Abstract

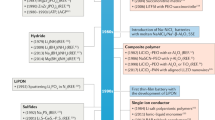

Electrolyte engineering is crucial for improving battery performance, particularly for lithium metal batteries. Recent advances in electrolytes have greatly improved cyclability by enhancing electrochemical stability at the electrode interfaces, but concurrently achieving high ionic conductivity has remained challenging. Here we report an electrolyte design strategy for enhanced lithium metal batteries by increasing the molecular diversity in electrolytes, which essentially leads to high-entropy electrolytes. We find that, in weakly solvating electrolytes, the entropy effect reduces ion clustering while preserving the characteristic anion-rich solvation structures, which is characterized by synchrotron-based X-ray scattering and molecular dynamics simulations. Electrolytes with smaller-sized clusters exhibit a twofold improvement in ionic conductivity compared with conventional weakly solvating electrolytes, enabling stable cycling at high current densities up to 2C (6.2 mA cm−2) in anode-free LiNi0.6Mn0.2Co0.2 (NMC622)||Cu pouch cells. The efficacy of the design strategy is verified by performance improvements in three disparate weakly solvating electrolyte systems.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data are available in the main text or the Supplementary Information.

References

Whittingham, M. S. Electrical energy storage and intercalation chemistry. Science 192, 1126–1127 (1976).

Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 12, 194–206 (2017).

Zhang, J. G., Xu, W., Xiao, J., Cao, X. & Liu, J. Lithium metal anodes with nonaqueous electrolytes. Chem. Rev. 120, 13312–13348 (2020).

Winter, M., Barnett, B. & Xu, K. Before Li ion batteries. Chem. Rev. 118, 11433–11456 (2018).

Lin, D. et al. Layered reduced graphene oxide with nanoscale interlayer gaps as a stable host for lithium metal anodes. Nat. Nanotechnol. 11, 626–632 (2016).

Zhou, L. et al. High areal capacity, long cycle life 4 V ceramic all-solid-state Li ion batteries enabled by chloride solid electrolytes. Nat. Energy 7, 83–93 (2022).

Fu, C. et al. Universal chemomechanical design rules for solid-ion conductors to prevent dendrite formation in lithium metal batteries. Nat. Mater. 19, 758–766 (2020).

Cao, X. et al. Monolithic solid–electrolyte interphases formed in fluorinated orthoformate-based electrolytes minimize Li depletion and pulverization. Nat. Energy 4, 796–805 (2019).

Ren, X. et al. Enabling high-voltage lithium metal batteries under practical conditions. Joule 3, 1662–1676 (2019).

Yu, Z. et al. Rational solvent molecule tuning for high-performance lithium metal battery electrolytes. Nat. Energy https://doi.org/10.1038/s41560-021-00962-y (2022).

Fan, X. et al. All-temperature batteries enabled by fluorinated electrolytes with non-polar solvents. Nat. Energy 4, 882–890 (2019).

Chen, Y. et al. Steric-effect-tuned ion solvation enabling stable cycling of high-voltage lithium metal battery. J. Am. Chem. Soc. https://doi.org/10.1021/jacs.1c09006 (2021).

Louli, A. J. et al. Diagnosing and correcting anode-free cell failure via electrolyte and morphological analysis. Nat. Energy 5, 693–702 (2020).

Kim, M. S. et al. Suspension electrolyte with modified Li+ solvation environment for lithium metal batteries. Nat. Mater. https://doi.org/10.1038/s41563-021-01172-3 (2022).

Wang, H. et al. Liquid electrolyte: the nexus of practical lithium metal batteries. Joule https://doi.org/10.1016/j.joule.2021.12.018 (2022).

Cao, X. et al. Effects of fluorinated solvents on electrolyte solvation structures and electrode/electrolyte interphases for lithium metal batteries. Proc. Natl Acad. Sci. USA 118, e2020357118 (2021).

Chen, S. et al. High-voltage lithium metal batteries enabled by localized high-concentration electrolytes. Adv. Mater. 30, 1706102 (2018).

Zheng, J. et al. High-fluorinated electrolytes for Li–S batteries. Adv. Energy Mater. 9, 1803774 (2019).

Xue, W. et al. Ultra-high-voltage Ni-rich layered cathodes in practical Li metal batteries enabled by a sulfonamide-based electrolyte. Nat. Energy https://doi.org/10.1038/s41560-021-00792-y (2021).

Holoubek, J. et al. Electrolyte design implications of ion pairing in low-temperature Li metal batteries. Energy Environ. Sci. 15, 1647–1658 (2022).

Yu, Z. et al. Molecular design for electrolyte solvents enabling energy-dense and long-cycling lithium metal batteries. Nat. Energy 5, 526–533 (2020).

Chen, S. et al. High-efficiency lithium metal batteries with fire-retardant electrolytes. Joule 2, 1548–1558 (2018).

Berhaut, C. L. et al. Ionic association analysis of LiTDI, LiFSI and LiPF6 in EC/DMC for better Li ion battery performances. RSC Adv. 9, 4599–4608 (2019).

Lundgren, H., Behm, M. & Lindbergh, G. Electrochemical characterization and temperature dependency of mass-transport properties of LiPF6in EC:DEC. J. Electrochem. Soc. 162, A413–A420 (2014).

Yamada, Y. et al. Unusual stability of acetonitrile-based superconcentrated electrolytes for fast-charging lithium ion batteries. J. Am. Chem. Soc. 136, 5039–5046 (2014).

Ren, X. et al. Role of inner solvation sheath within salt–solvent complexes in tailoring electrode/electrolyte interphases for lithium metal batteries. Proc. Natl Acad. Sci. USA 117, 28603–28613 (2020).

Ren, X. et al. Localized high-concentration sulfone electrolytes for high-efficiency lithium metal batteries. Chem 4, 1877–1892 (2018).

Niu, C. et al. Balancing interfacial reactions to achieve long cycle life in high-energy lithium metal batteries. Nat. Energy 6, 723–732 (2021).

Weber, R. et al. Long cycle life and dendrite-free lithium morphology in anode-free lithium pouch cells enabled by a dual-salt liquid electrolyte. Nat. Energy 4, 683–689 (2019).

Genovese, M. et al. Hot formation for improved low temperature cycling of anode-free lithium metal batteries. J. Electrochem. Soc. 166, A3342–A3347 (2019).

Louli, A. J. et al. Exploring the impact of mechanical pressure on the performance of anode-free lithium metal cells. J. Electrochem. Soc. 166, A1291–A1299 (2019).

Wang, H. et al. Dual-solvent Li-ion solvation enables high-performance Li metal batteries. Adv. Mater. 33, 2008619 (2021).

Perez Beltran, S., Cao, X., Zhang, J. G. & Balbuena, P. B. Localized high concentration electrolytes for high voltage lithium metal batteries: correlation between the electrolyte composition and its reductive/oxidative stability. Chem. Mater. 32, 5973–5984 (2020).

Liu, H. et al. Ultrahigh coulombic efficiency electrolyte enables Li||SPAN batteries with superior cycling performance. Mater. Today 42, 17–28 (2021).

Ye, Y. F., Wang, Q., Lu, J., Liu, C. T. & Yang, Y. High-entropy alloy: challenges and prospects. Mater. Today 19, 349–362 (2016).

Lun, Z. et al. Cation-disordered rocksalt-type high-entropy cathodes for Li ion batteries. Nat. Mater. 20, 214–221 (2021).

Oses, C., Toher, C. & Curtarolo, S. High-entropy ceramics. Nat. Rev. Mater. 5, 295–309 (2020).

Wang, Q. et al. Multi-anionic and -cationic compounds: new high-entropy materials for advanced Li ion batteries. Energy Environ. Sci. 12, 2433–2442 (2019).

Zeng, Y. et al. High-entropy mechanism to boost ionic conductivity. Science 378, 1320–1324 (2022).

Kim, S. C. et al. Potentiometric measurement to probe solvation energy and its correlation to lithium battery cyclability. J. Am. Chem. Soc. 143, 10301–10308 (2021).

Wang, H. et al. Correlating Li ion solvation structures and electrode potential temperature coefficients. J. Am. Chem. Soc. https://doi.org/10.1021/jacs.0c10587 (2021).

Qian, K., Winans, R. E. & Li, T. Insights into the nanostructure, solvation, and dynamics of liquid electrolytes through small-angle X-ray scattering. Adv. Energy Mater. 11, 2002821 (2021).

Saito, S. et al. Li+ local structure in hydrofluoroether diluted Li-glyme solvate ionic liquid. J. Phys. Chem. B 120, 3378–3387 (2016).

Zheng, J. et al. Understanding thermodynamic and kinetic contributions in expanding the stability window of aqueous electrolytes. Chem 4, 2872–2882 (2018).

Hassan, S. A. Morphology of ion clusters in aqueous electrolytes. Phys. Rev. E 77, 1–5 (2008).

Tan, P. et al. Solid-like nano-anion cluster constructs a free lithium-ion-conducting superfluid framework in a water-in-salt electrolyte. J. Phys. Chem. C 125, 11838–11847 (2021).

McEldrew, M., Goodwin, Z. A. H., Bi, S., Bazant, M. Z. & Kornyshev, A. A. Theory of ion aggregation and gelation in super-concentrated electrolytes. J. Chem. Phys. 152, 234506 (2020).

Xin, N., Sun, Y., He, M., Radke, C. J. & Prausnitz, J. M. Solubilities of six lithium salts in five non-aqueous solvents and in a few of their binary mixtures. Fluid Phase Equilib. 461, 1–7 (2018).

Mceldrew, M., Goodwin, Z. A. H., Zhao, H., Bazant, M. Z. & Kornyshev, A. A. Correlated ion transport and the gel phase in room temperature ionic liquids. J. Phys. Chem. B 125, 10, 2677–2689 (2021).

Gupta, A. & Manthiram, A. Unifying the clustering kinetics of lithium polysulfides with the nucleation behavior of Li2S in lithium–sulfur batteries. J. Mater. Chem. A 9, 13242–13251 (2021).

Fang, C. et al. Pressure-tailored lithium deposition and dissolution in lithium metal batteries. Nat. Energy 6, 987–994 (2021).

Xiao, B. J. How lithium dendrites form in liquid batteries. Science 366, 426–428 (2019).

Bai, P., Li, J., Brushett, F. R. & Bazant, M. Z. Transition of lithium growth mechanisms in liquid electrolytes. Energy Environ. Sci. https://doi.org/10.1039/C6EE01674J (2016).

Fan, X. et al. Highly fluorinated interphases enable high-voltage Li metal batteries. Chem 4, 174–185 (2018).

Oyakhire, S. T., Gong, H., Cui, Y., Bao, Z. & Bent, S. F. An X-ray photoelectron spectroscopy primer for solid electrolyte interphase characterization in lithium metal anodes. ACS Energy Lett. 7, 2540–2546 (2022).

Yao, Y. X. et al. Regulating interfacial chemistry in lithium ion batteries by a weakly solvating electrolyte. Angew. Chem. Int. Ed. 60, 4090–4097 (2021).

Xu, K. Non-aqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 104, 4303–4417 (2004).

Kaminski, G. A., Friesner, R. A., Tirado-Rives, J. & Jorgensen, W. L. Evaluation and reparametrization of the OPLS-AA force field for proteins via comparison with accurate quantum chemical calculations on peptides. J. Phys. Chem. B 105, 6474–6487 (2001).

Canongia Lopes, J. N. et al. Potential energy landscape of bis(fluorosulfonyl)amide. J. Phys. Chem. B 112, 9449–9455 (2008).

Neese, F., Wennmohs, F., Becker, U. & Riplinger, C. The ORCA quantum chemistry program package. J. Chem. Phys. 152, 224108 (2020).

Lu, T. & Chen, F. Multiwfn: a multifunctional wavefunction analyzer. J. Comput. Chem. 33, 580–592 (2012).

Michaud-Agrawal, N., Denning, E. J., Woolf, T. B. & Beckstein, O. MDAnalysis: a toolkit for the analysis of molecular dynamics simulations. J. Comput. Chem. 32, 2319–2327 (2011).

Acknowledgements

S.T.O. acknowledges support from the TomKat Center Fellowship for Translational Research at Stanford University. D.T.B. acknowledges the National Science Foundation Graduate Research Fellowship Program for funding. Z.H. acknowledges support from an American Association of University Women International Fellowship. The battery and electrolyte measurement parts were supported by the Assistant Secretary for Energy Efficiency and Renewable Energy, Office of Vehicle Technologies, of the U.S. Department of Energy under the Battery Materials Research Program and the Battery500 Consortium programme. Part of this work was performed at the Stanford Nano Shared Facilities. We acknowledge J. Nelson Weker for fruitful discussions on X-ray scattering experiments.

Author information

Authors and Affiliations

Contributions

S.C.K. and J.W. contributed equally. S.C.K. and Y. Cui conceived and designed the investigation. S.C.K. conducted materials synthesis and electrochemical performance testing. J.W. conducted MD simulations. R.X. conducted multiphysics simulations. P.Z. and Z.H. conducted X-ray scattering experiments. Y. Chen conducted DOSY-NMR experiments. Y. Yang conducted SEM characterizations. Z.Y. conducted electrolyte solvent synthesis. Z.H. conducted viscosity characterization. S.T.O. and L.C.G. conducted XPS characterization. S.C.K. conducted solvation measurements. W.Z., P.S., M.S.K., D.T.B. and Y. Ye assisted with interpretation of results. J.Q., Z.B. and Y. Cui supervised the project. S.C.K., J.W. and Y. Cui co-wrote the paper. All authors discussed the results and commented on the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Faezeh Makhlooghiazad, Xiqian Yu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–34 and Tables 1–12.

Supplementary Video 1

Flammability test: conventional.

Supplementary Video 2

Flammability test: EL2.

Supplementary Video 3

Flammability test: EL4.

Supplementary Video 4

Flammability test: EL5.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kim, S.C., Wang, J., Xu, R. et al. High-entropy electrolytes for practical lithium metal batteries. Nat Energy 8, 814–826 (2023). https://doi.org/10.1038/s41560-023-01280-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-023-01280-1

This article is cited by

-

Hybridizing carbonate and ether at molecular scales for high-energy and high-safety lithium metal batteries

Nature Communications (2024)

-

High-Entropy Strategy for Electrochemical Energy Storage Materials

Electrochemical Energy Reviews (2024)

-

Diversifying the solvent

Nature Energy (2023)