Abstract

In commercial Li-ion batteries, the internal short circuits or over-lithiation often cause structural transformation in electrodes and may lead to safety risks. Herein, we investigate the over-discharged mechanism of LiCoO2/graphite pouch cells, especially spatially resolving the morphological, surface phase, and local electronic structure of LiCoO2 electrode. With synchrotron-based X-ray techniques and Raman mapping, together with spectroscopy simulations, we demonstrate that over-lithiation reaction is a surface effect, accompanied by Co reduction and surface structure transformation to Li2CoO2/Co3O4/CoO/Li2O-like phases. This surface chemical distribution variation is relevant to the depth and exposed crystalline planes of LiCoO2 particles, and the distribution of binder/conductive additives. Theoretical calculations confirm that Li2CoO2-phase has lower electronic/ionic conductivity than LiCoO2-phase, further revealing the critical effect of distribution of conductive additives on the surface chemical heterogeneity evolution. Our findings on such surface phenomena are non-trivial and highlight the capability of synchrotron-based X-ray techniques for studying the spatial chemical phase heterogeneity.

Similar content being viewed by others

Introduction

As the vigorous development of “3C products” (Computer, Communication, and Consumer Electronics) and the rapid expansion of the energy storage and electric vehicle markets, the application of lithium-ion batteries (LIBs) has experienced explosive growth1,2. As a dominant cathode material, LiCoO2 is widely used in commercial Li-ion batteries due to its superior volumetric energy density and stability3,4. Nowadays, research on LIBs are mainly focusing on improving their energy density or exploring their capacity fade mechanisms. Many efforts have been devoted to exploring the structural transitions and capacity fading mechanisms of LiCoO2-based batteries at high voltages to improve the energy density of LIBs5,6,7,8. However, the higher the energy density the LIB possesses, the higher the corresponding safety risks.

Due to the inconsistency among the battery cells, over-lithiation can easily occur in LIB packs. For an individual cell, overuse and the differences in internal local structures or contacts can also lead to over-discharge. In the cases of internal short cricuits, over-discharge, or other abuse conditions of LIBs, the cathode/anode/separators/current collector of the full battery system may undergo significant degradation, thus giving rise to severe safety issues9. Therefore, it is necessary to understand the working mechanisms of the electrode material in the over-discharge state for broadening the battery operation tolerance, especially for safety. Previous reports have been demonstrated that over-discharge can significantly influence the anode10,11,12. Over-discharge will cause a voltage increase at the anode and serious dissolution of the copper current collector, degrading the electrochemical performance of LIBs13,14,15. Over-stoichiometric Li+ will also be intercalated into the cathode during the over-discharge process, and make irreversible changes to the local structure, accelerating the battery degradation16. Crompton et al.9,17 declared that Li+ over-insertion degrades the cathode material, which could be the primary degradation mechanism of batteries, and modifying the cathode to stabilize it against the near-zero volt storage conditions may further improve near-zero voltage storage tolerance of LIBs. Shu et al.18 carried out a comparative study to reveal the effect of over-discharged cathode materials (LiFePO4, LiNiO2, and LiMn2O4) and discovered that deep over-discharge has severely harmful impacts on most cathode materials.

However, recent results reveal that the impact of over-discharge is highly dependent on the local structures of the cathode: if the cathode material can safely and reversibly accommodate excess lithium, over-discharge can even be beneficial for battery performance. Over-lithiating the cathode before the first cycle offers the promise of retaining full battery capacity if the cathode material was specifically prepared to safely accommodate the excess lithium19. Improved performance by over-discharging was also demonstrated in Li3V2O5 and Li3Nb2O5 cathodes, which adopt a crystal structure that has plenty of vacancies to accommodate excess lithium20,21. On the other hand, over-discharging LiMn2O4 was shown to significantly degrade performance, as the M3O4 spinel structure does not easily accommodate excess metal ions22. In particular, the battery performance of Li- and Mg-doped LiCoO2 was shown to be resilient to over-discharge compared to native LiCoO223, however the location of the excess Li in LiCoO2 was not determined. These findings make it evident that detailed probes of electrode local structures are needed to elucidate the process of over-discharge.

Additionally, the over-lithiation behavior of LiCoO2 has also been revealed by the traditional characterization methods (such as charge-discharge cycling, XRD, XPS, Raman, and HRTEM)24, and found that reduction mechanisms of LiCoO2 with Li are associated with the irreversible formation of metastable phase Li1+xCoO2−y, and then the final products of Li2O and Co metal. Robert et al.10 analyzed the local structure evolution of LiNi0.80Co0.15Al0.05O2 with further lithiation by ex-XRD. The results indicated that the further lithiation allows the accommodation of an additional Li+ into the host lattice and promotes the R3̅m LiMO2 to P3̅m1 Li2MO2 phase transformation. However, despite tremendous efforts and significant achievements, the degradation mechanisms in terms of defect chemistry and defect electronic structure of over-discharged cathode active materials (no matter in bulk or surface regions), especially in real batteries at high spatial resolution, are still not well established. The absence of local chemical spatial information in electrode characterization using XPS16 and XANES25 might be insufficient to provide a full understanding of the role of surface coupling effects in metal and oxygen sites (structure and redox) in affecting the cathode’s stability or reversibility.

The study of the surface phenomena is non-trivial and limited by the scarcity of the suitable characterization tools, for example, transmission electron microscope (TEM) suffers from radiation damage and a limited statistics capability. Powerful synchrotron-based scanning transmission X-ray microscopy (STXM) and X-ray photoemission electron microscopy (X-PEEM) have been proved useful for characterizing bulk and surface chemical composition, electronic structure and conductivity variations on different crystalline facets, as well as revealing the primary causes of different reactions and stabilities of the crystalline facets26,27,28,29,30,31,32. X-PEEM, with the ultra-high vacuum compatibility and full-field imaging capabilities, can overcome the limitations of conventional STXM in the soft X-ray energy range; as the latter can only image thin sections or fine particles with the thickness/size of tens to hundreds of nanometers to obtain sample bulk information33,34.

In this work, X-PEEM, XANES, and Raman imaging analyses of the interface in the discharged/over-discharged LiCoO2 composite electrodes in a commercial LiCoO2/graphite pouch cell have been performed to gain an understanding of the over-discharge mechanisms, especially on the surface heterogeneity in terms of the morphological, surface phase structure, local electronic environment, element valence state, their interplay and the additive effects. Combining with theoretical calculations, we demonstrate that Li2CoO2/Li2O/Co3O4/CoO-like phases (exclusion of Li1+xCoO2-y) are non-uniformly distributed in the surface of over-discharged LiCoO2 particles, and their distribution variation is relevant to the size, depth and exposed crystalline planes of LiCoO2, and the distribution of binder/conductive agents. The spatial distribution of chemical heterogeneity, morphological degradation, and an unanticipated Co-containing compound phase in the surface of over-discharged LiCoO2 electrodes are further explored. In addition, it is expected that systematic and thorough studies of local chemical spatial information under abuse operations will provide other insights to develop advanced and safe electrode materials for LIBs, and guide the development of batteries with high tolerance.

Results

Chemical and structural evoluation of discharged LiCoO2

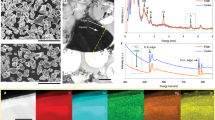

Here, the commercial LiCoO2 composite electrode in a LiCoO2/graphite pouch cell was used to study the over-discharge degradation mechanisms under different cut-off voltages. Detailed descriptions of the electrochemical performance of the LiCoO2/graphite pouch cell can be found in the Methods section33,35. The charging-discharging plots are displayed in Fig. 1a. The pouch cell was charged/discharged at a voltage range of 3.0–4.35 V, which results in the standard charging product (Li0.5CoO2) and discharging product (LiCoO2). When the cell was gradually deep-discharged to 0 V, the discharge curve is clearly divided into two stages, as shown in the enlarged view of Fig. 1a. The first stage shows a sharp drop in the voltage plot with a slow capacity increase, which is attributed to over-stoichiometric Li+ intercalated into the lattice of LiCO2 and transformed into Li1+xCoO2 (marked with a red arrow). Then, there follows a slow voltage drop accompanied by a larger capacity release, which is caused by the dissolution of the copper current collector triggered by an increase in the anode potential9. The Scanning Electron Microscope/Energy Dispersive X-ray (SEM/EDS) mapping in Fig. S1 illustrates the uniform distribution of Cu on the over-discharged LiCoO2 electrode (Named D-0.0 V in Fig. 1a), which proves the above-mentioned dissolution phenomenon of the copper current collector. The local electronic structure and chemical phase components in the discharged LiCoO2 electrode (D-3.0 V, as marked in Fig. 1a) and its evolution upon over-discharge (D-0.0 V) have been studied by X-ray absorption near edge structure (XANES) of the Co L-edge in Fig. 1b and O K-edge in Fig. 1c. The standard Co L-edge spectra of CoO and LiCoO2 are also displayed in Fig. 1b as reference. An obvious phase change can be observed upon over-discharging based on the comparison of the high-quality Co L3-edge spectrum of the deep-discharged D-0.0 V electrode to those of the D-3.0 V electrode and LiCoO2 in Fig. 1b. The Co L3-edge spectrum of the D-3.0 V electrode is very similar to that of LiCoO2, indicating the same chemical phase remaining in the structure, which can also be proven by the O K-edge spectra of the D-3.0 V electrode and LiCoO2 in Figs. 1c and S2f. The main peak (located at 781 eV) of the D-0.0 V electrode with a relatively higher intensity shoulder (located at 779 eV) is broadened compared with that of other samples, indicating the co-existence of Co2+ and Co3+ in the structure. The Co 2p X-ray photoelectron spectroscopy (XPS) spectra of D-3.0 V and D-0.0 V electrodes were used to detect the changes in chemical compositions in Figure S2. Compared with that of the D-3.0 V electrode (29.2% for Co2+), a large amount of Co2+ (62.8%) was found on the surface of the D-0.0 V electrode, confirming the surface Co reduction during overdischarge, which is highly consistent with the conclusions of XANES spectroscopy. This is due to the over-stoichiometric Li+ being intercalated into the lattice structure of LiCoO2 in the surface or near surface during the deep discharge, which induces Co reduction and the structural transformation to Li1+xCoO2/Co3O4/CoO/Li2O (The proof is as follows).

a The charge-discharge plot of LiCoO2, with the inset showing the expanded capacity range from 2.60 to 2.90 Ah; b Co L3-edge XANES spectra of CoO, D-0.0 V, D-3.0 V, and LiCoO2 samples. c Linear combination fit of O K-edge XANES of D-3.0 V and D-0.0 V samples using experimental CoO, Li2O, Co3O4, and LiCoO2 spectra, and the calculated Li2CoO2 spectrum. d Comparison of the fitting components between D-3.0 V and D-0.0 V samples. e The calculated O K-edge XANES and the geometrical configuration (inset) of Li1+xCoO2-y. f, g The geometrical configurations of LiCoO2 and Li2CoO2. h HRTEM, corresponding Fourier Transform (FT)/Inverse Fourier Transform (IFT) images (R1, R2, R3 and R4 region) of D-0.0 V electrode.

The O K-edge XANES spectrum of the D-0.0 V electrode shows some difference compared to that of the D-3.0 V electrode and the LiCoO2 reference, which displays the reduced π* (~530 eV) intensity relative to that of the σ* (536-542 eV), as seen in Figs. 1c and S2f. The O pre-edge features between 529 and 532 eV reflect the hybridization of O 2p and Co 3d orbitals, and the main peaks in the range of 534-552 eV are due to transitions into O 2p hybridized with Co 4sp states. Therefore, the valence states of Co play a key role in the local electronic structure of O. To better understand the structure of LiCoO2 electrodes under different discharge states, the experimental and calculated O K-edge XANES of Li2CO3, CoO, Li2O, Co3O4, and LiCoO2 are provided for comparison in Fig. S2. In addition, since Li2CoO2 and Li1+xCoO2-y have no real materials as a reference, only calculated O K-edge XANES can be provided (Figs. S2 and S3). Theoretical calculations were performed for the O K-edge using WIEN2k36, a full-potential, all-electron density functional theory (DFT) code, and details are described in the supporting information. The geometrical configurations of LiCoO2 and Li2CoO2 are displayed in Fig. 1f, g, respectively. The calculated and experimental data O K-edge XANES spectra are shown in Figs. 1c and S2 and S3. The linear combination fits of the O K-edge XANES spectra of D-3.0 V and D-0.0 V samples were performed using the experimental ental CoO, Li2O, Co3O4, LiCoO2 spectra, and the calculated Li2CoO2 spectrum, with only energy shifting and intensity scaling of each component while keeping the overall spectra shape to yield the best fitting correspondence. The fit yielded LiCoO2, Co3O4, and CoO contributions of 77.3, 14.9, and 7.8% to the O K-edge XANES of D-3.0 V, respectively. The fit yielded LiCoO2, Co3O4, CoO, Li2O, and Li2CoO2 contributions of 8.1, 22.9, 21.9, 29.3, and 17.7% to the O K-edge XANES of D-0.0 V, respectively. The comparison of the fitting components is displayed in Fig. 1d. The decrease in the contribution of LiCoO2 indicates the structure evolution of the electrode during overdischarge (structure transition from LiCoO2 + Li+ to Co3O4, CoO, Li2O, and Li2CoO2). Previous reports provided a chemical formula close to [Li]interslab[Co1-xLix]slab[O2-y] to explain the phenomenon of Li-over-stoichiometric37,38. Herein, the Li13Co11O23 model (inset of Fig. 1e) with substituted Li at the Co site and removed adjacent O was created to simulate the structure of Li1+xCoO2-y to calculate the O K-edge XANES spectra, and more details are described in the supporting document for Fig. S4. Unfortunately, the calculated Li1+xCoO2-y spectra do not agree well with the measured over-discharge D-0.0 V electrode data, as the measurements show a reduction in the pre-edge peak, not an enhancement in the features at even lower energies (red arrow in Fig. 1e). To sum up, the over-discharged LiCoO2 electrode has Co reduction, and XANES along with XANES simulations indicates that CoO, Li2O, Li2CoO2, and Co3O4-like phases (exclusion of LixCoO2-y) exist in the over-discharged LiCoO2 electrode.

In addition, HRTEM and in-situ synchrotron XRD (sXRD) analyses were performed to investigate the surface chemical/structural evolution of LiCoO2 electrodes during overdischarge, and the results are shown in Figs 1h and S5 and S6. The HRTEM and corresponding Fourier Transform (FT)/Inverse Fourier Transform (IFT) images clearly indicate that the existence of the cubic CoO/Co3O4/Li2O phase (Figs. 1h and S5). Further analysis is performed on the 4 regions in Fig. 1h: R1 represents the outer layered structure; R2 represents the inner layered structure; R3 represents the Co3O4 region; R4 represents the CoO region. The lattice fringes of a representative layer structure with a d-spacing of 4.90 Å in R1 and 4.76 Å in R2 could be assigned to the (003) plane of layered LiCoO2. The d(003)-spacing in outer layered structure R1 region is greater than that in the R2 region, which may be due to the expansion of the interlayer spacing caused by the intercalation of over-stoichiometric Li+ ions into the Li layer during the overlithiation process (the layered LiCoO2 transformed to the layered Li2CoO2). The lattice fringe with a d-spacing of 2.86 Å in R3 region could be assigned to the (220) plane of spinel Co3O4 (JCPDS file nos. 43–1003, a = 8.084 Å). It is worth noting that the R4 region exhibits a clear lattice fringe with a d-spacing of 2.13 Å, corresponding to the (200) plane of CoO (JCPDS file nos. 78–0431, a = 4.2667 Å)39. In addition, for the surface of the D-0.0 V electrode a thin coating with thickness 2–4 nm was bound to the surface of the LiCoO2 structure and distributed in regions in Fig. S5. It was confirmed from the enlarged area and the FT images that the outer layer in Fig. S5 is Li2O phase, in which a d-spacing of 0.263 nm corresponds to the (111) plane of Li2O40. Furthermore, in-situ synchrotron XRD of a LiCoO2/graphite pouch cell was also used to investigate the structural evolution of the LiCoO2 electrode during overdischarge from 3.0 to 0.0 V at 20 mA g−1, and the result is shown in Fig. S6. All the diffraction peaks have no significant change (the position of the main peak) and no impurity peaks appear (such as CoO/Co3O4/Li2O phase), only a slight difference in intensity, which indicates that overlithiation is only a surface phenomenon and has little effect on the bulk structure. However, a small enhancement of (006) peak intensity of the LiCoO2 phase can be observed during the overdischarge process, while the (012) peak intensity has no intensity change (insets of Fig. S6a). All synchrotron XRD data were collected under the same conditions, so the intensity change in the diffraction peak could only be due to introduction of atom(s) in the unit cell, which resulted in a change in the structure factor. So, the (006) peak increase may indicate excessive intercalation of Li+ in the Li layer, which in turn produces the Li2CoO2 structure, while the influence on other directions is small. It can be concluded that the formation of Li2CoO2/Li2O/Co3O4/CoO-like phases upon overlithiation of LiCoO2 (D-0.0 V electrode) has been confirmed by XANES, HRTEM, and sXRD, together with spectroscopy simulations. Hence, the overdischarging reaction can be described by the following equations: 5LiCoO2 + 3Li+ + 3e− → Li2CoO2 + Co3O4 + CoO + 3Li2O. This means that Co2+ occupies 60% in the overlithiated electrode surface, which is consistent with the results of 62.8% by XPS analysis and 66.8% by XANES simulation.

Chemical imaging analysis of D-3.0 V and D-0.0 V electrodes

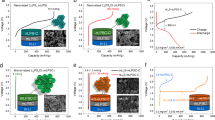

X-PEEM has excellent capability in resolving surface phase separation in practical porous composite electrodes, and consequently is a powerful tool to explore battery degradation mechanisms. The spatial distribution of different phases in the D-3.0 V and D-0.0 V electrodes has been confirmed by Co chemical mapping based on fitting the Co L3-edge PEEM image stacks, and illustrated in the red and green regions together with the Co L3-edge XANES, as shown in Fig. 2a, d, respectively. An obvious chemical phase difference in Co can be clarified by distinguishable spectral features in the over-discharged D-0.0 V electrode in Fig. 2d, and this phenomenon does not appear in the D-3.0 V electrode in Fig. 2a. As we mentioned above, the shift of the main peak at 781 eV and the appearance of a shoulder peak located at 779 eV suggest the presence of Co2+, indicating Co reduction during the over-discharge process26. In addition, the same analysis was performed on the another two regions on the D-0.0 V electrode, as shown in Fig. S7, and the same results were obtained, showing good consistency and statistics. This means that the over-discharged LiCoO2 electrode suffers from severe surface Co-reduction and phase heterogeneity. Spatially-resolved Raman spectroscopy was employed to further investigate the surface chemical heterogeneity and its relationship to the distribution of the conductive carbon additive during over-discharge, as seen in Fig. 2b (D-3.0 V electrode) and 2e (D-0.0 V electrode). The mapping images were constructed based on the band intensity of Co3O4 at 687 cm−1 and the A1g modes of LiCoO2 at 600 cm−1 41,42,43,44,45. The spatially-resolved Raman mapping images of the D-0.0 V electrode (Fig. 2e) show that more Co3O4-phase appears on the surface of the active particle (white dotted line region) and shows stronger intensity compared to that of the D-3.0 V electrode (Fig. 2b), indicating surface Co reduction and structure degradation after over-discharge, which is consistent with the above conclusion. Figure 2c, f display the Raman spectra extracted at the selected spots from Fig. 2b, e, respectively, and the composite electrodes produce Raman signals from both the LiCoO2 and the conductive carbon additive. The Raman bands between 400 and 750 cm−1 correspond to a mixed structure of the layered LiCoO2 phase and the spinel Co3O4 phase (marked as black arrows), and the bands at 1350 and 1600 cm−1 correspond to the D and G modes of the conductive carbon additive41,42. Raman spectra reveal that there is a small amount of Co3O4-like phase on the surface of the active particles in the D-3.0 V electrode, as shown in Fig. 2c. Compared to other spectra in Fig. 2f, stronger intensity of the D-band and G-band in the marked 4’ spectrum in the D-0.0 V electrode suggests it is a conductive region enriched with carbon additives46, where abundant Co3O4-like phase also forms. It can be concluded that there is a strong correlation between the formation of the Co3O4-like phase and the distribution of the conductive carbon additive. In other words, the conductive agent may accelerate the transformation of the surface structure and Co reduction of LiCoO2 during the over-discharge process and the surface of the over-discharged LiCoO2 electrode is characterized by phase heterogeneity.

a, d X-PEEM Co chemical mapping based on fitting Co L3-edge image stacks (illustrations are Co L3-edge XANES of red and green regions) of the electrode at two SOC states. b, e Bright-field reflection image (right) and Raman mapping of Co3O4 (687 cm−1 peak intensity) and LiCoO2 (A1g peak intensity) (left) of the electrode at two SOC states. c, f Raman spectra extracted at selected spots on (b, d). a–c are for the D-3.0 V electrode; d–f are for the D-0.0 V electrode.

To further explore the surface phase heterogeneity and its correlation with the conductive carbon additive and the PVDF binder, morphological and compositional mapping of the over-discharged D-0.0 V electrode was obtained by averaging the image stacks and performing on/off edge subtraction at the F, O K-edges and Co L-edge, as shown in Fig. 3. The X-PEEM elemental composite maps can be used to explore the distribution of LiCoO2 crystals with different sizes, crystalline orientation, and aggregation, together with nearby environments (PVDF and carbon black). Figure S8a shows the elemental distribution mapping of the D-0.0 V electrode by X-PEEM at individual F, O, and Co edges. Further visualization of the spatial distribution of the elements was obtained by color-coded correlation maps of individual elements derived at F (green color), O (red color), and Co (blue color) edges, as shown in Fig. 3a. O and Co are mainly constrained within LiCoO2 particles, which can be easily resolved, such as P1 and P2 in Fig. 3. Figures 3a and S5 illustrate that the P1 particle has a hexagonal-like shape with a smooth surface and extended sidewalls, suggesting that the particle has an exposed (001) facet, consistent with a previous report47,48. Furthermore, from the O and Co maps in Fig. S8, there are obvious sharp corners, edges, and lamellar shapes presented for the P2 particle, indicating that the exposed crystalline facets belong to the {010}/{100}/{110} facets, which is also displayed in the inset illustration of Fig. 3a. (Details are described in the supporting information for Fig. S8) The chemical distribution of F-containing compounds (PVDF and LiF) is shown in Fig. 3b49. It can be seen that PVDF is dispersed around or on the active particles. Compared with the P2 particle, a large amount of PVDF (red region in Fig. 3b) is enriched around the P1 particle. Meanwhile, a large amount of LiF (a component of the cathode/electrolyte interphase, green region in Fig. 3b) can be found covering the surface of the active particles and displays an inhomogeneous distribution on the electrode, implying the nature of the heterogeneous degradation of the electrode during over-discharge, which is relevant to the size, the exposed crystalline planes of LiCoO2 particles, and the distribution of binder/conductive agents.

a X-PEEM elemental composite mapping, b chemical distribution of the F-containing compounds (PVDF and LiF), c the O K-edge PCA and d Co L3-edge PCA analysis of the D-0.0 V electrode; the magnified P1 (e, f) and P2 (g, h) regions in c and d; i O K-edge and Co L3-edge XANES spectra extracted at various color regions from c and d.

Principal component analysis (PCA) is able to identify image pixels with similar spectral features, and the average of all similar pixels yields a spectrum that corresponds to a pure or mixed chemical phase27. The distribution of chemical phase and local electronic structure of the over-discharged D-0.0 V electrode can be mapped out by the O K-edge and Co L3-edge PCA analysis, as displayed in Fig. 3c–h. Figure 3e–h are enlarged views of the P1 and P2 particles. Different color regions represent different chemical phases with the different oxidation state and local electronic structure environment. The corresponding average XANES spectra at O K-edge and Co L3-edge in the different color regions were extracted from Fig. 3c–f, named as C1 to C5 phase in Fig. 3i. These XANES spectra display observable differences in chemical nature and electronic structure among these regions. The C1 phase (yellow color region) refers to the background or shadowed areas instead of active particles. In contrast, other phase regions (C2-C5) correlate well with the active particles in Fig. 3c–h, especially P1 and P2 particles, while there are large differences in the local electronic environment of O and Co between different phases, as displayed in Fig. 3i. The O pre-edge features between 529 and 532 eV reflect the hybridization of O 2p and Co 3d orbitals, and the main peaks in the range of 534-552 eV are due to transitions into O 2p hybridized with Co 4sp states. The C2 and C3 phase regions show a much lower pre-edge peak (529–532 eV) relative to the main broad features on the edge, in contrast to the C4 and C5 phases in Fig. 3i. This spectroscopic feature is a result of the lower Co-O covalence and lower Co oxidation state in C2 and C3 phases.The intensity of the Co2+ feature (~779 eV) in C2 and C3 phases is much stronger than that in the C4 and C5 phases, which confirms the above conclusion. As we discussed with regards to Fig. 1, the CoO, Li2O, Li2CoO2, and Co3O4-like phases (exclusion of LixCoO2-y) are present in the over-discharged LiCoO2 electrode, which is supported by O K-edge XANES simulation and Co L3-edge XANES spectra. According to the O edge features in conjunction with the Co L3-edge features, it can be concluded that the heterogeneity nature of over-lithiation reduction follows the order of C2/C3 phase > C4/C5 phase in the over-discharged D-0.0 V electrode. The distribution of chemical phase and local electronic structure of the discharged D-3.0 V electrode are also mapped out by O and Co edges PCA for comparison, as displayed in Fig. S9. No apparent surface phase inhomogeneity and Co reduction can be observed in the discharged D-3.0 V electrode. All the spectra of the discharged D-3.0 V electrode resemble those of LiCoO2, in which the O K-edge XANES is dominated by the Co3+ feature in the pre-edge33,50.

Additionally, such heterogeneity is also particularly evident in the spatial distribution and is closely related to the particle size and exposed crystal planes of the LiCoO2 particles, as well as to the aggregation of conductive agents and binders. The O and Co PCA map out the spatial distribution of over-lithiation (i.e., Li1+xCoO2) in the over-discharged D-0.0 V composite electrode in Fig. 3c–h. The larger P1 particle exposes the (001) facet and is surrounded by the aggregation of PVDF and carbon, showing the predominance of C2 and C3 phases, implying a severe over-lithiation reaction accompanied by a surface structure transformation of LiCoO2 to CoO/Li2O/Li2CoO2/Co3O4-like phases during the over-discharge process. In contrast, the smaller P2 particle with the {010}/{100}/{110} facets exposed mainly shows C4 and C5 phases. The results of HRTEM also confirmed these conclusions. From the HRTEM images of the overdischarged particle in Fig. 1h, it can be seen that the evolution of the surface structures generally occurs on the side parallel to the (003) crystal plane, while the sides perpendicular to the (003) crystal plane (i.e., {010} facets, perpendicular to the c-axis) still retain a better-layered structure (as shown in Fig. S10). The flat (001) facet in a perfect LiCoO2 particle is not active for intercalation/deintercalation of Li+, while the {010}/{100}/{110} facets are believed to be the active tunnels for Li+ transmission47,51. The surface phase heterogeneity of the over-discharge LiCoO2 particles, including the (001) facet of the large P1 particle in Fig. 3, could be related to the interaction of the defective surface with the aggregation of carbon and PVDF, where electrons are allowed for fast transmission under the influence of conductive carbon. The defects on the surface of LiCoO2 particles could be an intrinsic property or induced during the electrochemical formation. Such surface defects in the larger P1 particle with fast electron transmission accelerate the transformation of the surface structure and Co reduction during over-discharge. Thus, the distribution variation of CoO/Li2O/Li2CoO2/Co3O4-like phases is relevant to the size and exposed crystalline planes of LiCoO2 particles (the over-lithiated phases enriched in large particles with probable (001) facet), and the distribution of conductive carbon and PVDF. Very surprisingly, the spatial distribution map of the over-lithiation phase by O K-edge PCA is different from the map obtained by the Co L3-edge PCA, as seen in Fig. 3c, d, respectively. Based on the O K-edge and Co L3-edge XANES analysis, the C2 phase (red region) suffers from a more complete over-lithiation reaction and Co reduction than the C3 phase (green region). The amount of the over-lithiation C2 phase in the O PCA map is also lower than that in the Co PCA map. This fact may hint a different probe depth by O K-edge and Co L-edge. It can be concluded that the over-lithiation reaction and Co reduction are surface effects during discharge and its degree decreases with increasing depth. The much higher over-lithiation at surface highlights unique properties in LiCoO2 surface (thermal stability and ionic transport dynamics).

DFT calculation

To investigate the electronic structure differences between LiCoO2 and a over-lithiated Li2CoO2, a comparison of their stability in different magnetic structures was carried out. For LiCoO2, the singlet point energy difference between the low spin (LS) (t2g6eg0 with a theoretical magnetic moment of 0 μb) and high spin (HS) state (t2g4eg2 with a theoretical magnetic moment of 4 μb), namely, ELS − EHS, is -0.836 eV/f.u., indicating the LS configuration is more stable than the HS state of LiCoO2. In the case of Li2CoO2, the energy difference between LS (t2g6eg1 with a theoretical magnetic moment of 1 μb) and HS (t2g5eg2 with a theoretical magnetic moment of 3 μb) is 1.045 eV/f.u., demonstrating that the HS configuration is conducive to reduce the energy of the Li2CoO2 system. Such a phenomenon can be attributed to the relatively higher electron pair energies of LS-Li2CoO2 than its splitting energies. Moreover, the theoretical magnetic models of LiCoO2 and over-lithiated Li2CoO2 were restricted to LS and HS, respectively, in order to further investigate their total density of states (DOS) and partial density of states (PDOS). As shown in Fig. 4a, b, the O and Co states dominate the valence bands of both LiCoO2 and Li2CoO2, while the conduction bands are mainly provided by Co-O empty orbitals. Moreover, due to the strong d-d Coulomb interaction (U) in transition metal oxides, the antibonding (M–O)* band splits into one empty upper-Hubbard band (UHB) and one filled lower-Hubbard band (LHB). This splitting of Co-3d bands leads to an energy gap (Eg) of 2.136 and 2.215 eV for LiCoO2 and Li2CoO2, respectively, which is likely to determine the lower electronic conductivity of Li2CoO2 mode than that of LiCoO2 mode. This can be well explained in the above-mentioned Fig. 3, where the conductive carbon and PVDF aggregates with fast electron transmission are more likely to promote the formation of over-lithiated Li2CoO2 phase and Co reduction. Besides, the LHB of Li2CoO2 is closer to the Fermi level than that of LiCoO2, corresponding to the lower electrochemical redox potential in Li2CoO2, which implies that such phase is formed under over-discharge to a lower voltage. The Co-3d and O-2p PDOS of LiCoO2 and Li2CoO2 were also calculated and the details are displayed in Fig. S11. To obtain accurate electronic structures, we added theoretical calculations using the Heyd-Scuseria-Ernzerhof (HSE06) screened hybrid functional, in which an amount of exact Hartree-Fock exchange mixing parameter of 0.25 is used, and the results are shown in Fig. S12. However, as expected, the theory level impacts the band gap amplitude but not the global shape of the electronic band structures. Generally, the difference in electron structure will cause the change of electron transfer and then affect ionic diffusion dynamics. Thus, further calculation of the Li+ migration barrier within the Li2CoO2 and LiCoO2 frameworks was performed by using the CI-NEB method. The diffusion behavior of layered intercalation compounds has long been discussed, and two mechanisms are generally considered: oxygen dumbbell hopping (ODH) and tetrahedral site hopping (TSH)52. Previous studies showed that lithium diffusion in the early stage of charging (delithiation) was dominated by ODH52,53, so we are initially based on the isolated vacancy model and adopt the ODH mechanism to study the lithium diffusion barrier. Figure 4b, e show Li+ diffusion pathway within the octahedral Li sites of LiCoO2 and the tetrahedral Li sites of Li2CoO2 in the same Li slab, respectively. Compared with the diffusion modes of LiCoO2, the Li+ diffusion barriers of Li2CoO2, is found to be very sensitive to the local environment changes induced by lithium vacancies, as seen in Fig. 4c, f. The lowest energy barriers of Li+ diffusion for the above two diffusion modes are both obtained via Li dual-vacancies in the Li lattice as opposed to an isolated Li vacancy. Such Li dual-vacancies likely reduce the electrostatic repulsion between the diffused Li+ and its face-sharing species54. The Li2CoO2 mode has a higher activation barrier (0.672 eV) than that of the LiCoO2 mode (0.590 eV), which suggests the poorer Li+ diffusion kinetics for Li2CoO2 mode than that of LiCoO2 mode. Thus, the calculation provides a good interpretation that the over-lithiation reaction is a surface effect, and the poor ionic kinetics of Li2CoO2 further restricts the intercalation reaction of Li+ during over-discharge.

The total density of states (DOS), the partial density of states (pDOS), and the corresponding schematic energy bands in consideration of Mott-Hubbard splitting of LiCoO2 (a) and Li2CoO2 (d); The illustration of the Li+ diffusion pathways (b, e) and the calculated migration activation energy of the Li+ diffusing along with various trajectories in LiCoO2 (c) and Li2CoO2 (f). Ef represents the Fermi level, UHB for upper-Hubbard band and LHB for lower-Hubbard band.

Discussion

To summarize, synchrotron-based XANES and X-PEEM, and Raman mapping combined with XANES simulations have been applied to examine the chemical heterogeneity in a commercial discharge/over-discharge LiCoO2 composite electrodes. A combination of Co L3-edge, O K-edge XANES, and PCA analysis offers a comprehensive visualization approach in mapping out phase heterogeneous distribution at the surface of the over-discharged LiCoO2 in the practical composite electrode. It is found that the over-lithiation reaction is a surface effect with Co reduction and the heterogeneous degradation reaction of the surface structure to Li2CoO2/Co3O4/CoO/Li2O-like phases (exclusion of Li1+xCoO2-y) during over-discharge. The surface chemical heterogeneous distribution varies with the size, depth, and exposed crystalline planes of the LiCoO2 particle, and the distribution of binder PVDF/conductive carbon additive. Furthermore, DFT calculations provide strong evidence that lower electronic and ionic conductivity is present in the Li2CoO2 phase than that in the LiCoO2 phase, which further reveals the critical effect of the aggregated distribution of binder PVDF/conductive carbon additive on the surface chemical heterogeneity of the over-lithiated LiCoO2 particles during over-discharge. Our results emphasize that the surface heterogeneous nature of LiCoO2 interplays with the local environments and highlight the capability of resolving spatial chemical phase heterogeneity of XANES and PEEM for studying the degradation mechanisms of LIB electrodes.

Methods

Electrode preparation

The industry-fabricated LiCoO2/PE separator/Graphite pouch cells (2.7 Ah, provided by Zhuhai Guanyu Battery Co., Ltd, China) were used to study the over-discharged mechanism. The cathode electrode contained 97.2 wt.% LiCoO2 powders with a loading about 18.85 mg cm−2. The 2.70 Ah pouch cells were charging/discharging at 500 mA at the voltage range of 3.0–4.35 V for 10 cycles. And the cells were then further over-discharged to 0 V at 20 mA. The batteries were then disassembled under an inert environment. The cathodes were rinsed with DMC for three times and soaked in DMC for 24 h to remove the residual electrolyte, then fully dried under vacuum in a glovebox before it was transferred to PEEM in an airtight sample box for characterization.

Electrode material characterization

X-PEEM measurements were performed at the SM beamline of Canadian Light Source (CLS). The monochromatic X-ray beam was focused using an ellipsoidal mirror to a spot of ~50 μm on the sample in PEEM at a grazing incidence angle of 16°. The sample was biased at -20 kV to promote photoemission and the base pressure of the PEEM chamber was able to maintain at ~10−9 Torr after an extended time of pumping before measurement. The incident beam intensity (Io) was simultaneously recorded by measuring the photocurrent from an Au coated Si3N4 window, located in the upstream vacuum line of the PEEM main chamber, and the Io spectrum was used to normalize the acquired X-PEEM data. Image stacks for a specific FOV were acquired at the Co L-edge, and F and O K-edges with energy scan. The obtained X-PEEM data were analyzed using aXis2000 (http://unicorn.mcmaster.ca/aXis2000.html). HRTEM (JEOL JEM-2100F), EDS detector and SEM (JSM-6100LV, JEOL, Japan) were used to characterize the morphologies, element mapping and microstructures.XPS was conducted on a Thermo ScientificTM K-Alpha+TM spectrometer equipped with a monochromatic Al Kα X-ray source (1486.6 eV) operating at 100 W. Samples were analyzed under vacuum (P < 10−8 mbar) with a pass energy of 150 eV (survey scans) or 50 eV (high-resolution scans). All peaks were calibrated with the C1s peak binding energy at 284.8 eV for adventitious carbon. Synchrotron X-rays diffraction (sXRD) data was collected on the Brockhouse High Energy Wiggler beamline at the Canadian Light Source using 60.8319 keV X-rays. All data was collected in transmission mode using a Perkin Elmer area detector. For the battery experiments high-resolution diffraction data was obtained by having the high energy beam penetrate directly through the LiCoO2 pouch cell using a long sample to detector distance of ~875 mm. All data processing was done using the GSAS-II software55. To confirm distribution of the Co3O4-like spinel phase and conductive carbon additives in the LiCoO2 electrodes, confocal Raman mapping was conducted at the Saskatchewan Structural Sciences Center (SSSC). The Raman shifts were acquired with 80 points per line and 80 lines per image, using a scanning area of 40 µm × 40 µm. The mapping images were constructed with respect to the spinel-like phase band intensity of Co3O4 at 687 cm−1 and the A1g mode of LiCoO2 at 600 cm−1.

The principle component analysis and the following cluster analysis

The principle component analysis (PCA) and the following cluster analysis (CA) of the X-PEEM spectromicroscopic data of the D-0.0 V electrode sample was performed using the PCA_GUI 1.1.1 (Stony Brook University) free software56,57. First, the spectral covariance of the data was calculated by multiplication of any two X-PEEM images of the same or different photon energy to generate a spectral covariance matrix. Then, the eigenvalues, eigenspectra, and eigenimages of the covariance matrix were computed. The first eigenspectrum and eigenimage with the largest eigenvalue are just average of the entire X-PEEM image stack, while the rest significant eigenspectra and eigenimages are the corrections/variations to the average until a flat eigenvalue together with noise-level eigenspectrum and eigenimage appears. These selected eigenspectra and eigenimages were used as the principle components for the following cluster analysis, but they have abstract or no physical meaning except the first principle component. For the cluster analysis, basically a linear combination fit of the X-PEEM image stack at each pixel was performed using the selected principle components. The pixels having the same angle distance (i.e., same contribution from all the abstract principle components) were grouped and averaged to generate a color-coded X-PEEM cluster spectrum and image, which are physically and chemically meaningful. In this work, all the derived X-PEEM cluster spectra and images represent different phases or blank regions on the sample based on their spectral characteristics.

Computational details

Soft X-ray Spectroscopy Calculations for Li1+xCoO2

All calculations were performed for the O K-edge using WIEN2k36, a full-potential, all-electron DFT code. The calculation details are described in the supporting information Figure S3 and S4. Because the X-ray transition in XANES leave an O 1s core-hole in the final state, an additional calculation was performed with an explicit core-hole compensated by a background charge (to model the excited photoelectron). In our previous experience, this works quite well for accurately simulating the O K-edge XANES58,59,60. The literature suggests that over-stoichiometric Li1+xCoO2-y occurs when Li substitutes for Co (LiCo) and has an adjacent O vacancy (VO)37. So, we created a 2 × 2 × 1 LiCoO2 supercell (12 formula units of LiCoO2), substituted Li at on Co site, and removed an adjacent O, to create Li13Co11O23. The geometry of this structure was optimized using the PBE functional with the MSR1a mixing method61. After optimizing we calculated the electronic structure and O K-edge XANES using the mBJ method. The optimized calculated structure for Li2CoO2 from The Materials Project was used. The mBJ functional without a core-hole was used to simulate the O K-edge XANES. Both ferromagnetic (FM) and antiferromagnetic (AFM) structures for Li2CoO2 were tested, since Co2+ has non-zero net spin. The AFM structure is thermodynamically favorable by a very small margin (only 6 meV/unit cell) and magnetic ordering has negligible influence on the O K-edge XANES.

The electronic structures and ionic diffusion calculations of LiCoO2 and Li2CoO2 mode

Theoretical calculations for the lattice relaxations, electronic structures, and ionic diffusion were performed by using the CASTEP module of Materials Studio software package within the DFT framework62. The details are shown in the supporting information Fig. S11. Owing to considerations of precision and calculation time, supercells of Li27Co27O54 (composed of 27 units of LiCoO2), and over-lithiated Li54Co27O54 (composed of 27 units of Li2CoO2) were used for the calculation of Li+ diffusion. The minimum energy pathways of the Li+ diffusion from one lattice site to the adjacent ones were investigated by the climbing image nudged elastic band (CI-NEB) method. The internal atomic positions of the initial and final structures were both optimized before the CI-NEB calculations.

Data availability

The authors declare that all data supporting the finding of this study are available within the paper and its supplementary information files. Source data are provided with this paper.

References

Wu, F., Maier, J. & Yu, Y. Guidelines and trends for next-generation rechargeable lithium and lithium-ion batteries. Chem. Soc. Rev. 49, 1569–1614 (2020).

Canepa, P. et al. Odyssey of multivalent cathode materials: open questions and future challenges. Chem. Rev. 117, 4287–4341 (2017).

Manthiram, A. & Goodenough, J. B. Layered lithium cobalt oxide cathodes. Nat. Energy 6, 323 (2021).

Lyu, Y. et al. An overview on the advances of LiCoO2 cathodes for lithium‐ion batteries. Adv. Energy Mater. 11, 2000982 (2021).

Zhang, J. et al. Trace doping of multiple elements enables stable battery cycling of LiCoO2 at 4.6 V. Nat. Energy 4, 594–603 (2019).

Liu, Q. et al. Approaching the capacity limit of lithium cobalt oxide in lithium ion batteries via lanthanum and aluminium doping. Nat. Energy 3, 936–943 (2018).

Li, J. et al. Structural origin of the high-voltage instability of lithium cobalt oxide. Nat. Nanotechnol. 16, 599–605 (2021).

Zhitao, E. et al. Evolution of the morphology, structural and thermal stability of LiCoO2 during overcharge. J. Energy Chem. 55, 524–532 (2021).

Crompton, K. R. & Landi, B. J. Opportunities for near zero volt storage of lithium ion batteries. Energy Environ. Sci. 9, 2219–2239 (2016).

Robert, R. & Novák, P. Switch of the charge storage mechanism of LixNi0.80Co0.15Al0.05O2 at overdischarge conditions. Chem. Mater. 30, 1907–1911 (2018).

Ma, T. et al. Degradation mechanism study and safety hazard analysis of overdischarge on commercialized lithium-ion batteries. ACS Appl. Mater. Inter. 12, 56086–56094 (2020).

Erol, S., Orazem, M. E. & Muller, R. P. Influence of overcharge and over-discharge on the impedance response of LiCoO2|C batteries. J. Power Sources 270, 92–100 (2014).

Ouyang, D., Weng, J., Chen, M., Liu, J. & Wang, J. Experimental analysis on the degradation behavior of overdischarged lithium‐ion battery combined with the effect of high-temperature environment. Int. J. Energy Res. 44, 229–241 (2019).

Li, H., Gao, J. & Zhang, S. Effect of overdischarge on swelling and recharge performance of lithium ion cells. Chin. J. Chem. 26, 1585–1588 (2008).

Guo, R., Lu, L., Ouyang, M. & Feng, X. Mechanism of the entire overdischarge process and overdischarge-induced internal short circuit in lithium-ion batteries. Sci. Rep.-UK. 6, 30248 (2016).

Zhang, L. et al. Identifying the aging mechanism in multiple overdischarged LiCoO2/mesocarbon microbeads batteries. Ceram. Int. 47, 21253–21262 (2021).

Crompton, K. R., Hladky, M. P., Staub, J. W. & Landi, B. J. Enhanced overdischarge stability of LiCoO2 by a solution deposited AlPO4 coating. J. Electrochem. Soc. 164, A3214–A3219 (2017).

Shu, J. et al. A comparative study of overdischarge behaviors of cathode materials for lithium-ion batteries. J. Solid State Electrochem. 16, 819–824 (2012).

Zhan, R. et al. Promises and challenges of the practical implementation of prelithiation in lithium‐ion batteries. Adv. Energy Mater. 11, 2101565 (2021).

Liu, H. et al. A disordered rock salt anode for fast-charging lithium-ion batteries. Nature 585, 63–67 (2020).

Barnes, P. et al. Electrochemically induced amorphous-to-rock-salt phase transformation in niobium oxide electrode for Li-ion batteries. Nat. Mater. 21, 795–803 (2022).

Kosilov, V. V., Potapenko, A. V. & Kirillov, S. A. Effect of overdischarge (overlithiation) on electrochemical properties of LiMn2O4 samples of different origin. J. Solid State Electrochem. 21, 3269–3279 (2017).

Lahtinen, K. et al. Long-term cycling behavior of Mg-doped LiCoO2 materials investigated with the help of laboratory scale X-ray absorption near-edge spectroscopy. Mater. Today Energy 27, 101040 (2022).

Shu, J. et al. A new look at lithium cobalt oxide in a broad voltage range for lithium-ion batteries. J. Phys. Chem. C 114, 3323–3328 (2010).

Zhou, J. et al. Electronic structure variation of the surface and bulk of a LiNi0.5Mn1.5O4 cathode as a function of state of charge: X-ray absorption spectroscopic study. Phys. Chem. Chem. Phys. 16, 13838–13842 (2014).

Wang, J., Zhou, J., Hu, Y. & Regier, T. Chemical interaction and imaging of single Co3O4/graphene sheets studied by scanning transmission X-ray microscopy and X-ray absorption spectroscopy. Energy. Environ. Sci. 6, 926 (2013).

Sun, G. et al. In-situ surface chemical and structural self-reconstruction strategy enables high performance of Li-rich cathode. Nano Energy 79, 105459 (2021).

Sun, T. et al. Soft X-ray ptychography chemical imaging of degradation in a composite surface-reconstructed Li-rich cathode. ACS Nano 15, 1475–1485 (2021).

Yu, Y. et al. Dependence on crystal size of the nanoscale chemical phase distribution and fracture in LixFePO4. Nano Lett. 15, 4282–4288 (2015).

Shapiro, D. A. et al. Chemical composition mapping with nanometre resolution by soft X-ray microscopy. Nat. Photon. 8, 765–769 (2014).

Pfeiffer, F. X-ray ptychography. Nat. Photon. 12, 9–17 (2018).

Zhu, X. et al. Measuring spectroscopy and magnetism of extracted and intracellular magnetosomes using soft X-ray ptychography. Proc. Natl Acad. Sci. USA 113, E8219–E8227 (2016).

Wang, J., Ji, Y., Appathurai, N., Zhou, J. & Yang, Y. Nanoscale chemical imaging of the additive effects on the interfaces of high-voltage LiCoO2 composite electrodes. Chem. Commun. 53, 8581–8584 (2017).

Guo, H. et al. Enabling photoemission electron microscopy in liquids via graphene-capped microchannel arrays. Nano Lett. 17, 1034–1041 (2017).

Lu, M., Mao, Y., Wang, J., Hu, Y. & Zhou, J. Surface heterogeneity in Li0.5CoO2 within a porous composite electrode. Chem. Commun. 54, 8320–8323 (2018).

Blaha, P. et al. An augmented plane wave+ local orbital program for calculating crystal properties. http://www.wien2k.at/index.html (2001).

Levasseur, S. et al. Oxygen Vacancies and Intermediate Spin Trivalent Cobalt Ions in Lithium-Overstoichiometric LiCoO2. Chem. Mater. 15, 348–354 (2003).

Ménétrier, M., Shao-Horn, Y., Wattiaux, A., Fournès, L. & Delmas, C. Iron substitution in lithium-overstoichiometric “Li1.1CoO2”: Combined 57Fe Mössbauer and 7Li NMR spectroscopies studies. Chem. Mater. 17, 4653–4659 (2005).

Tung, C. et al. Reversible adapting layer produces robust single-crystal electrocatalyst for oxygen evolution. Nat. Commun. 6, 8106 (2015).

Shi, J. et al. High-rate and durable sulfide-based all-solid-state lithium battery with in situ Li2O buffering. Energy Storage Mater. 51, 306–316 (2022).

Chang, W. P., Lee, J. H., Seo, J. K., Jo, W. Y. & Kim, Y. J. Graphene collage on Ni-rich layered oxide cathodes for advanced lithium-ion batteries. Nat. Commun. 12, 2145 (2021).

Yang, L. et al. Anomalous thermal decomposition behavior of polycrystalline LiNi0. 8Mn0. 1Co0. 1O2 in PEO-based solid polymer electrolyte. Adv. Funct. Mater. 32, 2200096 (2022).

Ruther, R. E., Callender, A. F., Zhou, H., Martha, S. K. & Nanda, J. Raman microscopy of lithium-manganese-rich transition metal oxide cathodes. J. Electrochem. Soc. 162, A98–A102 (2014).

Sun, G. et al. Decoupling the voltage hysteresis of Li‐rich cathodes: electrochemical monitoring, modulation anionic redox chemistry and theoretical verifying. Adv. Funct. Mater. 31, 2002643 (2021).

Sun, G. et al. Local electronic structure modulation enhances operating voltage in Li-rich cathodes. Nano Energy 66, 104102 (2019).

Sethuraman, V. A., Hardwick, L. J., Srinivasan, V. & Kostecki, R. Surface structural disordering in graphite upon lithium intercalation/deintercalation. J. Power Sources 195, 3655–3660 (2010).

Wu, N. et al. Flakelike LiCoO2 with exposed {010} facets as a stable cathode material for highly reversible lithium storage. ACS Appl. Mater. Inter. 8, 2723–2731 (2016).

Balke, N. et al. Nanoscale mapping of ion diffusion in a lithium-ion battery cathode. Nat. Nanotechnol. 5, 749–754 (2010).

Zhao, X. et al. Revealing the role of poly(vinylidene fluoride) binder in Si/graphite composite anode for Li-ion batteries. ACS Omega 3, 11684–11690 (2018).

Yogi, C. et al. Soft X-ray absorption spectroscopic studies with different probing depths: Effect of an electrolyte additive on electrode surfaces. J. Power Sources 248, 994–999 (2014).

Kramer, D. & Ceder, G. Tailoring the morphology of LiCoO2: a first principles study. Chem. Mater. 21, 3799–3809 (2009).

Wei, Y. et al. Kinetics tuning of Li-ion diffusion in layered Li(NixMnyCoz)O2. J. Am. Chem. Soc. 137, 8364–8367 (2015).

Van der Ven, A. & Ceder, G. Lithium diffusion mechanisms in layered intercalation compounds. J. Power Sources 97, 529–531 (2001).

Lee, J. et al. Unlocking the potential of cation-disordered oxides for rechargeable lithium batteries. Science 343, 519–522 (2014).

Toby, B. H. & Von Dreele, R. B. GSAS-II: the genesis of a modern open-source all purpose crystallography software package. J. Appl. Crystallogr. 46, 544–549 (2013).

Lerotic, M., Jacobsen, C., Schäfer, T. & Vogt, S. Cluster analysis of soft X-ray spectromicroscopy data. Ultramicroscopy 100, 35–57 (2004).

Lerotic, M. et al. Cluster analysis in soft X-ray spectromicroscopy: Finding the patterns in complex specimens. J. Electron Spectrosc. 144-147, 1137–1143 (2005).

Liu, Y. et al. Influence of crystal phase on TiO 2 nanowire anodes in sodium ion batteries. J. Mater. Chem. A. 5, 20005–20013 (2017).

Xu, W. et al. Dissociation of methylammonium cations in hybrid organic–inorganic perovskite solar cells. Nano Lett. 16, 4720–4725 (2016).

McLeod, J. A., Skorikov, N. A., Finkelstein, L. D., Kurmaev, E. Z. & Moewes, A. Chemical Bonding and Hybridization in 5 p Binary Oxide. J. Phys. Chem. C 116, 24248–24254 (2012).

Marks, L. D. Fixed-point optimization of atoms and density in DFT. J. Chem. Theory Comput. 9, 2786–2800 (2013).

Clark, S. J. et al. First principles methods using CASTEP. Z. Kristallogr. 220, 567–570 (2005).

Acknowledgements

The research described in this paper was performed at the Canadian Light Source, a national research facility of the University of Saskatchewan, which is supported by the Canada Foundation for Innovation (CFI), the Natural Sciences and Engineering Research Council (NSERC), the National Research Council (NRC), the Canadian Institutes of Health Research (CIHR), the Government of Saskatchewan, and the University of Saskatchewan. We acknowledge the National Natural Science Foundation of China (Grant No. 51902072 (F.D.Y.) and 22075062 (Z.B.W.) and 21975212 (M.L.)), Heilongjiang Touyan Team (Grant No. HITTY-20190033 (Z.B.W.)), Heilongjiang Province “hundred million“project science and technology major special projects (2019ZX09A02; Z.B.W.), State Key Laboratory of Urban Water Resource and Environment (Harbin Institute of Technology No. 2020DX11(Z.B.W.)) and the Fundamental Research Funds for the Central Universities (Grant No. FRFCU5710051922; Z.B.W.), China postdoctoral science foundation (Grant No. 2021M702256 (G. S.)). We thank Instrument Analysis Center of Shenzhen University for the assistance with HRTEM and SEM analyses. Thanks to Dr. Graham King for his help in the XRD measurement of the battery over discharge experiment and data analysis.

Author information

Authors and Affiliations

Contributions

G.S. and F.Y. conceived the idea, designed the experiments, and wrote the manuscript. G.S., J.Z., J.W., and Z.W. carried out the electrochemical test, characterization, and analyzed the results with the help of M.L., Q.Z., Y.J., Y.M. J.M., J.M., and F.Y. conducted the DFT calculations.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sun, G., Yu, FD., Lu, M. et al. Surface chemical heterogeneous distribution in over-lithiated Li1+xCoO2 electrodes. Nat Commun 13, 6464 (2022). https://doi.org/10.1038/s41467-022-34161-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-34161-4

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.