress and prospects for ultrathin solar cells. Nat. Energy 5, 959–972 (2020).

Tohoda, S. et al. Future directions for higher-efficiency HIT solar cells using a thin silicon wafer. J. Non-Cryst. Solids 358, 2219–2222 (2012).

Sai, H., Umishio, H. & Matsui, T. Very thin (56 μm) silicon heterojunction solar cells with an efficiency of 23.3% and an open-circuit voltage of 754 mV. Sol. RRL 5, 2100634 (2021).

Herasimenka, S. Y., Dauksher, W. J. & Bowden, S. G. >750 mV open circuit voltage measured on 50 μm thick silicon heterojunction solar cell. Appl. Phys. Lett. 103, 053511 (2013).

Sai, H. et al. Potential of very thin and high-efficiency silicon heterojunction solar cells. Prog. Photovolt. 27, 1061–1070 (2019).

Liu, W. et al. Flexible solar cells based on foldable silicon wafers with blunted edges. Nature 617, 717–723 (2023).

Taguchi, M. et al. 24.7% record efficiency HIT solar cell on thin silicon wafer. IEEE J. Photovolt. 4, 96–99 (2014).

Himalaya HJT solar cell. Anhui Huasun Energy Co. https://www.huasunsolar.com/products/hjt-solar-cell/ (2022).

Richter, A. et al. Design rules for high-efficiency both-sides-contacted silicon solar cells with balanced charge carrier transport and recombination losses. Nat. Energy 6, 429–438 (2021).

Qu, X. et al. Identification of embedded nanotwins at c-Si/a-Si:H interface limiting the performance of high-efficiency silicon heterojunction solar cells. Nat. Energy 6, 194–202 (2021).

You, J. et al. Hydrogen-rich c-Si interfacial modification to obtain efficient passivation for silicon heterojunction solar cell. J. Mater. Sci. 31, 14608–14613 (2020).

Wang, J. et al. Performance of heterojunction solar cells with different intrinsic a-Si:H thin layers deposited by RF- and VHF-PECVD. J. Mater. Sci. 32, 25327–25331 (2021).

Ru, X. et al. 25.11% efficiency silicon heterojunction solar cell with low deposition rate intrinsic amorphous silicon buffer layers. Sol. Energy Mater. Sol. Cells 215, 110643 (2020).

Fujiwara, H., Kaneko, T. & Kondo, M. Application of hydrogenated amorphous silicon oxide layers to c-Si heterojunction solar cells. Appl. Phys. Lett. 91, 133508 (2007).

Seif, J. P. et al. Strategies for doped nanocrystalline silicon integration in silicon heterojunction solar cells. IEEE J. Photovolt. 6, 1132–1140 (2016).

Lei, C. et al. Phosphorus treatment to promote crystallinity of the microcrystalline silicon front contact layers for highly efficient heterojunction solar cells. Sol. Energy Mater. Sol. Cells 209, 110439 (2020).

Mazzarella, L. et al. Nanocrystalline n-type silicon oxide front contacts for silicon heterojunction solar cells: photocurrent enhancement on planar and textured substrates. IEEE J. Photovolt. 8, 70–78 (2018).

Zhao, Y. et al. Design and optimization of hole collectors based on nc-SiOx:H for high-efficiency silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 219, 110779 (2021).

Zhang, L. et al. Cerium-doped indium oxide as a top electrode of semitransparent perovskite solar cells. ACS Appl. Mater. Interfaces 15, 10838–10846 (2023).

Kobayashi, E., Watabe, Y. & Yamamoto, T. High-mobility transparent conductive thin films of cerium-doped hydrogenated indium oxide. Appl. Phys. Express 8, 015505 (2015).

Han, C. et al. Towards bifacial silicon heterojunction solar cells with reduced TCO use. Prog. Photovolt. 30, 750–762 (2022).

Adrian, A., Rudolph, D., Willenbacher, N. & Lossen, J. Finger metallization using pattern transfer printing technology for c-Si solar cell. IEEE J. Photovolt. 10, 1290–1298 (2020).

Adachi, D., Hernández, J. L. & Yamamoto, K. Impact of carrier recombination on fill factor for large area heterojunction crystalline silicon solar cell with 25.1% efficiency. Appl. Phys. Lett. 107, 233506 (2015).

Green, M. A. et al. Solar cell efficiency tables (version 61). Prog. Photovolt. 31, 3–16 (2023).

Yoshikawa, K. et al. Silicon heterojunction solar cell with interdigitated back contacts for a photoconversion efficiency over 26%. Nat. Energy 2, 17032 (2017).

Zhang, X. et al. Mass production of crystalline silicon solar cells with polysilicon-based passivating contacts: an industrial perspective. Prog. Photovolt. 31, 369–379 (2023).

JinkoSolar’s high-efficiency n-type monocrystalline silicon solar cell sets our new record with maximum conversion efficiency of 26.1%. Jinko Solar https://www.jinkosolar.com/en/site/newsdetail/1775 (2022).

JinkoSolar’s high-efficiency n-type monocrystalline silicon solar cell sets our new record with maximum conversion efficiency of 26.4%. Jinko Solar https://www.jinkosolar.com/en/site/newsdetail/1827 (2022).

LONGi Solar sets new bifacial mono-PERC solar cell world record at 24.06 percent. LONGi Solar https://www.longi.com/en/news/6821/ (2019).

210 PERC cell efficiency achieves 24.5%, Trina Solar breaks world record for the 24th time. Trina Solar https://www.trinasolar.com/en-glb/resources/newsroom/en210-perc-cell-efficiency-achieves-245-trina-solar-breaks-world-record-24th-time (2022).

Repins, I. L., Kersten, F., Hallam, B., VanSant, K. & Koentopp, M. B. Stabilization of light-induced effects in Si modules for IEC 61215 design qualification. Sol. Energy 208, 894–904 (2020).

Louwen, A., van Sark, W., Schropp, R. & Faaij, A. A cost roadmap for silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 147, 295–314 (2016).

Green, M. A. et al. Solar cell efficiency tables (version 62). Prog. Photovolt. 31, 651–663 (2023).

Yoshikawa, K. et al. Exceeding conversion efficiency of 26% by heterojunction interdigitated back contact solar cell with thin film Si technology. Sol. Energy Mater. Sol. Cells 173, 37–42 (2017).

Acknowledgements

This work has been supported by the National Natural Science Foundation of China (numbers 21606171 and 22179054), the China Postdoctoral Science Foundation (numbers 2021M691326, 2015M580205 and 2017T100160), the Natural Science Foundation of Jiangsu Province (number BK20211345) and the Ministry of Science and Technology of the People’s Republic of China (number DL2022014014L). Z.S. acknowledges the support from the Australian Research Council via Discovery Projects (numbers DP200103315, DP200103332 and DP230100685) and Linkage Projects (number LP220200920). Y.L. thanks Baoyu Huang and Zhengfeng Yang for assistance with the experiments; Jiating Wu and Yuxuan Li for assistance with the preparation for publication; and all group members of X.X. and Z.S. for continuous support. Jiangsu University of Science and Technology and LONGi Green Energy Technology Co., Ltd have equal rights of this work.

Author information

Authors and Affiliations

Contributions

Y.L. conceived the idea, designed the cells, explored the mechanisms, and wrote and revised the manuscript. X.R. designed the experiments and fabricated the solar cells. M.Y. guided the experimental fabrication technology. Y.Z. was responsible for the flexibility simulation and measurement, figures, tables and preparation for publication. S.Y. and C.H. developed the TCO process. F.P. developed the metallization process and conducted the efficiency certification. M.Q., C.X., J.L. and L.F. managed the project and participated in experiment design. C.S. assisted in characterization and data analysis. D.C., J.X. and C.Y. provided resources and funding support. Z.L. and X.X. organized the research. Z.S. supervised the project.

Corresponding authors

Ethics declarations

Competing interests

Jiangsu University of Science and Technology is in the process of applying for a Chinese invention patent (202311478687.5) related to the subject matter of this manuscript. Z.L. and X.X. are co-founders of LONGi Central R&D Institute. X.R., M.Y., S.Y., C.H., F.P., M.Q., C.X., J.L. and L.F. are employees of LONGi. The other authors declare no competing interests.

Peer review

Peer review information

Nature thanks Han-Don Um and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

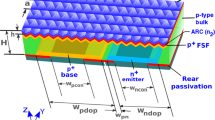

Extended Data Fig. 1 Cross-sectional HRTEM images.

a, Cross-sectional morphology of the c-Si/i:a-Si:H interface. b, Cross-sectional morphology of c-Si/hydrogen-rich i:a-Si:H/a-Si:H. c, Enlarged cross-sectional morphology of the i:a-SiOx:H (1)/a-Si:H (2) composite gradient passivation layers prepared via continuous-plasma CVD.

Extended Data Fig. 2 Hydrogen content.

Effect of hydrogen content (CH) variation in the epitaxy-preventing composite gradient passivation layers on cell performance. The dashed lines in the panels are fit lines to evaluate the data change trends.

Extended Data Fig. 3 Self-restoring nanocrystalline sowing and vertical growth induction (NSVGI).

a, Cross-sectional HRTEM image of the doped contact layer fabricated via conventional random growth. b, Cross-sectional HRTEM image of the doped contact layer fabricated via self-restoring NSVGI.

Extended Data Fig. 4 Self-restoring nanocrystalline sowing.

a, Relationship between the FF and crystallinity fraction of the n+:nc-SiOx:H window layer with a p+:a-Si:H rear emitter. b, Relationship between the FF and crystallinity fraction of the p+:nc-Si:H rear emitter with the optimal n+:nc-SiOx:H window layer. c,d, Variation of CH in i:a-Si:H (2) with sowing duration via self-restoring nanocrystalline sowing and unrestricted nanocrystalline sowing, respectively. e, Enlarged cross-sectional HRTEM image of i:a-Si:H (2) after the unrestricted nanocrystalline sowing. The dashed lines in the panels (a, b, c, d) are fit lines to evaluate the data change trends.

Extended Data Fig. 5 Contact-free laser transfer printing.

Comparison of the cell performance parameters via conventional screen printing and contact-free laser transfer printing (LTP).

Extended Data Fig. 6 Endurance assessment.

Encapsulation schematics for the SF and FT SHJ modules, as well as the laboratory accreditation certificate for the third-party assessment. The certificate is reproduced with permission from Changzhou Sveck Photovoltaic New Material Co., Ltd.

Extended Data Fig. 7 Durability analysis.

a, Impact of the different TCO layers on the PID resistance of the FT and SF SHJ cells for each thickness. b, Statistical analysis of the anti-PID capacities of the FT and SF cells with the ITO and ICO layers. Temperature: 85 °C, humidity: 85%, bias: −1,500 V, duration: 192 h. c, Statistical analysis of the anti-light-induced degradation capacities of the FT and SF cells with the different passivation and contact layers. d, Light-induced degradation resistance of the FT and SF cells for each thickness. Accumulated illumination of 210 kWh·m−2. The dashed lines in the panels (a, d) are fit lines to evaluate the data change trends.

Extended Data Fig. 8 Power recovery in light-induced degradation.

a, VOC, FF, JSC variation of the FT (57 μm) cell during light-induced degradation ageing. b, VOC, FF, JSC variation of the FT (84 μm) cell during light-induced degradation ageing. c, VOC, FF, JSC variation of the SF (125 μm) cell during light-induced degradation ageing. d, VOC, FF, JSC variation of the conventional SHJ (150 μm) cell during light-induced degradation ageing. The dashed lines in the panels are fit lines to evaluate the data change trends.

Extended Data Fig. 9 Visualization of the surface potential distribution during RF-PECVD.

a, Continuous-plasma CVD process with CRCS (fluctuation < ±0.5%). b, Conventional discontinuous-plasma CVD passivation (fluctuation < ±8%). c, Conventional discontinuous-plasma CVD passivation at the reignition moment.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Ru, X., Yang, M. et al. Flexible silicon solar cells with high power-to-weight ratios. Nature 626, 105–110 (2024). https://doi.org/10.1038/s41586-023-06948-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-023-06948-y

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.