Abstract

By passing the delegated acts supplementing the revised Renewable Energy Directive, the European Commission has recently set a regulatory benchmark for the classification of green hydrogen in the European Union. Controversial reactions to the restricted power purchase for electrolyser operation reflect the need for more clarity about the effects of the delegated acts on the cost and the renewable characteristics of green hydrogen. To resolve this controversy, we compare different power purchase scenarios, considering major uncertainty factors such as electricity prices and the availability of renewables in various European locations. We show that the permission for unrestricted electricity mix usage does not necessarily lead to an emission intensity increase, partially debilitating concerns by the European Commission, and could notably decrease green hydrogen production cost. Furthermore, our results indicate that the transitional regulations adopted to support a green hydrogen production ramp-up can result in similar cost reductions and ensure high renewable electricity usage.

Similar content being viewed by others

Main

The European Commission (EC) published the first regulatory framework for classifying renewable hydrogen (henceforth, green hydrogen), the delegated acts (DAs) supplementing the revised Renewable Energy Directive (RED II)1,2,3. Industry players condemn the regulations as overly strict, anticipating an inevitable production cost increase that could compromise the competitiveness of European green hydrogen and inhibit a local production ramp-up aligned with the REPowerEU plan goals4,5,6,7. Conversely, various non-governmental organizations (NGOs) condemn them as overly soft, labelling them a ‘gold standard for greenwashing’ due to potential risks of increased greenhouse gas (GHG) emissions from allowing the usage of fossil fuel electricity for green hydrogen production and counteracting power sector decarbonization8. To resolve this controversy, the present paper quantifies the effects of the DAs on green hydrogen production cost, its renewable characteristics and the design and operation of water electrolyser plants in the European Union.

Green hydrogen is pivotal in the European Union’s goal to reduce its GHG emissions by at least 55 percent by 2030 (ref. 9). The EC sees a rapid ramp-up of fossil-free and domestic European hydrogen production as a crucial factor to make hydrogen available not only for decarbonization but also to reduce the EU’s dependence on gas imports7. To support this ramp-up and provide legal certainty for investors, the EC published the DAs. Despite their exclusive applicability to green hydrogen used in the mobility sector, the therein-established rules will likely provide a benchmark for regulating further sectors.

Numerous studies on different factors influencing hydrogen production cost and the design of water electrolyser plants exist10,11,12,13,14,15. Particularly noteworthy among these is ref. 10, which uses linear optimization of the design and operation of electrolyser plants to evaluate how varying electricity prices and the uncertainty of photovoltaic (PV) and wind power supplies affect the cost of hydrogen production. Similarly, ref. 11 assesses how the purchase of grid electricity alongside using electricity from on-site renewable energy sources (RESs) influences hydrogen production cost. In addition, ref. 16 should be mentioned, which uses an electricity market model to show how possible regulations for green hydrogen classification could affect total welfare, carbon emissions and hydrogen supply cost in Germany.

To resolve the controversy surrounding the effects of the DAs, this work consists of the following steps. First we introduce the system set-up of the linear optimization model used to mathematically map and evaluate different power purchase scenarios for electrolyser operation. As aforementioned, linear optimization is a well-established method to quantify the effects of different influencing factors on hydrogen production cost. Second, the permissible and impermissible power purchase scenarios for green hydrogen production are derived from the DAs. Subsequently, four evaluation indices are presented, allowing the evaluation of the analysed power purchase scenarios regarding the production cost and the renewable characteristics of green hydrogen. Following this, a variable importance analysis is performed to identify the model’s most influential uncertain input parameters, in terms of their effect on the resulting indices in the analysed scenarios. Then, the effects of the DAs are quantified by comparing the permissible and impermissible power purchase scenarios using the evaluation indices and considering the previously identified uncertain input parameters. Since the DAs include softenings of regulations to support a ramp-up of green hydrogen production in a transition period, their effects are additionally quantified. Finally, the results of the quantifications allow an assessment of whether the controversy that has arisen can be resolved.

System set-up

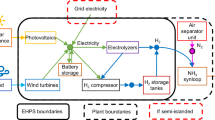

To quantify the cost of green hydrogen production and its renewable characteristics in the subsequently derived power purchase scenarios, the operational cost (COPEX) and the annualized installation cost (CCAPEX) for all components n of the hydrogen production system in Fig. 1 are mathematically minimized (equation (1)) given the economical and technical parameters listed in Supplementary Tables 2–5. All economical input parameters are set to present cost values derived from recent publications and converted into euros (2023 value, €2023) using the Chemical Engineering Plant Cost Index (CEPCI)17.

The dashed box on the left shows the power purchase options. The dashed box on the right shows the hydrogen production plant consisting of a proton exchange membrane (PEM) electrolyser including peripherals (P) and stack, a piston compressor powered by an electric motor (M), and a pressure gas tank as a hydrogen storage option. BB1, electricity bus bar; BB2, hydrogen bus bar.

The cost minimization includes the design and operation of all components included (Table 1) to cover a predefined hydrogen demand. The optimization time frame is one year with an hourly resolution. The formulated optimization problem, including objective function and constraints, is linear (Methods). To map the decrease in specific energy consumption of the electrolyser stack at operating points below the nominal load (Fig. 2a) while keeping the mathematical formulation of the optimization problem linear, the convex area for possible operation points depicted in Fig. 2b is constructed. Hereby, the curved upper bound in Fig. 2b resembles the stepwise linearized characteristic curve of the electrolyser stack that is derived from Fig. 2a. It is constructed by the set of inequality constraints introduced in equations (9)–(11), which, in addition to further detailed information, can be found in Methods.

a, The specific energy consumption of the electrolyser stack \({{\varepsilon }_{{{{\rm{Stack}}}},t}}\) as a function of the stack power consumption PStack,t. b, The convex search space between the stack power consumption PStack,t and the hydrogen mass flow of the electrolyser \(\dot{m}_{{\rm{Ely}},t}\). The red dots in a indicate the evenly distributed operation points {1, 2, 3, …, J} chosen to derive the linear inequality constraints in b that in turn form the characteristics curve of the electrolyser stack. The linear constraints act as an upper bound of the depicted search space for optimal operation points, and the black straight line, with the reciprocal of the specific energy consumption at nominal power \(\frac{1}{{\varepsilon }_{{{{\rm{nom}}}},{{{\rm{Stack}}}}}}\) as its gradient, acts as a lower bound. Detailed information in Methods, particulary around equations 9-12.

Power purchase scenarios

To quantify the effects of the DAs and thus resolve the controversy surrounding them, all relevant permissible and impermissible power purchase scenarios are derived from the DAs.

Permissible scenarios

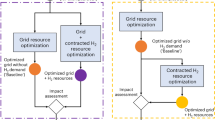

Pursuant to article 27 (3), seventh subparagraph and pursuant to article 25 (2) and article 28 (5), the EC has adopted two DAs (DA I and DA II) to supplement RED II by establishing a union methodology setting out detailed rules. These rules govern the criteria for calculating the share of renewable energy within the final consumption of energy in the transport sector. Regarding green hydrogen as a gaseous transport fuel of non-biological origin, the permissible purchase scenarios for renewable electricity in order to produce green hydrogen by electrolysis can be derived from articles 3 and 4 (1)–(4), DA I. They are hereafter outlined for the scope of this work. Figure 3 provides an overview of the presented scenarios and additional information on them.

-

The direct connection (DC) scenario: article 3 states that electricity is counted as fully renewable if the RES and electrolyser are directly connected or if energy generation and hydrogen production occur within the same installation. Since the DA I regulations aim to ensure emissions savings from green hydrogen usage and additionally to prevent a counteracting of power sector decarbonization, they stipulate a complementary additionality condition requiring a RES commissioning no more than 36 months before the electrolyser installation.

The left side shows that of the four permissible scenarios leading to a green hydrogen classification according to the delegated acts, two are selected for further analysis. As a counterpart, an impermissible power purchase scenario is presented that does not result in a green hydrogen classification. The right side shows that, due to simplifying assumptions regarding taxes and grid fees, the two permissible scenarios are merged into the Renewable scenario, while the impermissible scenario becomes the Mix scenario, for further analysis. Additional scenario information is as follows. Exceptions of conditions on additionality, temporal correlation and geographical correlation apply for the DC + PPA scenario if either the emission intensity of grid electricity on annual average or the day-ahead market coupling prices fall below specified lower thresholds in the respective bidding zone. In the case of the DC + Renewable Grid scenario, the hydrogen production must not exceed a maximum number of hours set in relation to the proportion of renewable electricity in the bidding zone. More detailed information can be found in the delegated act I (ref. 1). Art., Article.

In case additional electricity from the grid is used, it shall still count as fully renewable if:

-

Either, as in the scenario DC + Renewable Grid and as stated in article 4 (1), the electrolyser is located in a bidding zone where the average proportion of renewable electricity was at least 90% in the previous calendar year.

-

Or, as in the scenario DC + Renewable Redispatch and as stated in article 4 (3), the electricity is consumed during an imbalance settlement period during which the hydrogen producer can demonstrate that RESs were dispatched downwards and the production of hydrogen reduced the need for redispatching by a corresponding amount.

-

Or, as in the scenario DC + PPA and as stated in article 4 (2) and (4), the hydrogen producers have concluded one or more renewable power purchase agreements (PPAs) for an amount of electricity that is at least equivalent to the amount used for hydrogen production. Here, the same additionality condition as in the DC scenario applies, along with conditions on hourly temporal correlation and geographical correlation between RES generation and hydrogen production.

Impermissible scenario

To ensure GHG emissions savings compared to that of conventionally produced grey hydrogen, the EC prohibits purchasing grid electricity mix for green hydrogen production. However, low levelized cost for PV and wind power in comparison to recent electricity market prices should economically incentivize an integration of RES electricity in the power purchase for electrolyser operation, as indicated in ref. 11, and thus lead to a substantially lower emissions intensity compared to the exclusive use of grid electricity mix.

-

To quantify this effect, the impermissible scenario DC + PPA + Grid in Fig. 3 is presented, which extends the permissible DC + PPA scenario by the option to purchase grid electricity mix.

Selection process of analysed scenarios

Since not all scenarios derived are relevant for resolving the arisen controversy, some are excluded from further analysis (Fig. 3).

The DC + Renewable Grid scenario is excluded due to the average proportion of renewable electricity in the electricity mix of most European countries not being at least 90%. Furthermore, the DC + Renewable Redispatch scenario is excluded because the provision of ancillary services with electrolyser plants is not finally regulated in most European countries and thus can be seen as a special operation case.

To make broadly applicable findings, electricity taxes and grid fees are assumed to be zero due to their intra-European differences. Given the strict additionality condition, all RESs are considered new installations. Consequently, power purchase from local RESs becomes economically similar to purchase via PPAs. Therefore, the permissible scenarios DC and DC + PPA are merged into the Renewable scenario, and the impermissible DC + PPA + Grid scenario becomes the Mix scenario for further analysis (Fig. 3).

Ultimately, two scenarios remain: the Renewable scenario, which aligns with the DA rules for green classification, and the Mix scenario, which additionally includes optional grid electricity mix usage and thus fails to meet the criteria for a green classification.

Evaluation indices

Four different evaluation indices are introduced to compare the two remaining scenarios and thus quantify the effects of the DAs on the cost and the renewable characteristics of green hydrogen.

-

1.

The on-site hydrogen supply cost (OHSC) is used to measure the hydrogen production cost in each scenario. It quantifies the ratio between the minimized total cost for system design and operation (equation (1)) and the annually covered hydrogen demand.

The following three indices are used to evaluate the renewable characteristics of green hydrogen, covering different cornerstones of the DAs.

-

2.

The equivalent carbon dioxide emission intensity (EI) of hydrogen production \({i}_{{{{\rm{e}}}},{{{{\rm{H}}}}}_{2}}\) is calculated, allowing the evaluation of the GHG impact.

Due to the previously introduced conditions on additionality and temporal correlation, the following two indices are presented in addition to the EI, allowing a more comprehensive evaluation of the renewable characteristics.

-

3.

Assuming all RESs are new installations as per the strict additionality conditions, the additionality index iadd is used to quantify the magnitude of additionality by measuring the relation of the sum of totally installed RESs to nominal electrolyser power.

-

4.

The temporal correlation index itcorr measures the simultaneity between RES generation and electrolyser operation, ranging from zero (no simultaneity) to one (complete simultaneity).

Since this work does not cover the effects of geographical placement on grid infrastructures, the geographical correlation conditions are assumed to be fulfilled. Methods provide further details on index calculations and their limitations.

Variable importance analysis

To subsequently quantify the effects of the DAs as comprehensively but efficiently as possible, a variable importance analysis (VIA) is first performed to identify our model’s most influential uncertain input parameters in the compared scenarios. Supplementary Table 1 enlists the technical and economical uncertain parameters considered in the VIA. Studying the identified parameters in the following allows us to get the most comprehensive impression of the potential effects of the DAs. The performed VIA is a subfield of uncertainty quantification. More concisely, it focuses on a variance-based variable importance measure, quantifying the contribution of the uncertainties of a set of input variables to the uncertainty of the model output18.

The results of the VIA show that the uncertainty in the availability of renewables, represented by different European locations; the grid electricity price; and the grid electricity EI are the primary impact factors on the resulting evaluation indices in the Renewable and Mix scenarios. Supplementary Note 2, Supplementary Fig. 2 and Supplementary Table 1 provide further details on the performed VIA.

Effects of the delegated acts supplementing RED II

To get the most comprehensive impression of the effects of the DAs, the permissible Renewable scenario and the impermissible Mix scenario are compared, given a variation of the previously identified input parameters.

The detailed results of the availability of renewables (AoR) variation can be found in Supplementary Note 1 and Supplementary Fig. 1. The variation is implemented by going through the capacity factor time series for utility-scale PVs and onshore wind turbines of 20 different European locations, sorted by ascending potential yield for both technologies. The interim conclusion at the end of this section contains the main findings from this variation.

The variation in grid electricity price (GEP) shown in Fig. 4 is implemented by increasing the price for power purchase from the grid. The corresponding input parameter is the grid electricity price pGrid in equation (6).

a–d, The evaluation indices for the Renewable scenario (blue dash-dotted line) and the Mix scenario (blue solid line). For reasons of comparability, additional lines are included: the levelized cost of grey hydrogen produced by steam reforming as a function of the natural gas price (a) and the EI of grey hydrogen (b). EU, European Union unweighted average; GRC, Greece; GER, Germany; ESP, Spain; FRA, France. e,f, The added nominal power of the RESs (e) and the nominal electrolyser power and the annual full load hours (FLHa) of the electrolyser (f) in both scenarios. The chosen location for this analysis has a medium availability of renewables, which is represented by the potential yield for utility-scale PVs and onshore wind turbines in potential FLHa: 1,980 potential FLHa for onshore wind turbines and 1,036 potential FLHa for utility-scale PVs. The EIs of grid electricity for Greece, Germany, Spain and France can be found in the delegated act II (ref. 3). The covered hydrogen demand is 10,000 kg per day on average. An alternative visualization of the results as functions of the on-site hydrogen supply cost advantage of the Mix scenario over the Renewable scenario and a breakdown of the total cost in both scenarios can be found in Supplementary Figs. 3 and 4. All further technical and economical assumptions are summarized in Supplementary Tables 2–5. The calculation method for the levelized cost of grey hydrogen can be found in Methods.

The resulting evaluation indices from this variation are shown in Fig. 4a–d. Figure 4b additionally shows a variation of the grid electricity EI. This variation is implemented by increasing the average EI of grid electricity ie,Grid (equation (16)) using values from different European countries. Figure 4e,f shows the resulting design of the RESs and the design and utilization of the water electrolyser in annual full load hours (FLHa). Curves for grey hydrogen produced by steam reforming are added as an additional reference in Fig. 4a,b.

As expected, the Renewable scenario is insensitive to the performed GEP variation (Fig. 4a–d). By contrast, the optional grid electricity purchase in the Mix scenario results in a high dependency of all evaluation indices and design values on the GEP.

The OHSC advantages of the Mix scenario in Fig. 4a, resulting from the additional power purchase option, range from 5.93 €2023 per kilogram H2 for low GEPs to 0.23 €2023 per kilogram H2 for high GEPs at the chosen location with a medium AoR, indicating a medium potential yield for RESs in a European comparison. For the average European Union (EU) non-household GEP (first half of 2023; ref. 19) the advantage is 1 €2023 per kilogram H2.

Figure 4b shows a steep decrease in EI in the Mix scenario for GEPs above 0.05 €2023 kWh–1. For the average EU GEP, the reduction of EI in comparison to grey hydrogen ranges between 95% for France’s grid electricity EI and 75% for Greece’s grid electricity EI. However, the possibility to integrate grid electricity into the power purchase for electrolyser operation for a GEP below 0.12 €2023 kWh–1 can lead to EIs up to 2.73 times higher than those of grey hydrogen. When the integration of a power source is mentioned in the following, this always refers to the integration of electricity from the respective power source into the power purchase for electrolyser operation.

The decrease in EI for GEPs above 0.05 €2023 kWh–1 is the result of the economically favourable integration of RESs, which is reflected in an increase in the additionality index in Fig. 4c. For the average EU GEP, such a high integration of RESs is so favourable that the additionality index of the Mix scenario is about 95% of the RES-reliant Renewable scenario. Above 0.3 €2023 kWh–1, the additionality in the Mix scenario exceeds the additionality in the Renewable scenario. This is due to the higher flexibility in power purchase, which allows a higher integration of comparatively cheap PV power with a simultaneously lower decrease of wind power integration compared to the Renewable scenario, as shown in Fig. 4e.

Figure 4d shows that for GEPs above the EU average, integrating renewable electricity from RESs is economically favourable to the extent that a temporal correlation between electrolyser operation and RES generation above 90% is reached. Above this price level, the dimensioning of the water electrolyser and its utilization are almost identical between the Mix and Renewable scenarios (Fig. 4e). At lower GEPs, building a smaller electrolyser that is used at a higher rate is more economically viable when purchasing grid electricity mix is an option, as in the Mix scenario.

The parameter studies with varying GEP and AoR show that allowing the unrestricted grid electricity integration, which is considered impermissible for green hydrogen production according to the DAs, can lead to notable OHSC advantages, supporting industry players’ concerns about an overly strict regulation inevitably increasing production cost. In addition to the results of the GEP variation, the AoR variation produced advantages between 0.55 €2023 per kilogram H2 and 1.62 €2023 per kilogram H2 in most European locations and under the assumption of an average EU GEP. A visualization of the full range of potential OHSC advantages is shown in Supplementary Fig. 5. Simultaneously, as pointed out by the EC and various NGOs, the unrestricted integration of grid electricity in electrolyser operation can lead to an increase in EI compared to grey hydrogen1,8. However, an increase results only for comparably low GEPs and low AoR. As presumed, this is caused by the relatively low specific cost for RESs, leading to an economically incentivized integration of additional PV and wind power. The economically optimal share of RES electricity in electrolyser operation depends on GEP and AoR. At current electricity price levels, a reduction of the EI compared to grey hydrogen would be achieved in most European locations due to economic incentives alone.

Effects of the transitional rules

The EC softened the regulations set in DA I to support the ramp-up of domestic green hydrogen production in a transition period. Since the NGOs’ criticism about increased emissions focuses on these softenings, the effects of the softening regarding temporal correlation are additionally quantified to achieve a more comprehensible resolution of the current controversy about the effects of the DAs.

The softening allows a monthly instead of an hourly correlation between RES generation and hydrogen production until 2030 for electricity purchased via PPA. Therefore, grid electricity can be included as long as the monthly generation of the corresponding RES is equal to or higher than the monthly electricity consumption of the electrolyser. In the following, this softening scenario is called Balance.

Since the green hydrogen classification regulations for other sectors are still pending, an alternative softening option is additionally evaluated. Here, grid electricity mix usage is permissible as long as the annual share of RES electricity in hydrogen production is at least 90%. Regarding the share of renewable electricity in green hydrogen production, this scenario, here called RES Share, is similar to the permissible DC + Renewable Grid scenario from the DA I (Fig. 3).

Figure 5 extends Fig. 4 by the two softening scenarios. Figure 5a shows similar but slightly higher OHSC advantages over the Renewable scenario for the RES Share scenario compared to the Balance scenario. They range from 1.89 €2023 per kilogram H2 for low GEPs to 0.23 €2023 per kilogram H2 for high GEPs at the chosen location with medium AoR. Above the EU average GEP, these advantages are similar to those of the unrestricted but impermissible Mix scenario. Supplementary Fig. 6 shows a visualization of the full range of potential OHSC advantages for both transitional scenarios.

a–f, The optimization results from Fig. 4a–f complemented by the results of the Balance (dashed line) and RES Share (dotted line) scenarios. The Balance scenario allows the integration of electricity mix from the grid as long as the monthly electricity generation of the RESs equals or exceeds the electricity consumption of the electrolyser, whereas in the RES Share scenario, an integration of grid electricity is allowed, as long as the annual RES electricity share in electrolyser consumption equals or exceeds 90%. The legends in the graphs on the right side also apply to the respective left graphs. The EI of grid electricity is assumed to be the unweighted European average, which is 0.293 kg CO2 kWh–1. All other technical and economical assumptions are the same as in Fig. 4.

The similarities between the transitional scenarios and the impermissible Mix scenario for GEPs above the EU average also apply to the resulting EIs, being at least 85% that of grey hydrogen (Fig. 5b). For lower GEP, the resulting EI in the RES Share scenario is lower in comparison to the Balance scenario, although the additionality index in the Balance scenario is higher, as shown in Fig. 5c. This is due to the monthly balance condition, which necessitates an installation of higher wind power capacities that are less seasonally dependent but more expensive compared to PVs (Fig. 5e). By contrast, the RES Share scenario can rely more on the comparatively cheap PV option leading to the slight OHSC advantages in Fig. 5a.

The temporal correlation index in Fig. 5d at low GEPs indicates a less efficient usage of higher wind power capacities in the Balance scenario compared to the RES Share scenario, resulting in the higher EIs in Fig. 5b.

However, the use of the electrolyser in the Balance scenario is comparatively high. It allows a small dimensioning of the electrolyser, especially for low GEP, as shown in Fig. 5f. To continuously enable the most economical mode of operation possible after the expiry of the transitional rules, a RES and electrolyser design as similar as possible to the permissible Renewable scenario can be considered advantageous. Regarding the electrolyser design, the RES Share scenario shows more similarities with the Renewable scenario, whereas, as visible in Fig. 5e, the wind-power-based Balance scenario shows more similarities regarding the RES design.

In summary, at locations with medium AoR and a GEP equal to or higher than the EU average, the transitional softening of the DA I regulations leads to OHSC advantages being similar to an unrestricted grid electricity mix usage. These advantages, at least regarding the transitional softening, invalidate the criticism of industry players regarding inevitably increased production cost. In addition, they show the advantage of a power purchase via PPA over a power purchase from local RESs due to the exclusive applicability of the temporal correlation softening to the PPA option. The OHSC reduction comes with a higher EI and a lower temporal correlation. However, a steep economically incentivized increase in EI above the EI of grey hydrogen and the decrease of temporal correlation and additionality for GEPs below the EU average, caused by high usage of grid electricity mix, is prevented, partially invalidating the criticism of NGOs regarding increased emissions.

Compared to the RES Share scenario, the monthly balance condition leads to a higher wind power integration, causing a higher RES additionality and electrolyser use and a more sustainable RES design for post-transitional power purchase. On the downside, the monthly balance condition leads to higher EIs at low GEPs and lower OHSC advantages in comparison to the RES Share scenario, which shows a higher integration of comparatively cheap PV power. Furthermore, the electrolyser design in the RES Share scenario fits better for an economically optimized operation as soon as the transitional softening ceases to be valid.

Conclusion

To ensure emissions savings from green hydrogen use in the mobility sector, the EC has regulated power purchases for green hydrogen production for the first time. Controversial reactions to the adopted regulations from industry players and NGOs have raised questions about the effects on the cost of green hydrogen production and its renewable characteristics.

In this paper we show that the unrestricted usage of grid electricity mix for green hydrogen production, which is impermissible according to the regulations, does not necessarily lead to an increase in production-related GHG emissions compared to grey hydrogen, which partially invalidates the EC’s and NGOs’ concerns regarding increased emissions. At the same time, such unrestricted use could decrease green hydrogen production cost by between 0.55 €2023 and 1.62 €2023 per kilogram H2, supporting the concern of inevitable production cost increases expressed by industry players. Assuming current electricity price levels, this effect results from the economically incentivized use of comparably cheap renewable electricity from PVs and wind turbines in most European locations. However, in the case of unregulated electricity usage for green hydrogen production, low electricity price levels, in particular, could provide an economic incentive for high electricity mix usage. This, in turn, carries the risk of up to a 2.73-fold increase in production-related GHG emissions compared to grey hydrogen, supporting the NGOs’ criticism and possibly explaining the strict regulation made by the EC.

Furthermore, we show that the transitional softening regarding the regulation of temporal correlation ensures a high usage of renewable electricity and, thus, GHG emissions savings. To support the ramp-up of European green hydrogen production, the softening also provides similar production cost advantages as an unregulated power purchase, which together invalidates the criticism from both industry players and NGOs regarding this transitional softening. Assuming current electricity price levels, a European location with a medium potential yield of renewables and average grid electricity EI, the cost advantage is 1 €2023 per kilogram H2 and the production-related emissions savings is around 85% compared to grey hydrogen. Nevertheless, modifying the softening could result in higher cost and emissions reductions, and in an electrolyser design that fits better for both the transition period and operation as soon as the softening ceases to be valid. Therefore, this alternative softening could be an option for further sectors’ pending regulations of green hydrogen production.

Due to the controversial nature of the analysed topic, we explicitly emphasize that the conclusions drawn in this study are in the context of the assumptions made. One critical aspect here is the perspective of the study, focusing on the design and operation of single electrolyser plants. In addition, the calculations of production-related emissions in this work do not cover full life cycle emissions since the calculations are oriented towards the methodology presented by the EC. Further aspects whose consideration in subsequent studies could provide insightful findings are the changing emissions intensities of grid electricity over time, using offshore wind turbines for a renewable power supply and the usage of future cost data. Due to these limitations and the ambiguous results, this study alone cannot claim to provide an all-encompassing resolution of the controversy that has arisen. Nevertheless, its findings should contribute to a better understanding of the complex effects of the European regulatory framework on the economic viability and sustainability of green hydrogen production.

Methods

Mathematical description of optimization problem

To optimize design and operation, the total annual cost of the system Ctot is minimized (compare with equation (1)). It consists of the sum of annualized capital cost CCAPEX,i and annual operation cost COPEX,i for each component i and the total cost for power purchase from the grid CGrid.

The annualized capital cost of each component is calculated by multiplying the nominal power Pnom,i by the specific capital cost cCAPEX,i and the annuity factor Ai.

The annuity factor is calculated as follows, where rin,i is the interest rate and tdep,i is the depreciation time of the respective component. Hereby, the interest rate displays the real weighted average cost of capital.

The annual operational cost of each component is calculated by multiplying the nominal power Pnom,i by the specific capital cost cCAPEX,i and the operational cost factor fOPEX,i.

The total cost for power purchase from the grid is calculated by multiplying the sum of purchased power PGrid,t for all time steps t in the total optimization time frame {1, 2, 3, …, T} by the length of a time step Δt and the grid electricity price pGrid.

The following equations are the equality constraints that define the technical operation of the optimized electrolyser plant. All variables and parameters and their descriptions can be found in Tables 1 and 2.

The following equations are the inequality constraints that connect the operation and design of all components.

Equations (9), (10) and (11) are needed to construct the convex searchspace introduced in Fig. 2.

Hereby, blin,j is the y-axis intersect of the respective linear constraint j. The number of total linearization steps J − 1 defines the number of additional inequality constraints needed per time step t. The number of linearization steps chosen in this study is 20. The inequality constraint in equation (12) defines the lower bound of the search space for optimal operation points in Fig. 2b and is used to reduce the optimization time by minimizing the search space.

Due to the fact that minimal cost always results from an as-high-as-possible ratio of mass flow to electrical power, \(\frac{{\dot{m}}_{{{{\rm{Ely}}}},t}}{{P}_{{{{\rm{Stack}}}},t}}\), the solving algorithm always chooses operation points on the upper bound of the search space depicted in Fig. 2b, which is the linearized characteristic curve of the electrolyser stack.

Equation (13) shows the additional constraints for the Balance scenario. Hereby the sum of electrolyser system power in month k is not allowed to exceed the sum of potential RES power in the respective month.

Equation (14) shows the additional constraint for the RES Share scenario. Hereby 90% of the annual sum of electrolyser system power is not allowed to exceed the sum of potential RES power.

Details and limitations of evaluation indices

The OHSC is calculated by dividing the sum of all annualized capital expenses CCAPEX,i and all annual operational expenses COPEX,i for the design-optimized system components i by the annually covered hydrogen demand \({d}_{{{{{\rm{H}}}}}_{2}}\).

Besides annual operation and maintenance costs, \(\mathop{\sum }\nolimits_{i = 1}^{n}{C}_{{{{\rm{OPEX}}}},i}\) includes expenses for electricity from the grid and for the water needed for electrolysis.

The equivalent carbon dioxide EI of hydrogen production \(i_{\mathrm{e},\mathrm{H}_2}\) solely includes the EI of purchased grid electricity and is therefore calculated by dividing the product of the annually purchased grid energy EGrid and the average EI of grid electricity ie,Grid by the annually covered hydrogen demand \({d}_{{{{{\rm{H}}}}}_{2}}\).

Since the DA II (refs. 2,3) introduces a methodology to calculate the GHG emissions from the production of green hydrogen that does not consider emissions from the construction, decommissioning and waste management of plants, these emissions are also assumed to be zero in this study. Consequently the EI of electricity from PVs and wind turbines and of the construction of the electrolyser, the compressor and the hydrogen storage are assumed to be zero. However, we are aware of the fact that full life cycle analyses show emissions at a magnitude of 13–82 g CO2 kWhel–1 (kWhel, kWh electricity; refs. 20,21,22) for PV power generation and 7–30 g CO2 kWhel–1 (refs. 20,21,22,23) for wind power generation. Furthermore, full life cycle analyses of water electrolyser plant operation have shown that, besides the emissions from electricity generation, the electrolyser accounts for 4–7% (refs. 24,25,26) and the compression and storage for 18–22% (refs. 25,26) of total emissions.

An average EI of grid electricity is used because temporally resolved time series of electricity EI in Europe, calculated according to the DA II methodology, are not available.

The additionality index iadd is calculated by dividing the sum of totally installed nominal wind power Pnom,WT and PV power Pnom,PV by the totally installed nominal electrolyser power Pnom,Ely in the system.

The temporal correlation index itcorr is calculated as follows:

Here, the correlation index icorr indicates in which fraction of the analysed time steps the electrolyser runs parallel to the RES generation. The share of RESs in the total power purchase of the electrolyser sRES covers the quantity ratio between RES and electrolyser operation. Both indices can take values between zero and one.

Cost calculation of grey hydrogen from steam reforming

The levelized cost of grey hydrogen from steam reforming (LCOHSR) is calculated by adding the specific annualized capital cost, which is composed of the product of specific capital cost cCAPEX,SR and the annuity factor ASR, added to the specific annual operational cost cOPEX,SR, divided by the specific annual production mass of hydrogen from steam reforming \({m}_{{{{{\rm{H}}}}}_{2},{{{\rm{SR}}}}}\) as shown in equation (19).

The annuity factor ASR is calculated as in equation (4). The specific annual operational cost cOPEX,SR is composed of specific annual expenditures for operation and maintenance cOPEX,OM, specific annual expenditures for natural gas cOPEX,NG and specifc annual expenditures for emission certificates cOPEX,EC.

The specific expenditures for natural gas are calculated by multiplying the availability factor fava by the number of possible annual full load hours nFLH and the natural gas price pNG, and dividing this product by the efficiency of the steam reformer ηSR.

The specific expenditures for emission certificates result from the product of the availability factor fava, the number of possible annual full load hours nFLH, the EI of hydrogen from steam reforming \({i}_{{{{\rm{e}}}},{{{{\rm{H}}}}}_{2}{{{\rm{SR}}}}}\) and the price for emission certificates pEC divided by the lower heating value of hydrogen \({\mathrm{LH{V}}}_{{{{{\rm{H}}}}}_{2}}\).

The specific annual production mass of hydrogen from steam reforming is calculated by multiplying the availability factor fava and the number of possible annual full load hours nFLH, and dividing the product by the lower heating value of hydrogen \({\mathrm{LH{V}}}_{{{{{\rm{H}}}}}_{2}}\).

Software

The implementation of the optimization problem was written in Matlab27. Gurobi28 is used as the solver for all optimizations carried out in this work. The calculation of Sobol’ indices was performed by using UQLab29.

Data availability

All data used, generated or analysed in the course of this study are visualized in the article or can be found in Methods, Supplementary Information provided with this paper or via Zenodo at https://doi.org/10.5281/zenodo.10776992 (ref. 30).

Code availability

The mathematical description of the implemented optimization problem, including the objective function, all constraints and all parameter assumptions made, is documented in detail and comprehensively in the central article, Methods and Supplementary Information. If needed to better understand how the results were obtained, the implemented model can be found via Zenodo at https://doi.org/10.5281/zenodo.10776992 (ref. 30).

References

European Commission. Delegated regulation (EU) 2023/1184 on Union methodology for RFNBOs https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv%3AOJ.L_.2023.157.01.0011.01.ENG&toc=OJ%3AL%3A2023%3A157%3ATOC (2023).

European Commission. Delegated regulation (EU) 2023/1184 for a minimum threshold for GHG savings of recycled carbon fuels https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv%3AOJ.L_.2023.157.01.0020.01.ENG&toc=OJ%3AL%3A2023%3A157%3ATOC (2023).

European Commission. Delegated regulation (EU) 2023/1184 for a minimum threshold for GHG savings of recycled carbon fuels – annex https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv%3AOJ.L_.2023.157.01.0020.01.ENG&toc=OJ%3AL%3A2023%3A157%3ATOC (2023).

New Delegated Act puts brakes on green hydrogen. RWE https://www.rwe.com/en/press/rwe-ag/2022-05-23-new-delegated-act-puts-brakes-on-green-hydrogen/ (23 May 2022).

Collins, L. & Klevstrand, A. ‘Far from perfect’. Strict rules in new delegated act will ‘make green H2 projects more expensive’: Hydrogen Europe. Hydrogeninsight https://www.hydrogeninsight.com/policy/far-from-perfect-strict-rules-in-new-delegated-act-will-make-green-h2-projects-more-expensive-hydrogen-europe/2-1-1403241 (13 February 2023).

Impact Assessment of the RED II Delegated Acts on RFNBO and GHG Accounting: Hydrogen Europe Analysis. Technical Report https://hh2.hu/wp-content/uploads/2023/03/RED-DA-Additionality-Analysis.pdf (Hydrogen Europe, March 2023).

European Commission. REPowerEU: A plan to rapidly reduce dependence on Russian fossil fuels and fast forward the green transition https://ec.europa.eu/commission/presscorner/detail/en/ip_22_3131 (18 May 2022).

Collins, L. ‘A gold standard for greenwashing’. Climate campaigners unhappy with EU’s new delegated act on green hydrogen. Hydrogeninsight https://www.hydrogeninsight.com/policy/a-gold-standard-for-greenwashing-climate-campaigners-unhappy-with-eu-s-new-delegated-act-on-green-hydrogen/2-1-1403278 (13 February 2023).

European Commission. European Green Deal: Commission proposes transformation of EU economy and society to meet climate ambitions https://ec.europa.eu/commission/presscorner/detail/en/IP_21_3541 (14 July 2021).

Sebastian Oliva, H. & Matias Garcia, G. Investigating the impact of variable energy prices and renewable generation on the annualized cost of hydrogen. Int. J. Hydrog. Energy 48, 13756–13766 (2023).

Raab, M., Körner, R. & Dietrich, R. U. Techno-economic assessment of renewable hydrogen production and the influence of grid participation. Int. J. Hydrog. Energy 47, 26798–26811 (2022).

Sens, L. et al. Cost minimized hydrogen from solar and wind – production and supply in the European catchment area. Energy Convers. Manag. 265, 115742 (2022).

Martínez de León, C., Ríos, C. & Brey, J. J. Cost of green hydrogen: limitations of production from a stand-alone photovoltaic system. Int. J. Hydrog. Energy 48, 11885–11898 (2023).

Cooper, N., Horend, C., Röben, F., Bardow, A. & Shah, N. A framework for the design & operation of a large-scale wind-powered hydrogen electrolyzer hub. Int. J. Hydrog. Energy 47, 8671–8686 (2022).

Glenk, G. & Reichelstein, S. Economics of converting renewable power to hydrogen. Nat. Energy 4, 216–222 (2019).

Brauer, J., Villavicencio, M. & Trüby, J. Green hydrogen – how grey can it be? Robert Schuman Centre for Advanced Studies Research Paper No. 2022/44 https://doi.org/10.2139/ssrn.4214688 (2022).

The Chemical Engineering Plant Cost Index https://www.chemengonline.com/pci-home (Chemical Engineering, accessed 25 September 2023).

Wei, P., Lu, Z. & Song, J. Variable importance analysis: a comprehensive review. Reliab. Eng. Syst. Saf. 142, 399–432 (2015).

Electricity Prices for Non-household Consumers https://ec.europa.eu/eurostat/databrowser/view/nrg_pc_205/default/table?lang=en (Eurostat, accessed 30 December 2023).

Hengster, J. et al. Update and Evaluation of the Life Cycle Assessment of Wind Energy and Photovoltaic Systems Considering Current Technology Developments Technical Report 35 https://www.umweltbundesamt.de/sites/default/files/medien/5750/publikationen/2021-05-06_cc_35-2021_oekobilanzen_windenergie_photovoltaik.pdf (Umweltbundesamt, 2021).

Scarlat, N., Prussi, M. & Padella, M. Quantification of the carbon intensity of electricity produced and used in Europe. Appl. Energy 305, 117901 (2022).

Life Cycle Assessment of Electricity Generation Options Technical Report https://unece.org/sites/default/files/2021-10/LCA-2.pdf (UNECE, 2021).

Bonou, A., Laurent, A. & Olsen, S. I. Life cycle assessment of onshore and offshore wind energy-from theory to application. Appl. Energy 180, 327–337 (2016).

Bareiß, K., de la Rua, C., Möckl, M. & Hamacher, T. Life cycle assessment of hydrogen from proton exchange membrane water electrolysis in future energy systems. Appl. Energy 237, 862–872 (2019).

Bhandari, R., Trudewind, C. A. & Zapp, P. Life cycle assessment of hydrogen production via electrolysis – a review. J. Clean. Prod. 85, 151–163 (2014).

Ghandehariun, S. & Kumar, A. Life cycle assessment of wind-based hydrogen production in Western Canada. Int. J. Hydrog. Energy 41, 9696–9704 (2016).

MATLAB v.9.10.0 (MathWorks, 2021).

Gurobi Optimizer (Gurobi Optimization, LLC, 2023).

Marelli, S. & Sudret, B. UQLab: a Framework for Uncertainty Quantification in MATLAB. Proceedings of the 2nd International Conference on Vulnerability and Risk Analysis and Management (ICVRAM 2014), 2554–2563 https://doi.org/10.1061/9780784413609.257 (2014).

Brandt, J. Cost and competitiveness of green hydrogen and the effects of the European Union regulatory framework: model and result data. Zenodo https://doi.org/10.5281/zenodo.10776992 (2024).

Acknowledgements

This work was funded by the Ministry of Science and Culture of Lower-Saxony (MWK) as part of the innovation laboratory H2-Wegweiser. The results presented were achieved by computations carried out on the cluster system at the Leibniz Universität Hannover, Germany.

Funding

Open access funding provided by Technische Informationsbibliothek (TIB).

Author information

Authors and Affiliations

Contributions

J.B., A.B., B.B. and R.H.-R. designed the study. T.I. and H.W. supported the legal analyses. C.E. and M.B. supported the uncertainty quantification and the associated analyses. F.P. supported the modelling. J.B. performed the modelling, carried out the parameter studies and analysed and drafted the paper. A.B., T.I., C.E. and R.H.-R. cowrote the paper. R.H.-R. directed and supervised this project. J.B., T.I., C.E., F.P., B.B., A.B., M.B., H.W. and R.H.-R. discussed the results and commented on the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Jennifer Kurtz, Paolo Pisciella and Lucas Sens for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–4, Figs. 1–6, Tables 1–5 and References.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Brandt, J., Iversen, T., Eckert, C. et al. Cost and competitiveness of green hydrogen and the effects of the European Union regulatory framework. Nat Energy (2024). https://doi.org/10.1038/s41560-024-01511-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41560-024-01511-z