Abstract

Despite the widespread applications of 2-(hetero)aryl N-heteroarenes in numerous fields of science and technology, universal access to such compounds is hampered due to the lack of a general method for their synthesis. Herein, by a H2O-mediated H2-evolution cross-coupling strategy, we report an iridium(III)-catalyzed facile method to direct α-arylation of N-heteroarenes with both aryl and heteroaryl boronic acids, proceeding with broad substrate scope and excellent functional compatibility, oxidant and reductant-free conditions, operational simplicity, easy scalability, and no need for prefunctionalization of N-heteroarenes. This method is applicable for structural modification of biomedical molecules, and offers a practical route for direct access to 2-(hetero)aryl N-heteroarenes, a class of potential cyclometalated C^N ligands and N^N bidentate ligands that are difficult to prepare with the existing α-C-H arylation methods, thus filling an important gap in the capabilities of synthetic organic chemistry.

Similar content being viewed by others

Introduction

2-(Hetero)aryl N-heteroarenes represent a class of important compounds in numerous fields of science and technology, as they are extensively applied for the development of bioactive molecules, drugs, functional materials, ligands, and chemosensors1,2,3. For instance, N-Heteroarenes 1-3 illustrated exhibit diverse interesting bioactivities (Fig. 1)4,5,6. Selexipag (uptravi) 4 as a top-selling drug is used for the treatment of cardiovascular diseases7,8. 2-Pyridyl N-heteroarenes 5 possess unique binding capability towards various metals, which make them highly useful bidentate ligands in catalysis and organometallic chemistry9,10,11. In addition, 2-aryl N-heteroarenes also play a key role in photochemistry and functional materials12,13,14,15,16,17, as they can serve as C^N ligands to generate cyclometalated complexes with diverse photophysical properties (Fig. 1 example 6).

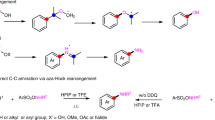

Due to the widespread applications, the introduction of (hetero)aryl groups to the α-site of N-heteroarenes is of significant importance, as it enables key step to access various desired 2-(hetero)aryl N-heteroarenes. Conventionally, such compounds are synthesized by Pd-catalyzed Suzuki cross-coupling of 2-halogenated N-heteroarenes with arylboronic acids18. However, the halo substrates used are often hard to prepare due to the difficulties in the control of the chemo- and regioselectivity during the halogenation processes. Later, the C–C cross-coupling at C2-position of quinolines or related N-heterocycles was achieved with ArZnEt and Ni(0) catalyst19,20, or with ArMgX by using Fe(III)21or Co(II) catalyst22,23, or preferentially with aryl bromides in the presence of Rh(I) catalyst but at 175–190 °C24,25 (Fig. 2a). Nevertheless, the need for high reaction temperatures or stringent protecting operations toward air and moisture-sensitive organometallic agents limit the practicality of these synthetic protocols. In recent years, Minisci-type radical coupling has also been nicely employed to arylate the α-C–H bond of N-heteroarenes (Fig. 2b)26,27,28,29,30,31, but the related transformations generally produce several regioisomers, and consume excess of less environmentally benign oxidants (K2S2O8 and Selectfluor). The substrates containing oxidant-sensitive groups (e.g., –NR2 and –SR) do not allow to afford the desired products. Moreover, all the above-described α-C-H arylation protocols19,20,21,22,23,24,25,26,27,28,29,30,31 are incompatible with heteroaryl bromides, metallic agents, and carboxylates, thus the preparation of 2-heteroaryl N-heteroarenes including N^N bidentate ligands is restricted. In this context, there is a high demand for strategies enabling the direct and efficient introduction of both aryl and heteroaryl groups into the α-site of N-heteroarenes, preferably with readily available and stable feedstocks 32,33.

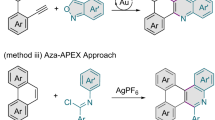

Inspired by our recent discovery of hydrogen-transfer-mediated α-functionalization of 1,8-Naphthyridines with tetrahydroquinolines under iridium catalysis (Fig. 3a)34, we were motivated to test a reductive α-arylation of non-activated quinoline A1 with p-tolyboronic acid B1. However, with the same iridium(III) catalyst system, the reaction of A1 and B1 in t-amyl alcohol employing different reductants (such as i-PrOH35,36,37, NH3BH338, Hantzsch esters39,40, HCO2H41, and HCO2Na42,43) all failed to afford the desired 2-aryl tetrahydroquinoline C1′ (Fig. 3b). Interestingly, the absence of reductant resulted in the production of 2-(p-tolyl)quinoline C1 in 22% yield at 110 °C.

Here, we wish to report a practical iridium-catalyzed direct α-arylation of N-heteroarenes with both aryl and heteroarylboronic acids by a H2O-mediated hydrogen-evolution cross-coupling strategy (Fig. 3c), which offers a practical platform for direct structural modification of pyridine-containing molecules including drugs and functional materials, and facile preparation of N-heteroarene bidentate ligands as well.

Results

Investigation of reaction conditions

Initially, we wished to screen an efficient reaction system and the coupling of substrates A1 and B1 was chosen as a model system to evaluate different parameters (Table 1). At first, the reaction in t-amyl alcohol was performed at 110 °C for 24 h by testing different catalyst precursors (Ir(III), Ir(I), Ru(0), and Pd(II)). [Cp*IrCl2]2 exhibited the best performance to afford product C1 in 22% yield (entries 1–4). So, [Cp*IrCl2]2 was utilized to further evaluate a series of additives (entries 5–8), the results showed that the bases had a detrimental effect on the reaction (entries 5 and 6), whereas amino acids, such as glycine and L-proline, significantly improved the product yields, and the use of 20 mol% L-proline showed to be the best choice (entries 7 and 8). Then, we tested different solvents, we noticed that the reaction performed in dry 1,4-dioxane failed to produce any product C1 (entry 9), whereas the use of aqueous solution significantly increased the product yield to 60% (entry 10), which clearly implies that the presence of H2O plays a decisive role on the product formation. Interestingly, the mixed solution of H2O and 1,4-dioxane (v/v = 10/1) further improved the yield to 72% (entry 11). However, change of volume ratios was unable to further increase the product yield (entry 12). In comparison, H2O in combination with other solvents in a volume ratio of 10: 1 showed to be inferior to the mixed solution of H2O and 1,4-dioxane (entries 13–15). Decrease or increase of the reaction temperature also failed to improve the reaction efficiency (entry 16). The blank experiments indicated that only the presence of both [Cp*IrCl2]2 and L-proline can constitute an efficient catalyst system (entries 17 and18). Finally, the application of other iridium catalysts showed that they were inferior to [Cp*IrCl2]2 (entry 19). Hence, the optimal conditions are as shown in entry 11 when the reaction is performed in mixed H2O and 1,4-dioxane solution (v/v = 10/1) at 110 °C for 24 h in the presence of 1 mol% of [Cp*IrCl2]2 and 20 mol% of L-proline.

Substrate scope

With the optimal reaction conditions in hand, we then examined the generality of the synthetic method. First, quinoline A1 in combination with a wide array of arylboronic acids B (see Supplementary Fig. 1 in Supplementary Information (SI) for structural information) were examined. As illustrated in Fig. 4, all the reactions proceeded smoothly and furnished the desired products in good to excellent isolated yields (C2–C28), these products have the potential to serve as C^N ligands and generate cyclometalates16,17. Interestingly, a variety of functionalities (i.e., alkyl, –OMe, –SMe, –F, –Cl, –Br, –SiMe3, –COMe, –CO2Et, –CF3, –NO2, acetal, –OPh, and–NPh2) on the aryl rings of boronic acids were well tolerated, and the retention of these functional groups offers the potential for molecular complexity via further chemical transformations. In general, arylboronic acids bearing electron-donating groups (C4–C6, C8–C9, and C20–C22) afforded the products in higher yields than those of arylboronic acids with strong electron-withdrawing groups (C15–C19), implying that the reaction involves a nucleophilic coupling step. Besides, ortho-substituted arylboronic acids resulted in relatively lower yields (C3, C7, and C10), showing that the steric hindrance has a certain influence on the reaction. In addition to arylboronic acids, heteroaryl boronic acids such as indolyl, pyridyl, furanyl, and thiophenyl ones (B24–B28) were also amenable to the transformation, affording the desired 2-heteroaryl N-heteroarenes in moderate yields (C24–C28).

Then, we screened the reaction with a variety of N-heteroarenes (A2-A22, see Supplementary Fig. 1 for their structures) employing p-tolyboronic acid B1. First, a variety of quinolines with different substitution patterns (A2–A18) were tested. As illustrated in Fig. 5, all the substrates underwent smooth cross-coupling to generate the desired products in moderate to excellent yields upon isolation (C29–C45). A series of functional groups on quinolyl skeleton (i.e., –Me, –OMe, –F, –Cl, –Br, –I, –CO2Me, –NO2) were also well tolerated, and N-heteroarenes containing electro-withdrawing groups gave relatively higher yields (C34-C37, C44 and C45) than those of electron-rich ones (C33 and C43), which is rationalized as the electron-deficient quinolines are beneficial to nucleophilic coupling with arylboronic acids. Except for quinoline derivatives, other types of N-heteroarenes such as quinoxaline, quinazoline, 1,5-naphthyridine, 1,8-naphthyridine, imidazo[1,2-a]pyrazine, 7,8-benzoquinoline, phenanthridine, and thieno[3,2-b]pyridine (A19-A26) were also compatible coupling partners to react with p-tolyboronic acid B1, delivering the desired cross-coupling products in reasonable yields (C46–C53). Noteworthy, reactants A19-A22 have two reactive α-sites, but the reaction only generated mono-arylated products even in the presence of excess boronic acids, showing that the reaction merits unique chemoselectivity. In addition, the more challenging pyrimidine and pyrazine can also give the corresponding products C54 and C55 by prolonging the reaction time. Interestingly, by introducing 20 mol% of CF3COOH as the activating agent, the α-arylation of pyridine derivatives was also successful, albeit the product yields were somewhat low (C56-C58). As shown in Figs. 4, 5, the demonstrated examples indicate that the synthetic protocol showed broad substrate scope and excellent functional group compatibility, regardless of oxidant and acid-sensitive ones (C9 and C23).

The preparation of N-bidentate ligands with the existing C–H arylation protocols still remains an unresolved goal due to the difficulties in the preparation of 2-heteroaryl organometallic reagents and in situ formation 2-heteroaryl radicals19,20,21,22,23,24,25,26,27,28,29,30,31. Herein, we successfully addressed such an issue by utilizing our synthetic method. As shown in Fig. 6, representative pyridin-2-yl and quinolin-8-yl boronic acids (B29 and B30) were employed to react with quinoline A1 and quinoxaline A19, respectively. All the reactions smoothly afforded the desired cross-coupling products in moderate yields. Interestingly, these obtained N^N bidentate ligands (C59–C63) and the commercially available 2,2′-bipyridine as well as 1,10-phenanthroline all did not undergo further α-arylation even in the presence of excess arylboronic acids, presumably because they can coordinate to the Ir(III) catalyst, and hamper the participation of Ir(III) in activation of these bis-nitrogen heteroarenes. Thus, the present work offers a practical platform for the direct and selective preparation of valuable N-bidentate ligands 9,10,11.

Mechanistic investigations

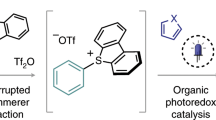

To gain mechanistic insights into the α-C–H arylation reaction, several control experiments were carried out (Fig. 7). First, the model reaction does not occur at all in the absence of Ir(III) catalyst (Table 1, entry 17), and both 1,2,3.4-tetrahydroquinoline (A1-a) and dihydroquinolines (A1-b and A1-c) were unable to couple with p-tolyboronic acid (B1) to yield product C1 (Fig. 7a) under the standard conditions, showing that the reaction involving tetrahydroquinoline and dihydroquinoline as the intermediates is not likely, as it was the case for reductive cross-coupling of N-heterocycles in t-amyl alcohols34, and the catalyst plays a crucial role in initiating the reaction. Upon a concurrent competition experiment of p-tolyboronic acid B1 with quinoline A1 and its α-deuterated counterpart A1-d (Supplementary Fig. 2), 1H-NMR analysis showed a kinetic isotope effect (KIE) value of 1.4 (Supplementary Fig. 3), indicating that the cleavage of α-C-H bond of quinoline A1 is not the rate-determining step in the reaction (Fig. 7b). Noteworthy, after completion of the reaction, B(OH)3 and H2 by-products44,45,46 were detected by means of 11B-NMR and GC, respectively (Figs. 7c and 7d, see Supplementary Figs. 4 and 5, Supplementary Table 1). To further understand the role of L-proline in the reaction, we prepared complex Cp*Ir(L-Pro)Cl from [Cp*IrCl2]2 and L-proline (Fig. 7e). The application of Cp*Ir(L-Pro)Cl in the model reaction resulted in product C1 in 75% yield, whereas the combination of this complex with additional L-proline failed to improve the product yields (Fig. 7f). In comparison, the use of [Cp*IrCl2]2 catalyst without L-proline only gave a 48% product yield (Table 1, entry 18). These experiments indicate that Cp*Ir(L-Pro)Cl is the reaction catalyst, and L-proline serves as a ligand to form the iridium catalyst.

Although the mechanistic details have not been fully elucidated, a plausible reaction pathway for the model reaction is depicted in Fig. 8 based on the above-described findings. Initially, the L-proline serves as a ligand47,48,49 of Ir(III) metal species (Fig. 7e) to form the complex [IrIIIX3Ln]. The transmetalation19,20 between p-tolyboronic acid B1 and [IrIIIX3Ln] forms aryl-Ir complex Int-1 with the elimination of XB(OH)2. The metathesis of XB(OH)2 and H2O produces HX and B(OH)3 (detected by 11B-NMR, Supplementary Fig. 4). Then, quinoline A1 undergoes carbon-Ir bond insertion of complex Int-1 into its imino motif (Int-2), and the subsequent β-hydride elimination from Int-2 gives rise to the desired product C1 along with the generation of metal hydride species [H-IrIIIX2Ln] (Int-3). Finally, the interaction of the hydride in [H-IrIIIX2Ln] with HX (as an oxidant) would regenerate the iridium(III) catalyst and liberate H2 gas (detected by gas chromatography, Supplementary Fig. 5). In the whole catalytic cycle, H2O-mediated H2 evolution plays a crucial role in facilitating the transmetalation process and regenerating the catalyst. The profitable role of the proline is likely coordinated through its carboxylate to Ir(III) as a X ligand as in copper(I) catalyst 44-47and as a L ligand via its R2NH group (Fig. 7e).

Application

Finally, we were interested in demonstrating the synthetic utility of the developed chemistry. As shown in Fig. 9, gram-scale synthesis of 2-arylquinoline C1 (1.42 g) was achieved by scaling up substrates A1 and B1 to 10 mmol and 12 mmol, respectively (Fig. 9a), and the reaction still afforded a desirable isolated yield (65%). Meanwhile, the transfer hydrogenation of compound C1 produced a synthetically useful tetrahydroquinoline50 C1’ in excellent yield (Fig. 9b). Brominated compound C37 underwent smooth Suzuki cross-coupling to afford arylated product C37’ in 75% yield (Fig. 9c). Moreover, the reaction is also applicable for structural functionalization of biomedical molecule such as hydroquinidine, delivering the desired p-tolyl-hydroquinidine hybrid in 40% yields (Fig. 9d).

Discussion

In conclusion, by a H2O-mediated H2-evolution cross-coupling strategy, we have developed an iridium(III)-catalyzed direct α-arylation of non-activated N-heteroarenes with both aryl and heteroaryl boronic acids. This chemical avenue to 2-(hetero)aryl N-heteroarenes proceeds with broad substrate scope and excellent functional compatibility under redox neutral conditions, is operationally simple, scalable, and applicable for structural modification of biomedical molecules, enables direct access to useful bidentate N-ligands that are inaccessible or difficult to prepare with the existing α-C–H arylation protocols, and does not need for prefunctionalization of N-heteroarenes, which fills an important gap in the capabilities of synthetic organic chemistry. This catalytic reaction is anticipated to be applied in numerous fields of science and technology due to the promising potentials of 2-(hetero)aryl N-heteroarenes. Moreover, the strategy employed should be useful in the functionalization of other unsaturated hydrocarbons and further design of other reactions.

Methods

Typical procedure I for the synthesis of α-arylation of N-heteroarenes

Under N2 atmosphere, [Cp*IrCl2]2 (1 mol%), L-proline (20 mol%), N-heteroarenes A (0.3 mmol), arylboronic acids B (0.36 mmol) and H2O/1,4-dioxane (10/1, 1.5 mL) were introduced in a Schlenk tube (50 mL), successively. Then, the Schlenk tube was closed and the resulting mixture was stirred at 110 °C (oil bath temperature) for 24 h. After cooling down to room temperature, quenched with water, extracted with ethyl acetate (3 × 5 mL), and dried over anhydrous Na2SO4. The reaction mixture was concentrated by removing the solvent under vacuum, and the residue was purified by preparative TLC on silica, eluting with petroleum ether (60–90 °C) and ethyl acetate to give the desired product C.

Data availability

The authors declare that all relevant data supporting the findings of this study are available within the paper and its supplementary information files.

References

Joule, J. A., & Mills, K. Heterocyclic Chemistry 5th edn (Wiley-Blackwell, 2010).

Taylor, R. D., MacCoss, M. & Lawson, A. D. G. Rings in drugs. J. Med. Chem. 57, 5845–5859 (2014).

Bunz, U. H. F. & Freudenberg, J. N‑heteroacenes and N-heteroarenes as N‑nanocarbon segments. Acc. Chem. Res. 52, 1575–1587 (2019).

Vitaku, E., Smith, D. T. & Njardarson, J. T. Analysis of the structural diversity, substitution patterns, and frequency of nitrogen heterocycles among U.S. FDA approved pharmaceuticals. J. Med. Chem. 57, 10257–10274 (2014).

Rodrigues, T., Reker, D., Kunze, J., Schneider, P. & Schneider, G. Revealing the macromolecular targets of fragment-like natural products. Angew. Chem. Int. Ed. 54, 10516–10520 (2015).

Sabatini, S. et al. Evolution from a natural flavones nucleus to obtain 2-(4-propoxyphenyl)quinoline derivatives as potent inhibitors of the S. aureus NorA efflux pump. J. Med. Chem. 54, 5722–5736 (2011).

Duggan, S. T., Keam, S. J. & Burness, C. B. Selexipag: a review in pulmonary arterial hypertension. Am. J. Cardiovasc. Drugs 17, 73–80 (2017).

Skoro-Sajer, N. & Lang, I. M. Selexipag for the treatment of pulmonary arterial hypertension. Expert Opin. Pharmacother. 15, 429–436 (2014).

Bruns, D. L., Musaev, D. G. & Stahl, S. S. Can donor ligands make Pd(OAc)2 a stronger oxidant? access to elusive palladium(II) reduction potentials and effects of ancillary ligands via palladium(II)/hydroquinone redox equilibria. J. Am. Chem. Soc. 142, 19678–19688 (2020).

Wei, C. Y., He, Y., Shi, X. D. & Song, Z. G. Terpyridine-metal complexes: applications in catalysis and supramolecular chemistry. Coord. Chem. Rev. 385, 1–19 (2019).

McPherson, J. N., Das, B. & Colbran, S. B. Tridentate pyridine-pyrrolide chelate ligands: An under-appreciated ligand set with an immensely promising coordination chemistry. Coord. Chem. Rev. 375, 285–332 (2018).

Skubi, K. L., Blum, T. R. & Yoon, T. P. Dual catalysis strategies in photochemical synthesis. Chem. Rev. 116, 10035–10074 (2016).

Yang, W., Fu, H., Song, Q. J., Zhang, M. & Ding, Y. Q. Amidate iridium(III) bis(2-pyridyl)phenyl complexes: application examples of amidate ancillary ligands in iridium(III)-cyclometalated complexes. Organometallics 30, 77–83 (2011).

Li, T.-Y. et al. Rational design of phosphorescent iridium(III) complexes for emission color tunability and their applications in OLEDs. Coord. Chem. Rev. 374, 55–92 (2018).

Caporale, C. & Massi, M. Cyclometalated iridium(III) complexes for life science. Coord. Chem. Rev. 363, 71–91 (2018).

Lepeltier, M., Le Bozec, H., Guerchais, V., Lee, T. K. M. & Lo, K. K. W. Tris-cyclometalated iridium(III) styryl complexes and their saturated analogues: direct functionalization of Ir(4-Me-ppy)3 and hydrogen transfer process. Organometallics 24, 6069–6072 (2005).

Beydoun, K., Zaarour, M., Williams, J. A. G., Doucet, H. & Guerchais, V. Palladium-catalysed direct arylation of a tris-cyclometallated Ir(III) complex bearing 2,2’-thienylpyridine ligands: a powerful tool for the tuning of luminescence properties. Chem. Commun. 48, 1260–1262 (2012).

Beletskaya, I. P., Alonso, F. & Tyurin, V. The Suzuki-Miyaura reaction after the Nobel prize. Coord. Chem. Rev. 385, 137–173 (2019).

Tobisu, M., Hyodo, I. & Chatani, N. Nickel-catalyzed reaction of arylzinc reagents with N-aromatic heterocycles: a straightforward approach to C-H bond arylation of electron-deficient heteroaromatic compounds. J. Am. Chem. Soc. 131, 12070–12071 (2009).

Hyodo, I., Tobisu, M. & Chatani, N. Catalytic arylation of a C-H bond in pyridine and related six-membered N-heteroarenes using organozinc reagents. Chem. Asian J. 7, 1357–1365 (2012).

Liu, K. M., Liao, L. Y. & Duan, X. F. Iron catalyzed oxidative assembly of N-heteroaryl and aryl metal reagents using oxygen as an oxidant. Chem. Commun. 51, 1124–1127 (2015).

Liao, L. Y., Liu, K. M. & Duan, X. F. Unified protocol for cobalt-catalyzed oxidative assembly of two aryl metal reagents using oxygen as an oxidant. J. Org. Chem. 80, 9856–9867 (2015).

Zhuo, F. F. et al. TMEDA-assisted effective direct ortho arylation of electron-deficient N-heteroarenes with aromatic Grignard reagents. J. Org. Chem. 78, 3243–3249 (2013).

Berman, A. M., Lewis, J. C., Bergman, R. G. & Ellman, J. A. Rh(I)-catalyzed direct arylation of pyridines and quinolines. J. Am. Chem. Soc. 130, 14926–14927 (2008).

Berman, A. M., Bergman, R. G. & Ellman, J. A. Rh(I)-catalyzed direct arylation of azines. J. Org. Chem. 75, 7863–7868 (2010).

Proctor, R. S. J. & Phipps, R. J. Recent advances in Minisci-type reactions. Angew. Chem. Int. Ed. 58, 13666–13699 (2019).

Seiple, I. B. et al. Direct C–H arylation of electron-deficient heterocycles with arylboronic acids. J. Am. Chem. Soc. 132, 13194–13196 (2010).

Wang, J., Wang, S., Wang, G., Zhang, J. & Yu, X. Q. Iron-mediated direct arylation with arylboronic acids through an aryl radical transfer pathway. Chem. Commun. 48, 11769–11771 (2012).

Singh, P. P., Aithagani, S. K., Yadav, M., Singh, V. P. & Vishwakarma, R. A. Iron-catalyzed cross-coupling of electron-deficient heterocycles and quinone with organoboron species via innate C–H functionalization: application in total synthesis of pyrazine alkaloid botryllazine A. J. Org. Chem. 78, 2639–2648 (2013).

Yuan, J.-W., Yang, L.-R., Mao, P. & Qu, L.-B. AgNO3-catalyzed direct C–H arylation of quinolines by oxidative decarboxylation of aromatic carboxylic acids. Org. Chem. Front. 4, 545–554 (2017).

Galloway, J. D., Mai, D. N. & Baxter, R. D. Silver-catalyzed Minisci reactions using selectfluor as a mild oxidant. Org. Lett. 19, 5772–5775 (2017).

Yang, S. D. et al. Palladium-catalyzed direct arylation of (hetero)arenes with aryl boronic acids. Angew. Chem. Int. Ed. 47, 1473–1476 (2008).

Bering, L. & Antonchick, A. P. Regioselective metal-free cross-coupling of quinoline N‑oxides with boronic acids. Org. Lett. 17, 3134–3137 (2015).

Chen, X. W., Zhao, H., Chen, C. L., Jiang, H. F. & Zhang, M. Hydrogen-transfer-mediated α-functionalization of 1,8-naphthyridines by a strategy overcoming the over-hydrogenation barrier. Angew. Chem. Int. Ed. 56, 14232–14236 (2017).

Elangovan, S. et al. Efficient and selective N-alkylation of amines with alcohols catalysed by manganese pincer complexes. Nat. Commun. 7, 12641 (2016).

Wang, D. W., Zhao, K. Y., Xu, C. Y., Miao, H. Y. & Ding, Y. Q. Synthesis, structures of benzoxazolyl iridium(III) complexes, and applications on C–C and C–N bond formation reactions under solvent-free conditions: catalytic activity enhanced by noncoordinating anion without silver effect. ACS Catal. 4, 3910–3918 (2014).

Deibl, N. & Kempe, R. General and mild cobalt-catalyzed C-alkylation of unactivated amides and esters with alcohols. J. Am. Chem. Soc. 138, 10786–10789 (2016).

Ding, F. W. et al. B(C6F5)3-promoted hydrogenations of N-heterocycles with ammonia borane. Chem. Commun. 53, 9262–9264 (2017).

Shugrue, C. R. & Miller, S. J. Phosphothreonine as a catalytic residue in peptide-mediated asymmetric transfer hydrogenations of 8-aminoquinolines. Angew. Chem. Int. Ed. 54, 11173–11176 (2015).

Rueping, M., Antonchick, A. R. & Theissmann, T. A highly enantioselective Brønsted acid catalyzed cascade reaction: organocatalytic transfer hydrogenation of quinolines and their application in the synthesis of alkaloids. Angew. Chem. Int. Ed. 45, 3683–3686 (2006).

Sundararaju, B., Achard, M., Sharma, G. V. M. & Bruneau, C. sp3 C–H bond activation with ruthenium(II) catalysts and C(3)-alkylation of cyclic amines. J. Am. Chem. Soc. 133, 10340–10343 (2011).

Chen, Z. W. et al. Formal direct cross-coupling of phenols with amines. Angew. Chem. Int. Ed. 54, 14487–14491 (2015).

Chen, Z. W., Zeng, H. Y., Gong, H., Wang, H. N. & Li, C. J. Palladium-catalyzed reductive coupling of phenols with anilines and amines: efficient conversion of phenolic lignin model monomers and analogues to cyclohexylamines. Chem. Sci. 6, 4174–4178 (2015).

Wang, H. M., Gao, X. L., Lv, Z. C., Abdelilah, T. & Lei, A. W. Recent advances in oxidative R1-H/R2-H cross-coupling with hydrogen evolution via photo-/electrochemistry. Chem. Rev. 119, 6769–6787 (2019).

Liu, K. et al. Electrooxidative para-selective C-H/N-H cross-coupling with hydrogen evolution to synthesize triarylamine derivatives. Nat. Commun. 10, 639 (2019).

Chen, B., Wu, L.-Z. & Tung, C.-H. Photocatalytic activation of less reactive bonds and their functionalization via hydrogen-evolution cross-couplings. Acc. Chem. Res. 51, 2512–2523 (2018).

Ma, D. W., Geng, Q., Zhang, H. & Jiang, Y. W. Assembly of substituted phenothiazines by a sequentially controlled CuI/L-proline-catalyzed cascade C-S and C-N bond formation. Angew. Chem. Int. Ed. 49, 1291–1294 (2010).

Diao, X. Q., Wang, Y. J., Jiang, Y. W. & Ma, D. W. Assembly of substituted 1H-benzimidazoles and 1,3-dihydrobenzimidazol-2-ones via CuI/L-proline catalyzed coupling of aqueous ammonia with 2-iodoacetanilides and 2-iodophenylcarbamates. J. Org. Chem. 74, 7974–7977 (2009).

Zhu, W. & Ma, D. W. Synthesis of aryl sulfones via L-proline-promoted CuI-catalyzed coupling reaction of aryl halides with sulfinic acid salts. J. Org. Chem. 70, 2696–2700 (2005).

Muthukrishnan, I., Sridharan, V. & Menendez, J. C. Progress in the chemistry of tetrahydroquinolines. Chem. Rev. 119, 5057–5191 (2019).

Acknowledgements

The authors thank the National Key Research and Development Program of China (2016YFA0602900), National Natural Science Foundation of China (21971071), Natural Science Foundation of Guangdong Province (2021A1515010155), and the Fundamental Research Funds for the Central Universities (2020ZYGXZR075) for financial support.

Author information

Authors and Affiliations

Contributions

M.Z. and L.C. conceived the idea, analyzed the data, M.Z. wrote the manuscript and directed the project. H.Z. carried out the hydrogen test experiment. R.-Q.G. synthesized part of the raw material. H.-F.J. and P.H.D. revised the manuscript and discussed the mechanistic details. All the authors have read the manuscript and agree with its content.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks Christopher Kozak and the other anonymous reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cao, L., Zhao, H., Guan, R. et al. Practical iridium-catalyzed direct α-arylation of N-heteroarenes with (hetero)arylboronic acids by H2O-mediated H2 evolution. Nat Commun 12, 4206 (2021). https://doi.org/10.1038/s41467-021-24468-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-021-24468-z

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.