Abstract

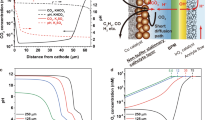

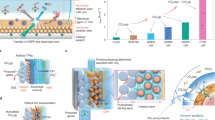

Continuous-flow electrolysers allow CO2 reduction at industrially relevant rates, but long-term operation is still challenging. One reason for this is the formation of precipitates in the porous cathode from the alkaline electrolyte and the CO2 feed. Here we show that while precipitate formation is detrimental for the long-term stability, the presence of alkali metal cations at the cathode improves performance. To overcome this contradiction, we develop an operando activation and regeneration process, where the cathode of a zero-gap electrolyser cell is periodically infused with alkali cation-containing solutions. This enables deionized water-fed electrolysers to operate at a CO2 reduction rate matching those using alkaline electrolytes (CO partial current density of 420 ± 50 mA cm−2 for over 200 hours). We deconvolute the complex effects of activation and validate the concept with five different electrolytes and three different commercial membranes. Finally, we demonstrate the scalability of this approach on a multicell electrolyser stack, with an active area of 100 cm2 per cell.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that all data supporting the findings of this study are available within the paper and Supplementary Information files. Source data are provided with this paper.

References

Hepburn, C. et al. The technological and economic prospects for CO2 utilization and removal. Nature 575, 87–97 (2019).

Endrődi, B. et al. Continuous-flow electroreduction of carbon dioxide. Prog. Energy Combust. Sci. 62, 133–154 (2017).

Weekes, D. M., Salvatore, D. A., Reyes, A., Huang, A. & Berlinguette, C. P. Electrolytic CO2 reduction in a flow cell. Acc. Chem. Res. 51, 910–918 (2018).

De Luna, P. et al. What would it take for renewably powered electrosynthesis to displace petrochemical processes? Science 364, eaav3506 (2019).

He, J. & Janáky, C. Recent advances in solar-driven carbon dioxide conversion: expectations versus reality. ACS Energy Lett. 5, 1996–2014 (2020).

Jouny, M., Luc, W. & Jiao, F. General techno-economic analysis of CO2 electrolysis systems. Ind. Eng. Chem. Res. 57, 2165–2177 (2018).

Verma, S. et al. A gross-margin model for defining technoeconomic benchmarks in the electroreduction of CO2. ChemSusChem 9, 1972–1979 (2016).

Schreier, M. et al. Solar conversion of CO2 to CO using Earth-abundant electrocatalysts prepared by atomic layer modification of CuO. Nat. Energy 2, 17087 (2017).

Arán-Ais, R. M., Scholten, F., Kunze, S., Rizo, R. & Roldan Cuenya, B. The role of in situ generated morphological motifs and Cu(i) species in C2+ product selectivity during CO2 pulsed electroreduction. Nat. Energy 5, 317–325 (2020).

Endrődi, B. et al. High carbonate ion conductance of a robust PiperION membrane allows industrial current density and conversion in a zero-gap carbon dioxide electrolyzer cell. Energy Environ. Sci. 13, 4098–4105 (2020).

Liu, K., Smith, W. A. & Burdyny, T. Introductory guide to assembling and operating gas diffusion electrodes for electrochemical CO2 reduction. ACS Energy Lett. 4, 639–643 (2019).

Burdyny, T. & Smith, W. A. CO2 reduction on gas-diffusion electrodes and why catalytic performance must be assessed at commercially-relevant conditions. Energy Environ. Sci. 12, 1442–1453 (2019).

Bhargava, S. S. et al. System design rules for intensifying the electrochemical reduction of CO2 to CO on Ag nanoparticles. ChemElectroChem 7, 2001–2011 (2020).

Kibria, M. G. et al. A surface reconstruction route to high productivity and selectivity in CO2 electroreduction toward C2+ hydrocarbons. Adv. Mater. 30, 1804867 (2018).

Ma, W. et al. Electrocatalytic reduction of CO2 to ethylene and ethanol through hydrogen-assisted C–C coupling over fluorine-modified copper. Nat. Catal. 3, 478–487 (2020).

De Gregorio, G. L. et al. Facet-dependent selectivity of Cu catalysts in electrochemical CO2 reduction at commercially viable current densities. ACS Catal. 10, 4854–4862 (2020).

Wang, X. et al. Efficient methane electrosynthesis enabled by tuning local CO2 availability. J. Am. Chem. Soc. 142, 3525–3531 (2020).

García de Arquer, F. P. et al. CO2 electrolysis to multicarbon products at activities greater than 1 A cm−2. Science 367, 661–666 (2020).

Verma, S., Lu, S. & Kenis, P. J. A. Co-electrolysis of CO2 and glycerol as a pathway to carbon chemicals with improved technoeconomics due to low electricity consumption. Nat. Energy 4, 466–474 (2019).

Na, J. et al. General technoeconomic analysis for electrochemical coproduction coupling carbon dioxide reduction with organic oxidation. Nat. Commun. 10, 5193 (2019).

Vass, Á., Endrődi, B. & Janáky, C. Coupling electrochemical carbon dioxide conversion with value-added anode processes: an emerging paradigm. Curr. Opin. Electrochem. 25, 100621 (2021).

Larrazábal, G. O. et al. Analysis of mass flows and membrane cross-over in CO2 reduction at high current densities in an MEA-type electrolyzer. ACS Appl. Mater. Interfaces 11, 41281–41288 (2019).

Ma, M. et al. Insights into the carbon balance for CO2 electroreduction on Cu using gas diffusion electrode reactor designs. Energy Environ. Sci. 13, 977–985 (2020).

Endrödi, B. et al. Multilayer electrolyzer stack converts carbon dioxide to gas products at high pressure with high efficiency. ACS Energy Lett. 4, 1770–1777 (2019).

Wang, R. et al. Maximizing Ag utilization in high-rate CO2 electrochemical reduction with a coordination polymer-mediated gas diffusion electrode. ACS Energy Lett. 4, 2024–2031 (2019).

Kaczur, J. J., Yang, H., Liu, Z., Sajjad, S. D. & Masel, R. I. A review of the use of immobilized ionic liquids in the electrochemical conversion of CO2. J. Carbon Res. 6, 33 (2020).

Yin, Z. et al. An alkaline polymer electrolyte CO2 electrolyzer operated with pure water. Energy Environ. Sci. 12, 2455–2462 (2019).

Gabardo, C. M. et al. Combined high alkalinity and pressurization enable efficient CO2 electroreduction to CO. Energy Environ. Sci. 11, 2531–2539 (2018).

Wheeler, D. G. et al. Quantification of water transport in a CO2 electrolyzer. Energy Environ. Sci. 13, 5126–5134 (2020).

Zhao, C., Chen, X. & Zhao, C. Carbonation behavior of K2CO3 with different microstructure used as an active component of dry sorbents for CO2 capture. Ind. Eng. Chem. Res. 49, 12212–12216 (2010).

Chioyama, H., Luo, H., Ohba, T. & Kanoh, H. Temperature-dependent double-step CO2 occlusion of K2CO3 under moist conditions. Adsorpt. Sci. Technol. 33, 243–250 (2015).

Verma, S. et al. Insights into the low overpotential electroreduction of CO2 to CO on a supported gold catalyst in an alkaline flow electrolyzer. ACS Energy Lett. 3, 193–198 (2018).

Kudo, Y. et al. Carbon dioxide electrolytic device and carbon dioxide electrolytic method. US patent 20180274109A1 (2018).

Leonard, M. E., Clarke, L. E., Forner‐Cuenca, A., Brown, S. M. & Brushett, F. R. Investigating electrode flooding in a flowing electrolyte, gas‐fed carbon dioxide electrolyzer. ChemSusChem 13, 400–411 (2020).

Liu, Z., Yang, H., Kutz, R. & Masel, R. I. CO2 electrolysis to CO and O2 at high selectivity, stability and efficiency using sustainion membranes. J. Electrochem. Soc. 165, J3371–J3377 (2018).

Luo, X., Rojas-Carbonell, S., Yan, Y. & Kusoglu, A. Structure-transport relationships of poly(aryl piperidinium) anion-exchange membranes: effect of anions and hydration. J. Memb. Sci. 598, 117680 (2020).

Ringe, S. et al. Understanding cation effects in electrochemical CO2 reduction. Energy Environ. Sci. 12, 3001–3014 (2019).

Resasco, J. et al. Promoter effects of alkali metal cations on the electrochemical reduction of carbon dioxide. J. Am. Chem. Soc. 139, 11277–11287 (2017).

Lobaccaro, P. et al. Effects of temperature and gas–liquid mass transfer on the operation of small electrochemical cells for the quantitative evaluation of CO2 reduction electrocatalysts. Phys. Chem. Chem. Phys. 18, 26777–26785 (2016).

Pérez-Gallent, E., Marcandalli, G., Figueiredo, M. C., Calle-Vallejo, F. & Koper, M. T. M. Structure- and potential-dependent cation effects on CO reduction at copper single-crystal electrodes. J. Am. Chem. Soc. 139, 16412–16419 (2017).

Chen, L. D., Urushihara, M., Chan, K. & Nørskov, J. K. Electric field effects in electrochemical CO2 reduction. ACS Catal. 6, 7133–7139 (2016).

Birdja, Y. Y. et al. Advances and challenges in understanding the electrocatalytic conversion of carbon dioxide to fuels. Nat. Energy 4, 732–745 (2019).

Murata, A. & Hori, Y. Product selectivity affected by cationic species in electrochemical reduction of CO2 and CO at a Cu electrode. Bull. Chem. Soc. Jpn 64, 123–127 (1991).

Singh, M. R., Kwon, Y., Lum, Y., Ager, J. W. & Bell, A. T. Hydrolysis of electrolyte cations enhances the electrochemical reduction of CO2 over Ag and Cu. J. Am. Chem. Soc. 138, 13006–13012 (2016).

Thorson, M. R., Siil, K. I. & Kenis, P. J. A. Effect of cations on the electrochemical conversion of CO2 to CO. J. Electrochem. Soc. 160, F69–F74 (2013).

Carmo, M., Fritz, D. L., Mergel, J. & Stolten, D. A comprehensive review on PEM water electrolysis. Int. J. Hydrog. Energy 38, 4901–4934 (2013).

Acknowledgements

This project has received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation programme (grant no. 716539 and 899747, to C.J.). The research was supported by the National Research, Development and Innovation Office (NKFIH) through the FK-132564 project (to E.B.), and by the ‘Széchenyi 2020’ program in the framework of GINOP-2.2.1-15-2017-00041 project (to C.J.). Financial support for purchasing the CT instrument was also provided by NKFIH through the GINOP-2.3.3-15-2016-00010 project (to C.J. and D.S.). This project was supported by the János Bolyai Research Scholarship of the Hungarian Academy of Sciences (to B.E. and D.S.). We thank L. Janovák, Á. Balog, G. F. Samu and G. Bencsik at University of Szeged for assistance in contact angle, SEM–EDX, X-ray diffraction (with Rietveld analysis) and ion chromatography measurements, respectively. We also thank T. Pajkossy (Hungarian Academy of Sciences) for his valuable contribution in the design, analysis and interpretation of EIS measurements. We thank P. Kamat (University of Notre Dame) for critical comments on an earlier version of the manuscript and B. Janáky-Bohner for her support in the preparation of the manuscript.

Author information

Authors and Affiliations

Contributions

B.E. and C.J. conceived and supervised the project and designed all experiments. A.S. and T.H. prepared the gas diffusion electrodes and assembled the cells. A.S., T.H. and E.K. carried out all electrochemical and product analysis experiments. D.S. performed and analysed micro-CT measurements. B.E., E.K. and C.J. designed the electrodes, the electrochemical cells and the electrolyser system. All authors discussed the results and assisted during manuscript preparation.

Corresponding authors

Ethics declarations

Competing interests

Two patent applications have been filed on the continuous-flow electrolysis of CO2 by some authors of this paper (B.E., A.S., E.K., C.J., all University of Szeged) and their collaborating partner, ThalesNano Zrt. Application numbers: PCT/HU2019/095001 and PCT/HU2020/050033. T.H. and D.S. declare no competing interests.

Additional information

Peer review information Nature Energy thanks the anonymous reviewers for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–8 and Figs. 1–24.

Supplementary Data 1

Source data for figures in the Supplementary Information.

Source data

Source Data Fig. 3a

Raw data for contact angle measurements.

Source Data Fig. 5

Raw partial current density data.

Rights and permissions

About this article

Cite this article

Endrődi, B., Samu, A., Kecsenovity, E. et al. Operando cathode activation with alkali metal cations for high current density operation of water-fed zero-gap carbon dioxide electrolysers. Nat Energy 6, 439–448 (2021). https://doi.org/10.1038/s41560-021-00813-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-021-00813-w

This article is cited by

-

Durable CO2 conversion in the proton-exchange membrane system

Nature (2024)

-

Pure-water-fed, electrocatalytic CO2 reduction to ethylene beyond 1,000 h stability at 10 A

Nature Energy (2024)

-

Paired photoelectrochemical conversion of CO2/H2O and glycerol at high rate

Nature Catalysis (2024)

-

Designing Membrane Electrode Assembly for Electrochemical CO2 Reduction: a Review

Transactions of Tianjin University (2024)

-

Enhancing carbon utilization

Nature Energy (2023)