Abstract

The development of high-temperature photodetectors can be beneficial for numerous applications, such as aerospace engineering, military defence and harsh-environments robotics. However, current high-temperature photodetectors are characterized by low photoresponsivity (<10 A/W) due to the poor optical sensitivity of commonly used heat-resistant materials. Here, we report the realization of h-BN-encapsulated graphite/WSe2 photodetectors which can endure temperatures up to 700 °C in air (1000 °C in vacuum) and exhibit unconventional negative photoconductivity (NPC) at high temperatures. Operated in NPC mode, the devices show a photoresponsivity up to 2.2 × 106 A/W, which is ~5 orders of magnitude higher than that of state-of-the-art high-temperature photodetectors. Furthermore, our devices demonstrate good flexibility, making it highly adaptive to various shaped surfaces. Our approach can be extended to other 2D materials and may stimulate further developments of 2D optoelectronic devices operating in harsh environments.

Similar content being viewed by others

Introductions

Photodetectors are considered to be the core of modern communication components. As the development of aerospace, military, underground exploration, and harsh environment robotics, photodetector capable of operating at harsh environments are highly desired. Current high-temperature photodetectors are mainly based on wide-bandgap materials, such as SiC, GaN, or Ga2O3. Their optical sensing capability is barely satisfactory. A typical SiC photodetector can endure 550 °C and its photoresponsivity (one of the most essential figures of merit for photodetector) is only 0.54 A/W1. GaN photodetector is able to operate in a wide temperature range from −196 °C to 527 °C2, but it demonstrates very low photoresponsivity of 0.02 A/W. So et al. reported a AlGaN/GaN photodetector with operation temperature of 200 °C and photoresponsivity of 5 A/W3. Zhou et al. developed a Ga2O3 photodetector with operation temperature of 200 °C and photoresponsivity of 0.1 A/W4. There is a trend that photodetectors which can endure high temperature demonstrate very low photoresponsivity. The photoresponsivity of state-of-the-art high-temperature photodetectors is usually below 10 A/W. As such, weak light detection at high temperature is challenging. Furthermore, flexibility is an important development trend for next generation photodetectors. Flexible high-temperature photodetectors are desired in many applications, such as aeroengine blade with flexible (optical) sensors attached on its curved surface, and fully adaptive soft robot working in high-temperature environment with highly flexible sensors integrated on soft artificial muscle. However, high-temperature photodetectors reported so far are rigid. Limited by the poor thermal stability of traditional flexible materials5 (polyethylene terephthalate (PET), polyimide (PI), polydimethylsiloxane (PDMS) and so forth), the temperatures that existing flexible optoelectronic devices can endure are below 300 °C6,7. Consequently, highly-sensitive high-temperature photodetectors with good flexibility are highly desired.

Two-dimensional transition metal dichalcogenides (TMDs) have drawn a great deal of attention in optoelectronics field due to their fascinating physical properties8,9 and facile preparation. They can reach monolayer or few layer by mechanical exfoliation10, liquid-phase exfoliation11, or chemical vapor deposition method12,13. Although graphene is the most well-investigated 2D material, TMDs have the advantages of higher sensitivity and lower dark current, and demonstrate remarkable optical sensing capability at room temperature. The photoresponsivity of monolayer MoS2 photodetector reaches 880 A/W14. Xie et al. reported photodetectors based on multilayer WSe2 flake with photoresponsivity of 1.5 × 105 A/W10. Monolayer WSe2 photodetector demonstrates higher photoresponsivity of 1.8 × 105 A/W12. Additionally, good mechanical properties (large fracture strain15,16) make TMDs promising channel materials for flexible photodetector. However, TMD electronic/optoelectronic devices cannot survive at high-temperature. MoS2 starts to oxidize and degrade at 300 °C in air, resulting in many triangular etch pits on its surface17,18,19. The edge of WSe2 flake begins to oxidize at 300 °C in air20. It hinders the application of TMDs in aerospace and many other harsh environments. Importantly, it hinders the exploration of optoelectronic properties of TMDs at ultrahigh temperature.

Here, we developed WSe2 photodetectors with h-BN (hexagonal boron nitride)/GF (graphite flake) heterostructure protection which can endure 700 °C in air and 1000 °C in vacuum. Unconventional negative photoconductivity (NPC) phenomenon appeared at high temperature. Operated in NPC mode, the device exhibited photoresponsivity of 2.2 × 106 A/W, which is ~105-fold higher than that of state-of-the-art high-temperature photodetectors, and even higher than that of existing WSe2 photodetectors. The photodetector demonstrated good flexibility and realized in situ high-temperature optical sensing under bending state.

Results

WSe2 photodetector fabrication and characterization

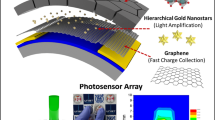

We fabricated WSe2 field-effect transistor (FET) as photodetector with h-BN encapsulation and GF source/drain electrodes (Fig. 1a) by mechanically stacking each atomic layer sequentially on freshly cleaved mica surface (Supplementary Fig. 1) followed by photolithography, Pt deposition, and lift-off for top gate fabrication. The optical microscope image of a representative WSe2 device is shown in Fig. 1c (Pt top gate is not shown). Mica substrate with thickness of ~100 μm is highly flexible (bending radius <2 mm, Fig. 1b), high-temperature-resistant, and transparent. Additionally, compared with other flexible substrates, mica provides atomically flat terraces over large areas, so 2D materials can approach the limit of atomic flatness on mica surface and get rid of the microscopic corrugations which result in carrier scattering and degradation of electrical properties21. Multilayer WSe2 flake was chosen as channel material of high-performance photodetector. Hexagonal boron nitride (h-BN) has been reported in previous work to be excellent oxygen-resistant coating22. We placed two h-BN flakes with thickness of ~50 nm on top and bottom of WSe2, respectively as high-temperature encapsulation, where top h-BN also serves as gate dielectric (Supplementary Fig. 2). The 2D material flakes were all characterized by Raman spectroscopy (Supplementary Fig. 3 and Fig. 2c). Sharp Raman peaks imply that the 2D materials studied in this work have nearly perfect lattice structures. Figure 1d is the high-resolution transmission electron microscopy (HRTEM) cross-sectional image of h-BN/GF/WSe2/h-BN van der Waals heterostructures in the WSe2 FET (Supplementary Fig. 4). The thickness of monolayer WSe2 (~0.7 nm) is consistent with reported values23,24. It can be seen clearly that the 2D materials are atomically flat and no air gap is observed at interface, indicating good encapsulation, which is essential for high-temperature protection.

a Schematic view of WSe2 photodetector with h-BN encapsulation and GF (graphite flake) electrodes on mica substrate. b Optical image of the WSe2 device on flexible mica substrate. c Optical microscopy image of the WSe2 device which is consist of 5 pieces of 2D-material flakes (Pt top gate is not shown). Dashed lines are used to indicate the outline of WSe2 (white), GF (black), bottom h-BN (blue) and top h-BN (yellow). d HRTEM cross-sectional image of h-BN/GF/WSe2/h-BN van der Waals heterostructure in WSe2 device.

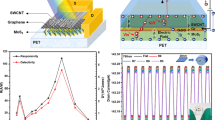

a As-fabricated WSe2 FET. Dashed lines are used to indicate the outline of WSe2 (white) and GF (black). b WSe2 FET after 700 °C heating. c Raman spectra of WSe2 with h-BN encapsulation and GF electrodes before (black) and after (red) 700 °C heating. Raman spectrum of a bare WSe2 after 500 °C heating (blue). d As-fabricated WSe2 FET with h-BN encapsulation and Pt electrodes. e WSe2 FET with Pt electrodes after 500 °C heating. Dashed lines are used to indicate the outline of WSe2 (white) and Pt electrodes (black). f HRTEM cross-sectional image of h-BN/GF interface and schematical cross-sectional view of WSe2 FET with GF electrodes. Oxygen cannot diffuse into h-BN encapsulation through h-BN/GF interface. g HRTEM cross-sectional image of h-BN/Pt interface and schematical cross-sectional view of WSe2 FET with Pt electrodes. A white dashed line is used to indicate the bottom interface outline of h-BN and top interface outline of Pt electrodes. Oxygen can diffuse into h-BN encapsulation through h-BN/Pt interface.

High-temperature-resistant capability

To investigate the high-temperature-resistant capability of our device, the WSe2 FET was heated at 500 °C, 600 °C, and 700 °C for 15 min sequentially in an open quartz furnace. The high-temperature experiments in this work were all carried out in air, unless otherwise noted. WSe2 flake protected by h-BN showed negligible change after heating (Fig. 2b, Pt top gate is not shown). Raman spectra showed E12g peak (~249 cm−1) and A1g peak (~258 cm−1) corresponding to WSe2, whereas no WO3 character peaks (~700 cm−1 or ~810 cm−1) was observed25,26,27 (Fig. 2c), implying that WSe2 was not oxidized. After 700 °C heating, flexible mica substrate was in good shape as well. Then the same device was heated at 750 °C for 15 min. The WSe2 channel still showed negligible change (Supplementary Fig. 5), but mica substrate became brittle and less transparent. As control groups, bare WSe2 and WSe2 covered with 100 nm Al2O3 (a widely used oxidation-resistant coating) by atomic layer deposition were heated at 500 °C for 15 min. In both situations, the WSe2 flakes were strongly oxidized and became almost transparent (Supplementary Fig. 6) inasmuch as WO3 is transparent under visible light. Raman spectrum shows prominent WO3 character peaks around 700 cm−1 and 810 cm−1 (Fig. 2c). Therefore, bare WSe2 has poor thermal stability, which is consistent with previous reports20. The h-BN is superior to Al2O3 as high-temperature protection layer.

Next, we investigated the high-temperature-resistant capability in vacuum of our devices. Since mica substrate cannot endure temperature above 750 °C, we replaced it with Si substrate with 300 nm SiO2 on top. We heated the WSe2 FETs at 1000 °C for 15 min in vacuum with Argon flow rate of 100 sccm. The WSe2 FET showed negligible change after heating (Supplementary Fig. 7). Raman spectrum demonstrates prominent WSe2 character peaks and no WO3 character peak, indicating that WSe2 lattice structure remained intact after heating. As a control group, bare WSe2 flake on SiO2/Si substrate completely vanished after 1000 °C heating (Supplementary Fig. 7). Therefore, the h-BN/GF structure effectively protects WSe2 at ultrahigh temperature of 1000 °C in vacuum. Dark current increased slightly after 700 °C in air and 1000 °C in vacuum annealing (Supplementary Fig. 8). The temperature that our devices can tolerate is much higher than that of current 2D material devices, both in air and vacuum environments (Table 1). Our research expands the working temperature range of 2D materials, allowing the good electrical properties of 2D materials to be applied in high-temperature environments.

Graphite flake electrodes are essential to high-temperature protection. We replaced the GF in WSe2 FET with conventional (Pt) metal electrodes (Fig. 2d). After heating at 500 °C for 10 min, WSe2 flake within different sizes of h-BN encapsulation was strongly oxidized (Fig. 2e, Supplementary Fig. 9 and Supplementary Table 1). This is because Pt film deposited by sputtering has much larger surface roughness than that of GF. Top h-BN cannot completely conform to the topography of Pt surface (HRTEM cross-sectional image in Fig. 2g), leading to oxygen molecules diffusion into h-BN encapsulation through Pt/h-BN interface. Atomic force microscopy (AFM) characterization demonstrates that the height variation of Pt surface is ~6.8 nm (Supplementary Fig. 10), while the height variation of GF measured (~0.6 nm) appears to be limited by instrument noise and is identical to that obtained from the surface of highly oriented pyrolytic graphite (HOPG) which approaches the limit of atomic flatness. As such, good contact is formed between h-BN and GF (HRTEM cross-sectional image in Fig. 2f) which can effectively prevent oxygen diffusion. To further prove the oxygen diffusion through Pt/h-BN interface, we transferred a WSe2 flake on Pt surface and covered it with h-BN. After heating at 500 °C for 15 min, WSe2 inside h-BN/Pt encapsulation was strongly oxidized (Supplementary Fig. 11). GF/WSe2/h-BN sandwich structure was prepared and tested under the same experimental condition. The WSe2 flake inside h-BN/GF encapsulation was still in good shape after heating. Therefore, GF electrode prevents oxygen diffusion and plays an important role in high-temperature protection.

High-temperature electrical properties

We systematically investigated the temperature-dependent electrical properties of the WSe2 FET in dark environment without the influence of photoexcitation. Electrical measurements were carried out below 550 °C for safety reason. Figure 3a demonstrates the transfer curves of a representative WSe2 device with channel width/length of 10 μm/5 μm (source/drain voltage Vds = 100 mV). At room temperature (20 °C), on/off ratio of 2 × 106 and subthreshold swing (SS) of 130 mV/dec were obtained (SS = dVgs/dlgIds, where Vgs is gate bias, and Ids is source/drain current). Carrier mobility derived from p branch reached ~35 cm2/V·s. The excellent room-temperature electrical performance is comparable to that of the best WSe2 field-effect transistors reported28,29. As the temperature increased, larger Ids for all values of gate voltage from −3 V to 3 V were observed, and the device demonstrated ambipolar behavior under different temperatures (Fig. 3a). Under 500 °C, the WSe2 FET still showed good transfer properties. Linear and symmetric Ids-Vds curves obtained at 500 °C further demonstrated ambipolar behavior and suggested near-ohmic contact between WSe2 and GF electrodes (Fig. 3b). Photoluminescence spectra illustrated that the bandgap of WSe2 decreased from 1.55 eV to 1.40 eV as temperature increased from 150 °C to 500 °C (Supplementary Fig. 12). Theoretically, smaller bandgap resulted in smaller on/off ratio. As temperature varied from 20 °C to 500 °C, on/off ratio of the WSe2 FET decreased from 2 × 106 to 1 × 102 (Fig. 3c). According to the equation30:

where k is Boltzmann constant, T is absolute temperature, q is the charge per carrier, \({C}_{{ox}}\) and \({C}_{s}\) are dielectric capacity and depletion capacity, respectively, higher temperature leads to larger SS. The SS of our device increased from 130 mV/dec to 600 mV/dec as the temperature varied from 20 °C to 500 °C (Fig. 3c). After 500 °C heating in air, the device was tested at room temperature again. Interestingly, due to the high temperature (500 °C) annealing, which improves WSe2/GF contact, the electrical properties of our device did not degrade but slightly improved (SS became smaller, Supplementary Fig. 13). Lower resistance of GF electrode was observed after high temperature annealing (Supplementary Fig. 14), indicating that annealing will not affect the conducting properties of GF electrode.

a Transfer curves of WSe2 FET measured under different temperatures. Ids is the drain current and Vds is voltage between drain and source. b Ids-Vds curves of WSe2 FET measured under 500 °C. Vgs is voltage between gate and source. c Ion/Ioff ratio and SS (subthreshold swing) of WSe2 FET derived under different temperatures. Ion is the on-state current and Ioff is the off-state current. d Ioff and Igs (h-BN leakage current) measured under different temperatures.

The off-state current Ioff of WSe2 FET increased from 10−12 A to 10−8 A as temperature varied from 20 °C to 500 °C (Fig. 3d). The h-BN gate dielectric leakage current (Igs) of the same device measured at the same Vgs and Vds under the same temperature was 1-2 orders of magnitude smaller than Ioff (Fig. 3d), indicating that the off-state current of WSe2 FET at high temperature is dominated by the intrinsic turn-off characteristics of WSe2 instead of h-BN leakage current. Therefore, h-BN is not only a good oxygen-resistant coating, but also an effective high-temperature dielectric layer. The remarkable high-temperature isolation properties of h-BN contribute to the high-performance of our WSe2 devices.

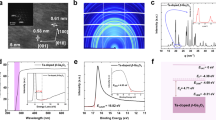

WSe2 photodetector with negative photoconductivity

We next explored the photoelectric characteristics of the WSe2 photodetectors. Under 25 W/m2 white light illumination at 20 °C, the Ids-Vgs transfer curve moved upward for all values of gate bias from −3 V to 3 V (Fig. 4b), indicating positive photoconductivity (PPC). Interestingly, under high temperature (400 °C), white light illumination resulted in a left shift of transfer curve (Fig. 4c). Larger shift was observed as light intensity increased. The N branch of transfer curve mainly demonstrated PPC, while P branch demonstrated negative photoconductivity (NPC). NPC phenomenon has been observed in low dimensional materials at room temperature31,32,33. As Vgs was set at a constant value of 3 V, Ids increased under white light illumination at 400 °C, and the WSe2 device act as a PPC photodetector (Fig. 4d). In contrast, as Vgs was set at 0 V, Ids decreased under illumination at 400 °C, and the WSe2 device act as an NPC photodetector (Fig. 4e). Therefore, high-temperature reconfigurable photodetector was realized which can switch between NPC and PPC photodetector under the same temperature by adjusting gate voltage Vgs. NPC and PPC photodetector are building blocks of photoelectric logic gate. Reconfigurability makes it a great advantage for our device to be applied to photoelectric logic gate.

a Schematical image of WSe2 photodetector under illumination. b Transfer curves of WSe2 device under white light illumination at 20 °C. c Transfer curves of WSe2 device under white light illumination at 400 °C. A white dashed line is used to distinguish the NPC device (blue area) and PPC device (orange area). d Ids-Vds curves under white light illumination at 400 °C, Vgs = 3 V. e Ids-Vds curves under illumination at 400 °C, Vgs=0 V. f Schematical views of optical sensing mechanism. At relatively low temperature, photoexcited electron-hole pairs are responsible for photocurrent (process 1). At high temperature, charge carriers have more chance to enter h-BN. Photogenerated holes trapped by the defect states in h-BN act as an equivalent positive gate bias (process 2).

To investigate the origin of the unconventional NPC phenomenon, control groups were prepared and tested under the same experimental condition: 1) WSe2 with GF electrodes and mica encapsulation (two mica flakes with the thickness of 40–60 nm were placed on top and bottom of WSe2), 2) Bare WSe2 with GF electrodes (without h-BN encapsulation), 3) Bare WSe2 with Pt electrodes (without h-BN encapsulation), 4) WSe2 with Pt electrodes and h-BN encapsulation. The high-temperature measurements were done in a short time to minimize the oxidation of WSe2. Vgs=0 V, or Vgs was not applied. The first 3 types of devices all demonstrated PPC from room temperature to 400 °C (Supplementary Figs. 15–17). Only the last type of devices demonstrated NPC at 400 °C (Supplementary Fig. 18), indicating that h-BN is responsible for the NPC phenomenon.

At relatively low temperature, photoexcited electron-hole pairs are restricted in WSe2 channel due to the excellent insulation of h-BN, and can be extracted by applying Vds. As such, the current increases after photoexcitation (process 1 in Fig. 4f). The h-BN gate dielectric leakage current increased from 10−13 A to 10−10 A as temperature varied from 20 °C to 500 °C (Fig. 3d), implying that the chance for charge carriers to enter h-BN layer significantly increases at elevated temperature. Photogenerated holes trapped by the defect states inside h-BN act as an equivalent positive gate voltage (photogating effect, process 2 in Fig. 4f), leading to a left shift of Ids-Vgs transfer curve as shown in Fig. 4c and Supplementary Fig. 19. Photogenerated charge carriers trapped by the defect state inside low-dimensional materials is one of the main reasons for NPC phenomenon34. For example, Xu et al., reported room temperature NPC phenomenon of graphene/black phosphorus heterojunction which is due to the electrons trapped in black phosphorus35.

To figure out the temperature that process 2 starts to dominate and the impact of light wavelength, we utilized 385 nm wavelength purple light (18 W/m2), 440 nm wavelength blue light (480 W/m2), and 532 nm wavelength green light (440 W/m2) to illuminate the WSe2 photodetector respectively (Vgs = 0 V) under different temperatures. The photodetector exhibited PPC at low temperatures (Fig. 5a). For all the three wavelengths, the device switched to NPC as temperature reached ~275 °C, indicating that NPC phenomenon happens in a wide wavelength range. It is worth mentioning that the NPC occurs due to the defect states inside h-BN, which means that different WSe2 photodetectors may exhibit slightly different PPC/NPC transition temperatures. The absolute value of NPC responsivity was significantly larger than that of PPC at room temperature (under 385 nm illumination, the responsivity at 400 °C was ~2000-fold higher than that at room temperature), and shorter wavelengths usually resulted in higher responsivity at the same temperature. Our devices exhibited ultrahigh responsivity of 2.2 × 106 A/W at 400 °C under 0.2 W/m2 365 nm illumination (Fig. 5b and Fig. S17). At 500 °C, we also obtained an impressive photoresponsivity of 1.1 × 106 A/W (Supplementary Fig. 20). The photoresponsivity is not only higher than that of state-of-the-art high-temperature photodetectors, but also higher than that of existing WSe2 devices (Fig. 5d). High responsivity at high temperatures results in a large signal-to-noise ratio of 152.9, which is sufficient to meet the needs of optical sensing (Supplementary Fig. 21 and Supplementary Table 2). The detectivity D* can be derived from12:

where \(A\) is the sensing area, \(R\) is the photoresponsivity, \(q\) is the unit of charge and \({I}_{{{{{{{{{{\rm{d}}}}}}}}}}}\) is the dark drain current. Our device demonstrate detectivity of 1.6 × 1013 Jones at 400 °C and 2.63 × 1012 Jones at 500 °C. The detectivity of our devices is comparable to those of state-of-the-art 2D materials, III-V materials, and Si photodetectors (Supplementary Table 3).

a Responsivity of WSe2 photodetector under 385 nm, 440 nm, and 520 nm wavelength illumination at different temperatures (Vgs = 0). Purple (385 nm light), blue (440 nm light), green (520 nm light) dashed lines are used to indicate the switch temperature of PPC and NPC phenomenon. b Responsivity as a function of Vds derived from a typical WSe2 photodetector at 400 °C. c High-temperature optical sensing under bending state (Vgs = 0). A flexible photodetector is placed on a heating rod with temperature of 450 °C. Bending radius is 3 cm. The dynamic resistance variation demonstrates negative photoconductivity. The average rise time is ~0.3 s and the recovery time is about 13 s. d Comparison of our photodetector and state-of-the-art photodetectors.

In situ high-temperature optical sensing under bending state

Flexible WSe2 photodetector with a bending radius of 3 cm was attached on a ceramic heating rod with temperature of 450 °C. We utilized 18 W/m2 385 nm wavelength light to illuminate the device (Vgs = 0 V). Its optical sensing performance is coupled with the impact of strain (~0.17%) and high temperature. The dynamic resistance variation is shown in Fig. 5c. The resistance of the device increased rapidly from 1.5 MΩ to 2.5 MΩ within 0.3 s after illumination, indicating NPC phenomenon. As the light was turned off, it took approximately 13 s for the resistance to dropped back to the dark state value. This process was repeated for over 5 times and demonstrated good repeatability. Therefore, our flexible photodetectors can adapt to non-coplanar working conditions with good optical sensing performance which cannot be achieved by conventional rigid high-temperature photodetectors.

Discussion

We developed WSe2 photodetectors which can endure temperature up to 700 °C in air and 1000 °C in vacuum. Our research greatly expands the working temperature range of 2D materials, allowing the good properties of 2D materials to be applied in high temperature environments. The device exhibited unconventional NPC phenomenon, and the photoresponsivity in NPC mode (2.2 × 106 A/W) is ~105-fold higher than that of existing high-temperature photodetectors, and also higher than that of existing WSe2 photodetectors. This work bridges the technology gap between highly-sensitive photodetectors and high-temperature photodetectors. Current high-temperature photodetectors are rigid, which largely limits their applications. Our device is both highly flexible and can endure ultrahigh temperature and thus we realized in situ high-temperature optical sensing under bending state. Our approach opens up opportunities for 2D-material devices working in harsh environment, and may stimulate fundamental research of the fascinating properties and new phenomena of 2D materials at high temperature.

Methods

Device fabrication

A freshly cleaved mica substrate was firstly immersed in acetone, alcohol, and deionized water successively for 2 min ultrasonic cleaning in order to remove possible impurities. Then, bottom h-BN (40–60 nm), WSe2 (10–20 nm), two GF electrodes and top h-BN (40–60 nm) were mechanically exfoliated using scotch tape and transferred onto mica substrate by PDMS film. The transfer process was carried out using an accurate transfer platform (Metatest, E1-T). Finally, a platinum electrode of 30 nm thick as top gate was fabricated using photolithography, metal deposition, and a lift-off process. As-fabricated devices were annealed in N2 atmosphere at 250 °C for 30 min to remove residuals between the layers.

Device characterizations

The thicknesses of the 2D materials and the surface roughness of GF and Pt were characterized by AFM (Bruker, Dimension Icon) using ScanAsyst-air mode. The Raman spectra were derived by Raman spectrometer (HORIBA Jobin Yvon, LabRAM HR Evolution) with 532 nm laser (0.325 mW/cm2) and acquisition time of 120 s. The cross-sectional images of van der Waals heterostructures and h-BN/Pt interface were characterized by high-resolution transmission electron microscopy (JEOL-2100 TEM) with acceleration voltage of 200 kV. The samples for HRTEM were prepared using Xenon focused ion beam (Helios G4). High-temperature photoluminescence (PL) spectrum was detected on a temperature-control stage (Inspec HCP621G+) by PL spectrometer (Andor KYMERA-328I-B1, grating 300 grooves/mm), and a 532 nm continuous wave laser (commercial Coherent Genesis MX, intensity = 0.05 mW) was applied.

Device measurements

The transfer characteristics and I-t characteristics of the WSe2 FETs were measured by semiconductor parameter analyzer (Agilent B1500A). The devices were fixed and tested on a temperature-control stage. For the purpose of investigating electrical characteristics of the devices under strain, we fixed it on the home-made matrix with different bending radius, and then tested it with semiconductor parameter analyzer. The dynamic resistance variation of the photodetectors was measurement by digital multimeter (Agilent 34470A). The devices were fixed and tested on a ceramic heating rod.

Data availability

Relevant data supporting the key findings of this study are available within the article and the Supplementary Information file. All raw data generated during the current study are available from the corresponding authors upon request. Source data are provided with this paper.

References

Du, F. et al. Demonstration of high-performance 4H-SiC MISIM ultraviolet photodetector with operation temperature of 550 °C and high responsivity. IEEE Trans. Electron. Devices 68, 5662–5665 (2021).

Madhusoodhanan, S. et al. High-temperature analysis of GaN-based MQW photodetector for optical galvanic isolations in high-density integrated power modules. IEEE Trans. Emerg. Sel. Top. Power Electron. 9, 3877–3882 (2020).

So, H. et al. Continuous V-grooved AlGaN/GaN surfaces for high-temperature ultraviolet photodetectors. IEEE Sens. J. 16, 3633–3639 (2016).

Zhou, H. T. et al. High-performance high-temperature solar-blind photodetector based on polycrystalline Ga2O3 film. J. Alloy. Compd. 847, 156536 (2020).

Yang, C. et al. A flexible strain sensor of Ba (Ti, Nb) O3/mica with a broad working temperature range. Adv. Mat. Technol. 4, 1900578 (2019).

Tak, B. R. et al. Wearable gallium oxide solar-blind photodetectors on muscovite mica having ultrahigh photoresponsivity and detectivity with added high-temperature functionalities. ACS Appl. Electron. Mater. 1, 2463–2470 (2019).

Lin, C. et al. A flexible solar-blind 2D boron nitride nanopaper-based photodetector with high thermal resistance. NPJ 2D Mater. Appl. 2, 1–6 (2018).

Long, M. et al. Progress, challenges, and opportunities for 2D material based photodetectors. Adv. Funct. Mater. 29, 1803807 (2019).

Zhang, W. et al. High-gain phototransistors based on a CVD MoS2 monolayer. Adv. Mater. 25, 3456–3461 (2013).

Xie, Y. et al. Enhancing electronic and optoelectronic performances of tungsten diselenide by plasma treatment. Nanoscale 10, 12436–12444 (2018).

Wang, H. et al. Transition-metal doped edge sites in vertically aligned MoS2 catalysts for enhanced hydrogen evolution. Nano Res. 8, 566–575 (2015).

Zhang, W. et al. Role of metal contacts in high-performance phototransistors based on WSe2 monolayers. ACS nano 8, 8653–8661 (2014).

Manzeli, S. et al. 2D transition metal dichalcogenides. Nat. Rev. Mater. 2, 1–15 (2017).

Lopez-Sanchez, O. et al. Ultrasensitive photodetectors based on monolayer MoS2. Nat. Nanotechnol. 8, 497–501 (2013).

Yun, W. S. et al. Thickness and strain effects on electronic structures of transition metal dichalcogenides: 2H-MX2 semiconductors (M= Mo, W; X= S, Se, Te). Phys. Rev. B 85, 033305 (2012).

Castellanos-Gomez, A. et al. Elastic properties of freely suspended MoS2 nanosheets. Adv. Mater. 24, 772–775 (2012).

Jia, F. et al. Microscale control of edge defect and oxidation on molybdenum disulfide through thermal treatment in air and nitrogen atmospheres. Appl. Surf. Sci. 462, 471–479 (2018).

Park, S. et al. Operando study of thermal oxidation of monolayer MoS2. Adv. Sci. 8, 2002768 (2021).

Spychalski, W. L. et al. Microscale insight into oxidation of single MoS2 crystals in air. J. Phys. Chem. C. 121, 26027–26033 (2017).

Liu, Y. et al. Thermal oxidation of WSe2 nanosheets adhered on SiO2/Si substrates. Nano Lett. 15, 4979–4984 (2015).

Ostendorf, F. et al. How flat is an air-cleaved mica surface? Nanotechnology 19, 305705 (2008).

Jo, S. H. et al. A high-performance WSe2/h-BN photodetector using a triphenylphosphine (PPh3)-based n-doping technique. Adv. Mater. 28, 4824–4831 (2016).

Fang, H. et al. High-performance single layered WSe2 p-FETs with chemically doped contacts. Nano Lett. 12, 3788–3792 (2012).

Liu, W. et al. Role of metal contacts in designing high-performance monolayer n-type WSe2 field effect transistors. Nano Lett. 13, 1983–1990 (2013).

Li, H., Wu, J., Yin, Z. & Zhang, H. Preparation and applications of mechanically exfoliated single-layer and multilayer MoS2 and WSe2 nanosheets. Acc. Chem. Res. 47, 1067–1075 (2014).

Santato, C. et al. Crystallographically oriented mesoporous WO3 films: synthesis, characterization, and applications. J. Am. Chem. Soc. 123, 10639–10649 (2001).

Tan, C. et al. Laser-assisted oxidation of multi-layer tungsten diselenide nanosheets. Appl. Phys. Lett. 108, 083112 (2016).

Takeyama, K. et al. Low-temperature p-type ohmic contact to WSe2 using p+-MoS2/WSe2 van der Waals interface. Appl. Phys. Lett. 117, 153101 (2020).

Ma, H. et al. In-plane epitaxial growth of 2D Co/Se-WSe2 metal-semiconductor lateral heterostructures with improved WSe2 transistors performance. InfoMat 3, 222–228 (2020).

Liu, X. et al. Monolayer WxMo1-xS2 grown by atmospheric pressure chemical vapor deposition: bandgap engineering and field effect transistors. Adv. Funct. Mater. 27, 1606469 (2017).

Yang, Y. et al. Hot carrier trapping induced negative photoconductance in InAs nanowires toward novel nonvolatile memory. Nano Lett. 15, 5875–5882 (2015).

Fan, Y. et al. Negative Electro-Conductance in Suspended 2D WS2 Nanoscale Devices. ACS Appl. Mater. Interfaces 8, 32963–32970 (2016).

Xiao, X. et al. Negative photoconductivity observed in polycrystalline monolayer molybdenum disulfide prepared by chemical vapor deposition. Appl. Phys. A 125, 1–7 (2019).

Cui, B. et al. Negative photoconductivity in low-dimensional materials. Chin. Phys. B 30, 028507 (2021).

Xu, J. et al. Graphene/black phosphorus heterostructure photodetector. Solid State Electron. 144, 86–89 (2018).

Bao, Y. et al. Flexible, heat-resistant photodetector based on MoS2 nanosheets thin film on transparent muscovite mica substrate. Nanotechnology 32, 025206 (2020).

Shah, P. B. et al. Analysis of temperature dependent hysteresis in MoS2 field effect transistors for high frequency applications. Solid State Electron 91, 87–90 (2014).

Tsai, D. S. et al. Few-layer MoS2 with high broadband photogain and fast optical switching for use in harsh environments. ACS Nano 7, 3905–3911 (2013).

Wang, B. et al. Monolayer MoS2 Synaptic Transistors for High-Temperature Neuromorphic Applications. Nano Lett. 21, 10400–10408 (2021).

Jeong, S. H. et al. Temperature-dependent electrical properties of Al2O3-passivated multilayer MoS2 thin-film transistors. Appl. Sci. 8, 424 (2018).

Lee, Y. et al. High-temperature electrical behavior of a 2D multilayered MoS2 transistor. J. Korean Phys. Soc. 64, 945–948 (2014).

Jiang, C. et al. High-temperature performance of MoS2 thin-film transistors: Direct current and pulse current-voltage characteristics. J. Appl. Phys. 117, 064301 (2015).

Goyal, N. et al. Enhanced thermally aided memory performance using few-layer ReS2 transistors. Appl. Phys. Lett. 116, 052104 (2020).

Ahmed, F. et al. Multilayer MoTe2 Field-Effect Transistor at High Temperatures. Adv. Mater. Interfaces 8, 2100950 (2021).

Šiškins, M. et al. High-temperature electronic devices enabled by hBN-encapsulated graphite flake. Appl. Phys. Lett. 114, 123104 (2019).

Shaikh, S. F. & Hussain, M. M. Multisensory graphite flake-skin for harsh-environment applications. Appl. Phys. Lett. 117, 074101 (2020).

Prakash, N. et al. Long-term, high-voltage, and high-temperature stable dual-mode, low dark current broadband ultraviolet photodetector based on solution-cast r-GO on MBE-grown highly resistive GaN. Adv. Opt. Mater. 7, 1900340 (2019).

Zou, R. et al. High detectivity solar-blind high-temperature deep-ultraviolet photodetector based on multi-layered (l00) facet-oriented β-Ga2O3 nanobelts. Small 10, 1848–1856 (2014).

Lien, W. C. et al. 4H-SiC metal-semiconductor-metal ultraviolet photodetectors in operation of 450 °C. IEEE Electron. Device Lett. 33, 1586–1588 (2012).

Hou, C., Gazoni, R. M., Reeves, R. J. & Allen, M. W. High-temperature β-Ga2O3 Schottky diodes and UVC photodetectors using RuOx contacts. IEEE Electron. Device Lett. 40, 1587–1590 (2019).

Wei, T. C. et al. See-through Ga2O3 solar-blind photodetectors for use in harsh environments. IEEE J. Sel. Top. Quantum Electron. 20, 112–117 (2014).

Acknowledgements

P. L. acknowledges financial support from National Natural Science Foundation of China (Grants No. 51775306) and Beijing Municipal Natural Science Foundation (Grants No. 4192027). The authors thank Prof. Rong Zhao for the discussion.

Author information

Authors and Affiliations

Contributions

P.L. conceived the experiments. P.L., Y.Z., and Z.Z. fabricated the devices and performed the electrical measurements. P.L., Y.Z., and J.Y. performed the photoelectrical measurements. L.L. and G.H. performed the PL measurements. P.L., Y.Z. and Y.T. analysed the results. P.L., Y.Z. and Y.T. co-wrote the manuscript. Z.Y. Supervised the project. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zou, Y., Zhang, Z., Yan, J. et al. High-temperature flexible WSe2 photodetectors with ultrahigh photoresponsivity. Nat Commun 13, 4372 (2022). https://doi.org/10.1038/s41467-022-32062-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-32062-0

This article is cited by

-

Multilayer SnS2/few-layer MoS2 heterojunctions with in-situ floating photogate toward high-performance photodetectors and optical imaging application

Science China Materials (2023)

-

Black phosphorus unipolar transistor, memory, and photodetector

Journal of Materials Science (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.