Abstract

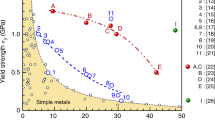

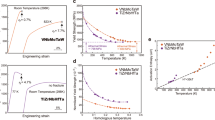

Body-centred cubic refractory multi-principal element alloys (MPEAs), with several refractory metal elements as constituents and featuring a yield strength greater than one gigapascal, are promising materials to meet the demands of aggressive structural applications1,2,3,4,5,6. Their low-to-no tensile ductility at room temperature, however, limits their processability and scaled-up application7,8,9,10. Here we present a HfNbTiVAl10 alloy that shows remarkable tensile ductility (roughly 20%) and ultrahigh yield strength (roughly 1,390 megapascals). Notably, these are among the best synergies compared with other related alloys. Such superb synergies derive from the addition of aluminium to the HfNbTiV alloy, resulting in a negative mixing enthalpy solid solution, which promotes strength and favours the formation of hierarchical chemical fluctuations (HCFs). The HCFs span many length scales, ranging from submicrometre to atomic scale, and create a high density of diffusive boundaries that act as effective barriers for dislocation motion. Consequently, versatile dislocation configurations are sequentially stimulated, enabling the alloy to accommodate plastic deformation while fostering substantial interactions that give rise to two unusual strain-hardening rate upturns. Thus, plastic instability is significantly delayed, which expands the plastic regime as ultralarge tensile ductility. This study provides valuable insights into achieving a synergistic combination of ultrahigh strength and large tensile ductility in MPEAs.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding authors upon request.

References

Lei, Z. F. et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature 563, 546–550 (2018).

Miracle, D. B. & Senkov, O. N. A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448–511 (2017).

Wang, L. et al. Tailoring planar slip to achieve pure metal-like ductility in body-centred-cubic multi-principal element alloys. Nat. Mater. 22, 950–957 (2023).

Wei, S. L. et al. Natural-mixing guided design of refractory high-entropy alloys with as-cast tensile ductility. Nat. Mater. 19, 1175–1181 (2020).

Feng, R. et al. Superior High-temperature strength in a supersaturated refractory high-entropy alloy. Adv. Mater. 33, 2102401 (2021).

Senkov, O. N. et al. Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy. J. Alloys Compd 509, 6043–6048 (2011).

Ma, E. & Wu, X. Tailoring heterogeneities in high-entropy alloys to promote strength-ductility synergy. Nat. Commun. 10, 5623 (2019).

Senkov, O. N. & Semiatin, S. L. Microstructure and properties of a refractory high-entropy alloy after cold working. J. Alloys Compd 649, 1110–1123 (2015).

Wang, S.-P., Ma, E. & Xu, J. New ternary equi-atomic refractory medium-entropy alloys with tensile ductility: Hafnium versus titanium into NbTa-based solution. Intermetallics 107, 15–23 (2019).

Senkov, O. N., Wilks, G. B., Scott, J. M. & Miracle, D. B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 19, 698–706 (2011).

George, E. P., Raabe, D. & Ritchie, R. O. High-entropy alloys. Nat. Rev. Mater. 4, 515–534 (2019).

George, E. P. & Ritchie, R. O. High-entropy materials. MRS Bull. 47, 145–150 (2022).

Li, Z. M., Pradeep, K. G., Deng, Y., Raabe, D. & Tasan, C. C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature 534, 227–230 (2016).

An, Z. B. et al. A novel HfNbTaTiV high-entropy alloy of superior mechanical properties designed on the principle of maximum lattice distortion. J. Mater. Sci. Tech. 79, 109–117 (2021).

Ma, E. & Zhu, T. Towards strength–ductility synergy through the design of heterogeneous nanostructures in metals. Mater. Today 20, 323–331 (2017).

Lilensten, L. et al. Study of a bcc multi-principal element alloy: tensile and simple shear properties and underlying deformation mechanisms. Acta Mater. 142, 131–141 (2018).

Basinski, Z. S., Szczerba, M. S. & Embury, J. D. Tensile instability in face-centred cubic materials. Philos. Mag. A 76, 743–752 (1997).

Huang, H. L. et al. Phase-transformation ductilization of brittle high-entropy alloys via metastability engineering. Adv. Mater. 29, 1701678 (2017).

Su, I.-A. et al. Strengthening mechanisms and microstructural evolution of ductile refractory medium-entropy alloy Hf20Nb10Ti35Zr35. Scr. Mater. 206, 114225 (2022).

Zhang, X. B. et al. Deformation twinning in Ti48.9Zr32.0Nb12.6Ta6.5 medium entropy alloy. Mater. Sci. Eng. A 809, 140931 (2021).

Bu, Y. Q. et al. Local chemical fluctuation mediated ductility in body-centered-cubic high-entropy alloys. Mater. Today 46, 28–34 (2021).

An, Z. B. et al. Spinodal-modulated solid solution delivers a strong and ductile refractory high-entropy alloy. Mater. Horiz. 8, 948–955 (2021).

Mills, L. H. et al. Temperature-dependent tensile behavior of the HfNbTaTiZr multi-principal element alloy. Acta Mater. 245, 118618 (2023).

Li, T. X. et al. CALPHAD-aided design for superior thermal stability and mechanical behavior in a TiZrHfNb refractory high-entropy alloy. Acta Mater. 246, 118728 (2023).

Chen, Y. J. et al. Achieving high strength and ductility in high-entropy alloys via spinodal decomposition-induced compositional heterogeneity. J. Mater. Sci. Tech. 141, 149–154 (2023).

Cui, D. C. et al. Oxygen-assisted spinodal structure achieves 1.5 GPa yield strength in a ductile refractory high-entropy alloy. J. Mater. Sci. Tech. 157, 11–20 (2023).

Williams, D. B. & Carterm, C. B. Transmission Electron Microscopy: A Textbook for Materials Science (Springer, 2009).

Zhang, B. et al. Element-resolved atomic structure imaging of rocksalt Ge2Sb2Te5 phase-change material. Appl. Phys. Lett. 108, 191902 (2016).

Yang, T. et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 362, 933–937 (2018).

Wu, X. L. Chemical short-range orders in high-/medium-entropy alloys. J. Mater. Sci. Tech. 147, 189–196 (2023).

Dini, G., Ueji, R., Najafizadeh, A. & Monir-Vaghefi, S. M. Flow stress analysis of TWIP steel via the XRD measurement of dislocation density. Mater. Sci. Eng. A 527, 2759–2763 (2010).

Smallman, R. E. & Westmacott, K. H. Stacking faults in face-centred cubic metals and alloys. Philos. Mag. 2, 669–683 (1957).

Eleti, R. R. et al. Plastic deformation of solid-solution strengthened Hf-Nb-Ta-Ti-Zr body-centered cubic medium/high-entropy alloys. Scri. Mater. 200, 113927 (2021).

Xian, X. et al. A high-entropy V35Ti35Fe15Cr10Zr5 alloy with excellent high-temperature strength. Mater. Design 121, 229–236 (2017).

Li, H. et al. Uniting tensile ductility with ultrahigh strength via composition undulation. Nature 604, 273–279 (2022).

Li, Z. et al. Dynamic mechanisms of strengthening and softening of coherent twin boundary via dislocation pile-up and cross-slip. Mater. Res. Lett. 10, 539–546 (2022).

Wang, L. et al. Lightweight Zr1.2V0.8NbTixAly high-entropy alloys with high tensile strength and ductility. Mater. Sci. Eng. A 814, 141234 (2021).

Yurchenko, N. et al. Overcoming the strength-ductility trade-off in refractory medium-entropy alloys via controlled B2 ordering. Mater. Res. Lett. 10, 813–823 (2022).

Wu, Y. D. et al. Phase stability and mechanical properties of AlHfNbTiZr high-entropy alloys. Mater. Sci. Eng. A 724, 249–259 (2018).

Zeng, S. et al. Microstructure and mechanical properties of lightweight Ti3Zr1.5NbVAlx (x = 0, 0.25, 0.5 and 0.75) refractory complex concentrated alloys. J. Mater. Sci. Tech. 130, 64–74 (2022).

Yurchenko, N. et al. Effect of B2 ordering on the tensile mechanical properties of refractory AlxNb40Ti40V20−x medium-entropy alloys. J. Alloys Compd. 937, 168465 (2023).

Ding, Q. Q. et al. Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature 574, 223–227 (2019).

Ma, E. Unusual dislocation behavior in high-entropy alloys. Scri. Mater. 181, 127–133 (2020).

Chen, X. F. et al. Direct observation of chemical short-range order in a medium-entropy alloy. Nature 592, 712–716 (2021).

Xun, K. H. et al. Local chemical inhomogeneities in TiZrNb-based refractory high-entropy alloys. J. Mater. Sci. Tech. 135, 221–230 (2023).

Bi, L. X. et al. Weak enthalpy-interaction-element-modulated NbMoTaW high-entropy alloy thin films. Appl. Surf. Sci. 565, 150462 (2021).

Williamson, G. K. & Smallman, R. E. III Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray Debye–Scherrer spectrum. Philos. Mag. 1, 34–46 (1956).

Xu, N. et al. Micromechanical behaviors of Fe20Co30Cr25Ni25 high entropy alloys with partially and completely recrystallized microstructures investigated by in-situ high-energy X-ray diffraction. Metall. Mater. Trans. A 52, 3674–3683 (2021).

Rosenauer, A. et al. Measurement of specimen thickness and composition in Al(x)Ga(1−x)N/GaN using high-angle annular dark field images. Ultramicroscopy 109, 1171–1182 (2009).

Lebeau, J. M. & Stemmer, S. Experimental quantification of annular dark-field images in scanning transmission electron microscopy. Ultramicroscopy 108, 1653–1658 (2008).

LeBeau, J. M., Findlay, S. D., Allen, L. J. & Stemmer, S. Quantitative atomic resolution scanning transmission electron microscopy. Phys. Rev. Lett. 100, 206101 (2008).

Van Aert, S. et al. Procedure to count atoms with trustworthy single-atom sensitivity. Phys. Rev. B 87, 064107 (2013).

Zhang, Y. et al. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 10, 534–538 (2008).

Senkov, O. N., Senkova, S. V. & Woodward, C. Effect of aluminum on the microstructure and properties of two refractory high-entropy alloys. Acta Mater. 68, 214–228 (2014).

Cantor, B. Multicomponent high-entropy Cantor alloys. Prog. Mater Sci. 120, 100754 (2021).

Takeuchi, A. & Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 46, 2817–2829 (2005).

Acknowledgements

This research was supported by the National Key R&D Program of China (grant no. 2021YFA1200201), Beijing Outstanding Young Scientists Projects (grant no. BJJWZYJH01201910005018), Basic Science Center Program for Multiphase Evolution in Hypergravity of the National Natural Science Foundation of China (grant no. 51988101) and the Natural Science Foundation of China (grant nos. 52071003, 91860202). The methodology of high-energy synchrotron X-ray scattering was supported by the National Key Basic Research Program of China (grant no. 2020YFA0406101), Beijing Nova Program (grant no. Z211100002121170), Beijing Municipal Education Commission Project (grant no. PXM2020_014204_000021), China Postdoctoral Science Foundation (grant no. 2022M720311), ‘111’ project (grant no. DB18015) and the Hong Kong Research Grant Council with CityU grant no. 21205621. We also thank Y. Du and F. Liu for discussions on spinodal decomposition and the phase diagram.

Author information

Authors and Affiliations

Contributions

X.H., S.M. and Z.A. designed the study. Z.A., T.Y., B.C., L.Z., R.W., Z.W., B.Z., R.S., J. Zhang, C.S., Y.R., C.L., X.W., L.S., A.L. and J. Zhao carried out the main experiments under the supervision of X.H., S.M. and Y.R. The data were analysed by Z.A., S.M., X.H., Z.Z., Y.C., Z.L., F.R., H.L., W.L., Z.W., L.Y., F.H., C.-T.L. and X.Z. All authors contributed to the discussion of the results and commented on the manuscript. The draft was written by Z.A., S.M. and X.H. X.H. finalized the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Sheng Guo, Eun Soo Park and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Mechanical properties of the annealed HNTVAx (x = 0, 5, 10, 15) alloys.

a, True stress–true strain curves of the four alloys. b, Yield strength against mixing enthalpy of the four alloys. c, Ductility (true strain) against mixing enthalpy of the four alloys.

Extended Data Fig. 2 L-CF structure in the annealed HNTVA10 alloy.

a, STEM-HAADF images of annealed HNTVA10 samples cut from three orthogonal directions. b, Three-dimensional (3D) constructed STEM-HAADF image. c, STEM-HAADF images of L-CFs taken at different tilt angles. d, A 3D constructed image showing the interlocking structure of L-CFs.

Extended Data Fig. 3 Microstructure of the HNTVAx (x = 0, 5, 10, 15) alloys.

(a-d), SEM secondary electron images of cast HNTVA0, HNTVA5, HNTVA10, and HNTVA15 alloys, showing dendrite structure. (e-f), STEM-HAADF image of the cast HNTVA0, HNTVA5, and HNTVA10 alloys, showing L-CFs heterogeneous solid solution structure. The inset shows the corresponding SAED pattern. h, TEM image of the cast HNTVA15 alloy, showing B2 structure. The inset shows the corresponding SAED pattern. (i-l), SEM secondary electron images of the homogenized HNTVA0, HNTVA5, HNTVA10, and HNTVA15 alloys. (m-o), EBSD-IPF images of the HNTVA0, HNTVA5, and HNTVA10 alloys after cold-rolling and annealing at 1200 °C for 5 min. p, EBSD-IPF image of the HNTVA15 alloy after annealing at 1200 °C for 5 min. (q-s), HAADF-STEM images of the HNTVA0, HNTVA5, and HNTVA10 alloys after cold-rolling and annealing at 1200 °C for 5 min, showing L-CF heterogeneous microstructure. t, TEM image of the annealed HNTVA15 alloy, showing B2 structure.

Extended Data Fig. 4 Microstructure of the annealed HNTVAx (x = 5, 10, 15) alloys.

a, XRD patterns showing the phase of the annealed HNTVA5, HNTVA10, and HNTVA15 alloys. All three alloys exhibit a BCC structure. b, Zoomed-in view of the (310) peak of the HNTVA10 alloy reveals that it is an overlap of two peaks, indicating the presence of two BCC variants in this alloy.

Extended Data Fig. 6 STEM-HAADF images show dislocation pinning in the annealed HNTVA10 alloy.

a, Low-magnification STEM-HAADF image showing dislocation pinning (red arrow). b-c, Continuously magnified STEM-HAADF images showing the dislocation pinning structure down to the atomic scale. d, Integrated intensity of each atomic column in the pink box of c, showing the existence of M-CFs (black dashed cycles represent the light atoms and solid cycles represent the heavy atoms) around the dislocation pinning structure.

Extended Data Fig. 7 Atomic-resolution STEM-HAADF image and the corresponding energy-dispersive Xray spectroscopy (EDS) maps for individual elements of Hf, Nb, Ti, V, and Al in the annealed HNTVA10 alloy, taken with \([11\bar{1}]\) zone axis.

The yellow symbol “⊥” marks out the dislocation, white circle lines marked out the M-CFs by V-enriched column.

Extended Data Fig. 8 TEM and STEM-HAADF images show the dislocation configuration of the annealed HNTVA10 alloy at a tensile strain of 5%.

a, TEM image showing the dislocation dipole walls, which indicate dislocation cross-slip. b, TEM image showing the dislocation cross-slip from the primary slip band (yellow dashed line). The red arrows show the tangled dislocations and the interaction structure, indicating dislocation pinning and sluggish motion. c, Atomic-resolution STEM-HAADF image showing edge dislocations, indicating a substantial increase in dislocations at heterointerfaces.

Extended Data Fig. 9 Mechanical behavior and microstructural analysis of the annealed HNTVA10 alloy during in situ tensile testing through SEM at room temperature.

a, Scanning electron microscopy, sample dimensions and the Gatan microtension tester used in the tension tests. b, Stress–strain curves of the HNTVA10 sample. The inset SEM image shows the sample micrographs before and after the tensile test. c-e, SEM images of the slip traces on the sample surfaces of the different interrupted strains. The schematic below illustrates the slip traces, slip system and Schmid factor. Regarding the dislocation substructure during tensile testing, dipolar walls that mainly contain a high density of primary dislocation dipoles are observed, suggesting a typical cross-slip to form a wavy slip line (red arrow). With increasing strain, an additional slip system is activated, resulting in the formation of highly dense straight slip line (pink arrow) in different directions.

Extended Data Fig. 10 Relationship between enhanced yield strength and Al content and mixing enthalpy.

a, Effect of Al content on the yield strength. b, Effect of mixing enthalpy on the yield strength, showing the increment of yield strength as the negative mixing enthalpy becomes more negative, and exhibiting a quasi-linear trend, such as, Zr1.2V0.8NbTi3.6Alx (~27 MPa/(kJ/mol))37, (NbTiZr)100−xAlx (~27 MPa/(kJ/mol))38, (TiZrHfNb)100−xAlx (~28 MPa/(kJ/mol))39, and Ti3Zr1.5NbVAlx (~28 MPa/(kJ/mol))40. However, some scattered data points are also observed, for instance, (NbTiV)100−xAlx (~10 MPa/(kJ/mol))41.

Supplementary information

Supplementary Information

Supplementary Figs. 1–20, Tables 1–3, Notes 1–4 and references.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

An, Z., Li, A., Mao, S. et al. Negative mixing enthalpy solid solutions deliver high strength and ductility. Nature 625, 697–702 (2024). https://doi.org/10.1038/s41586-023-06894-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-023-06894-9

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.