Abstract

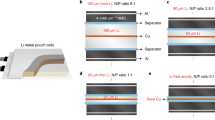

Achieving extremely fast charging yet maintaining high energy density remains a challenge in the battery field. Traditional current collectors, being impermeable to electrolytes, hinder the movement of Li+ ions and restrict the high-rate capability of thick electrodes. Here we conceptualize a porous current collector for energy-dense and extremely fast-charging batteries. This porous design allows Li+ ions to pass through both the current collector and the separator simultaneously, thereby reducing the effective Li+ transport distance by half and quadrupling the diffusion-limited C-rate capability without compromising the energy density. Multilayer pouch cells equipped with this current collector demonstrate high specific energy (276 Wh kg−1) and remarkable fast-charging capabilities at rates of 4 C (78.3% state of charge), 6 C (70.5% state of charge) and 10 C (54.3% state of charge). This porous current collector design is compatible with existing battery manufacturing processes and other fast-charging strategies, enriching battery configurations for designing next-generation batteries.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study have been included in this article and its Supplementary Information. Source data are provided with this paper.

References

Crabtree, G. The coming electric vehicle transformation. Science 366, 422–424 (2019).

Viswanathan, V. et al. The challenges and opportunities of battery-powered flight. Nature 601, 519–525 (2022).

Schäfer, A. W. et al. Technological, economic and environmental prospects of all-electric aircraft. Nat. Energy 4, 160–166 (2019).

Yang, X.-G., Liu, T., Ge, S., Rountree, E. & Wang, C.-Y. Challenges and key requirements of batteries for electric vertical takeoff and landing aircraft. Joule 5, 1644–1659 (2021).

Deng, J., Bae, C., Denlinger, A. & Miller, T. Electric vehicles batteries: requirements and challenges. Joule 4, 511–515 (2020).

Liu, Y., Zhu, Y. & Cui, Y. Challenges and opportunities towards fast-charging battery materials. Nat. Energy 4, 540–550 (2019).

Tomaszewska, A. et al. Lithium-ion battery fast charging: a review. eTransportation 1, 100011 (2019).

Li, G. Regulating mass transport behavior for high-performance lithium metal batteries and fast-charging lithium-ion batteries. Adv. Energy Mater. 11, 2002891 (2021).

Gallagher, K. G. et al. Optimizing areal capacities through understanding the limitations of lithium-ion electrodes. J. Electrochem. Soc. 163, A138 (2015).

Mao, C., Ruther, R. E., Li, J., Du, Z. & Belharouak, I. Identifying the limiting electrode in lithium ion batteries for extreme fast charging. Electrochem. Commun. 97, 37–41 (2018).

Logan, E. & Dahn, J. Electrolyte design for fast-charging li-ion batteries. Trends Chem. 2, 354–366 (2020).

Li, J. et al. Methyl acetate as a co-solvent in NMC532/graphite cells. J. Electrochem. Soc. 165, A1027 (2018).

Yang, X.-G. et al. Asymmetric temperature modulation for extreme fast charging of lithium-ion batteries. Joule 3, 3002–3019 (2019).

Yang, X.-G., Zhang, G., Ge, S. & Wang, C.-Y. Fast charging of lithium-ion batteries at all temperatures. Proc. Natl Acad. Sci. USA 115, 7266–7271 (2018).

Ye, Y. et al. Cold-starting all-solid-state batteries from room temperature by thermally modulated current collector in sub-minute. Adv. Mater. 34, 2202848 (2022).

Heubner, C., Schneider, M. & Michaelis, A. Diffusion-limited C-rate: a fundamental principle quantifying the intrinsic limits of li-ion batteries. Adv. Energy Mater. 10, 1902523 (2020).

Newman, J. Optimization of porosity and thickness of a battery electrode by means of a reaction-zone model. J. Electrochem. Soc. 142, 97 (1995).

Paul, P. P. et al. A review of existing and emerging methods for lithium detection and characterization in Li-ion and Li-metal batteries. Adv. Energy Mater. 11, 2100372 (2021).

Feng, X., Ren, D., He, X. & Ouyang, M. Mitigating thermal runaway of lithium-ion batteries. Joule 4, 743–770 (2020).

Zhu, P. et al. A review of current collectors for lithium-ion batteries. J. Power Sources 485, 229321 (2021).

Yang, Y. et al. Quantification of heterogeneous degradation in Li-ion batteries. Adv. Energy Mater. 9, 1900674 (2019).

Xu, R. et al. Heterogeneous damage in Li-ion batteries: experimental analysis and theoretical modeling. J. Mech. Phys. Solids 129, 160–183 (2019).

Ebner, M., Chung, D. W., García, R. E. & Wood, V. Tortuosity anisotropy in lithium‐ion battery electrodes. Adv. Energy Mater. 4, 1301278 (2014).

Yang, X.-G., Leng, Y., Zhang, G., Ge, S. & Wang, C.-Y. Modeling of lithium plating induced aging of lithium-ion batteries: transition from linear to nonlinear aging. J. Power Sources 360, 28–40 (2017).

Yan, K. et al. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat. Energy 1, 16010 (2016).

Choudhury, R., Wild, J. & Yang, Y. Engineering current collectors for batteries with high specific energy. Joule 5, 1301–1305 (2021).

Ye, Y. et al. Ultralight and fire-extinguishing current collectors for high-energy and high-safety lithium-ion batteries. Nat. Energy 5, 786–793 (2020).

Pegel, H., Wycisk, D. & Sauer, D. U. Influence of cell dimensions and housing material on the energy density and fast-charging performance of tabless cylindrical lithium-ion cells. Energy Storage Mater. 60, 102796 (2023).

Park, S.-H. et al. High areal capacity battery electrodes enabled by segregated nanotube networks. Nat. Energy 4, 560–567 (2019).

Song, M. & Choe, S.-Y. Fast and safe charging method suppressing side reaction and lithium deposition reaction in lithium ion battery. J. Power Sources 436, 226835 (2019).

Vikrant, K., McShane, E., Colclasure, A. M., McCloskey, B. D. & Allu, S. Quantification of dead lithium on graphite anode under fast charging conditions. J. Electrochem. Soc. 169, 040520 (2022).

Liu, F. et al. Dynamic spatial progression of isolated lithium during battery operations. Nature 600, 659–663 (2021).

Huang, W. et al. Onboard early detection and mitigation of lithium plating in fast-charging batteries. Nat. Commun. 13, 7091 (2022).

Tranter, T. G., Timms, R., Shearing, P. R. & Brett, D. Communication—prediction of thermal issues for larger format 4680 cylindrical cells and their mitigation with enhanced current collection. J. Electrochem. Soc. 167, 160544 (2020).

Doyle, M., Fuller, T. F. & Newman, J. Modeling of galvanostatic charge and discharge of the lithium/polymer/insertion cell. J. Electrochem. Soc. 140, 1526 (1993).

Acknowledgements

This work is supported by Murata Manufacturing Co., Ltd. S.T.O. acknowledges support from the TomKat Center Fellowship for Translational Research at Stanford University. We thank the Stanford Nano Shared Facilities and the Stanford Nanofabrication Facility for the SEM, contact angle, tensile strength characterizations and Lesker sputter fabrication. We thank Dupont for providing the porous Kevlar film.

Author information

Authors and Affiliations

Contributions

Y.Y. and Y.C. conceived the concept. R.X., Y.M. and T.Y. performed the COMSOL simulation. W.H., F.L. and T.L. helped with the battery pressure testing and analysis. H.A., W.Z., J.O.A., A.C., Z.C., X.X., Z.Z., Y.P. and S.T.O. assisted with electrochemical experiments. Y.W. carried out the electronic conductivity measurement. X.G., H.K., R.M., Y.S., Y.M., T.Y. and Y.N. helped with the device fabrication, simulation and data analysis. Y.Y. and Y.C. wrote the paper. W.Z., R.A.V. and Y.C. revised the paper. All the authors contributed to the discussion of the results.

Corresponding author

Ethics declarations

Competing interests

H.K., Y.S., R.M., Y.M., T.Y. and Y.N. are employed by Murata Manufacturing Co., Ltd. The other authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Leif Nyholm and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Methods, Note 1, Figs. 1–22 and Table 1.

Source data

Source Data Fig. 2

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Source Data Fig. 5

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ye, Y., Xu, R., Huang, W. et al. Quadruple the rate capability of high-energy batteries through a porous current collector design. Nat Energy (2024). https://doi.org/10.1038/s41560-024-01473-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41560-024-01473-2