Abstract

A long-standing trade-off exists between improving crystallinity and minimizing particle size in the synthesis of perovskite-type transition-metal oxynitride photocatalysts via the thermal nitridation of commonly used metal oxide and carbonate precursors. Here, we overcome this limitation to fabricate ATaO2N (A = Sr, Ca, Ba) single nanocrystals with particle sizes of several tens of nanometers, excellent crystallinity and tunable long-wavelength response via thermal nitridation of mixtures of tantalum disulfide, metal hydroxides (A(OH)2), and molten-salt fluxes (e.g., SrCl2) as precursors. The SrTaO2N nanocrystals modified with a tailored Ir–Pt alloy@Cr2O3 cocatalyst evolved H2 around two orders of magnitude more efficiently than the previously reported SrTaO2N photocatalysts, with a record solar-to-hydrogen energy conversion efficiency of 0.15% for SrTaO2N in Z-scheme water splitting. Our findings enable the synthesis of perovskite-type transition-metal oxynitride nanocrystals by thermal nitridation and pave the way for manufacturing advanced long-wavelength-responsive particulate photocatalysts for efficient solar energy conversion.

Similar content being viewed by others

Introduction

Perovskite-type oxynitrides of early transition metals and alkaline-earth or rare-earth elements, in optimal cases, can combine the advantages of oxides and nitrides, exhibiting greater stability in air and moisture than pure nitrides and narrower bandgaps than comparable oxides1,2. In recent decades, this superiority has made these perovskite-type compounds an important class of functional materials used in nontoxic pigments3, colossal magnetoresistors4, high-permittivity dielectrics5, and long-wavelength-responsive photocatalysts6. In response to an urgent worldwide need to reduce carbon emissions to mitigate global warming, perovskite oxynitride semiconductor-based particulate photocatalysts have attracted particular attention because they potentially enable the direct synthesis of sustainable fuels and chemical products using sunlight as the sole energy source6,7,8,9. The tantalum oxynitride perovskites, ATaO2N (A = Ca, Sr, Ba), are rare semiconducting materials with excellent stability in aqueous solutions, narrow bandgaps (1.9‒2.4 eV), and conduction and valence bands appropriately positioned to straddle the water redox potential6,10. As such, they are regarded as among the most promising photocatalyst materials for overall water splitting (OWS), which can be used in particulate-photocatalyst-sheet-based panel systems for large-scale solar H2 production6,11.

Nitridation of oxide (with carbonate) precursors in flowing ammonia (NH3) at high temperatures is the most widely applied method for the synthesis of perovskite oxynitrides2. Such oxynitrides, including ATaO2N (A = Sr, Ca, Ba) produced by thermal nitridation of polymetallic oxides, are generally polycrystalline and incorporate structural defects that act as recombination and trapping centers for photogenerated charge carriers12,13. This disadvantage can be overcome by using a mixture of polymetallic oxides (or metal oxides and carbonates) together with a molten-salt flux (e.g., NaCl, KCl, or RbCl) as the nitridation precursor14,15,16,17. The best-in-class ATaO2N semiconductors are prepared by this approach and are characterized by well-crystallized single crystals and improved photocatalytic activity15,16,17. However, the sizes of the resultant particles are uncontrollable and inevitably large (several hundred nanometers at minimum)15,16,17, leading to long distances for the photoexcited charge carriers to migrate to reach active sites on the surface. This problem points to a long-standing trade-off between improving crystallinity and minimizing particle size in the synthesis of metal oxynitride perovskites via the flux-assisted thermal nitridation process. Overcoming this limitation would represent a critical advancement in long-wavelength-responsive perovskite oxynitride-based photocatalyst manufacturing yet remains a grand challenge.

Here, we show that using a mixture of tantalum(IV) sulfide (TaS2), metal hydroxide (A(OH)2, A = Ca, Sr, Ba), and a molten salt (e.g., SrCl2) as the nitridation precursor enables the fabrication of highly crystalline ATaO2N (A = Ca, Sr, Ba) single nanocrystals with sub-50 nm particle sizes and a tunable long-wavelength response. Each precursor material was found to be critical to the formation of single nanocrystals that simultaneously exhibit a high degree of crystallinity and a small particle size of a few tens of nanometers. This approach leads to high photocatalytic efficiency of the resultant SrTaO2N nanocrystals toward sacrificial H2 and O2 evolution and Z-scheme water splitting. In particular, Ir–Pt alloy@Cr2O3-modified SrTaO2N nanocrystals evolved H2 approximately two orders of magnitude more efficiently than the previously reported SrTaO2N photocatalysts and were used, for the first time, as a H2-evolution photocatalyst (HEP) for Z-scheme water splitting, providing a solar-to-hydrogen (STH) energy conversion efficiency of 0.15%.

Results and discussion

Synthesis and characterization of ATaO2N (A = Sr, Ca, Ba) nanocrystals

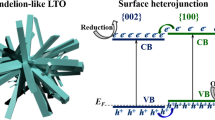

Nitridation of a powder containing TaS2 (Supplementary Fig. 1), Sr(OH)2, and SrCl2 in a molar ratio of 1:2.5:1 under a flow of gaseous NH3 at 1223 K for 3 h yielded an orange powder (see details in Methods). The X-ray diffraction (XRD) pattern for the obtained powder indicated a single phase associated with perovskite-type SrTaO2N (Fig. 1a). The product also exhibited a light-absorption edge at approximately 600 nm, characteristic of SrTaO2N (Fig. 1b), and an average particle size of approximately 50 nm (Fig. 1c, d). Lattices fringes with the same orientation (Supplementary Fig. 2a) and a well-defined spot-like selected-area electron diffraction (SAED) pattern (Supplementary Fig. 2b) for a single particle, together with highly ordered lattice fringes at the outermost surface (Supplementary Fig. 3), were observed when a cross-sectional specimen of this material was examined by high-resolution transmission electron microscopy (HRTEM). On the basis of an elemental analysis, the chemical formula for the material was estimated to be Sr1.00Ta1.01O2.07N1.03 (Supplementary Table 1); the sulfur content (0.004 wt%) was below the detection limit (0.01 wt%). In keeping with this result, elemental mapping of a cross-sectional SrTaO2N sample using annular dark-field scanning transmission electron microscopy coupled with energy dispersive X-ray spectroscopy (ADF STEM–EDS) (Fig. 1e–i) indicated that Sr, Ta, O, and N were evenly distributed within single particles, whereas negligible sulfur was detected (Supplementary Fig. 4). Notably, the SrTaO2N nanocrystals exhibited extremely weak background absorption at longer wavelengths (>600 nm) (Fig. 1b), suggesting a low defect density18,19. These results indicate the formation of highly crystalline SrTaO2N single nanocrystals.

XRD pattern (a), UV–vis diffuse-reflectance spectrum (b), Scanning electron microscopy image (c), and particle size distribution (d) of the synthesized SrTaO2N. ADF–STEM image (e) and STEM–EDS elemental mapping images of Sr (f), Ta (g), O (h), and N (i) of a cross-sectional SrTaO2N sample. j UV–vis diffuse-reflectance spectra of the synthesized CaTaO2N and BaTaO2N. SEM image (k) and particle size distribution (l) of CaTaO2N. SEM image (m) and particle size distribution (n) of BaTaO2N. The mean value and standard deviation (SD) of the particle sizes in (d, l, n) were determined by Gaussian fitting (red lines). The insets in (b, j) show photographs of the respective materials.

We found that each precursor component was critical to the formation of single nanocrystals of SrTaO2N with high crystallinity, and that the optimized TaS2/Sr(OH)2/SrCl2 molar ratio in the precursor was 1/2.5/1 (see details in Supplementary Figs. 5–7). A several-micron-sized 2H-TaS2 phase (Supplementary Fig. 1) has not been previously used for synthesizing perovskite-type oxynitrides; it was found to play an irreplaceable role in the developed approach. Nitridation of the Ta2O5/Sr(OH)2/SrCl2 (molar ratio: 0.5/2.5/1) mixture, where TaS2 was replaced with Ta2O5 (the most widely used Ta source for synthesizing oxynitrides2,14,15), did not produce SrTaO2N when reacted under the same conditions but generated predominantly Sr6Ta2O10.188 (Supplementary Fig. 5). Replacement of Sr(OH)2 with SrCO3 resulted in SrTaO2N nanoparticles but with relatively larger sizes (Supplementary Fig. 8). The molten-salt-assisted fragmentation of TaS2 under the nitridation conditions is presumably a key reason for the formation of SrTaO2N nanocrystals (see detailed discussion below Supplementary Fig. 9). The SrCl2 used as a molten-salt flux could be replaced with another congeneric flux. For instance, the use of NaCl, KCl, or RbCl instead of SrCl2 led to SrTaO2N nanocrystals with an average particle size of approximately 20 nm (Supplementary Figs. 10 and 11). However, the crystallinity of the resultant SrTaO2N samples was lower, as indicated by the large increase in the full-width at half-maximum (FWHM) of their characteristic XRD peaks, associated with a decrease in the melting point of the molten-salt flux (see explanation below Supplementary Fig. 10).

We readily extended the proposed approach to the synthesis of CaTaO2N and BaTaO2N nanocrystals by simply replacing Sr(OH)2 in the precursor with Ca(OH)2 and Ba(OH)2, respectively (Supplementary Fig. 12). The obtained yellow-colored CaTaO2N and crimson-colored BaTaO2N (Fig. 1j) exhibited average particle sizes of ~65 (Fig. 1k, l) and 50 nm (Fig. 1m, n), respectively. The light-absorption edges for the prepared CaTaO2N and BaTaO2N were located at 519 and 630 nm (Fig. 1j), respectively, whereas the typical values are 500 nm for CaTaO2N and 650 nm for BaTaO2N6. This difference is attributable to the slight substitution of Ca2+ and Ba2+ in the oxynitrides by Sr2+ as a result of the use of the molten-SrCl2 flux. Accordingly, the XRD peak positions for the CaTaO2N and BaTaO2N samples were shifted to lower and higher angles, respectively (Supplementary Fig. 12). These results demonstrate that nitridation of mixtures of TaS2, metal hydroxides, and molten-salt fluxes can be a universal and flexible approach for fabricating perovskite-type tantalum oxynitride nanocrystals with tunable light-absorption edge wavelengths.

H2-evolution and Z-scheme water-splitting performance of the SrTaO2N-nanocrystal photocatalyst

As a demonstration, the H2-evolution activity of SrTaO2N nanocrystals was evaluated after the nanocrystals were sequentially modified with Ir and Pt by microwave heating in water and ethylene glycol (EG), respectively, and finally with Cr2O3 by photodeposition (see details in Methods). The obtained photocatalyst (denoted as Cr2O3/Pt (MWEG)/Ir (MWH2O)/SrTaO2N nanocrystals) was found to evolve H2 efficiently from an aqueous methanol solution (solid circles in Fig. 2a) in which the feeding concentrations of Ir, Pt, and Cr (relative to the mass of SrTaO2N) were optimized to be 0.5, 1.0, and 0.5 wt%, respectively (Supplementary Fig. 13). The H2-evolution rate for the Cr2O3/Pt (MWEG)/Ir (MWH2O)/SrTaO2N nanocrystals was approximately five times higher than that for the SrTaO2N modified with the same cocatalysts but synthesized by nitridation of a typical Ta2O5/SrCO3/SrCl2 precursor and exhibiting an average particle size of 200 nm (open squares in Fig. 2a; see characterization results in Supplementary Fig. 14). Moreover, the single-nanocrystal SrTaO2N evolved H2 four times higher than the polycrystalline SrTaO2N exhibiting aggregates composed of several polycrystalline nanoparticles with an average size of 63 nm (see detailed discussion in Supplementary Fig. 15) and 2.4 times higher than the SrTaO2N previously developed from a Ta2O5/NaOH/SrCl2 precursor17 (Supplementary Fig. 16). These results demonstrate the importance of both a small particle size and a high degree of crystallinity to the photocatalytic performance and the superiority of the developed approach in producing highly crystalline single nanocrystals of ATaO2N (A = Sr, Ca, Ba). The onset irradiation wavelength for H2 generation agreed with the absorption edge for this SrTaO2N photocatalyst (Fig. 2b), indicating that the photoreaction proceeded via bandgap transitions. The associated apparent quantum yield (AQY) for H2 evolution was calculated to be 3.0% at 422 nm, 2.6% at 479 nm, and 0.5% at 580 nm (Fig. 2b). Notably, the previously reported SrTaO2N photocatalysts evolve H2 inefficiently with a rate well below 5 µmol h−1, and the associated AQY is too low to be detected (Supplementary Table 2). An estimation based on the evolution rates for H2 indicates that the developed Cr2O3/Pt (MWEG)/Ir (MWH2O)/SrTaO2N nanocrystal photocatalyst evolves H2 approximately two orders of magnitude more efficiently than the previously reported SrTaO2N photocatalysts (Supplementary Table 2).

a Time courses of the photocatalytic H2-evolution reaction in aqueous methanol (13 vol%) solution over the Cr2O3/Pt (MWEG)/Ir (MWH2O)-modified SrTaO2N nanocrystals (solid circles) and over the Cr2O3/Pt (MWEG)/Ir (MWH2O)-modified large-sized SrTaO2N crystals (Supplementary Fig. 13) prepared from the Ta2O5/SrCO3/SrCl2 precursor (open squares). Error bars indicate the standard deviation of three measurements. b AQY as a function of the incident-light wavelength during visible-light-driven H2 production over Cr2O3/Pt (MWEG)/Ir (MWH2O)-modified SrTaO2N nanocrystals. The solid line indicates the UV–vis diffuse-reflectance spectrum of SrTaO2N. The above reactions were carried out under illumination from a Xe lamp (300 W, λ ≥ 420 nm) with or without various bandpass filters. c Time courses of gas evolution during photocatalytic Z-scheme OWS under simulated sunlight using Cr2O3/Pt (MWEG)/Ir (MWH2O)-modified SrTaO2N nanocrystals (solid circles) or large-sized SrTaO2N (precursor: Ta2O5/SrCO3/SrCl2, Supplementary Fig. 13) (open squares) as the HEP, Ir-CoFeOx/BiVO4 as the OEP, and [Fe(CN)6]3−/[Fe(CN)6]4− as a redox mediator. Conditions: HEP, 50 mg; Ir-CoFeOx/BiVO4, 100 mg; 150 mL of 25 mM phosphate buffer solution (pH = 6) containing K4[Fe(CN)6] (5 mM); light source, solar simulator (AM 1.5 G, 0.87 sun); irradiation area for solar simulator, 9.3 cm2; background pressure, 5 kPa.

When the H2-evolving Cr2O3/Pt (MWEG)/Ir (MWH2O)/SrTaO2N nanocrystals were combined with the reported Ir and FeCoOx nanocomposite co-modified BiVO4 (Ir-FeCoOx/BiVO4)20 (see characterization results in Supplementary Fig. 17) as the O2-evolution photocatalyst (OEP) and [Fe(CN)6]3−/[Fe(CN)6]4− as a redox mediator, both H2 and O2 were stably evolved under simulated sunlight at a near-stoichiometric molar ratio of 2:1 for 33 h with negligible deactivation (Fig. 2c). Upon modification with the same Cr2O3/Pt (MWEG)/Ir (MWH2O) cocatalyst, the SrTaO2N nanocrystals (solid circles in Fig. 2c) exhibited notably higher photocatalytic activity in Z-scheme water splitting than the large-sized SrTaO2N prepared from the typical Ta2O5/SrCO3/SrCl2 precursor (open squares in Fig. 2c). The STH energy conversion efficiency for this redox-mediated Z-scheme system was 0.15%, and the AQY was measured to be 4.0% at approximately 420 nm (Supplementary Fig. 18). These STH and AQY values are still lower than those for Z-scheme systems constructed with RhyCr2−yO3-loaded ZrO2-modified TaON (AQY of 12.3% at 420 nm and STH efficiency of 0.6%)20 or Ru-modified SrTiO3:La,Rh (AQY of 33% at 419 nm and STH of 1.1%)21 as HEPs. Nevertheless, this AQY is comparable to that for the Z-scheme system constructed with Pt/BaTaO2N as the HEP15, both representing the most efficient bias-free Z-scheme water-splitting systems involving 600-nm-class photocatalysts. More importantly, our proposed Z-scheme system is, to the best of our knowledge, the first involving SrTaO2N as the HEP because previous SrTaO2N photocatalysts evolved H2 inefficiently (Supplementary Table 2). Further improvements are expected by refining the operating parameters and exploring long-wavelength-responsive OEPs and more effective redox mediators or solid conductive mediators.

Nanostructure and promotion effects of Cr2O3/Pt (MWEG)/Ir (MWH2O) cocatalyst

The substantial improvement in the H2-evolution and Z-scheme water-splitting activity of the SrTaO2N nanocrystals also relied on the multicomponent Cr2O3/Pt (MWEG)/Ir (MWH2O) cocatalyst that can accelerate the surface H2-evolution reactions much more efficiently than Pt, a representative H2-evolution cocatalyst (Fig. 3a). Specifically, the addition of Ir and Cr2O3 increased the H2-evolution rate approximately twofold (photocatalyst vi versus v in Fig. 3a) and sixfold (photocatalyst iii versus v in Fig. 3a), respectively, compared with the case when either of them were absent. Because individual Ir- or Cr2O3-modified SrTaO2N exhibited negligible activities toward H2 evolution (Supplementary Fig. 19), the promotion effect of both components most likely resulted from their interactions with Pt that promote charge separation and transfer and/or promote surface reactions. This result motivated us, above all, to investigate the nanostructure of the Cr2O3/Pt (MWEG)/Ir (MWH2O) cocatalyst and, in particular, the interactions between different cocatalyst components.

a Photocatalytic H2-evolution rate (calculated in the first one hour) for bare and different cocatalyst-modified SrTaO2N nanocrystals: i, bare SrTaO2N; ii, Pt (MWEG)/SrTaO2N; iii, Pt (MWEG)/Ir (MWH2O)/SrTaO2N; iv, Cr2O3/Pt (MWEG)/SrTaO2N; v, Cr2O3/Pt (MWEG)/Ir (MWH2O)/SrTaO2N. Error bars indicate the standard deviation of three measurements. ADF STEM image (b), and Pt (c) and Ir (d) EDS mapping images of a cross-sectional Pt (MWEG)/Ir (MWH2O)/SrTaO2N sample. e Pt and Ir EDS line-scan spectra across the nanoparticle marked with a yellow arrow in (b). ADF STEM image (f), and Pt (g), Ir (h), and Cr (i) EDS mapping images of a cross-sectional Cr2O3/Pt (MWEG)/Ir (MWH2O)/SrTaO2N sample. j HRTEM image of the surface of a Cr2O3/Pt (MWEG)/Ir (MWH2O)-modified SrTaO2N nanocrystal. k TA kinetic profiles of photoexcited electrons probed at 2000 nm over bare and different cocatalyst-modified SrTaO2N nanocrystals in subfigure (a).

Decoration with Ir (MWH2O) formed highly dispersed IrO2 species according to X-ray photoelectron spectroscopy (XPS) (Supplementary Fig. 20a) and ADF STEM (Supplementary Fig. 21a) analyses. Further decoration with Pt (MWEG) via a microwave heating process with EG as a reducing agent generated noticeable tiny nanoparticles on the surface of the SrTaO2N (Supplementary Fig. 21b). This step not only produced metallic Pt (Supplementary Fig. 22a) but also reduced approximately one-half of the previous IrO2 decoration species to metallic Ir (Supplementary Fig. 20c). This result is consistent with the observation that, when Ir (MWH2O)/SrTaO2N was subjected to a similar EG-mediated microwave treatment (denoted as Ir (MWH2O-MWEG)/SrTaO2N), approximately 43% of the IrO2 species was reduced to metallic Ir (Supplementary Fig. 20b). Interestingly, the XPS 4 f peak position for Ir0 in Pt (MWEG)/Ir (MWH2O)/SrTaO2N (Supplementary Fig. 20c) was negatively shifted by approximately 0.8 eV compared with that for Ir0 in the Ir (MWH2O-MWEG)/SrTaO2N specimen (Supplementary Fig. 20b). Meanwhile, the XPS 4 f peak position for Pt0 in Pt (MWEG)/Ir (MWH2O)/SrTaO2N (Supplementary Fig. 22b) was positively shifted by approximately 0.6 eV compared with that for Pt0 in the Pt (MWEG)/SrTaO2N specimen (Supplementary Fig. 22a). These shifts clearly point to strong electronic interactions between Ir0 and Pt0 species in Pt (MWEG)/Ir (MWH2O)/SrTaO2N, which indicates the formation of metal alloys17,22,23. STEM–EDS mapping and line-scan images (Fig. 3b–e) further indicate that the fed Ir and Pt species in Pt(MWEG)/Ir (MWH2O)/SrTaO2N dominantly form Ir–Pt alloy nanoparticles because both the Ir and Pt elements were confined across the area of individual nanoparticles. Cr2O3 was lastly photodeposited, forming Ir–Pt alloy@Cr2O3 core–shell nanostructured particles in Cr2O3/Pt (MWEG)/Ir (MWH2O)/SrTaO2N, as is evident in the STEM–EDS elemental maps (Fig. 3f–i) and HRTEM image (Fig. 3j). Notably, on the basis of the identification of both Cr2O3 and Cr(OH)3 species by XPS (Supplementary Fig. 23) and previous studies6,24, the Cr2O3 shell was composed of amorphous Cr(III)O1.5−m(OH)2m·xH2O and the Cr2O3 decoration did not alter the chemical state of Ir (Supplementary Fig. 20d) or Pt (Supplementary Fig. 22c).

The transient absorption (TA) kinetic profiles probed at 2000 nm (Fig. 3k) reflect the intraband transition of long-lived electrons in oxynitride materials15,25. The observed decrease in the TA signal intensity upon decoration with a cocatalyst indicates electron transfer from the SrTaO2N to the cocatalyst for the water reduction reaction. The slight decrease (from line i to ii in Fig. 3k) in the TA signal intensity upon decoration with Pt (MWEG) indicates that electrons were not effectively injected into the Pt. Decoration with Pt (MWEG)/Ir (MWH2O) resulted in a more substantial decrease (from line i to iii in Fig. 3k) in the TA signal intensity. This result confirms that the Ir–Pt alloy acts as a more efficient electron collector and H2-evolution catalyst than Pt alone, consistent with the higher H2-evolution rate for Pt(MWEG)/Ir (MWH2O)/SrTaO2N compared with that for Pt(MWEG)/SrTaO2N (Fig. 3a). The most notable decrease in the TA signal intensity was observed when Pt or Ir–Pt alloy was capped with a Cr2O3 overlayer (from line ii to iv and from iii to v in Fig. 3k). This result provides direct evidence that Cr2O3 greatly promotes electron transfer, consistent with our recent finding that a Cr2O3 coating on Rh nanoparticles on a fluorine-doped tin oxide (FTO) substrate substantially enhanced the current density26. The enhancement was most likely attributable to the Cr2O3 overlayer inhibiting hole transfer from the vicinity of the Pt or Ir–Pt alloy nanoparticles and thereby greatly reducing charge recombination at the metal nanoparticles or the SrTaO2N–metal interfaces. Moreover, the Cr2O3 shell is known to function as a molecular sieve to allow the permeation of H+, H2, and H2O species while preventing the oxidized species generated by holes from reaching the metal core and being reduced back24,26,27. Therefore, the deposition of Cr2O3 improved the H2-evolution rate approximately sixfold (Fig. 3a) and notably improved the photocatalytic durability by suppressing unfavorable side reactions (Supplementary Fig. 24).

O2-evolution performance of CoOx-modified SrTaO2N nanocrystals

Upon modification with a classic cobalt oxide (CoOx) cocatalyst (Supplementary Fig. 25) with an optimized feed concentration of 1.0 wt% (relative to the mass of SrTaO2N; Supplementary Fig. 26), the SrTaO2N nanocrystals also exhibited high photocatalytic O2-evolution performance from an aqueous AgNO3 solution (Fig. 4a). The associated AQYs were estimated to be 9.0%, 6.6%, and 0.2% at 422, 479, and 580 nm, respectively (Fig. 4b). These values are higher than most of those reported for SrTaO2N-based OEPs with CoOx as the cocatalyst (Supplementary Table 2). This result demonstrates again the importance of the developed approach to afford high-quality SrTaO2N single nanocrystals. Consistent with the findings of previous studies16, CoOx is critical for achieving efficient O2 evolution (Fig. 4c) because it can efficiently capture holes for the water oxidation reaction. Interestingly, the TA signal intensity probed at 5000 nm (Fig. 4d), which reflects the dynamics of free and/or shallowly trapped electrons28, was enhanced by approximately one order of magnitude following decoration by CoOx. This suggests that one-step-excitation OWS over this material will be a viable process in the near future if these populous long-lived electrons resulting from the CoOx modification can be further extracted and used for H2 evolution via appropriate surface modification and/or cocatalyst design.

Time course (a) of photocatalytic O2-evolution reaction in 20 mM AgNO3 solution over a CoOx-modified SrTaO2N photocatalyst under visible-light irradiation and the associated AQY at various wavelengths (b). The above reactions were carried out under illumination from a Xe lamp (300 W, λ ≥ 420 nm) with or without various bandpass filters. The solid line in (b) indicates the UV–vis diffuse-reflectance spectrum of SrTaO2N. Photocatalytic O2-evolution rates calculated at 0.5 h (c) and TA kinetic profiles of photoexcited electrons probed at 5000 nm (d) over pristine and NH3-treated SrTaO2N without CoOx and over CoOx/SrTaO2N. Error bars in (a, c) indicate the standard deviation of three measurements.

This work demonstrates that highly crystalline single nanocrystals of perovskite-type tantalum oxynitrides can be easily synthesized by thermal nitridation of mixtures of TaS2, metal hydroxides, and molten salts. Upon modification with a tailored Ir–Pt alloy@Cr2O3 cocatalyst, the SrTaO2N nanocrystals produced by this approach evolved H2 around two orders of magnitude more efficiently than the previously reported SrTaO2N photocatalysts, with an apparent quantum yield of 3% at the wavelength of 420 nm, from a methanol aqueous solution, and an STH energy conversion efficiency of 0.15% in Z-scheme water splitting. The CoOx-modified SrTaO2N nanocrystals also evolved oxygen efficiently, surpassing most of the reported SrTaO2N photocatalysts. We envision that appropriate surface and cocatalyst modifications would enable efficient one-step-excitation OWS over these ATaO2N (A = Sr, Ca, Ba) nanocrystals in the near future. The proposed synthetic strategy is expected to be applicable to a broad range of perovskite-type transition-metal oxynitride single nanocrystals, and can advance the manufacturing of long-wavelength-responsive particulate photocatalysts for efficient solar energy conversion.

Methods

Synthesis of nanocrystalline ATaO2N (A = Sr, Ca, Ba)

ATaO2N (A = Sr, Ca, Ba) nanocrystals were synthesized by heating of a mixture of TaS2, A(OH)2, and SrCl2 with a molar ratio of 1:2.5:1 under gaseous NH3 flow. In a typical synthesis of SrTaO2N nanocrystals, 1.20 g of TaS2 (99%; Kojundo Chemical Laboratory, Supplementary Fig. 1), 3.25 g of Sr(OH)2·8H2O (90.0+%; FUJIFILM Wako Pure Chemical), 0.78 g of SrCl2 (98.0%; Kanto Chemical), and 5 mL of ethanol were well mixed in an agate mortar with the aid of sonication and agitation. After desiccation by a mild heating process, the resultant powder was loaded into an alumina crucible and heated at 1223 K for 3 h under a 200 mL min−1 flow of gaseous NH3. SrTaO2N nanocrystals were obtained after the resultant solids were rinsed and then dried overnight at 313 K under vacuum. CaTaO2N and BaTaO2N nanocrystals were synthesized by a similar procedure in which Ca(OH)2 (99.9%; FUJIFILM Wako Pure Chemical) and Ba(OH)2·8H2O (98.0%; FUJIFILM Wako Pure Chemical) were used, respectively, instead of Sr(OH)2·8H2O.

Cocatalyst modification for SrTaO2N

For H2-evolution reactions, SrTaO2N was decorated with Ir and Pt sequentially by microwave heating in water and EG, respectively, and finally with Cr2O3 by photodeposition via a modified version of a recently reported method29. The resultant material is denoted herein as Cr2O3/Pt (MWEG)/Ir (MWH2O)/SrTaO2N. In a typical process, SrTaO2N nanoparticles were first dispersed in distilled water (15 mL) containing the desired amount of IrCl3·3H2O (99.9%; Kanto Chemical) and the suspension was subsequently heated at 423 K for 10 min using a microwave reactor (Anton Paar, Monowave 200) while the suspension was stirred at 1000 rpm. After the sample cooled naturally, it was washed, filtered, and then dried at 313 K under vacuum to obtain Ir (MWH2O)/SrTaO2N. This sample was further subjected to similar microwave heating in a mixture of 13 mL of EG and 2 mL of distilled water containing the required amount of H2PtCl6·6H2O (>98.5%; Kanto Chemical) under the same conditions, resulting in Pt (MWEG)/Ir (MWH2O)/SrTaO2N. After washing and filtration, the wet Pt (MWEG)/Ir (MWH2O)/SrTaO2N was dispersed in an aqueous methanol solution (13 vol%) containing the required amount of K2CrO4 (99.0%; Kanto Chemical). After complete degassing, the suspension was irradiated with visible light (λ ≥ 420 nm) for 0.5 h; Cr2O3/Pt (MWEG)/Ir (MWH2O)-modified SrTaO2N was obtained.

For O2-evolution reactions, SrTaO2N was modified with the CoOx cocatalyst by impregnation, followed by heating under a gaseous NH3 flow. A quantity of the SrTaO2N powder was immersed in an aqueous solution containing the required amount of Co(NO3)2·6H2O ( > 98.0%; Kanto Chemical) as a Co precursor, and the resultant slurry was continuously stirred with intense sonication for 2 min to disperse the SrTaO2N. After the slurry was dried on a hot-water bath, the powder sample was heated at 1173 K for 1 h under a 200 mL min−1 flow of gaseous NH3 to obtain the CoOx/SrTaO2N nanoparticulate photocatalyst.

Preparation of Ir-CoFeOx/BiVO4

Ir-CoFeOx/BiVO4 was prepared according to the method reported elsewhere20. NH4VO3 (10 mmol; 99.0%; FUJIFILM Wako Pure Chemical) and Bi(NO3)3·5H2O (10 mmol; 99.5%; FUJIFILM Wako Pure Chemical) were dissolved in 2.0 M nitric acid solution, whose pH was then adjusted to ~0.5 by addition of an NH3 solution (25–28 wt%). The mixed solution was strongly stirred until a light-yellow precipitate was observed; the precipitate was further aged for ~2 h and then transferred to a Teflon-lined stainless-steel autoclave for a 24 h hydrothermal treatment at 473 K. BiVO4 was obtained after the collected powder was washed with distilled water and dried in vacuum at 313 K for 6 h. The BiVO4 was further suspended in 150 mL of 25 mM phosphate buffer solution (pH = 6) containing a calculated amount of Na2IrCl6 (0.8 wt% Ir, relative to the mass of BiVO4), Co(NO3)2 (0.2 wt% Co, relative to the mass of BiVO4), and K3[Fe(CN)6] (0.1 mM). After irradiation with UV–vis light for 2 h under static air conditions, Ir-CoFeOx/BiVO4 was collected, washed, and dried for further use.

Characterization of materials

The crystal phases were characterized by XRD analysis using a Rigaku MiniFlex 300 powder diffractometer equipped with a Cu Kα radiation source (λ = 1.5418 Å). Diffuse-reflectance spectra were acquired with an ultraviolet–visible–near-infrared spectrometer (V-670, JASCO) and converted from reflectance into the Kubelka–Munk function. The contents of Sr and Ta metals in the SrTaO2N were determined by inductively coupled plasma atomic emission spectroscopy (ICP-AES; ICPS-8100, Shimadzu). The oxygen, and nitrogen contents of the SrTaO2N were determined with an oxygen–nitrogen analyzer (Horiba, EMGA-920); while the sulfur content was determined with a carbon-sulfur analyzer (Horiba, EMIA-Pro). XPS analysis was carried out using a PHI Quantera II spectrometer equipped with an Al Kα radiation source. All binding energies were referenced to the C 1 s peak (284.8 eV) arising from adventitious carbon. Scanning electron microscopy (SEM) and TEM images were acquired with a Hitachi HD-2300A scanning transmission electron microscope using the SEM and TEM modes, respectively. STEM images, EDS mapping images and SAED patterns were recorded using a JEOL JEM-ARM200F Cold FE (Cs-STEM), a JEOL JEM-ARM200F Thermal FE (Cs-STEM) and a JEOL JEM-2800 equipped with an Oxford Instruments X-MAX 100TLE SDD detector, respectively. The cross-sectional sample for STEM observation was made by Ar ion milling using a JEOL EM-09100IS ion slicer.

Mid-infrared (IR) time-resolved TA spectroscopic investigations were performed using a pump–probe nanosecond system equipped with a Nd:YAG laser (Continuum, Surelite I; duration: 6 ns) and custom-built spectrometers17,28,30. Photoexcited charge carriers were monitored in the mid-IR region, with probe energies from 6000 to 1200 cm−1 (from 1667 to 8333 nm), providing dynamics of photogenerated electrons in the photocatalysts17,28,30. The IR probe light from a MoSi2 coil was focused on the photoexcited sample, and the transmitted IR beam was then passed through the monochromatic grating spectrometer. The transmitted light was subsequently detected by a mercury-cadmium-telluride detector (Kolmar). To excite the photocarriers in SrTaO2N with and without cocatalysts, 440 nm laser pulses with a fluence of 500 μJ pulse−1 generated from an optical parametric oscillator were used. The output electrical signal was amplified using an alternating-current coupled amplifier (Stanford Research Systems (SR560), bandwidth: 1 MHz). The time resolution of the spectrometer was limited to 1 μs by the bandwidth of the amplifier. For data acquisition, 1000 TA signals were accumulated to generate a decay profile at the probe wavelength. For preparation of the sample film, a suitable amount of bare or cocatalyst-loaded SrTaO2N was dispersed on water and then drop-cast onto a CaF2 substrate to obtain a film with a density of 1.09 mg cm−2; the film was then dried in air overnight. TA spectroscopic measurements were carried out under N2 ambient (20 Torr) and at room temperature.

Photocatalytic reactions of H2 and O2 evolution and Z-scheme OWS

All photocatalytic reactions were carried out at 288 K under a background pressure of 5 kPa in a Pyrex top-illuminated reaction vessel connected to a closed gas circulation system. For the photocatalytic H2-evolution reaction, 150 mg of photocatalyst was well dispersed in 150 mL of an aqueous methanol solution (13 vol%) without adjustment of the pH. After air was completely removed from the reaction slurry by evacuation, Ar gas was introduced to generate a background pressure of approximately 5 kPa and the reactant solution was irradiated with a 300 W Xe lamp equipped with a cold mirror and a cut-off filter (L42, λ ≥ 420 nm). For the photocatalytic O2-evolution reaction, 150 mg of photocatalyst together with 100 mg of La2O3 as a pH buffer was well dispersed in 150 mL of an aqueous 20 mM AgNO3 solution. After air was completely removed from the reaction vessel, the photocatalyst suspension was irradiated with a 300 W Xe lamp equipped with a cold mirror and a cut-off filter (L42, λ ≥ 420 nm). For the photocatalytic Z-scheme OWS reaction, Cr2O3/Pt (MWEG)/Ir (MWH2O)-modified SrTaO2N (50 mg) as the HEP and Ir-FeCoOx-modified BiVO4 (100 mg) as the OEP were dispersed in 150 mL of 25 mM sodium phosphate buffer solution (pH = 6.0) containing K4[Fe(CN)6] (5 mM). After air was completely removed from the reaction slurry by evacuation, Ar gas was introduced to generate a background pressure of approximately 5 kPa and the suspension was irradiated by a solar simulator (SAN-EI Electronic, XES40S1, AM 1.5 G, 87 mW cm−2). The top window of the reaction vessel was covered with a mask to confine the irradiated sample area to 9.3 cm2. The gaseous products evolved during these reactions were analyzed using an integrated online gas chromatography system consisting of a GC-8A chromatograph (Shimadzu) equipped with molecular sieve 5 Å columns and a thermal conductivity detector, with Ar as the carrier gas.

AQY measurements

The AQY for the photocatalytic reactions was calculated according to the equation

where R and I are the rate of gas evolution and the incident photon flux, respectively, and A is the number of electrons needed to generate one molecule of H2 or O2 (i.e., two or four for photocatalytic sacrificial H2 or O2 evolution, respectively, and four for H2 evolution in Z-scheme water splitting based on two-step photoexcitation). The photocatalytic reactions were carried out using the same experimental setup and conditions described above, except for the use of bandpass filters with central wavelengths of 422, 460, 479, 517, 540, 557, 580, and 620 nm. The FWHM of the 422 nm bandpass filter was 21 nm, whereas that of the other bandpass filters was 13 nm. The number of incident photons was measured using an LS-100 grating spectroradiometer (EKO Instruments).

STH energy conversion efficiency measurements

The water-splitting reaction was performed under simulated solar radiation generated with a solar simulator (SAN-EI Electronic, XES40S1, AM 1.5 G). The STH conversion efficiency was calculated as

where RH2, ΔG, P, and S denote the rate of H2 evolution during the OWS reaction, the Gibbs energy for the OWS reaction (237 kJ mol−1 at 288 K), the energy intensity (87 mW cm−2) of the AM 1.5 G solar radiation used (equivalent to 0.87 sun), and the irradiated sample area (9.32 cm2), respectively.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information files. Source data are provided with this paper.

References

Yang, M. et al. Anion order in perovskite oxynitrides. Nat. Chem. 3, 47–52 (2011).

Fuertes, A. Chemistry and applications of oxynitride perovskites. J. Mater. Chem. 22, 3293–3299 (2012).

Jansen, M. & Letschert, H. P. Inorganic yellow-red pigments without toxic metals. Nature 404, 980–982 (2000).

Yang, M., Oró-Solé, J., Kusmartseva, A., Fuertes, A. & Attfield, J. P. Electronic tuning of two metals and colossal magnetoresistances in EuWO1+xN2−x perovskites. J. Am. Chem. Soc. 132, 4822–4829 (2010).

Kim, Y.-I. et al. Epitaxial thin-film deposition and dielectric properties of the perovskite oxynitride BaTaO2N. Chem. Mater. 19, 618–623 (2007).

Xiao, J., Hisatomi, T. & Domen, K. Narrow-band-gap particulate photocatalysts for one-step-excitation overall water splitting. Acc. Chem. Res. 56, 878–888 (2023).

Tao, X., Zhao, Y., Wang, S., Li, C. & Li, R. Recent advances and perspectives for solar-driven water splitting using particulate photocatalysts. Chem. Soc. Rev. 51, 3561–3608 (2022).

Oshima, T. et al. Undoped layered perovskite oxynitride Li2LaTa2O6N for photocatalytic CO2 reduction with visible light. Angew. Chem. Int. Ed. 130, 8286–8290 (2018).

Bao, Y., Li, C., Domen, K. & Zhang, F. Strategies and methods of modulating nitrogen-incorporated oxide photocatalysts for promoted water splitting. Acc. Mater. Res. 3, 449–460 (2022).

Balaz, S., Porter, S. H., Woodward, P. M. & Brillson, L. J. Electronic structure of tantalum oxynitride perovskite photocatalysts. Chem. Mater. 25, 3337–3343 (2013).

Segev, G. et al. The 2022 solar fuels roadmap. Journal of Physics D: Applied Physics 55, 323003 (2022).

Higashi, M., Abe, R., Takata, T. & Domen, K. Photocatalytic overall water splitting under visible light using ATaO2N (A = Ca, Sr, Ba) and WO3 in a IO3−/I− shuttle redox mediated system. Chem. Mater. 21, 1543–1549 (2009).

Wang, Y., Wei, S. & Xu, X. SrTaO2N-CaTaO2N solid solutions as efficient visible light active photocatalysts for water oxidation and reduction. Appl. Catal. B: Environ. 263, 118315 (2020).

Luo, Y. et al. Fabrication of single-crystalline BaTaO2N from chloride fluxes for photocatalytic H2 evolution under visible light. Cryst. Growth Des. 20, 255–261 (2020).

Wang, Z. et al. Sequential cocatalyst decoration on BaTaO2N towards highly-active Z-scheme water splitting. Nat. Commun. 12, 1005 (2021).

Jadhav, S. et al. Efficient photocatalytic oxygen evolution using BaTaO2N obtained from nitridation of perovskite-type oxide. J. Mater. Chem. A 8, 1127–1130 (2020).

Chen, K. et al. Overall water splitting by a SrTaO2N-based photocatalyst decorated with an Ir-promoted Ru-based cocatalyst. J. Am. Chem. Soc. 145, 3839–3843 (2023).

Xiao, J. et al. Enhanced overall water splitting by a zirconium-doped TaON-based photocatalyst. Angew. Chem. Int. Ed. 61, e202116573 (2022).

Wang, Z. et al. Overall water splitting by Ta3N5 nanorod single crystals grown on the edges of KTaO3 particles. Nat. Catal. 1, 756–763 (2018).

Qi, Y. et al. Unraveling of cocatalysts photodeposited selectively on facets of BiVO4 to boost solar water splitting. Nat. Commun. 13, 484 (2022).

Wang, Q. et al. Scalable water splitting on particulate photocatalyst sheets with a solar-to-hydrogen energy conversion efficiency exceeding 1%. Nat. Mater. 15, 611–615 (2016).

Wakisaka, M. et al. Electronic structures of Pt-Co and Pt-Ru alloys for CO-tolerant anode catalysts in polymer electrolyte fuel cells studied by EC-XPS. J. Phys. Chem. B 110, 23489–23496 (2006).

Luo, L. et al. Hydrogen-assisted scalable preparation of ultrathin Pt shells onto surfactant-free and uniform Pd nanoparticles for highly efficient oxygen reduction reaction in practical fuel cells. Nano Res. 15, 1892–1900 (2022).

Yoshida, M. et al. Role and function of noble-metal/Cr-layer core/shell structure cocatalysts for photocatalytic overall water splitting studied by model electrodes. J. Phys. Chem. C 113, 10151–10157 (2009).

Li, H. et al. One-step excitation overall water splitting over a modified Mg-doped BaTaO2N photocatalyst. ACS Catal. 12, 10179–10185 (2022).

Higashi, T. et al. Mechanistic insights into enhanced hydrogen evolution of CrOx/Rh nanoparticles for photocatalytic water splitting. Chem. A Eur. J. 29, e202204058 (2023).

Qureshi, M., Shinagawa, T., Tsiapis, N. & Takanabe, K. Exclusive hydrogen generation by electrocatalysts coated with an amorphous chromium-based layer achieving efficient overall water splitting. ACS Sustainable Chem. Eng. 5, 8079–8088 (2017).

Xiao, J. et al. Simultaneously tuning the defects and surface properties of Ta3N5 nanoparticles by Mg-Zr codoping for significantly accelerated photocatalytic H2 evolution. J. Am. Chem. Soc. 143, 10059–10064 (2021).

Yoshida, H. et al. An oxysulfide photocatalyst evolving hydrogen with an apparent quantum efficiency of 30% under visible light. Angew. Chem. Int. Ed. e202312938 (2023).

Vequizo, J. J. M. et al. Trapping-induced enhancement of photocatalytic activity on brookite TiO2 powders: comparison with anatase and rutile TiO2 powders. ACS Catal. 7, 2644–2651 (2017).

Acknowledgements

This work was financially supported by the Artificial Photosynthesis Project of the New Energy and Industrial Technology Development Organization (NEDO), and the Advanced Research Infrastructure for Materials and Nanotechnology (ARIM) of the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan (grant nos. JPMXP1222UT0023 and JPMXP1223UT0004). J.X. thanks Ms. Michiko Obata (Shinshu University) and Ms. Keiko Kato (University of Tokyo) for their assistance in performing XPS and elemental analyses, respectively. W. L. thanks 2021 MEXT Scholarship with Embassy Recommendation and China Scholarship Council Scholarship (grant no. 202008440289) for the financial support of his doctoral study in Japan.

Author information

Authors and Affiliations

Contributions

J.X. and K.D. conceived and designed the research. J.X. prepared the photocatalyst materials, performed conventional material characterization and photocatalytic performance evaluation. M.N. and N.S. carried out STEM–EDS-related measurements and analyzed the resulting data. J.J.M.V. and A.Y. conducted the TAS experiments and analyzed the resulting data. W.L., K.C., and X.T. helped with the preparation of BiVO4 and establishment of the Z-scheme OWS system. J.X., T.H., M.N., J.J.M.V., T.T., Y.I., and K.D. discussed the results. K.D. supervised the entire research work. J.X., T.H., and K.D. wrote and revised the paper with contributions from the other authors.

Corresponding author

Ethics declarations

Competing interests

J.X., T.H. and K.D. of Shinshu University and Y.I. of Japan Technological Research Association of Artificial Photosynthetic Chemical Process hold a patent related to this work (Japanese Unexamined Patent Application Publication No. 2023-031163). The remaining authors declare no competing interests.

Peer review

Peer review information

: Nature Communications thanks Gang Liu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xiao, J., Nakabayashi, M., Hisatomi, T. et al. Sub-50 nm perovskite-type tantalum-based oxynitride single crystals with enhanced photoactivity for water splitting. Nat Commun 14, 8030 (2023). https://doi.org/10.1038/s41467-023-43838-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-023-43838-3

This article is cited by

-

Synergistically regulating d-band centers of heterojunction redox sites by ligand effect for photocatalytic H2 evolution

Science China Materials (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.