Abstract

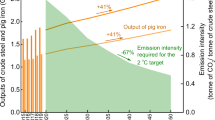

The highly energy-intensive iron and steel industry contributed about 25% (ref. 1) of global industrial CO2 emissions in 2019 and is therefore critical for climate-change mitigation. Despite discussions of decarbonization potentials at national and global levels2,3,4,5,6, plant-specific mitigation potentials and technologically driven pathways remain unclear, which cumulatively determines the progress of net-zero transition of the global iron and steel sector. Here we develop a CO2 emissions inventory of 4,883 individual iron and steel plants along with their technical characteristics, including processing routes and operating details (status, age, operation-years etc.). We identify and match appropriate emission-removal or zero-emission technologies to specific possessing routes, or what we define thereafter as a techno-specific decarbonization road map for every plant. We find that 57% of global plants have 8–24 operational years, which is the retrofitting window for low-carbon technologies. Low-carbon retrofitting following the operational characteristics of plants is key for limiting warming to 2 °C, whereas advanced retrofitting may help limit warming to 1.5 °C. If each plant were retrofitted 5 years earlier than the planned retrofitting schedule, this could lead to cumulative global emissions reductions of 69.6 (±52%) gigatonnes (Gt) CO2 from 2020 to 2050, almost double that of global CO2 emissions in 2021. Our results provide a detailed picture of CO2 emission patterns associated with production processing of iron and steel plants, illustrating the decarbonization pathway to the net-zero-emissions target with the efforts from each plant.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Data for the numerical results plotted in Figs. 1–4 are provided at https://doi.org/10.5281/zenodo.8138490. The link consists of two groups of information on global iron and steel plants: (1) CO2 emission for each iron and steel plant globally; (2) ownership information for iron and steel plants globally. This study also used data and information from other sources. Data for global iron and steel production by country are available from the World Steel Association website: https://worldsteel.org/steel-topics/statistics/. Data for energy consumption for the iron and steel industry by fuel type are available from the IEA World Energy Statistics datasets: https://www.iea.org/data-and-statistics/data-product/world-energy-statistics.

Code availability

Data processing code for the plant-level CO2 emissions can be found at https://doi.org/10.5281/zenodo.7895709.

References

International Energy Agency (IEA). Iron and Steel Technology Roadmap. Towards More Sustainable Steelmaking (IEA, 2020).

Ren, L., Zhou, S., Peng, T. & Ou, X. A review of CO2 emissions reduction technologies and low-carbon development in the iron and steel industry focusing on China. Renew. Sustain. Energy Rev. 143, 110846 (2021).

Kuramochi, T. Assessment of midterm CO2 emissions reduction potential in the iron and steel industry: a case of Japan. J. Clean. Prod. 132, 81–97 (2016).

Hasanbeigi, A., Arens, M., Cardenas, J. C. R., Price, L. & Triolo, R. Comparison of carbon dioxide emissions intensity of steel production in China, Germany, Mexico, and the United States. Resour. Conserv. Recycl. 113, 127–139 (2016).

Fan, Z. & Friedmann, S. J. Low-carbon production of iron and steel: technology options, economic assessment, and policy. Joule 5, 829–862 (2021).

Flores-Granobles, M. & Saeys, M. Minimizing CO2 emissions with renewable energy: a comparative study of emerging technologies in the steel industry. Energy Environ. Sci. 13, 1923–1932 (2020).

van Soest, H. L., den Elzen, M. G. J. & van Vuuren, D. P. Net-zero emission targets for major emitting countries consistent with the Paris Agreement. Nat. Commun. 12, 2140 (2021).

Tong, D. et al. Committed emissions from existing energy infrastructure jeopardize 1.5 °C climate target. Nature 572, 373–377 (2019).

Intergovernmental Panel on Climate Change (IPCC). IPCC Special Report on Global Warming of 1.5 °C. (IPCC, 2018).

Wang, P. et al. Efficiency stagnation in global steel production urges joint supply- and demand-side mitigation efforts. Nat. Commun. 12, 2066 (2021).

International Energy Agency (IEA). The Challenge of Reaching Zero Emissions in Heavy Industry (IEA, 2020).

World Steel Association (WSA). 2021 World Steel in Figures (WSA, 2021).

International Energy Agency (IEA). Energy Technology Perspectives 2020 (IEA, 2020).

Xylia, M., Silveira, S., Duerinck, J. & Meinke-Hubeny, F. Weighing regional scrap availability in global pathways for steel production processes. Energy Effic. 11, 1135–1159 (2017).

Sekiguchi, N. Steel trade structure and the balance of steelmaking technologies in non-OECD countries: the implications for catch-up path. Miner. Econ. 32, 257–285 (2019).

World Steel Association (WSA). worldsteel Short Range Outlook October 2020 (WSA, 2020).

World Steel Association (WSA). worldsteel Short Range Outlook April 2021 (WSA, 2021).

An, R., Yu, B., Li, R. & Wei, Y.-M. Potential of energy savings and CO2 emission reduction in China’s iron and steel industry. Appl. Energy 226, 862–880 (2018).

Tanaka, K. A comparison study of EU and Japan methods to assess CO2 emission reduction and energy saving in the iron and steel industry. Energy Policy 51, 578–585 (2012).

Wen, Z., Wang, Y., Li, H., Tao, Y. & De Clercq, D. Quantitative analysis of the precise energy conservation and emission reduction path in China’s iron and steel industry. J. Environ. Manage. 246, 717–729 (2019).

Wu, F., Huang, N., Zhang, F., Niu, L. & Zhang, Y. Analysis of the carbon emission reduction potential of China’s key industries under the IPCC 2 °C and 1.5 °C limits. Technol. Forecast. Soc. Change 159, 120198 (2020).

Li, Z. & Hanaoka, T. Plant-level mitigation strategies could enable carbon neutrality by 2060 and reduce non-CO2 emissions in China’s iron and steel sector. One Earth 5, 932–943 (2022).

Wang, X. et al. A unit-based emission inventory of SO2, NOx and PM for the Chinese iron and steel industry from 2010 to 2015. Sci. Total Environ. 676, 18–30 (2019).

Axelson, M., Robson, I., Wyns, T. & Khandekar, G. Breaking Through: Industrial Low-CO2 Technologies on the Horizon (Institute for European Studies, 2018).

International Energy Agency. Global industrial CO2 emissions in the Sustainable Development Scenario, 2019-2070. https://www.iea.org/data-and-statistics/charts/global-industrial-co2-emissions-in-the-sustainable-development-scenario-2019-2070 (IEA, 2020).

Ren, M. et al. Decarbonizing China’s iron and steel industry from the supply and demand sides for carbon neutrality. Appl. Energy 298, 117209 (2021).

Yu, X. & Tan, C. China’s pathway to carbon neutrality for the iron and steel industry. Glob. Environ. Change 76, 102574 (2022).

Intergovernmental Panel on Climate Change (IPCC). 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories (IPCC, 2019).

International Energy Agency. World energy statistics and balances. https://www.iea.org/data-and-statistics/data-product/world-energy-statistics-and-balances (IEA, 2020).

World Steel Association. Steel statistical yearbook 2019 (WSA, 2019)

Britz, W. & Roson, R. G-RDEM: a GTAP-based recursive dynamic CGE model for long-term baseline generation and analysis. J. Glob. Econ. Anal. 4, 50–96 (2019).

Dobrota, G., & Căruntu, C. The analysis of the correlation between the economic growth and crude steel production in the period 1991-2011. Metalurgija 52, 425–428 (2013).

Dixon, P. B. & Jorgenson, D. Handbook of Computable General Equilibrium Modeling (Elsevier, 2012).

Wang, D. et al. Economic impacts of climate-induced crop yield changes: evidence from agri-food industries in six countries. Clim. Change 166, 30 (2021).

Corong, E. L., Hertel, T. W., McDougall, R., Tsigas, M. E. & van der Mensbrugghe, D. The standard GTAP model, version 7. J. Glob. Econ. Anal. 2, 1–119 (2017).

Van der Mensbrugghe, D. The standard GTAP model in GAMS, version 7. J. Glob. Econ. Anal. 3, 1–83 (2018).

Aguiar, A., Narayanan, B. & McDougall, R. An overview of the GTAP 9 data base. J. Glob. Econ. Anal. 1, 181–208 (2016).

Fricko, O. et al. The marker quantification of the Shared Socioeconomic Pathway 2: a middle-of-the-road scenario for the 21st century. Glob. Environ. Change 42, 251–267 (2017).

Dellink, R., Bertrand, M., Lanzi, E. & Chateau, J. Long-term economic growth projections in the Shared Socioeconomic Pathways. Glob. Environ. Change 42, 200–214 (2017).

Samir, K. C. & Lutz, W. The human core of the shared socioeconomic pathways: population scenarios by age, sex and level of education for all countries to 2100. Glob. Environ. Change 42, 181–192 (2017).

Bataille, C. et al. A review of technology and policy deep decarbonization pathway options for making energy-intensive industry production consistent with the Paris Agreement. J. Clean. Prod. 187, 960–973 (2018).

Acknowledgements

We thank all group members of CEADs (Carbon Emission Accounts & Datasets; http://www.ceads.net) for data compilation and validation. CEADs advocates for transparent and free data compilation and sharing to the public. We thank Qiang Zhang from the Department of Earth System Science, Tsinghua University, for valuable discussion. We acknowledge support from the National Natural Science Foundation of China (41921005, 7221101088), the National Key R&D Program of China (2022YFE0208500, 2022YFE0208700), the UK Natural Environment Research Council (NE/V002414/1) and the Energy Foundation (G-2009-32416 and G-2015-32938).

Author information

Authors and Affiliations

Contributions

D.G. and T.L. designed the study. T.L. performed the analyses, with support from D.W., W.Z. and C.C. on datasets and from S.M., W.Z., J.M. S.T. and X.Y. on analytical approaches and discussions. T.L. led the writing, with input from all co-authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Wolfgang Bleck and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Schematic diagram of building the CEADs-GSEI.

The whole process includes three main parts: (1) data collection; cylinders represent data categories and circular parallelograms represent specific external data sources; (2) annual activity data calculation; rectangles represent specific information covered in the steelworks information database, rounded rectangles represent processing units within iron and steel plants and diamonds represent calculation processes; (3) CO2 emission estimations and uncertainty analysis; diamonds represent calculation processes.

Extended Data Fig. 2 Maps of the crude steel capacity of iron and steel plants in 2019.

Iron and steel plants are classified into 17 types by iron and steel processing routes and annual crude steel capacity in 2019 (≤9 Mt, ≤ 17 Mt and ≤26 Mt). Colour of points shows the iron and steel processing routes and size of points indicates the capacity size.

Extended Data Fig. 3 Definition of the ten regions in this study.

Colours of areas represent the region classification in this study.

Extended Data Fig. 4 Cumulative annual CO2 emissions in the current operating round from all existing iron and steel plants by region.

Annual CO2 emissions under the 25-year retrofitting cycle are shown with darker shade and annual CO2 emissions under the corresponding average retrofitting cycle are shown with lighter shade.

Extended Data Fig. 5 Cumulative CO2 emissions of the iron and steel industry under SSP1, SSP2 and SSP5 by region from 2020 to 2050.

Colours of bars represent the low-carbon scenarios under different SSPs. Lines of each bar indicate the cumulative emission gap caused by faster and slower retrofitting under the corresponding low-carbon scenario compared with the default scenario under SSP1, SSP2 and SSP5.

Extended Data Fig. 6 Map of the capacity of global iron and steel processing units.

Colour of points shows the processing type of each unit, including 14 types, namely: iron making and casting, steelmaking (BOF, EAF, others), steel refining, coking, powdering, sintering, steel casting and forgings, steel rolling, coal-recovery plants, oxygen-producing plants, power supply units, reheating furnaces, air-separation plants and other plants; size of points indicates the capacity size.

Extended Data Fig. 7 Parameters setting of low-carbon pathways for iron and steel plants in countries planning to achieve carbon neutrality earlier than 2050 or by 2050 (C1).

Grey rectangles represent the processing routes. Blue rectangles represent the corresponding processing routes after low-carbon retrofitting. Rounded rectangles represent the emission-reduction strategies. Diamonds represent the judgement condition.

Extended Data Fig. 8 Parameters setting of low-carbon pathways for iron and steel plants in countries planning to achieve carbon neutrality by 2060 or later (C2).

Grey rectangles represent the processing routes. Blue rectangles represent the corresponding processing routes after low-carbon retrofitting. Rounded rectangles represent the emission-reduction strategies. Diamonds represent the judgement condition.

Supplementary information

Supplementary Information

This file contains Supplementary Sections 1–11 and Supplementary Tables 1–6.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lei, T., Wang, D., Yu, X. et al. Global iron and steel plant CO2 emissions and carbon-neutrality pathways. Nature 622, 514–520 (2023). https://doi.org/10.1038/s41586-023-06486-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-023-06486-7

This article is cited by

-

Plant-by-plant decarbonization strategies for the global steel industry

Nature Climate Change (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.