Abstract

Charge loss at grain boundaries of kesterite Cu2ZnSn(S, Se)4 polycrystalline absorbers is an important cause limiting the performance of this emerging thin-film solar cell. Herein, we report a Pd element assisted reaction strategy to suppress atomic vacancy defects in GB regions. The Pd, on one hand in the form of PdSex compounds, can heterogeneously cover the GBs of the absorber film, suppressing Sn and Se volatilization loss and the formation of their vacancy defects (i.e. VSn and VSe), and on the other hand, in the form of Pd(II)/Pd(IV) redox shuttle, can assist the capture and exchange of Se atoms, thus contributing to eliminating the already-existing VSe defects within GBs. These collective effects have effectively reduced charge recombination loss and enhanced p-type characteristics of the kesterite absorber. As a result, high-performance kesterite solar cells with a total-area efficiency of 14.5% (certified at 14.3%) have been achieved.

Similar content being viewed by others

Introduction

Kesterite solar cell has emerged as one of the most promising thin-film photovoltaics since the absorber, Cu2ZnSn(S, Se)4 (CZTSSe), is a nontoxic material composed of earth-abundant elements and has excellent thermodynamic stability and moreover this cell technology is compatible with current thin-film photovoltaics industry1,2,3,4. This solar cell has garnered increasing research attention in recent years and efficiency breakthroughs have been successively reported, with the most recent achievements successively reaching 13% and 14% using environmentally-friendly solution methods5,6,7. Nonetheless, these cell efficiencies still fall significantly short of its Shockley-Queisser limit. This efficiency gap, particularly exhibiting as significant deficits in the open-circuit voltage (VOC), are primarily caused by intricate defects in CZTSSe absorbers and the induced charge non-radiative recombination loss.

For polycrystalline CZTSSe, the complex phase evolution processes, the coexistence of secondary phases, and the disorder of multinary elements are considered as main causes of defects and charge loss8,9,10,11. In previous studies, a variety of efforts have been paid to relieve these issues and particularly to suppress intrinsic point defects within the bulk grain interiors (GI)12,13,14,15,16, which has made considerable contribution to the efficiency improvement of the cell. In addition to these widely concerned issues, Hao et al17. recently highlighted that the grain boundary (GB) within CZTSSe absorbers actually played a more substantial role in influencing charge recombination velocity and charge loss. Several factors contribute to this phenomenon regarding GBs. Firstly, GBs typically exhibit a higher degree of structural distortion and atomic disorder, leading to the formation of various types of defects, such as Se-Se dimers18,19,20. Secondly, conductive secondary phases such as CuxSe and SnSex tend to segregate at GBs21,22,23, creating current shunting pathways within these boundaries. Thirdly, during the later stages of the selenization process, the low-Se-pressure reaction environment struggles to maintain CZTSSe crystals in a stable state, leading to gradual surface decomposition24,25.

Due to the aforementioned reasons, precise regulation of defects at GBs of CZTSSe absorbers has become an essential prerequisite for further enhancing the efficiency of kesterite solar cells. Researchers have attempted several strategies for overcoming issues such as the detrimental Se-Se dimers and the segregation of secondary phases, by using alkali metal incorporation26,27, surface etching22,28, composition control29,30,31, and optimization of reaction pathways6,7. These efforts have yielded promising results sequentially; however, the previously generally believed positive effect of GB on charge transport32,33,34 and the intricate growth process of CZTSSe polycrystalline films at elevated temperatures has led to a dearth of investigations into the characteristics of defects situated in the GB regions and their impacts. Consequently, no matter from physics understanding or from the material engineering, the regulation of defects within the GBs of CZTSSe remains a substantial challenge in this field.

Herein, we propose that vacancy defects caused by the inevitable and irreversible volatilization loss of Se or Sn elements at GBs of the CZTSSe film at elevated temperatures are important origins for the charge loss. To overcome this issue directly related to the thermodynamic properties of the constituent elements of CZTSSe, we started from the perspective of controlling the volatilization kinetics and developed a local reaction strategy leveraging palladium (Pd). In this strategy, non-volatile PdSex compounds were introduced to heterogeneously fill into and cover GBs of the CZTSSe film by taking advantage of the spontaneous segregation of Pd from the CZTSSe GIs. This local covering can effectively suppress the element volatilization loss and the formation of vacancy defects. Moreover, Pd(II)/Pd(IV) is a redox shuttle, which can capture vaporized Se from the reaction environment and subsequently supply to the CZTSSe absorber, further diminishing vacancy defects. These effects enable the fabrication of low-defect-density CZTSSe absorbers and consequently achieve the highest certified efficiency of 14.3% reported to date in kesterite solar cells.

Results

Influence of Pd on the selenization process

In previous investigations of the Se vapor evolution in the graphite box, it was found that the Se vapor concentration shows a very significant decrease in the middle and late stages of the selenization6. From the perspective of solid-vapor equilibrium at high temperatures, this would induce irreversible escape of Se atom from the CZTSSe crystal surface and GBs, resulting in the formation Se vacancy defect (VSe). With the emergence of a large number of VSe, the binding of metal atoms on the crystal surface also declines, making the volatile Sn also easy to escape, probably in the form of SnSe vapor, causing the appearance of Sn vacancy defect (VSn)24,25,35. Through explorations, we found that the issue of Se and Sn volatilization loss can be effectively addressed by employing Pd incorporated kesterite absorber.

In our approach, PdCl2 was introduced into the precursor solution for the fabrication of Ag-alloyed CZTSSe (ACZTSSe) film, in which Ag was used to promote the film crystallization36. For clarity, we refer to the ACZTSSe film with Pd as ACZTSSe-Pd, while the Pd-free ACZTSSe is considered as the control sample. These films were subsequently used for the solar cell fabrication, and the best cell performance was achieved when the Pd/Zn ratio was at 1% (Supplementary Figs. 1 and 2). Through spherical aberration-corrected scanning transmission electron microscopy (STEM) and electron energy loss spectroscopy (EELS) characterization, we found that in the final-state ACZTSSe-Pd film, Pd element is primarily localized along the GB (Fig. 1a, b and Supplementary Fig. 3). A similar spatial distribution pattern was observed for the Se element in the GB regions (Fig. 1c and Supplementary Fig. 3). It suggests that the introduced Pd was mainly distributed in the GB regions, in the form of PdSex compounds such as PdSe2 and PdSe. Besides the GBs, Pd was also detected on the film surfaces by using X-ray photoelectron spectra (XPS), with higher intensity than that in the etched bulk region (Supplementary Fig. 4). This implies that PdSex compounds mainly existed both at the GBs and on the film surfaces, forming effective heterogeneous coverings over the ACZTSSe grains. X-ray diffraction (XRD) and Raman investigations indicated that the incorporation of Pd did not alter the size and vibration properties of the ACZTSSe lattice, even when the Pd/Zn ratio was increased to 3% (Supplementary Fig. 5). Even during the high temperature selenization reaction, Pd did not change the relative positions of the XRD peaks of the ACZTSSe phase. Therefore, we speculate that the doping of Pd atoms into the kesterite lattice is negligible. In the ACZTSSe crystallization growth process, Pd was mainly segregated to the GBs and the surfaces, forming PdSex coverings. This hypothesis is further supported by density functional theory (DFT) calculations, which shows a high formation energy of >1.0 eV for Pd/M (M = Cu, Zn, or Sn) substitutions in the kesterite lattice (Supplementary Fig. 6).

a Cross-sectional HAADF STEM image of the ACZTSSe-Pd film. The green rectangle represents the EELS mapping region. b, c EELS mapping image of Pd (M4 and M5 peaks) and Se (L2 and L3 peaks). d–f Evolutions of element composition and Sn 3d XPS spectra of the films during the selenization process. g Gaussian fitting of the XPS spectra of the final-state ACZTSSe films. h, i Evolutions of surface CPD of the two samples during the selenization process.

We further delved into the impact of Pd on the selenization process of ACZTSSe films. We employed X-ray fluorescence (XRF) to quantify the element composition of films sampled at various selenization stages (Fig. 1d and Supplementary Fig. 7). It is evident that the volatilization loss of Sn and Se elements conspicuously and continuously occurred in the control sample when the selenization reaction exceeded 5 minutes. In contrast, the ACZTSSe-Pd sample effectively suppressed element loss, with the Sn/(Cu+Ag+Zn+Sn) ratio remaining nearly constant throughout the entire process. Additionally, a higher and more stable Se/(Cu+Ag+Zn+Sn) ratio was observed during the intermediate selenization process. This suppression of element loss consequently stabilized the electronic structure of Sn. The XPS peak position of Sn in the ACZTSSe-Pd sample remained almost unchanged as selenization proceeded (Fig. 1e, g, and Supplementary Figs. 8 and 9). This is in stark contrast to the control sample, in which the Sn XPS peak continuously shifted towards the lower-energy direction (Fig. 1f, g).

By further fitting, we found that the Sn XPS spectrum of the final-state control sample was composed of two peaks with comparable intensities, locating at 486.9 eV and 486.3 eV, which can be ascribed to Sn(IV) and Sn(II), respectively (Fig. 1g)37,38,39. In contrast, the XPS spectrum of the ACZTSSe-Pd sample was dominated by the higher-energy peak (Fig. 1g). DFT calculations revealed that the appearance of Sn(II) is arisen from VSe defects, which results in lone pair electrons in the 5 s orbit of the nearest neighboring Sn atom (Supplementary Figs. 10 and 11). As such, the continuous shift of Sn XPS spectra during the selenization process is indicative of the ongoing formation of VSe, which is a donor defect that would weaken the p-type carriers of the kesterite absorber (Supplementary Fig. 12)10,35. This result was confirmed by surface contacting potential difference (CPD) mapping of these films using Kelvin probe force microscopy (KPFM) (Fig. 1h, i and Supplementary Fig. 13). For the control sample, its average CPD evolved from −93 mV to 70 mV as selenization progressed, resulting in an upshift of the Fermi energy level by more than 160 mV. In comparison, the CPD evolution of the ACZTSSe-Pd sample was limited to less than 40 mV (from −129 to −90 mV), demonstrating much more stable surface electrical properties and a more pronounced p-type nature.

Characterization of ACZTSSe absorbers

We further characterize the impact of Pd on the element distribution in final-state ACZTSSe absorber films using STEM based energy-dispersive X-ray spectroscopy (EDX) analysis. In the case of the control film (Fig. 2a–d and Supplementary Figs. 14 and 15), a clear deficiency of Sn and Se elements is evident in the GB region, while other elements display a relatively uniform distribution profile across the GBs. This observation indicates that Sn and Se elements in GB regions did indeed experience volatilization loss. In contrast, in the ACZTSSe-Pd film, the Se content in the GB region is slightly higher than that in the GI, and the distribution of Sn is uniform, similar to other elements (Fig. 2e–h and Supplementary Figs. 14 and 15). This suggests that the loss of Sn and Se elements in GB regions has been effectively mitigated. This result was further confirmed on a larger scale using scanning electron microscopy (SEM) (Supplementary Figs. 16 and 17).

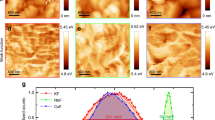

a–h Cross-sectional STEM-EDX mappings of Se and Sn elements in the films (a, b Se, control film, c, d Sn, control film, e, f Se, ACZTSSe-Pd film, g, h Sn, ACZTSSe-Pd film). i, j KPFM mapping images of the two absorber films (i Control, j ACZTSSe-Pd) and (k, l) schematic diagram of the energy band bending near the GB regions (k Control, l ACZTSSe-Pd). “e−” represents electron and “h+” represents hole. m Steady-state PL spectra of the absorber films. n–o Modulated transient photocurrent and photovoltage dynamics of the cells.

CPD mapping results revealed that the suppression of element loss in GBs has significantly altered the energy band bending behaviors of the ACZTSSe absorber film. In the control film, obviously higher CPD was observed in the GB regions compared to the GIs (Fig. 2i), indicating a downward bending of the energy band (Fig. 2k). Under this case, the photo-generated minority electrons would be driven to the defective GB regions and cause carrier loss. The existence of high concentration of donor defects in the GBs is the primary reason for this phenomenon. In contrast, the ACZTSSe-Pd film exhibited an inversion of the energy band bending (Fig. 2j, l), benefiting from an effective reduction in the VSe donor defect. This upward bending would facilitate the spatial separation of minority electrons, thereby reducing carrier recombination40,41,42. This was confirmed by transient photoluminescence (PL) measurements (Supplementary Fig. 18), which revealed that the ACZTSSe-Pd film exhibited a significantly prolonged carrier lifetime. Due to the reduced carrier recombination, the ACZTSSe-Pd film also displayed a higher steady-state PL intensity (Supplementary Fig. 19). Moreover, the ACZTSSe-Pd film exhibited a notably smaller PL bathochromic shift relative to its bandgap (Eg), more than 20 meV lower than that of the control sample (Fig. 2m). This indicates a reduction in electrostatic potential fluctuations within the absorber film43,44,45, which is also evidence of the suppressed defects.

These absorber films were subsequently used to fabricate solar cells following a standard device configuration (Supplementary Fig. 20). We investigated the charge transport and recombination losses of the cells using modulated transient photocurrent/photovoltage measurements (M-TPC/TPV). It is evident that the ACZTSSe-Pd cell exhibited much faster photocurrent decays at both −1 and 0 V, with the photocurrent rise velocity and peak position remaining unaffected by the bias voltage (Fig. 2n). In contrast, these dynamics in the control cell were noticeably delayed when the built-in electric field within the cell was weakened by altering the bias voltage (Fig. 2n). These findings demonstrate that the impact of electrostatic potential fluctuations and carrier trapping processes on the charge transport have been effectively reduced in the ACZTSSe-Pd absorber46,47. These improvements also suppressed charge recombination, as evidenced by the slower photovoltage decay observed in the cell under different positive bias voltages (Fig. 2o).

Device performance and characterization

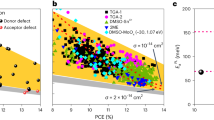

The top-performing cell achieved an impressive power conversion efficiency (PCE) of 14.5%, with a short-circuit current density (JSC) of 36.7 mA cm−2, a VOC of 0.555 V, and a fill factor (FF) of 0.712 (Fig. 3a). In comparison, the control cell exhibited a lower PCE of only 12.8%, with noticeably lower JSC at 35.5 mA cm−2, VOC at 0.519 V, and FF at 0.695. A statistical analysis of these parameters further highlighted the performance disparity between these two cell types (Supplementary Fig. 21). External quantum efficiency (EQE) spectra indicated that the absorbers in both cells had a similar bandgap of 1.1 eV. The improvement in JSC, approximately 1 mA cm−2, primarily originated from EQE enhancement in the wavelength range from 600 to 1080 nm (Supplementary Fig. 22). This suggests that photocarriers generated within the bulk absorber were more effectively extracted4,48, due to reduced charge losses within the GBs. The reduction in charge losses is also responsible for the significant improvements in VOC and FF.

a Current density-voltage (J–V) characteristics of the champion control and ACZTSSe-Pd devices. b Certified J–V curves of the cell at both forward and reverse scanning directions. c Maximum power point tracking of the cell for 300 s. d Charge extraction and collection efficiencies of the cells derived from modulated electrical transient measurements. e Charge profiles of the cells measured by DLCP and C–V at 11 kHz. f Temperature-dependent VOC of the cells.

Moreover, the cell has received a certified PCE of 14.3% from an accredited independent testing laboratory, the National PV Industry Measurement and Testing Center (NPVM) (Fig. 3B and Supplementary Fig. 23). The maximum power point tracking (MPPT) of the cell was also conducted in the certification process. When biased at 435.9 mV, the cell gave constant current output of about 32.95 mA cm−2 for 300 s, achieving a steady-state PCE of approaching 14.4% (Fig. 3c). This achievement stands as the highest result reported to date.

We further quantified the charge loss in the cell based on the modulated electrical transient measurements (Fig. 3d). The primary difference between these two cells lies in the charge extraction efficiency (ηext), which is correlated to the charge loss in the bulk absorber. At 0.4 V, the ACZTSSe-Pd solar cell achieved a 1.4-fold enhancement in ηext. Furthermore, the ACZTSSe-Pd solar cell also exhibited higher charge collection efficiency (ηC) at voltages exceeding 0.35 V. This indicates that interface defect-induced charge loss in the cell has also been reduced. The findings from the electrical transient analysis are further substantiated by a direct measurement of charge spatial distribution within the cell employing capacitance-voltage (C-V) and drive-level capacitance profiling (DLCP) methods (Fig. 3e). Based on the difference in charge density measured by DLCP and C-V 49, the volume defect density (NIT) near the ACZTSSe/CdS interface region in the ACZTSSe-Pd solar cell is estimated to be 4.4 × 1015 cm−3, which is approximately one-third of that observed in the control solar cell (1.2 × 1016 cm−3). Furthermore, the ACZTSSe-Pd absorber exhibited a higher charge density at 0 V, indicative of improved p-type doping. This aligns well with the CPD mapping results and serves as direct evidence of the suppressed VSe donor defect in the surface region. The enhancement of film surface quality is also evident from temperature-dependent VOC measurements50. In the ACZTSSe-Pd device, the activation energy (EA) was determined to be 1.02 eV, closely matching the optical Eg of the absorber (1.1 eV), whereas the control device exhibited a considerably lower EA of 0.93 eV (Fig. 3f).

Microscopic mechanism of the Pd-assisted GB engineering

We proceeded to explore the microscopic mechanisms underlying the defect regulation at GBs after Pd incorporation. To ascertain the form in which PdSex compounds existed, we measured XPS spectra of the Pd element throughout the selenization process. In the precursor film, Pd predominantly exhibited a + 2-valence state (Supplementary Fig. 24). During the intermediate selenization reaction stages (at 4 minutes and 6 minutes), a proportion of Pd appeared in the +4-valence state (Fig. 4a), indicating the formation of PdSe2, while other Pd ions remained in the +2-valence state, possibly as PdSe. These PdSex compounds were also corroborated through XRD and Raman characterization (Supplementary Figs. 25 and 26). Through DFT calculations, we discovered that PdSe2 and PdSe possess higher cohesive energy than the corresponding SnSex compounds (Fig. 4b), signifying superior compound stability and lower volatility. Consequently, from a reaction dynamics perspective, the PdSex heterogeneous coverage could mitigate element volatilization from the GBs and surfaces of the ACZTSSe absorber by creating a locally saturated environment. This, in turn, reduces the formation of VSn and VSe defects. Since this effect accompanied the entire process of crystal growth, the vacancy defects inside the CZTSSe grains should also be reduced accordingly.

a XPS spectra of the Pd element during the selenization process. b Cohesive energies of PdSe2, SnSe2, PdSe and SnSe. c c1 XRD patterns of PdCl2 (bottom) and its selenization product PdSe2 (top); c2 XRD patterns of PdSe2 and SnSe mixture (bottom) and their reaction products (top). d Schematic diagram of possible roles that Pd played in the selenization process. Left: preventing element volatilization loss through heterogeneous coverings; right: compensating the VSe defect through Se atom exchange between reaction environment, PdSe2 and ACZTSSe film with Se vacancies.

Moreover, during the later stages of selenization, XPS results indicated a disappearance of the +4 valent Pd, with Pd predominantly remaining in the +2-valence state (Fig. 4a). This phenomenon was further validated by XRD and Raman spectra (Supplementary Figs. 25 and 26). The valence state evolution of Pd suggests the occurrence of redox reactions. Firstly, through selenization conducted at different temperatures (as described in Supplementary Note 1), we observed that the oxidation of Pd(II) to Pd(IV), leading to the formation of PdSe2, readily occurred even at relatively low temperatures and under low-Se vapor partial pressure (Fig. 4c1 and Supplementary Fig. 27). Secondly, we discovered that PdSe2 exhibits a high oxidation ability when it is mixed with SnSe at elevated temperatures (Supplementary Note 2). XRD analysis indicated that SnSe would undergo oxidations to form SnSe2, while PdSe2 was reduced to form PdSex compounds, such as PdSe and Pd17Se15 (Fig. 4c2), as described by the reaction:

The occurrence of this redox reaction was substantiated through DFT calculations, which revealed an enthalpy change of −3.3 kJ/mol at x = 1. Furthermore, the notable difference in standard electrode potential (E θ) between Pd(IV)/Pd(II) (E θ > 1 V) and Sn(IV)/Sn(II) (E θ < 0.2 V) provided additional support for this redox reaction51. These findings imply that PdSe2 can assist in maintaining Sn in a +4-valence state by supplying Se atoms and capturing excess electrons. In our view, this redox mechanism is also applicable to the mixing system comprising PdSe2 and ACZTSSe containing low-valence Sn and VSe, as follows:

This scenario is reasonable because the electron and Se transfer in reaction (2) closely resembles that in the confirmed reaction (1), primarily occurring between Pd(IV) and Sn(II). It is evident that the occurrence of reaction (2) will assist in mitigating the VSe defects that have already formed in the GB regions and on the surfaces of ACZTSSe absorbers. For clarity, we have schematically depicted the microscopic mechanism of Pd-assisted defect suppression in the kesterite absorber in Fig. 4d. First, the PdSex compounds formed during the selenization process act as a heterogeneous covering layer of the GBs and the absorber’s surface. This effectively suppresses the Sn and Se element volatilization, preventing the formation of VSn and VSe defects. Second, Pd(II)/Pd(IV) functions as a redox shuttle, capturing vapor Se from the reaction environment to form PdSe2. Subsequently, PdSe2 can provide Se atoms to the ACZTSSe absorber by being reduced to PdSe, thereby aiding in the elimination of VSe defects. Overall, this redox reaction mechanism offers a promising avenue for the precise regulation of defects in kesterite solar cells, and also holds implications for the GB engineering in other photoelectric devices.

Discussion

In this study, we focused on the vacancy defects at GBs in kesterite solar cells and have implemented a redox reaction strategy utilizing palladium (Pd) to suppress these defects. Pd2+ was introduced into the ACZTSSe precursor solution, subsequently undergoing reactions to form PdSex compounds (PdSe and PdSe2). These compounds can heterogeneously cover the GBs and surfaces, thus suppressing the Sn and Se volatilization loss and the formation of VSn and VSe defects. Moreover, Pd(II)/Pd(IV) can perform as a redox shuttle, capturing vaporized Se from the reaction environment and subsequently supplying Se atoms to the ACZTSSe absorber, further diminishing the already-existed VSe defects. These effects have effectively reduced defects and additionally enhanced the p-type nature of the ACZTSSe absorber, thus resulting in significantly suppressed charge non-radiative recombination loss in the ACZTSSe solar cell. Consequently, we have achieved the highest certified efficiency of 14.3% reported to date for kesterite solar cells.

Our study here and previously reported works have widely demonstrated the promising role of cation incorporation in enhancing the performance of kesterite solar cells. However, the introduction of a variety of cations also complexes this material system and causes controversies about the material physical mechanisms through which these cations exert their effects, alloying, doping or others. This demands us to better understand the crystallization growth and defect formation processes in the CZTSSe material. In particular, we need to pay more attention to the effects of these incorporated cations on the initial and intermediate states of the CZTSSe material, rather than just on the semiconducting and defective properties of the final-state material. These efforts will help us more effectively determine the origins for current issues of CZTSSe materials and thus guide us more synergistically exploit the positive role of these cations.

Methods

Materials

CuCl (99.999%, Alfa), Zn(CH3COO)2 (99.99%, Aladdin), PdCl2 (59-60% Pd, Innochem), SnCl4 (99.998%, Macklin), SnCl4 (99.998%, Macklin), AgCl (99.5%, Innochem), thiourea (99.99%, Aladdin, recrystallized twice), 2-methoxyethanol (MOE, 99.8%, Aladdin), Se pellets (99.999%, Zhong Nuo Advanced Material), CdSO4·8/3H2O (99.99%, Aladdin), and ammonia (25.0~28.0%, Sinopharm Chemical Reagent Co. Ltd.) were used. The chemicals were used directly without further purification.

Film preparation

ACZTSSe precursor film preparation: The control ACZTSSe precursor solution was prepared by dissolving 7.311 g thiourea, 2.160 g CuCl, 0.345 g AgCl, 3.126 g Zn(Ac)2 and 3.963 g SnCl4 into 30 ml MOE and stirred at 50 °C to obtain a colorless solution. The Pd incorporated precursor solution was prepared by adding Pd contents of 0.5%, 1%, 2%, 3% (Pd/Zn, molar ratio) into the control ACZTSSe precursor solution. All the above steps are carried out in a N2-filled glove box. The obtained precursor solution was spin-coated on Mo substrate at 3000 rpm for 25 s, followed by annealing on a 280 °C hot plate in the air. This coating-annealing process was repeated several times to give a precursor film with ~1.5 μm-thickness. Then, precursor films were placed in a graphite box containing Se particles and selenized in a rapid heating tube furnace. The detailed selenization condition was as followed: the temperature was first raised to 540 °C within 1 min and maintained for 19 min, then reduced naturally to room temperature.

Device preparation

The ACZTSSe devices were fabricated with a typical structure of Mo/ACZTSSe/CdS/ZnO/ ITO/Ni/Al/MgF2. A 40–50 nm CdS buffer layer was deposited at 70 °C using chemical bath deposition (CBD) method. Specifically, ACZTSSe films were immersed into the aqueous solution (200 ml water) pre-dissolved CdSO4 (~12 mM) and ammonia (~10 ml) in a beaker. Thiourea (~48 mM) was then added into the solution. After the thiourea was completely dissolved, the beaker was immersed into the 70 °C water bath to start the CdS deposition. The CBD was performed for about 10–11 min to get the desired thinckness. These films were then cleaned by water and dried by N2 for the following window layer deposition. Afterwards, a 20–30 nm ZnO layer and a 180 nm ITO layer were deposited by magnetron sputtering technique. A Ni (40 nm)/Al (2 μm) metal grid were deposited by thermal evaporation to complete the whole device. Finally, a MgF2 layer was thermally evaporated as the anti-reflection coating (ARC).

Film characterization

Morphologies of the absorber films were measured on Hitachi S4800 scanning electron microscope (SEM). Element mappings were obtained by energy-dispersive spectrometer (EDS, AZtec X-Max 50). The microstructure and elemental distribution were also measured by a JEOL-F200CF scanning transmission electron microscope (STEM) equipped with an EDS system. Electron energy loss spectroscopy (EELS) was obtained using a beam of an electron microscope. XPS measurement was carried out on an ESCALAB 250Xi (Themo Fisher) instrument. X-ray diffraction (XRD) patterns were collected by using an X-ray diffractometer Cu Ka as the radiation source (Empyrean, PANaltcal). Raman spectra were carried out on Raman spectrometer (Lab-RAM HR Evolution, HORIBA) by using 532 nm laser diode as the excitation source. The compositions of films were determined by an energy-dispersive X-ray fluorescence (XRF) spectrometer (EDX-7000, Shimadzu). Atomic force microscope (AFM) and Kelvin probe force microscope (KPFM) images were obtained on Bruker, Multimode 9. For the KPFM, the CPD was measured as the potential difference between the sample and the probe tip, that is CPD = ϕsample - ϕtip = (Wtip – Wsample)/e, where ϕ is the electric potential, W is the work function and e is the elementary charge. Temperature-dependent steady-state PL and time-resolved PL spectra were obtained on PL spectrometer, FLS 900, Edinburgh Instruments, excited with a picosecond-pulsed diode laser (EPL-445) with the wavelength of 638.2 nm and measured at 730 nm after excitation.

Device characterization

The current density-voltage (J-V) curves of the solar cells were measured by using Keithley 2400 Source Meter under simulated AM 1.5 sunlight at 100 mW cm−2 from a solar simulator (Zolix SS150A) calibrated with Si reference cell (calibrated by National Institute of Metrology, China). The voltage was forward scanned from −50 mV to 600 mV with a scanning rate of 90 mV·s−1. The J-V tests were conducted in air at 25 °C, and no preconditioning of the device was performed before the measurement. In the certification in NPVM, the mask area is 0.2694 cm2. External quantum efficiency (EQE) was measured by Enlitech QE-R test system using calibrated Si and Ge diodes as references. Modulated transient photocurrent and photovoltage (m-TPC/TPV) measurements were obtained by our lab-made setup, in which the cell was excited by a 532 nm pulse laser (Brio, 10 Hz, 4 ns) and the decay process was recorded by a sub-nanosecond resolved digital oscilloscope (Tektronix, DPO 7104). The C-V profiles, driven level capacity profiles (DLCP) and temperature-dependent J-V were measured with an electrochemical workstation (Versa STAT3, Princeton)

DFT calculation

All the calculations were performed within the density functional theory (DFT) as implemented in Vienna ab initio simulation package (VASP) code52,53. The projector augmented-wave (PAW)54 pseudopotentials were employed with an energy cutoff of 479 eV. Since PdSe2, SnSe2 and SnSe are two-dimensional (2D) materials with van der Waals (vdW) interactions, we combined with the exchange-correlation functional of Perdew-Burke-Ernzerhof (PBE)55 and the vdw correction (DFT-D3)56 in the calculation of cohesive energies. To correctly assess the bandgap and defect energy levels, we employed the hybrid exchange-correlation functional of Heyd-Scuseria-Ernzerhof (HSE06)57 in the calculation of defect formation energies. A 6 × 6 × 3 k-mesh58 was used to optimize the conventional cell and only the Γ point was considered for the Brillouin zone integration of 2 × 2 × 2 expanded supercell (128 atoms). The atom coordinates were optimized until the residual forces were less than 0.01 eV/ Å. The obtained bandgap is 0.97 eV, which agree well with previous reported results59,60,61,62. The defect formation energy can be calculated by63 ΔEf (α, q) = E (α, q) – E (host) + Σni•(μi + Ei) + q•(EF + EVBM) + Ecorr, where E (α, q) is the total energy of the supercell with defect α in charge state q and E (host) is the total energy of the pure Cu2ZnSnSe4 supercell. ni represents the number of atoms exchanged with supercell. μi and Ei are elemental chemical potential and the total energy of the pure elemental phase, respectively. EVBM is the valence band maximum (VBM) level in the pure supercell and EF is the Fermi energy referenced to the VBM level. Ecorr includes the correction of formation energy with the scheme proposed by Freysoldt64. For the chemical potentials used in the defect formation calculation, they were selected from the calculated phase diagram of CZTSe, including typical endpoints of the Cu-Zn-Sn 3-dimensional stable phase region and some representative points at different Cu chemical potentials.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The photoelectric characterization and device performance data generated in this study are provided in the Supplementary Information/Source Data file. Source data are provided with this paper.

References

Wang, W. et al. Device characteristics of CZTSSe thin-film solar cells with 12.6% efficiency. Adv. Energy Mater. 4, 1301465 (2014).

Yan, C. et al. Cu2ZnSnS4 solar cells with over 10% power conversion efficiency enabled by heterojunction heat treatment. Nat. Energy 3, 764–772 (2018).

Fonoll-Rubio, R. et al. Insights into interface and bulk defects in a high efficiency kesterite-based device. Energy Environ. Sci. 14, 507–523 (2021).

Wang, J. et al. Ge bidirectional diffusion to simultaneously engineer back interface and bulk defects in the absorber for efficient CZTSSe solar cells. Adv. Mater. 34, e2202858 (2022).

Gong, Y. et al. Elemental de-mixing-induced epitaxial kesterite/CdS interface enabling 13%-efficiency kesterite solar cells. Nat. Energy 7, 966–977 (2022).

Zhou, J. et al. Control of the phase evolution of kesterite by tuning of the selenium partial pressure for solar cells with 13.8% certified efficiency. Nat. Energy 8, 526–535 (2023).

Gong, Y. et al. Identify the origin of the Voc deficit of kesterite solar cells from the two grain growth mechanisms induced by Sn2+ and Sn4+ precursors in DMSO solution. Energy Environ. Sci. 14, 2369–2380 (2021).

Chernomordik, B. D., Béland, A. E., Deng, D. D., Francis, L. F. & Aydil, E. S. Microstructure evolution and crystal growth in Cu2ZnSnS4 thin films formed by annealing colloidal nanocrystal coatings. Chem. Mater. 26, 3191–3201 (2014).

Kim, S. Y. et al. Effect of Cu–Sn–Se liquid phase on grain growth and efficiency of CZTSSe solar cells. Adv. Energy Mater. 10, 1903173 (2020).

Chen, S., Walsh, A., Gong, X. G. & Wei, S. H. Classification of lattice defects in the kesterite Cu2ZnSnS4 and Cu2ZnSnSe4 earth-abundant solar cell absorbers. Adv. Mater. 25, 1522–1539 (2013).

Kumar, M., Dubey, A., Adhikari, N., Venkatesan, S. & Qiao, Q. Strategic review of secondary phases, defects and defect-complexes in kesterite CZTS-Se solar cells. Energy Environ. Sci. 8, 3134–3159 (2015).

Su, Z. et al. Device postannealing enabling over 12% efficient solution-processed Cu2ZnSnS4 solar cells with Cd2+ substitution. Adv. Mater. 32, 2000121 (2020).

Li, J. et al. Defect control for 12.5% efficiency Cu2ZnSnSe4 kesterite thin-film solar cells by engineering of local chemical environment. Adv. Mater. 32, 2005268 (2020).

Gong, Y. et al. Ag incorporation with controlled grain growth enables 12.5% efficient kesterite solar cell with open circuit voltage reached 64.2% Shockley–Queisser limit. Adv. Funct. Mater. 31, 2101927 (2021).

He, M. et al. Systematic efficiency improvement for Cu2ZnSn(S,Se)4 solar cells by double cation incorporation with Cd and Ge. Adv.Funct. Mater. 31, 2104528 (2021).

Zhao, Y. et al. Controllable double gradient bandgap strategy enables high efficiency solution‐processed kesterite solar cells. Adv. Funct. Mater. 34, 2311992 (2023).

Li, J. et al. Unveiling microscopic carrier loss mechanisms in 12% efficient Cu2ZnSnSe4 solar cells. Nat. Energy 7, 754–764 (2022).

Wang, K. et al. Structural and elemental characterization of high efficiency Cu2ZnSnS4 solar cells. Appl. Phys. Lett. 98, 051912 (2011).

Li, J., Mitzi, D. B. & Shenoy, V. B. Structure and electronic properties of grain boundaries in earth-abundant photovoltaic absorber Cu2ZnSnSe4. ACS Nano 5, 8613–8619 (2011).

Yin, W. et al. Engineering grain boundaries in Cu2ZnSnSe4 for better cell performance: a first-principle study. Adv. Energy Mater. 4, 1300712 (2014).

Tanaka, T. et al. Existence and removal of Cu2Se second phase in coevaporated Cu2ZnSnSe4 thin films. J. Appl. Phys. 111, 053522 (2012).

Xie, H. et al. Impact of Sn(S,Se) secondary phases in Cu2ZnSn(S,Se)4 solar cells: a chemical route for their selective removal and absorber surface passivation. ACS Appl. Mater. Interfaces 6, 12744–12751 (2014).

Becerril-Romero, I. et al. CZTSe solar cells developed on polymer substrates: effects of low-temperature processing. Prog. Photovolt: Res. Appl. 26, 55–68 (2018).

Redinger, A., Berg, D. M., Dale, P. J. & Siebentritt, S. The consequences of kesterite equilibria for efficient solar cells. J. Am. Chem. Soc. 133, 3320–3323 (2011).

Scragg, J. J., Ericson, T., Kubart, T., Edoff, M. & Platzer-Björkman, C. Chemical insights into the instability of Cu2ZnSnS4 films during annealing. Chem. Mater. 23, 4625–4633 (2011).

Liu, C. et al. Sodium passivation of the grain boundaries in CuInSe2 and Cu2ZnSnS4 for high-efficiency solar cells. Adv. Energy Mater. 7, 1601457 (2017).

Dong, L. et al. Passivation of grain boundaries and defects in CZTSSe solar cells by in situ Na doping. Solar RRL 7, 2300061 (2023).

Schubert, B.-A. et al. Cu2ZnSnS4 thin film solar cells by fast coevaporation. Prog. Photovolt: Res. Appl. 19, 93–96 (2011).

Larramona, G. et al. Fine-tuning the Sn content in CZTSSe thin films to achieve 10.8% solar cell efficiency from spray-deposited water-ethanol-based colloidal inks. Adv. Energy Mater. 5, 1501404 (2015).

Ren, G. et al. Influences of Cu concentration on electrical properties of CZTSSe absorbers and their device performances. Vacuum 173, 109121 (2020).

Karade, V. et al. Achieving low VOC-deficit characteristics in Cu2ZnSn(S,Se)4 solar cells through improved carrier separation. ACS Appl. Mater. Interfaces 13, 429–437 (2021).

Li, J. B., Chawla, V. & Clemens, B. M. Investigating the role of grain boundaries in CZTS and CZTSSe thin film solar cells with scanning probe microscopy. Adv. Mater. 24, 720–723 (2012).

Muhunthan, N., Singh, O. P., Toutam, V. & Singh, V. N. Electrical characterization of grain boundaries of CZTS thin films using conductive atomic force microscopy techniques. Mater. Res. Bull. 70, 373–378 (2015).

Vishwakarma, M. et al. A direct measurement of higher photovoltage at grain boundaries in CdS/ CZTSe solar cells using KPFM technique. Sol. Energy Mater. Sol. Cells 183, 34–40 (2018).

Kim, S., Park, J.-S. & Walsh, A. Identification of killer defects in kesterite thin-film solar cells. ACS Energy Lett 3, 496–500 (2018).

Shi, J. et al. Multinary alloying suppresses defect formation in emerging inorganic solar cells. https://arxiv.org/pdf/2306.14629 (2023).

Morgan, W. E. & Van Wazer, J. R. Binding energy shifts in the x-ray photoelectron spectra of a series of related Group IV-a compounds. J. Phys. Chem. C 77, 964–969 (2002).

Stranick, M. A. & Moskwa, A. Sn02 by XPS. Surf. Sci. Spectra 2, 50–54 (1993).

Won-Kook Choi, Jung, H.-J. & Koh, S.-K. Chemical shifts and optical properties of tin oxide films grown by a reactive ion assisted deposition. J. Vac. Sci. Technol. A 14, 359–366 (1996).

Yu, Z. et al. Unveiling the selenization reaction mechanisms in ambient air‐processed highly efficient kesterite solar cells. Adv. Energy Mater. 13, 2300521 (2023).

Xin, H. et al. Lithium-doping inverts the nanoscale electric field at the grain boundaries in Cu2ZnSn(S,Se)4 and increases photovoltaic efficiency. Phys. Chem. Chem. Phys. 17, 23859–23866 (2015).

Zhao, X. et al. Lithium-assisted synergistic engineering of charge transport both in GBs and GI for Ag-substituted Cu2ZnSn(S,Se)4 solar cells. J. Energy Chem. 50, 9–15 (2020).

Rey, G. et al. The band gap of Cu2ZnSnSe4: effect of order-disorder. Appl. Phys. Lett. 105, 112106 (2014).

Scragg, J. J. S., Choubrac, L., Lafond, A., Ericson, T. & Platzer-Björkman, C. A low-temperature order-disorder transition in Cu2ZnSnS4 thin films. Appl. Phys. Lett. 104, 041911 (2014).

Bourdais, S. et al. Is the Cu/Zn disorder the main culprit for the voltage deficit in kesterite solar cells? Adv. Energy Mater. 6, 1502276 (2016).

Shi, J., Li, D., Luo, Y., Wu, H. & Meng, Q. Opto-electro-modulated transient photovoltage and photocurrent system for investigation of charge transport and recombination in solar cells. Rev. Sci. Instrum. 87, 123107 (2016).

Li, Y. et al. Exploiting electrical transients to quantify charge loss in solar cells. Joule 4, 472–489 (2020).

Giraldo, S. et al. Cu2ZnSnSe4 solar cells with 10.6% efficiency through innovative absorber engineering with Ge superficial nanolayer. Prog. Photovolt: Res. Appl. 24, 1359–1367 (2016).

Heath, J. T., Cohen, J. D. & Shafarman, W. N. Bulk and metastable defects in CuIn1−xGaxSe2 thin films using drive-level capacitance profiling. J. Appl. Phys. 95, 1000–1010 (2004).

Lou, L. et al. Crown ether-assisted colloidal ZnO window layer engineering for efficient kesterite (Ag,Cu)2ZnSn(S,Se)4 solar cells. ACS Energy Lett. 8, 3775–3783 (2023).

Bratsch, S. G. Standard electrode potentials and temperature coefficients in water at 298.15 k. J. Phys. Chern. Ref. Data 18, 1–21 (1989).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169 (1996).

Kresse, G. & Hafner, J. Ab initiomolecular dynamics for liquid metals. Phys. Rev. B 47, 558–561 (1993).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Heyd, J., Scuseria, G. E. & Ernzerhof, M. Hybrid functionals based on a screened Coulomb potential. J. Chem. Phys. 118, 8207–8215 (2003).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Persson, C. Electronic and optical properties of Cu2ZnSnS4 and Cu2ZnSnSe4. J. Appl. Phys. 107, 053710 (2010).

Luckert, F. et al. Optical properties of high quality Cu2ZnSnSe4 thin films. Appl. Phys. Lett. 99, 062104 (2011).

Chen, S., Gong, X. G., Walsh, A. & Wei, S.-H. Crystal and electronic band structure of Cu2ZnSnX4 (X=S and Se) photovoltaic absorbers: first-principles insights. Appl. Phys. Lett. 94, 041903 (2009).

Botti, S., Kammerlander, D. & Marques, M. A. L. Band structures of Cu2ZnSnS4 and Cu2ZnSnSe4 from many-body methods. Appl. Phys. Lett. 98, 241915 (2011).

Freysoldt, C. et al. First-principles calculations for point defects in solids. Rev. Mod. Phys. 86, 253–305 (2014).

Freysoldt, C., Neugebauer, J. & Van de Walle, C. G. Fully ab initio finite-size corrections for charged-defect supercell calculations. Phys. Rev. Lett. 102, 016402 (2009).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant nos. U2002216 (Q.M.), 52222212 (J.S.), 52172261 (Y.L.), 52227803 (Q.M.), 51972332 (H.W.), 12174060 (S.C.) and 12334005 (S.C.)). J.S. also gratefully acknowledges the support from the Youth Innovation Promotion Association of the Chinese Academy of Sciences (2022006).

Author information

Authors and Affiliations

Contributions

Jinlin Wang, Jiangjian Shi, Dongmei Li, and Qingbo Meng conceived the idea and designed the experiments. Jinlin Wang and Jiangjian Shi did the experiments and the data analysis. Licheng Lou, Jiazheng Zhou, and Xiao Xu supported CZTSSe solar cell fabrication. Fanqi Meng and Kang Yin performed STEM and DLCP measurements. Huijue Wu and Yanhong Luo supported M-TPC/TPV characterization and discussions. Jinlin Wang, Jiangjian Shi, Dongmei Li, and Qingbo Meng participated in writing the manuscript. Shanshan Wang and Shiyou Chen provided DFT results and valuable discussion of the work.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Sascha Sadewasser and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, J., Shi, J., Yin, K. et al. Pd(II)/Pd(IV) redox shuttle to suppress vacancy defects at grain boundaries for efficient kesterite solar cells. Nat Commun 15, 4344 (2024). https://doi.org/10.1038/s41467-024-48850-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-48850-9

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.