Abstract

Crackling noise is a scale-invariant phenomenon found in various driven nonlinear dynamical material systems as a response to external stimuli such as force or external fields. Jerky material movements in the form of avalanches can span many orders of magnitude in size and follow universal scaling rules described by power laws. The concept was originally studied as Barkhausen noise in magnetic materials and now is used in diverse fields from earthquake research and building materials monitoring to fundamental research involving phase transitions and neural networks. Here, we demonstrate a method for nanoscale crackling noise measurements based on AFM nanoindentation, where the AFM probe can be used to study the crackling of individual nanoscale features, a technique we call crackling noise microscopy. The method is successfully applied to investigate the crackling of individual topological defects, i.e. ferroelectric domain walls. We show that critical exponents for avalanches are altered at these nanoscale features, leading to a suppression of mixed-criticality, which is otherwise present in domains. The presented concept opens the possibility of investigating the crackling of individual nanoscale features in a wide range of material systems.

Similar content being viewed by others

Introduction

Crackling noise is a general physical phenomenon in material systems exposed to external stimuli (force, fields, etc.)1,2,3,4. These stimuli induce atomic-sized kink movements in the material’s crystal structure in the form of jerks or avalanches accompanied by crackling noise (actual sound waves). Similar concepts apply to many other systems, from crumpling paper5, various phase transitions in solid materials6, deformed crystals and porous materials7, and neural networks8, to the seismic activity found in earthquakes9,10,11. Renormalization group theory predicts that these diverse crackling systems approach fixed points, indicating universal scaling behaviour4. For example, various types of universality classes can be found in crackling noise statistics, associated power laws, and scaling functions and can be studied with various macroscopic techniques2. Identification of universality classes enables efficient prediction of material properties in a wide range of applications12.

Indentation is one way to produce crackling noise in materials13,14, in addition to compression and bending15,16. Beirau and Salje investigated crackling noise avalanches in indentation measurements of mesoporous synthetic silica14, showing that mechanical properties are a function of depth and sensitive to chain reactions of collapsing pores during the indentation process. The crackling noise was shown to be power-law distributed with exponents of approximately 1.5 over several decades, confirming avalanche criticality. One drawback of conventional indentation is that individual nanoscale features cannot be chosen for investigation, as these systems do not incorporate imaging of materials surfaces. A solution to this problem is to use a scanning probe system capable of various imaging modes to locate and study nanoscale features prior to indentation. With the availability of calibrated hard solid diamond probes and rigid, stable scanners for long indentation time to record sufficient statistical data of >103 individual jerk events occurring typically within 10−4 s4, this concept appears feasible.

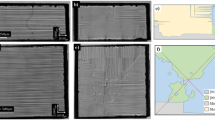

Here, we examine the ability to use AFM-based nanoindentation to investigate crackling noise in ferroelectric lead titanate (PbTiO3) as a test material system. A maximum loading force of 30 µN is applied to the surface over a long time (hours) through a single crystal diamond AFM cantilever. During that time, we detect the signal produced by any surface movements. Individual movements are typically in the sub-Å to pm range and at the limit of the AFM’s sensitivity. To determine the twin domains and domain walls as well as the difference in mechanical response of different area, we used other AFM-based imaging techniques which are well-defined in our current reports17,18. While crackling noise has been investigated in the context of ferroelectric materials19,20,21 in macroscopic and bulk measurements, our technique provides insight into the single topological defect level. The test material PbTiO3 can be considered a prototypical tetragonal ferroelectric system22,23,24, that has been shown to possess functional topological defects, i.e. conductive domain walls with intrinsically different nanoscale material properties from the bulk material18,22,25. Due to the structure of the tetragonal phase, both 90° and 180° domains exist in ferroelectric PbTiO3 single crystals18,24,26,27,28. The difference between the in-plane (IP) and out-of-plane (OOP) domains is a rotation of the c-axis by 90°. This leads to the twinning of the material and twin boundaries separating the IP and OOP domains. In this research, the crackling noise in a variety of regions on a PbTiO3 single-crystal sample has been investigated, including twin domains (i.e. IP and OOP domains) and 180° domain walls.

Results

The measurement concept

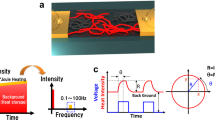

A jerk is defined as an individual spike in the crackling noise spectrum. Jerk energy can be represented by the squared time derivative of the height (dh/dt)2 measured through an AFM probe (Fig. 1a). In AFM-based indentation, the AFM probe in contact with the sample is simultaneously used to apply a force and to measure the reaction of the material under the tip in the form of an indentation depth. Figure 1b presents an example of results detected by the AFM probe during one indentation measurement. The black line displays the measured indentation depth h(t), and the blue line shows the squared velocity v2(t) = (dh/dt)2. Both curves are shown versus time while increasing the force exerted by the AFM probe from 0 to 30 µN with a very low rate of 2.08 nN/s. At low loading force, the AFM probe does not create indents on the sample surface. Thus, the indentation depth is zero. When the force is strong enough, the AFM probe generates surface deformation and jerks. The indentation depth and jerk intensity are increased with the increase of force. It can be seen as a shift of the height value to the negative side, and the jerky evolution of the indentation depth is apparent. This data is the key spectrum for all of the following avalanche analyses.

a A constant force, typically in the nN range and depending on material hardness, is applied over a long period (hours) through an AFM probe and surface movement is detected at the limit of the AFM’s sensitivity, typically in the sub-Å to pm range, depending on the specific setup. Individual nanoscale features, such as domain walls in ferroelectrics, can be selected prior by other AFM-based imaging techniques which are well-defined in our current reports17, 18. b Example of a recorded avalanche distribution under the AFM probe.

The probability distribution of the jerk energy can be extracted from an indentation process by analyzing the indentation depth of a loading curve. A reliable statistical analysis of the crackling noise is generated by a large data set, typically with at least ~103 jerks induced by an increasing force on the cantilever. On a log–log plot, the energy distribution g(E) of jerks is a function of the energy E of avalanche events and is given by refs. 21,29,30:

where Emin is the lower cutoff needed for normalization, and ε is the energy exponent.

The energy exponent describes the universal power laws of the crackling noise and can directly be extracted from the jerk energy distribution. A power-law dependence indicates that the crackling behaviour only depends on symmetries or dimensions of the material and is independent of microscopic details11. However, measured crackling noise can have several sources or be distorted by exponential damping factors that do not allow for the direct extraction of the exponent from the distribution of the jerk energy. The maximum-likelihood ε (ML) fitting method that estimates the exponent ε above a fixed jerk energy value E0 can be used to identify deviations from a unique crackling noise source21,29,30. The exponent ε is given by:

It is important to note that not all jerks are manifestations of avalanches, they can also be produced by the measuring device or sample vibrations. Therefore, such artifacts have to be eliminated before avalanche statistics based on a jerk spectrum can be discussed. Soprunyuk et al.11 reported that jerks with squared velocities less than 10 nm2 s−2 do not contribute to the power-law behaviour and behave like white noise. Moreover, strain rates of 10−5 /s are typically required for slip avalanche experiments on crystal materials, as discussed by Salje et al.2. This indicates that observation time plays an important role in the avalanche experiment. The time should be long enough to obtain high-quality jerk measurements with reliable statistics2.

In our experiment, we thus first investigate the crackling noise as a function of different indentation periods of 10 s, 150 s, 1500 s, 14,400 s (4 h), and 28,800 s (8 h), i.e. the time used to measure one indentation cycle. The total number of data points in each cycle (including loading and unloading curves) is independent of the indentation period and was set to 104. Figure 2 shows time-dependent measurements of probability distribution of jerk energy P(E) and the ML exponent ε acquired on the IP domain of a single crystal PbTiO3 sample. The P(E) curves look roughly similar independent of indentation speed or sample location, which makes it difficult to determine the energy exponent. The ML curves accentuate the exponent ε and it can be seen that the PbTiO3 shows a clear difference from the PET samples. This is a clear indication that there is crackling noise occurring in the material. At indentation times less than 1500 s, the ML curves are the same as the polymer ones and do not show any plateau or deflection. Meanwhile, for indentation times between 1500 s and 8 h, there is a clear deviation from the curves indicating the existence of a jerk energy distribution of avalanches in the material. These results suggest that the jerks are only observable when the indentation time is long enough to distinguish clearly between individual jerks2.At indentation times less than 1500 s, a slight change of ε around 103 aJ is visible. For longer indentation times between 1500 s to 8 h, there is a clear deviation and cut-off indicating the existence of a jerk energy distribution of avalanches in the material. This is the first indication that the crackling noise occurring in the material can be successfully recorded with our AFM-based method. These results suggest that the jerks are only observable when the indentation time is long enough to distinguish clearly between individual jerks2. Therefore, for further investigation, we used the longest indentation time of 8 h to analyse and compare the crackling noise of different PbTiO3 regions.

In consideration of the above, the validity of our measurement concept was tested by comparative measurements on viscoelastic materials that creep, i.e. deform continually as long as the stress is present, which is the case for many polymer materials31. Detailed data of measurements on polyethylene terephthalate (PET, see Fig. 2), polypropylene (PP), and polystyrene (PS) can be found in Fig. S1 of the supplementary material. The utilization of high viscoelastic polymer materials allows us to test for artifacts in the measurements (laboratory and system noise, sample vibrations). As shown in Fig. 2b and the Supplementary material, all polymer samples reveal a similar behaviour independent of their indentation times. It is harder to see the difference from the probability distribution of jerk energy P(E) plots, but the ML curves of the PbTiO3 exhibit a clear exponent ε with a kink and plateau which does not appear in the polymer samples. No cut-off energies and avalanches occur in the polymer samples, thus showing that our AFM-based method is working properly without artifacts impacting the measurements.

In the case of a single exponential crackling noise source, the ML exponent ε stabilizes at a fixed value for higher jerk energies (E > Emin). This perfect behaviour is represented by the red line in the graph of Fig. 3a that is calculated for synthetic generated crackling noise values with exponent 2. The calculation has been reported by E.K.H. Salje et al.9. Below Emin, there is a kink and a fast decrease of the exponent ε that is justified by the reduced number of low jerk energies that are found in experiments coming from the limitations of the measuring system. The other three curves show examples of mixing of two exponents (purple line), predamping (green line) and exponential damping (blue dotted line). This understanding of the ML curves can be used to analyse our experiments on PbTiO3.

a Different ML fitted exponent ε behaviour. b ML fitted exponent ε for crackling noise measurements at OOP, IP domain, and 180° OOP domain wall in PbTiO3. Dashed lines indicate averaged exponents at medium jerk energies. All ML curves coincide at 2.3 near E = 2 × 103 aJ which represents the lower common critical exponent.

Crackling noise of domains and domain walls

Figure 3b shows the measured ML curves of the IP and OOP twin domains and 180° OOP domain wall of the PbTiO3 sample with an indentation time of 8 h. Both domains and domain wall show a clear discontinuity in the ML slope which is the signature of avalanches in PbTiO3. All the ML curves show an increase in exponent ε with increasing energy until Emin, where a sharp kink appears. This cut-off energy of 4.09 × 102 aJ is the same for IP domain and OOP domain wall while the OOP domain has a higher apparent cut-off energy at about 8.15 × 102 aJ but there is a small break of slope at lower energies at about 4.09 × 102 aJ as same as the IP domain and OOP domain wall. This result is reasonable as they were measured with the same cantilever and system. For higher jerk energies the ML curves show a certain level of plateauing with a typical increase of ε at higher jerk energies. Interestingly, the shape of the plateau is different for the IP domain, OOP domain, and 180o OOP domain wall. For the 180° OOP domain wall, there is a plateau at a value of 2.3, whereas ε of the OOP domain reaches up to 3.0 and then falls back to about 2.3, where ε for the IP domain only goes up to 2.5 and then falls back to 2.3. This behaviour of both domains is typical for a mixture of two power-law contributions as reported by Salje et al.9. If a mixture of power-law contributions exists, the ML curve normally does not show a pure plateau but varies between two power-law contributions. This can also depend on how strong the mechanism is behind each of them. Therefore, analyzing the ML curves on different PbTiO3 areas shows that there is a common exponent of 2.3 in each of the measurements with an additional contribution for the OOP and IP domains. Model simulations9 have shown that the lower exponent is readily seen in the experimental ML curves while the upper exponent is much harder to identify. The maximum of the ML curves represents a lower bound of the upper exponent. Our results confirm this mechanism by showing a common exponent of 2.3 for all samples which can be taken as the characteristic bulk value for mesoscopic twin movements32,33,34. The larger additional exponent in the domains could relate to different avalanche movements and may include surface effects.

Typically, the energy exponent ε varies between 1 and 32,4,13,30,35 for crackling noise investigated by macroscopic and bulk measurements. In our measurement, we enable using AFM-based nanoindentation as a driver for crackling noise to analyse microscopic areas on a ferroelectric material. The results reveal higher crackling noise values for the IP and OOP domains than expected for the mean-field solution (1.33 and 1.66)2. Enhanced exponents were also found in complex twin structures reported by Casals et al.29. These jerks occurring in twin reconfigurations induced by an electric field follow a power law with a strongly increased damping and hence, have a larger energy exponent (ε = 1.6) compared to the simple twin pattern (ε = 1.4). Additionally, the twinning in metals36,37, and the jerky movement of ferroelastic domain walls of PbZrO3 and LaAlO338 show exponents near 1.8–2.0. Equally, the mixture of power laws with high exponents was observed in martensitic transitions39 where the upper exponent was also reported as ε = 2. Therefore, the higher exponent values ε in the IP and OOP domains are reasonable due to the complex structure of the twin domains.

Moreover, from a more general perspective, avalanches and criticality have also been studied in other topological defects than domain walls, including skyrmions40 and dislocation-heavy metals41. Díaz et al.40 reported avalanches with power-law distribution of both size and duration, with exponents of 1.55 and 1.63. For a larger value of the considered Magnus term, the average avalanche shape became strongly asymmetric and indicated that the observed effective negative mass was similar to avalanche distribution in domain walls. Additionally, dislocations as another form of topological defect have also been investigated41 showing the coexistence of two deformation modes of conventional thermally-activated smooth plastic flow and sporadic bursts. Dislocation avalanches in bcc metals have revealed an extended dislocation-avalanche velocity-relaxation.

In this study, we demonstrate a method for the crackling of individual nanoscale features based on AFM probe, a technique we call crackling noise microscopy. The method is successfully applied to investigate crackling noise and avalanches in the ferroelectric domains and domain walls of ferroelectric PbTiO3. The indentation time plays an important role as it needs to be long enough to distinguish every single jerk of the avalanches. Analyzing the energy distribution of the jerks and maximum-likelihood exponent curves allow for the identification of unique crackling noise at domains and domain walls of PbTiO3 single crystal. The energy exponents of the different PbTiO3 areas show a common value of 2.3 in each of the measurements with an additional contribution for the twin domains.

The presented concept opens the possibility of investigations of the crackling of individual nanoscale features in a wide range of material systems. Samples with ferroic patterns, such as complex twinning, could be analyzed on a local scale of some estimated 100 × 100 × 50 nm. In this region, the presence of a single twin boundary with a width of approximately 2 nm leads to a 2% increase in the internal jerk spectrum. When multiple twin boundaries act collectively, the resulting signal is much stronger than that of a single boundary, resulting in significantly larger signals in a dense pattern. The dense twin patterns show twin walls with distances less than 20 nm and the jerk contribution, therefore, raises to more than 10% which is likely to be seen by the mixing procedure. In this case, the response of the twin walls to the AFM stress is a sideways movement, its contribution increases steeply and our method should be ideal for such investigations.

Methods

PbTiO3 single crystals were grown from PbO and TiO2 precursors (Sigma-Aldrich, high-purity 5 N (99.999%). The precursors have been first ground to powder in an agate mortar. Powder PbO and TiO2 are then synthesized in a sealed quartz crucible (10−6 mbar) by the solid-state reaction method for 48 h at 850° C in a horizontal muffle furnace. The purity of the synthesis of PbTiO3 powder was verified by X-ray diffraction42,43 and then put into a platinum crucible with additional PbO in molar ratios of 1:1 to 1:3. The crucible was covered to avoid PbO evaporation during crystal growth. The whole system is then placed in a cubic muffle furnace and heated up to 1200 °C in a period of 5 h. After 10 h at 1200 °C, the system is cooled down to 550 °C for a duration of 60 h. Further cooling to room temperature was performed at a cooling rate of 1 °C/h to avoid cracking at the phase transition from cubic to tetragonal (490 °C)44,45,46. Finally, hot acetic acid was used to extract the PbTiO3 from the PbO molten mass.

The AFM-based nanoindentation was performed by a Smart SPM 1000 system (AIST-NT, USA) using an NM-RC-C diamond probe with a force constant k = 470 N/m (Bruker, USA). The precise spring constant of each cantilever was determined using the thermal-noise technique47,48. The cantilever was calibrated on a fused-silica standard sample to determine its accuracy.

Data availability

Source Data file has been deposited in Figshare under accession code DOI link49.

References

Zapperi, S., Castellano, C., Colaiori, F. & Durin, G. Signature of effectivemass in crackling-noise asymmetry. Nat. Phys. 1, 46–49 (2005).

Salje, E. K. H. & Dahmen, K. A. Crackling noise in disordered materials. Annu. Rev. Condens. Matter Phys. 5, 233–254 (2014).

Salje, E. K. H. & Jiang, X. Crackling noise and avalanches in minerals. Phys. Chem. Miner. 48, 1–15 (2021).

Sethna, J. P., Dahmen, K. A. & Myers, C. R. Crackling noise. Nature 410, 242–250 (2001).

Houle, P. A. & Sethna, J. P. Acoustic emission from crumpling paper. Phys. Rev. E Stat. Phys. Plasmas, Fluids Relat. Interdiscip. Topics 54, 278–283 (1996).

Nataf, G. F. & Salje, E. K. H. Avalanches in ferroelectric, ferroelastic and coelastic materials: phase transition, domain switching and propagation. Ferroelectrics 569, 82–107 (2020).

Schröder, M., Rahbari, S. H. E. & Nagler, J. Crackling noise in fractional percolation. Nat. Commun. 4, 2222 (2013).

Barés, J. & Bonamy, D. Controlling crackling dynamics by triggering low-intensity avalanches. Phys. Rev. E 103, 2–7 (2021).

Salje, E. K. H., Planes, A. & Vives, E. Analysis of crackling noise using the maximum-likelihood method: Power-law mixing and exponential damping. Phys. Rev. E 96, 1–9 (2017).

Koslowski, M., LeSar, R. & Thomson, R. Avalanches and scaling in plastic deformation. Phys. Rev. Lett. 93, 12–15 (2004).

Soprunyuk, V. et al. Strain intermittency due to avalanches in ferroelastic and porous materials. J. Phys. Condens. Matter 29, 224002 (2017).

Friedman, N. et al. Statistics of dislocation slip avalanches in nanosized single crystals show tuned critical behavior predicted by a simple mean field model. Phys. Rev. Lett. 109, 1–5 (2012).

Salje, E. K. H., Saxena, A. & Planes, A. Avalanches in Functional Materials and Geophysics (Springer International Publishing, 2017).

Beirau, T. & Salje, E. K. H. Nano-indentation and avalanches in compressed porous SiO2. Appl. Phys. Lett. 115, 071902 (2019).

Salje, E. K. H. et al. Failure mechanism in porous materials under compression: Crackling noise in mesoporous SiO2. Philos. Mag. Lett. 91, 554–560 (2011).

Timár, G. & Kun, F. Crackling noise in three-point bending of heterogeneous materials. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 83, 046115 (2011).

Nguyen, C. P. T., Schoenherr, P. & Seidel, J. Intrinsic Mechanical Compliance of 90° Domain Walls in PbTiO3. Adv. Funct. Mater. 33, 2211906 (2023).

Faraji, N., Yan, Z. & Seidel, J. Electrical conduction at domain walls in lead titanate (PbTiO3) single crystals. Appl. Phys. Lett. 110, 1–6 (2017).

Salje, E. K. H., Xue, D., Ding, X., Dahmen, K. A. & Scott, J. F. Ferroelectric switching and scale invariant avalanches in BaTiO3. Phys. Rev. Mater. 3, 1–8 (2019).

Yazawa, K., Ducharne, B., Uchida, H., Funakubo, H. & Blendell, J. E. Barkhausen noise analysis of thin film ferroelectrics. Appl. Phys. Lett. 117, 012902 (2020).

Casals, B., Nataf, G. F. & Salje, E. K. H. Avalanche criticality during ferroelectric/ferroelastic switching. Nat. Commun. 12, 1–7 (2021).

Meyer, B. & Vanderbilt, D. Ab initio study of ferroelectric domain walls in PbTiO3. Phys. Rev. B 65, 104111 (2002).

Shimada, T., Tomoda, S. & Kitamura, T. First-principles study on ferroelectricity at PbTiO3 surface steps. J. Phys. Condens. Matter 22, 355901 (2010).

Wang, Y. G., Dec, J. & Kleemann, W. Study on surface and domain structures of PbTiO3 crystals by atomic force microscopy. J. Appl. Phys. 84, 6795–6799 (1998).

Seidel, J. et al. Conduction at domain walls in oxide multiferroics. Nat. Mater. 8, 229–234 (2009).

Lehnen, P., Dec, J. & Kleemann, W. Ferroelectric domain structures of PbTiO3 studied by scanning force microscopy. J. Phys. D. Appl. Phys. 33, 1932–1936 (2000).

Fesenko, E. G., Martynenko, M. A., Gavrttyatghfnko, V. G. & Semenchev, A. F. Phase transition and switching in lead titanate crystals. Ferroelectrics 7, 309–310 (1974).

Chou, C. C. & Chen, C. S. Banded domain structures and polarization arrangements in PbTiO3 single crystals. Ceram. Int. 26, 693–697 (2000).

Casals, B., Van Dijken, S., Herranz, G. & Salje, E. K. H. Electric-field-induced avalanches and glassiness of mobile ferroelastic twin domains in cryogenic SrTiO3. Phys. Rev. Res. 1, 1–6 (2019).

Lu, C., Mai, Y. W. & Shen, Y. G. Optimum information in crackling noise. Phys. Rev. E Stat. Nonlinear, Soft Matter Phys. 72, 2–5 (2005).

McCrum, N. G., Buckley, C. P. & Bucknall, C. B. Principles of Polymer Engineering (Oxford Science Publications, 2003).

Salje, E. K. H. Multi-scaling and mesoscopic structures. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 368, 1163–1174 (2010).

Salje, E. K. H., Bismayer, U., Hayward, S. A. & Novak, J. Twin walls and hierarchical mesoscopic structures. Mineral. Mag. 64, 201–211 (2000).

Salje, E. K. H. & Ishibashi, Y. Mesoscopic structures in ferroelastic crystals: Needle twins and right-angled domains. J. Phys. Condens. Matter 8, 8477–8495 (1996).

Salje, E. K. H. & Jiang, X. Crackling noise and avalanches in minerals. Phys. Chem. Miner. 48, 22 (2021).

Chen, Y., Gou, B., Ding, X., Sun, J. & Salje, E. K. H. Real-time monitoring dislocations, martensitic transformations and detwinning in stainless steel: Statistical analysis and machine learning. J. Mater. Sci. Technol. 92, 31–39 (2021).

Soto-Parra, D. et al. Avalanches in compressed Ti-Ni shape-memory porous alloys: An acoustic emission study. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 91, 1–5 (2015).

Puchberger, S. et al. The noise of many needles: Jerky domain wall propagation in PbZrO3 and LaAlO3. APL Mater. 5, 046102 (2017).

Vives, E. et al. Avalanche criticalities and elastic and calorimetric anomalies of the transition from cubic Cu-Al-Ni to a mixture of 18R and 2H structures. Phys. Rev. B 94, 1–8 (2016).

Díaz, S. A., Reichhardt, C., Arovas, D. P., Saxena, A. & Reichhardt, C. J. O. Avalanches and criticality in driven magnetic skyrmions. Phys. Rev. Lett. 120, 117203 (2018).

Rizzardi, Q. et al. Mild-to-wild plastic transition is governed by athermal screw dislocation slip in bcc Nb. Nat. Commun. 13, 1–9 (2022).

Soh, J.-R., Lee, H. M. & Kwon, H.-S. Thermodynamic evaluation and phase diagram of PbO-TiO2 system. Calphad 18, 237–244 (1994).

Sahu, N. & Panigrahi, S. Mathematical aspects of Rietveld refinement and crystal structure studies on PbTiO3 ceramics. Bull. Mater. Sci. 34, 1495–1500 (2011).

Chou, C. C. & Wayman, C. M. Cubic to tetragonal martensitic transformation in lead titanate (PbTiO3) single crystals. Mater. Trans. JIM 33, 306–317 (1992).

Shirane, G., Hoshino, S. & Suzuki, K. X-ray study of the phase transition in lead titanate. Phys. Rev. 80, 1105–1106 (1950).

Chou, C. C. & Hou, C. S. Structural Instability during Cubic–Tetragonal Transformation in Lead Titanate Single Crystals. J. Am. Ceram. Soc. 82, 1294–1298 (1999).

Cleveland, J. P., Manne, S., Bocek, D. & Hansma, P. K. A nondestructive method for determining the spring constant of cantilevers for scanning force microscopy. Rev. Sci. Instrum. 64, 403–405 (1993).

Sader, J. E., Chon, J. W. M. & Mulvaney, P. Calibration of rectangular atomic force microscope cantilevers. Rev. Sci. Instrum. 70, 3967–3969 (1999).

Nguyen, C. P. T., Schoenherr, P., Salje, E. K. H., Seidel, J. Crackling noise microscopy, Figshare, https://doi.org/10.6084/m9.figshare.23694153 (2023).

Acknowledgements

We acknowledge support from the Australian Research Council through Discovery Grants and the ARC Centre of Excellence in Future Low Energy Electronics Technologies (FLEET). C.P.T.N. acknowledges support from an Australian Government Research Training Program Scholarship.

Author information

Authors and Affiliations

Contributions

J.S. and E.S. conceived the project. P.S. and C.-P. T. N. designed and performed the experiments. P.S. and C.-P. T. N. analyzed the collected data. All authors discussed the data and contributed to the writing of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks John Blendell and Alexei Bokov for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nguyen, CP.T., Schoenherr, P., Salje, E.K.H. et al. Crackling noise microscopy. Nat Commun 14, 4963 (2023). https://doi.org/10.1038/s41467-023-40665-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-023-40665-4

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.