Abstract

We previously reported the quantitative main-chain scission reaction of polymers by a conjugate substitution reaction in aqueous ammonia, although the detailed behavior of the reaction was not analyzed. Herein, the degradation of a poly(conjugated ester), prepared from 1,4-butylene bis[α-(bromomethyl)acrylate] and fluorescein, with aqueous solution of various nucleophiles was investigated. Direct observation using UV‒vis spectrometry was effective for the analysis at the earliest stage of degradation, while size-exclusion chromatography was used for long-term degradation. The main-chain scissions were observed by a conjugate substitution reaction with ammonia, n-propylamine, diethylamine and α-amino acids, while similar degradation was observed with sodium acetate and water in the presence of triethylamine as a catalyst. The nucleophilicity of the nucleophiles and their affinity for the polymer affected the reaction rates in the earliest stage. On the other hand, to achieve complete chain scission, ammonia was most effective, probably because the dissolution of the degradation products led to the exposure of new polymer surfaces.

Similar content being viewed by others

Introduction

Synthetic polymers are superior in providing materials with various properties by selecting monomers and polymerization methods. Over the past century, the chemistry of monomers and polymerization has evolved in the process of performance optimization. On the other hand, little attention has been given to the degradability of synthetic polymers. As a result, environmental pollution, particularly in marine environments, by plastic wastes has become a significant global issue [1, 2]. In this context, biodegradable polymers that are finally metabolized to carbon dioxide, water, and other nontoxic products seem to be ideal materials. However, it is known that biodegradation is dependent on the environment [3]; for example, poly(butylene succinate) is degradable in soil but not in the sea [4].

To improve the environmental dependence of biodegradation, polymer materials equipped with a mechanism that assists biodegradation have been developed. For example, biodegradable plastics containing enzymes [5] and spores [6] have been reported. These are stable when used but acquire degradability in environments, including the sea, after pulverization into microplastics. This approach also excels in that it is a plastic material with a ‘switch’ that initiates degradation after environmental spills. On the other hand, taking advantage of the tunability of the molecular structure, synthetic polymers exhibiting chemical degradation to assist or replace biodegradation have also been developed; for example, disulfide [7, 8], thioacetal [9, 10] and thioaminal [11] bonds have been reported for oxidative degradation.

The enzymes [5] and spores [6] work as catalysts for the ester cleavage of biodegradable polyesters. Thus, it can be regarded as replacing a part of the biodegradation process with chemical degradation. Similarly, polymers exhibiting both bio and chemo-degradability are expected to yield environmentally degradable polymer materials equipped with a ‘switch’ that controls the timing of degradation. Consequently, we consider that exploring chemical degradation mechanisms working in aqueous media is an important process to develop novel environmentally degradable polymer materials.

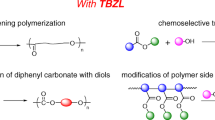

Recently, we reported that the conjugate substitution reaction of allyl-substituted methacrylates [12] is effective for polymer degradation not only in organic solutions but also in aqueous suspensions [13, 14]. Scheme 1A shows the reaction mechanism of the conjugate substitution reaction; the methacrylate moiety accepts nucleophilic attack, and the double bond is reformed by eliminating the allyl substituent. Since the methacrylate moiety is an excellent Michael-addition acceptor, the conjugate substitution reaction proceeds with various nucleophiles, such as amines [15,16,17], carboxylate anions [15], alkoxide anions [15] and thiols [18,19,20,21]. Therefore, the reaction was applied to a polycondensation reaction, affording poly(conjugated ester)s with various nucleophilic monomers [20]. Notably, the poly(conjugated ester)s with bisphenols underwent chemical degradation in aqueous ammonia (NH3 aq) through a conjugate substitution reaction (Scheme 1B) [13, 14]; the polymer recovered the bisphenol monomer quantitatively at room temperature after 24 h. That is, chemical degradation by a conjugate substitution reaction quantitatively progressed with ammonia in aqueous media under ambient conditions. This fact suggests that the conjugate substitution reaction has a potential application to polymer degradation in the environment. To examine the potential, it is important to clarify the nucleophiles and conditions under which the polymer exhibits resistance to or initiates polymer degradation. Unfortunately, however, the details of aqueous degradation by conjugated substitution reactions are not yet understood. In previous work, the degradation products were extracted and analyzed using size-exclusion chromatography (SEC) and NMR to monitor the progress of the reaction. However, this method was only effective after the degradation progressed to some extent. In other words, no information was available about the earliest stage of degradation. At the earliest stage, the reaction system was determined to be in a heterogeneous suspension. We are thus interested in the polymer degradation rate in this earliest suspended state.

In this report, the degradation of polymers in the earliest stage was investigated by direct observation using UV‒vis spectrometry, and the obtained information was combined with conventional SEC evaluations to describe the overall process of degradation. Hence, the effective conditions and nucleophiles for chemical degradation were revealed, suggesting the design of environmentally degradable polymer materials.

Results and discussion

Synthesis of poly(conjugated ester)s

In our previous work, polymer degradation in aqueous media was achieved via conjugate substitution and acyl substitution reactions [13, 14]. However, the polymer used in this report contains regioisometry in the repeating units, which may affect the degradation behavior. Therefore, P6/7, which does not contain regioisometry in the repeating units, was newly prepared (Scheme 2).

We previously prepared the monomer 6a via three steps from tert-butyl acrylate (1) [20]. On the other hand, a more efficient route starting from diacrylate has recently been reported [22]. Thus, the procedure was traced to prepare 6b; in the literature, the authors synthesized 1,6-hexylene bis[α-(bromomethyl)acrylate] as a liquid [22], whereas 6b was obtained as a colorless crystal. Since the high crystallinity of 6b was convenient to purify by recrystallization, we chose 6b as a monomer in this study.

The polymerization of 6b and fluorescein (7) was conducted in acetone in the presence of triethylamine (Et3N) under reflux for 23 h. The initial reaction system was heterogeneous at 25 °C but became homogeneous under reflux, and an orange precipitate was formed after 23 h. Unfortunately, the obtained polymer as the precipitate, P6/7H, was not completely soluble in tetrahydrofuran (THF) and chloroform (CHCl3), so the exact characterization was impossible. The number-averaged molar mass (Mn) and molar mass dispersity (Ð) of the THF-soluble fraction of P6/7H were 12800 g‧mol−1 and 2.31, respectively (Fig. S3). The glass-transition temperature (Tg) was 85 °C (Fig. S4), suggesting that the polymer was in a glass state at 25 °C. To confirm the chemical structure, P6/7H was decomposed using excess diethylamine (Et2NH) in acetone-d6. The 1H NMR spectrum of the reaction mixture agreed with the expected structures (Fig. S5), suggesting that the initial polymer was obtained without any side reactions. In our initial attempt using 6b with low purity that did not form crystals, a similar polymer with a lower molar mass was obtained (P6/7L, Mn = 3300 g‧mol−1, Ð = 2.65, Figs. S6, 7). This sample was also used in the degradation test to investigate the effects of molar masses.

Degradation of poly(conjugated ester)s in aqueous media

Monitoring of the main-chain scission

In this report, UV‒vis spectrometry was applied to monitor the recovery of monomers by the degradation of P6/7H and P6/7L via a conjugate substitution reaction (Scheme 3). Since UV‒vis spectrometry can detect the recovered monomer with high sensitivity and can be measured in a short period, this procedure has an advantage in monitoring the earliest stage of the reaction. On the other hand, this procedure is not effective for the later stage of degradation, as UV‒vis spectrometry is not suitable for samples at high concentrations. As SEC provides more information, this technique was used in the later stage.

Before the degradation test was employed, the polymer samples were comminuted using a mixer mill to make the particle sizes and their surface areas uniform, which would affect the reaction rate (Fig. 1A). The polymer powder (1.0 mg) was then soaked in NH3 aq (1 M, ca. 2 wt%, 3.0 mL). The temperature during the reaction was kept at 25 °C using a temperature-control apparatus attached to the UV‒vis spectrometer. As shown in Fig. 1B, the initial reaction system was heterogeneous, and the aqueous phase was a colorless solution; after the reaction progressed, the aqueous phase turned yellow due to the dissolution of recovered 7 (Fig. 1C). The color changes were monitored by UV‒vis spectrometry in real time (Fig. 2A), and the concentration of 7 was determined according to the calibration line prepared in advance (Fig. S1B). It should be noted that the reaction was monitored as a yield of recovered 7 but not the degree of progress of conjugate substitution (Fig. 2B). Thus, even if main-chain scission occurred by conjugate substitution, it was not detected as long as the fragments were not monomers but oligomers. In fact, there were no significant changes in the absorption spectra except for peak growth from recovered 7 (Fig. 2A). Furthermore, degradation by acyl substitution of hydrolysis could not be detected in this procedure. In fact, P6/7H was treated in 0.1 M aqueous tetrabutylammonium hydroxide (0.1 M Bu4N+‧OH− aq), but the yield of 7 determined from UV‒vis spectra was less than 4% even after 74 days (Fig. S8A). Since the measurement was discontinued at this point, visual observations were conducted thereafter; nevertheless, the color of the aqueous phase did not change significantly even after 103 days. On the other hand, the SEC curves of the freeze-dried reaction mixture after 103 days suggested complete degradation of polymers to small molecules (Fig. S8B). The differences between the evaluation of degradation progress by UV‒vis spectrometry and SEC can be explained by the reaction mechanism. As hydroxide anions are hard nucleophiles, they favor acyl substitution by carbonyl attack rather than conjugate substitution reactions (Scheme 3). Since acyl substitution did not afford 7, the UV‒vis spectra did not show a significant absorption peak. In other words, the evaluation of UV‒vis spectrometry selectively detected the main-chain scission by conjugate substitution. This was convenient for this study because our purpose was to evaluate the potential of the conjugate substitution reaction as a tool for polymer degradation in aqueous media.

Mechanism of polymer degradation

Figure 2B shows the concentration of 7 in each reaction period in the degradation test using P6/7H and 1 M NH3 aq. The increase in the concentration of 7 over the reaction time implied the degradation of P6/7H in a heterogeneous system, although the polymer was in a glass state. The reaction was very slow until approximately 155 min after the start of the reaction, while it accelerated rapidly thereafter. After 200 min, the concentration of 7 increased at an almost constant rate. For convenience, these three periods are named the induction period (t ≤ 155 min), transition period (155 min < t ≤ 200 min), and constant-rate period (200 min < t). To explain this behavior, the following hypothesis was proposed: Given random chain-scission by the conjugate substitution reaction, fragmentation of the polymer chain should occur from the beginning of the reaction. Moreover, the recovery of 7 occurs only for chain scission at the end. For this reason, the recovery of 7 was very slow in the induction period. Since the number of chain ends increases as fragmentation progresses, the possibility of the recovery of 7 increases drastically. This corresponds to the transition period. The constant-rate period can be attributed to the adsorption of NH3 or the dissolution of 7.

To verify this hypothesis, the effects of molar mass were first investigated. A similar degradation test using 1 M NH3 aq was applied to P6/7L. As a result, the induction period for degradation became much shorter (25 min) than that for P6/7H (155 min) (Fig. S9). That is, the lower the molar mass was, the shorter the induction period; this suggests that the induction period and the later transition period are related to the possibility of main-chain scission at the chain end.

If the constant-rate period was attributed to the dissolution of 7, the release rate of 7 should be independent of the concentration of NH3. Therefore, degradation tests were conducted for P6/7H and P6/7L using 0.1 M NH3 aq (Fig. 2C). Although the induction period was significantly lengthened, the tendency of P6/7L to exhibit a shorter induction period was the same as that of degradation with 1 M NH3 aq. The concentration-increase rates of 7 in the constant-rate period were estimated from the slope of plots and the theoretical yield of 7 (1.80 × 10−6 mol). The rate was much slower for the degradation with 0.1 M NH3 aq (5.21 × 10−9 mol·min−1) than that with 1 M NH3 aq (1.68 × 10−7 mol·min−1). This suggests that the rate-constancy was due to the adsorption of NH3 rather than the dissolution of 7.

Effects of temperature

The degradation tests of P6/7H in 1 M NH3 aq were conducted at different temperatures (Fig. 3A). The induction periods became shorter as the temperature increased. In particular, degradation at 60 °C proceeded so fast that the UV‒vis spectra saturated after 15 min. In all experiments, constant-rate periods were clearly observed. Then, Arrhenius plots of the rates in these periods were prepared (Fig. 3B). Since the plots were on straight lines, it was revealed that the degradation mechanism was not dependent on temperature and that a higher temperature was effective in promoting degradation.

Degradation using various amines

The degradation tests were conducted using 0.1 M aqueous solution of NH3, n-propylamine (PrNH2), Et2NH, and Et3N. PrNH2 and Et2NH resulted in much faster degradation than NH3 (Fig. 4A). Since the degradation was so fast, the induction periods and transition periods were not clearly observed. As mentioned above, the degradation in the constant-rate period was dependent on the absorption of nucleophiles. Since PrNH2 and Et2NH were more hydrophobic than NH3, the absorption onto the polymer would be faster than that of NH3. Therefore, the degradation progressed faster in the presence of these amines. For degradation using Et3N, the details are discussed later.

Figure 4B shows the SEC curves of the samples treated with NH3 and Et2NH after 100 days. No polymeric peak was observed for the sample treated with NH3, suggesting complete degradation. On the other hand, although the peak was shifted to the lower molar-mass region, the polymeric peak remained in the SEC curve of the sample with Et2NH. This tendency was in sharp contrast to the degradation in the earliest stage, where the degradation with Et2NH progressed faster. We speculate that this result is related to the water solubility of the degradation products. Since the dimethacrylate formed by the conjugate substitution reaction with Et2NH was hydrophobic, it remained on the surface of the polymer particles and inhibited the subsequent degradation reaction. However, we do not have conclusive evidence at the current stage, as we have not performed surface analysis of the polymer particles during degradation.

Notably, degradation was also observed in the presence of Et3N. Xu et al. reported the self-degradation of poly(conjugated ester)s to a cyclic oligomer catalyzed by Et3N [23]; although they referred to the reaction mechanism as acyl substitution, we suspect it the reaction was a conjugate substitution reaction due to its reversibility [12]. A possible scheme is self-degradation (Scheme 4, path A). As the reaction in this paper was conducted in aqueous media, the reaction with water catalyzed by Et3N (path B) is a relatively reasonable mechanism to explain the degradation.

Degradation using a carboxylate anion

While the pKas of 7 are 4.31 and 6.43 [24], that of acetic acid is 4.73 [25]. Therefore, the bond exchange of P6/7H with the acetate anion by a conjugate substitution reaction was expected. In the previous section, Et3N promoted conjugate substitution with water. Similarly, we expected that Et3N would promote conjugate substitution with acetate anions. Therefore, P6/7H was soaked in 1 M aqueous sodium acetate (Na+ −OAc aq) in the presence of Et3N (10 mol%) as a catalyst. Figure 5A shows the growth at a concentration of 7. The degradation progressed without a clear induction period. This was probably because of the reaction mechanism consisting of two steps; Et3N formed an ammonium intermediate as described in Scheme 4, followed by conjugate substitution with acetate anion. In fact, the degradation in the absence of Et3N scarcely progressed within 880 min. As mentioned above, Et3N also promoted conjugate substitution with water (Scheme 4, path B); however, the degradation in the presence of Na+ −OAc (Fig. 5A) was much faster than that in its absence (Fig. 4A). This difference also supported the reaction mechanism described in Scheme 4. Although the degradation in the absence of Et3N was slow and incomplete, the SEC curves after 100 days shifted to a lower molar-mass region (Fig. 5B).

Degradation using α-amino acids

Since degradation using amines and acetate anions progressed, we were interested in using α-amino acids bearing both amino and carboxy groups for the degradation of poly(conjugated ester)s by a conjugate substitution reaction. Then, P6/7H was soaked with 1 M aqueous solutions of alanine (Ala), arginine (Arg), and proline (Pro). Figure 6A shows the increase in the concentration of 7 in the solution of Arg and Pro. The dissolution of 7 was observed for the solution of Arg, while that of Pro did not exhibit the significant absorption peak of 7 in the UV‒vis spectra. Similarly, no spectral change was observed for the degradation test with Ala. However, the solubility of 7 in Pro and Ala solutions should be considered, as 7 was insoluble in acidic and neutral water. Therefore, the degradation in Pro solution was monitored by SEC (Fig. 6B). The polymer peak shifted to the lower molar-mass region over reaction time, although the degradation rate was slow. Figure 6C shows the comparison of SEC curves of the reaction mixtures after 100 days. The decrease in molar mass was more significant in the Pro solution than in the Ala solution. Considering the reaction mechanism of conjugate substitution, amino acids with stronger nucleophilicity are more effective. Thus, the results that the degradation by Pro was faster than that by Ala seem reasonable.

Conclusion

For the development of degradable polymers in marine, we evaluated the potential for degradation using conjugate substitution reactions in aqueous media. In this study, fluorescein was used as a monomer for the direct observation of degradation using UV‒vis spectrometry. This procedure was effective in monitoring the earliest stages of the reaction. Combined with long-term observations using SEC, the behavior of this reaction has been clarified. At the earliest stage, the affinity between the nucleophile and the polymer affected the reaction rate, leading to faster degradation for relatively hydrophobic amines. On the other hand, to achieve complete chain scission, ammonia, which led to the slowest degradation at the earliest stage, was effective. The dissolution of the degradation products was suggested to be important to cause the exposure of new polymer surfaces. Notably, Et3N functioned as a catalyst to accelerate the degradation, particularly by Na+·−OAc and water. Poly(conjugated ester)s were also cleaved by α-amino acids such as proline, although the reaction was slow relative to the concentration of amino acids; incomplete degradation was observed even after 100 days.

Unlike acyl substitution reactions, including ester hydrolysis, conjugate substitution reactions do not require harsh conditions such as strong acids/bases or heating. However, the above results suggested that poly(conjugated ester)s should be used together with tertiary amine catalysts or nucleophiles for application to marine-degradable polymers. In practice, such chemical main-chain scission is expected to be used not as a single process of degradation but as a switch to promote biodegradation. We have previously reported a method to insert a conjugated ester skeleton into a biodegradable polymer by copolymerization [21]. We are currently applying the knowledge obtained here to develop marine-degradable polymers.

References

Moore CJ. Synthetic polymers in the marine environment: A rapidly increasing, long-term threat. Environ Res. 2008;108:131–9.

Chamas A, Moon H, Zheng J, Qiu Y, Tabassum T, Jang JH, et al. Degradation rates of plastics in the environment. ACS Sustain Chem Eng. 2020;8:3494–511.

Manfra L, Marengo V, Libralato G, Costantini M, De Falco F, Cocca M. Biodegradable polymers: A real opportunity to solve marine plastic pollution? J Hazard Mater. 2021;416:125763.

Suzuki M, Tachibana Y, Kazahaya J, Takizawa R, Muroi F, Kasuya K. Difference in environmental degradability between poly(ethylene succinate) and poly(3-hydroxybutyrate). J Polym Res. 2017;24:217.

Haung Q, Kimura S, Iwata T. Development of self-degradable aliphatic polyesters by embedding lipases via melt extrusion. Polym Degrad Stab. 2021;191:109647.

Suzuki M, Tachibana Y, Soulenthone P, Suzuki T, Takeno H, Kasuya K. Control of marine biodegradation of an aliphatic polyester using endospores. Polym Degrad Stab. 2023;215:110466.

Tsutsuba T, Tachibana Y, Shimizu M, Kasuya K. Marine biodegradation of poly(butylene succinate) incorporating disulfide bonds triggered by a switch function in response to reductive stimuli. ACS Appl Polym Mater. 2023;5:2964–70.

Tachibana Y, Baba T, Kasuya K. Environmental biodegradation control of polymers by cleavage of disulfide bonds. Polym Degrad Stab. 2017;138:18–26.

Uchiyama M, Murakami Y, Satoh K, Kamigaito M. Synthesis and degradation of vinyl polymers with evenly distributed thioacetal bonds in main chains: cationic dt copolymerization of vinyl ethers and cyclic thioacetals. Angew Chem Int Ed. 2022;62:e202215021.

Kamiki R, Kubo T, Satoh K. Addition–fragmentation ring-opening polymerization of bio-based thiocarbonyl l-lactide for dual degradable vinyl copolymers. Macromol Rapid Commun. 2022;44:202200537.

Watanabe H, Kamigaito M. Direct radical copolymerizations of thioamides to generate vinyl polymers with degradable thioether bonds in the backbones. J Am Chem Soc. 2023;145:10948–53.

Kohsaka Y. Conjugate substitution reaction of α-(substituted methyl)acrylates in polymer chemistry. Polym J. 2020;52:1175–83.

Kohsaka Y, Nagai K. Degradable and curable poly(conjugated ester)s prepared by acryl- and conjugate-substitutions of the ‘smallest’ monomer. Eur Polym J. 2020;141:110049.

Kohsaka Y, Nagai K. Controls and effects of monomer junctions and sequences in curable and degradable polyarylate containing acrylate moieties. Macromol Rapid Commun. 2021;42:2000570.

Thompson R, Barclay T, Basu K, Mathias LJ. Facile synthesis and polymerization of ether substituted methacrylates. Polym J. 1995;27:325–38.

Kohsaka Y, Matsumoto Y, Kitayama T. α-(Aminomethyl)acrylate: polymerization and spontaneous post-polymerization modification of β-amino acid ester for a pH/temperature-responsive material. Polym Chem. 2015;6:5026–9.

Kohsaka Y, Nagatsuka N. End-reactive poly(tetrahydrofuran) for functionalization and graft copolymer synthesis via a conjugate substitution reaction. Polym J. 2020;52:75–81.

Habaue S, Shibagaki T, Okamoto Y. Polym J. 1999;31:942–7.

Evans RA, Moad G, Rizzardo E, Thang SH. New free-radical ring-opening acrylate monomers. Macromolecules. 1994;27:7935–7.

Kohsaka Y, Miyazaki T, Hagiwara K. Conjugate substitution and addition of α-substituted acrylate: a highly efficient, facile, convenient, and versatile approach to fabricate degradable polymers. Polym Chem. 2018;9:1610–7.

Kohsaka Y, Yamashita M, Matsuhashi Y, Yamashita S. Synthesis of poly(conjugated ester)s by ring-opening polymerization of cyclic hemiacetal ester bearing acryl skeleton. Eur Polym J. 2019;120:109185.

Zhuang J, Zhao B, Meng X, Schiffman JD, Perry SL, Vachet RW, et al. A programmable chemical switch based on triggerable Michael acceptors. Chem Sci. 2020;11:2103–11.

Xu Y-C, Ren W-M, Zhou H, Gu G-G, Lu X-B. Functionalized polyesters with tunable degradability prepared by controlled ring-opening (co)polymerization of lactones. Macromolecules. 2017;50:3131–42.

Sjöback R, Nygren J, Kubista M. Absorption and fluorescence properties of fluorescein. Spectrochim Acta A Mol Biomol Spectrosc. 1995;51:L7–21.

Goldberg RN, Kishore N, Lennen RM. Thermodynamic Quantities for the Ionization Reactions of buffers. J Phys Chem Ref Data. 2002;31:231–370.

Acknowledgements

This paper is based on results obtained from a project, JPNP18016, commissioned by the New Energy and Industrial Technology Development Organization (NEDO). 1,4-Butylene diacrylate (4) was a kind gift from Osaka Organic Chemical Industry Ltd.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Noda, T., Kitagawa, T. & Kohsaka, Y. Degradation of poly(conjugated ester)s using a conjugate substitution reaction with various amines and amino acids in aqueous media. Polym J 56, 343–351 (2024). https://doi.org/10.1038/s41428-023-00859-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00859-5