Abstract

Hyperpolarization by dissolution dynamic nuclear polarization (dDNP) has enabled promising applications in spectroscopy and imaging, but remains poorly widespread due to experimental complexity. Broad democratization of dDNP could be realized by remote preparation and distribution of hyperpolarized samples from dedicated facilities. Here we show the synthesis of hyperpolarizing polymers (HYPOPs) that can generate radical- and contaminant-free hyperpolarized samples within minutes with lifetimes exceeding hours in the solid state. HYPOPs feature tunable macroporous porosity, with porous volumes up to 80% and concentration of nitroxide radicals grafted in the bulk matrix up to 285 μmol g−1. Analytes can be efficiently impregnated as aqueous/alcoholic solutions and hyperpolarized up to P(13C) = 25% within 8 min, through the combination of 1H spin diffusion and 1H → 13C cross polarization. Solutions of 13C-analytes of biological interest hyperpolarized in HYPOPs display a very long solid-state 13C relaxation times of 5.7 h at 3.8 K, thus prefiguring transportation over long distances.

Similar content being viewed by others

Introduction

Nuclear magnetic resonance (NMR) and magnetic resonance imaging (MRI) have become, within 50 years, techniques of reference for both analytical chemistry and medical diagnostic. The development of very high magnetic fields has led to an incessant increase in resolution and sensitivity, which has enabled faster acquisitions at ever decreasing concentrations. However, sensitivity still remains the Achilles heel of magnetic resonance. Today, the development of hyperpolarization methods to further enhance sensitivity by large factors is one of the most important topics of research in magnetic resonance.

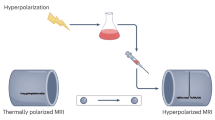

Dissolution dynamic nuclear polarization (dDNP) is one of these hyperpolarization game-changing approaches applicable for both NMR and MRI. dDNP enables hyperpolarization of small molecules therefore spectacularly amplifying their magnetic resonance signals by up to four orders of magnitude1,2,3. Such hyperpolarization is typically carried out in a dedicated apparatus (a dDNP polarizer) and under harsh conditions (high magnetic field, cryogenic temperatures) where the close to unity electron-spin alignment of polarizing agents (PAs, typically molecules containing unpaired electrons) is transferred to the nuclear spins (1H, 13C, 31P, 15N, etc.) of target molecules. Despite promising proofs of concepts such as the detection of intermediates in fast chemical reactions4, the observation of protein folding in real time5, or the early detection and monitoring of tumours in humans6, dDNP remains unfortunately restricted to a small number of specialized research groups around the globe. Indeed, some severe limitations restrain the widespread use of the method, amongst which the experimental complexity involving sterility (for clinical studies7), cryogenic temperatures (1.2 < T < 4.2 K), high magnetic fields (up to B0 = 9 T8), and microwave irradiation sometimes coupled to synchronized radiofrequency irradiations9,10. It also requires trained personnel, and finally represents an overall excessive price for the equipment and cryogenic fluids.

Most of these issues would be virtually fixed from the user perspective if one could transport hyperpolarized molecules from a large-scale hyperpolarization preparation centre to the end users’ remote locations. In a word, one would need to turn hyperpolarization into a long-lived transportable consumable, thus alleviating the struggle of local preparation. Unfortunately, the short-lived character of hyperpolarization in solution (on the order of a minute apart from some exotic cases11,12 and long-lived states13,14,15,16), requires that the complex dDNP preparation of the hyperpolarized samples be performed “on-site”, next to the NMR or MRI machine.

This fundamental drawback arises from the very nature of dDNP sample formulations featuring an intimate contact of a few nanometres distance between target molecules (typically 13C-labelled metabolites) and paramagnetic PAs (which was for a long time thought to be necessary for efficient hyperpolarization). Therefore, the PAs and the target molecule are usually homogeneously mixed then shock-frozen in a glassy state. Such rapid freezing ensures a statistical distribution of both components17,18. Yet, this close proximity also leads to paramagnetic nuclear spin relaxation induced by electron spin flip-flops of the PAs19,20,21,22, which causes complete hyperpolarization loss within milliseconds in solids23 to seconds in liquids when the sample is removed from magnetic field of the polarizer and its cryogenic environment.

One promising answer to this roadblock relies on the use of non-persistent PAs such as photoexcited triplets24 or photogenerated radicals25,26,27. We have recently introduced another approach that deliberately avoids intimate mixing of the target molecules and PAs through phase separation. In this previous work28, we designed a dDNP sample formulation in which the 13C-labelled target molecules were provided in the form of micro-crystals (typically 1–10 μm large) dispersed in an organic phase (for example, toluene/THF) containing the PAs. While direct hyperpolarization of 13C may appear impossible at first sight in such sample formulations given the long distances (several μm) between 13C nuclear spins and PAs, the 1H abundance in the two phases enables an indirect three-step polarization procedure:

-

i.

Microwave irradiation rapidly builds 1H polarization in the frozen solvent containing the PAs.

-

ii.

This 1H spin polarization spontaneously diffuses to the 1H spins within the micro-crystals.

-

iii.

The 1H spin polarization is then transferred to the 13C spins of the target molecule by irreversible 1H → 13C cross-polarization29,30 (CP).

This method offered hyperpolarization lifetimes exceeding tens of hours on some 13C-labelled target molecules, thus enabling the transport and storage of hyperpolarized molecules at 4.2 K. This method is, however, restricted to small molecules amenable to well-tailored micro-crystals and involves poisonous organic solvents along with PA residues, which precludes its use with proteins, living cells or animals.

A definitive answer to this issue would be to find a way to generalize the phase-separation strategy to other sample formulations (molecules, mixtures, biological fluids, etc.) without the use of any contaminants (such as the organic solvents hosting the PAs). This would have the potential to transform and democratize the benefits of hyperpolarization to a very wide NMR and MRI community. Target molecules could be hyperpolarized in dedicated centres and delivered as “consumables” ready for dissolution and injection to NMR or MRI.

Many materials containing PAs freely dispersed31 or covalently bound onto polymers32,33 and covalent organic frameworks34 have been designed for MAS- or Overhauser-DNP (i.e. not requiring effective separation of polarizing medium and hyperpolarized analytes). The design of polarizing media for dDNP is, however, more complex as it requires convenient loading and extraction of the analytes as well as optimized separation from the PAs. Previous generations of polarizing materials for dDNP involve, for instance, surface grafted nitroxide mesoporous silica, HYPSO35,36,37, that featured quick and efficient 13C polarization build-up, and also fast relaxation in the solid state (typically T1 = 20 min at 4.2 K) due to short separation length between target molecules and nitroxide radicals (ca. 6 nm). Contaminant-free hyperpolarized solutions can thus be obtained, but off-site transportation could not be envisioned. Other ingenious strategies to control the separation length between analytes and PA involve thermoresponsive polymers38 or hydrogels39,40 in which phase separation and collapse of the polymer chains happens upon dissolution with hot water and expels the hyperpolarized analytes and enables separation from the polarizing polymers, but only in the liquid state. In this case also, 13C relaxation times in the solid state still remain relatively short (T1 = 2800 s) even at low temperatures (1.1 K)39, which essentially precludes transportation.

Here, we describe the straightforward synthesis of macroporous hyperpolarizing polymers (HYPOP) featuring characteristic separation length above 100 nm, considerably larger than for any previous polarization media, and that contain PAs located not only at the porous surface, but also in the bulk of the polymer. These materials enable efficient 13C polarization of impregnated metabolite solutions within tens of minutes, and preserve the polarization for hours in the solid state.

Results and discussion

Short summary of HYPOP features

Figure 1 introduces the various features of HYPOPs, discussed below in this manuscript, that have been tailored with suitable structure and pore size range to give high performances both as polarization source and storage matrix for dDNP applications. HYPOPs are able to withstand both extreme cryogenic temperatures (down to superfluid helium) and very fast temperature jumps from 1.2 K to ca. 350 K in a few milliseconds. They feature an open porosity up to 80 vol% with pore sizes varying from 150 nm to 2 μm (Fig. 1a), and can contain various concentrations of stable radical species (TEMPO derivatives, 0–285 μmol g−1). HYPOPs can be loaded by incipient wetness impregnation (IWI) (Fig. 1b, c) with a variety of liquids ranging from pure pyruvic acid (the gold standard in hyperpolarized metabolic imaging6) to complex aqueous solutions. This opens the path towards complex analyses such as mixtures of ligands for fragment-based drug discovery41, or mixtures of metabolites originating from cell extracts42. The 1H spins of both the HYPOP and the target solution can be polarized in ca. 20 min to very high levels exceeding P(1H) > 60%. This polarization originates from epoxy particles of HYPOP in which PAs are hosted, and spontaneously propagates to the frozen solution by 1H nuclear spin diffusion (Fig. 1d)43. This high 1H polarization is sheltered on low-gamma 13C nuclear spins of target molecules after brief CP contacts of a few milliseconds10. High levels of 13C polarization exceeding P(13C) > 30% can thus be achieved in tens of minutes (Fig. 1d), and further stored at low temperatures (3.8 K) for hours in view of transport to a remote point of use (Fig. 1e). We finally show how the hyperpolarized solutions can be extracted from HYPOPs with high efficiency leading to hyperpolarized solution of metabolites that show very good signal enhancements upon immediate analysis with 13C NMR (Fig. 1f).

a Scanning electron microscopy of the HYPOP material used in this study. b Photograph of the impregnation step of powdered HYPOP. c Schematic representation of the porous polymer (yellow) with its PAs (black dots) impregnated with a 13C-labelled molecule (red dots) in aqueous solution (blue). 1H spins (grey dots) are abundant both in the HYPOP material and aqueous solution. d Schematic representation of the polarization transfer from the electrons of the PAs located within the HYPOP material to the 1H nuclei located within the HYPOP material, followed by 1H ↔ 1H spin diffusion across the material interface towards the aqueous frozen solution impregnated in the pores, and finally ended by a cross-polarization (CP) transferring the 1H polarization to the 13C spins of the target molecules. e Schematic representation of the slow 13C nuclear spin-lattice relaxation in solid state, mostly free from any paramagnetic relaxation since the 13C spins are physically well isolated from the PAs. f Carbonyl region of the 13C-NMR spectrum measured on a 80 MHz Bruker BioSpin Fourier 80 benchtop spectrometer (1 scan, 2 s), of a sample containing 1 M [1-13C]sodium acetate, 1 M [1-13C]sodium formate and 1 M [1-13C]glycine, hyperpolarized with HYPOP materials, displaying a liquid-state polarization enhancement exceeding 5000.

HYPOP synthesis and characterization

A considerable number of strategies can lead to polymer networks with open porosity of various sizes44,45, such as selective degradation of block copolymers assembled in co-continuous morphologies46, high internal phase emulsions (HIPE)47, colloid templating48, aerogels or open-cell foams49. These methods also share some of the following shortcomings: (i) synthetic complexity or incompatibility of polymerization strategies with the presence of stable radicals; (ii) presence of additives in the materials such as surfactants; or (iii) high temperature or chemical treatments incompatible with the survival of the TEMPO radicals. Other strategies, often applied to the synthesis of polymer membranes involve spinodal decomposition between a polymer and solvents through thermal transitions or changes in the solvent composition50. The porous network can then be obtained through straightforward removal of the solvents, but often displays significant heterogeneities. We rather opted for an analogous method, where spinodal decomposition between the polymer and the solvent is caused by the polymerization process itself. This process is also relatively easy to implement using thermosetting polymers with superior thermo-mechanical properties such as epoxy resins. Formulations of epoxy resin, hardener and a non-reactive solvent that display initially full miscibility, and that undergoes phase separation during the curing have been previously studied to form either epoxy materials as dispersed particles51, solids with closed porosity52,53, and also solids with open porosities54.

Thanks to an extensive study of the formulation (nature of the non-reactive solvent and relative fraction to the epoxy resin precursors), we were able to construct a pseudo-phase diagram of such a system and to target network morphologies in close adequacy with our requirements. We selected conventional epoxy resin precursors leading to high Tg thermosets above 150 °C: diglycidyl ether of bisphenol A (DGEBA) and isophorone diamine (IPDA) (Fig. 2a). The mixture was cured at 373 K for 24 h in the presence of polypropylene glycols (PPGs) of different molar mass acting as non-reactive solvents (see detailed synthesis in the “Methods” section). Thorough variations of the fraction of non-reactive solvents (from 30 to 90 wt%) and of their molar mass (from 192 to 2000 g mol−1) have been tested in the absence of 4-amino-TEMPO (n = 0). This results in the formation of epoxy particles aggregated in a variety of morphologies such as stable latexes, unstable suspensions, gels, and monolithic networks with closed and opened porosities. The corresponding pseudo-phase diagram, presented in Fig. 2b, was built from a series of experiments (each dot) and the nature of porosity, opened or closed, was assessed by gravimetry after extraction of the PPG (see SI Section 2.2 for details). The functionalization of this resin with commercially available 4-amino-TEMPO is straightforward and was obtained by merely mixing this commercial TEMPO derivative with IPDA in various molar ratios; the amount of DGEBA was adjusted to maintain a proper stoichiometry between amines and epoxydes (\({n}_{{{{\rm{epoxy}}}}}/{n}_{{{{{\rm{NH}}}}}_{2}}\) = 2). Solid samples were characterized, after proper removal of PPG using solvent washes and freeze-drying, by SEM, N2 physisorption and Hg intrusion porosimetry when appropriate. All experimental details are given in the “Methods” section and in Section 2 in the SI.

a Synthesis of TEMPO-functional and structured epoxy resins from diglycidyl ether of bisphenol A (DGEBA), isophorone diamine (IPDA) and 4-amino-TEMPO in the presence of various amounts of non-reactive polypropylene glycol (PPG). b The various morphologies obtained in the absence of 4-amino-TEMPO, when varying the fraction and the average molar mass in number (M̅n) of PPGs are reported in a pseudo-phase diagram: liquids (slurry and suspensions) in dark blue, solids with closed porosity in red, heterogeneous mixtures of solids and liquids in grey and solids with open porosity in light blue. The highlighted data (85 wt% of PPG-400 g mol−1) corresponds to the HYPOP-I series (c) that was functionalized with 4-amino-TEMPO and is reported in the remainder of the manuscript.

Spinodal decomposition leading to bicontinuous and homogeneous morphologies, and thus to solids with open porosity after extraction of the PPG, occurred only in a narrow range of solvent fractions (60–90 wt%), and for low molar mass of PPG. The corresponding size of aggregated epoxy particles was critically dependent on the molar mass of PPG, and varied from 1 to 5 μm, 100 nm and ca. 10 nm for PPG-725, PPG-400 and PPG-192, respectively (see Section 2.4 in the SI). The latter networks were obtained as transparent gels (i.e. not demonstrating extended phase separation between the epoxy and the solvent) and display structures typical of aerogels. Thus, the morphologies of the sample obtained with 85 wt% of PPG-400, showing a bicontinuous morphology composed of ca. 100 nm large aggregated epoxy particles forming a solid with hierarchical porosity (SBET = 96 m² g−1), was particularly well suited to our requirements, with a Tg estimated to be 134 °C and the absence of fracture when immersed in liquid N2. The proper curing of this particular network was monitored with in situ rheology (Section 2.6 in the SI) that enabled the identification of a first phase-separation event after 3 h of reaction, followed 30 min later by the formation of a network between aggregated particles. As the storage modulus reached a plateau after about 15 h of reaction, we kept a curing time of 24 h for all samples. After subsequent extraction of the PPG and drying of the porous polymers, we found that the final weights of the solids are, within experimental error, the same as the epoxy-amine precursors. In addition, swelling tests indicate the complete absence of a soluble fraction and therefore a complete cross-linking process.

The epoxy formulation using 85 wt% of PPG-400 was modified with increasing amounts of 4-amino-TEMPO (with r = nTEMPO-NH2/nIPDA ranging from 0 to 1.06) to obtain a series of seven HYPOP-I samples that are further used for the dDNP experiments. The concentration of radicals present in the final materials cannot be directly estimated from the initial amount of 4-aminoTEMPO as significant deactivation by disproportionation reaction is occuring55. Thus, we quantified the effective concentrations of radicals by Electron Paramagnetic Resonance EPR (see Section 3 in the SI), and found a fairly constant and reproducible survival yield of 34% in comparison to the concentration of 4-aminoTEMPO initially added (Table S2 in the SI). This value, seemingly low, was to be expected from the long curing times (24 h) at 100 °C. This low rate is, however, acceptable in the HYPOP-I series given (a) the relatively low cost of precursors and the simplicity of the synthesis and (b) the large range of radical concentrations that are still attainable, up to 285 μmol g−1, which goes beyond optimal concentrations required for dDNP (see below). Incorporating such large amounts of 4-aminoTEMPO in the epoxy networks in place of the tetra-functional IPDA, and therefore at the surface of the pores as well as in the bulk of the material, can yet induce significant changes in the final materials morphology due to (i) the decrease of both cross-link density and Tg in the epoxy network and (ii) changes of solubility parameters between epoxy and PPG that govern the spinodal decomposition and the final morphology of the materials. While an inspection of the HYPOP-I series with SEM (Section 2.5 in the SI) hardly displays evidence of variations in the morphology, a more thorough analysis involving mercury intrusion porosimetry indicates noteworthy changes in the pore size distribution (Section 2.7 in the SI). While all samples display similar distribution of pore sizes in the 10–100 nm range, i.e. within the interstices of the epoxy particles, micrometric pores corresponding to voids between particle aggregates are progressively disappearing when the amount of 4-amino-TEMPO is increased. Concomitantly, the total porous volume decreases from about 3.5 to 1 mL g−1 and the surface area determined by nitrogen physisorption from an SBET of 96 to 42 m2 g−1 (Fig. S4 in the SI). We believe this to be due to an increased compatibility of the TEMPO-rich epoxy with the PPG, and thus a more extensive plasticization and susceptibility to pore collapse upon removal of the solvent.

HYPOP impregnation with aqueous solutions

While HYPOP-I samples could be completely backfilled by immersion in a few centimetres of pure water or aqueous solutions, their low surface energy does not allow for spontaneous capillary impregnation. Due to the high costs of concentrated 13C-labelled solutions, we rather resorted to use water/ethanol mixtures (9/1 v/v) to enable direct capillary impregnation. Swelling of the HYPOP matrix is another important parameter to consider that could affect the PA concentration either by scavenging the radical56, or simply by increasing the volume of the polymer and therefore decreasing the radical concentration and the dynamics of polarization. While a few organic solvents demonstrated extensive swelling, the water:ethanol mixtures used in this paper induced only a moderate swelling of 19% (see Table S3 in the SI).

In a final step, the HYPOP-I monoliths were ground and sieved into ca. 250–500 μm powders (Fig. 2c). The initial polarizability of 1H spins in the HYPOP-I series was first characterized in the absence of an impregnated solution to optimize the PA concentration necessary for optimum DNP conditions. In the remaining study, wet dDNP samples were obtained by slightly under-impregnating 20 mg of HYPOP-I powder with 60 μL of solutions.

1H polarization with HYPOPs

DNP was performed at 7.05 T and 1.4 K in a Bruker prototype dDNP polarizer according to a standard DNP protocol described in the “Methods” section. The 1H polarization kinetics followed a conventional first-order mono-exponential increase for all samples. Corresponding final 1H polarization values and build-up rates are presented in blue in Fig. 3a, b, respectively. A maximal 1H polarization of about 40% was reached for HYPOP-I samples containing radicals at concentrations between 60 and 120 μmol g−1 while the build-up rates increased continuously with the radical concentration. Such behaviour was previously observed in HYPSO materials, which demonstrated optimal polarizations at radical concentrations between 50 and 100 μmol g−1 36.

Samples were compared before (blue open circles) and after (red filled circles) impregnation with a solution of ethanol-d6/H2O/D2O (1/1/8 v/v/v), polarized at 1.4 K and 7.05 T, with a microwave frequency of fuw = 197.648 GHz using a triangular frequency modulation of width Δfuw = 160 MHz and a modulation rate fmod = 500 Hz. a Steady-state 1H polarization levels (in case of incomplete build-up, asymptotic polarization values have been extrapolated from the fits in Sections 8.2 and 8.3 in the SI) and b corresponding polarization build-up rate RDNP(1H) = 1/TDNP(1H) values. *,▪,Δ Please see details in Sections 8.2 and 8.3 in the SI.

After impregnation of HYPOP-I samples with 1H concentrations ca. 11 mol L−1 (D2O/H2O/ethanol-d6 mixture (8/1/1 v/v/v)), we performed DNP experiments with the same DNP protocol, which led to a similar optimal PA concentration, but significantly higher maximal levels of polarization of about P(1H) = 55% (Fig. 3a, b, in red dots). This increase in polarization to levels beyond those of dry HYPOP-I samples was unexpected. One possible explanation for this phenomenon would be that the PAs are to some extent heterogeneously distributed across the aggregated particles forming HYPOP-I, some particles exhibiting a lower 1H polarization than others and, being connected to the others through a tortuous path, are unable to polarize by long-range 1H spin diffusion. However, once the porous polymer is impregnated with a 1H containing solution, 1H spin diffusion across the whole sample is strongly facilitated, which may help to reach proper hyperpolarization in all parts of the sample. In addition, the 1H polarization kinetics diverge significantly from first-order, which indicates heterogeneous build-up kinetics. This feature is typical for DNP build-up curves when polarization in the vicinity of the radicals is coupled to significant long-range spin diffusion into radical-poor domains (the frozen solutions in our case)28. In order to provide comparable build-up rates, the 1H polarization kinetics were fitted with stretched exponentials

with β being the breadth of the distribution of build-up rates. The average build-up rate \({R}_{{{{\rm{DNP}}}}}^{\ast }\) is defined as:

with Γ the gamma function57. Both dry and impregnated matrix build-up rates follow a similar trend, albeit understandably slower for impregnated HYPOP-I than for empty materials. The optimal formulation chosen for the rest of this work, HYPOP-IA containing radicals at 95 μmol g−1, provides fast and extensive 1H polarizability to the frozen solution. Such nitroxide concentration is close to the optimal concentration of 50 μmol g−1 generally reported under dDNP conditions. Increasing further the concentration of radicals has been reported to accentuate electron spin dipolar couplings and to eventually lead to an electron spin resonance broadening and thus a decrease in final nuclear spin polarization. Polarization values higher than P(1H) = 55% might potentially be obtained by partially deuterating the HYPOP material.

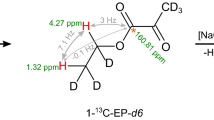

Generating and storing 13C hyperpolarization in HYPOP-IA

Firstly, 60.2 mg of HYPOP-IA sample was impregnated with 120 µL a D2O:ethanol (9:1 v/v) solution also including 1 M [13C]urea, 1 M [1-13C]glycine, 1 M [13C]sodium carbonate and 1 M [13C]sodium formate (four distinct target molecules) and 150 mM of sodium ascorbate. The latter is a reducing agent that readily scavenges paramagnetic oxygen in the aqueous solution as well as the PAs at the surface of the porous polymers and thus attenuates the corresponding paramagnetic relaxations56. The quick and efficient 1H polarization generated in HYPOP-IA and in the impregnated solution, reaching about P(1H) = 53% after a 2 min build-up time (Fig. 4a), is efficiently transferred to 13C spins by 1H → 13C multiple-contact CP repeated every 4 min10, and leads to a polarization of the 13C target molecules of about P(13C) ~25% with a 7.8 min build-up time (Fig. 4b). Sequence is detailed in the “Methods” section as well as in Section 4.2 in the SI.

a 1H DNP build-up of HYPOP-IA sample impregnated with a solution (see in the text) measured at 1.4 K and 7.05 T, with a microwave frequency of fuw = 197.648 GHz with a triangular frequency modulation of width Δfuw = 160 MHz and rate fmod = 500 Hz. b Subsequent multi-CP transfer of polarization to 13C of target molecules. c Subsequent 13C relaxation after warming the sample to 3.8 K, showing a characteristic decay constant T1(13C) = 5.7 ± 0.1 h.

Such performances in the presence of sodium ascorbate in the impregnation solution confirm that a significant part of the radicals is located within the bulk of the HYPOP matrix. Yet, the major innovation in our system does not only consists in high 13C polarizability, but also and primarily in the extended hyperpolarization lifetime in solid state, T1(13C). The latter was assessed from the 13C relaxation at 3.8 K and 7.05 T (Fig. 4c), monitored over 15 h by 13C detection with small flip angle pulses every 30 min. The pulse angle was chosen to be ∼5° prevent excessive perturbation of the hyperpolarization. The relaxation time constant T1 was estimated about 5.7 ± 0.1 h, taking into account the slight depletion of polarization due to the radiofrequency pulses (see Section 8.4 in the SI). This relaxation process is essentially due to paramagnetic relaxations towards the PAs in the bulk HYPOP-I through 13C–13C nuclear spin diffusion. In comparison to previous polarization sources for dDNP such as surface-functionalized mesoporous silica35, or thermoresponsive hydrogels39, we attribute the dramatically slower relaxations to the low 13C abundance in the bulk HYPOP (natural abundance), and mostly to the structured morphology of the HYPOP materials featuring pore sizes of around 100 nm and a glassy, relatively hydrophobic matrix that ensures a limited diffusion of 13C analytes within the bulk HYPOP during the impregnation step. Quantification of the resulting spatial separation between the PAs embedded in the bulk of HYPOP and the 13C nuclear spins of metabolites in the impregnating solution will be addressed in a forthcoming publication.

Such a long solid-state T1 relaxation time in the case of a solution of target molecules paves the way towards transport of hyperpolarized frozen solutions. As we previously demonstrated, transport can in principle be achieved using a helium Dewar, equipped with an assembly of permanent magnets providing a moderate magnetic field (1 T)23,28. Different strategies for fast transfers23 have been reported, which could also be implemented in the future in combination with our approach.

Dissolution and analysis of hyperpolarized solutions from HYPOP-IA

Dissolution was performed by standard dDNP methods1, using superheated D2O (180 °C) injected directly after CP in the sample holder located in the polarizer as previously described10. The impregnated HYPOP powder was flushed out of the cryostat during the process together with the hyperpolarized solution. Therefore, an additional inline filter (see Section 6 in the SI) was used to retain the HYPOP powder while letting through the melted hyperpolarized solution. The extracted hyperpolarized solution was transferred into a benchtop 80 MHz NMR apparatus (Bruker F80) equipped with a dedicated injector (Bruker BioSpin prototype), coupled to a conventional 5 mm NMR tube and ready for analysis. The whole transfer (dissolution, filtration and injection in the NMR tube) up to the start of the NMR pulse sequence took approximately 1.7 s. A magnetic tunnel23 (4 mT solenoid) was implemented along the transfer capillary to prevent excessive polarization losses at low field, except at the position of the HYPOP filtration device (we believe that minor technological improvements solving this shortcoming may considerably increase the overall performance of the method).

After hyperpolarization of a solution of 1 M [1-13C]sodium acetate, 1 M [13C]sodium formate and 1 M [13C]glycine in HYPOP-IA, the immediate dissolution and recording of 13C spectra gave an intense signal (Fig. 5a, 1 scan) measured on a Bruker Fourier 80 benchtop NMR spectrometer (80 MHz 1H frequency). The asymmetry of the 13C signals indicates a substantial proton polarization of the J-coupled 1Hs58. Enhancement factors were calculated (see Section 8.5 in the SI) to be ca. 12'000 for [1-13C]-acetate and 6'200 for 13C formate (i.e. about 2% and 1% absolute 13C polarization, respectively). Time-resolved 13C spectra were measured every 5 s with 5° (Fig. 5b). T1(13C) relaxation time in liquid of about 90 s for sodium acetate and of about 24 s for sodium formate were observed. These values are within the range expected for 13C polarization in the absence of paramagnetic electron spins59, and demonstrate the efficient removal of HYPOP particles upon filtering. Surprisingly, 13C-glycine signals could not be observed, which indicates a complete loss of polarization upon transfer. The 13C glycine polarization loss is not related to the usage of HYPOP-IA, but happens in low-field regions during transfer, more precisely in the filtration system that could not be embedded in our magnetic tunnel. Such low fields are indeed known to favour scalar relaxation on 14N60. Moreover, we observed the same behaviour for 13C-glycine upon dDNP of a standard frozen sample formulations doped with TEMPOL (no HYPOP). The final polarization values reported here do not yet match state-of-the-art values obtained with conventional dDNP sample formulation (ca. 50%10), and a lengthy work of optimization is certainly still pending. However, this work illustrates the great potential of dDNP using HYPOPs as polarization generation, storage and transport matrices, which paves the way to a widespread use of dDNP in NMR or MRI experiments. Further technological improvements on the transfer line (e.g. magnetic tunnel over the whole line) still need to be implemented and may help to further increase the performance of the method.

a Full and detailed view of the first 13C spectrum. b Time series of the 13C hyperpolarized spectra measured every 5 s with a 5° nutation angle pulse in the liquid state after hyperpolarization of a 100 μL solution of 0.9 M [1-13C]glycine at, 0.9 M [1-13C]sodium formate, 0.9 M [1-13C]sodium acetate, in 90% D2O and 10% ethanol-d6 in HYPOP-I and dissolution with 7 mL of D2O, filtration transfer and injection into a Bruker Fourier 80 benchtop NMR spectrometer (80 MHz 1H frequency).

In this paper, we have demonstrated that porous polymers (HYPOP-I) containing TEMPO derivatives as PAs and featuring a porosity spanning from 50 nm to 1 μm can be used as multipurpose matrices for dDNP applications, with the antagonistic properties of rapidly generating 13C hyperpolarization in frozen aqueous mixtures, while preserving this high polarization for extended lifetimes of several hours in view of transport experiments. Together with the facile extraction of pure hyperpolarized solutions of target molecules, our strategy paves the route to a broader democratization of the use of dDNP in NMR or MRI experiments. Our strategy was illustrated with porous epoxy resins that combine straightforward synthesis and tunable morphologies, and we anticipate that this concept of PA/target molecules’ separation will be further generalized to a variety of porous solids, with potentially further improved performances.

Methods

HYPOP synthesis and preparation

In a polypropylene tube, diglycidyl ether of bisphenol A (DGEBA), isophorone diamine (IPDA), amino TEMPO were mixed with polypropylene glycol (PPG) as a solvent. Amount of DGEBA was calculated in order to maintain a ratio 2/1 with primary amines of IPDA and amino TEMPO. Quantity of amino TEMPO was calculated to reach a desired concentration taking into account the survival yield of the synthesis and the quantity of solvent was fixed at 85% of the total weight of the solution. Solutions were mixed and degassed under partial vacuum (>0.01 mbar). Heating the sample during this operation with a heat gun (<100 °C) can accelerate the process. Polymerization took place at 100 °C for 24 h. PPG was finally extracted by 3 exchanges with a large quantity of ethanol followed by 3 exchanges with water during at least 3 h each before freeze-drying them. Further details of the synthesis, including effects of PPG size on porosity, are given in Section 2 in the SI. HYPOP-I monoliths are manually ground and sifted to select particles between 250 and 500 μm.

Chemicals supply

All chemicals used (reactants, monomers, solvents, analytes, etc.) are currently commercially available. The list of suppliers is accessible in Section 1 in the SI.

Scanning electron microscopy

Scanning electron microscopy experiments were performed on a ZEISS Merlin Compact or on a Quanta FEI 250 after deposition of 10 nm of copper using secondary electrons detectors.

Polarizer apparatus

All DNP measurements were performed with a prototype dDNP Polarizer developed by Bruker BioSpin, with a helium bath cryostat operating within a range of 1.2 K < T < 4.2 K at a magnetic field of 7.05 T and equipped with 1H/13C homemade NMR probe. Microwaves were generated with a Virginia Diode system (8–20 GHz VDI synthesizer with a 198 GHz AMC amplifier/multiplier chain). For the characterization of HYPOP, a KelF sample holder was used to reduce the 1H signal background. For dissolution experiments, a more robust PEEK sample holder was used.

1H DNP experiments

Prior to DNP experiments, HYPOP powders were used as is or impregnated with solutions to be hyperpolarized, placed in the sample cup, and inserted in the liquid helium bath of the dDNP polarizer at 4.2 K. 1H NMR signals were measured at 3.8 K (700 mbar pressure), with 0.1° pulses every 5 s during 10 min until reaching the thermal equilibrium plateau. The quality factor of the 1H NMR circuit was by attenuated by adding a 50 Ohm resistor in series with the tuning and matching box, so as to decrease radiation-damping (potentially very intense at high polarization values), which can lead to underestimation of the polarized 1H signal. 1H polarization curves were recorded at 1.4 K and 7.05 T, with the following microwave parameters: frequency of fuw = 197.648 GHz, triangular frequency modulation of width Δfuw = 160 MHz, modulation rate fmod = 500 Hz, and estimated power in the sample cavity Puw = 30 mW.

13C DNP experiments

After inserting the sample, 13C NMR signals were measured with 5° pulse every 30 min during 6 h at 3.8 K and once the plateau was reached, the thermal equilibrium NMR signal was recorded with a series of 64 pulses for improved sensitivity (see Section 8.4 in the SI). The same procedure was previously applied for the measurement of the 13C background signal (without sample). 1H → 13C CP was performed using a 6 ms contact every 5 min to allow time for 1H polarization to build-up and diffuse in the frozen solution in the pores of HYPOP. The CP matching condition was realized with 23 kHz B1 field on both 1H and 13C channels (with 8 ms square pulse of 1H (8 W) and an amplitude of 13C pulse ramped linearly from 50% to 100% (150 W at maximum)). Adiabatic half-passage pulses (100 kHz, 175 μs with 12 W for the 1H channel and 150 W for the 13C channel) were used to flip the 1H and 13C magnetization in the transverse plane before CP contact and to restore magnetization along z afterwards.

Dissolution, transfer and injection experiments

A solenoid of 1.5 m length has been built around the transfer capillary, and fed with a current of 2 A, thus generating a 4 mT field all along the transfer line except for the filtering system placed in close proximity to the benchtop spectrometer. First, 7 mL of D2O solvent was pressurized at 6 bar and heated to reach 9 bar. After the dissolution, the HYPOP-I matrices mixed together with the molecules of interest are pushed with hot D2O through a filtering device described in Section 6 in the SI. Finally, the solution was fed into a Bruker’s prototype NMR injector directly placed in the Fourier80 benchtop NMR spectrometer.

Hyperpolarized liquid-state NMR measurements

Liquid-state hyperpolarized NMR spectra were measured in a Fourier 80 MHz Bruker BioSpin benchtop spectrometer (1H frequency 80.222 MHz and 13C frequency 20.1718 MHz). After injection, 13C signals were recorded every 5 s with a 5° nutation angle pulse. Final hyperpolarization enhancement was calculated by cross-calibration with a highly concentrated 3 M [1-13C]sodium acetate reference sample, with a simple method described in detail in Section 8.5 in the SI.

Data availability

The characterization of porosity, RPE and raw NMR data used in this study is freely available in the Materials Cloud archive: 10.24435/materialscloud:kv-6q.

Materials availability

The materials of this study are available from the corresponding authors upon reasonable request.

References

Ardenkjaer-Larsen, J. H. et al. Increase in signal-to-noise ratio of >10,000 times in liquid-state NMR. Proc. Natl Acad. Sci. USA 100, 10158–10163 (2003).

Zhang, G. & Hilty, C. Applications of dissolution dynamic nuclear polarization in chemistry and biochemistry. Magn. Reson. Chem. 56, 566–582 (2018).

Elliott, S. J. et al. Practical dissolution dynamic nuclear polarization, Progress in Nuclear Magnetic Resonance Spectroscopy. (2021) https://doi.org/10.1016/j.pnmrs.2021.04.002.

Lee, Y., Heo, G. S., Zeng, H., Wooley, K. L. & Hilty, C. Detection of living anionic species in polymerization reactions using hyperpolarized NMR. J. Am. Chem. Soc. 135, 4636–4639 (2013).

Chen, H. Y., Ragavan, M. & Hilty, C. Protein folding studied by dissolution dynamic nuclear polarization. Angew. Chem. Int. Ed. 52, 9192–9195 (2013).

Nelson, S. J. et al. Metabolic imaging of patients with prostate cancer using hyperpolarized [1-13C]pyruvate. Sci. Transl. Med. 5, 198ra108 (2013).

Ardenkjaer-Larsen, J. H. et al. Dynamic nuclear polarization polarizer for sterile use intent. NMR Biomed. 24, 927–932 (2011).

Baudin, M., Vuichoud, B., Bornet, A., Bodenhausen, G. & Jannin, S. A cryogen-consumption-free system for dynamic nuclear polarization at 9.4 T. J. Magn. Reson. 294, 115–121 (2018).

Jannin, S., Bornet, A., Colombo, S. & Bodenhausen, G. Low-temperature cross polarization in view of enhancing dissolution dynamic nuclear polarization in NMR. Chem. Phys. Lett. 517, 234–236 (2011).

Bornet, A. et al. Boosting dissolution dynamic nuclear polarization by cross polarization. J. Phys. Chem. Lett. 4, 111–114 (2013).

Miéville, P., Jannin, S., Helm, L. & Bodenhausen, G. Kinetics of yttrium-Ligand complexation monitored using hyperpolarized 89Y as a model for gadolinium in contrast agents. J. Am. Chem. Soc. 132, 5006–5007 (2010).

Cudalbu, C. et al. Feasibility of in vivo15N MRS detection of hyperpolarized 15N labeled choline in rats. Phys. Chem. Chem. Phys. 12, 5818 (2010).

Kress, T., Walrant, A., Bodenhausen, G. & Kurzbach, D. Long-lived states in hyperpolarized deuterated methyl groups reveal weak binding of small molecules to proteins. J. Phys. Chem. Lett. 10, 1523–1529 (2019).

Dumez, J. N. et al. Dynamic nuclear polarization of long-lived nuclear spin states in methyl groups. J. Phys. Chem. Lett. 8, 3549–3555 (2017).

Carravetta, M. & Levitt, M. H. Long-lived nuclear spin states in high-field solution NMR. J. Am. Chem. Soc. 126, 6228–6229 (2004).

Carravetta, M., Johannessen, O. G. & Levitt, M. H. Beyond the T1 limit: singlet nuclear spin states in low magnetic fields. Phys. Rev. Lett. 92, 153003 (2004).

Hu, K.-N. Polarizing agents and mechanisms for high-field dynamic nuclear polarization of frozen dielectric solids. Solid State Nucl. Magn. Reson. 40, 31–41 (2011).

Hall, D. A. et al. Polarization-enhanced NMR spectroscopy of biomolecules in frozen solution. Science 276, 930–932 (1997).

Rorschach, H. E. Jr & Rorschach, H. E. Nuclear relaxation in solids by diffusion to paramagnetic impurities. Physica 30, 38–48 (1964).

Tse, D. & Hartmann, S. R. Nuclear spin-lattice relaxation via paramagnetic centers without spin diffusion. Phys. Rev. Lett. 21, 511–514 (1968).

Stevens, K. W. H. The theory of paramagnetic relaxation. Rep. Prog. Phys. 30, 189–226 (1967).

Blumberg, W. E. Nuclear spin-lattice relaxation caused by paramagnetic impurities. Phys. Rev. 119, 79–84 (1960).

Kouřil, K., Kouřilová, H., Bartram, S., Levitt, M.H. & Meier, B. Scalable dissolution-dynamic nuclear polarization with rapid transfer of a polarized solid.Nat. Commun. 10, 1733 (2019).

Kouno, H. et al. Triplet dynamic nuclear polarization of crystalline ice using water-soluble polarizing agents.Chem. Commun. 56, 3717–3720 (2020).

Eichhorn, T. R. et al. Hyperpolarization without persistent radicals for in vivo real-time metabolic imaging. Proc. Natl Acad. Sci. USA 110, 18064–18069 (2013).

Pinon, A. C., Capozzi, A. & Ardenkjær-Larsen, J. H. Hyperpolarized water through dissolution dynamic nuclear polarization with UV-generated radicals. Commun. Chem. 3, 1–9 (2020).

Capozzi, A., Karlsson, M., Petersen, J. R., Lerche, M. H. & Ardenkjaer-Larsen, J. H. Liquid-state 13C polarization of 30% through photoinduced nonpersistent radicals. J. Phys. Chem. C. 122, 7432–7443 (2018).

Ji, X. et al. Transportable hyperpolarized metabolites. Nat. Commun. 8, 1–7 (2017).

Perez Linde, A. J. Application of Cross Polarisation Techniques to Dynamic Nuclear Polarisation Dissolution Experiments. PhD thesis, University of Nottingham (2010).

Hartmann, S. R. & Hahn, E. L. Nuclear double resonance in the rotating frame. Phys. Rev. 128, 2042–2053 (1962).

Noda, Y., Kumada, T., Yamaguchi, D. & Shamoto, S. I. Thermosetting polymer for dynamic nuclear polarization: solidification of an epoxy resin mixture including TEMPO. Nucl. Instrum. Methods Phys. Res. A 776, 8–14 (2015).

Verde-Sesto, E. et al. DNP NMR studies of crystalline polymer domains by copolymerization with nitroxide radical monomers. Macromolecules 51, 8046–8053 (2018).

Bruck, D., Dudley, R., Fyfe, C. A. & Van Delden, J. Sample magnetization using immobilized free radicals for use in flow NMR systems. J. Magn. Reson. 42, 51–59 (1981).

Wang, W. et al. Exploring applications of covalent organic frameworks: homogeneous reticulation of radicals for dynamic nuclear polarization. J. Am. Chem. Soc. 140, 6969–6977 (2018).

Gajan, D. et al. Hybrid polarizing solids for pure hyperpolarized liquids through dissolution dynamic nuclear polarization. Proc. Natl Acad. Sci. USA 111, 14693–14697 (2014).

Cavaillès, M. et al. Tailored microstructured hyperpolarizing matrices for optimal magnetic resonance imaging. Angew. Chem. 130, 7575–7579 (2018).

Gajan, D. et al. Solid-phase polarization matrixes for dynamic nuclear polarization from homogeneously distributed radicals in mesostructured hybrid silica materials. J. Am. Chem. Soc. 135, 15459–15466 (2013).

Vuichoud, B. et al. Filterable agents for hyperpolarization of water, metabolites, and proteins. Chem. Eur. J. 22, 14696–14700 (2016).

Cheng, T., Mishkovsky, M., Junk, M. J. N., Münnemann, K. & Comment, A. Producing radical-free hyperpolarized perfusion agents for in vivo magnetic resonance using spin-labeled thermoresponsive hydrogel. Macromol. Rapid Commun. 37, 1074–1078 (2016).

Dollmann, B. C. et al. Thermoresponsive, spin-labeled hydrogels as separable DNP polarizing agents. Phys. Chem. Chem. Phys. 12, 5879 (2010).

Kim, Y. & Hilty, C. Affinity screening using competitive binding with fluorine-19 hyperpolarized ligands. Angew. Chem. Int. Ed. 54, 4941–4944 (2015).

Dumez, J.-N. et al. Hyperpolarized NMR of plant and cancer cell extracts at natural abundance. Analyst 140, 5860–5863 (2015).

Khutsishvili, G. R. Spin diffusion. Sov. Phys. Usp. 8, 743 (1966).

Yang, X.-Y. et al. Hierarchically porous materials: synthesis strategies and structure design. Chem. Soc. Rev. 46, 481–558 (2017).

Wu, D. et al. Design and preparation of porous polymers. Chem. Rev. 112, 3959–4015 (2012).

Hillmyer, M. A. Nanoporous materials from block copolymer precursors. Adv. Polym. Sci. 190, 137–181 (2005).

Zhang, T., Sanguramath, R. A., Israel, S. & Silverstein, M. S. Emulsion templating: porous polymers and beyond. Macromolecules 52, 5445–5479 (2019).

Stucki, M., Loepfe, M. & Stark, W. J. Porous polymer membranes by hard templating – a review. Adv. Eng. Mater. 20, 1–18 (2018).

Zhao, S., Malfait, W. J., Guerrero-Alburquerque, N., Koebel, M. M. & Nyström, G. Biopolymer aerogels and foams: chemistry, properties, and applications. Angew. Chem. Int. Ed. 57, 7580–7608 (2018).

Lu, W. et al. Porous membranes in secondary battery technologies. Chem. Soc. Rev. 46, 2199–2236 (2017).

Traina, M., Galy, J., Gérard, J. F., Dikic, T. & Verbrugge, T. Synthesis of cross-linked epoxy microparticles: effect of the synthesis parameters. J. Colloid Interface Sci. 368, 158–164 (2012).

Kiefer, J., Hilborn, J. G., Månson, J. A. E., Leterrier, Y. & Hedrick, J. L. Macroporous epoxy networks via chemically induced phase separation. Macromolecules 29, 4158–4160 (1996).

Loera, A. G., Cara, F., Dumon, M. & Pascault, J. P. Porous epoxy thermosets obtained by a polymerization-induced phase separation process of a degradable thermoplastic polymer. Macromolecules 35, 6291–6297 (2002).

Tsujioka, N., Ishizuka, N., Tanaka, N., Kubo, T. & Hosoya, K. Well-controlled 3D skeletal epoxy-based monoliths obtained by polymerization induced phase separation. J. Polym. Sci. A 46, 3272–3281 (2008).

Nutting, J. E., Rafiee, M. & Stahl, S. S. Tetramethylpiperidine N-oxyl (TEMPO), phthalimide N-oxyl (PINO), and related N-oxyl species: electrochemical properties and their use in electrocatalytic reactions. Chem. Rev. 118, 4834–4885 (2018).

Miéville, P. et al. Scavenging free radicals to preserve enhancement and extend relaxation times in NMR using dynamic nuclear polarization.Angew. Chem. Int. Ed. Engl. 49, 6182–6185 (2010). Erratum 49, 7834 (2010).

Johnston, D. C. Stretched exponential relaxation arising from a continuous sum of exponential decays. Phys. Rev. B 74, 1–7 (2006).

Vuichoud, B. et al. Measuring absolute spin polarization in dissolution-DNP by Spin PolarimetrY Magnetic Resonance (SPY-MR). J. Magn. Reson. 260, 127–135 (2015).

Pell, A. J., Pintacuda, G. & Grey, C. P. Paramagnetic NMR in solution and the solid state. Prog. Nucl. Magn. Reson. Spectrosc. 111, 1–271 (2019).

Chiavazza, E. et al. Earth’s magnetic field enabled scalar coupling relaxation of 13C nuclei bound to fast-relaxing quadrupolar 14N in amide groups. J. Magn. Reson. 227, 35–38 (2013).

Acknowledgements

In memory of Prof. Jean-Pierre Pascault. This research was supported by ENS-Lyon, the French CNRS, Lyon 1 University, the Institute of Chemistry at Lyon (ICL), the European Research Council under the European Union’s Horizon 2020 research and innovation program (ERC Grant Agreements No. 714519 / HP4all and Marie Skłodowska-Curie Grant Agreement No. 766402 / ZULF). The authors acknowledge Bruker BioSpin for providing the dDNP system and for their support; Venita Decker and Frank Decker from Bruker BioSpin for providing the F80 spectrometer and for their support; David Gajan, Arianna Ferrari, and Stuart J. Elliott for their assistance on the dDNP apparatus; Xiao Ji, Fanny Russel, Adrien Alonzo and Alexandra Erdmann for their synthesis work; Catherine Jose and Christophe Pages from the “service prototype” of the “Institut des Sciences Analytiques”; Stephane Martinez from the “Atelier de mecanique de l’UCBL”. Emilien Etienne and Bruno Guigliarelli from the interdisciplinary French EPR network Renard at Univ. Aix. Marseille. The “Centre Technologique des Microstructures” (CTµ) and Pierre-Yves Dugas for their help with SEM.

Author information

Authors and Affiliations

Contributions

T.E.D. and D.M. designed and synthesized HYPOP materials. T.E.D., L.G. and D.M. characterized HYPOP materials. S.F.C., T.E.D., O.C., Q.S., A.B., J.M. and B.V. performed the dDNP experiments. T.E.D., S.F.C. and Q.S. analysed the DNP results. M.C., J.K., R.M., D.E. and M.S. designed and built the dDNP hardware. S.J. designed the project and supervised the team effort. S.F.C., T.E.D., S.J. and D.M. wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks Thierry AZAIS and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El Daraï, T., Cousin, S.F., Stern, Q. et al. Porous functionalized polymers enable generating and transporting hyperpolarized mixtures of metabolites. Nat Commun 12, 4695 (2021). https://doi.org/10.1038/s41467-021-24279-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-021-24279-2

This article is cited by

-

Possible Applications of Dissolution Dynamic Nuclear Polarization in Conjunction with Zero- to Ultralow-Field Nuclear Magnetic Resonance

Applied Magnetic Resonance (2023)

-

Design and performance of a small bath cryostat with NMR capability for transport of hyperpolarized samples

Scientific Reports (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.