Abstract

Direct photocatalytic CO2 reduction from primary sources, such as flue gas and air, into fuels, is highly desired, but the thermodynamically favored O2 reduction almost completely impedes this process. Herein, we report on the efficacy of a composite photocatalyst prepared by hyper-crosslinking porphyrin-based polymers on hollow TiO2 surface and subsequent coordinating with Pd(II). Such composite exhibits high resistance against O2 inhibition, leading to 12% conversion yield of CO2 from air after 2-h UV-visible light irradiation. In contrast, the CO2 reduction over Pd/TiO2 without the polymer is severely inhibited by the presence of O2 ( ≥ 0.2 %). This study presents a feasible strategy, building Pd(II) sites into CO2-adsorptive polymers on hollow TiO2 surface, for realizing CO2 reduction with H2O in an aerobic environment by the high CO2/O2 adsorption selectivity of polymers and efficient charge separation for CO2 reduction and H2O oxidation on Pd(II) sites and hollow TiO2, respectively.

Similar content being viewed by others

Introduction

Photocatalytic CO2 reduction into useful fuels is a promising approach to tackle the challenges of carbon emission and global warming by directly utilizing sustainable solar energy1,2,3. Despite extensive efforts and many attempts at harnessing various semiconductor photocatalysts for CO2 reduction, most of the photocatalytic reactions occur only at high CO2 concentration and sometimes CO2-philic organic solvents are required to make them operate efficiently, due to low CO2 uptake of the photocatalysts1,2,3,4,5,6. Physisorptive microporous solids such as microporous organic polymers and metal-organic frameworks have recently emerged as promising candidates to replace aqueous amines for CO2 capture and storage7,8,9,10,11. Several reports demonstrated the integration of metals into CO2-adsorptive materials could convert diluted CO2 due to the high CO2 uptake and high reduction activity of metals during the photocatalytic reactions12,13,14. However, metal sites suffer from poor H2O oxidation activity and highly active for H2 evolution from H2O, so that these photocatalysts require addition of Ru-containing photosensitizer together with organic sacrificial reagent and solvent12,13,14, which present unsustainable and negative environmental impact issues. More importantly, anaerobic environment is essential to avoid the competitive reaction of oxygen reduction because it is thermodynamically favored compared to CO2 reduction15,16,17,18,19,20.

An ideal catalyst is capable of taking gaseous feedstocks21. In practice, the CO2 concentration in air is as low as 300~400 ppm, and flue gas after fossil fuel combustion typically consists of about 72–77 vol% N2, 12–14 vol% CO2, 8–10 vol% H2O, 3–5 vol% O2, and other minor components21,22,23,24. In air and flue gas, the CO2 adsorption and activation on the surface of photocatalysts are low, due to the competitive O2 adsorption and reduction, as well as the low CO2 concentration15,16,17,18,19,20. Catalytic CO2 reduction is strongly influenced by the presence of 5 ppm of O2 and completely inhibited in 5 vol% O2, because O2 reduction is thermodynamically favored compared to CO2 reduction20. Therefore, to control CO2 emission from exhaust gas and reduce CO2 concentration in air, developing efficient photocatalysts with selective CO2 adsorption and conversion in an aerobic environment remains a challenge.

To address the challenge, we envisioned that significantly increasing CO2 concentration around the catalytic active sites for CO2 reduction via preferential adsorption of CO2 over O2 could lessen the inhibitive impact of O2 and promoting H2O oxidation could increase CO2 conversion. High CO2 adsorption capability and selectivity of microporous polymers with heterocyclic skeleton and large π-conjugated structure can bring opportunities for directly using low concentration of CO2 without separation from aerobic mixtures if the catalytic active sites for CO2 reduction are built in the polymer. For the photocatalytic CO2 reduction with H2O in such an aerobic environment, another essential requirement is to assemble the photocatalytic sites for CO2 reduction and H2O oxidation for efficient separation of photogenerated electrons and holes, respectively. Meanwhile, H2O provides protons for reacting with the intermediates from CO2 reduction, increasing CH4 production. Electron transfer at the heterointerface between two components is required for the occurrence of CO2 reduction and H2O oxidation at different active sites in a composite structure.

In this work, a proof-of-concept study was conducted to verify this hypothesis. We prepared a porous composite photocatalyst by in situ hyper-crosslinking porphyrin-based polymers (HPP) on a hollow TiO2 surface, followed by loading Pd(II) via coordination with HPP to form the CO2 reduction sites (Pd-HPP-TiO2). Hollow TiO2 was used to increase the heterointerface between TiO2 and Pd-HPP. The choice of Pd allows us to confirm the influence of CO2 adsorption and charge separation on the reduction. The heteroatom-rich microporous structure can not only improve the capability and selectivity of CO2 adsorption in an aerobic environment but also stabilize Pd(II) sites, while anatase TiO2 surface is highly efficient for H2O oxidation with holes that generated in the valence band from the bandgap excitation. Pd-HPP-TiO2 achieves the efficient conversion of CO2 in an aerobic environment, i.e., 12 % of CO2 in air is converted after 2-h UV-visible light irradiation with a CH4 production of 24.3 μmol g−1, which is 4.5 times higher than that over Pd/TiO2. Based on the catalytic activity, we identify the active sites for photocatalytic CO2 reduction and discuss the overall reaction mechanism.

Results and discussion

Preparation of porous Pd-HPP-TiO2

The synthetic processes of porous Pd-HPP-TiO2 are depicted in Fig. 1. HPP were knitted together from 5,10,15,20-tetraphenylporphyrin (TPP) building blocks on the surface of core-shell SiO2@TiO2 with the diameter of 100–150 nm used as solid templates. The SiO2 cores were then etched by NaOH solution to produce hollow TiO2 with the thickness of about 10 nm coated by layers of HPP with the thickness of about 5–7 nm (HPP-TiO2), finally Pd(II) coordinates with the core of porphyrin unit, leading to the formation of porous Pd-HPP-TiO2 (details are provided in the Methods). The photocatalytic activity was evaluated in a gas-solid reaction without the addition of photosensitizer or organic sacrificial reagent under UV-visible light irradiation. CH4 and CO were detected as the main products, in accordance with the results from many gas-solid reactions25,26. To clarify the effect of HPP, Pd/TiO2 was synthesized as a control by photo-deposition of Pd nanoparticles on the surface of hollow TiO2.

Photocatalytic CO2 reduction

Figure 2a shows the comparison of CH4 and CO evolution rates over a series of photocatalysts in pure CO2. Hollow TiO2 presented evolution rates of 4.2 and 1.6 μmol g−1 h−1 for CH4 and CO, respectively. HPP-TiO2 caused a moderate increase of CO evolution rate, mainly arising from the introduction of an abundance of micropores on HPP, favoring the CO2 uptake. When building Pd(II) sites into HPP-TiO2, the CO2 reduction efficiency was further enhanced, reaching high evolution rates of 48.0 and 34.0 μmol g−1 h−1 (average value within 4 h) for CH4 and CO, respectively. The comparison to the reported results under similar reaction conditions suggests the excellent photocatalytic activity of porous Pd-HPP-TiO2 composite (Supplementary Table 1). The high selectivity as 59% for CH4 production over Pd-HPP-TiO2 can be attributed to the Pd(II) sites with sufficient energy overcoming the Schottky barrier with TiO2 and improving the charge separation efficiency27. In a long-term test, Pd-HPP-TiO2 showed continuous CH4 and CO production up to 20 h under UV-visible light irradiation (Supplementary Fig. 1). Although there is somewhat loss in catalytic activity, the superior performance of porous Pd-HPP-TiO2 to Pd/TiO2 during long-term photocatalytic reaction suggests that the introduction of microporous HPP greatly contributes to stabilizing Pd(II) sites. No detectable H2 during the photocatalytic reaction suggests the higher CO2 reduction selectivity than H2O reduction. It is noted that Pd-HPP exhibits the ability to catalyze the conversion of CO2 to CO, which is consistent with the reports on various metal complexes12,13,14,28. Only CH4 was produced over the photocatalysts containing TiO2. The surface of anatase TiO2 efficiently adsorbs H2O to facilitate H2O oxidation and provide protons for the CO2 reduction to yield CH429,30,31. The efficient consumption of light-generated holes on the TiO2 surface can accelerate the overall reaction.

a The evolution rates of CH4 and CO in pure CO2. b On-line monitoring of O2 evolution during the photocatalytic reaction over Pd-HPP-TiO2. c Photocurrent response during light on-off cycling. d Comparison of the CH4 evolution rates in pure CO2 and air. e The conversion yield of CO2 by measuring the CO2 concentration. f Effect of O2 concentration (vol%) in CO2/O2 gas mixture on the CH4 evolution rate. The results in (a, d, e, f) are the average values of three parallel experiments. The error bar represents the standard deviation of the measurements.

The photocatalytic CO2 reduction was confirmed by a series of control experiments, (1) dark reaction, (2) without photocatalyst, (3) in N2, and (4) isotopic label using 13CO2. No detectable product in the dark or the absence of photocatalysts indicates that the CO2 reduction proceeded as a light driven catalytic process (Fig. 2a). Upon replacing CO2 with N2, trace amounts of CH4 and CO were detected after the photocatalytic reaction (Supplementary Fig. 2), presumably due to the slight decomposition of HPP and the presence of pre-adsorbed CO2 on the photocatalyst or reactor surface. Isotopically labeled 13CO2 (13C enrichment of ≥ 97%) was used as the reactant to study the origin of products. According to the ion fragment analysis, the peaks at 2.5 min and 7.2 min in the gas chromatography could be assigned to CH4 and CO, respectively. As compared to the signals of products under 12CO2, the appearance of ion fragment peaks at m/z = 17 and 29 reveals that the produced 13CH4 and 13CO originated from 13CO2 reduction over Pd-HPP-TiO2 (Supplementary Fig. 3). The overall reaction involves CO2 reduction and H2O oxidation cycles to produce CH4, CO, and O2, respectively, but their concentration changes in the whole cycle have seldom been measured in the literature32. The in-situ monitoring of O2 evolution during the photocatalytic reaction was performed to further verify the CO2 reduction by H2O (Fig. 2b). When the experiment was conducted in the dark, low O2 concentration in the reaction remained unchanged and came from the residual air, which was not completely removed by the degassing procedure. By way of contrast, during the photocatalytic reaction, the concentration of O2 increased linearly with an evolution rate of 127 μmol g−1 h−1. Thus, the electrons (e−) being provided from the 4-e− oxidation are comparable to the total electrons for CH4 and CO production via 8-e− and 2-e− reduction processes. When UV-visible light irradiation was turned off, the O2 concentration remained constant. This result illustrates that CO2 is reduced by H2O during photocatalytic reaction over Pd-HPP-TiO2 and that the backward reaction does not take place.

As for the photocatalytic CO2 reduction, the reaction involved several steps, light absorption to generate electrons and holes in TiO2, electron transfer from the conduction band of TiO2 to Pd-HPP, electron trapping at the catalytic Pd(II) sites in Pd-HPP, reduction of the adsorbed CO2 on Pd(II) sites33. The charge separation and charge transfer efficiency were investigated by electrochemical, photochemical, and photoelectrochemical measurements. The hollow TiO2 displays a large semicircle arc at the high frequency of electrochemical impedance spectrum (EIS), indicating less electronic conductivity and larger electron transfer resistance (Rct) (Supplementary Fig. 4). The value of Rct in the EIS of HPP-TiO2 is smaller than those of both TiO2 and Pd-HPP, indicating that the interface between the polymer and TiO2 facilitates the electron transfer. The smallest value of Rct in the EIS of Pd-HPP-TiO2 illustrates the efficient interfacial electron transfer by the surface binding HPP coordinating with Pd on hollow TiO2. When coating with Pd-HPP, the photoluminescence of TiO2 was almost quenched, indicating the efficient suppression of photogenerated charge recombination through radiative pathways (Supplementary Fig. 5). The photogenerated electrons are expected to transfer from the photoexcited TiO2 to Pd(II) sites in HPP, leading to effective separation of electrons from the holes left in TiO2. In addition, the introduction of Pd enhanced the interaction with gas molecules such as O2 and CO2 from air, which also causes the quenching of photoluminescence on TiO2 surface34,35,36. Similar results for Pd/TiO2 to Pd-HPP-TiO2 in Supplementary Figs. 4 and 5 reveal that Pd in Pd-HPP contributes to the efficient charge separation. The amperometric signals provide further information on the relative efficiency of the electron transfer in the materials under UV-visible light irradiation. The electronic conductivity of Pd-HPP appears to be higher than TiO2, and Pd-HPP exhibits the lowest photocurrent among the samples (Fig. 2c). Generally, the photoinduced charge separation in organic polymers does not occur dominantly as compared with exciton migration, leading to the lower capability as redox photocatalysts37. Although Pd-HPP possesses strong absorption in the visible region (Supplementary Fig. 6), both Pd-HPP and Pd-HPP-TiO2 exhibit low photocatalytic activity for CO2 reduction under visible light irradiation, suggesting the low efficiency of charge separation in HPP (Supplementary Fig. 7). It is found that such results are comparable to the recently reported analogous polymer photocatalyst38. The comparison of visible light driven CO2 reduction to that under UV-visible light is presented in Supplementary Fig. 8. Thus, the photocatalytic CO2 reduction reaction over Pd-HPP-TiO2 depended on UV light of UV-visible light irradiation. The visible light is absorbed by HPP, and most of photons absorbed are changed to heat. When TiO2 is irradiated with UV light to generate electrons and holes in conduction band and valence band, respectively, the electrons transfer at the heterointerface to HPP with π-conjugated structure and can be trapped at Pd(II). It is well know that metals work as electron trap sites to enhance the charge separation efficiency39. The highest photocurrent of Pd-HPP-TiO2 can be attributed to the photogenerated electrons transferring from TiO2 to Pd-HPP and to be trapped at Pd. The order of gas evolution rates shown in Fig. 2a is consistent with that of the photocurrent in Fig. 2c, suggesting that efficient electron transfer in Pd-HPP is the dominant influence on the photocatalytic activity with pure CO2.

Pd in Pd-HPP increases the charge separation efficiency, while Pd does not response to the selective CO2 reduction in an aerobic environment. In pure CO2, Pd/TiO2 exhibits high activity for CH4 production with a rate of 104 μmol g−1 h−1 compared to Pd-HPP-TiO2 (48.0 μmol g−1 h−1), as shown in Fig. 2d. In the case of similar Pd loading, the higher rate over Pd/TiO2 is ascribed to Pd-HPP absorbing light in a part (Supplementary Fig. 6) and thus decreasing absorbed photon numbers by TiO2. Besides, the light-induced electron transfer from TiO2 to Pd in Pd/TiO2 is more efficient compared with that in Pd-HPP-TiO2, in which Pd sites do not directly contact with hollow TiO2. When the reaction proceeded in diluted CO2 (diluted in N2), the CH4 evolution rate over Pd/TiO2 was higher than that over Pd-HPP-TiO2 (Supplementary Fig. 9a), but the difference between them was less with decreasing the CO2 concentration (Supplementary Fig. 9b), due to the enrichment of low CO2 concentration by the abundant micropores of HPP. The activities for two photocatalysts were close each other using the synthetic gas containing 0.03 vol% CO2 (approximate concentration of air, Supplementary Fig. 9b). However, in air, the CO2 reduction was almost completely inhibited over Pd/TiO2, while it still proceeded over Pd-HPP-TiO2 with the evolution rates of 12.2 μmol g−1 h−1 and 4.9 μmol g−1 h−1 for CH4 and CO production, respectively (Fig. 2d and Supplementary Table 2). The calculated conversion yields of CO2 over two catalysts in air and a mixture of CO2 and N2 are compared in Fig. 2e. Monitoring of change in CO2 concentration is important in providing direct evidence for the CO2 conversion, but it has been seldom achieved in the literatures because the change is negligibly little in pure CO2. It is noted that the reduction efficiency in the gas mixture of 0.15 vol% CO2 in N2 is close to that in pure CO2, and the change in CO2 concentration is large enough to calculate the conversion yield, as listed in Supplementary Table 3. Pd/TiO2 is more efficient than Pd-HPP-TiO2 in an anaerobic environment, while the reverse results were observed in air; CO2 conversion yields of 12% and 2.7% over Pd-HPP-TiO2 and Pd/TiO2, respectively, after 2 h UV-visible light irradiation. The yield of 12% is the highest among the CO2 conversions in air reported in the literatures (Supplementary Table 2). The difference between the CO2 conversion yields in 0.15 vol% CO2 in N2 and air is resulted from the absence and presence of O2, respectively. Thus, we investigated the effect of O2 concentration on the photocatalytic reaction. As can be seen in Fig. 2f, for Pd/TiO2, the presence of 0.2 vol% O2 suppressed the CH4 evolution rate, and the presence of 5 vol% O2 dropped it steeply to 6% of that in pure CO25. Interestingly, the negative effect of O2 on the CH4 evolution is significantly less over Pd-HPP-TiO2: the presence of 5 vol% O2 decreased it to 46% of that in pure CO2.

Porosity and gas uptake

For heterogeneous catalysis, the reaction rate is usually proportional to the surface coverage of reactants on the catalyst, so the CO2 conversion efficiency particularly relies on the CO2 adsorption on the photocatalysts33,40,41. The surface properties including porosity as well as the CO2 adsorption capability and selectivity of as-prepared samples were investigated. As shown in Fig. 3a, the N2 adsorption-desorption isotherms of Pd-HPP and Pd-HPP-TiO2 exhibit a steep increase at relative low pressure (P/P0 < 0.001) and an obvious hysteresis at medium pressure, which indicate the existence of abundant micropores and mesopores42. This result may be due to a fast rate of hyper-crosslinking and the low degree of free packing for building blocks by Friedel-Crafts alkylation reaction. In contrast, pure hollow TiO2 shows the character of type IV isotherm with a hysteresis loop at medium pressure, which suggests the formation of mesoporous structure and gives a Brunauer–Emmett–Teller surface area (SBET) of 75 m2 g−1. Owing to the high microporosity of HPP (0.7 and 1.3 nm), Pd-HPP-TiO2 has a large surface area of 323 m2 g−1 and micropore volume of 0.22 cm3 g−1 (Supplementary Table 4). The introduction of TiO2 caused a moderate decrease of the ultra-micropore of HPP, while micropores centered at 1.3 nm were largely remained (Fig. 3b). The microporous nature of Pd-HPP-TiO2 causes the CO2 enrichment around the catalytic active Pd sites in Pd-HPP. The CO2 adsorption capability of Pd-HPP-TiO2 reaches as high as 54.0 cm3 g−1 at 1.0 bar and 273 K, which is 4.9 times higher than that of TiO2 (Fig. 3c and Supplementary Fig. 10). In contrast, the as-obtained Pd/TiO2 shows a low CO2 uptake of 6.5 cm3 g−1 under similar conditions. To study the effect of porphyrin concentration on the adsorption of CO2 and photocatalytic reaction, we have prepared porous Pd-HPP-TiO2 composites with different mass percentage of porphyrin unit by adjusting the adding amount of porphyrin monomer. The CO2 uptake of porous Pd-HPP-TiO2 composites with 53.8 and 74.9 wt% of Pd-HPP was presented in Supplementary Fig. 11. According to the adding amount of porphyrin monomer and the yield of resulted polymer, the mass percentage of porphyrin unit in Pd-HPP is calculated to be about 70.5%. Thus the molar ratios of porphyrin unit/adsorbed CO2 can be calculated and compared in Supplementary Table 5. The results suggest that the ratio of porphyrin/CO2 almost keeps constant. A little lower porphyrin/CO2 ratio in Pd-HPP-TiO2 composites than that in pure Pd-HPP is presumably due to the introduction of TiO2 slightly blocking the crosslinking of porphyrin monomer. It can be concluded that the adsorption of CO2 molecules strongly depends on the porphyrin content. Besides the CO2 adsorption, electron generation on TiO2 photocatalyst and trapping by Pd(II) sites are crucial processes that involved in the photocatalytic reactions. The result of photocatalytic CO2 reduction in Supplementary Fig. 12 reveals that there is an appropriate porphyrin content that balanced the CO2 adsorption and conversion efficiency.

The selectivity ratio of CO2/O2 over Pd/TiO2 is 3.1 calculated by initial slopes of adsorption isotherms in the low pressure region (Fig. 3d and Supplementary Fig. 13), indicating a mediocre CO2 adsorption selectivity in the presence of O2. Interestingly, Pd-HPP-TiO2 exhibits a high CO2/O2 selectivity ratio of 23.9. Moreover, CO2 has delocalized π-bonds with higher quadrupole moment (−13.4 × 10−40 C m2) than O2 ( − 1.03 × 10−40 C m2)43,44. Introducing porphyrin with a core of four pyrrole rings as the building blocks into microporous materials endows them polarizing N-containing groups and large π-conjugated structure, which could response to the enhanced interaction with CO29,10,11,45. The high affinity for CO2 instead of O2 for microporous Pd-HPP-TiO2 is consistent with the selective CO2 adsorption and reduction. Thus the photocatalytic CO2 reduction is achieved in an aerobic environment by taking the advantage of selective CO2 adsorption in microporous HPP.

Structural analysis

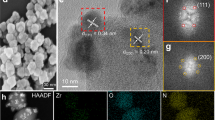

Structural characterizations provide more information for understanding the selective CO2 adsorption and conversion. Pd-HPP-TiO2 displays the X-ray diffraction (XRD) peaks of pure TiO2 anatase (Fig. 4a). No diffraction peak of Pd crystal indicates Pd (II) coordinates to the porphyrin in Pd-HPP. The observation by scanning electron microscopy (SEM) reveals the morphology of the core-shell SiO2@TiO2 to have a uniform size of 100~200 nm for template-assisted knitting of TPP (Supplementary Fig. 14). The transmission electron microscopy (TEM) and high-resolution TEM (HRTEM) images indicate that hollow TiO2 has the characteristic lattice plane of anatase TiO2 (101), coated by Pd-HPP (Fig. 4b–d and Supplementary Fig. 15). The structure of Pd-HPP-TiO2 was observed by TEM, and no Pd nanoparticle was detected in the HRTEM image, which is consistent with the XRD analysis. As further evidence, the elemental distributions were analyzed by scanning transmission electron microscopy (STEM) and energy-dispersive X-ray (EDX) mapping tests. Figure 4e–i display that hollow TiO2 is embedded in Pd-HPP with a homogeneous distribution of C, N, and Pd elements.

The chemical structure of Pd-HPP-TiO2 was investigated by Fourier transform infrared (FT-IR) absorption, solid-state 13C cross-polarization magic-angle spinning nuclear magnetic resonance (CP-MAS NMR), and X-ray photoelectron spectroscopy (XPS) measurements. As shown in FT-IR spectrum, the C-H stretching band at 2920–2960 cm−1 indicates the methylene linkage of HPP by solvent knitting (Supplementary Fig. 16)46. The broad bands of Ti-O-Ti stretching vibrations at 400–1000 cm−1 are observed for TiO2 and Pd-HPP-TiO2. The CP-MAS NMR spectrum of Pd-HPP-TiO2 indicates evidence for the hyper-crosslinking process at the molecular level. The resonance peaks at 128, 137, and 146 ppm are attributed to the carbon atoms in the benzene ring and porphyrin ring (Fig. 5a). The peak with a chemical shift at 37 ppm corresponds to the methylene linkers, indicating the successful linking of TPP via the Friedel-Crafts reaction47. The chemical states of elements were analyzed by the XPS spectrum to display the presence of C, N, Ti, O, and Pd in the corresponding samples and the coexistence of them in Pd-HPP-TiO2 (Supplementary Fig. 17). The high-resolution Pd 3d spectra in Fig. 5b show distinct doublet peaks at 343.3 and 338.1 eV, assigned to 3d5/2 and 3d3/2 of the coordinated Pd(II)48,49. In contrast, metallic Pd is predominantly observed in Pd/TiO2 XPS, together with a weak shoulder peak of the adsorbed Pd2+ that remained without reducing49,50. Combined with the Pd-N signal in N 1 s spectrum of Pd-HPP-TiO2 (Supplementary Fig. 17), it is deduced that Pd coordinates successfully with the core of the porphyrin unit as Pd(II) but not as free Pd2+ or metallic Pd. The formation of Pd-HPP on hollow TiO2 caused the binding energy of Ti 2p shifting to 0.7-eV higher energy (Supplementary Fig. 17). This shift reflects that the electron density of Ti is decreased by the electronic interaction with Pd-HPP, which is favorable for the electron transfer from TiO2 to Pd-HPP during the photocatalytic reactions under UV-visible light irradiation.

a Solid-state 13C CP-MAS NMR spectrum. b Comparison of Pd 3d XPS spectra for three photocatalysts. c Pd K-edge XANES and d Fourier transformed EXAFS spectra of Pd-HPP-TiO2 and references. e Fourier transformed EXAFS spectrum of Pd-HPP-TiO2 and fitting curve. f In situ DRIFTS test of gas adsorption on Pd-HPP-TiO2 in the dark and during the photocatalytic CO2 reduction under UV-visible light irradiation.

Synchrotron-based X-ray absorption spectroscopy was employed to provide further information on the valence state. Figure 5c shows the Pd K-edge X-ray absorption near-edge structure (XANES) spectra. The absorption edge energy of Pd-HPP-TiO2 is close to that of PdO but higher than that of Pd foil, confirming Pd(II) in Pd-HPP-TiO2. Fourier transform of the extended X-ray absorption fine structure (EXAFS) displays the main peak at 1.5 Å for Pd-HPP-TiO2 (Fig. 5d), arising from Pd-N bonding. No obvious peak was observed at the Pd-Pd position (2.5 Å) of Pd foil, indicating that Pd(II) sites were dispersed in Pd-HPP-TiO248,51. The structural parameters were obtained by the quantitative EXAFS curve fitting (Fig. 5e). Supplementary Table 6 reveals that the coordination number of Pd in Pd-HPP-TiO2 is close to 4.0, indicating that Pd(II) coordinates to four N atoms of the porphyrin. The measured Pd-N bond distance of 2.03 Å is also close to the reported results of Pd-N4 center48,49. Inductively coupled plasma mass spectrometry (ICP-MS) provides the accurate element composition, showing that the weight ratios of TiO2 and Pd were 34.4% and 2.72%, respectively (Supplementary Table 7). Meanwhile, the similar Pd content was ensured in the control (Pd/TiO2) to avoid the effect of metal amount on the photocatalytic activity. Based on the above characterizations, it is concluded that HPP is successfully formed on the surface of hollow TiO2 and then Pd(II) coordinates to the porphyrin core of HPP to form Pd-HPP-TiO2.

Photocatalytic mechanism of CO2 reduction with H2O

To clarify the reaction pathway, the reaction intermediates of CO2 adsorption and photocatalytic reduction on the surface of Pd-HPP-TiO2 were monitored by in-situ diffuse reflectance infrared Fourier transform spectra (DRIFTS). The spectra demonstrate the adsorption of CO2 and H2O on Pd-HPP-TiO2 in the dark. The absorption band in the range of 3500–3800 cm−1 are in good agreement with those assigned to the stretching vibrations of surface-bonded OH groups and H2O, suggesting the H2O adsorption on the catalyst surface (Supplementary Fig. 18)52,53. The peaks at 1740, 1690, and 1640 cm−1 can be assigned to the surface adsorbed carbonate species (Fig. 5f)54,55. Under UV-visible light irradiation, the peaks at 1690 and 1640 cm−1 were significantly weakened. Meanwhile, the peak at 1740 cm−1 first became flat at 2 min and then changed to a negative peak with prolonged irradiation, which could be explained by the existence of pre-adsorbed carbonate species on the Pd-HPP-TiO2 surface before collecting the baseline due to its high CO2 uptake. The results indicate the efficient consumption of surface carbonate during the photocatalytic reaction. Meanwhile, a new peak at 1589 cm−1 emerged in the spectra is suggested to be the C = O stretching vibration of *COOH groups, which was the vital intermediate for *CO formation and then transformed to CO and other fuels.56,57,58 According to the detailed studies on the mechanism of CO2 reduction, there are two possible pathways, i.e., one is the formaldehyde pathway and the other is the carbene pathway59,60,61. Although formaldehyde and methanol have been reported as products in some setups, they are not detected in this work. The photocatalytic CO2 reduction in the gas-solid reaction can normally form CO and CH4.25,26 Therefore, the CO2 reduction is more likely to be a carbene pathway as CO2 → COOH → CO → •C → •CH3 → CH4. The CO2 molecules are activated at Pd(II) sites in Pd-HPP and then react with the proton and electron to produce the intermediate *COOH. Subsequent reaction with the electron and proton results in the splitting of *COOH into *CO and H2O. At this time, part of CO is produced by *CO desorption. Since Pd can also function efficiently for the decomposition of H2O to generate Pd-H species62,63, the adsorbed *CO on Pd will be further react with the dissociated H to the formation of •C radicals, which can successively combine with •H radicals, thereby forming •CH, •CH2, •CH3, and finally CH4 product53,64,65,66.

The cycling experiment and related characterizations were carried out to investigate the photocatalytic sites of CH4 evolution and the stability of Pd-HPP-TiO2. As shown in Supplementary Fig. 19, Pd-HPP-TiO2 showed about 80% of the initial photocatalytic activity for the CO2 conversion after five consecutive cycles. The thermal stability of HPP is maintained up to 330 °C, as confirmed by thermogravimetric analysis (Supplementary Fig. 20). The comparison in FT-IR spectra of Pd-HPP-TiO2 before and after the photocatalytic reaction reveals no obvious change in the chemical structure of Pd-HPP (Supplementary Fig. 21). A new peak at 40.1° is observed in the XRD pattern of Pd-HPP-TiO2 after the cycling test to be assigned to Pd(0) (Supplementary Fig. 22), implying that a fraction of the coordinated Pd(II) was reduced to Pd(0) dissociating from the coordination sites to form Pd nanoparticles. XPS analysis in Supplementary Fig. 23a corroborates the reduction, leading to a decrease of the photocatalytic activity during the recycle. Such reduction suggests the electron trapped at Pd(II) for CO2 reduction67. After five cycles, ~79% Pd existed as Pd(II) owing to the coordination to the porphyrin in microporous HPP, indicating the considerable stability of Pd-HPP-TiO2 structure during the photocatalytic reaction. Pd nanoparticles are less active for the photocatalytic CO2 reduction in air (Fig. 2e), compared to Pd(II) in Pd-HPP-TiO2. Therefore, a tentative mechanism of photocatalytic CO2 reduction over Pd-HPP-TiO2 is proposed in Fig. 1. Benefiting from the high CO2 adsorption capability and selectivity of HPP, CO2 can be selectively enriched in Pd-HPP. Under UV light irradiation, the photogenerated electrons in the conduction band of TiO2 transfer efficiently to Pd-HPP, the electrons are trapped at the coordinated Pd(II) in Pd-HPP, and the adsorbed CO2 on Pd(II) is reduced to produce CH4 and CO accompanied by the recovery of Pd(II), while the holes in the valence band of TiO2 can oxidize water that adsorbed on hollow TiO2 to produce O2. The simultaneous monitoring of concentrations of CO2 (decreased), CH4, CO, and O2 (produced), corroborates the overall redox reaction over Pd-HPP-TiO2, applicable to aerobic environment, especially for flue gas with 3~5 vol% O2 and air with 300~400 ppm of CO2 and ~21 vol% O2 content.

In summary, we have demonstrated that Pd-HPP-TiO2, constructed based on higher CO2 adsorption capability than O2 and efficient charge separation for CO2 reduction and H2O oxidation, exhibits high photocatalytic activity for CO2 reduction in an aerobic environment. In the presence of 5 vol% O2, the CO2 reduction over a catalyst without HPP (Pd/TiO2) steeply drops to 6% of that in pure CO2. In contrast, the O2 inhibition is significantly less over Pd-HPP-TiO2, which maintained 46% of the CH4 evolution rate in pure CO2. Pd-HPP-TiO2 shows the photocatalytic activity even in air with the CO2 conversion yield of 12% and the CH4 production of 24.3 μmol g−1 after 2 h UV-visible light irradiation, 4.5 times higher than those over Pd/TiO2. The HPP layer effectively enriches CO2 at Pd(II) to lessen the O2 reduction. Water adsorbed on TiO2 is oxidized by the holes in the valence band of TiO2, leading to reduce the charge recombination and enhance CO2 conversion. This study presents an insight into realizing the photocatalytic selective CO2 reduction for effectively reducing CO2 concentration in air or flue gas and producing valuable solar fuels as well.

Methods

Preparation of core-shell SiO2@TiO2 and hollow TiO2 sphere

The preparation of SiO2@TiO2 was referenced in the literature68. In a 100 mL round bottom flask, a mixture containing 79 mL of ethanol, 3.9 mL of ammonia solution, and 1.4 mL of water was mixed with 1.0 g of SiO2 nanoparticles with diameter of about 100 nm to obtain a SiO2 colloidal solution. Then, 28 mL of acetonitrile was added to the above mixture with stirring at 4 °C. A solution containing 36 mL of ethanol, 12 mL of acetonitrile, and 1 mL of titanium isoporpoxide was added dropwise to the colloidal SiO2 solution. The mixture was stirred vigorously for 12 h, and the resulting white solution was dried in an oven at 80 °C. After calcining the solution at 600 °C for 6 h, core-shell SiO2@TiO2 with diameter of 100–150 nm was obtained as a white powder. Hollow TiO2 with thickness of about 10 nm were prepared by etching SiO2@TiO2 in 10 mL of 2.5 M NaOH solution for 2 days.

Preparation of Pd-HPP-TiO2

HPP-TiO2 was synthesized by an in-situ knitting method using SiO2@TiO2, 5,10,15,20-tetraphenylporphyrin (TPP), and dichloromethane (DCM, 8 mL) as a solid template, building block, and solvent, respectively. After uniform dispersion of SiO2@TiO2 and TPP in DCM, AlCl3 catalyst was added at 0 °C with constant stirring. The reaction mixture was stirred at 0 °C for 4 h, 30 °C for 8 h, 40 °C for 12 h, 60 °C for 12 h, and 80 °C for 24 h under the protection of N2 gas. Then, the sample was filtrated and washed twice with water and twice with ethanol, followed by further purification by extracting with ethanol for 2 days. Finally, the obtained solid was dried in a vacuum drying oven at 60 °C for 24 h, and etched in a 2.5 M NaOH solution for 2 days to yield HPP-TiO2. 40 mg of HPP-TiO2 or HPP was dispersed in 4 mL of acetonitrile and ultra-sounded for 5 min to obtain a homogeneous solution. Then 3 mL of H2PdCl4 solution (1.08 mg mL−1 Pd) was added and kept at 40 °C for 12 h. After the reaction stopped, the product was washed twice with water and twice with acetone, and vacuum dried at 60 °C overnight.

Preparation of Pd/TiO2 as a reference

Pd nanoparticles were deposited on the surface of hollow TiO2 from the photoreduction of Pd(II) on TiO2: 100 mg of hollow TiO2 was dispersed in 90 mL of deionized water and 10 mL of methanol. After ultrasonic treatment for 20 min, a certain amount of H2PdCl4 solution was added. Then, N2 was continuously flowed into the solution for 20 min to ensure N2-saturation. A mercury lamp was used for the photoreduction of H2PdCl4 on hollow TiO2. After the photocatalytic reaction for 4 h, the solution was centrifuged and washed three times with ethanol and twice with water, and then dried overnight in a vacuum at 60 °C to yield Pd/TiO2 as a gray powder.

Characterizations

Gas (N2, CO2, O2) adsorption-desorption isotherms were analyzed by TriStar II 3flex adsorption apparatus (Micromeritics, USA). Samples were degassed at 100 °C for 12 h under vacuum before analysis. The structure and crystallinity of the samples were characterized using X-ray diffraction (XRD) analysis on an X-Pert PRO diffractometer with Cu-Kα radiation. The field emission scanning electron microscopy (FESEM) images were recorded by using a field emission scanning electron microscope (FEI Sirion 200, USA) at 10 kV. The high-resolution transmission electron microscopy (HR-TEM) and scanning transmission electron microscopy (STEM) images of samples were recorded on Tecnai G2 F30 microscope (FEI, Holland). The FT-IR experiment was conducted on a Bruker ALPHA Fourier transform infrared spectrometer. The Solid-state 13C CP/MAS NMR spectra were tested on a WB 400 MHz Bruker Avance II spectrometer. The 13C CP/MAS NMR spectra were collected on a 4 mm double resonance MAS probe at a rotation rate of 10 kHz. X-ray photoelectron spectroscopy (XPS) was measured with a monochromatic Mg Kα source on Thermo VG scientific ESCA MultiLab-2000, and the data were calibrated according to the C (carbon) 1 s peak (binding energy = 284.6 eV). The X-ray absorption spectra were collected on the beamline BL01C1 in NSRRC, and were provided technical support by Ceshigo Research Service “www.ceshigo.com”. The radiation was monochromatized by a Si (111) double-crystal monochromator. XANES and EXAFS data reduction and analysis were processed by Athena software. The actual contents of Ti and different metals were measured by inductively coupled plasma mass spectrometry (NexION 300X, Perkin Elmer, USA). Photoluminescence (PL) emission spectra were collected by a Hitachi F-7000 spectrofluorometer at the excitation wavelength of 360 nm. UV-vis diffuse reflectance spectra (DRS) were obtained using a UV-vis spectrophotometer (UV-3600, Shimadzu, Japan). The reduction products from 13CO2 were analyzed by HP 5973 gas chromatography-mass spectrometry (GC-MS). Thermogravimetric analysis (TGA) was carried out in N2 and air from room temperature to 850 °C using the Perkin Elmer instrument Pyris1 TGA with a heating rate of 10 °C min−1. The electrochemical and photoelectrochemical properties of the sample were tested using an electrochemical workstation (CHI650E, Chenhua Com., China) with a standard three-electrode system. A Pt wire and Ag/AgCl were used as the counter and reference electrodes, respectively. 5 mg of a catalyst was dispersed into 1 mL of 1:1 isopropanol/H2O containing 10 μL of Nafion. Then, 50 μL of the above suspension was coated on an ITO glass as a working electrode. Electrochemical impedance spectra (EIS) were obtained in 0.1 M KCl electrolyte containing 5 mM Fe(CN)63−/Fe(CN)64−. Photocurrent signals were detected in 1 M Na2SO4 solution during light-on and light-off cycles.

Photocatalytic CO2 reduction

30 mg of powder sample was dispersed on the middle of the culture ware, placed in the sealed custom-made glass vessel, 10 cm away from the light source. The photocatalytic CO2 reduction reaction was performed under 1 atm of a certain atmosphere (pure CO2, CO2/O2 mixed gas, or air). 2 mL of water, as proton source for the CH4 production, was dropped to the bottom of glass vessel and vaporized on standing. The reaction mixture was irradiated using a 300 W Xenon lamp (PLS-SXE300D, Beijing Perfectlight Technology, China) as light source. The full spectrum locates in the UV-visible light region (325~780 nm), as shown in Supplementary Fig. 24. For the visible light driven experiment, a cut-off filter of 420 nm was equipped with the lamp. The generated gases were analyzed by a gas chromatography analyzer (Shimadzu GC-2014C, Japan) with a flame ionization detector (FID) and an optic fiber oxygen sensor (Ocean-Optics, UK). The yield of CO2 conversion was conducted in 0.2 vol% CO2 in N2 or air under irradiation for 4 h. To exclude the self-decomposition of samples, the sample was firstly irradiated for 4 h under N2 to confirm the stability.

Data availability

The data supporting the findings of this study are available in the paper and Supplementary Information. Source data are provided with this paper.

References

Tan, T. H. et al. Unlocking the potential of the formate pathway in the photo-assisted Sabatier reaction. Nat. Catal. 3, 1034–1043 (2020).

Li, X., Yu, J., Jaroniec, M. & Chen, X. Cocatalysts for selective photoreduction of CO2 into solar fuels. Chem. Rev. 119, 3962–4179 (2019).

Jiang, Z. et al. Filling metal-organic framework mesopores with TiO2 for CO2 photoreduction. Nature 586, 549–554 (2020).

Lu, K.-Q. et al. Rationally designed transition metal hydroxide nanosheet arrays on graphene for artificial CO2 reduction. Nat. Commun. 11, 5181 (2020).

Xu, F. et al. Unique S-scheme heterojunctions in self-assembled TiO2/CsPbBr3 hybrids for CO2 photoreduction. Nat. Commun. 11, 4613 (2020).

Wang, G. et al. Photoinduction of Cu single atoms decorated on UiO-66-NH2 for enhanced photocatalytic reduction of CO2 to liquid fuels. J. Am. Chem. Soc. 142, 19339–19345 (2020).

Wu, H. et al. Metal-organic frameworks decorated cuprous oxide nanowires for long-lived charges applied in selective photocatalytic CO2 reduction to CH4. Angew. Chem. Int. Ed. 60, 8455–8459 (2021).

Wang, S. et al. Porous hypercrosslinked polymer-TiO2-graphene composite photocatalysts for visible-light-driven CO2 conversion. Nat. Commun. 10, 676 (2019).

Kanti, D. S., Piyali, B., Kundu, S. K., Saptarsi, M. & Asim, B. Role of surface phenolic-OH groups in N-rich porous organic polymers for enhancing the CO2 uptake and CO2/N2 selectivity: experimental and computational studies. ACS Appl. Mater. Interfaces 10, 23813–23824 (2018).

Alahmed, A. H., Briggs, M. E., Cooper, A. I. & Adams, D. J. Post-synthetic fluorination of scholl-coupled microporous polymers for increased CO2 uptake and selectivity. J. Mater. Chem. A 7, 549–557 (2019).

Comesaña-Gándara, B. et al. Redefining the robeson upper bounds for CO2/CH4 and CO2/N2 separations using a series of ultrapermeable benzotriptycene-based polymers of intrinsic microporosity. Energy Environ. Sci. 12, 2733–2740 (2019).

Han, B. et al. Nickel metal-organic framework monolayers for photoreduction of diluted CO2: metal-node-dependent activity and selectivity. Angew. Chem. Int. Ed. 57, 16811–16815 (2018).

Wang, Y. et al. Hydroxide ligands cooperate with catalytic centers in metal-organic frameworks for efficient photocatalytic CO2 reduction. J. Am. Chem. Soc. 140, 38–41 (2018).

Zhong, W. et al. A covalent organic framework bearing single Ni sites as a synergistic photocatalyst for selective photoreduction of CO2 to CO. J. Am. Chem. Soc. 141, 7615–7621 (2019).

Wu, X. et al. Photocatalytic CO2 conversion of M0.33WO3 directly from the air with high selectivity: insight into full spectrum-induced reaction mechanism. J. Am. Chem. Soc. 141, 5267–5274 (2019).

Saito, D., Yamazaki, Y., Tamaki, Y. & Ishitani, O. Photocatalysis of a dinuclear Ru(II)-Re(I) complex for CO2 reduction on a solid surface. J. Am. Chem. Soc. 142, 19249–19258 (2020).

Dilla, M., Schlögl, R. & Strunk, J. Photocatalytic CO2 reduction under continuous flow high-purity conditions: quantitative evaluation of CH4 formation in the steady-state. ChemCatChem 9, 696–704 (2017).

Yu, X. et al. Eosin Y-functionalized conjugated organic polymers for visible-light-driven CO2 reduction with H2O to CO with high efficiency. Angew. Chem. Int. Ed. 58, 632–636 (2019).

Dilla, M., Jakubowski, A., Ristig, S., Strunk, J. & Schlogl, R. The fate of O2 in photocatalytic CO2 reduction on TiO2 under conditions of highest purity. Phys. Chem. Chem. Phys. 21, 15949–15957 (2019).

Lu, X. et al. A bio-inspired O2-tolerant catalytic CO2 reduction electrode. Sci. Bull. 64, 1890–1895 (2019).

Wagner, A., Sahm, C. D. & Reisner, E. Towards molecular understanding of local chemical environment effects in electro- and photocatalytic CO2 reduction. Nat. Catal. 3, 775–786 (2020).

Kajiwara, T. et al. Photochemical reduction of low concentrations of CO2 in a porous coordination polymer with a ruthenium (II)-CO complex. Angew. Chem. Int. Ed. 55, 2697–2700 (2016).

Kang, S. & Lee, H. Recovery of CO2 from flue gas using gas hydrate: thermodynamic verification through phase equilibrium measurements. Environ. Sci. Technol. 34, 4397–4400 (2000).

Markewitz, P. et al. Worldwide innovations in the development of carbon capture technologies and the utilization of CO2. Energy Environ. Sci. 5, 7281–7305 (2012).

Li, H. et al. Selective visible-light-driven photocatalytic CO2 reduction to CH4 mediated by atomically thin CuIn5S8 layers. Nat. Energy 4, 690–699 (2019).

Bian, J. et al. Dimension-matched Zinc phthalocyanine/BiVO4 ultrathin nanocomposites for CO2 reduction as efficient wide-visible-light-driven photocatalysts via a cascade charge transfer. Angew. Chem. Int. Ed. 58, 10873–10878 (2019).

Blommaerts, N. et al. Tuning the turnover frequency and selectivity of photocatalytic CO2 reduction to CO and methane using platinum and palladium nanoparticles on Ti-Beta zeolites. Chem. Eng. J. 410, 128234 (2021).

Li, Y. et al. Facile top-down strategy for direct metal atomization and coordination achieving a high turnover number in CO2 photoreduction. J. Am. Chem. Soc. 142, 19259–19267 (2020).

Zheng, Z. et al. Correlation of the catalytic activity for oxidation taking place on various TiO2 surfaces with surface OH-groups and surface oxygen vacancies. Chem. Eur. J. 16, 1202–1211 (2010).

Corma, A. & Garcia, H. J. Photocatalytic reduction of CO2 for fuel production: Possibilities and challenges. J. Catal. 308, 168–175 (2013).

Mori, K., Yamashita, H. & Anpo, M. Photocatalytic reduction of CO2 with H2O on various titanium oxide Photocatalysts. RSC Adv. 2, 3165–3172 (2012).

Kamat, P. V. & Jin, S. Semiconductor photocatalysis: “ tell us the complete story! ACS Energy Lett. 3, 622–623 (2018).

Chang, X., Wang, T. & Gong, J. CO2 photo-reduction: in-sights into CO2 activation and reaction on surfaces of photocatalysts. Energy Environ. Sci. 9, 2177–2196 (2016).

Anpo, M. et al. Applications of photoluminescence techniques to the characterization of solid surfaces in relation to adsorption, catalysis, and photocatalysis. Adv. Catal. 44, 119–257 (1999).

Anpo, M. et al. Photoluminescence of zinc oxide powder as a probe of electron-hole surface processes. J. Phys. Chem. 88, 5556–5560 (1984).

Anpo, M. et al. Photocatalytic reduction of CO2 with H2O on titanium oxides anchored within micropores of zeolites: effects of the structure of the active sites and the addition of Pt. J. Phys. Chem. B 101, 2632–2636 (1997).

Lan, Z.-A. et al. Reducing the exciton binding energy of donor-acceptor based conjugated polymers to promote charge-induced reactions. Angew. Chem. Int. Ed. 58, 10236–10240 (2019).

Schukraft, G. E. M. et al. Hypercrosslinked polymers as a photocatalytic platform for visible-light-driven CO2 photoreduction using H2O. ChemSusChem 14, 1720–1727 (2021).

Zhang, H. et al. Isolated cobalt centers on W18O49 nanowires perform as a reaction switch for efficient CO2 photoreduction. J. Am. Chem. Soc. 143, 2173–2177 (2021).

Singh, G. et al. Emerging trends in porous materials for CO2 capture and conversion. Chem. Soc. Rev. 49, 4360–4404 (2020).

Xia, C., Wang, H., Kim, J. K. & Wang, J. Rational design of metal oxide-based heterostructure for efficient photocatalytic and photoelectrochemical systems. Adv. Funct. Mater. 31, 2008247 (2021).

Thommes, M. et al. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 87, 1051–1069 (2015).

Graham, C., Pierrus, J. & Raab, R. E. Measurement of the electric quadrupole moments of CO2, CO and N2. Mol. Phys. 67, 939–955 (1989).

Couling, V. W. & Ntombela, S. S. The electric quadrupole moment of O2. Chem. Phys. Lett. 614, 41–44 (2014).

Chen, L., Cao, F. & Sun, H. Ab initio study of the π-π interactions between CO2 and benzene, pyridine, and pyrrole. Int. J. Quantum Chem. 113, 2261–2266 (2013).

Wang, S. et al. Layered microporous polymers by solvent knitting method. Sci. Adv. 3, 1602610 (2017).

Wang, S. et al. A novel metalporphyrin-based microporous organic polymer with high CO2 uptake and efficient chemical conversion of CO2 under ambient conditions. J. Mater. Chem. A 5, 1509–1515 (2017).

He, Q. et al. Accelerating CO2 electroreduction to CO over Pd single-atom catalyst. Adv. Funct. Mater. 30, 2000407 (2020).

Zhou, S. et al. Pd single-atom catalysts on nitrogen-doped graphene for the highly selective photothermal hydrogenation of acetylene to ethylene. Adv. Mater. 31, 1900509 (2019).

Selishchev, D. S. et al. Deposition of Pd nanoparticles on TiO2 using a Pd(acac)2 precursor for photocatalytic oxidation of CO under UV-LED irradiation. Appl. Catal. B-Environ. 235, 214–224 (2018).

Yan, H. et al. Single-atom Pd1/Graphene catalyst achieved by atomic layer deposition: remarkable performance in selective hydrogenation of 1,3-Butadiene. J. Am. Chem. Soc. 137, 10484–10487 (2015).

Long, R. et al. Isolation of Cu atoms in Pd lattice: forming highly selective sites for photocatalytic conversion of CO2 to CH4. J. Am. Chem. Soc. 139, 4486–4492 (2017).

Neaţu, Ş., Maciá-Agulló, J. A., Concepción, P. & Garcia, H. Gold-copper nanoalloys supported on TiO2 as photocatalysts for CO2 reduction by water. J. Am. Chem. Soc. 136, 15969–15976 (2014).

Zhang, H. et al. An unprecedent hydride transfer pathway for selective photocatalytic reduction of CO2 to formic acid on TiO2. Appl. Catal. B-Environ. 284, 119692 (2021).

Sheng, J. et al. Identification of halogen-associated active sites on bismuth-based perovskite quantum dots for efficient and selective CO2-to-CO photoreduction. ACS Nano 14, 13103–13114 (2020).

Zhu, J. et al. Asymmetric triple-atom sites confined in ternary oxide enabling selective CO2 photothermal reduction to acetate. J. Am. Chem. Soc. 143, 18233–18241 (2021).

Di, J. et al. Surface local polarization induced by bismuth-oxygen vacancy pairs tuning non-covalent interaction for CO2 photoreduction. Adv. Energy Mater. 11, 2102389 (2021).

Wang, S. et al. Intermolecular cascaded π-conjugation channels for electron delivery powering CO2 photoreduction. Nat. Commun. 11, 1149 (2020).

Rawool, S. A. et al. Defective TiO2 for photocatalytic CO2 conversion to fuels and chemicals. Chem. Sci. 12, 4267 (2021).

Habisreutinger, S. N. et al. Photocatalytic reduction of CO2 on TiO2 and other semiconductors. Angew. Chem. Int. Ed. 52, 7372–7408 (2013).

Ji, Y. F. et al. Theoretical study on the mechanism of photoreduction of CO2 to CH4 on the anatase TiO2 (101) surface. ACS Catal. 6, 2018–2025 (2016).

Gao, D. et al. Pd-containing nanostructures for electrochemical CO2 reduction reaction. ACS Catal. 8, 1510–1519 (2018).

Fan, Z. et al. Synthesis of 4H/fcc noble multimetallic nanoribbons for electrocatalytic hydrogen evolution reaction. J. Am. Chem. Soc. 138, 1414 (2016).

Anpo, M. et al. Photocatalytic reduction of CO2 with H2O on various titanium oxide catalysts. J. Electroanal. Chem. 396, 21–26 (1995).

Fan, J. et al. Insight into synergetic mechanism of Au@Pd and oxygen vacancy sites for coupling light-driven H2O oxidation and CO2 reduction. J. Catal. 378, 164–175 (2019).

Liu, J. et al. Mechanism of CO2 photocatalytic reduction to methane and methanol on defected anatase TiO2 (101): A DFT study. J. Phys. Chem. C. 123, 3505–3511 (2019).

Han, N. et al. Supported cobalt polyphthalocyanine for high-performance electrocatalytic CO2 reduction. Chem 3, 652–664 (2017).

Son, S., Hwang, S. H., Kim, C., Yun, J. & Jang, J. Designed synthesis of SiO2/TiO2 core/shell structure as light scattering material for highly efficient dye-sensitized solar cells. ACS Appl. Mater. Interfaces 5, 4815–4820 (2013).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (22122602, 21771070, 22161142005) and the Fundamental Research Funds for the Central Universities (2019KFYRCPY104, 2018KFYYXJJ120). We thank the Analysis and Testing Center, Huazhong University of Science and Technology for the characterization of materials.

Author information

Authors and Affiliations

Contributions

J.W. conceived the project and designed the experiments. Y.M. and X.Y. performed the experiments and analyzed the data. S.W. helped the synthesis. T.L. and B.T. discussed the results. C.C. designed the photocatalytic tests. B.T., C.C., T.M., E.R.W. and H.Z. helped in improving the manuscript. Y.M., J.W., and H.Z. co-wrote the manuscript.

Corresponding author

Ethics declarations

Materials availability

Correspondence and requests for materials should be addressed to J.W

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Masakazu Anpo and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ma, Y., Yi, X., Wang, S. et al. Selective photocatalytic CO2 reduction in aerobic environment by microporous Pd-porphyrin-based polymers coated hollow TiO2. Nat Commun 13, 1400 (2022). https://doi.org/10.1038/s41467-022-29102-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-29102-0

This article is cited by

-

Bifunctional core–shell co-catalyst for boosting photocatalytic CO2 reduction to CH4

Nano Research (2024)

-

Spherical cationic polymer networks with porphyrin photosensitizer for sustainable and efficient photocatalysis

Nano Research (2024)

-

CO2 photocatalytic reduction with robust and stable metal–organic framework: a review

Materials for Renewable and Sustainable Energy (2024)

-

Interfacial interaction promoted titanium oxide-based organic-inorganic nanoheterojunctions by chiral host-guest binding

Communications Materials (2023)

-

Photocatalytic CO2 reduction

Nature Reviews Methods Primers (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.