Abstract

Polyhalogenated carbazoles (PHCZs) are emerging global pollutants found in environmental matrices, e.g., 3000 tonnes of PHCZs have been detected in the sediments of the Great Lakes. Recognition of PHCZ emissions from ongoing industrial activities worldwide is still lacking. Here, we identify and quantify PHCZ emissions from 13 large-scale industries, 12 of which previously have no data. Congener profiles of PHCZs from investigated industrial sources are clarified, which enables apportioning of PHCZ sources. Annual PHCZ emissions from major industries are estimated on the basis of derived emission factors and then mapped globally. Coke production is a prime PHCZ emitter of 9229 g/yr, followed by iron ore sintering with a PHCZ emission of 3237 g/yr. China, Australia, Japan, India, USA, and Russia are found to be significant emitters through these industrial activities. PHCZ pollution is potentially a global human health and environmental issue.

Similar content being viewed by others

Introduction

PHCZs, as emerging dioxin-like compounds (DLCs)1 (structures provided in Supplementary Fig. 1), have been detected in soil2,3, sediment4,5, biota5,6,7, air8, and water9,10,11 in more than 20 regions of Asia, North America, and Europe. Their concentrations are comparable to or even exceed those of some traditional DLCs. The total concentration of 11 PHCZs in Lake Tai is 1.54 ng/g4, which is close to that of polychlorinated biphenyls (PCBs) and polybrominated diphenyl ethers (PBDEs). PHCZs with concentrations of up to 13 ng/g were found in soils from an e-waste dismantling areas12, where polychlorinated dibenzo-p-dioxins and polychlorinated dibenzo-p-furans (PCDD/Fs), as well as PBDEs, were found at 3.23 ng/g and 1.91 ng/g. An investigation of the pollution status of the Great Lakes revealed the existence of 26 PHCZs with a median concentration of 23.7 ng/g in surface grabs, leading to an estimated >3000 tonnes in sediment, which is orders of magnitude greater than those of PCBs and PBDEs13,14,15.

Fungal activity can be a natural PHCZ source. Mumbo et al.16 confirmed that in the presence of H2O2 and chloride and bromide ions, fungi can bio-transform carbazole (CZ) to PHCZs. The load of 1,3,6,8-BCZ and other 12 unknown PHCZs constituting 64% of more than 3000 tonnes of PHCZ residues in sediments from the Great Lakes is concluded to be generated from natural activity, implying on the significant natural formation of PHCZs14. It is widely believed that anthropogenic activities also play a role in PHCZ pollution of the environment4,5. Recently, PHCZs have been found in the disinfection of drinking water10. The production of halogenated indigo dyes17 and specific photoelectric materials18 are also considered potential sources of PHCZs. 2,7- and 3,6- halogenated carbazoles are possible intermediates of two polymers present in electronic devices, which have not been detected directly in these industrial samples. The synthesis of halogenated indigo dyes is also considered a source of PHCZ emission19,20, although one modern indigo dye, 5,5’,7,7’-tetrabromoindigo was proved not to contain PHCZs19. Only 1,3,6,8-CCZ, 1,3,6,8-BCZ, and 1,8-B-3,6-CCZ were the main impurities in historical synthetic dye19. The postulation that industrial activities unintentionally releases PHCZs is generally based on the decrease in PHCZ concentration over time when relevant activities cease, distance-dependent distribution patterns around factories, and the correlation of environmental levels with the activities of surrounding industries in some specific areas21,22,23. Thus, current research on source identification is woefully inadequate and does not support any reasonable explanation of the abundant residues, wide distribution, and complicated congener profiles of PHCZs in the environment14. Artificial sources of PHCZs remain unresolved but urgently need to be identified for emission control and pollution management24,25,26.

Here, we conducted field investigations of 13 industries, covering 122 factories. These industries are organic chemical production (OC), co-processing in cement kilns (CK), municipal solid waste incineration (MSWI), hazard waste incineration (HWI), coke production (COP), electric arc furnace for steel-making (EAF), iron ore sintering (IOS), primary copper smelting (PCu), secondary aluminum smelting (SAl), secondary copper smelting (SCu), secondary lead smelting (SPb), secondary zinc smelting (SZn) and coal fire power plants (CFP). Industrial fine particulate matter (i-PM) and chemical bottom liquids were analyzed to identify the 11 PHCZ congeners frequently detected in the environment (Supplementary Table 1). PHCZ congener profiles of industrial samples were compared with those of environmental samples (Supplementary Fig. 2). Annual global PHCZ emissions from studied industrial activities producing PHCZs at relatively high concentrations were also estimated and mapped using the emission factor method.

Results and discussion

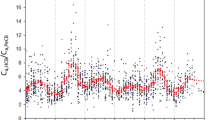

PHCZ concentrations in fine particle matter from multiple industries

Material samples potentially with PHCZs originated in the following industries: OC, CK, MSWI, HWI, COP, EAF, IOS, PCu, SAl, SCu, and SZn. Data obtained are shown in Fig. 1. The concentration of all PHCZ congeners (Σ11PHCZs) in an individual i-PM matrix and the mean Σ11PHCZs in i-PM matrices collections from all factories in each industry (removing minimax through box plot) were both used to describe the emission potential of each industry. The highest Σ11PHCZs in all i-PM samples (188 ng/g) and the highest mean Σ11PHCZs (30 ng/g) are associated with COP, in which matrices from COP-3, COP-5, and COP-1 had high contents: 85 ng/g, 59 ng/g, and 49 ng/g, respectively. Carbazole is an important by-product of coke production from coal tar27. The possible halogenation of carbazole might lead to highly elevated Σ11PHCZs in i-PM from coke production, making COP a significant industrial source of PHCZs. Relatively high Σ11PHCZs were found in i-PM samples from IOS, SAl, SCu, SZn, MSWI, and HWI, ranging from 8 ng/g to 60 ng/g. The IOS and SCu are considered high-level emitters, with mean Σ11PHCZs of nearly 20 ng/g and 10 ng/g, respectively, and at least two i-PM samples containing more than 15 ng/g PHCZs. The coke powder and cable cover of copper scrap (Supplementary Table 2) might be the major reason for the high PHCZ contents of i-PM from the IOS and SCu sources. Within each of MSWI, HWI, and SAl, Σ11PHCZs vary (Fig. 1) owing to discrepancies in raw material compositions28. Nevertheless, SAl-1, MSWI-3, and HWI-4 release i-PM with Σ11PHCZs higher than 14 ng/g, indicating their PHCZ emission potential. Some i-PM samples from CK, EAF, and SZn contain more than 3 ng/g PHCZs. Among investigated industries, coke-participating industries are significant but previously ignored PHCZ sources. Secondary smelting is also an important source of PHCZ emissions. In particular, SAl-1 emits i-PM with Σ11PHCZs as high as 45 ng/g and SCu-7 emits i-PM with Σ11PHCZs of 34 ng/g, which show their PHCZ pollution potential. However, Σ11PHCZs less than 68 pg/g can be seen in i-PM from SPb, except SPb-9, which is much lower than those from SAl, SCu, and SZn. This is consistent with the previously reported discrepancy in diverse secondary smelting sources of unintentional emissions of polychlorinated naphthalenes, which share similar mechanisms to the unintentional emissions of persistent organic pollutants (POPs)29. The limited ability of lead to promote the formation of POPs might be the reason for the relatively low Σ11PHCZs of i-PM from SPb30. Representing the waste disposal industry, MSWI releases i-PM with a greater PHCZ content than CK and HWI, for example, 29 ng/g PHCZs in i-PM from MSWI-3. The variety of raw materials and burning processes contribute to the differences, similar to variations observed for PCDD/PCDF released from waste incinerators31. For example, Σ11PHCZs from CK-1 are much higher than those from other factories (Supplementary Table 2), which is similar to results obtained for PCDFs reported in our previous study32. The incineration of laboratory wastes, such as plastic products and organic reagents, leads to higher Σ11PHCZs in i-PM from CK-1 compared with that in other i-PM from the incineration of industrial wastes (Supplementary Table 2). Apart from these, Σ11PHCZs as low as 0.37 ng/g are also observed in primary copper production, much lower than that in secondary copper production. Compared with the scrap smelted in SCu, the primary copper in PCu is relatively clean with a lower chlorine content33, which inhibits the formation of PHCZs. Low Σ11PHCZs have been detected in i-PM samples from 15 CFP facilities owing to the possible inhibitory effect of sulfur in coal34. High Σ11PHCZs have been detected in matrices collected from chemical manufacturing plants. Previous studies have demonstrated that the nitrobiphenyl group is an important precursor of bromocarbazole synthesis35,36. The existence of nitrobenzene, biphenyl, and chlorobenzene in material from chemical manufacturing plants was confirmed using high-resolution Q-TOF mass spectrometry screening (Supplementary Table 3). The co-existence of multiple precursors might lead to the formation of significant amounts of PHCZs during chemical manufacturing processes. Even though the bottom liquid requires further disposal, the high Σ11PHCZs from OC-1 (0.10 mg/L) and OC-2 (0.19 mg/L) demonstrate that certain OC processes are a significant industrial source of PHCZs.

CK, co-processing in cement kilns; MSWI municipal solid waste incineration, HWI hazard waste incineration, COP coke production, EAF electric arc furnace for steel-making; IOS iron ore sintering, PCu, primary copper smelting; SAl, secondary aluminum smelting; SCu, secondary copper smelting; SPb, secondary lead smelting; SZn, secondary zinc smelting; CFP coal fire power plants.

The toxic equivalent PHCZ concentration (TEQc) of PHCZs in i-PM from SCu-7 is 15 pg/g and that of PHCZs in i-PM from SAl-1 is 8 pg/g, which greatly exceeds the TEQc of PHCZs in other i-PM samples (Supplementary Table 2). Thus, these mentioned above industries seem to pose the highest PHCZ-related human health risk from PHCZs. Compared with i-PM from COP, i-PM products from SCu-7 and SAl-1 have lower PHCZ concentrations but higher contents of more toxic congeners, 1,3,6,8-CCZ and 2,3,6,7-CCZ, which leads to a higher TEQc (Supplementary Table 4). Because PHCZs have a lower TEQc than PCDD/Fs31, PHCZs are not a major TEQc issue in thermal processes.

Congener profiles and homologue patterns of PHCZs in matrices from industrial activities

All target congeners were detected in i-PM material from COP, SAl, EAF, and MSWI (Supplementary Table 4), while specific congeners, especially chlorobromocarbazoles, were not detected in most i-PM from other industries. The proportions of congeners substituted with different halogens vary depending on the type of industry. As shown in Fig. 2, compared with other halogen-substituted carbazoles, chlorinated carbazoles count for more than 70% in samples from EAF, HWI, PCu, SCu, and SZn, demonstrating that chlorinated carbazoles are the dominant congener type in the unintentional production of PHCZs (data processing in Supplementary Method 1). Notably, 3-CCZ and 3,6-CCZ are dominant congeners, with total proportions ranging from 30 to 86% in all investigated industries. The proportion of 1,3,6,8-CCZ is high, exceeding 25% in SCu, EAF, and HWI, and although the proportion of 2,3,6,7-CCZ is only 18% in SCu, it is the highest in the other industries. Brominated carbazoles were also detected in all i-PM samples, although high-bromine congeners, especially 1,3,6,8-BCZ, had a very low detection frequency and were found in only several i-PM samples from CK, MSWI, and EAF. 3-BCZ is the major brominated congener, especially in COP (48%), SAl (27%), and IOS (27%). The proportions of 2,7-BCZ (8%) and 3,6-BCZ (10%) in SAl are much higher than those in other secondary metal smelting processes. The two bromo-substituted carbazoles might be particular to PHCZ production in SAl, distinguishing SAl from other secondary metal smelting processes. Only three industries (EAF, SZn, and MSWI) seem potential producers of chlorobromocarbazoles, with the highest proportion of only 4% in EAF. The proportion of chlorinated carbazoles is higher in OC than in other industries owing to the presence of certain raw materials and the specific synthesis pathway. Specifically, the chlorine content is considerably higher than the bromine content, which is also favorable for the formation of halogenated dibenzo-p-dioxins and dibenzofurans37,38.

CK, co-processing in cement kilns; MSWI municipal solid waste incineration, HWI hazard waste incineration, COP coke production; EAF electric arc furnace for steel-making; IOS iron ore sintering, PCu, primary copper smelting; SAl, secondary aluminum smelting; SCu, secondary copper smelting; SZn, secondary zinc smelting.

Characteristics of PHCZs from industrial sources

Spearman analysis of the congener concentrations and environmental occurrences of PHCZs produced by the investigated industries (see Supplementary Table 4 and Supplementary Fig. 2) was conducted to understand the source and environmental characteristics of PHCZs (data processing in Supplementary Method 1). As shown in Fig. 3 (brown and green indicate positive and negative correlations, respectively), certain congeners display a strong positive correlation with other congeners in SAl, MSWI, and CK. In the other industries, such as COP, SZn, and IOS, correlations exist between minority of congeners including 3-CCZ, 3-BCZ, 3,6-CCZ, and 1,3,6,8-CCZ. Interestingly, strong negative correlations between certain congeners in the environment are absent in every industry. For example, 3,6-CCZ has negative correlations with 10 other congeners in sediment and soil but weak or positive correlations with these congeners in all industries. The proportion of 3,6-CCZ in i-PM samples is high but the correlations between 3,6-CCZ and other congeners in the environment and industries differ, suggesting that anthropogenic and natural sources might jointly contribute to 3,6-CCZ pollution in sediment. The result is consistent with findings reported by Guo et al.14, but more field studies are needed to further confirm pollution contribution from these investigated sources as well as natural sources and other unexplored artificial sources in specific areas. The mutual interferences of 3,6-CCZ and pesticide DDT39,40 in laboratory analysis should also be taken into consideration when the discrepancy appeared. The concentrations of 1-B-3,6-CCZ, 1,8-B-3,6-CCZ, 1,3,6-BCZ, 1,3,6,8-BCZ, and 2,3,6,7-CCZ are low, while the concentrations of 2,7-BCZ and 3,6-BCZ are high in some i-PM samples, such as from COP-1 and SAl-1 (Supplementary Table 4). 3-CCZ, 3-BCZ, 3,6-CCZ, and 1,3,6,8-CCZ exist in high concentrations in i-PM samples from most industries, indicating that industrial activities are part of their sources.

The Σ11PHCZs in i-PM samples are high and consistent with environmental investigations, suggesting that industrial activities are sources of some congeners. However, the diverse correlations among congener concentrations in industries and the environment indicate the existence and important contribution of natural sources.

Comparison of congener and homologue patterns between i-PM and environmental samples

The proportion of chlorocarbazoles, ranging from 62–94%, is higher than those of bromocarbazoles and chlorobromocarbazoles in most industries (excluding CFP and SPb because of the much lower Σ11PHCZs). The proportion of brominated carbazoles is high in i-PM samples from COP (56%) and SAl (45%) but ranges from 4 to 38% in i-PM samples from the other investigated industries. The proportion of chlorobromocarbazole is 0–4% of Σ11PHCZs. These results coincide with the concentrations in sediment (63% chlorocarbazoles, 30% bromocarbazoles, and 7% chlorobromocarbazole) and soil (71% chlorocarbazoles, 21% bromocarbazoles, and 8% chlorobromocarbazole) (Fig. 2). Specifically, 3,6-CCZ is the dominant congener, constituting nearly 50% of Σ11PHCZs in both soil and sediment. 3-CCZ and 3-BCZ are also important congeners, with proportions of 13 and 9% in soil, while 3,6-BCZ (12%) is an important congener in sediment. In our research, 3,6-CCZ is considered the main congener and constitutes 15–60% of Σ11PHCZs in industries other than SAl. 3-CCZ is the dominant congener owing to its high proportion (18–45%), which is slightly higher than that of 3-BCZ (1–48%). Wu et al.5 reported that 3,6-CCZ accounts for more than 70% of Σ11PHCZs in sediment from San Francisco Bay. A similar congener pattern was obtained for samples from China. Sediment and soil samples from Jiangsu4, Zhejiang39, and Yunnan provinces41 all contain 3,6-CCZ with proportions from 55 to 86%. In some early studies, 3-CCZ and 3,6-CCZ were detectable while other congeners are not. The concentration of 3,6-CCZ is up to 50 ng/g in Lipple River42 and 3500 ng/g in industrial coastal areas of Greece2. The concentrations of 3-CCZ and 3,6-CCZ in soil from Bavaria were 8.3 ng/g and 149 ng/g, respectively43. The preponderance of 3-CCZ, 3-BCZ, and 3,6-CCZ in both i-PM and environmental samples indicates that PHCZ pollution is significantly influenced by industrial sources.

Principal component analysis of PHCZ congener profiles of i-PM samples and environmental occurrences was also conducted (Supplementary Method 1). As shown in Fig. 4, almost all environmental occurrences are classified into one group, in which some i-PM samples from CK, HWI, MSWI, SZn, and SCu are also grouped. Noticeably, i-PM samples with high PHCZ concentrations, including CK-1, HWI-3, SCu-6, and MSWI-3, are also found in this group. Most sampling sites of environmental investigations of PHCZs are in or surrounded by big cities (Supplementary Fig. 2), such as San Francisco in the USA and Wuxi and Dali in China, which generate considerable amounts of municipal solid wastes and scrap non-ferrous metals. Wu4,5 pointed out that although the sources of PHCZs in San Francisco Bay and Lake Tai have not been determined, the abundance of PHCZs indicates that anthropogenic activities are likely sources. The results show that secondary metal smelting and waste incineration, which are intense in populated areas, might be potential sources of PHCZ residues.

CK, co-processing in cement kilns; MSWI, municipal solid waste incineration;HWI: hazard waste incineration; COP coke production, EAF, electric arc furnace for steel-making, IOS iron ore sintering; PCu, primary copper smelting; SAl, secondary aluminum smelting; SCu, secondary copper smelting; SZn, secondary zinc smelting.

Historically, there used to be many industrial activities around Lake Tai and other PHCZ-polluted sites. However, without PHCZ emission data, these anthropogenic sources have not been identified. The present research provides not only data for the potential industrial sources of PHCZs in these areas but also a set of PHCZ fingerprints from long-neglected thermal sources, triggering further work for the establishment of a PHCZ fingerprint database.

Preliminary estimation of PHCZ release from priority industrial sources into the environment

Although PHCZs are generally released from the 13 investigated industries, no global emission estimate could be allocated to activities producing i-PM with a low PHCZ content, such as PCu, secondary lead smelting (SPb), coal-fired power (CFP), CK, HWD, and SZn (Section 3.1). An estimation of PHCZ emission from OC with a high concentration in the first two processes investigated (tetrachloroethylene and chlorobenzene production) is not given either because further comprehensive investigations are required. However, our field study of Yaer Lake (Supplementary Fig. 3) demonstrated the significance of historical chlor-alkali industries (via gas diffusion, solid residues, and wastewater) for environmental PHCZ residues. The rest of the investigated industries, namely high-polluting industries including EAF, SAl, COP, SCu, SZn, and MSWI, are given an estimation of PHCZ emission.

The biggest emitter among the investigated industries is COP, contributing 9229 g of PHCZs through the release of industrial fine particles in total per year globally, representing a high contribution. In 2019, the global production of coke approached 683 million tonnes (Fig. 5a), the highest among these industries44. Moreover, COP consists of several procedures that emit particulate matter (PM)45 (Supplementary Table 5), such as coal loading, coke discharging, coke oven heating, and dry coke quenching. The total emission factor of i-PM (EF) is relatively large, close to that of secondary metal smelting (Fig. 5b). The high yield, EF45, and PHCZ concentration make COP the primary source of PHCZs (Fig. 5c). China is one of the important contributors of PHCZ global emissions, releasing 6364 g of PHCZs every year (Fig. 6) due to the high industrial activities. The other regions, including Russia, India, America, Japan, and the European Union, also emit significant amounts of PHCZs, ranging from 149 g to 472 g. China was the biggest coke producer in the world in 2019, producing 471 million tonnes (Supplementary Fig. 4), which explains its high PHCZ emission. IOS is another significant PHCZ source and can contribute 3237 g of PHCZs into the environment every year, the second highest emission of PHCZs. Australia has been considered as the biggest emitter of PHCZs, accounting for 1/3 of the global annual emission of PHCZs owing to its high production of iron ore (Supplementary Fig. 4), while Brazil, United States, India, and China annually emit more than 300 g of PHCZs.

a Production/incineration amount44, 46,47,48,55, b emission factors45,49 of industrial particulate matter (i-PM) and c estimated annual global emission of polyhalogenated carbazoles (PHCZs) of selected industries. MSWI, municipal solid waste incineration; COP, coke production; EAF, electric arc furnace for steel-making; IOS iron ore sintering, SAl, secondary aluminum smelting; SCu, secondary copper smelting.

EAF has relatively high global emissions of PHCZs among the high-polluting industries. The annual PHCZ emission of 90 g is attributed to EAF, which is higher than that from SCu (Fig. 5c). EAF has similar industrial outputs to COP, approaching 523 million tonnes46 in 2019 (Fig. 5a), resulting in considerable PHCZ emissions despite the lower Σ11PHCZs and EF of PM45. SCu emits 18 g of 11 PHCZs into the environment every year. The low PM (Fig. 5b) discharge reduces its PHCZ input into the environment. Mapping of PHCZ emissions from EAF (Fig. 6) indicated that China, America, and India are the top three emitters of PHCZs, with emissions of 19 g, 11 g, and 11 g, respectively. Other countries, such as Japan, South Korea, Iran, and Turkey, potentially contribute to the relatively high PHCZ discharge of 4 g per year through EAF, in contrast to COP (Supplementary Fig. 4). MSWI and SAl are not major emitters, with global PHCZ emissions of less than 7 g per year (Fig. 5c) owing to low production outputs47,48 (Fig. 5a) or EF of PM49 (Fig. 5b). Therefore, pollution control is a priority for COP and IOS and less urgent for EAF and other industries.

These estimated industrial sources might deliver a more considerable amount of PHCZs into the environment in historical industrial activities than now, considering that POP reduction technology had not been intensively adopted historically. The mapping of these results showed that PHCZs are a global environmental pollution issue and a human health risk. As for source emission assessment, further research should be conducted for (1) emissions from these industries in other countries to develop more robust emission factors for different technology levels; (2) investigation of PHCZ emissions from other more industrial processes; (3) field studies or model-based to quantify PHCZ emissions from historical industrial activities; and (4) comprehensive investigations of natural PHCZ source emission to clarify their significance for PHCZ pollution.

Methods

Sample information

In total, 122 industrial plants from 13 industries were included in this study. This comprehensive field investigation enables source identification and emission estimation of POPs in one single study31. i-PM samples were collected using bag filters, the most popular and effective dust-removing device in the world today. Each i-PM contained a mixture of PM generated during at least 48 h of regular production. The bag filter was placed in the total discharge outlet and represented the PHCZ release level. The particle size of each i-PM sample was normally lower than 2.5 μm (Supplementary Fig. 5). Airborne PM was formed when the sample was released into the atmosphere.

Specifically, the i-PM samples were from 15 CFP plants, 6 CK plants, 13 MSWI plants, 12 HWI plants, 13 COP plants, 14 EAF plants, 7 PCu plants, 7 SCu plants, 6 SAl plants, 8 SZn plants, 11 SPb plants, and 8 IOS plants. Chemical bottom liquid samples, collected from the reaction still in the final manufacturing step of the end product, were from 2 OC plants producing tetrachloroethylene and chlorobenzene.

Some research suggests that the load, mainly the PM, is the original site for the formation of numerous heterogeneous organic pollutants, which contribute to the environmental input50. The Σ11PHCZs of i-PM samples are accepted to represent the industrial emission situation of PHCZs.

Chemicals and reagents

The standard mixture of 11 PHCZs, namely 3-chlorocarbazole (3-CCZ), 3,6-CCZ, 1,3,6,8-tetrachlorocarbazole (1,3,6,8-CCZ), 2,3,6,7-CCZ, 3-monobromocarbazole (3-BCZ), 2,7-dibromocarbazole (2,7-BCZ), 3,6-BCZ, 1-bromo-3,6-dichlorocarbazole (1-B-3,6-CCZ), 1,8-dibromo-3,6-dichlorocarbazole (1,8-B-3,6-CCZ), 1,3,6-tribromocarbazole (1,3,6-BCZ), and 1,3,6,8-tetrabromocarbazole (1,3,6,8-BCZ), with a purity of >98% was purchased from Wellington Laboratories (Ontario, Canada). 13C-1,3,6,8-marked CCZ (13C-1,3,6,8-MCCZ) and 13C-3,6-marked CCZ (13C-3,6-MCCZ) (2.5 µg/mL, Wellington Laboratories) were all diluted to 1 µg/mL with n-hexane and used as a cleanup standard and injection standard, respectively. Anhydrous sodium sulfate was baked at 600 °C for 6.5 h. Silica gel was activated at 450 °C for 6.5 h.

Sample pretreatment and instrumental analysis

The detailed analysis method is described in Supplementary Method 2. Briefly, 10 ng of 13C-1,3,6,8-MCCZ as the surrogate standard was added to 5 g of i-PM. After 2 days of aging, the mixture was Soxhlet extracted for 12 h using acetone/n-hexane (1:1, v/v). Then, the extract was purified using a glass column packed with silica and anhydrous granulated sodium sulfate. After concentration, 10 ng of 13C-3,6-MCCZ was added as the injection standard to the eluate, which was analyzed using a gas chromatography (GC) system coupled to a triple quadrupole mass spectrometer (MS/MS) to achieve target compound detection. Chemical bottom liquid samples were similarly purified before GC–MS/MS analysis.

Quality control

The method has been evaluated in terms of method stability and sensitivity in our previous research. The recoveries of all congeners in parallel spiked samples range from 82 to 137%, and the relative standard deviations (RSDs) range from 2.4% to 35.8%. The method detection limit of each congener ranges from 1.46 to 3.82 ng/mL for liquid samples and from 0.009 to 0.023 ng/g for solid samples. In this research, 11 PHCZs were not detected in the blank control samples, and the recoveries of surrogate standards were in the range of 54–118%.

Emission and TEQc calculation

Quantification of POP release has been formulated as a set of systematic calculations method on the basis of numerous research51,52, which is documented in open-source guides, such as the Toolkit for PCDD/Fs published and endorsed by UNEP and the Stockholm Convention53. Computational models are common in emission estimation54, largely owing to the scarcity of analytical methods and samples, while emission factors are based on experimental data directly representing real emissions31. To estimate the emissions of 11 PHCZs in high-polluting industries as well as some countries and regions, we adopted equation (2):

where E represents the annual emission of PHCZs in each high-polluting industry, \(\bar{{C}_{i}}\) is the average value of Σ11PHCZs in i-PMs from all factories (removing minimax through box plot) in the same industry, EFi represents the average emission factor of fine particulate matter (PM) (described in Uncertainty Reduction), and Yi is the yield in a specific industry. Yi (Fig. 5b) is the annual production of each industry around the world, which was collected from relevant international statistics organizations44,46,47,48,55. EFi (Fig. 5c) was collected from China’s Industrial Source Pollution Production and Discharge Coefficient Manual and research results45,49. The yields of SCu and SAl are for 2021, and the yields of COP, EAF, IOS, and MSWI are for 2019. We also collected the yields of EAF (Supplementary Fig. 4), IOS (Supplementary Fig. 4), COP (Supplementary Fig. 4), and MSWI (Supplementary Fig. 4) in major regions, which was applied for mapping of the regional emission of PHCZs (Fig. 6). Because of the lack of usable data for SCu and SAl, only the global emissions are given in Fig. 5c.

Details for calculating the TEQc and relative effect potencies (REPs) of PHCZs can be found in Supplementary Method 3 and Supplementary Table 6, respectively.

Uncertainty

Uncertainty is unavoidable in estimations based on the emission factor owing to variations of production procedures and facilities, measuring time, pollution control measures, and diverse raw materials56,57. Here, some measures were taken to reduce uncertainty. For example, i-PM samples were collected in bag filters as PM emissions over several days owing to the constant ash-dumping period, making the PHCZ concentration a steady emission situation. More than six industrial plants were sampled for each industry (Supplementary Table 2). To reduce the variation associated with diverse plants, the box plot was used to exclude the minimax of Σ11PHCZs in each industry, and then the average Σ11PHCZs of diverse factories was used. Moreover, the EFs of SCu, IOS, COP, and EAF were determined following a nationwide survey of pollution emissions with the help of each industrial association in China, having been the recommended handbook for the Second National Pollution Source Census, indicating their reliability.

The EF of MSWI is the value in latest research49, and it is close to the values in other regions. To our best knowledge, a reliable EF is unavailable for SAl. Pyro smelting is mainly used to smelt scrap aluminum, which is also used in SCu. Therefore, the EF of SCu is used to estimate the PM emission of SAl. As shown in Supplementary Table 5, the EF of PM is determined by various factors in various industries. For COP, the sum of the EFs of PM released from four procedures is the final EF of PM. Wet coke quenching is not considered here because of its low usage rate. For example, in China, wet coke quenching is only allowed to operate when the dry coke quenching machine is under maintenance. The final EF of PM is the average of the values of two production technologies (top-charging and stamp-charging). For EAF, the end product is the core factor affecting PM emission. Carbon steel accounts for 80% of steel production, which is the reason the EF of carbon steel production represents the overall emission level. For IOS, the EF of PM is determined by sintering machines, of which more than 360 m2 is used because of the popularization of large-size machines. The raw materials in SCu production determine the EF of PM. The average of EFs determined by high-grade scrap copper and low-grade scrap copper is used here for comprehensive calculation.

Data availability

The minimum dataset necessary to interpret, verify and extend the work is provided in the supplementary information. The concentrations of ployhaleganated carbazoles for Figs. 1–6 are provided in supplementary information. The published data about congener concentrations and profiles in the environment used in Figs. 2–4 is from references summarized in supplementary Fig. 2. Data in Figs. 5 and 6, Supplementary Fig. 4 and Table 5 for emission assessment is collected from research results, international industry associations and official government document, which are introduced in Method and provided in references. Unpublished data is used for supplementary Fig. 3.

References

Altarawneh, M. & Dlugogorski, B. Z. Formation and chlorination of carbazole, phenoxazine, and phenazine. Environ. Sci. Technol. 49, 2215–2221 (2015).

Grigoriadou, A. & Schwarzbauer, J. Non-target screening of organic contaminants in sediments from the industrial coastal area of Kavala city (NE Greece). Water Air. Soil Pollut. 214, 623–643 (2011).

Mumbo, J. et al. Persistence and dioxin-like toxicity of carbazole and chlorocarbazoles in soil. Environ. Sci. Pollut. Res. 22, 1344–1356 (2015).

Wu, Y., Qiu, Y., Tan, H. & Chen, D. Polyhalogenated carbazoles in sediments from Lake Tai (China): Distribution, congener composition, and toxic equivalent evaluation. Environ. Pollut. 220, 142–149 (2017).

Wu, Y., Tan, H., Sutton, R. & Chen, D. From sediment to top predators: broad exposure of polyhalogenated carbazoles in san francisco bay (USA). Environ. Sci. Technol. 51, 2038–2046 (2017).

Chen, Y. et al. Formation of environmentally relevant polyhalogenated carbazoles from chloroperoxidase-catalyzed halogenation of carbazole. Environ. Pollut. 232, 264–273 (2018).

Wu, Y. et al. Bioaccumulation and spatiotemporal trends of polyhalogenated carbazoles in great lakes fish from 2004 to 2016. Environ. Sci. Technol. 52, 4536–4545 (2018).

Fromme, H. et al. Occurrence of carbazoles in dust and air samples from different locations in Germany. Sci. Total Environ. 610–611, 412–418 (2018).

Xu, X., Wang, D., Li, C., Feng, H. & Wang, Z. Characterization of the reactivity and chlorinated products of carbazole during aqueous chlorination. Environ. Pollut. 225, 412–418 (2017).

Wang, G. et al. New insight into the formation of polyhalogenated carbazoles: Aqueous chlorination of residual carbazole under bromide condition in drinking water. Water Res. 159, 252–261 (2019).

Li, Z. et al. Distribution characteristics and risk assessment of polyhalogenated carbazoles in sea water of the Yellow Sea. Mar. Pollut. Bull. 161, 111656 (2020).

Liu, R. et al. Field study of PAHs with their derivatives emitted from e-waste dismantling processes and their comprehensive human exposure implications. Environ. Int. 144, 106059 (2020).

Guo, J. et al. Polyhalogenated carbazoles in sediments of Lake Michigan: a new discovery. Environ. Sci. Technol. 48, 12807–12815 (2014).

Guo, J. et al. Spatial and temporal trends of polyhalogenated carbazoles in sediments of upper great lakes: insights into their origin. Environ. Sci. Technol. 51, 89–97 (2017).

Li, A. et al. Polyhalogenated carbazoles in sediments of lower laurentian great lakes and regional perspectives. ACS EST Water 2, 1544–1554 (2022).

Mumbo, J., Lenoir, D., Henkelmann, B. & Schramm, K. W. Enzymatic synthesis of bromo- and chlorocarbazoles and elucidation of their structures by molecular modeling. Environ. Sci. Pollut. Res. 20, 8996–9005 (2013).

Parette, R. et al. Halogenated indigo dyes: A likely source of 1,3,6,8-tetrabromocarbazole and some other halogenated carbazoles in the environment. Chemosphere 127, 18–26 (2015).

Karon, K., Lapkowski, M. & Juozas, G. Electrochemical and UV-Vis/ESR spectroelectrochemical properties of polymers obtained from isomeric 2,7- and 3,6-linked carbazole trimers; Influence of the linking topology on polymers properties. Electrochim. Acta 123, 176–182 (2014).

Parette, R. et al. Response to the comment on ‘Halogenated indigo dyes: A likely source of 1,3,6,8-tetrabromocarbazole and some other halogenated carbazoles in the environment’. Chemosphere 150, 414–415 (2016).

Peverly, A. A. & Hites, R. A. Comment on ‘Halogenated indigo dyes: A likely source of 1,3,6,8-tetrabromocarbazole and some other halogenated carbazoles in the environment’. Chemosphere 144, 273–274 (2016).

Kuehl, D. W., Durhan, E., Butterworth, B. C. & Linn, D. Tetrachloro-9H-carbazole, a previously unrecognized contaminant in sediments of the buffalo river. J. Gt. Lakes Res. 10, 210–214 (1984).

Zhu, H. et al. Distribution and ecotoxicological effects of polyhalogenated carbazoles in sediments from Jiaozhou Bay wetland. Mar. Pollut. Bull. 146, 393–398 (2019).

Zhu, L. & Hites, R. A. Identification of brominated carbazoles in sediment cores from Lake Michigan. Environ. Sci. Technol. 39, 9446–9451 (2005).

Zhou, W. et al. Occurrence and distribution of polyhalogenated carbazoles (PHCs) in sediments from the northern South China Sea. Sci. Total Environ. 753, 142072 (2021).

Sun, Y. et al. Method development for determination of polyhalogenated carbazoles in industrial waste through gas chromatography / triple quadrupole tandem mass spectrometry. https://doi.org/10.1002/rcm.9324 (2022).

Wang, G. et al. Occurrence and exposure risk evaluation of polyhalogenated carbazoles (PHCZs) in drinking water. Sci. Total Environ. 750, 141615 (2021).

Sun, H. Review on the extraction process of refined anthracene/carbazole in tar. COAL Convers. 21, 29–32 (1998).

Wang, M. et al. Formation and emission of brominated dioxins and furans during secondary aluminum smelting processes. Chemosphere 146, 60–67 (2016).

Ba, T. E. et al. Estimation and congener-specific characterization of polychlorinated naphthalene emissions from secondary nonferrous metallurgical facilities in China. Environ. Sci. Technol. 44, 2441–2446 (2010).

Wu, X. et al. Thermochemical formation of polychlorinated dibenzo-p-dioxins and dibenzofurans on the fly ash matrix from metal smelting sources. Chemosphere 191, 825–831 (2018).

UNEP. Toolkit for identification and quantification of releases of dioxins, furans and other unintentional POPs under Article 5 of the Stockholm Convention on Persistent Organic Pollutants. 241–287 (2013).

Chen, C. et al. Concentrations, congener patterns, and correlations of unintentional persistent organic pollutants in cement kilns co-processing hazardous waste. Sci. Total Environ. 854, 158793 (2023).

Nie, Z., Liu, G., Liu, W., Zhang, B. & Zheng, M. Characterization and quantification of unintentional POP emissions from primary and secondary copper metallurgical processes in China. Atmos. Environ. 57, 109–115 (2012).

Chen, Z., Lin, X., Lu, S., Li, X. & Yan, J. Suppressing formation pathway of PCDD/Fs by S-N-containing compound in full-scale municipal solid waste incinerators. Chem. Eng. J. 359, 1391–1399 (2019).

Elmabruk, A. et al. Design, synthesis, and pharmacological characterization of carbazole based dopamine agonists as potential symptomatic and neuroprotective therapeutic agents for parkinson’s disease. ACS Chem. Neurosci. 10, 396–411 (2019).

Chau, N. Y., Ho, P. Y., Ho, C. L., Ma, D. & Wong, W. Y. Color-tunable thiazole-based iridium(III) complexes: Synthesis, characterization and their OLED applications. J. Organomet. Chem. 829, 92–100 (2017).

Weber, R. & Kuch, B. Relevance of BFRs and thermal conditions on the formation pathways of brominated and brominated-chlorinated dibenzodioxins and dibenzofurans. Environ. Int. 29, 699–710 (2003).

Du, B. et al. Occurrence and characteristics of polybrominated dibenzo-p-dioxins and dibenzofurans in stack gas emissions from industrial thermal processes. Chemosphere 80, 1227–1233 (2010).

Zhou, Y. et al. Method development for analyzing ultratrace polyhalogenated carbazoles in soil and sediment. Ecotoxicol. Environ. Saf. 182, 109470 (2019).

Reischl, A., Joneck, M. & Dumler-Gradl, R. Chlorcarbazole in Böden. Umweltwissenschaften und Schadst.-forsch. 17, 197–200 (2005).

Tao, W. et al. Determination of polyhalogenated carbazoles in soil using gas chromatography-triple quadrupole tandem mass spectrometry. Sci. Total Environ. 710 (2020).

Kronimus, A., Schwarzbauer, J., Dsikowitzky, L., Heim, S. & Littke, R. Anthropogenic organic contaminants in sediments of the Lippe river, Germany. Water Res. 38, 3473–3484 (2004).

Tröbs, L., Henkelmann, B., Lenoir, D., Reischl, A. & Schramm, K. W. Degradative fate of 3-chlorocarbazole and 3,6-dichlorocarbazole in soil. Environ. Sci. Pollut. Res. 18, 547–555 (2011).

Ministry of ecology and environment of the people’s republic of china. specification for compilation of emission standards for atmospheric pollutants of the coking chemical industry. https://www.mee.gov.cn (2021).

Ministry of ecology and environment of the people’s republic of china. handbook of emission sources inventory survey, pollution discharge calculation methods, and coefficients. https://www.mee.gov.cn (2021).

World Steel Association. World Steel in Figures 2020. https://www.worldsteel.org/media-centre/press-releases/2019/World-Steel-in-Figures-2019.html. (2020)

The Word Bank. What-a-Waste-Global-Database. https://datacatalog.worldbank.org/search/dataset/0039597/What-a-Waste-Global-Database (2019).

International aluminium institute. global aluminium cycle. https://alucycle.world-aluminium.org/public/global/index.html (2021).

Chen, X. et al. Emission characteristics and impact factors of air pollutants from municipal solid waste incineration in Shanghai, China. J. Environ. Manag. 310, 114732 (2022).

Alderson, J. C. & Wall, D. Influencing the production of dioxin/furan in solid waste incineration plants by measures affecting the combustion as well as the flue gas cleaning systems. Jpn. Soc. Biofeedback Res. 19, 709–715 (1992).

Gullett, B. K. et al. PCDD/F, PBDD/F, and PBDE emissions from open burning of a residential waste dump. Environ. Sci. Technol. 44, 394–399 (2010).

Brzuzy, L. P. & Hites, R. A. Global mass balance for polychlorinated dihenzo-p-dioxins and dibenzofurans. Environ. Sci. Technol. 30, 1797–1804 (1996).

United Nations Environment Programme. Guidance on preparing inventories of polychlorinated naphthalenes (PCNs). http://chm.pops.int/Implementation/NationalImplementationPlans/GuidanceArchive/NewlyDevelopedGuidance/GuidanceforPCN/tabid/6231/Default.aspx (2019).

Conesa, J. A., Ortuño, N. & Palmer, D. Estimation of industrial emissions during pyrolysis and combustion of different wastes using laboratory data. Sci. Rep. 10, 1–11 (2020).

International copper study group. THE WORLD COPPER FACTBOOK 2022. https://icsg.org/copper-factbook/ (2022).

Shen, H. et al. from 1960 to 2008 and future predictions. Environ. Sci. Technol. 47, 6415–6424 (2013).

Lee, R. G. M., Coleman, P., Jones, J. L., Jones, K. C. & Lohmann, R. Emission factors and importance of PCDD/Fs, PCBs, PCNs, PAHs and PM 10 from the domestic burning of coal and wood in the U.K. Environ. Sci. Technol. 39, 1436–1447 (2005).

Acknowledgements

This work was supported by the Second Tibetan Plateau Scientific Expedition and Research Program (STEP) (grant number 2019 QZKK0605), the National Natural Science Foundation of China (grant numbers 92143201, 22076201, 21936007 and 21906165), and the CAS Interdisciplinary Innovation Team (grant number JCTD-2019-03).

Author information

Authors and Affiliations

Contributions

Y.S. conducted the laboratory analysis of samples, data analysis, and wrote the paper; L.Y. and M.Z. conducted part of the data analysis and interpretation; R.W., F.J., and L.G. conducted the analysis, evaluation, and interpretation of data and supported manuscript writing; C.Z. conducted part of the laboratory analysis of samples; C.C. and Q.Y. collected relevant information; G.L. designed the research, conducted data analysis, and revised the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks An Li, Kunde Lin and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sun, Y., Yang, L., Zheng, M. et al. Industrial source identification of polyhalogenated carbazoles and preliminary assessment of their global emissions. Nat Commun 14, 3740 (2023). https://doi.org/10.1038/s41467-023-39491-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-023-39491-5

This article is cited by

-

Mutual interference between 3,6-dichlorinated carbazole and p,p′-dichlorodiphenyltrichloroethane in gas chromatography mass spectrometry analysis

Environmental Monitoring and Assessment (2023)

-

Analysis of polyhalogenated carbazoles and two related compounds in earthworms using a modified QuEChERS method with GC/MS and GC/MS/MS

Environmental Science and Pollution Research (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.