Abstract

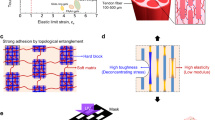

Load-bearing tissues, such as muscle and cartilage, exhibit high elasticity, high toughness and fast recovery, but have different stiffness (with cartilage being significantly stiffer than muscle)1,2,3,4,5,6,7,8. Muscle achieves its toughness through finely controlled forced domain unfolding–refolding in the muscle protein titin, whereas articular cartilage achieves its high stiffness and toughness through an entangled network comprising collagen and proteoglycans. Advancements in protein mechanics and engineering have made it possible to engineer titin-mimetic elastomeric proteins and soft protein biomaterials thereof to mimic the passive elasticity of muscle9,10,11. However, it is more challenging to engineer highly stiff and tough protein biomaterials to mimic stiff tissues such as cartilage, or develop stiff synthetic matrices for cartilage stem and progenitor cell differentiation12. Here we report the use of chain entanglements to significantly stiffen protein-based hydrogels without compromising their toughness. By introducing chain entanglements13 into the hydrogel network made of folded elastomeric proteins, we are able to engineer highly stiff and tough protein hydrogels, which seamlessly combine mutually incompatible mechanical properties, including high stiffness, high toughness, fast recovery and ultrahigh compressive strength, effectively converting soft protein biomaterials into stiff and tough materials exhibiting mechanical properties close to those of cartilage. Our study provides a general route towards engineering protein-based, stiff and tough biomaterials, which will find applications in biomedical engineering, such as osteochondral defect repair, and material sciences and engineering.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper.

References

Wainwright, S. A., Biggs, W. D., Currey, J. D. & Gosline, J. M. Mechanical Design in Organisms (Princeton Univ. Press, 1982).

Higuchi, H. Viscoelasticity and function of connectin/titin filaments in skinned muscle fibers. Adv. Biophys. 33, 159–171 (1996).

Linke, W. A., Popov, V. I. & Pollack, G. H. Passive and active tension in single cardiac myofibrils. Biophys. J. 67, 782–792 (1994).

Hayes, W. C. & Mockros, L. F. Viscoelastic properties of human articular cartilage. J. Appl. Physiol. 31, 562–568 (1971).

Temple, D. K., Cederlund, A. A., Lawless, B. M., Aspden, R. M. & Espino, D. M. Viscoelastic properties of human and bovine articular cartilage: a comparison of frequency-dependent trends. BMC Musculoskelet. Disord. 17, 419 (2016).

Williamson, A. K., Chen, A. C., Masuda, K., Thonar, E. J. & Sah, R. L. Tensile mechanical properties of bovine articular cartilage: variations with growth and relationships to collagen network components. J. Orthop. Res. 21, 872–880 (2003).

Kerin, A. J., Wisnom, M. R. & Adams, M. A. The compressive strength of articular cartilage. Proc. Inst. Mech. Eng. H 212, 273–280 (1998).

Almarza, A. J. & Athanasiou, K. A. Design characteristics for the tissue engineering of cartilaginous tissues. Ann. Biomed. Eng. 32, 2–17 (2004).

Lv, S. et al. Designed biomaterials to mimic the mechanical properties of muscles. Nature 465, 69–73 (2010).

Wu, J. et al. Rationally designed synthetic protein hydrogels with predictable mechanical properties. Nat. Commun. 9, 620 (2018).

Khoury, L. R., Shmilovich, N. J. & Popa, K. I. Study of biomechanical properties of protein-based hydrogels using force-clamp rheometry. Macromolecules 51, 1441–1452 (2018).

Jiang, Y. & Tuan, R. S. Origin and function of cartilage stem/progenitor cells in osteoarthritis. Nat. Rev. Rheumatol. 11, 206–212 (2015).

Treloar, L. R. G. The Physics of Rubber Elasticity (Oxford Univ. Press, 1975).

Gosline, J. et al. Elastic proteins: biological roles and mechanical properties. Phil. Trans. R. Soc. Lond. B 357, 121–132 (2002).

Li, Y., Xue, B. & Cao, Y. Synthetic protein hydrogels. ACS Macro Lett. 9, 512–524 (2020).

Elvin, C. M. et al. Synthesis and properties of crosslinked recombinant pro-resilin. Nature 437, 999–1002 (2005).

McGann, C. L., Levenson, E. A. & Kiick, K. L. Resilin-based hybrid hydrogels for cardiovascular tissue engineering. Macromolecules 214, 203–213 (2013).

Fang, J. et al. Forced protein unfolding leads to highly elastic and tough protein hydrogels. Nat. Commun. 4, 2974 (2013).

McCutchen, C. W. Lubrication of Joints,The Joints and Synovial Fluid Vol. 1, 437–483 (Academic, 1978).

Lu, X. L. & Mow, V. C. Biomechanics of articular cartilage and determination of material properties. Med. Sci. Sports Exerc. 40, 193–199 (2008).

Rief, M., Gautel, M., Oesterhelt, F., Fernandez, J. M. & Gaub, H. E. Reversible unfolding of individual titin immunoglobulin domains by AFM. Science 276, 1109–1112 (1997).

Li, H. et al. Reverse engineering of the giant muscle protein titin. Nature 418, 998–1002 (2002).

Koga, N. et al. Principles for designing ideal protein structures. Nature 491, 222–227 (2012).

Colby, R. H. Structure and linear viscoelasticity of flexible polymer solutions: comparison of polyelectrolyte and neutral polymer solutions. Rhol. Acta 49, 425–442 (2010).

Fancy, D. A. & Kodadek, T. Chemistry for the analysis of protein–protein interactions: rapid and efficient cross-linking triggered by long wavelength light. Proc. Natl Acad. Sci. USA 96, 6020–6024 (1999).

Partlow, B. P., Applegate, M. B., Omenetto, F. G. & Kaplan, D. L. Dityrosine cross-linking in designing biomaterials. ACS Biomater. Sci. Eng. 2, 2108−2121 (2016).

Fang, J. & Li, H. A facile way to tune mechanical properties of artificial elastomeric proteins-based hydrogels. Langmuir 28, 8260–8265 (2012).

Johnson, C. P., Tang, H. Y., Carag, C., Speicher, D. W. & Discher, D. E. Forced unfolding of proteins within cells. Science 317, 663–666 (2007).

Partlow, B. P. et al. Highly tunable elastomeric silk biomaterials. Adv. Funct. Mater. 24, 4615–4624 (2014).

Lei, H. et al. Stretchable hydrogels with low hysteresis and anti-fatigue fracture based on polyprotein cross-linkers. Nat. Commun. 11, 4032 (2020).

Minajeva, A., Kulke, M., Fernandez, J. M. & Linke, W. A. Unfolding of titin domains explains the viscoelastic behavior of skeletal myofibrils. Biophys. J. 80, 1442–1451 (2001).

Gong, J. P., Katsuyama, Y., Kurokawa, T. & Osada, Y. Double-network hydrogels with extremely high mechanical strength. Adv. Mater. 15, 1155–1158 (2003).

Gong, J. P. Why are double network hydrogels so tough? Soft Matter 6, 2583–2590 (2010).

Xu, L., Zhao, X., Xu, C. & Kotov, N. A. Water-rich biomimetic composites with abiotic self-organizing nanofiber network. Adv. Mater. 30, 1703343 (2018).

Xu, L. et al. Conjoined-network rendered stiff and tough hydrogels from biogenic molecules. Sci. Adv. 5, eaau3442 (2019).

Engler, A. J., Sen, S., Sweeney, H. L. & Discher, D. E. Matrix elasticity directs stem cell lineage specification. Cell 126, 677–689 (2006).

Discher, D. E., Janmey, P. & Wang, Y. L. Tissue cells feel and respond to the stiffness of their substrate. Science 310, 1139–1143 (2005).

Huey, D. J., Hu, J. C. & Athanasiou, K. A. Unlike bone, cartilage regeneration remains elusive. Science 338, 917–921 (2012).

Hunziker, E. B. Articular cartilage repair: basic science and clinical progress. A review of the current status and prospects. Osteoarthritis Cartilage 10, 432–463 (2002).

Hayami, T. et al. The role of subchondral bone remodeling in osteoarthritis: reduction of cartilage degeneration and prevention of osteophyte formation by alendronate in the rat anterior cruciate ligament transection model. Arthritis Rheum. 50, 1193–1206 (2004).

Leahy, D. J., Hendrickson, W. A., Aukhil, I. & Erickson, H. P. Structure of a fibronectin type III domain from tenascin phased by MAD analysis of the selenomethionyl protein. Science 258, 987–991 (1992).

Yokota, M. et al. Spontaneous hyaline cartilage regeneration can be induced in an osteochondral defect created in the femoral condyle using a novel doublenetwork hydrogel. BMC Musculoskelet. Disord. 12, 49 (2011).

Li, L. et al. Biofabrication of a biomimetic supramolecular-polymer double network hydrogel for cartilage regeneration. Mater. Des. 189, 108492 (2020).

Okumura, K. I. K. The polyrotaxane gel: a topological gel by figure-of-eight cross-links. Adv. Mater. 13, 485–487 (2001).

Bin Imran, A. et al. Extremely stretchable thermosensitive hydrogels by introducing slide-ring polyrotaxane cross-linkers and ionic groups into the polymer network. Nat. Commun. 5, 5124 (2014).

Liu, J. et al. Tough supramolecular polymer networks with extreme stretchability and fast room-temperature self-healing. Adv. Mater. 29, 1605325 (2017).

Wang, J., Lin, L., Cheng, Q. & Jiang, L. A strong bio-inspired layered PNIPAM-clay nanocomposite hydrogel. Angew. Chem. Int. Edn 51, 4676–4680 (2012).

Sun, W. et al. Molecular engineering of metal coordination interactions for strong, tough, and fast-recovery hydrogels. Sci. Adv. 6, eaaz9531 (2020).

Sun, J. Y. et al. Highly stretchable and tough hydrogels. Nature 489, 133–136 (2012).

Zhao, X. Multi-scale multi-mechanism design of tough hydrogels: building dissipation into stretchy networks. Soft Matter 10, 672–687 (2014).

Lillie, M. A., Chalmers, G. W. & Gosline, J. M. The effects of heating on the mechanical properties of arterial elastin. Connect. Tissue Res. 31, 23–35 (1994).

Bello, A. B., Kim, D., Kim, D., Park, H. & Lee, S. H. Engineering and functionalization of gelatin biomaterials: from cell culture to medical applications. Tissue Eng. Part B 26, 164–180 (2020).

Gao, J. et al. Cell-free bilayered porous scaffolds for osteochondral regeneration fabricated by continuous 3D-printing using nascent physical hydrogel as ink. Adv. Healthc. Mater. 10, e2001404 (2021).

Tsai, C. C. et al. Enzyme-cross-linked gelatin hydrogel enriched with an articular cartilage extracellular matrix and human adipose-derived stem cells for hyaline cartilage regeneration of rabbits. ACS Biomater. Sci. Eng. 6, 5110–5119 (2020).

van den Borne, M. P. et al. International Cartilage Repair Society (ICRS) and Oswestry macroscopic cartilage evaluation scores validated for use in autologous chondrocyte implantation (ACI) and microfracture. Osteoarthritis Cartilage 15, 1397–1402 (2007).

O’Driscoll, S. W., Keeley, F. W. & Salter, R. B. Durability of regenerated articular cartilage produced by free autogenous periosteal grafts in major full-thickness defects in joint surfaces under the influence of continuous passive motion. A follow-up report at one year. J. Bone Joint Surg. Am. 70, 595–606 (1988).

Stanish, W. D. et al. Novel scaffold-based BST-CarGel treatment results in superior cartilage repair compared with microfracture in a randomized controlled trial. J. Bone Joint Surg. Am. 95, 1640–1650 (2013).

Cao, Y., Kuske, R. & Li, H. Direct observation of markovian behavior of the mechanical unfolding of individual proteins. Biophys. J. 95, 782–788 (2008).

Cao, Y. & Li, H. Polyprotein of GB1 is an ideal artificial elastomeric protein. Nat. Mater. 6, 109–114 (2007).

Khoury, L. R. & Popa, I. Chemical unfolding of protein domains induces shape change in programmed protein hydrogels. Nat. Commun. 10, 5439 (2019).

Alexander, P. A., He, Y., Chen, Y., Orban, J. & Bryan, P. N. A minimal sequence code for switching protein structure and function. Proc. Natl Acad. Sci. USA 106, 21149–21154 (2009).

Leahy, D. J., Aukhil, I. & Erickson, H. P. 2.0 A crystal structure of a four-domain segment of human fibronectin encompassing the RGD loop and synergy region. Cell 84, 155–164 (1996).

Acknowledgements

This work is supported by the Natural Sciences and Engineering Research Council of Canada (H.L.), the National Key R&D Program of China (grant no. 2020YFA0908100) (Y.C.), the National Natural Science Foundation of China (81991514 (Q.J.) and 32271408 (L.L.)), and the Natural Science Foundation of Jiangsu Province (BK202200121 (L.L.) and BK20202013 (Q.J.)). We thank R. Shadwick for assistance with Instron tests.

Author information

Authors and Affiliations

Contributions

H.L. conceived the project. L.F. conceptualized the DC hydrogelation strategy and performed experiments on the engineering and characterization of hydrogels and analysed the data. Q.B. and B.X. performed some of the engineering and characterization work on hydrogels and prepared hydrogel scaffolds for in vitro and in vivo experiments. J.L. performed part of the protein engineering work. L.L., Y.C., Q.J. and H.L. designed the in vivo experiments. L.L. and J.J. carried out the in vitro and in vivo experiments. L.F., L.L. and H.L. wrote the initial manuscript. All authors discussed the results and contributed to the final manuscript.

Corresponding author

Ethics declarations

Competing interests

L.F. and H.L. are co-inventors on a provisional patent application (application number PCT/CA2021/051622, submitted by The University of British Columbia) covering the N-DC hydrogelation method described in this article. The other authors declare no competing interests.

Peer review

Peer review information

Nature thanks Elliot Chaikof and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Viscosity of native and denatured (FL)8 protein solutions in PBS and 7M GdHCl.

Denatured (FL)8 (red triangles) displays higher viscosity than native (FL)8 (blue diamonds).

Extended Data Fig. 2 Schematics of the NC-(FL)8 (native crosslinked) hydrogels.

The elastomeric protein (FL)8 was first dissolved in PBS to a high concentration (~200 mg/mL) (a). Upon photo-crosslinking, (FL)8 were crosslinked into a hydrogel network lacking any chain entanglements, owing to the short length of folded (FL)8, resulting in the N-NC (native NC) hydrogel (b). When denatured in GdHCl, the (FL)8 in the hydrogel network unfold, and behave as random coils. The resultant D-NC (denatured NC) hydrogel also remains free of chain entanglements (c).

Extended Data Fig. 3 Photographs of scanning electron microscopy imaging of N-DC and N-NC (FL)8 hydrogels.

Both hydrogels have porous network structures; however, the pore size of the N-DC hydrogel (~2 μm) is significantly smaller than that of the N-NC hydrogel (~20 μm).

Extended Data Fig. 4 Mechanical properties of N-DC and D-DC (FL)8 hydrogels in tensile testing.

(a) Young’s modulus and breaking strain of 20% N-DC and D-DC (FL)8 hydrogels. (b) Toughness and swelling ratio of 20% N-DC and D-DC (FL)8 hydrogels. It is evident that the N-DC (FL)8 hydrogels exhibited much higher Young’s modulus and higher toughness than the N-NC hydrogel. (c-d) Young’s modulus/breaking strain (c) and toughness/swelling ratio (d) of N-DC (FL)8 hydrogels at different protein concentrations. (e-f) Young’s modulus/breaking strain (e) and toughness/swelling ratio (f) of 20% N-DC hydrogels based on (FL)4, (FL)8 and (FL)16, which consist of 4, 8 and 16 tandem repeats of FL. 20% N-DC (FL)4 hydrogels showed similar mechanical properties as those of (FL)8 and (FL)16, suggesting that the length of unfolded (FL)4 is sufficient for chain entanglements. The data is presented as average ± standard deviation (ave. ± S.D.). The number of events n ranges from 3–5 for different experiments, with the exception that n = 18 for the Young’s modulus of 20% (FL)8 N-DC hydrogel.

Extended Data Fig. 5 Compression properties of N-DC (FL)8 hydrogels.

(a) Stress-strain curves of a N-DC (FL)8 hydrogel compressed to failure. Inset shows the photographs of the hydrogel right after failure (1st cycle) and after three more consecutive compression-unloading cycles (4th cycle). Cracks were observed right after failure. Subsequent compression led to propagation of the crack, but the failure is not brittle. (b) Photographs of the N-DC (FL)8 hydrogel during various stages of compression. After unloading, the hydrogel recovered its shape rapidly. (c) Schematics of the hydrogel network structure during compression-unloading. The structure is drawn in a highly schematic manner, and for illustration purpose only. Red circle indicates the chain entanglement, red arrows point to two folded FL domains that may undergo forced-unfolding at high strain, and then refolding after unloading. When compressed to 50% strain and then unloaded, the hydrogel can quickly recover. When compressed to 80% strain, a small number of FL domains unfold. Upon unloading, a large fraction of unfolded FL domains refolds quickly, while a small fraction refolds following a slower kinetics. For simplicity, hydrophobically collapsed FL aggregates are not shown. The force-induced unfolding of the folded FL domains help dissipate energy during loading, and upon unloading, the refolding of FL domains help the hydrogel to regain its shape and mechanical properties. (d—e) Consecutive compression-unloading curves of a N-DC (FL)8 hydrogel at a frequency of 0.08 Hz (d) and 0.67 Hz (e). The loading rate was 20 mm/min in (d) and 200 mm/min in (e). The N-DC hydrogels showed limited fatigue (insets). The percentage is the peak stress of each cycle compared to the initial stress when loaded to strain of 60%.

Extended Data Fig. 6 N-DC Fn-(Cys-FL)4-RGD-(Cys-FL)4-RDG (FLRGD) hydrogels support cell adhesion, spreading, proliferation and differentiation of mouse osteoprogenitor MC3T3-E1 cells.

(a) Epi-fluorescence images of stained cells on N-DC FLRGD hydrogels (On gel) and cell-culture dish (Control). Cells were simultaneously stained with Calcein AM dye and propidium iodide (PI) for staining live and dead cells, respectively. (b) Cell viability determined by live/dead cell staining on N-DC FLRGD hydrogels and cell-culture dish (Control). Error bars correspond to the standard deviation. (c–d) Immunostaining of MC3T3-E1 cells after cultured for 5 days (c) and 10 days (d) in blank, N-DC FLRGD hydrogel and PS culturing dish control groups. The Col I and Runx2 are specific markers for the differentiation in the direction of osteoblast. Clearly, Col I and Runx2 were up-regulated in MC3T3-E1 cells cultured on N-DC-FLRGD hydrogel (Gel) and on coated cell culture dish (control) groups, while Col I and Runx2 were hardly observed in blank (uncoated cell culture dish) groups. (e and f) Expression of osteoblast differentiation-related genes (Col I, RUNX2, ALP and OPN) for MC3T3-E1 cells after cultured for 5 and 10 days. The data represent the relative mRNA levels of the target genes normalized to the levels of the reference genes and are expressed with the levels in the blank group as 1. The values represent the mean ± s.d. Differences between groups were assessed by student’s t-test; NS: p > 0.05; *: p < 0.05; **: p < 0.01; ***: p < 0.001. Cells were cultured on uncoated cell culture dish (Blank), N-DC-FLRGD hydrogel (Gel), and coated cell culture dish (Control).

Extended Data Fig. 7 Tissue remodelling and regeneration process at different time points.

(a) Imaging results and histological staining at week 4 and week 8. Scale bars: 100 μm. Arrows indicate the remaining hydrogel implants after 4 weeks of implantation. After 8 weeks of implantation, all hydrogel implants were degraded. (b) The quantitative analysis at week 4 and week 8, including Micro CT analysis, ICRS scoring system, and O’Driscoll scoring system. Data are presented as mean ± s.d. (n = 6). No obvious difference was observed at week 4 among the three groups. However, the subchondral bone and cartilage in stiff hydrogel treated group exhibited better regeneration phenomenon at week 8. The statistical difference was observed in trabecular parameters and O’Driscoll scoring system. *: p < 0.05; **: p < 0.01; ***: p < 0.001; N.S.: not significant.

Extended Data Fig. 8 Immunological response at different time points evaluated using histology staining.

(a) Histological analysis (H&E staining) of major organs and skins at time point of 48 h and 7 days. Scale bars: 100 μm. (b) Liver function test results at two time points. Data are presented as mean ± s.d. (n = 3). (c) Histological analysis (H&E staining) of the major organs from the New Zealand rabbits after implantation for 12 weeks. Scale bars: 100 μm.

Extended Data Fig. 9 The repairing effect of highly stiff (FL-M23C)8-Fn hydrogel at three time points.

(a) General view of the cartilage and subchondral defects regions at three time points post implantation of the highly stiff hydrogel. Irregular tissue remained in the defect region after 12 weeks implantation. Micro MRI analysis (b) and Micro CT analysis (c) indicated that the regeneration of cartilage regeneration was scarce, and the remolding of subchondral bone was also limited. (d) Histological analysis (H&E staining) of cartilage and subchondral bone regeneration. The hydrogel implants (indicated by the arrows) can be clearly observed even after implantation for 12 weeks. Scale bars: 100 μm.

Supplementary information

Supplementary Information

This file contains Supplementary Fig. 1 and Tables 1–5.

Supplementary Video 1

Consecutive compression–unloading cycles of the N-DC (FL)8 hydrogel. The vdeo shows the deformation and recovery of the N-DC (FL)8 hydrogel during a consecutive loading–unloading test. The final strain is 65%.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fu, L., Li, L., Bian, Q. et al. Cartilage-like protein hydrogels engineered via entanglement. Nature 618, 740–747 (2023). https://doi.org/10.1038/s41586-023-06037-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-023-06037-0

This article is cited by

-

Tough double network hydrogels with rapid self-reinforcement and low hysteresis based on highly entangled networks

Nature Communications (2024)

-

An entanglement association polymer electrolyte for Li-metal batteries

Nature Communications (2024)

-

Building block aspect ratio controls assembly, architecture, and mechanics of synthetic and natural protein networks

Nature Communications (2023)

-

Mimicking stiff tissues through chain entanglements

Nature Reviews Materials (2023)

-

Multi-functional hydrogel electrodes for emerging electronic and robotic applications

Korean Journal of Chemical Engineering (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.