Abstract

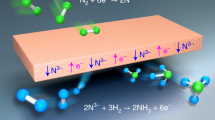

The advantage of a membrane/catalyst system in the oxidative coupling of methane compared with conventional reactive systems is that by introducing oxygen into the catalytic sites through a membrane, the parasitic gas-phase reactions of O2(g)—responsible for lowering product selectivity—can be avoided. The design and fabrication of membrane/catalyst systems has, however, been hampered by low volumetric chemical conversion rates, high capital cost and difficulties in co-designing membrane and catalyst properties to optimize the performance. Here we solve these issues by developing a dual-layer additive manufacturing process, based on phase inversion, to design, fabricate and optimize a hollow-fibre membrane/catalyst system for the oxidative coupling of methane. We demonstrate the approach through a case study using BaCe0.8Gd0.2O3–δ as the basis of both catalyst and separation layers. We show that by using the manufacturing approach, we can co-design the membrane thickness and catalyst surface area so that the flux of oxygen transport through the membrane and methane activation rates in the catalyst layer match each other. We demonstrate that this ‘rate matching’ is critical for maximizing the performance, with the membrane/catalyst system substantially overperforming conventional reactor designs under identical conditions.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All the relevant data generated during this study are available either in the main text or Supplementary Information. Data are also available from the corresponding author upon request. Source data are provided with this paper.

References

Horn, R. & Schlögl, R. Methane activation by heterogeneous catalysis. Catal. Lett. 145, 23–39 (2015).

McFarland, E. Unconventional chemistry for unconventional natural gas. Science 338, 340–342 (2012).

Schwach, P., Pan, X. & Bao, X. Direct conversion of methane to value-added chemicals over heterogeneous catalysts: challenges and prospects. Chem. Rev. 117, 8497–8520 (2017).

Olivos-Suarez, A. I. et al. Strategies for the direct catalytic valorization of methane using heterogeneous catalysis: challenges and opportunities. ACS Catal. 6, 2965–2981 (2016).

Zavyalova, U., Holena, M., Schlögl, R. & Baerns, M. Statistical analysis of past catalytic data on oxidative methane coupling for new insights into the composition of high-performance catalysts. ChemCatChem 3, 1935–1947 (2011).

Gambo, Y., Jalil, A. A., Triwahyono, S. & Abdulrasheed, A. A. Recent advances and future prospect in catalysts for oxidative coupling of methane to ethylene: a review. J. Ind. Eng. Chem. 59, 218–229 (2018).

Farrell, B. L., Igenegbai, V. O. & Linic, S. A viewpoint on direct methane conversion to ethane and ethylene using oxidative coupling on solid catalysts. ACS Catal. 6, 4340–4346 (2016).

Keller, G. E. & Bhasin, M. M. Synthesis of ethylene via oxidative coupling of methane: I. Determination of active catalysts. J. Catal. 73, 9–19 (1982).

Spivey, J. J. & Hutchings, G. Catalytic aromatization of methane. Chem. Soc. Rev. 43, 792–803 (2014).

Guo, X. et al. Direct, nonoxidative conversion of methane to ethylene, aromatics, and hydrogen. Science 344, 616–619 (2014).

Wang, D. J., Rosynek, M. P. & Lunsford, J. H. Oxidative coupling of methane over oxide-supported sodium-manganese catalysts. J. Catal. 155, 390–402 (1995).

Arndt, S. et al. Mn–Na2WO4/SiO2 as catalyst for the oxidative coupling of methane. What is really known? Appl. Catal. A 425–426, 53–61 (2012).

Ito, T., Wang, J., Lin, C. H. & Lunsford, J. H. Oxidative dimerization of methane over a lithium-promoted magnesium oxide catalyst. J. Am. Chem. Soc. 107, 5062–5068 (1985).

Schucker, R. C., Derrickson, K., Ali, A. & Caton, N. The effect of strontium content on the activity and selectivity of Sr-doped La2O3 catalysts in oxidative coupling of methane. Appl. Catal. A 607, 117827 (2020).

Borchert, H. & Baerns, M. The effect of oxygen-anion conductivity of metal–oxide doped lanthanum oxide catalysts on hydrocarbon selectivity in the oxidative coupling of methane. J. Catal. 168, 315–320 (1997).

Zhao, M., Ke, S., Wu, H., Xia, W. & Wan, H. Flower-like Sr-La2O3 microspheres with hierarchically porous structures for oxidative coupling of methane. Ind. Eng. Chem. Res. 58, 22847–22856 (2019).

Kumar, G., Lau, S. L. J., Krcha, M. D. & Janik, M. J. Correlation of methane activation and oxide catalyst reducibility and its implications for oxidative coupling. ACS Catal. 6, 1812–1821 (2016).

Kuo, J. C. W., Kresge, C. T. & Palermo, R. E. Evaluation of direct methane conversion to higher hydrocarbons and oxygenates. Catal. Today 4, 463–470 (1989).

Luo, L. et al. Gas-phase reaction network of Li/MgO-catalyzed oxidative coupling of methane and oxidative dehydrogenation of ethane. ACS Catal. 9, 2514–2520 (2019).

Fleischer, V. et al. Investigation of the role of the Na2WO4/Mn/SiO2 catalyst composition in the oxidative coupling of methane by chemical looping experiments. J. Catal. 360, 102–117 (2018).

Cheng, Z. et al. C2 selectivity enhancement in chemical looping oxidative coupling of methane over a Mg–Mn composite oxygen carrier by Li-doping-induced oxygen vacancies. ACS Energy Lett. 3, 1730–1736 (2018).

Cruellas, A., Melchiori, T., Gallucci, F. & van Sint. Annaland, M. Advanced reactor concepts for oxidative coupling of methane. Catal. Rev. 59, 234–294 (2017).

Tan, X. & Li, K. Oxidative coupling of methane in a perovskite hollow-fiber membrane reactor. Ind. Eng. Chem. Res. 45, 142–149 (2006).

ten Elshof, J. E., Bouwmeester, H. J. M. & Verweij, H. Oxidative coupling of methane in a mixed-conducting perovskite membrane reactor. Appl. Catal. A 130, 195–212 (1995).

Czuprat, O., Schiestel, T., Voss, H. & Caro, J. Oxidative coupling of methane in a BCFZ perovskite hollow fiber membrane reactor. Ind. Eng. Chem. Res. 49, 10230–10236 (2010).

Othman, N. H., Wu, Z. & Li, K. An oxygen permeable membrane microreactor with an in-situ deposited Bi1.5Y0.3Sm0.2O3−δ catalyst for oxidative coupling of methane. J. Membr. Sci. 488, 182–193 (2015).

Lu, Y. Oxygen-permeable dense membrane reactor for the oxidative coupling of methane. J. Membr. Sci. 170, 27–34 (2000).

Wang, H., Cong, Y. & Yang, W. Oxidative coupling of methane in Ba0.5Sr0.5Co0.8Fe0.2O3−δ tubular membrane reactors. Catal. Today 104, 160–167 (2005).

Dimitrakopoulos, G., Koo, B., Yildiz, B. & Ghoniem, A. F. Highly durable C2 hydrocarbon production via the oxidative coupling of methane using a BaFe0.9Zr0.1O3−δ mixed ionic and electronic conducting membrane and La2O3 catalyst. ACS Catal. 11, 3638–3661 (2021).

Arndt, S. et al. A critical assessment of Li/MgO-based catalysts for the oxidative coupling of methane. Catal. Rev. 53, 424–514 (2011).

Vamvakeros, A. et al. Real time chemical imaging of a working catalytic membrane reactor during oxidative coupling of methane. Chem. Commun. 51, 12752–12755 (2015).

Igenegbai, V. O., Meyer, R. J. & Linic, S. In search of membrane-catalyst materials for oxidative coupling of methane: performance and phase stability studies of gadolinium-doped barium cerate and the impact of Zr doping. Appl. Catal. B 230, 29–35 (2018).

Igenegbai, V. O., Almallahi, R., Meyer, R. J. & Linic, S. Oxidative coupling of methane over hybrid membrane/catalyst active centers: chemical requirements for prolonged lifetime. ACS Energy Lett. 4, 1465–1470 (2019).

Ormerod, R. M. Solid oxide fuel cells. Chem. Soc. Rev. 32, 17–28 (2003).

Lin, Y. S. Inorganic membranes for process intensification: challenges and perspective. Ind. Eng. Chem. Res. 58, 5787–5796 (2019).

Cruellas, A. et al. Oxidative coupling of methane in membrane reactors; a techno-economic assessment. Processes 8, 274 (2020).

Song, J. et al. Catalyst-modified perovskite hollow fiber membrane for oxidative coupling of methane. Chin. J. Chem. Eng. 41, 412–419 (2022).

Xu, S. J. & Thomson, W. J. Perovskite-type oxide membranes for the oxidative coupling of methane. AlChE J. 43, 2731–2740 (1997).

Wu, Z., Wang, B. & Li, K. A novel dual-layer ceramic hollow fibre membrane reactor for methane conversion. J. Membr. Sci. 352, 63–70 (2010).

de Jong, J., Benes, N. E., Koops, G. H. & Wessling, M. Towards single step production of multi-layer inorganic hollow fibers. J. Membr. Sci. 239, 265–269 (2004).

Balakotaiah, V., Sun, Z., Gu, T. & West, D. H. Scaling relations for autothermal operation of catalytic reactors. Ind. Eng. Chem. Res. 60, 6565–6582 (2021)

Taniguchi, N., Hatoh, K., Niikura, J., Gamo, T. & Iwahara, H. Proton conductive properties of gadolinium-doped barium cerates at high temperatures. Solid State Ion. 53–56, 998–1003 (1992).

Tsang, W. & Hampson, R. F. Chemical kinetic data base for combustion chemistry. Part I. Methane and related compounds. J. Phys. Chem. Ref. Data 15, 1087–1279 (1986).

Zhu, X., Liu, H., Cong, Y. & Yang, W. Permeation model and experimental investigation of mixed conducting membranes. AlChE J. 58, 1744–1754 (2012).

Haag, S., van Veen, A. C. & Mirodatos, C. Influence of oxygen supply rates on performances of catalytic membrane reactors: application to the oxidative coupling of methane. Catal. Today 127, 157–164 (2007).

van Hassel, B. A., ten Elshof, J. E. & Bouwmeester, H. J. M. Oxygen permeation flux through La1–ySryFeO3 limited by carbon monoxide oxidation rate. Appl. Catal. A 119, 279–291 (1994).

Stansch, Z., Mleczko, L. & Baerns, M. Comprehensive kinetics of oxidative coupling of methane over the La2O3/CaO catalyst. Ind. Eng. Chem. Res. 36, 2568–2579 (1997).

Beck, B. et al. Oxidative coupling of methane—a complex surface/gas phase mechanism with strong impact on the reaction engineering. Catal. Today 228, 212–218 (2014).

Vamvakeros, A. et al. Real-time tomographic diffraction imaging of catalytic membrane reactors for the oxidative coupling of methane. Catal. Today 364, 242–255 (2021).

Vamvakeros, A. et al. Real-time multi-length scale chemical tomography of fixed bed reactors during the oxidative coupling of methane reaction. J. Catal. 386, 39–52 (2020).

Tan, X., Liu, Y. & Li, K. Preparation of LSCF ceramic hollow-fiber membranes for oxygen production by a phase-inversion/sintering technique. Ind. Eng. Chem. Res. 44, 61–66 (2005).

Hufenus, R. et al. Melt-spun polymer fibers with liquid core exhibit enhanced mechanical damping. Mater. Des. 110, 685–692 (2016).

Li, T. et al. X-ray tomography-assisted study of a phase inversion process in ceramic hollow fiber systems—towards practical structural design. J. Membr. Sci. 528, 24–33 (2017).

Li, S. et al. Feasibility and mechanism of lithium oxide as sintering aid for Ce0.8Sm0.2Oδ electrolyte. J. Power Sources 205, 57–62 (2012).

van Hassel, B. A. et al. Oxygen permeation modelling of perovskites. Solid State Ion. 66, 295–305 (1993).

Schiestel, T. et al. Hollow fibre perovskite membranes for oxygen separation. J. Membr. Sci. 258, 1–4 (2005).

Acknowledgements

We thank R. J. Meyer, S. F. Liu and J. R. Johnson at ExxonMobil for helpful discussions. This work was supported by the US Department of Energy, Office of Basic Energy Sciences, Division of Chemical Sciences (DE-SC0021008). We acknowledge financial support from the University of Michigan College of Engineering and technical support from the Michigan Center for Materials Characterization. R.A. acknowledges support from the National Science Foundation Graduate Research Fellowship under grant DGE 1256260.

Author information

Authors and Affiliations

Contributions

All authors designed the plan of the project and experiments. J.W. and A.H.M. designed the additive manufacturing equipment setup. J.W. fabricated the membranes and performed the measurements. J.W., R.A., V.O.I. and A.H.M. performed the membrane/catalyst characterization and characterization data analysis. All authors analysed the data. J.W. and S.L. wrote the paper. All authors edited the paper. S.L. supervised the project.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Andrew Beale, Reinhard Schomäcker and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–5, Tables 1 and 2 and Discussion.

Supplementary Data 1

Source data for Supplementary Fig. 3.

Supplementary Data 2

Source data for Supplementary Fig. 4.

Supplementary Data 3

Source data for Supplementary Fig. 5.

Source data

Source Data Fig. 2

Statistical source data for Fig. 2 (XRD data).

Source Data Fig. 3

Statistical source data for Fig. 3.

Source Data Fig. 4

Statistical source data for Fig. 4.

Source Data Fig. 5

Statistical source data for Fig. 5.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wortman, J., Igenegbai, V.O., Almallahi, R. et al. Optimizing hierarchical membrane/catalyst systems for oxidative coupling of methane using additive manufacturing. Nat. Mater. 22, 1523–1530 (2023). https://doi.org/10.1038/s41563-023-01687-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-023-01687-x