Abstract

Developing eco-friendly chiral organocatalysts with the combined advantages of homogeneous catalysis and heterogeneous processes is greatly desired. In this work, a family of amphiphilic one-handed helical polyisocyanides bearing phosphine pendants is prepared, which self-assembles into well-defined chiral micelles in water and showed thermo-responsiveness with a cloud point of approximately 38.4 °C. The micelles with abundant phosphine moieties at the interior efficiently catalyze asymmetric cross Rauhut-Currier reaction in water. Various water-insoluble substrates are transferred to target products in high yield with excellent enantioselectivity. The yield and enantiomeric excess (ee) of the product generated in water are up to 90% and 96%, respectively. Meanwhile, the yields of the same R-C reaction catalyzed by the polymer itself in organic solvents is <16%, with an ee < 72%. The homogeneous reaction of the chiral micelles in water turns to heterogeneous at temperatures higher than the cloud point, and the catalyst precipitation facilitates product isolation and catalyst recovery. The polymer catalyst is recycled 10 times while maintaining activity and enantioselectivity.

Similar content being viewed by others

Introduction

One of the important goals in catalysis is the development of eco-friendly catalysts with the combined advantages of homogeneous catalysis and heterogeneous processes, which not only maintain or even improve the catalytic activity and selectivity of homogeneous catalysts but also facilitate product isolation and catalyst recycling1,2,3,4. Homogeneous catalysts are widely used in fine-chemical synthesis because typical solid-supported heterogeneous catalysts do not provide the nonpolar environments often required for organic reactions. Soluble polymers are less routinely used catalyst supports that could provide a solvent-like environment for organic reactions5,6,7,8,9. Therefore, polymer skeletons to support catalysts that can increase both catalytic activity and selectivity are greatly desired, especially for chiral catalysts utilized in asymmetric reactions10,11.

Homochirality is one of the most remarkable features of biological molecules12. Biopolymers can express their homochirality by twisting into one-handed helices (e.g., the α-helix of proteins and the double helix of DNA)13,14. Enzyme-catalyzed stereospecific reactions are believed to arise from the homochirality of macromolecular helix15,16. Inspired by such helices of biomacromolecules, artificial helical polymers have attracted great research attention because of not only their unique structures but also their broad applications, such as chiral recognition and resolution, circularly polarized luminescence, and so forth17,18,19,20,21,22,23,24,25,26,27,28,29,30. Helical polymers are good skeletons to support chiral organocatalysts because helical backbones can provide additional chiral microenvironments, and improve the stereoselectivity of an asymmetric reaction31,32. Helicity itself could induce the high enantioselectivity of some asymmetric reactions33,34. Reversing helicity can switch enantioselectivity, thus allowing the obtaining of enantiomeric products35,36. Moreover, the high molecular weight of helical polymers can simplify product isolation and facilitate catalyst recycling, which are particularly desirable for expensive and hardly available chiral catalysts10,37,38,39. In this respect, polyisocyanide is one of the most attractive helical polymers because of its unique rigid rod-like backbone, high stability, and good self-assembly tendency17,18,19,20,21,25. Therefore, it is a good skeleton for fabricating chiral catalysts for asymmetric reactions.

Water is the cheapest and the most environmentally friendly solvent. As organic compounds are generally nonpolar and water-insoluble, organic reactions in water are commonly restricted40. However, enzymes perform catalytic reactions in aqueous systems with high efficiency and excellent selectivity41,42. On the basis of the understanding of enzyme catalysis, polymer-based chiral catalysts have been explored43,44,45,46. In contrast, the knowledge about organocatalytic chiral micelles for asymmetric reactions in water with high enantioselectivity and efficiency is still in its infancy. During the past decades, asymmetric organocatalysis has gained great attention because of its advantages, including inexpensive and easily available catalysts, no metal residues, and mild reaction conditions47,48,49. The Rauhut–Currier (R–C) reaction of two active olefins is a unique and efficient approach for constructing carbon-carbon bonds and densely functionalized organic building blocks50,51,52,53,54. Phosphine-catalyzed intermolecular cross R–C reaction is particularly intriguing among various organocatalyzed reactions52. Moreover, because of the poor solubility of reactants and limited catalysts, efficient cross R–C reaction in water with high enantioselectivity has not been realized to date.

We herein describe the construction of chiral organocatalytic micelles using amphiphilic helical polyisocyanide copolymers, composed of hydrophobic helical polyisocyanide bearing phosphine pendants and hydrophilic polyisocyanide carrying methyl triglycol chains. In water, the polymers self-assembled into well-defined chiral micelles with the hydrophobic phosphine pendants at the interior. The micelles catalyzed the asymmetric cross R–C reaction of various water-insoluble substrates in water and yielded the desired products in high yields with excellent enantioselectivity. The enantiomeric excess (ee) and yield of the product were up to 96% and 90%, respectively. Moreover, the block copolymers had excellent thermo-responsiveness in water with a cloud point of 38.4 °C. The precipitation of polymers at temperatures higher than the cloud point facilitated product isolation and catalyst recycling. The polymer catalyst was recycled 10 times with maintained activity and enantioselectivity.

Results

Polymer synthesis and characterization

The block copolymers were prepared following Fig. 1a. Chiral isocyanides (1r and 1 s) bearing boron hydride-protected phosphine were polymerized by an alkyne-Pd(II) catalyst and gave the desired polymers in high yield with predicted molar mass (Mn) and low dispersity (Mw/Mn)17. For example, the Mn and Mw/Mn of poly-1s50 (the footnote indicates the initial monomer-to-catalyst feed ratio, as below) were 23.1 kDa and 1.22, respectively, as determined by size exclusion chromatography (SEC) (Fig. 1b). Because polymerization follows a living polymerization mechanism, poly-1s50 bearing an active Pd(II)-complex on the chain end was chain extended with achiral isocyanide (2) bearing methyl triglycol chains17. The Mn of the resulting poly(1s50-b-2100) copolymer was 84.2 kDa, and it maintained a low dispersity with Mw/Mn = 1.25 (Fig. 1b). The afforded block copolymer was successively treated with triethylphosphine and trifluoroacetic acid to remove the boron hydride that protected the phosphine pendants and the Pd(II)-terminal. Then, poly(1sm-b-2n) copolymers with different compositions and various block ratios were prepared using the living nature of polymerization (Fig. 1b and Supplementary Table 1). Similarly, poly(1rm-b-2n) copolymers using enantiomeric 1r instead of 1s were also prepared (Supplementary Table 1). Apart from SEC, these polymers were characterized by 1H and 31P NMR and FT-IR (Supplementary Figs. 1–9). Because the polymerizations proceeded in a well-controlled living polymerization mechanism, the degree of polymerization was consistent with the initial monomer-to-catalyst feed ratio, according to the detailed studies we reported previously11,17,55,56.

The helicity of the prepared polymers was studied using circular dichroism (CD) spectroscopy in tetrahydrofuran (THF) at 25 °C. Because of the asymmetric induction of the chiral monomer, poly-1s50 showed an intense negative CD in the absorption region of the polyisocyanide backbone, suggesting that the backbone was twisted into a left-handed helix (Fig. 1c)55,56. After chain extension, the resulting poly(1s50-b-2n) showed a negative CD similar to that of the poly-1s50 macroinitiator, whereas the recorded molecular CD intensity was decreased (Fig. 1c). Detailed analyses revealed that the molecular CD intensity of the poly-1sm segment was maintained during block copolymerization (Supplementary Fig. 10). The CD decrease was ascribed to 2 being achiral, and the resulting poly-2n segment could not maintain one-handed helicity; thus, the entire molecularly optical activity was decreased. This study confirmed that the poly-1sm segment bearing catalytic phosphine pendants of the block copolymers adopted left-handed helicity. The helicity was quite stable, and no obvious change could be detected in various solvents at temperatures from 5 to 60 °C (Supplementary Fig. 11). As anticipated, the poly-1rm segment of poly(1rm-b-2n) copolymers adopted right-handed helicity, as revealed by CD and adsorption spectroscopy techniques (Fig. 1c and Supplementary Fig. 12)55,56.

Because of their amphiphilic character, the block copolymers could be dissolved in various organic solvents and in water. Interestingly, the transparent aqueous solution of poly(1s50-b-2100) turned turbid upon heating and became transparent again after cooling to room temperature, suggesting the turbidimetry-responsiveness with temperature (Fig. 2a). Detailed UV‒vis absorption studies revealed that the cloud point was 38.4 °C for poly(1s50-b-2100), determined from the temperature corresponding to 50% transmittance of the antisigmoidal transmittance–temperature curve during the heating process57. The cloud point decreased with the elongation of poly-2n block of the copolymers, it was 46.7, 38.4, and 30.0 °C for poly(1s50-b-250), poly(1s50-b-2100), and poly(1s50-b-2150), respectively (Fig. 2a).

a Plots of the transmittance of poly(1s50-b-2100) in water versus temperature (the solid and dashed lines represent the heating and cooling process, respectively. Insets: photographs of poly(1s50-b-2100) in H2O at 25 and 55 °C, 1.0 mg/mL). b DLS traces for poly(1s50-b-2100) in the mixture of H2O and THF with different volume ratios (0.2 mg/mL). The polydispersities for the DLS analyses are 0.387 (H2O), 0.235 (H2O/THF = 75/25), 0.341 (H2O/THF = 50/50), 0.312 (H2O/THF = 25/75), and 0.222 (THF), respectively. c AFM and d TEM images of poly(1s50-b-2100) casted from the aqueous solution at room temperature.

The self-assembly property of the block copolymers was investigated by adding water to their THF solutions. Dynamic light scattering (DLS) analyses indicated that poly(1s50-b-2100) had a hydrodynamic diameter of ca. 8 nm in THF, suggestive of molecular dissolution (Fig. 2b). After adding water, the diameters were 506 and 280 nm for the water contents of 50% and 75%, respectively, suggesting that the amphiphilic block copolymer was self-assembled into micelles with hydrophilic poly-2100 at the exterior and hydrophobic poly-1s50 at the interior. In pure water, the diameter further decreased to 85 nm, indicating that poly(1s50-b-2100) was self-assembled into a more compact micelle (Fig. 2b). The critical aggregation concentration (CAC) in water was as low as 0.040 mg/mL, suggesting that this polymer had good self-assembly property (Supplementary Fig. 13). The morphology of the micelles was confirmed by atomic force microscopy (AFM) and transmission electron microscopy (TEM). As displayed in Fig. 2c, the AFM phase image of poly(1s50-b-2100) cast from the aqueous solution showed spherical nanoparticles in good homogeneity with a diameter of 75 nm. Meanwhile, TEM images further supported that the block copolymer was self-assembled into core-shell-like micelles with a diameter of 72 nm (Fig. 2d). The relatively large size of the micelles was ascribed to the formation of hollowed spherical micelles because of the distinct rigid and rod-like backbone of polyisocyanides58,59. The hollowed micelles might facilitate substrate exchange during the following asymmetric R–C reaction. The cryo-TEM image of poly(1s50-b-2100) in water also supported the formation of spherical micelles with a diameter of ca. 90 nm (Supplementary Fig. 14). Other block copolymers showed similar self-assembly properties in water, as revealed by the DLS analyses (Supplementary Fig. 15). Accordingly, poly(1r50-b-2100), possessing opposite handed helicity, showed a similar self-assembly behavior (Supplementary Fig. 16).

Asymmetric cross R–C reactions

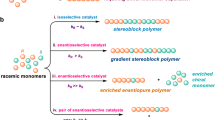

The catalytic activity of poly(1sm-b-2n) micelles for intermolecular cross R-C reactions was explored using ethyl (E)-4-oxo-4-phenylbut-2-enoate (3a) and but-3-en-2-one (4a) as model substrates. Initially, the reaction was conducted at room temperature with 10 mol% catalyst loading of the phosphine pendants of poly(1s50-b-2100) in various organic solvents for 48 h. Then, homogeneous reactions occurred and gave the target product R-5aa. However, the reaction efficiency was quite low, and the yields of R-5aa were only approximately 16% (runs 1–5, Table 1). The homogeneous cross-R–C reaction in THF and CHCl3 could give the target product R-5aa, but the yield and ee values were not satisfactory (runs 1 and 5, Table 1). The ee of R-5aa was generally <72%, as determined by high-performance liquid chromatography (HPLC) using a chiral column (see the Supplementary Information for more details). Then, we conducted the reaction in a mixture of THF and water with different volume ratios. We found that both the reaction rate and enantioselectivity were improved with the addition of water to THF (Fig. 3a and Supplementary Fig. 17). For example, the yields of R-5aa were 20%, 43%, and 61% with the addition of 25%, 50%, and 75% water to the THF solution, respectively (runs 6–8, Table 1). In pure water, the isolated yield of R-5aa was higher than 84%. The enantioselectivity of the reactions showed the same tendency. As plotted in Fig. 3b, the ee values of the generated R-5aa were 75%, 80%, and 84% for the reactions conducted in mixtures of THF and water with 25%, 50%, and 75% water content at room temperature, respectively. As expected, the reaction in water catalyzed by poly(1s50-b-2100) showed the best enantioselectivity, the ee of the target was as high as 90%. The polymer catalysts carried chiral carbon centers on the pendants and possessed a chiral helical backbone. Thus, to obtain details on enantioselectivity, asymmetric R–C reaction of 3a with 4a catalyzed by the poly-1s50 homopolymer, 1r and 1s monomers were conducted under identical conditions (runs 19–23, Table 1). The reactions in water gave 5aa in 51% yield with 69% ee using poly-1s50 as the catalyst, whereas it gave 5aa in 57% yield with 48% ee using 1s as the catalyst. The homogeneous reactions in CHCl3 gave the desired 5aa in 82% yield and 76% ee using poly-1s50; and 78% yield and 57% ee using 1s. The 1r showed behaviors similar to those of 1s but with opposite enantioselectivity (run 21, Table 1). The relatively higher yield and ee values obtained by poly-1s50 than those of 1s confirmed the synergistic effect of the helical backbone and the chiral pendants. In addition, an increase in Mn of poly-1sn could further improve the enantioselectivity of 5aa until the degree of the polymerization of poly-1sn reached 50 (Supplementary Fig. 18a). These results indicated the Mn-dependent helicity of the poly-1sn backbone and further supported that the enhanced enantioselectivity came from the helical chirality of the polymer catalyst56. Considering the local concentration of substrates within the micelle might influence the catalysis, experiments at different substrate concentrations were performed. The best results were obtained using 0.1 mmol of 3a with 0.3 mmol of 4a in water (5 mL) (Supplementary Fig. 18b). A further increase in concentration caused precipitation, whereas the dilution of the substrates gave the product in lower yield. Note that <5% volume of THF was used in case the substrates could not be dissolved in water.

a Plot of conversion of 3a versus reaction time catalyzed by poly(1s50-b-2100) in different H2O/THF ratios. Error bars of measured conversion versus reaction time. b The yield and ee of R-5aa generated in different ratios of H2O/THF using poly(1s50-b-2100) as catalyst. c Photographs of the poly(1s50-b-2100) catalyst recycling. d The results for recycling poly(1s50-b-2100) in the reaction of 3a and 4a.

The results inspired us to investigate the effect of catalyst composition on reactions. The cross R–C reaction catalyzed by poly(1s50-b-250), poly(1s50-b-2100), and poly(1s50-b-2150) was performed in water under the same conditions. Therein, poly(1s50-b-2100) showed the best results in terms of the yield and ee of the target product (runs 9–11, Table 1). Thus, this polymer was applied in the following studies. Because poly(1s50-b-2100) had good solubility in water, the reaction of 3a and 4a was performed in water at 0 °C. As summarized in Table 1, the reaction gave the expected R-5aa in 81% yield and 96% ee. Because the CAC of the block copolymer was quite low, the loading of the block polymer catalyst was further decreased to 2 mol% of phosphine pendants; however, both the reaction rate and enantioselectivity decreased considerably (run 12, Table 1). According to these studies, the optimized conditions were carrying the R–C reaction in water at 0 °C with 4 mol% loading of the catalyst (based on the phosphine). Given these results, the intermolecular cross R–C reaction was conducted using the poly(1r50-b-2100) catalyst possessing the opposite, right-handed helical backbone under the same conditions described above. Gratifyingly, the reaction of 3a with 4a delivered the desired enantiomeric product S-5aa in 82% yield and 95% ee. These results suggest that the enantioselectivity of the R–C reaction could be reversed by tuning the helicity of the polymer backbone.

The aforementioned results encouraged us to explore the substrate scope of the R–C reaction. Thus, 2-ene-1,4-diones and vinyl ketones with different substituents were prepared and applied in an asymmetric cross-R–C reaction using the poly(1s50-b-2100) catalyst. As shown in Table 2, the catalyst was applicable to a wide range of 3-aroyl acrylates (3b–3h) with different aryl substituents. The targeted products with high yields and excellent enantioselectivities were attained regardless of the electron-donating or electron-withdrawing substituents (runs 1–7, Table 2). Notably, when the ethyl ester group of 3a was replaced by the less hindered methyl ester (3i) or the more hindered isopropyl ester (3j) and benzyl ester (3k), the desired products (5ia–5ka) were also obtained with good yield (82–85%) and excellent enantioselectivity (95–96% ee) (runs 8–10, Table 2). Encouraged by these results, the helical polymer-based catalyst was applied to the cross-R–C reaction using aryl-substituted vinyl ketones (4b−4d). Gratifyingly, these ketones could also react with various 3-aroyl acrylates (3g and 3h) catalyzed by poly(1s50-b-2100) in water and gave the expected products in good yields (69–72%) with high ee (90–93%) (runs 11–15, Table 2). Furthermore, the substrate scope exploration suggested that poly(1s50-b-2100) was also an efficient catalyst for substrates containing heteroaryl groups and aliphatic chains. For example, the reaction of 3l, 3m, and 3n with 4a gave the expected products 5la, 5ma, and 5na in good yield and high enantioselectivity (runs 16–18, Table 2). Collectively, these studies revealed that the helical polymer is an excellent chiral catalyst for cross-R–C reactions and is applicable to a wide range of substrates.

The amphiphilic poly(1s50-b-2100) copolymer had a higher Mn than those of the reactants and products of the R–C reaction and exhibited excellent thermo-responsiveness in water. These characterizations facilitated not only product isolation but also polymer recovery and recycling. Thus, when the R–C reaction of 3a and 4a catalyzed by poly(1s50-b-2100) in water was accomplished, the aqueous solution was heated to 55 °C, higher than the cloud point of poly(1s50-b-2100). The transparent solution immediately turned turbid because of polymer precipitation (Fig. 3c). The precipitated solid was filtrated and washed completely using n-hexane to remove the residues of the product and unreacted substrates. The filtrate containing the R–C reaction product was purified and subjected to further analyses. The filter cake of the poly(1s50-b-2100) catalyst was reused in the cross-R–C reaction of 3a and 4a. To our delight, the recovered catalyst showed high catalytic activity and enantioselectivity. The yield and ee values of the R-5aa product using the recycled catalyst were almost the same as those generated using the fresh poly(1s50-b-2100) catalyst. Poly(1s50-b-2100) was recycled 10 times and maintained high activity and enantioselectivity (Fig. 3d). The yield and ee of the product R-5aa after the 10th reaction were 75% and 94%, respectively.

Discussion

Mechanism study

Because the reactants of the R–C reaction were insoluble in water, the enhanced activity and enantioselectivity of the catalytic block copolymer in water were ascribed to the hydrophobic core of the self-assembled micelles. The amphiphilic block copolymer was self-assembled into spherical micelles in water with hydrophobic and organocatalytic phosphine pendants at the interior and the hydrophilic poly-2n block at the exterior. The water-insoluble reactants were mainly located in the hydrophobic pocket of the micelles. The helical poly-1sm block bearing catalytic phosphine pendants at the interior provided not only catalytic phosphine for the R–C reaction but also a hydrophobic and asymmetric environment for enhancing the enantioselectivity. The asymmetric R–C reaction was catalyzed by the phenyl phosphine pendants. The one-handed helical backbone just provided an additional chiral environment and improved the enantioselectivity31,32,33,34,35,36,56. Thus, the reaction followed a mechanism similar to that of phenyl phosphine-catalyzed R–C reaction50,51,52,53,54. Moreover, the enriched local concentration of the water-insoluble reactants at the interior accelerated the reaction rate. Collectively, the synergistic effects of the self-assembled micelle facilitated the R–C reaction of water-insoluble materials in water and improved its activity and enantioselectivity. In order to obtain more information, the reaction of 3a with 4a catalyzed by poly(1s50-b-2100) in water was further monitored using 31P NMR spectroscopy. Clearly, there was no interaction between 3a and poly(1s50-b-2100) as no change was observed on the 31P NMR spectrum (Supplementary Fig. 19). Meanwhile, an obvious interaction between 4a and poly(1s50-b-2100) was observed because of a new appearance of a 31P peak at 33.26 ppm. The Raman analyses also evidenced the intermolecular interaction between poly(1s50-b-2100) with 4a in water (Supplementary Fig. 20)22. Based on the abovementioned results and previous works, we propose a possible mechanism for the reaction52,53,54. As shown in Fig. 4, the asymmetric cross R-C reaction was initiated by a Michael addition of the phosphine pendant to 4a and gave an intermediate I. The subsequent nucleophilic addition of I to 3a yielded intermediate II. Because of the asymmetric environment of the helical backbone, the addition mainly took place from the less steric side of the helix and thus gave intermediate II with high enantioselectivity. Following proton transfer, the final R–C product R-5aa and the phosphine catalyst were extruded from intermediate III. Another possible route was the elimination of β-H of intermediate II to obtain the target product. However, based on the work reported by Yu et al., the energy of migration followed by elimination is lower than that for the elimination of β-H in intermediate II60. Thus, migration followed by an elimination process is more likely to take place. The amide bonds on the pendants stabilized the one-handed helicity of the polyisocyanide backbone via intramolecular hydrogen bonding17,18,55,56. Moreover, the amide group contributed intramolecular hydrogen bonds and thus stabilized the intermediate I, which enhanced the enantioselectivity of the cross-R–C reaction61. To obtain more information about the R–C reaction, we conducted the poly(1s50-b-2100) catalyzed reaction of deuterium-labeled 3a-d1 and 4e-d2 in H2O, and the reaction of undeuterated 3a with 4e in deuterium water D2O according to above procedure (Fig. 5). The deuterium-labeled experiments gave the desired products with deuterium located at the expected positions. Meanwhile, the reaction conducted in D2O yielded the same product as that in H2O. All these studies further confirmed the proposed mechanism.

In summary, we synthesized a family of amphiphilic helical polyisocyanide block copolymers that self-assembled into well-defined chiral micelles in water with catalytic phosphine buried inside the hydrophobic pocket. Such an organocatalytic chiral micelle could efficiently catalyze asymmetric cross R–C reaction of various water-insoluble materials in water and deliver the desired products in high yields with excellent ee values. Here, the ee of the product reached 96% in >81% yields. Moreover, the enantioselectivity could be reversed using helical polyisocyanide copolymers possessing an opposite backbone helicity. The polymer catalysts were applicable to various reactants with just 4 mol% catalyst loading. Moreover, the block copolymers had excellent thermo-responsiveness in water with a cloud point of ~38.4 °C. Taking advantage of the thermo-responsiveness and high Mn, the polymer catalyst was recycled 10 times with maintained its high reactivity and enantioselectivity. This study not only provides excellent and environment-friendly catalysts for asymmetric R–C reactions in water but also facilitates the exploration of green catalysts for producing chiral materials.

Data availability

The synthetic details and experimental data generated in this study are all provided in the Supplementary Information. All other data are available from the corresponding author upon request.

References

Zaera, F. Designing sites in heterogeneous catalysis: are we reaching selectivities competitive with those of homogeneous catalysts? Chem. Rev. 122, 8594–8757 (2022).

McMorn, P. & Hutchings, G. J. Heterogeneous enantioselective catalysts: strategies for the immobilisation of homogeneous catalysts. Chem. Soc. Rev. 33, 108–122 (2004).

Zhang, X. et al. Pickering emulsion-derived liquid−solid hybrid catalyst for bridging homogeneous and heterogeneous catalysis. J. Am. Chem. Soc. 141, 5220–5230 (2019).

Astruc, D., Lu, F. & Aranzaes, J. R. Nanoparticles as recyclable catalysts: the frontier between homogeneous and heterogeneous catalysis. Angew. Chem. Int. Ed. 44, 7852–7872 (2005).

Chi, Y., Scroggins, S.-T. & Fréchet, J. M. J. One-pot multi-component asymmetric cascade reactions catalyzed by soluble star polymers with highly branched non-interpenetrating catalytic cores. J. Am. Chem. Soc. 130, 6322–6323 (2008).

Bergbreiter, D. E. Soluble polymers as tools in catalysis. ACS Macro Lett. 3, 260–265 (2014).

Min, H., Miyamura, H., Yasukawa, T. & Kobayashi, S. Heterogeneous Rh and Rh/Ag bimetallic nanoparticle catalysts immobilized on chiral polymers. Chem. Sci. 10, 7619–7626 (2019).

Dickerson, T. J., Reed, N. N. & Janda, K. D. Soluble polymers as scaffolds for recoverable catalysts and reagents. Chem. Rev. 102, 3325–3344 (2002).

Altava, B., Burguete, M. I., García-Verdugo, E. & Luis, S. V. Chiral catalysts immobilized on achiral polymers: effect of the polymer support on the performance of the catalyst. Chem. Soc. Rev. 47, 2722–2771 (2018).

Akai, Y., Yamamoto, T., Nagata, Y., Ohmura, T. & Suginome, M. Enhanced catalyst activity and enantioselectivity with chirality-switchable polymer ligand PQXphos in Pd-catalyzed asymmetric silaborative cleavage of meso-methylenecyclopropanes. J. Am. Chem. Soc. 134, 11092–11095 (2012).

Song, X., Li, Y.-X., Zhou, L., Liu, N. & Wu, Z.-Q. Controlled synthesis of one-handed helical polymers carrying achiral organoiodine pendants for enantioselective synthesis of quaternary all-carbon stereogenic centers. Macromolecules 55, 4441–4449 (2022).

Sallembien, Q., Bouteiller, L., Crassous, J. & Raynal, M. Possible chemical and physical scenarios towards biological homochirality. Chem. Soc. Rev. 51, 3436–3476 (2022).

Yan, X. et al. Single-handed supramolecular double helix of homochiral bis(N-amidothiourea) supported by double crossed C−I···S halogen bonds. Nat. Commun. 10, 3610 (2019).

Du, G. et al. Condensed supramolecular helices: the twisted sisters of DNA. Angew. Chem. Int. Ed. 61, e202113279 (2022).

Kasprzyk-Hordern, B. Pharmacologically active compounds in the environment and their chirality. Chem. Soc. Rev. 39, 4466–4503 (2010).

Romanazzi, G., Degennaro, L., Mastrorilli, P. & Luisi, R. Chiral switchable catalysts for dynamic control of enantioselectivity. ACS Catal. 7, 4100–4114 (2017).

Liu, N., Zhou, L. & Wu, Z.-Q. Alkyne-palladium(II)-catalyzed living polymerization of isocyanides: an exploration of diverse structures and functions. Acc. Chem. Res. 54, 3953–3967 (2021).

Yashima, E., Maeda, K., Iida, H., Furusho, Y. & Nagai, K. Helical polymers: synthesis, structures, and functions. Chem. Rev. 109, 6102–6211 (2009).

Ikai, T. et al. Helix-sense-selective encapsulation of helical poly(lactic acid)s with in a helical cavity of syndiotactic poly(methyl methacrylate) with helicity memory. J. Am. Chem. Soc. 142, 21913–21925 (2020).

Xu, L. et al. Crystallization-driven asymmetric helical assembly of conjugated block copolymers and the aggregation induced white-light emission and circularly polarized luminescence. Angew. Chem. Int. Ed. 59, 16675–16682 (2020).

Ikai, T., Okubo, M. & Wada, Y. Helical assemblies of one-dimensional supramolecular polymers composed of helical macromolecules: generation of circularly polarized light using an infinitesimal chiral source. J. Am. Chem. Soc. 142, 3254–3261 (2020).

Cai, S., Chen, J., Wang, S., Zhang, J. & Wan, X. Allostery-mimicking self-assembly of helical poly(phenylacetylene) block copolymers and the chirality transfer. Angew. Chem. Int. Ed. 60, 9686–9692 (2021).

Chen, J. et al. Polymerization-induced self-assembly of conjugated block copoly(phenylacetylene)s. Macromolecules 53, 1638–1644 (2020).

Arias, S., Rodríguez, R., Quiñoá, E., Riguera, R. & Freire, F. Chiral coalition in helical sense enhancement of copolymers: the role of the absolute configuration of comonomers. J. Am. Chem. Soc. 140, 667–674 (2018).

Jimaja, S. et al. Nickel-catalyzed coordination polymerization-Induced self-assembly of helical poly(aryl isocyanide)s. ACS Macro Lett. 9, 226–232 (2020).

Pfukwa, R., Kouwer, P. H. J., Rowan, A. E. & Klumperman, B. Templated hierarchical self-assembly of poly(p-aryltriazole) foldamers. Angew. Chem. Int. Ed. 52, 11040–11044 (2013).

Hirose, D., Isobe, A., Quiñoá, E., Freire, F. & Maeda, K. Three-state switchable chiral stationary phase based on helicity control of an optically active poly(phenylacetylene) derivative by using metal cations in the solid state. J. Am. Chem. Soc. 141, 8592–8598 (2019).

Yuan, J. & Liu, M. Chiral molecular assemblies from a novel achiral amphiphilic 2-(heptadecyl) naphtha[2,3]imidazole through interfacial coordination. J. Am. Chem. Soc. 125, 5051–5056 (2003).

Huang, X. et al. Self-assembled spiral nanoarchitecture and supramolecular chirality in Langmuir–Blodgett films of an achiral amphiphilic barbituric acid. J. Am. Chem. Soc. 126, 1322–1323 (2004).

Shen, Z., Jiang, Y., Wang, T. & Liu, M. Symmetry breaking in the supramolecular gels of an achiral gelator exclusively driven by π–π stacking. J. Am. Chem. Soc. 137, 16109–16115 (2015).

Ikai, T. et al. Emergence of highly enantioselective catalytic activity in a helical polymer mediated by deracemization of racemic pendants. J. Am. Chem. Soc. 143, 12725–12735 (2021).

Yamamoto, T., Murakami, R. & Suginome, M. PQXdpap: helical poly(quinoxaline-2,3-diyl)s bearing 4-(dipropylamino)pyridin-3-yl pendants as chirality-switchable nucleophilic catalysts for the kinetic resolution of secondary alcohols. Org. Lett. 23, 8711–8716 (2021).

Yoshinaga, Y., Yamamoto, T. & Suginome, M. Enantioconvergent Cu-catalyzed intramolecular C−C coupling at boron-bound C(sp3) atoms of α-aminoalkylboronates using a C1-symmetrical 2,2′-bipyridyl ligand attached to a helically chiral macromolecular scaffold. J. Am. Chem. Soc. 142, 18317–18323 (2020).

Wu, Z.-Q. et al. Achiral organoiodine-functionalized helical polyisocyanides for multiple asymmetric dearomative oxidations. Nat. Commun. 14, 566 (2023).

Yamamoto, T., Yamada, T., Nagata, Y. & Suginome, M. High-molecular-weight polyquinoxaline-based helically chiral phosphine (PQXphos) as chirality-switchable, reusable, and highly enantioselective monodentate ligand in catalytic asymmetric hydrosilylation of styrenes. J. Am. Chem. Soc. 132, 7899–7901 (2010).

Nagata, Y. et al. Solvent-dependent switch of helical main-chain chirality in sergeants-and-soldiers-type poly(quinoxaline-2,3-diyl)s: effect of the position and structures of the “sergeant” chiral units on the screw-sense induction. J. Am. Chem. Soc. 135, 10104–10113 (2013).

Barbaro, P. & Liguori, F. Ion exchange resins: catalyst recovery and recycle. Chem. Rev. 109, 515–529 (2009).

Kitanosono, T., Masuda, K., Xu, P. & Kobayashi, S. Catalytic organic reactions in water toward sustainable society. Chem. Rev. 118, 679–746 (2018).

Hastings, C. J., Adams, N. P., Bushi, J. & Kolb, S. J. One-pot chemoenzymatic reactions in water enabled by micellar encapsulation. Green Chem. 22, 6187–6193 (2020).

García-Fernández, A., Megens, R. P., Villarino, L. & Roelfes, G. DNA-accelerated copper catalysis of Friedel–Crafts conjugate addition/enantioselective protonation reactions in water. J. Am. Chem. Soc. 138, 16308–16314 (2016).

Kuepfert, M., Ahmed, E. & Weck, M. Self-assembled thermoresponsive molecular brushes as nanoreactors for asymmetric aldol addition in water. Macromolecules 54, 3845–3853 (2021).

Qu, P., Kuepfert, M., Jockusch, S. & Weck, M. Compartmentalized nanoreactors for one-pot redox-driven transformations. ACS Catal. 9, 2701–2706 (2019).

Qu, P. et al. Compartmentalisation of molecular catalysts for non-orthogonal tandem catalysis. Chem. Soc. Rev. 51, 57–70 (2022).

Soares, B. M. et al. Chiral organocatalysts based on lipopeptide micelles for aldol reactions in water. Phys. Chem. Chem. Phys. 19, 1181–1189 (2017).

Rodríguez-Llansola, F., Miravet, J. F. & Escuuder, B. A supramolecular hydrogel as a reusable heterogeneous catalyst for the direct aldol reaction. Chem. Commun. 47, 7303–7305 (2009).

Lu, A., Cotanda, P., Patterson, J. P., Longbottom, D. A. & O’Reilly, R. K. Aldol reactions catalyzed by l-proline functionalized polymeric nanoreactors in water. Chem. Commun. 48, 9699–9701 (2012).

Han, B. et al. Asymmetric organocatalysis: an enabling technology for medicinal chemistry. Chem. Soc. Rev. 50, 1522–1586 (2021).

Volla, C. M. R., Atodiresei, I. & Rueping, M. Catalytic C−C bond-forming multi-component cascade or domino reactions: pushing the boundaries of complexity in asymmetric organocatalysis. Chem. Rev. 114, 2390–2431 (2014).

Dondoni, A. & Massi, A. Asymmetric organocatalysis: from infancy to adolescence. Angew. Chem. Int. Ed. 47, 4638–4660 (2008).

Methot, J. L. & Roush, W. R. Nucleophilic phosphine organocatalysis. Adv. Synth. Catal. 346, 1035–1050 (2004).

Xie, P. & Huang, Y. Domino cyclization initiated by cross-Rauhut–Currier reactions. Eur. J. Org. Chem. 28, 6213–6226 (2013).

Li, K., Jin, Z., Chan, W.-L. & Lu, Y. Enantioselective construction of bicyclic pyran and hydrindane scaffolds via intramolecular Rauhut–Currier reactions catalyzed by thiourea-phosphines. ACS Catal. 8, 8810–8815 (2018).

Dong, X., Liang, L., Li, E. & Huang, Y. Highly enantioselective intermolecular cross Rauhut–Currier reaction catalyzed by a multifunctional Lewis base catalyst. Angew. Chem. Int. Ed. 54, 1621–1624 (2015).

Zhou, W. et al. Chiral sulfinamide bisphosphine catalysts: design, synthesis, and application in highly enantioselective intermolecular cross-Rauhut–Currier reactions. Angew. Chem. Int. Ed. 54, 14853–14857 (2015).

Li, Y.-X. et al. Helicity- and molecular-weight-driven self-sorting and assembly of helical polymers towards two-dimensional smectic architectures and selectively adhesive gels. Angew. Chem. Int. Ed. 60, 7174–7179 (2021).

Shen, L., Xu, L., Hou, X.-H., Liu, N. & Wu, Z.-Q. Polymerization amplified stereoselectivity (PASS) of asymmetric Michael addition reaction and aldol reaction catalyzed by helical poly(phenyl isocyanide) bearing secondary amine pendants. Macromolecules 51, 9547–9554 (2018).

Cao, G. et al. LCST-type hyperbranched polyoligo(ethylene glycol) with thermo- and CO2-responsive backbone. Macromol. Rapid Commun. 39, 1700684 (2018).

Su, M. et al. Facile synthesis of poly(phenyleneethynylene)-block-polyisocyanide copolymers via two mechanistically distinct, sequential living polymerizations using a single catalyst. Macromolecules 49, 110–119 (2016).

Wu, Z.-Q. et al. One-Pot Synthesis of Conjugated Poly(3-hexylthiophene)-b-poly(phenyl isocyanide) Hybrid Rod–Rod Block Copolymers and its Self-Assembling Properties. J. Polym. Sci., Part A: Polym. Chem. 51, 2939–2947 (2013).

Xia, Y. et al. An unexpected role of a trace amount of water in catalyzing proton transfer in phosphine-catalyzed (3 + 2). J. Am. Chem. Soc. 129, 3470–3471 (2007).

Zhou, W. et al. Enantioselective intermolecular cross Rauhut–Currier reactions of activated alkenes with acrolein. Chem. Commun. 52, 7612–7615 (2016).

Acknowledgements

This work is supported by the Natural Science Foundation of China (NSFC, Nos. 92256201 (Z.-Q.W.), 52273204 (L.Z.), 52273006 (N.L.), 22071041 (Z.-Q.W.), 21971052 (N.L.), 51903072 (L.Z.), and 21871073 (Z.-Q.W.)) and the Fundamental Research Funds for the Central Universities. L. Zhou thanks Anhui Provincial Natural Science Foundation (Grant No. 2008085MB51).

Author information

Authors and Affiliations

Contributions

Z.-Q.W., N.L. and L.Z. designed and directed the project; L.X., Y.-X.L., and R.-T.G. performed the experiments and analyzed the data. Z.-Q.W., N.L. L.Z. and Z.C. wrote the manuscript with input from all other authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Guohua Liu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xu, L., Zhou, L., Li, YX. et al. Thermo-responsive chiral micelles as recyclable organocatalyst for asymmetric Rauhut-Currier reaction in water. Nat Commun 14, 7287 (2023). https://doi.org/10.1038/s41467-023-43092-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-023-43092-7

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.