Abstract

All-solid-state batteries (ASSBs) with Li metal anodes or Si anodes are promising candidates to achieve high energy density and improved safety, but they suffer from undesirable lithium dendrite growth or huge volume expansion, respectively. Here we synthesize a hard-carbon-stabilized Li–Si alloy anode in which sintering of Si leads to the transformation of micro-metre particles into dense continuum. A 3D ionic-electronic-conductive network composed of plastically deformable Li-rich phases (Li15Si4 and LiC6) that enlarges active area and relieves stress concentration is created in the anode, leading to improved electrode kinetics and mechanical stability. With the hard-carbon-stabilized Li-Si anode, full cells using LiCoO2 or LiNi0.8Co0.1Mn0.1O2 cathodes and Li6PS5Cl electrolyte achieve favourable rate capability and cycle stability. In particular, the ASSB with LiNi0.8Co0.1Mn0.1O2 at high loading of 5.86 mAh cm−2 delivers 5,000 cycles at 1 C (5.86 mA cm−2), demonstrating the potential of using hard-carbon-stabilized Li–Si alloy anodes for practical applications of ASSBs.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data generated and analysed in this study are included in the paper and Supplementary Information. Source data are provided with this paper.

References

Peng, J. et al. High current density and long cycle life enabled by sulfide solid electrolyte and dendrite‐free liquid lithium anode. Adv. Funct. Mater. 32, 2105776 (2022).

Fan, X. et al. Fluorinated solid electrolyte interphase enables highly reversible solid-state Li metal battery. Sci. Adv. 4, eaau9245 (2018).

Luo, S. et al. Growth of lithium-indium dendrites in all-solid-state lithium-based batteries with sulfide electrolytes. Nat. Commun. 12, 6968 (2021).

Ye, L. & Li, X. A dynamic stability design strategy for lithium metal solid state batteries. Nature 593, 218–222 (2021).

Lee, Y.-G. et al. High-energy long-cycling all-solid-state lithium metal batteries enabled by silver–carbon composite anodes. Nat. Energy 5, 299–308 (2020).

Obrovac, M. N. & Krause, L. J. Reversible cycling of crystalline silicon powder. J. Electrochem. Soc. 154, A103–A108 (2007).

Cao, D. et al. High performance sulfide‐based all‐solid‐state batteries enabled by electrochemo‐mechanically stable electrodes. Adv. Mater. 34, 2200401 (2022).

Yan, W. et al. Application of Si-based anodes in sulfide solid-state batteries. Energy Storage Sci. Technol. 10, 821–835 (2021).

Tan, D. H. S. et al. Carbon-free high-loading silicon anodes enabled by sulfide solid electrolytes. Science 373, 1494–1498 (2021).

Miyazaki, R. et al. An amorphous Si film anode for all-solid-state lithium batteries. J. Power Sources 272, 541–545 (2014).

Sakabe, J. et al. Porous amorphous silicon film anodes for high-capacity and stable all-solid-state lithium batteries. Commun. Chem. 1, 24 (2018).

Ohta, N. et al. Anode properties of Si nanoparticles in all-solid-state Li batteries. ACS Appl. Energy Mater. 2, 7005–7008 (2019).

Cangaz, S. et al. Enabling high‐energy solid‐state batteries with stable anode interphase by the use of columnar silicon anodes. Adv. Energy Mater. 10, 2001320 (2020).

He, Y. et al. Shape evolution of patterned amorphous and polycrystalline silicon microarray thin film electrodes caused by lithium insertion and extraction. J. Power Sources 216, 131–138 (2012).

Wang, Z. et al. Composition dependence of lithium diffusion in lithium silicide: a density functional theory study. ChemElectroChem 2, 1292–1297 (2015).

Berla, L. A. et al. Mechanical behavior of electrochemically lithiated silicon. J. Power Sources 273, 41–51 (2015).

Li, H. et al. The crystal structural evolution of nano-Si anode caused by lithium insertion and extraction at room temperature. Solid State Ionics 135, 181–191 (2000).

Zhou, G. W. et al. Controlled Li doping of Si nanowires by electrochemical insertion method. Appl. Phys. Lett. 75, 2447–2449 (1999).

Yang, L. et al. Failure mechanisms of 2D silicon film anodes: in situ observations and simulations on crack evolution. Chem. Commun. 54, 3997–4000 (2018).

Zhao, K. et al. Lithium-assisted plastic deformation of silicon electrodes in lithium-ion batteries: a first-principles theoretical study. Nano Lett. 11, 2962–2967 (2011).

Schlenker, R. et al. Structure and diffusion pathways in Li6PS5Cl argyrodite from neutron diffraction, pair-distribution function analysis, and NMR. Chem. Mater. 32, 8420–8430 (2020).

Kim, H. et al. Structure and properties of Li−Si alloys: a first-principles study. J. Phys. Chem. C 115, 2514–2521 (2011).

Yan, K. et al. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat. Energy 1, 16010 (2016).

Xie, L. et al. Hard carbon anodes for next‐generation Li‐ion batteries: review and perspective. Adv. Energy Mater. 11, 2101650 (2021).

Zhang, W. et al. A ‘cation-anion regulation’ synergistic anode host for dendrite-free lithium metal batteries. Sci. Adv. 4, eaar4410 (2018).

Moon, J. et al. Interplay between electrochemical reactions and mechanical responses in silicon-graphite anodes and its impact on degradation. Nat. Commun. 12, 2714 (2021).

Rehnlund, D. et al. Lithium‐diffusion induced capacity losses in lithium‐based batteries. Adv. Mater. 34, 2108827 (2022).

Li, L. et al. Self-heating–induced healing of lithium dendrites. Science 359, 1513–1516 (2018).

Kanamura, K. et al. XPS analysis of the surface of a carbon electrode intercalated by lithium ions. Chem. Mater. 9, 1797–1804 (1997).

Hori, H. et al. Analysis of hard carbon for lithium-ion batteries by hard X-ray photoelectron spectroscopy. J. Power Sources 242, 844–847 (2013).

Shang, Y. et al. Scalable synthesis of LiF‐rich 3D architected Li metal anode via direct lithium‐fluoropolymer pyrolysis to enable fast Li cycling. Energy Environ. Mater. 4, 213–221 (2020).

Grehk, T. M. et al. Absorption of Li on the Si(100)2×1 surface studied with high-resolution core-level spectroscopy. Phys. Rev. B 52, 16593–16601 (1995).

Wenzel, S. et al. Interfacial reactivity and interphase growth of argyrodite solid electrolytes at lithium metal electrodes. Solid State Ionics 318, 102–112 (2018).

Ito, S. et al. A rocking chair type all-solid-state lithium ion battery adopting Li2O–ZrO2 coated LiNi0.8Co0.15Al0.05O2 and a sulfide based electrolyte. J. Power Sources 248, 943–950 (2014).

Tian, H.-K. et al. Interfacial electronic properties dictate Li dendrite growth in solid electrolytes. Chem. Mater. 31, 7351–7359 (2019).

Zhou, L. et al. High areal capacity, long cycle life 4 V ceramic all-solid-state Li-ion batteries enabled by chloride solid electrolytes. Nat. Energy 7, 83–93 (2022).

Li, X. et al. High-performance Li-SeSx all-solid-state lithium batteries. Adv. Mater. 31, 1808100 (2019).

Jung, S.-K. et al. Pliable lithium superionic conductor for all-solid-state batteries. ACS Energy Lett. 6, 2006–2015 (2021).

Zhang, Z. et al. Flexible sulfide electrolyte thin membrane with ultrahigh ionic conductivity for all-solid-state lithium batteries. Nano Lett. 21, 5233–5239 (2021).

Woo, M.-H. et al. Reinforcing effect of single-wall carbon nanotubes on the LiNi0.6Co0.2Mn0.2O2 composite cathode for high-energy–density all-solid-state Li-ion batteries. Appl. Surf. Sci. 568, 150934 (2021).

Han, X. et al. All solid thick oxide cathodes based on low temperature sintering for high energy solid batteries. Energy Environ. Sci. 14, 5044–5056 (2021).

Poetke, S. et al. Nanostructured Si−C composites as high-capacity anode material for all-solid-state lithium‐ion batteries**. Batter. Supercaps 4, 1323–1334 (2021).

Peng, L. et al. Chlorine-rich lithium argyrodite enabling solid-state batteries with capabilities of high voltage, high rate, low-temperature and ultralong cyclability. Chem. Eng. J. 430, 132896 (2022).

Kraft, M. A. et al. Inducing high ionic conductivity in the lithium superionic argyrodites Li6+xP1–xGexS5I for all-solid-state batteries. J. Am. Chem. Soc. 140, 16330–16339 (2018).

Zhang, Q. et al. Nickel sulfide anchored carbon nanotubes for all-solid-state lithium batteries with enhanced rate capability and cycling stability. J. Mater. Chem. A 6, 12098–12105 (2018).

Kato, Y. et al. All-solid-state batteries with thick electrode configurations. J. Phys. Chem. Lett. 9, 607–613 (2018).

Lee, M. J. et al. Elastomeric electrolytes for high-energy solid-state lithium batteries. Nature 601, 217–222 (2022).

Zhang, B. et al. Solid-state lithium metal batteries enabled with high loading composite cathode materials and ceramic-based composite electrolytes. J. Power Sources 442, 227230 (2019).

Lin, D. et al. A silica-aerogel-reinforced composite polymer electrolyte with high ionic conductivity and high modulus. Adv. Mater. 30, 1802661 (2018).

Yang, X. et al. High-areal-capacity all-solid-state lithium batteries enabled by rational design of fast ion transport channels in vertically-aligned composite polymer electrodes. Nano Energy 61, 567–575 (2019).

Zhang, Z. et al. Enabling high-areal-capacity all-solid-state lithium-metal batteries by tri-layer electrolyte architectures. Energy Storage Mater. 24, 714–718 (2020).

Shen, H. et al. Oriented porous LLZO 3D structures obtained by freeze casting for battery applications. J. Mater. Chem. A 7, 20861–20870 (2019).

Hippauf, F. et al. Overcoming binder limitations of sheet-type solid-state cathodes using a solvent-free dry-film approach. Energy Storage Mater. 21, 390–398 (2019).

Nam, Y. J. et al. Toward practical all-solid-state lithium-ion batteries with high energy density and safety: comparative study for electrodes fabricated by dry- and slurry-mixing processes. J. Power Sources 375, 93–101 (2018).

Kim, D. H. et al. Sheet-type Li6PS5Cl-infiltrated Si anodes fabricated by solution process for all-solid-state lithium-ion batteries. J. Power Sources 426, 143–150 (2019).

Kim, J. Y. et al. Graphite–silicon diffusion-dependent electrode with short effective diffusion length for high-performance all-solid-state batteries. Adv. Energy Mater. 12, 2103108 (2022).

Han, S. Y. et al. Stress evolution during cycling of alloy-anode solid-state batteries. Joule 5, 2450–2465 (2021).

Gong, Y. et al. Lithium-ion conductive ceramic textile: a new architecture for flexible solid-state lithium metal batteries. Mater. Today 21, 594–601 (2018).

Yang, X. et al. Phase evolution of a prenucleator for fast Li nucleation in all‐solid‐state lithium batteries. Adv. Energy Mater. 10, 2001191 (2020).

Gao, X. et al. Fast charging all solid‐state lithium batteries enabled by rational design of dual vertically aligned electrodes. Adv. Funct. Mater. 30, 2005357 (2020).

Han, Q. et al. Outstanding cycle stability and rate capabilities of the all-solid-state Li–S battery with a Li7P3S11 glass-ceramic electrolyte and a core–shell S@BP2000 nanocomposite. J. Mater. Chem. A 7, 3895–3902 (2019).

Hovington, P. et al. New lithium metal polymer solid state battery for an ultrahigh energy: nano C-LiFePO4 versus nano Li1.2V3O8. Nano Lett. 15, 2671–2678 (2015).

Li, X. et al. Water-mediated synthesis of a superionic halide solid electrolyte. Angew. Chem. Int. Ed. 58, 16427–16432 (2019).

Acknowledgements

This work is supported by Outstanding Youth Fund Project by the Department of Science and Technology of Jiangsu Province (grant number BK20220045), Key R&D Project funded by Department of Science and Technology of Jiangsu Province (grant number BE2020003), Key Program-Automobile Joint Fund of the National Natural Science Foundation of China (grant number U1964205), General Program of the National Natural Science Foundation of China (grant number 51972334), General Program of National Natural Science Foundation of Beijing (grant number 2202058), cultivation project of leading innovative experts in Changzhou City (CQ20210003), National Overseas High-level Expert Recruitment Program (grant number E1JF021E11), Talent Program of the Chinese Academy of Sciences, ‘Scientist Studio Program Funding’ from Yangtze River Delta Physics Research Center and Tianmu Lake Institute of Advanced Energy Storage Technologies (grant number TIES-SS0001) and Science and Technology Research Institute of China Three Gorges Corporation (grant number 202103402).

Author information

Authors and Affiliations

Contributions

W.Y. and F.W. conceived and designed the experimental work. W.Y. prepared samples and carried out experiments. Z.M., Y.X. and S.S. performed the simulation using phase field simulation. M.Y., T.M. and X.Z. assisted with sample preparation. Y.H. and Y.W. assisted with characterization. W.Y., Z.M. and F.W. wrote the paper. D.W., Y.H. and P.L. helped with visualization. Z.W., J.L., J.X., P.L., F.W., H.L. and L.C. discussed the results and revised or commented on the manuscript. F.W. acquired funding and supervised/managed the whole project.

Corresponding author

Ethics declarations

Competing interests

Z.M., Y.X. and S.S. are employed by ByteDance Research. The other authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Felix Hippauf, Dong-Wan Kim and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs, 1–36, Notes 1–4 and Tables 1–12.

Supplementary Table

The raw data about thicknesses in this article.

Source data

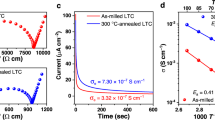

Source Data Fig. 1

Cycle test data and rate test data.

Source Data Fig. 2

Battery test source data and phase field simulation data.

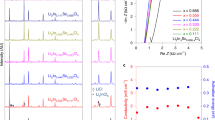

Source Data Fig. 3

Cycle test data, rate test data, XRD source data and surface area source data.

Source Data Fig. 4

Rate test data and comparison data.

Source Data Fig. 5

Cycle test data and comparison data.

Source Data Fig. 6

Charge–discharge test source data, cycle test data, fast discharge test data and comparison data.

Source Data Fig. 7

XRD and XPS data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yan, W., Mu, Z., Wang, Z. et al. Hard-carbon-stabilized Li–Si anodes for high-performance all-solid-state Li-ion batteries. Nat Energy 8, 800–813 (2023). https://doi.org/10.1038/s41560-023-01279-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-023-01279-8

This article is cited by

-

Designing Organic Material Electrodes for Lithium-Ion Batteries: Progress, Challenges, and Perspectives

Electrochemical Energy Reviews (2024)