Abstract

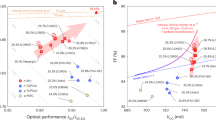

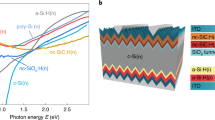

To unlock the full performance potential of silicon heterojunction solar cells requires reductions of parasitic absorption and shadowing losses. Yet the translation of the hydrogenated nanocrystalline silicon oxide (nc-SiOx:H) window layer and copper-plated electrodes to a cost-effective and scalable production-relevant context remains one of the largest roadblocks towards mainstream adoption of silicon heterojunction technology. Here we address the first challenge by developing an industrial-scale high-frequency plasma-enhanced chemical vapour deposition system with a minimized standing wave effect, enabling the deposition of doped nc-SiOx:H with excellent electron selectivity, low parasitic absorption and high uniformity. Next, we demonstrate seed-free copper plating, resulting in grids with a high aspect ratio and low metal fraction. By implementing the doped nc-SiOx:H window layer, certified efficiencies of 25.98% and 26.41% are obtained for M6-size bifacial silicon heterojunction devices with screen-printed silver electrodes and copper-plated electrodes, respectively. These results underline the performance potential of silicon heterojunction technology and lower the threshold towards their mass manufacturing.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in the published Article and its Supplementary Information. Source data are provided with this paper.

References

Ballif, C., Haug, F.-J., Boccard, M., Verlinden, P. J. & Hahn, G. Status and perspectives of crystalline silicon photovoltaics in research and industry. Nat. Rev. Mater. 7, 597–616 (2022).

Yoshikawa, K. et al. Silicon heterojunction solar cell with interdigitated back contacts for a photoconversion efficiency over 26%. Nat. Energy 2, 17032 (2017).

Sun, Z. et al. Toward efficiency limits of crystalline silicon solar cells: recent progress in high‐efficiency silicon heterojunction solar cells. Adv. Energy Mater. 12, 2200015 (2022).

De Wolf, S., Descoeudres, A., Holman, Z. C. & Ballif, C. High-efficiency silicon heterojunction solar cells: a review. Green 2, 7–24 (2012).

Qu, X. et al. Identification of embedded nanotwins at c-Si/a-Si:H interface limiting the performance of high-efficiency silicon heterojunction solar cells. Nat. Energy 6, 194–202 (2021).

Lin, H. et al. Silicon heterojunction solar cells with up to 26.81% efficiency achieved by electrically optimized nanocrystalline-silicon hole contact layers. Nat. Energy 8, 789–799 (2023).

Yoshikawa, K. et al. Exceeding conversion efficiency of 26% by heterojunction interdigitated back contact solar cell with thin film Si technology. Sol. Energy Mater. Sol. Cells 173, 37–42 (2017).

Holman, Z. C. et al. Current losses at the front of silicon heterojunction solar cells. IEEE J. Photovolt. 2, 7–15 (2012).

Antognini, L. et al. Integration of thin n-type nc-Si:H layers in the window-multilayer stack of heterojunction solar cells. Sol. Energy Mater. Sol. Cells 248, 111975 (2022).

Zhao, Y. et al. Ultra‐thin electron collectors based on nc‐Si:H for high‐efficiency silicon heterojunction solar cells. Prog. Photovolt. Res. Appl. 30, 809–822 (2022).

Umishio, H., Sai, H., Koida, T. & Matsui, T. Nanocrystalline‐silicon hole contact layers enabling efficiency improvement of silicon heterojunction solar cells: impact of nanostructure evolution on solar cell performance. Prog. Photovolt. Res. Appl. 29, 344–356 (2021).

Qiu, D. et al. Front contact optimization for rear-junction SHJ solar cells with ultra-thin n-type nanocrystalline silicon oxide. Sol. Energy Mater. Sol. Cells 209, 110471 (2020).

Zhao, Y. et al. Doped hydrogenated nanocrystalline silicon oxide layers for high‐efficiency c‐Si heterojunction solar cells. Prog. Photovolt. Res. Appl. 28, 425–435 (2020).

Mazzarella, L., Morales-Vilches, A. B., Korte, L., Schlatmann, R. & Stannowski, B. Ultra-thin nanocrystalline n-type silicon oxide front contact layers for rear-emitter silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 179, 386–391 (2018).

Klingsporn, M. et al. Resolving the nanostructure of plasma-enhanced chemical vapor deposited nanocrystalline SiOx layers for application in solar cells. J. Appl. Phys. 119, 223104 (2016).

Köhler, M. et al. A silicon carbide-based highly transparent passivating contact for crystalline silicon solar cells approaching efficiencies of 24%. Nat. Energy 6, 529–537 (2021).

Kohler, M. et al. Optimization of transparent passivating contact for crystalline silicon solar cells. IEEE J. Photovolt. 10, 46–53 (2020).

Kim, K. S. et al. Deposition of very-low-hydrogen-containing silicon at a low temperature using very-high-frequency (162 MHz) SiH4 plasma. Micromachines 13, 173 (2022).

Wang, J. et al. Performance of heterojunction solar cells with different intrinsic a-Si:H thin layers deposited by RF- and VHF-PECVD. J. Mater. Sci. 32, 25327–25331 (2021).

Juneja, S., Sudhakar, S., Gope, J. & Kumar, S. Mixed phase silicon thin films grown at high rate using 60 MHz assisted VHF-PECVD technique. Mater. Sci. Semicond. Process. 40, 11–19 (2015).

Oda, S. & Yasukawa, M. High quality a-Si:H films and interfaces prepared by VHF plasma CVD. J. Non-cryst. Solids 137–138, 677–680 (1991).

Finger, F. et al. Influences of a high excitation frequency (70 MHz) in the glow discharge technique on the process plasma and the properties of hydrogenated amorphous silicon. J. Appl. Phys. 71, 5665–5674 (1992).

Heintze, M., Zedlitz, R. & Bauer, G. H. Analysis of high-rate a-Si:H deposition in a VHF plasma. J. Phys. Appl. Phys. 26, 1781–1786 (1993).

Kawamura, K. et al. Development of large-area a-Si:H films deposition using controlled VHF plasma. Thin Solid Films 506–507, 22–26 (2006).

Ferreira, G. M. et al. Comparison of phase diagrams for vhf and rf plasma-enhanced chemical vapor deposition of Si:H films. MRS Online Proc. Lib. 808, 299–304 (2003).

Heintze, M., Zedlitz, R. & Bauer, G. H. Mechanism of high rate a-Si:H deposition in a VHF plasma. MRS Online Proc. Lib. 297, 49–54 (1993).

Ramanujam, J. & Verma, A. Photovoltaic properties of a-Si:H films grown by plasma enhanced chemical vapor deposition: a review. Mater. Express 2, 177–196 (2012).

Davidsson, S. & Höök, M. Material requirements and availability for multi-terawatt deployment of photovoltaics. Energy Policy 108, 574–582 (2017).

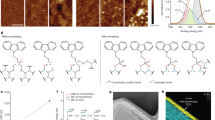

Yu, J. et al. Copper metallization of electrodes for silicon heterojunction solar cells: process, reliability and challenges. Sol. Energy Mater. Sol. Cells 224, 110993 (2021).

Razzaq, A., Allen, T. G., Liu, W., Liu, Z. & De Wolf, S. Silicon heterojunction solar cells: techno-economic assessment and opportunities. Joule 6, 514–542 (2022).

Zhang, Y., Kim, M., Wang, L., Verlinden, P. & Hallam, B. Design considerations for multi-terawatt scale manufacturing of existing and future photovoltaic technologies: challenges and opportunities related to silver, indium and bismuth consumption. Energy Environ. Sci. 14, 5587–5610 (2021).

Wang, X. et al. Laser-doped metal-plated bifacial silicon solar cells. Sol. Energy Mater. Sol. Cells 131, 37–45 (2014).

Geissbuhler, J. et al. Silicon heterojunction solar cells with copper-plated grid electrodes: status and comparison with silver thick-film techniques. IEEE J. Photovolt. 4, 1055–1062 (2014).

Lee, S. H., Lee, D. W., Lim, K., Shin, W. & Kim, J. Copper–nickel alloy plating to improve the contact resistivity of metal grid on silicon heterojunction solar cells. Electron. Mater. Lett. 15, 314–322 (2019).

Dong, G. et al. Power conversion efficiency of 25.26% for silicon heterojunction solar cell with transition metal element doped indium oxide transparent conductive film as front electrode. Prog. Photovolt. Res. Appl. 30, 1136–1143 (2022).

Green, M. A. Solar cell fill factors: general graph and empirical expressions. Solid State Electron. 24, 788–789 (1981).

Peibst, R. et al. On the chances and challenges of combining electron‐collecting nPOLO and hole‐collecting Al‐p+ contacts in highly efficient p‐type c‐Si solar cells. Prog. Photovolt. Res. Appl. 31, 327–340 (2023).

Javier, G. M. N. et al. Improvements and gaps in the empirical expressions for the fill factor of modern industrial solar cells. Sol. Energy Mater. Sol. Cells 253, 112183 (2023).

Cox, R. H. & Strack, H. Ohmic contacts for GaAs devices. Solid State Electron. 10, 1213–1218 (1967).

Demaurex, B., De Wolf, S., Descoeudres, A., Charles Holman, Z. & Ballif, C. Damage at hydrogenated amorphous/crystalline silicon interfaces by indium tin oxide overlayer sputtering. Appl. Phys. Lett. 101, 171604 (2012).

Yang, Y. & Kushner, M. J. Modeling of dual frequency capacitively coupled plasma sources utilizing a full-wave Maxwell solver: I. Scaling with high frequency. Plasma Sources Sci. Technol. 19, 055011 (2010).

Kim, H. J., Yang, W. & Joo, J. Effect of electrode spacing on the density distributions of electrons, ions, and metastable and radical molecules in SiH4/NH3/N2/He capacitively coupled plasmas. J. Appl. Phys. 118, 614–623 (2015).

Wang, L., Hartmann, P., Donko, Z., Song, Y. H. & Schulze, J. Effects of structured electrodes on electron power absorption and plasma uniformity in capacitive RF discharges. J. Vac. Sci. Technol. A 39, 063004 (2021).

Schmidt, N., Schulze, J., Schüngel, E. & Czarnetzki, U. Effect of structured electrodes on heating and plasma uniformity in capacitive discharges. J. Phys. Appl. Phys. 46, 505202 (2013).

Liu, W. et al. Light-induced activation of boron doping in hydrogenated amorphous silicon for over 25% efficiency silicon solar cells. Nat. Energy 7, 427–437 (2022).

Smets, A. H. M., Kessels, W. M. M. & van de Sanden, M. C. M. Vacancies and voids in hydrogenated amorphous silicon. Appl. Phys. Lett. 82, 1547–1549 (2003).

Knights, J. C., Lucovsky, G. & Nemanich, R. J. Defects in plasma-deposited a-Si:H. J. Non-cryst. Solids 32, 393–403 (1979).

Jiang, K. et al. Balance of efficiency and stability of silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 243, 111801 (2022).

Liu, W. et al. Damp-heat-stable, high-efficiency, industrial-size silicon heterojunction solar cells. Joule 4, 913–927 (2020).

Hatt, T. et al. Stable copper plated metallization on SHJ solar cells and investigation of selective Al/AlOx laser patterning. In 38th European PV Solar Energy Conference and Exhibition (EUPVSEC) 326–330 (EUPVSEC, 2021).

Lachowicz, A. et al. Patterning techniques for copper electoplated metallization of silicon heterojunction cells. In 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC) 1530–1533 (IEEE, 2021).

Tang, T. et al. Achievement of 25.54% power conversion efficiency by optimization of current losses at the front side of silicon heterojunction solar cells. Prog. Photovolt. Res. Appl. 31, 449–460 (2023).

Acknowledgements

X.Y. acknowledges the financial support from the National Natural Science Foundation of China (no. 62174114), the National Key R&D Program of China (no. 2022YFB4200203), the Department of Science and Technology of Jiangsu Province (no. BE2022027, no. BE2022036, no. BE2022023), the Distinguished Professor Award of Jiangsu Province and the ‘Dual Carbon’ Science and Technology Project of Suzhou (no. ST202219). X.Z. acknowledges the financial support from the Major Research Plan of the National Natural Science Foundation of China (no. 91833303) and the Foundation for Innovation Research Groups of the National Natural Science Foundation of China (no. 51821002). J. Zhou acknowledges the financial support from the Carbon Emission Peak and Carbon Neutrality Special Fund of Jiangsu Province (no. BA2022205). This work is partly supported by the Australian Renewable Energy Agency (ARENA) under 2020/ARP006. The views expressed herein are not necessarily the views of the Australian Government, and the Australian Government does not accept responsibility for any information or advice contained herein. We thank X. Ran, J. Allen and S. Drury for sample preparation and device fabrication.

Author information

Authors and Affiliations

Contributions

X.Y. and C.Y. conceived the idea, designed the experiments and led the project. C.Y. and K.G. fabricated the devices, performed the device characterizations and wrote the paper. C.-W.P. and C.H. helped with the device optimization and analysis. S.W. and W.S. performed the Raman spectra and contact resistivity measurements. J. Zhang and D.W. performed the large-scale uniformity experiment. V.A., Y.H., J.C., Huiting Wu, L.G., D.C. and A.L. designed and carried out the copper plating. G.T., Y.Z., W.J. and Y.S. performed the simulation validation of the voltage distribution on excitation frequency and substrate size. G.D. performed the TCO deposition, and H.J. performed screen printing. Haihong Wu performed lifetime, EQE and HR-TEM measurements. C.X., Q.M. and X.W. performed HR-TEM and EQE measurements. K.L. and D.X. performed the absorption spectra and optical bandgap measurement. J.P. and W.L. helped with the TOF-SIMS result analysis and discussion. X.C. designed the PECVD chamber. S.D.W. helped with the discussion of the results. J. Zhou, X.Y. and X.Z. supervised the project. All authors contributed to the discussion of the results and revision of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

C.Y., C.-W.P., C.H., J. Zhou, D.W., G.T., G.D., H.J., Haihong Wu, X.C. and J. Zhang are employees of Suzhou Maxwell Technologies Co. Ltd. V.A., D.C., A.L., Y.H., J.C., Huiting Wu and L.G. are employees of SunDrive Solar Pty., Ltd. All other authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Delfina Muñoz and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Tables 1 and 2, Figs. 1–12, note and references.

Supplementary Data 1

Source data for Supplementary Fig. 2.

Supplementary Data 2

Source data for Supplementary Fig. 3.

Supplementary Data 3

Source data for Supplementary Fig. 4.

Supplementary Data 4

Source data for Supplementary Fig. 7.

Supplementary Data 5

Source data for Supplementary Figs. 8 and 11.

Source data

Source Data Fig. 1

Certified I–V and EQE data.

Source Data Fig. 2

Photovoltaic parameter data.

Source Data Fig. 3

Raman and contact resistivity data.

Source Data Fig. 4

Thickness and PCE uniformity data.

Source Data Fig. 5

Voltage distribution simulation data.

Source Data Fig. 6

PCE and TOF-SIMS data.

Source Data Fig. 7

Certified I–V data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yu, C., Gao, K., Peng, CW. et al. Industrial-scale deposition of nanocrystalline silicon oxide for 26.4%-efficient silicon heterojunction solar cells with copper electrodes. Nat Energy 8, 1375–1385 (2023). https://doi.org/10.1038/s41560-023-01388-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-023-01388-4

This article is cited by

-

Highlights of mainstream solar cell efficiencies in 2023

Frontiers in Energy (2024)