Abstract

Novel muraminomicin derivatives with antimicrobial activity against methicillin-resistant Staphylococcus aureus (MRSA) were synthesized by esterification of the hydroxy group on the diazepanone ring of muraminomicin Z1. Compound 1b (DS14450354) possessed a diheptoxybenzyl-β-Alanyl-β-Alanyl group and exhibited minimum inhibitory concentrations (MICs) against MRSA comparable to those against methicillin-susceptible S. aureus (MSSA). The MICs that inhibited 50 and 90% of the strains were 1 and 2 μg/mL, respectively. Compound 1a (DS60182922) possessed an aminoethylbenzoyldodecylglycyl moiety and showed bactericidal activity against MSSA Smith. The bactericidal activity of 1a against MRSA 10925 was comparatively lower, whilst 1b exhibited dose-dependent bactericidal activity against MRSA 10925. The mutation frequency of 1b was lower than that of 1a. An amino acid substitution (F226I) was observed in MraY mutants isolated from culture plates containing 1a or 1b. Subcutaneous 1a and 1b administration showed good therapeutic efficacy in murine systemic infection models with MSSA Smith and MRSA 10925, comparable to that of vancomycin, suggesting that the novel muraminomicin derivatives may be effective therapeutic agents against MRSA that warrant further investigation. A scheme for the formulation of the key ester intermediate, requiring no HPLC preparation, was also established.

Similar content being viewed by others

Introduction

Staphylococcus aureus is a leading cause of bacterial infections worldwide, ranging from minor skin and soft tissue infections to life-threatening endocarditis, pneumonia, and osteomyelitis [1, 2]. Recently, the number of bacteria resistant to existing antimicrobials has increased in clinical practice and has become a major therapeutic problem. Methicillin-resistant S. aureus (MRSA) exhibits resistance to almost all therapeutic β-lactams and other classes of antibiotics. Several anti-MRSA drugs have been launched in the past few decades, such as linezolid [3], daptomycin [4], and ceftaroline [5]; however, vancomycin remains the most important first-line therapy for severe MRSA infection. Furthermore, the emergence of MRSA with reduced susceptibility to vancomycin [6] as well as linezolid [7] and daptomycin resistance [8] has been reported; therefore, novel drugs to treat antibiotic-resistant infections and drugs with new mechanisms of action are urgently needed.

Bacterial phospho-N-acetylmuramylpentapeptide translocase (MraY: EC 2.7.8.13) is an enzyme involved in the second stage of the peptidoglycan biosynthetic pathway that constitutes the bacterial cell-wall [9]. The enzyme is regarded as a promising target for novel antibiotics since it is essential for viability [10, 11] and has no counterparts in mammalian cells. MraY is the target of many naturally produced nucleoside antibiotics, such as tunicamycin [12], liposidomycins [13], capuramycins [14], mureidomycins [15], pacidamycins [16], naspamycins [17], muraymycins [18], caprazamycins [19], A-102395 [20], A-94964 [21], and A-90289s [22]. Structure-function studies have been carried out on these nucleosides [9, 23], finding that the structures of each family have a specific antibacterial spectrum. For example, mureidomycin A is active against Pseudomonas aeruginosa [15, 24], liposidomycin and capuramycin are active against Mycobacterium spp. [13, 14], muraymycin B1, tunicamycin, and muraminomicins are active against gram-positive bacteria [12, 18, 25], and caprazamycin is active against Mycobacterium spp. and gram-positive bacteria [19]. A series of liposidomycin and muraymycin analogs were shown to exhibit broader spectrums of activity against Escherichia coli and P. aeruginosa, respectively [26, 27]. Consequently, the antibacterial spectrum could be a result of effective uptake into the target organism (compounds that are not efflux pump substrates) and structural features. Numerous chemical modification approaches have been reported for improving and expanding antibacterial activities, including liposidomycin analogs with simple amines and amides replacing its diazepanone ring [26], muraymycin derivatives possessing two functional groups, a lipophilic side chain, and a guanidine group at the accessory moiety [27], and caprazamycin derivatives which are 1″′-alkylanilide analogs of caprazene [28].

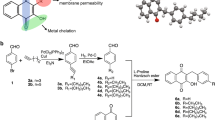

Muraminomicins are novel liponucleoside antibiotics isolated from the culture broth of Streptosporangium sp. SANK 60501, which are composed of a 2-deoxyuridine moiety, a 5-amino-d-2-deoxyribose moiety, a diazepanone ring system, and a fatty acid moiety [25]. Figure 1 shows the principal member of the muraminomicin family, muraminomicin F, and related minor members, muraminomicins G and H. Under mild alkaline hydrolysis, muraminomicins form the deacyl products, muraminomicin Z1 and Z2, which inhibit MraY but exhibit no antimicrobial activity in whole-cell assays (Fig. 1) [25]. We hypothesized that chemically modifying the 3″′-hydroxyl diazepanone ring of muraminomicin Z1 with a lipid moiety to modulate its cell membrane permeability whilst retaining its MraY potency could improve its antimicrobial potency. Here, we report an efficient semisynthetic methodology for obtaining a key 3″′-hydroxyl muraminomicin Z1 ester precursor by selectively protecting the muraminomicin core structure and hydrolyzing the fatty acid side chain, which does not require muraminomicin HPLC purification. By screening a series of muraminomicin derivatives for therapeutic efficacy in the murine infection model, we selected DS60182922 (1a) and DS14450354 (1b), which possess an aminoethylbenzoyldedecylglycyl moiety, and a diheptoxybenzyl-β-Ala- β-Ala moiety, respectively (Fig. 1). In this study, we evaluated the in vitro and in vivo activities of these muraminomicin derivatives against S. aureus.

Materials and methods

General

1H nuclear magnetic resonance (NMR) spectra were measured using a Varian Mercury 400 spectrometer at 400 MHz in CDCl3 or CD3OD, with 0.03% tetramethylsilane as an internal standard. Mass spectra were obtained using an Agilent Technologies Agilent 1100 series LC/MS.

Benzhydryl 2-[[(2S,3S,5R)-5-(2,4-dioxopyrimidin-1-yl)-3-hydroxy-tetrahydrofuran-2-yl]-[4-hydroxy-5-[[(4-nitrophenyl)methoxycarbonylamino]methyl]tetrahydrofuran-2-yl]oxy-methyl]-1,4-dimethyl-3-oxo-6-[(E)-tetradec-2-enoyl]oxy-1,4-diazepane-5-carboxylate (2)

To a solution of tetrahydrofuran (300 mL), water (100 mL), partially purified muraminomicin complex obtained by ethyl acetate extraction following reverse extraction with 0.2 M phosphate buffer (containing muraminomicin F 5.8 g, 4.89 mmol, calculated by HPLC analysis) was added p-nitrobenzyloxycarbonyl chloride (4.21 g, 19.5 mmol) and sodium carbonate (2.07 g, 19.5 mmol) at 0 °C. After stirring at 0 °C for 2 h, the reaction mixture was quenched with aqueous potassium hydrogen sulfate solution and ethyl acetate extraction was performed three times. The combined organic phases were washed with water three times and with saturated aqueous sodium chloride solution once, then dried over sodium sulfate and filtrated. The solvent was removed under reduced pressure and the resultant residue was used in the next reaction without further purification. Diphenyldiazomethane (15.0 g, 75.7 mmol) was added to a solution of p-nitrobenzyloxycarbonyl in dichloromethane (150 mL) at room temperature. After stirring at room temperature overnight, the solvent was removed under reduced pressure and the resultant residue was purified by flash column chromatography on neutral silica gel (0–10% methanol in ethyl acetate) to produce the title compound (12.0 g, 45%) as a pale yellow amorphous substance.

1H-NMR (400 MHz, CDCl3) δ: 0.85-0.90 (3H, m), 1.20−1.50 (16H, m), 1.80−2.10 (5H, m), 2.15−2.30 (3H, m), 2.40−2.50 (3H, m), 3.08−3.25 (2H, m), 3.25−3.33 (3H, m), 3.60−3.80 (3H, m), 4.00−4.20 (2H, m), 4.25−4.30 (1H, m), 4.40−4.60 (2H, m), 4.90−5.00 (1H, m), 5.05−5.20 (2H, m), 5.28−5.50 (2H, m), 5.75−5.83 (1H, m), 6.78−6.82 (1H, m), 6.95−7.05 (1H, m), 7.20−7.33 (8H, m), 7.33−7.55 (3H, m), 7.68−7.75 (1H, m), 8.15−8.23 (2H, m), 9.46−9.56 (1H, m). MS (FAB) m/z 1097 (M + H)+.

Benzhydryl 2-[[(2S,3S,5R)-5-(2,4-dioxopyrimidin-1-yl)-3-[(4-methoxyphenyl)methoxy]tetrahydrofuran-2-yl]-[4-[(4-methoxyphenyl)methoxy]-5-[[(4-nitrophenyl)methoxycarbonylamino]methyl]tetrahydrofuran-2-yl]oxy-methyl]-6-hydroxy-1,4-dimethyl-3-oxo-1,4-diazepane-5-carboxylate (7)

p-Methoxybenzyl trichloroacetimidate (61.4 g, 217 mmol) and p-toluenesulfonic acid monohydrate (3.50 g, 18.4 mmol) were added to a solution of 2 (12.0 g, 7.07 mmol) in dichloromethane (300 mL) at 0 °C. After stirring at room temperature for 6 h, the reaction was quenched with saturated sodium hydrogen carbonate solution in water and dichloromethane extraction was performed three times. The combined organic phases were washed with saturated aqueous sodium chloride solution once, dried over sodium sulfate, and filtrated, then the solvent was removed under reduced pressure and the resultant residue was purified by flash column chromatography on neutral silica gel (20–70% ethyl acetate in hexane) to produce the di-methoxybenzyl compound 3 (11.15 g, 81%) as a pale yellow amorphous substance. Palladium on carbon (10 wt%, 3.70 g) was added to a solution of 3 (11.1 g, 8.30 mmol) in tetrahydrofuran (70 mL) and water (50 mL) under an argon atmosphere. The flask was evacuated and purged with hydrogen gas five times on a hydrogen manifold, then the mixture was stirred under a hydrogen atmosphere at room temperature for 4 h. After complete conversion (monitored by thin layer chromatography), the catalyst was removed by filtration through celite, which was washed with tetrahydrofuran and water. The filtrate was used in the next reaction without further purification. p-Nitrobenzyloxycarbonyl chloride (4.21 g, 19.5 mmol) and sodium carbonate (2.07 g, 19.5 mmol) were added to the filtrate of 4 at 0 °C. After stirring at 0 °C for 0.5 h, the reaction mixture was quenched with aqueous potassium hydrogen sulfate solution and ethyl acetate extraction was performed three times. The combined organic phases were washed with water three times and with saturated aqueous sodium chloride solution once, dried over sodium sulfate, and filtrated. The solvent was removed under reduced pressure and the resultant residue was purified by flash column chromatography on neutral silica gel (0–30% methanol in ethyl acetate) to produce the carboxylic acid 5 (7.79 g, 80%) as a pale yellow amorphous substance. Potassium carbonate (4.63 g, 33.5 mmol) was added to a solution of 5 (7.79 g, 6.64 mmol) in methanol (380 mL) at room temperature. After stirring at room temperature for 4 days, the pH of the reaction mixture was adjusted to 4 using Dowex 50 W (H+ form), then the mixture was filtered. The remaining Dowex 50 W was washed with 5% aqueous ammonium solution. The combined filtrate was concentrated in vacuo and the resultant residue was used for the next step without further purification. Diazodiphenylmethane (3.00 g, 15.4 mmol) and acetic acid (0.5 mL) were added to a solution of the resulting residue of 6 in dichloromethane (100 mL) at room temperature. After stirring at room temperature for 0.5 h, the solvent was removed under reduced pressure and the resultant residue was purified by flash column chromatography on neutral silica gel (20–100% ethyl acetate in hexane) to produce the title compound (2.93 g, 53%) as a colorless solid.

1H-NMR (400 MHz, CDCl3) δ: 1.78−1.88 (2H, m), 1.95−2.02 (1H, m), 2.03−2.13 (1H, m), 2.35−2.45 (3H, m), 2.90−3.03 (1H, m), 3.18−3.33 (2H, m), 3.33 (3H, s), 3.50−3.60 (1H, m), 3.75−3.80 (6H, m), 3.39−4.00 (2H, m), 4.12−4.23 (3H, m), 4.30−4.45 (7H, m), 5.50−5.38 (5H, m), 6.70−6.90 (5H, m), 7.08−7.38 (14H, m), 7.42−7.50 (2H, m), 7.60−7.66 (1H, m), 8.15−8.20 (2H, m), 8.42−8.50 (1H, m). MS (FAB) m/z 1129 (M + H)+.

4-(2-azidoethyl)benzoic acid (9)

Sodium azide (8.51 g, 131 mmol) was added to a solution of 4-(2-bromoethyl)benzoic acid 8 (20.0 g, 87.3 mmol) in dimethylformamide (200 mL) at room temperature. After stirring at 50 °C for 2 h, the reaction mixture was cooled to room temperature, quenched with water, and ethyl acetate extraction was performed three times. The combined organic phases were washed with water three times and with saturated aqueous sodium chloride solution once, dried over sodium sulfate, and filtrated. The filtrate was concentrated in vacuo to produce an azide compound (15.44 g, 93%) as a colorless solid.

1H-NMR (400 MHz, CDCl3) δ: 2.93 (2H, t, J = 7.0 Hz), 3.55 (2H, t, J = 7.0 Hz), 7.32 (2H, d, J = 9.0 Hz), 8.05 (2H, d, J = 9.0 Hz). MS (FAB) m/z 192 (M + H)+.

4-[2-[(4-nitrophenyl)methoxycarbonylamino]ethyl]benzoic acid (10)

Triphenylphosphine (8.51 g, 89 mmol) and water (2.9 mL, 90 mmol) were added to a solution of 9 (15.44 g, 80.8 mmol) in tetrahydofuran (155 mL) at room temperature. After stirring at room temperature for 2 h, the reaction mixture was filtrated and concentrated in vacuo to produce an amino compound (31.21 g, 91%) as a colorless solid. p-Nitrobenzyl chloride (18.4 g, 80.8 mmol) and 1 N NaOH solution (160 mL, 160 mmol) were added to a solution of 4-(2-aminoethyl)benzoic acid (31.21 g, 80.8 mmol) in tetrahydofuran (155 mL) at 0 °C. After stirring at 0 °C for 2 h, the reaction mixture was washed with ethyl acetate and the organic phase was extracted with 1 N NaOH solution once, then the combined water phases were acidified with saturated KHSO4 solution and ethyl acetate extraction was performed three times. The combined organic phases were washed with saturated aqueous sodium chloride solution once, dried over sodium sulfate, filtrated, and concentrated in vacuo to produce a carboxylic acid compound (27.3 g, 92% in two steps) as a colorless solid.

1H-NMR (DMSO-D6) δ: 2.79 (2H, t, J = 7.0 Hz), 3.22−3.32 (3H, m), 5.13 (2H, s), 7.31 (2H, d, J = 7.8 Hz), 7.52 (2H, d, J = 7.8 Hz), 7.84 (2H, d, J = 7.8 Hz), 8.21 (2H, d, J = 7.8 Hz), 12.81 (1H, s). MS (FAB) m/z 345 (M + H)+.

2-[dodecyl-[4-[2-[(4-nitrophenyl)methoxycarbonylamino]ethyl]benzoyl]amino]acetic acid (11)

1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide, hydrochloride (water soluble carbodiimide) (17.0 g, 89 mmol), dimethylaminopyridine (10.9 g, 89 mmol), and methyl 2-(dodecylamino)acetate (19.1 g, 74 mmol) were added to a solution of 10 (25.5 g, 74.1 mmol) in dichloromethane (250 mL) at 0 °C. After stirring at room temperature for 5 h, the reaction mixture was quenched with water and ethyl acetate extraction was performed three times. The combined organic phases were washed with saturated aqueous sodium chloride solution, dried over sodium sulfate, and filtrated. The filtrate was concentrated in vacuo and the resultant residue was purified by flash column chromatography on neutral silica gel (10–60% ethyl acetate in hexane) to produce the methyl ester (33.0 g, 76%) as a colorless solid. Potassium hydroxide solution (1.0 mol/L) in water (8.5 mL, 8.5 mmol) was added to a solution of methyl ester (1.65 g, 2.83 mmol) in tetrahydrofuran (20 mL) and water (20 mL) at room temperature. After stirring for 15 min, the reaction mixture was quenched with saturated aqueous potassium hydrogen sulfate solution and ethyl acetate extraction was performed three times. The combined organic phases were washed with brine, dried over sodium sulfate, and filtrated. The resultant filtrate was concentrated in vacuo to produce the title compound (1.58 g, 98%) as a yellow amorphous substance.

Benzhydryl 2-[[(2S,3S,5R)-5-(2,4-dioxopyrimidin-1-yl)-3-[(4-methoxyphenyl)methoxy]tetrahydrofuran-2-yl]-[4-[(4-methoxyphenyl)methoxy]-5-[[(4-nitrophenyl)methoxycarbonylamino]methyl]tetrahydrofuran-2-yl]oxy-methyl]-6-[2-[dodecyl-[4-[2-[(4-nitrophenyl)methoxycarbonylamino]ethyl]benzoyl]amino]acetyl]oxy-1,4-dimethyl-3-oxo-1,4-diazepane-5-carboxylate (16a)

Compound 7 (270 mg, 0.239 mmol), 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide hydrochloride (366 mg, 1.91 mmol), and N,N-dimethylaminopyridine (116 mg, 0.95 mmol) were added to a solution of 11 (1.09 g, 1.91 mmol) in dichloromethane (30 mL) at 0 °C. After stirring at 0 °C for 1 h, the reaction mixture was quenched with aqueous potassium hydrogen sulfate solution and dichloromethane extraction was performed three times. The combined organic phases were washed with saturated sodium chloride solution in water, dried over sodium sulfate, and filtrated. The filtrate was concentrated in vacuo and the resultant residue was purified by flash column chromatography on silica gel (20–90% ethyl acetate in hexane) to produce the title compound (541 mg, containing starting material 11) as a colorless amorphous substance.

6-[2-[[4-(2-aminoethyl)benzoyl]-dodecylamino]acetyl]oxy-2-[[5-(aminomethyl)-4-hydroxy-tetrahydrofuran-2-yl]oxy-[(2S,3S,5R)-5-(2,4-dioxopyrimidin-1-yl)-3-hydroxy-tetrahydrofuran-2-yl]methyl]-1,4-dimethyl-3-oxo-1,4-diazepane-5-carboxylic acid (1a)

Water (1 mL) and 2,3-dichloro-5,6-dicyano-p-benzoquinone (219 mg, 0.87 mmol) were added to a solution of 16a (541 mg, containing starting material 11) in dichloromethane (20 mL) at 0 °C. After stirring at room temperature for 5 h, the reaction mixture was quenched with aqueous sodium hydrogen carbonate solution and dichloromethane extraction was performed three times. The combined organic phases were washed with saturated sodium chloride solution in water, dried over sodium sulfate, and filtrated. The filtrate was concentrated in vacuo and the resultant residue was purified by flash column chromatography on silica gel (5–10% methanol in dichloromethane) to produce the diol compound (232 mg, 67% in two steps) as a colorless amorphous substance. Palladium on carbon (10 wt%, 250 mg) was added to a solution of the diol compound (230 mg, 0.161 mmol) in tetrahydrofuran (20 mL) under an argon atmosphere. The flask was evacuated and purged with hydrogen gas five times on a hydrogen manifold, then the mixture was stirred under a hydrogen atmosphere at room temperature for 1 h. After complete conversion (monitored by thin layer chromatography), the catalyst was removed by filtration through celite, which was then washed with tetrahydrofuran. The filtrate was concentrated in vacuo and the resultant residue was purified by reverse phase column chromatography on C18 silica gel (0−50% acetonitrile in water) to produce the title compound (40.5 mg, 27%) as a colorless amorphous substance.

1H-NMR (400 MHz, D2O) δ: 1.50 (3H, t, J = 5.9 Hz), 1.68−1.97 (22H, m), 2.12−2.22 (2H, m), 2.60−2.64 (3H, m), 2.77−3.02 (4H, m), 3.04 (3H, s), 3.47−3.67 (4H, m), 3.69 (2H, s), 3.72−4.04 (5H, m), 4.34−4.61 (2H, m), 4.83−5.07 (3H, m), 6.00−6.21 (2H, m), 6.39−6.44 (1H, m), 6.58−6.63 (1H, m), 7.89−8.04 (4H, m), 8.36−8.45 (1H, m). MS (FAB) m/z 916 (M + H)+.

(3,4-diheptoxyphenyl)methanamine (13)

Potassium carbonate (79.7 g, 576 mmol) and 1-bromoheptane (86.53 g, 391 mmol) were added to a solution of 3,4-dihydroxybenzonitrile 12 (25.1 g, 186 mmol) in N,N-dimethylformamide (240 mL) at room temperature. After stirring at 80 °C for 2 h, the reaction mixture was cooled to room temperature, quenched with saturated aqueous sodium chloride solution, and ethyl acetate extraction was performed three times. The combined organic phases were washed with saturated aqueous sodium chloride solution, dried over magnesium sulfate, and filtrated. The filtrate was concentrated in vacuo and the resultant residue was recrystallized with hexane and ethyl acetate to produce 3,4-diheptoxybenzonitrile (56.0 g, 91%) as a pale red solid. The nitrile compound (51.5 g, 155 mmol) dissolved in tetrahydrofuran (200 mL) was added to a suspension of lithium aluminum hydride (8.00 g, 210 mmol) in tetrahydrofuran (300 mL) at 0 °C using a dropping funnel. After stirring at 60 °C for 20 min, the reaction mixture was cooled to 0 °C, then water (8 mL), 15% aqueous sodium hydroxide (8 mL), and water (24 mL) were added successively at 0 °C. After stirring at room temperature for 40 min, the reaction mixture was filtered through celite and the filter cake was washed with ethyl acetate. The filtrate was concentrated in vacuo and the resultant residue was purified by flash column chromatography on silica gel (10–50% methanol in ethyl acetate) to produce the title compound (51.5 g, 98%) as a pale red solid.

1H-NMR (400 MHz, CDCl3) δ: 0.87 (4H, t, J = 6.8 Hz), 1.24−1.37 (8H, m), 1.39−1.52 (8H, m), 1.74−1.83 (4H, m), 3.77 (2H, s), 3.97 (3H, dt, J = 12.0, 4.7 Hz), 6.76−6.85 (3H, m). MS (FAB) m/z 336 (M + H)+.

3-[3-[(3,4-diheptoxyphenyl)methyl-[(4-nitrophenyl)methoxycarbonyl]amino]propanoylamino]propanoic acid (14)

Methyl acrylate (8.18 g, 45 mmol) was added to a solution of 13 (33.5 g, 100 mmol) in methanol (100 mL) at room temperature. After stirring at room temperature for 24 h, the reaction mixture was concentrated in vacuo and the resultant residue was purified by flash column chromatography on neutral silica gel (20–70% ethyl acetate in hexane) to produce an amine compound (31.2 g, 74%) as a colorless amorphous substance. p-Nitrobenzyloxycarbonyl chloride (15.6 g, 72.5 mmol) and sodium carbonate (7.68 g, 72.5 mmol) were added to amine compound (29.08 g, 69.0 mmol) dissolved in tetrahydrofuran (200 mL) and water (200 mL) at 0 °C. After stirring at 0 °C for 2 h, the reaction mixture was quenched with water and ethyl acetate extraction was performed three times. The combined organic phases were washed with saturated aqueous sodium chloride solution, dried over sodium sulfate, and filtrated. The filtrate was concentrated in vacuo and the resultant residue was purified by flash column chromatography on silica gel (10–50% ethyl acetate in hexane) to produce a PNZ-protected compound (43.3 g, 94%) as a pale yellow amorphous substance. A solution of 1 N sodium hydroxide in water (180 mL) was added to the PNZ-protected compound (43.3 g, 72.2 mmol) dissolved in 1,4-dioxane (700 mL) and water (300 mL) at 0 °C. After stirring at room temperature for 20 min, the reaction mixture was quenched with aqueous potassium hydrogen sulfate solution and ethyl acetate extraction was performed three times. The combined organic phases were washed with saturated aqueous sodium chloride solution, dried over sodium sulfate, and filtrated. The filtrate was concentrated in vacuo to produce the title compound (39.9 g, 94%) as a colorless solid. The resultant residue was used in the next reaction without any further purification.

1H-NMR (CD3OD) δ: 0.85−0.90 (6H, m), 1.25−1.50 (12H, m), 1.65−1.78 (4H, m), 2.45−2.57 (2H, m), 3.50−3.58 (2H, m), 3.75−3.91 (2H, m), 3.94 (2H, t, J = 6.6 Hz), 4.46 (2H, d, J = 17.2 Hz), 5.26 (2H, d, J = 11.3 Hz), 6.71−6.87 (3H, m), 7.39−7.48 (1H, m), 7.56−7.65 (1H, m), 8.10−8.26 (2H, m). MS (FAB) m/z 609 (M + Na)+.

3-[3-[(3,4-diheptoxyphenyl)methyl-[(4-nitrophenyl)methoxycarbonyl]amino]propanoylamino]propanoic acid (15)

β-alanine ethyl ester hydrochloride (11.5 g, 74.8 mmol), 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide hydrochloride (16.9 g, 88.4 mmol), and 2-dimethylaminopyridine (10.8 g, 88.4 mmol) were added to 14 (39.9 g, 72.2 mmol) dissolved in dichloromethane (400 mL) at 0 °C. After stirring at room temperature for 1 h, the reaction mixture was quenched with 1 N hydrogen chloride solution and dichloromethane extraction was performed three times. The combined organic phases were washed with saturated sodium hydrogen carbonate solution in water, dried over sodium sulfate, and filtrated. The filtrate was concentrated in vacuo and the resultant residue was purified by flash column chromatography on silica gel (10–80% ethyl acetate in hexane) to produce the ethyl ester compound (40.2 g, 86%) as a colorless amorphous substance. A solution of 1 N sodium hydroxide in water (170 mL) was added to the ethyl ester compound (40.2 g, 58.6 mmol) dissolved in 1,4-dioxane (300 mL) at 0 °C. After stirring at room temperature for 20 min, the reaction mixture was quenched with 1 N hydrogen chloride solution in water and ethyl acetate extraction was performed three times. The combined organic phases were washed with saturated aqueous sodium chloride solution, dried over sodium sulfate, and filtrated. The filtrate was concentrated in vacuo to produce the title compound (37.3 g, 97%) as a colorless solid. The resultant residue was used in the next reaction without any further purification.

1H-NMR (CD3OD) δ: 0.83−0.92 (6H, m), 1.20−1.50 (12H, m), 1.63−1.78 (4H, m), 2.36−2.49 (4H, m), 3.31−3.41 (2H, m), 3.50−3.58 (2H, m), 3.74−3.90 (2H, m), 3.93 (2H, t, J = 6.4 Hz), 4.37−4.47 (2H, m), 5.21−5.31 (2H, m), 6.69−6.87 (3H, m), 7.37−7.48 (1H, m), 7.56−7.66 (1H, m), 8.01−8.26 (2H, m). MS (FAB) m/z 680 (M + Na)+.

Benzhydryl 6-[3-[3-[(3,4-diheptoxyphenyl)methyl-[(4-nitrophenyl)methoxycarbonyl]amino]propanoylamino]propanoyloxy]-2-[[(2S,3S,5R)-5-(2,4-dioxopyrimidin-1-yl)-3-[(4-methoxyphenyl)methoxy]tetrahydrofuran-2-yl]-[4-[(4-methoxyphenyl)methoxy]-5-[[(4-nitrophenyl)methoxycarbonylamino]methyl]tetrahydrofuran-2-yl]oxy-methyl]-1,4-dimethyl-3-oxo-1,4-diazepane-5-carboxylate (16b)

Compound 7 (7.0 g, 6.20 mmol), 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide hydrochloride (7.1 g, 37.0 mmol), and 2-dimethylaminopyridine (1.97 g, 16.1 mmol) were added to 15 (14.2 g, 21.6 mmol) dissolved in dichloromethane (700 mL) at 0 °C. After stirring at 0 °C for 2 h, the reaction mixture was quenched with aqueous potassium hydrogen sulfate solution and dichloromethane extraction was performed three times. The combined organic phases were washed with saturated sodium chloride solution in water, dried over sodium sulfate, and filtrated. The filtrate was concentrated in vacuo and the resultant residue was purified by flash column chromatography on silica gel (10–80% ethyl acetate in dichloromethane) to produce the title compound (9.58 g, 87%) as a colorless amorphous substance.

1H-NMR (400 MHz, DMSO-D6) δ: 0.78−0.87 (6H, m), 1.16−1.30 (10H, m), 1.30−1.43 (4H, m), 1.53−1.70 (4H, m), 1.78−2.45 (4H, m), 2.94−3.50 (7H, m), 3.65−3.75 (6H, m), 3.74−4.19 (8H, m), 4.20−4.41 (4H, m), 4.90−5.53 (9H, m), 6.51−6.93 (8H, m), 7.14−7.27 (15H, m), 7.36−7.65 (6H, m), 7.97−8.24 (6H, m), 11.27 (1H, s). MS (FAB) m/z 1769 (M + H)+.

2-[[5-(aminomethyl)-4-hydroxy-tetrahydrofuran-2-yl]oxy-[(2S,3S,5R)-5-(2,4-dioxopyrimidin-1-yl)-3-hydroxy-tetrahydrofuran-2-yl]methyl]-6-[3-[3-[(3,4-diheptoxyphenyl)methylamino]propanoylamino]propanoyloxy]-1,4-dimethyl-3-oxo-1,4-diazepane-5-carboxylic acid (1b)

Water (18 mL) and 2,3-dichloro-5,6-dicyano-p-benzoquinone (3.69 g, 16.3 mmol) were added to 16b (9.58 g, 5.42 mmol) dissolved in dichloromethane (335 mL) at 0 °C. After stirring at room temperature for 5 h, the reaction mixture was quenched with aqueous sodium hydrogen carbonate solution and dichloromethane extraction was performed three times. The combined organic phases were washed with saturated sodium chloride solution in water, dried over sodium sulfate, and filtrated. The filtrate was concentrated in vacuo and the resultant residue was purified by flash column chromatography on silica gel (5–10% methanol in dichloromethane) to produce a diol compound (5.50 g, 58%) as a colorless amorphous substance. Palladium on carbon (10 wt%, 1.28 g) was added to the diol compound (1.81 g, 5.41 mmol) dissolved in tetrahydrofuran (100 mL) under an argon atmosphere. The flask was evacuated and purged with hydrogen gas five times on a hydrogen manifold, then the mixture was stirred under a hydrogen atmosphere at room temperature for 2 h. After complete conversion (monitored by thin layer chromatography), the catalyst was removed by filtration through celite, which was washed with tetrahydrofuran. The filtrate was concentrated in vacuo and the resultant residue was purified by reverse phase column chromatography on C18 silica gel (0–40% acetonitrile in water) to produce the title compound (736 mg, 60%) as a colorless amorphous substance.

1H-NMR (400 MHz, CD3CN + D2O) δ: 0.84 (6H, t, J = 6.6 Hz), 1.23−1.34 (16H, m), 1.38−1.44 (2H, m), 1.68−1.73 (5H, m), 2.13−2.32 (4H, m), 2.34 (3H, s), 2.48−2.56 (4H, m), 2.85 (1H, dd, J = 13.7, 7.8 Hz), 2.99−3.04 (1H, m), 2.99 (3H, s), 3.07 (2H, t, J = 6.6 Hz), 3.11−3.16 (1H, m), 3.27−3.32 (1H, m), 3.38 (2H, t, J = 6.6 Hz), 3.88 (1H, dd, J = 6.6, 1.7 Hz), 3.93−3.97 (4H, m), 4.00 (2H, s), 4.07−4.16 (2H, m), 4.18−4.21 (1H, m), 4.27−4.32 (1H, m), 4.33−4.37 (1H, m), 5.40−5.43 (1H, m), 5.43−5.45 (1H, m), 5.74 (1H, d, J = 7.8 Hz), 5.95 (1H, dd, J = 6.8, 4.4 Hz), 6.91−6.93 (2H, m), 6.97 (1H, s), 7.73 (1H, d, J = 8.3 Hz). MS (FAB) m/z 1004 (M + H)+.

Bacterial strains

The S. aureus clinical isolates (24 strains of MSSA and 22 strains of MRSA) used in the susceptibility tests were obtained from the Tokyo Clinical Research Center in Japan. S. aureus ATCC 29213 was used as the control strain for the susceptibility test, S. aureus ATCC 6538P was used to measure spontaneous mutation frequency, and MSSA Smith was used in the in vitro time-kill studies and the murine systemic infection model. The strains were obtained from the American Type Culture Collection, the National Institute of Infectious Diseases, and Toho University, respectively. Methicillin-resistant S. aureus (MRSA) 10925 was a clinical isolate obtained from the Tokyo Clinical Research Center for use in the in vitro time-kill studies and the murine systemic infection model.

Susceptibility tests

The MICs of 1b and vancomycin against MSSA and MRSA were determined using a standard microdilution broth method [29], with Mueller−Hinton broth (Becton Dickinson and Company, Sparks, MD) containing 25 mg of Ca2+ and 12.5 mg of Mg2+ per liter (cation-adjusted Mueller−Hinton broth: CAMHB) and a 4 × 105 CFU/mL inoculum. The MIC was defined as the lowest concentration of the compound that inhibited the visible growth of the organism on the microdilution plates.

In vitro time-kill studies

The bactericidal activity of 1a and vancomycin against MSSA Smith, and that of 1a, 1b, and vancomycin against MRSA 10925, were determined using the time-kill method according to CLSI guideline M26-A [30]. S. aureus was grown overnight in brain heart infusion medium (BHI), then the cells (optical density at 620 nm = ~0.10) were diluted with CAMHB and cultured at 37 °C to yield an initial cell count of approximately 1 × 105 CFU/mL during exponential growth. Test compounds were added to the bacterial cultures at concentrations 0.25, 1, 4, 16, and 64 times the MIC, and incubated at 37 °C. At 0, 1, 2, 6, and 24 h after the addition of the test compounds, samples were collected from the culture medium, serially diluted, spread on BHI, and cultured at 37 °C. The number of colonies growing on the plate was counted after 24 h. The detection limit was 1 log10 CFU/mL; if no colonies were detected, the value of 1 log10 CFU/mL was adopted.

Spontaneous mutation frequency measurement

The frequency of spontaneous single-step mutations for 1a and 1b was determined by inoculating cultures (~109 CFU/mL; 100 μL) into Mueller−Hinton agar containing each compound at 2, 4, and 8 times the MIC. Plates were incubated aerobically at 35 °C for 72 h. The mutation frequency was calculated as the number of grown colonies on compound-containing medium per inoculum. The MICs for the parent and mutant strains were determined using the microdilution broth method.

A DNA fragment containing the mraY gene was amplified from the mutant strains by the polymerase chain reaction (PCR) and used for sequence analysis. mraY mutations (GenBank accession number NC 007795) responsible for resistance were identified by comparing the nucleotide sequence with that of the parent strain.

Animals

Male ddY (Japan SLC, Inc., Shizuoka, Japan) specific-pathogen-free mice were used in this study. All animal experiments were carried out according to the guidelines provided by the Institutional Animal Care and Use Committee of Daiichi Sankyo.

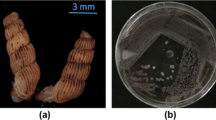

Murine systemic infection model

Mice were intraperitoneally infected with 0.2 mL of bacterial suspensions of MSSA Smith and MRSA 10925. The MRSA 10925 bacterial suspension was mixed with hog stomach gastric mucin to a final concentration of 5% prior to inoculation. MSSA Smith and MRSA 10925 were inoculated at concentrations of 7.4 × 106 – 2.5 × 107 CFU/mouse and 3.1 × 108 – 4.7 × 108 CFU/mouse, respectively. Solutions (0.1 mL) of 1a, 1b, and vancomycin were administered subcutaneously immediately and 4 h after inoculation. Five doses of serial twofold dilutions were used for each 50% effective dose (ED50) determination, with seven mice used for each dose. After inoculation, the mortality of the mice was recorded daily for 7 days. The ED50 and 95% confidence intervals were calculated from the survival rates on the seventh day after inoculation using the probit method.

Results and discussion

Semisynthesis of 3″′-ester precursor of muraminomicin Z1

In preliminary studies, when the 1″′-ester derivatives of muraminomicin F were treated under basic conditions, such as with sodium hydroxide solution, the major product was muraminomicin Z2; however, when the 1″′-carboxylic acid free derivatives of crude muraminomicins were treated under basic conditions, the major product was muraminomicin Z1. The 1″′-carboxylic acid chemical modification appeared to influence 3″′-fatty acid ester hydrolysis and elimination; therefore, we developed a scheme for synthesizing a key intermediate of the 3″′-ester modification of muraminomicin Z1 (Scheme 1). As described in our previous paper, culturing SANK 60501 with 0.5% myristic acid enhances muraminomicin F production and generates low levels of muraminomicins G and H. All three muraminomicins possessed 3a-methylglutaryl myristyl esters at their 3″′-hydroxyl diazepanone moieties. Partially purified muraminomicin complexes were obtained by ethyl acetate extraction and reverse extraction with 0.2 M phosphate buffer [25]. Following p-nitrobenzylcarbonate (PNZ) protection of the 5″-amino group, the complexes were treated under basic cooling conditions with an ice bath to generate 2,3-didehydro-tetradecanoyl esters via 3a-methylglutaryl ester elimination. Diphenylmethyl ester protection of the 1″′-carboxylic acid then produced compound 2, which was easily purified via silica gel column chromatography. We used the 2,3-didehydro-tetradecanoyl ester to protect the 3″′-hydroxyl group of the diazepanone ring during successive modification. Using p-methoxybenzyl (PMB) trichloroacetimidate and p-toluenesulfonic acid (TsOH) to protect 2 produced PMB ether 3. Hydrogenation selectively deprotected the diphenylmethyl and PNZ groups to produce PMB ether 4, with PNZ reprotection yielding carboxylic acid 5. Methanolysis of compound 5 using sodium carbonate produced alcohol 6, whilst reprotection of the carboxylic acid in the diphenylmethyl ester yielded the key intermediate ester precursor 7. The semisynthesis of compound 7 using partially purified muraminomicin complexes was successfully developed without any HPLC preparation. Thus, it is possible to increase the processing speed while facilitating scale-up synthesis.

Reagents and conditions: a p-nitrobenzyloxycarbonyl chloride, Na2CO3, tetrahydrofuran (THF), water, 0 °C; b diphenyldiazomethane, CH2Cl2, room temperature (rt), 45% (2 steps); c p-methoxybenzyl trichloroacetimidate, p-toluenesulfonic acid monohydrate, CH2Cl2, rt, 81%; d H2, Pd-C, THF, water, rt; e p-nitrobenzyloxycarbonyl chloride, Na2CO3, THF, water, 0 °C, 80% (two steps); (f) Na2CO3, methanol, rt, then Dowex 50 W (H+); and g diphenyldiazomethane, CH2Cl2, rt, 53% (two steps)

Muraminomicins possessing new side chains

1a and 1b (Fig. 1) were selected by in vitro and in vivo screening. Their unique side chains were synthesized as shown in Scheme 2. Compound 11, the side chain of 1a, was yielded by treating methyl 2-(dodecylamino)acetate with 4-[2-[(4-nitrophenyl)methoxycarbonylamino]ethyl]benzoic acid 10, which was derived from 4-(2-bromoethyl)benzoic acid 8 via azide replacement, reduction, and protection, followed by hydrolysis. The alkylation of 3,4-dihydroxybenznitrile using 1-bromoheptane and potassium carbonate, followed by reduction of the nitrile group using lithium aluminum hydride, produced 3,4-diheptoxybenzylamine 13. Michael addition using methyl acrylate in methanol, PNZ protection, and hydrolysis yielded beta-alanine derivative 14, whilst methyl beta-alanine condensation and hydrolysis produced carboxylic acid 15, the side chain of 1b. As shown in Scheme 3, the acylation of ester precursor 7 with carboxylic acids 11 and 15 was readily accomplished using WSCI and 4-dimethylaminopyridine (DMAP) to obtain esters 16a and 16b, respectively. The deprotection of PMB using 2,3-dichloro-5,6-dicyano-p-benzoquinone (DDQ) followed by diphenylmethyl ester hydrogenation and p-nitrobenzyloxycarbonate deprotection yielded 1a and 1b.

Reagents and conditions: a NaN3, DMF, 50 °C, 93%; b triphenylphosphine, water, THF, room temperature (rt), 91%; c p-nitrobenzyloxycarbonyl chloride, NaOH, THF, water, 0 °C, 91% (two steps); d methyl 2-(dodecylamino)acetate, 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide, hydrochloride (water soluble carbodiimide, WSC), dimethylaminopyridine (DMAP), 0 °C; e NaOH, THF, water, rt, 81%; f 1-bromoheptane, K2CO3, rt, 91%; g LiAlH4, THF, 0 °C, 98 %; h methyl acrylate, methanol, rt, 74%; i p-nitrobenzyloxycarbonyl chloride, Na2CO3, THF, water, 0 °C, 94%; j NaOH, 1,4-dioxane, water, rt, 94%; k β-alanine ethyl ester hydrochloride, WSC, DMAP, 0 °C, 94%; and l NaOH, 1,4-dioxane, water, rt, 97%

Antibacterial activity

The MICs that inhibited 50 and 90% of the strains (MIC50 and MIC90, respectively) of MSSA and MRSA of 1b were 1 and 2 μg/mL, respectively. The MICs of 1b against MSSA were the same as those against MRSA, suggesting that no cross resistance exists between methicillin and muraminomicin derivatives. The MIC50 and MIC90 of MSSA and MRSA of vancomycin were 0.5 and 1 μg/mL, respectively. Moreover, muraminomicin derivatives exhibited almost same antibacterial activity against vancomycin-resistant enterococci as the susceptible strain (data not shown).

Bactericidal activity

Figure 2a, b shows the time-kill curves for 1a and vancomycin against MSSA Smith. 1a reduced the viable cell count of MSSA Smith to almost 2 log10 CFU/mL of the inoculum within 4 h of exposure to the MIC and higher concentrations; however, regrowth was observed 24 h after treatment with 1a at the MIC. Concentrations of 1a higher than the MIC reduced the viable cell count by at least 3 log10 CFU/mL after 24 h. Both 1a and vancomycin killed MRSA 10925 in a time-dependent manner (Fig. 2c, e); however, 1b killed MRSA 10925 in a stronger, concentration-dependent manner. 1b also reduced the viable cell count to 3 log10 CFU/mL of the inoculum within 6 h of exposure to 16 times the MIC (Fig. 2d). The reason for the difference between the bactericidal activities of 1a and 1b against MRSA is unclear; however, cell permeability, membrane cytotoxicity or target protein affinity may be contributing factors.

Time-killing curves against MSSA Smith (a, b) and MRSA 10925 (c–e). Arrows with asterisks indicate the addition of the antibiotic to the bacterial culture. Symbols: cross, drug-free control; filled circle, 0.25 times the MIC; filled triangle, MIC; filled square, four times the MIC; open circle, 16 times the MIC; open triangle, 64 times the MIC. The dotted line indicates a 3 log10 reduction from the inoculum size

Spontaneous mutation frequency

The mutation frequencies of 1a at 2, 4, and 8 times the MIC were 7.7 × 10−5, 3.2 × 10−5, and 3.1 × 10−7, respectively (Table 1). Susceptibility tests were performed on ten colonies grown on plates containing 1a (Table 2); all colonies were 4−16-fold less susceptible to 1a. The only mutant that was 16-fold less susceptible harbored a single mraY gene mutation which caused a phenylalanine to isoleucine substitution at the 226 position (F226I) of the MraY protein, indicating that MraY was the primary target. The mutation frequencies of 1b at 2, 4, and 8 times the MIC were 1.4 × 10−8, below the limit of detection, and below the limit of detection (Table 1), respectively. Of the 11 colonies, 8 were twofold less susceptible to 1b, eightfold less susceptible to 1a, and possessed the F226I MraY substitution (Table 3). The difference between the 1b susceptibility of these mutants and the parent strain was only twofold, and was smaller than that of 1a. Both the F226I mutants and the parent strains were susceptible to vancomycin, suggesting that there was no cross resistance between muraminomicin derivatives and vancomycin. No mutation in mraY gene was identified in the nine 1a-resistant mutants, suggesting the presence of other mechanisms of resistance such as impermeability and efflux pumps; however, further studies are required to clarify this.

Murine systemic infection model

The ED50 and 95% confidence intervals of 1a, 1b, and vancomycin against systemic murine infection caused by MSSA Smith and MRSA 10925 are summarized in Table 4. The therapeutic efficacy of 1a against MSSA Smith and MRSA 10925 infections was comparable to that of vancomycin. For 1b, five of the seven mice infected by MSSA Smith survived at a dose of 1.56 mg/kg, and four of the seven mice infected by MRSA 10925 survived at a dose of 0.78 mg/kg (Supplement). The therapeutic efficacies of mureidomycin A and muraymycin B1 have been reported for murine systemic infection models induced by P. aeruginosa and S. aureus, respectively [18, 24]. Although not a simultaneous comparison, the therapeutic efficacies of the muraminomicin derivatives are comparable to that of muraymycin B1.

In conclusion, these results suggest that muraminomicin derivatives have potent antistaphylococcal activities in vitro and in vivo, and are excellent candidates for further evaluation as MRSA infection treatments in humans. (Tables 1–4)

References

Liu C. et al. Clinical practice guidelines by the Infectious Diseases Society of America for the treatment of methicillin-resistant Staphylococcus aureus infections in adults and children. Clin Infect Dis. 2011;52:e18–e55. https://doi.org/10.1093/cid/ciq146.

Lowy FD. Staphylococcus aureus infections. N Engl J Med. 1998;339:520–32.

Chien JW, Kucia ML, Salata RA. Use of linezolid, an oxazolidinone, in the treatment of multidrug-resistant gram-positive bacterial infections. Clin Infect Dis. 2000;30:146–51.

Arbeit RD. et al. The safety and efficacy of daptomycin for the treatment of complicated skin and skin-structure infections. Clin Infect Dis. 2004;38:1673–81.

Jorgenson MR, DePestel DD, Carver PL. Ceftaroline fosamil: a novel broad-spectrum cephalosporin with activity against methicillin-resistant Staphylococcus aureus. Ann Pharmacother. 2011;45:1384–98.

McGuinness WA, Malachowa N, DeLeo FR. Vancomycin resistance in Staphylococcus aureus. Yale J Biol Med. 2017;90:269–81.

Gómez CN, Siller RM, Muñoz BJL. Mechanisms of resistance to daptomycin in Staphylococcus aureus. Rev Esp Quimioter. 2017;30:391–96.

Musumeci R, et al. Resistance to linezolid in Staphylococcus spp. clinical isolates associated with ribosomal binding site modifications: novel mutation in domain V of 23S rRNA. New Microbiol. 2016;39:269–73.

Kimura K, Bugg TDH. Recent advances in antimicrobial nucleoside antibiotics targeting cell wall biosynthesis. Nat Prod Rep. 2003;20:252–73.

Boyle DS, Donachie WD. MraY is an essential gene for cell growth in Escherichia coli. J Bacteriol. 1998;180:6429–32.

Thanassi JA, Hartman-Neumann SL, Dougherty TJ, Dougherty BA, Pucci MJ. Identification of 113 conserved essential genes using a high-throughput gene disruption system in Streptococcus pneumoniae. Nucleic Acids Res. 2002;30:3152–62.

Takatsuki A, Arima K. Tamura G. Tunicamycin, a new antibiotic. I. Isolation and characterization of tunicamycin. J Antibiot. 1971;24:215–23.

Isono K, et al. Liposidomycins: novel nucleoside antibiotics which inhibit bacterial peptidoglycan synthesis. J Antibiot. 1985;38:1617–21.

Yamaguchi H, et al. Capuramycin, a new nucleoside antibiotic. Taxonomy, fermentation, isolation and characterization. J Antibiot. 1986;39:1047–53.

Inukai M, et al. Mureidomycins A-D, novel peptidylnucleoside antibiotics with spheroplast forming activity. I. Taxonomy, fermentation, isolation and physico-chemical properties. J Antibiot. 1989;42:662–6.

Karwowski JP, et al. Pacidamycins, a novel series of antibiotics with anti-Pseudomonas aeruginosa activity. I. Taxonomy of the producing organism and fermentation. J Antibiot. 1989;42:506–11.

Chatterjee S, et al. Napsamycins, new Pseudomonas active antibiotics of the mureidomycin family from Streptomyces sp. HIL Y-82,11372. J Antibiot. 1994;47:595–8.

McDonald LA, et al. Structures of the muraymycins, novel peptidoglycan biosynthesis inhibitors. J Am Chem Soc. 2002;124:10260–1.

Igarashi M, et al. Caprazamycin B, a novel anti-tuberculosis antibiotic, from Streptomyces sp. J Antibiot. 2003;56:580–3.

Murakami R, et al. A-102395, a new inhibitor of bacterial translocase I, produced by Amycolatopsis sp. SANK 60206. J Antibiot. 2007;60:690–5.

Murakami R, et al. A-94964, a novel inhibitor of bacterial translocase I, produced by Streptomyces sp. SANK 60404. I. Taxonomy, isolation and biological activity. J Antibiot. 2008;61:537–44.

Fujita Y, et al. A-90289 A and B, new inhibitors of bacterial translocase I, produced by Streptomyces sp. SANK 60405. J Antibiot. 2011;64:495–501.

Bugg TD, Lloyd AJ, Roper DI. Phospho-MurNAc-pentapeptide translocase (MraY) as a target for antibacterial agents and antibacterial proteins. Infect Disord Drug Targets. 2006;6:85–106.

Isono F, Katayama T, Inukai M, Haneishi T. Mureidomycins A-D, novel peptidylnucleoside antibiotics with spheroplast forming activity. III. Biological properties. J Antibiot. 1989;42:674–9.

Fujita Y, et al. Muraminomicins, new lipo-nucleoside antibiotics from Streptosporangium sp. SANK 60501-structure elucidations of muraminomicins and supply of the core component for derivatization. J Antibiot. 2019. https://doi.org/10.1038/s41429-019-0215-7

Dini C, et al. Synthesis of sub-micromolar inhibitors of MraY by exploring the region originally occupied by the diazepanone ring in the liposidomycin structure. Bioorg Med Chem Lett. 2002;12:1209–13.

Takeoka Y, et al. Expansion of antibacterial spectrum of muraymycins toward Pseudomonas aeruginosa. ACS Med Chem Lett. 2014;5:556–60.

Takahashi Y. et al. Novel semisynthetic antibiotics from caprazamycins A–G: caprazene derivatives and their antibacterial activity. J Antibiot. 2013;66:171–8.

Clinical and Laboratory Standards Institute. Methods for dilution antimicrobial susceptibility tests for bacteria that grow aerobically—9th ed.: Approved Standard M07-A9. Wayne, PA, USA: CLSI; 2012.

National Committee for Clinical Laboratory Standards. Methods for determining bactericidal activity of antimicrobial agents; approved guideline, NCCLS document M26-A. Wayne, PA, USA: NCCLS; 1999.

Acknowledgements

We thank Mr. Yoshikazu Nezu (Specialty Medicine Research Laboratory), Dr. Naoyuki Maeda (Biomarker & Translational Research Department) and Dr. Yasuyuki Abe (Specialty Medicine Research Laboratory) for the safety evaluation and Dr. Takahiro Shibayama (Clinical Pharmacology Department) for the PK analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Kagoshima, Y., Tokumitsu, A., Masuda, T. et al. Muraminomicins, novel ester derivatives: in vitro and in vivo antistaphylococcal activity. J Antibiot 72, 956–969 (2019). https://doi.org/10.1038/s41429-019-0235-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41429-019-0235-3