Abstract

Recent developments in materials showing photo-induced liquefaction and softening, including molecular materials, gels, and polymers, are described. A macrocyclic azobenzene molecule that has long alkoxy chains was first reported to show a photo-induced solid–liquid phase transition at room temperature through trans–cis photoisomerization. The structure–property relationship for understanding the photo-induced phase transition has since been investigated by using model compounds with a simple molecular design. Such azobenzene-based materials also exhibited dynamic motion on glass and water surfaces; these motions are driven by continuous liquefaction/crystallization and dissolution of the liquefied material. Photo-induced liquefaction has been further developed in middle molecular and polymeric materials. The effects of the alkyl chain length, functional groups, and number of azobenzene units on the photo-induced behavior have been extensively investigated. In addition, by using photoresponsive gelators, the photo-induced quasi-solid–liquid (gel–sol) phase transition of gels was accomplished. Moreover, very recently, a photoresponsive plasticizer that can plasticize “photo-inactive” polymers by light irradiation has been proposed.

Similar content being viewed by others

INTRODUCTION

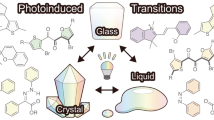

A chemical substance commonly exists in three states—solid, liquid, and gas. The transition between each state can usually be achieved by heating and cooling the substance. For example, H2O is a liquid (water) under the standard conditions for temperature and pressure. When heated above 100 °C, H2O changes its state from liquid to gas (vapor), while it freezes into a solid state (ice) when cooled below 0 °C. The melting point of a chemical substance is generally affected by its chemical properties, such as molecular weight, functional groups, and molecular shapes. Among these factors, molecular shapes significantly affect the melting point. For example, there are two isomers of 9-octadecenoic acid: elaidic acid (trans isomer) and oleic acid (cis isomer). Although the chemical formula of the two acids is the same (C18H34O2), elaidic acid and oleic acid are in solid and liquid states under normal conditions, respectively. A similar example is stilbene. The melting points of the trans and cis isomers of stilbene are markedly different, being 124 and 6 °C, respectively [1, 2]. Stilbene also has an intriguing character, which is photoisomerization [3]. Under irradiation with light of an appropriate wavelength, stilbene shows a reversible isomerization between the trans and cis forms. Therefore, an isothermal transition can be induced between the solid and liquid states of stilbene via photoisomerization and not by a thermal method. However, in the photoisomerization of stilbene, an irreversible oxidative side reaction that produces phenanthrene has often been observed [4]. Hence, it is practically difficult to induce such a photochemical solid–liquid transition in stilbene. Meanwhile, azobenzene is another compound that shows a reversible cis–trans photoisomerization without any serious side reactions (Fig. 1) [5, 6].

The photoisomerization of azobenzene and its derivatives is frequently used as a tool for photochemically modulating the structures and properties of soft materials, such as liquid crystals (LCs) and polymers. For instance, the orientations of LC molecules can be modulated in out-of-plane and in-plane directions by using a command surface, where azobenzene compounds are chemically or physically immobilized on solid substrates in sandwiched cells [7, 8]. Recently, a command surface was successfully developed from a free surface, in which azobenzene compounds were segregated at the interface between air and the material [9, 10]. When azobenzene derivatives are dissolved in LCs, multiple phase transitions such as nematic-isotropic and smectic Q-isotropic phase transitions can be isothermally controlled via photoisomerization (photochemical phase transition) [11,12,13,14]. In the case of polymeric materials, photo-mechanical behaviors in which polymer films show a variety of dynamic movements upon photoisomerization have been reported and proposed as a novel driving force for actuators [15,16,17]. Furthermore, the photofabrication of surface-relief gratings on azopolymers by means of holographic techniques has been widely studied by various research groups [18, 19]. In these studies, photo-induced fluidization and softening, where the trans–cis–trans photoisomerization cycle occurs, have been reported for several azopolymers and considered to be one of the possible mechanisms for the formation of surface-relief gratings [20,21,22,23,24,25,26]. Nevertheless, intensive discussions continue on the mechanisms [27, 28]. In recent years, the photo-induced liquefaction of a variety of materials, where a liquid state can be obtained even after terminating light irradiation, has become an emerging research field in materials science and technology because of its potential applications to photolithography, self-healing materials, and reworkable adhesives. In this article, recent studies on the photo-induced liquefaction and softening behaviors of molecular materials, polymers, and related compounds from the viewpoint of the photoisomerization of azobenzene compounds are reviewed.

Small molecular materials

First, we describe the molecular materials that contain azobenzene units, as well as their properties and applications. Molecular materials often exhibit a crystalline property in the solid state; thus, controlling the photochemical properties in crystalline phases is important. The melting points of trans and cis isomers of azobenzene are 68 and 71 °C, respectively [29]. The difference in the melting points is rather small in the case of azobenzene, and thus, it might be difficult to induce the transition between solid and liquid states by photoisomerization. In addition, the crystal packing prevents the azobenzene molecules from changing their molecular geometry. An IR analysis of a ground crystal of azobenzene revealed that photoisomerization from the trans-to-cis isomer does not occur in the solid state [29].

The surface of an azobenzene crystal, however, shows some indications of photoisomerization, such as morphological changes [30] and spectral changes for nanoparticles [31] of azobenzene crystals, indicating that the photoisomerization of azobenzene is possible on the crystal surface. Azobenzene molecules on the surface face a free space and should have more degrees of freedom to change their geometry from the trans-to-cis configuration, whereas the molecules inside the crystal lack the free volume required for isomerization. For azobenzene incorporated in a polymer matrix, the free volumes for isomerization were estimated as 0.12 [32] and 0.38 [33] nm3 for the inversion and rotation pathways, respectively. The effect of packing on isomerization was also investigated for a self-assembled monolayer of alkylthiol-functionalized azobenzene molecules [33].

Recently, the photo-induced solid–liquid phase transition has become of great research interest since the discovery of a phase transition in a macrocyclic azobenzene possessing long alkoxy chains 1, as shown in Fig. 2 [34,35,36]. The melting point of this compound is 100 °C, and it shows a liquid-crystalline phase of ~120 °C. Interestingly, at room temperature, this compound melts upon irradiation with ultraviolet (UV) light. At room temperature, 1 is in a crystalline phase, and the thin film of 1 exhibits birefringence under a polarizing optical microscope. Upon UV-light irradiation, the crystals lose their birefringence and convert into an isotropic (liquid) phase. On further irradiation with UV light, the isotropic phase converts into another crystal phase, which is assigned to the cis,cis-isomer. These phase transitions have been confirmed by the changes in X-ray diffraction patterns and absorption spectra upon photoirradiation.

The high photoresponsivity of the crystal of 1 compared with that of azobenzene is quite intriguing, and the single crystal structure was determined [36] to investigate the structure–property relationship in systems that exhibit a photo-induced crystal-to-liquid phase transition. At room temperature, the crystal of 1 shows the characteristic coexistence of structurally ordered chromophores through a one-dimensional network of π–π interactions and disordered alkyl chains. The phase transition occurs because of the trans-to-cis photoisomerization of the azobenzene moiety, involving the loss of the one-dimensional order of the π–π network.

The above-mentioned phase transition found in 1 is important from an application point of view because materials undergoing simple and drastic changes in their phases have potential applications in reworkable adhesives, reusable photoresists, and other functional materials. Because of the complex molecular structure and the difficulty in synthesizing 1 [34], a simplified molecular design was required to establish the structure–property relationship underlying the phase transition. A simple molecular design criterion was reported for molecules having a methyl group at the 3-position on rod-shaped azobenzene derivatives (Fig. 3) [37]. The introduction of a single methyl group onto one of the two benzene rings of azobenzene drastically alters the photo-induced phase transition behavior. In contrast, the azobenzene containing two methyl groups at 3- and 3′-positions and that containing no methyl groups did not show the phase transition. For example, the crystal of 2-C6 exhibited a photo-induced phase transition, yielding a liquid state. The viscosity of the liquid state was 460 mPa·s, and the liquid phase remained for ca. 1 h at room temperature in the dark. The melting temperature of photoirradiated 2-C6 was estimated as −6 °C. As the azobenzene derivative containing only one methyl group exhibited a higher photoresponsivity in the phase transition, the effect of chain length (Cn = 1–18) of the alkoxy groups at the 4- and 4′-positions was investigated [38]. It was found that alkyl chains with Cn = 6–10 showed a relatively fast phase transition.

As the deactivation process of the photoexcited molecules dissipate energy as heat, an increase in temperature cannot be avoided. The temperature increase of the crystal powder of the 2-Cn series was ~3 K upon irradiation at 200 mW cm−2, as measured by an infrared radiation thermometer [37]. In addition, an irradiation experiment with various intensities of UV light (5–408 mW cm−2) was carried out by using 2-C6 [38]. It was found that the photo-induced phase transition did not depend on light intensity, and a complete liquefaction was observed at the same total dose. Therefore, the heating effects are not the main reason for liquefaction, but the photoisomerization reaction is indeed the driving force for the phase transition.

Figure 4 shows other azobenzene-based molecular materials that demonstrate the photo-induced crystal–liquid phase transition. Han et al. reported that a rod-shaped amphiphilic azobenzene possessing a hydrophilic tetra(ethylene glycol) chain (3) exhibits the crystal-to-liquid phase transition [39]. The melting temperature of the trans isomer is 50 °C, and the two ethyl groups assumingly weaken the intermolecular π–π interactions between the aromatic rings. Credi and co-workers [40] designed tetra(azobenzene)methane compounds, which consist of four azobenzene units covalently linked to a tetrahedral carbon atom (4). These compounds form porous crystals, and irradiation with UV light converts them into a non-porous liquid phase. In addition, it was demonstrated that the crystals adsorb/release CO2 gas. Surprisingly, these compounds exhibited the phase transition even when the melting temperatures were above 300 °C. Kimizuka and co-workers [41] demonstrated that the photo-induced crystal-to-ionic liquid phase transition can be used to store photon energy by using cationic azobenzene derivatives (5).

There are numerous potential applications of materials that show the photo-induced phase transition. Currently, the promising potential applications are reworkable adhesives and reusable photoresists. The former is the main topic of the next section on middle- and macromolecular compounds. Such adhesion properties have also been demonstrated by low molecular weight azobenzene derivatives (2 with alkyl chain lengths from -C6 to -C18) [38]. The adhesion force was evaluated by the tensile lap-shear adhesive strength test (pulling test) of two thermally fused glass slides containing the sample compound. Irradiation with UV light liquefied the azobenzene, and the tensile shear strength values decreased to nearly zero. On the other hand, irradiation with visible light recovered the adhesion strength up to ca. 50 N cm−2. These adhesion forces are similar to that of a commercially available double-sided tape. These types of materials may be suitable for a temporary adhesive, and the adhesion force can be improved by molecular design including polymers.

In general, conventional photoresists are not reusable because they involve irreversible reactions such as photopolymerization, degradation, or cross-linking. For the development or washing processes in photolithography, significant amounts of acids and/or bases are used to remove the photoresists. By using phase-transition materials such as the azobenzenes described here, solid/liquid patterning on surfaces is possible, which would provide simple development processes, such as wiping, blowing, or washing. This is expected to be an environmentally friendly process because it would require only a few harsh reagents. Moreover, the material can be applied onto surfaces that are sensitive to acids and/or bases. The rod-shaped azobenzene 2-C10 has been used for photolithography processes involving copper [37] and biodegradable polymer surfaces [42]. The azobenzene 2-C10 has a good film-forming property on glass and copper surfaces [37]. Irradiation with UV light through a photomask can generate a solid/liquid pattern of the azobenzene film on a copper substrate. Etching of the copper substrate was then achieved by immersing the substrate (Fig. 5). It is interesting that the development (washing process to remove the liquefied azobenzene) and etching processes can be combined by optimizing the etching solution.

Biodegradable polymers are environmentally friendly materials, whose degradation is initiated by the action of hydrolytic enzymes of microorganisms. Ideally, biodegradable polymers should maintain their functions during use and degrade just after disposal. By using 2-C10 as a coating layer, it was shown that the enzymatic degradation of biodegradable polymers, such as poly(l-lactide) and poly(ε-caprolactone), can be switched on by UV-light irradiation [42]. The solid phase of 2-C10 prevents enzymes (proteinase K or lipase) from degrading the polymer layers. However, after UV-light irradiation, the enzymes begin to degrade the polymer surfaces.

By using azobenzenes with simple molecular structures, interesting motions of crystals on a glass surface [43] and water surface [44] were observed. The driving force of the crawling motion on a glass surface is presumably the continuous photo-induced phase transition between the crystal and liquid phases. When irradiated simultaneously with two different wavelengths (UV and visible lights) from different directions, crystals of 3,3′-dimethylazobenzene (6) crawl on a glass surface (Fig. 6) and can even climb vertical surfaces [43]. The motion is continuous, and the direction of the motion can be controlled by the position of the light sources. It is notable that special light sources, such as a laser, are not required. In addition, there is no need for any special treatment of the solid surface. The motion is likely caused by crystallization and melting taking place at the front and rear end of the crystal, respectively.

Crystals of 4-methoxyazobenzene move on a water surface when the crystals are irradiated by UV light [44]. The mechanism of this swimming motion is thought to be the liquefaction and subsequent dissolution of the cis isomer. As the crystals move away from the light source, the direction of motion can be controlled by the orientation of the light source. In addition, a photoresponsive boat was demonstrated, indicating that light can be used as a fuel for the boat. A filter paper containing the azobenzene was observed to move under irradiation, and the maximum speed was ~5 cm s−1.

Middle molecular and macromolecular materials

A characteristic of a relatively high molecular weight compound is that it shows a glass transition. We proposed a reworkable adhesive as one of the applications of photo-induced phase-transition materials [45,46,47,48]. For this purpose, it is useful to have the glass-transition characteristic. The reason is that the material rapidly solidifies without an alignment change, and the volume shrinkage is expected to be suppressed upon the liquid-to-solid phase transition. There is a discussion as to whether the vitreous state is a solid or not; however, it is reasonable to treat the material as a solid because it behaves as an elastic body. The azobenzene moiety in the trans state is a conjugate unit with high planarity and is intrinsically disposed to aggregate. It is known that many of the polymers formed by connecting multiple azobenzene units have liquid crystallinity [49,50,51,52]. Such an ordered structure affects the phase change behavior, as is described later.

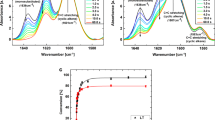

The photo-induced phase transition in macromolecules, as well as in low molecular weight compounds, is significantly affected by alkyl chain length [45]. Figure 7 shows azobenzene-containing macromolecules whose backbones are acrylates. All of these polymers are obtained as solids. The azobenzene moiety of the as-prepared polymers is a thermally stable trans state. Upon irradiation with UV light, these polymers darken due to isomerization to the cis state. Polymers with short alkyl chains (7-C4) are less flowable with no change in shape. When the alkyl chain length becomes longer (m ≥ 6), the polymers liquefy upon light irradiation and their shape changes to droplets. Among these, the longest alkyl-chained polymer (7-C12), in which plastic deformation was observed under stress, is a soft solid. All of the photoliquefied samples can solidify upon irradiation with visible light. Zhou et al. [53] reported that the polyacrylates (8 and 9) and methacrylate (10) with azobenzene side chains shown in Fig. 8 liquefied and solidified under light irradiation, however, not the nitroazobenzene polymer (11). The phase transition was confirmed by using a piezorheometer.

There are limitations in controlling the molecular weight distribution, terminal structure, and purity of polymeric materials. A polyvalent azobenzene compound having a sugar-alcohol scaffold whose structure is strictly controllable has a similar structure to that of a side-chain-type polymer. Therefore, there is an advantage in that it is easy to correlate the molecular structure and phase transition behavior. First, the effect of the number of azobenzene groups was investigated (Fig. 9) [48]. Interestingly, photoisomerization does not progress in compounds with monomer or dimer structures (12 and 13), and the photo-induced solid–liquid phase transition does not occur. As these compounds have a high crystallinity, it was considered that there is an absence of free volume required for isomerization. In contrast, trimers or higher oligomers (14–16) show the photo-induced phase transition. Zha et al. [54] reported that monodispersed siloxane oligomers bearing azobenzene units at both ends (17 and 18), as shown in Fig. 10, undergo a rapid thermal solid-to-liquid transition, which can be reversed using blue light because of the unexpectedly fast two-dimensional crystallization that is facilitated by phase segregation. In this class of compounds, isomerization became possible probably due to the introduction of soft siloxane chains.

The effect of alkyl chain length was investigated using a hexameric-structured compound. Four different types were compared (Fig. 11) [46]. Among them, the compound having no alkyl end group and a short spacer (19: p = 5, q = 0) remained in the solid state after isomerization. On the other hand, the compound having an alkyl terminus and a long spacer (16: p = 10, q = 5) exhibited the highest glass-transition temperature (80 °C) and liquefied and solidified upon irradiation with UV and visible light, respectively. The other two compounds (20: p = 5, q = 5; and 21: p = 10, q = 0) also liquefied and solidified in response to light irradiation; however, the thermal transition temperatures between liquid and solid were 50–70 °C. Interestingly, the thermal transition temperature of 19, which does not undergo the photo-induced phase transition, is also low (50 °C). To clarify this, the order property of the azobenzene moiety was estimated from the UV–visible absorption spectra of the thin films of 16 and 19. It was found that 16, which has a long alkyl chain, had a greater contribution from aggregates; while 19, with the smallest alkyl chains, was nearly amorphous with a lesser contribution from the aggregates. That is, the reason for the high glass-transition temperature is that the mobility of the entire molecule is restricted by the aggregated azobenzene moiety. This implies that trans-azobenzene moieties with long alkyl chains (high degrees of freedom) can easily aggregate. However, when azobenzene changes to a bent cis structure, the bent structure interrupts the formation of aggregates, and the compound liquefies because of the high degrees of freedom of the long alkyl chains. On the other hand, the compounds of azobenzene having short alkyl chains have low degrees of freedom in the first place and are not liquefied regardless of the trans or cis state. d-Sorbitol and allitol (22 and 23), which have different stereostructures, as shown in Fig. 12, were used as central scaffolds instead of d-mannitol, where azobenzene moieties corresponding to 16 shown in Fig. 11 were used. These hexameric compounds showed a similar liquid crystal phase transition at a similar transition temperature to those of the d-mannitol derivative and exhibited the reversible liquid-solid phase transition in any case. The only difference appeared in the glass-transition temperature, which was 80 °C for the d-mannitol derivative (16), 70 °C for the d-sorbitol derivative (22), and 60 °C for the allitol derivative (23) [47]. This implies that the difference in configuration of the sugar-alcohol scaffold corresponding to the main chain in a polymer affects the thermodynamic properties.

Other related materials

In previous sections, we reviewed the photochemical solid–liquid transition of a variety of materials containing azobenzene units. In this section, other photo-induced changes such as gel–sol (quasi-solid–liquid) and glass–rubber transitions are described. Gels have infinite 3-dimensional internal networks constructed through the chemical bonding or physical aggregation of gelators, including low molecular weight compounds and polymers. A variety of liquids, such as water and organic solvents, can be converted to quasi-solids by using the appropriate gelators. By changing the physical aggregation of a gelator by an external stimulus, the structure of the gel can be dynamically controlled. Figure 13 shows low molecular weight gelators containing azobenzene units [55,56,57]. Zhang and co-workers [55] investigated the gelation behaviors of dicholeterol-linked photoresponsive gelators 24–26 using a variety of organic solvents. They demonstrated that the cyclopentanone gel using 25 exhibited the reversible gel–sol transition upon irradiation with UV and visible light. The change in molecular polarity of 25 because of the trans–cis photoisomerization leads to the breaking of van der Waals interactions between the gelator, resulting in the gel–sol transition. On the other hand, photoresponsive organic salt gelators 27–31 showed the photo-induced reversible gel–sol transition in acetonitrile gels [56]. In that study, the authors revealed that the response time of the gel–sol transition was affected by the chemical structure of the amino acid units, which affected the aggregation mode of the azobenzene units (J-aggregate for 27, 28 and H-aggregate for 29–31). In addition, a gelator containing hydrazide and azobenzene units 32 formed self-assembled globular aggregates through both intermolecular hydrogen bonding and π–π stacking interactions. Furthermore, tetrahydrofuran gels using 32 exhibited the photo-induced gel–sol transition [57]. The photoreversible gel–sol transition was also investigated for block copolymers in ionic liquids [58,59,60]. An ionic gel using a tetra-arm diblock copolymer containing azobenzene groups was successfully applied to photo-healing materials using the photo-induced gel–sol transition [58]. Meanwhile, Kato et al. reported the photochemical transition between gel and sol states by using a photoresponsive gelator in liquid-crystalline solvents, as well as non-liquid-crystalline solvents [61,62,63,64]. For example, liquid-crystalline mixtures containing the photoresponsive gelator 33 form nematic LC gels in the initial state. Upon exposure of the nematic mixtures to UV light, the mixtures change their structures from the nematic gel state to the cholesteric sol state because of the dissociation of the gelator hydrogen bonds and the dissolution of chiral gelator 33 into a nematic LC [61]. The cholesteric sol state converted into the cholesteric gel state upon visible-light irradiation. The authors proposed that such a photochemical gel–sol transition will be applicable to a wide range of fields such as optics, photonics, and molecular electronics [62].

In liquid-crystalline physical gels, the photo-induced gel–sol transition can be achieved by changing the phase structure of LC media, as well as the physical aggregation of gelators. Mixtures of microparticles and LCs containing azobenzene derivatives (microparticle/azo-doped LC composites) exhibit the gel state when the azo-doped LCs show a liquid-crystalline phase [65]. The microparticles consist of polymerized divinylbenzene and have the role of a non-photoresponsive gelator in the mixtures. Although the microparticles are homogeneously dispersed in the LC media as an isotropic phase, network structures are formed with microparticles because of the elastic properties of LCs upon the phase transition from the isotropic phase into the liquid-crystalline phase. Meanwhile, by changing the phase structure of the azo-doped LCs from a liquid-crystalline phase to an isotropic phase by means of the photochemical phase transition, the gel state of the composites is transformed into the sol state because of the redispersion of the microparticles in the isotropic phase (Fig. 14) [65]. Using the photochemical gel–sol transition, photoresponsive self-healing materials have been successfully developed (Fig. 15) [65]. A small cut is made on the surface of a microparticle/azo-doped LC composite (Fig. 15a), and the surface damage is locally irradiated with UV light to induce the gel-to-sol transition by the photochemical nematic-to-isotropic phase transition of the azo-doped LC matrix (Fig. 15b). The resulting suspension pours into the cut when the damaged area is located inside the photoirradiated area, indicating that the cut is healed. The photochemical healing is completed by the reconstruction of the network structure with homogeneously redispersed particles after the exposure of the healed area to the appropriate visible light, which induced the photochemical phase transition of the UV-light-induced isotropic phase into the initial liquid-crystalline phase (Fig. 15c). Furthermore, in liquid crystals, photochemical control of the gel–sol transition by changing the physical properties of the matrix was recently reported in a mixture of a non-photoresponsive polymer and an azobenzene ionic liquid by Watanabe and co-workers [66].

The mechanical properties of the microparticle/azo-doped LC composite can be tuned by changing the concentration of microparticles and the phase structure of the LC medium [65, 67]. Furthermore, by introducing polymer chains on the particle surface, the mechanical strength of the microparticle/azo-doped LC composites against applied stress could be remarkably improved [68]. At the same time, polymer-reinforced photoresponsive composites exhibited dual self-healing abilities (light-assisted mending of surface cracks and spontaneous repairing of surface dents) [68]. Apart from the photochemical gel–sol transition, the polymer-reinforced composites exhibited photo-induced changes in their optical transparency while retaining the stable gel state [69]. This will be useful for the development of self-supporting photonic materials.

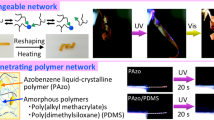

As described in the previous sections, intensive research for the development of materials showing the photo-induced phase transition has been conducted in recent years. However, azobenzene-based polymeric materials showing photo-induced softening and liquefaction are still rare. Therefore, the development of photoresponsive plasticizers applicable to “photo-inactive” general-purpose polymers will greatly expand the diversity of materials that show such photo-induced effects. From this point of view, the plasticization effect of LCs is useful for the development of photoresponsive plasticizers. Up to a certain critical composition, LCs are molecularly mixed with polymers and act as a plasticizer [70]. However, once a LC phase separates from the polymer above a critical composition, the phase-separated LC forms a liquid-crystalline phase and never shows a plasticization effect. This situation implies that such systems contain a certain quantity of phase-separated LCs with the potential ability to serve as a plasticizer. If one can render the phase-separated LCs miscible with polymers by appropriate isothermal techniques, the phase-separated LCs will act as an additional plasticizer. As an approach to develop photoresponsive plasticizers, it is presumed that the phase-separated LCs could exhibit the plasticization effect by photochemically changing their phase structures from the liquid-crystalline phase to an isotropic phase. This hypothesis was recently demonstrated in mixtures of poly(methyl methacrylate) and a photoresponsive plasticizer 34 consisting of a nematic LC and an azobenzene derivative, as shown in Fig. 16a [71]. In phase-separated mixtures, a photo-induced softening could be observed upon UV-light irradiation (Fig. 16b), which induced the photochemical nematic-to-isotropic phase transition of 34, thereby improving the miscibility between the polymer and the azo-doped LC (Fig. 16c). Under optimized conditions, the photo-induced glass–rubber transition was accomplished. Photosoftening by means of photoresponsive plasticizers will greatly contribute to the development of novel photo-healing materials and reworkable materials because a variety of photo-inactive general-purpose polymers can be employed.

Conclusion

We have summarized the recent research on the photo-induced liquefaction and softening of molecular materials, polymers, and other related compounds containing azobenzene units. Although the states of matter are generally controlled by using the thermal method (heating and cooling), some azobenzene-based materials also exhibit isothermal solid–liquid, gel–sol, and glass–rubber phase transitions resulting from the photochemical change in the molecular shape of azobenzene units, i.e., trans–cis photoisomerization. From the structure–property relationship of the photo-induced solid–liquid phase transition, it is seen that the chemical structures that affect the assembling states of azobenzene units significantly influence the photoresponsivity. In these phase transition behaviors, the photo-induced change in intermolecular interactions, such as π–π interactions induced by photoisomerization, is a common key point. Recently, photo-induced liquefaction and softening have attracted increasing attention in materials science and technology. At this stage, the azobenzene moiety is a main photoresponsive contender. However, these research fields can be greatly developed by employing other photoresponsive units. Then, such photo-induced phase-transition materials will open the door to novel applications such as gas and photon energy-storage materials, reusable and environmentally friendly photoresists, reworkable adhesives, and self-healing materials.

References

Brackman DS, Plesch PH. Some physical properties of cis-stilbene. J. Chem. Soc. 1952;2188–90.

Young WR, Aviram A, Cox RJ. Stilbene derivatives—new class of room-temperature nematic liquids. J Am Chem Soc. 1972;94:3976–81.

Waldeck DH. Photoisomerization dynamics of stilbenes. Chem Rev. 1991;91:415–36.

Moore WM, Morgan DD, Stermitz FR. Photochemical conversion of stilbene to phenanthrene—nature of intermediate. J Am Chem Soc. 1963;85:829–30.

Kumar GS, Neckers DC. Photochemistry of azobenzene-containing polymers. Chem Rev. 1989;89:1915–25.

Bandara HMD, Burdette SC. Photoisomerization in different classes of azobenzene. Chem Soc Rev. 2012;41:1809–25.

Ichimura K, Suzuki Y, Seki T, Hosoki A, Aoki K. Reversible change in alignment mode of nematic liquid-crystals regulated photochemically by command surfaces modified with an azobenzene monolayer. Langmuir. 1988;4:1214–6.

Seki T, Tamaki T, Suzuki Y, Kawanishi Y, Ichimura K, Aoki K. Photochemical alignment regulation of a nematic liquid-crystal by langmuir-blodgett layers of azobenzene polymers as command surfaces. Macromolecules. 1989;22:3505–6.

Fukuhara K, Nagano S, Hara M, Seki T. Free-surface molecular command systems for photoalignment of liquid crystalline materials. Nat Commun. 2014;5:3320.

Nakai T, Tanaka D, Hara M, Nagano S, Seki T. Free surface command layer for photoswitchable out-of-plane alignment control in liquid crystalline polymer films. Langmuir. 2016;32:909–14.

Tazuke S, Kurihara S, Ikeda T. Amplified image recording in liquid-crystal media by means of photochemically triggered phase transition. Chem Lett. 1987;16:911–14.

Ikeda T, Tsutsumi O. Optical switching and image storage by means of azobenzene liquid-crystal films. Science. 1995;268:1873–5.

Ikeda T. Photomodulation of liquid crystal orientations for photonic applications. J Mater Chem. 2003;13:2037–57.

Yamamoto T, Nishiyama I, Yokoyama H. Novel photo-induced phase transition observed in three-dimensional liquid-crystalline phase of azobenzene compound. Chem Lett. 2007;36:1108–9.

Ikeda T, Nakano M, Yu YL, Tsutsumi O, Kanazawa A. Anisotropic bending and unbending behavior of azobenzene liquid-crystalline gels by light exposure. Adv Mater. 2003;15:201–5.

Ube T, Takado K, Ikeda T. Photomobile materials with interpenetrating polymer networks composed of liquid-crystalline and amorphous polymers. J Mater Chem C. 2015;3:8006–9.

Ube T, Kawasaki K, Ikeda T. Photomobile liquid-crystalline elastomers with rearrangeable networks. Adv Mater. 2016;28:8212–7.

Kim DY, Tripathy SK, Li L, Kumar J. Laser-induced holographic surface-relief gratings on nonlinear-optical polymer-films. Angew Chem Int Ed. 1995;66:1166–8.

Rochon P, Batalla E, Natansohn A. Optically induced surface gratings on azoaromatic polymer-films. Angew Chem Int Ed. 1995;66:136–8.

Viswanathan NK, Balasubramanian S, Li L, Kumar J, Tripathy SK. Surface-initiated mechanism for the formation of relief gratings on azo-polymer films. J Phys Chem B. 1998;102:6064–70.

Srikhirin T, Laschitsch A, Neher D, Johannsmann D. Light-induced softening of azobenzene dye-doped polymer films probed with quartz crystal resonators. Angew Chem Int Ed. 2000;77:963–5.

Kim HK, Wang XS, Fujita Y, Sudo A, Nishida H, Fujii M, Endo T. Reversible photo-mechanical switching behavior of azobenzene-containing semi-interpenetrating network under UV and visible light irradiation. Macromol Chem Phys. 2005;206:2106–11.

Mechau N, Saphiannikova M, Neher D. Dielectric and mechanical properties of azobenzene polymer layers under visible and ultraviolet irradiation. Macromolecules. 2005;38:3894–902.

Yang K, Yang SZ, Kumar, J. Formation mechanism of surface relief structures on amorphous azopolymer films. Phys. Rev. B 2006;73:165204 (2006).

Shimamura A, Priimagi A, Mamiya J, Ikeda T, Yu YL, Barrett CJ, Shishido A. Simultaneous analysis of optical and mechanical properties of cross-linked azobenzene-containing liquid-crystalline polymer films. ACS Appl Mater Interfaces. 2011;3:4190–6.

Karageorgiev P, Neher D, Schulz B, Stiller B, Pietsch U, Giersig M, Brehmer L. From anisotropic photo-fluidity towards nanomanipulation in the optical near-field. Nat Mater. 2005;4:699–703.

Sava E, Simionescu B, Hurduc N, Sava I. Considerations on the surface relief grating formation mechanism in case of azo-polymers, using pulse laser irradiation method. Opt Mater. 2016;53:174–80.

Kim CB, Wistrom JC, Ha H, Zhou SX, Katsumata R, Jones AR, Janes DW, Miller KM, Ellison CJ. Marangoni instability driven surface relief grating in an azobenzene-containing polymer film. Macromolecules. 2016;49:7069–76.

Tsuda M, Kuratani K. Isomerization of cis-azobenzene in the solid phase. Bull Chem Soc Jpn. 1964;37:1284–8.

Nakayama K, Jiang L, Iyoda T, Hashimoto K, Fujishima A. Photo-induced structural transformation on the surface of azobenzene crystals. Jpn J Appl Phys. 1997;36:3898–902.

Ichimura K. Reversible photoisomerisability and particle size changes of mill-dispersed azobenzene crystals in water. Chem. Commun. 2009;1496–8.

Naito T, Horie K, Mita I. Photochemistry in polymer solids. The effects of the size of reaction groups and the mode of photoisomerization on photochromic reactions in polycarbonate film. Macromolecules. 1991;24:2907–11.

Lamarre L, Sung CSP. Studies of physical aging and molecular-motion by azochromophoric labels attached to the main chains of amorphous polymers. Macromolecules. 1983;16:1729–36.

Norikane Y, Hirai Y, Yoshida M. Photo-induced isothermal phase transitions of liquid-crystalline macrocyclic azobenzenes. Chem Commun. 2011;47:1770–2.

Uchida E, Sakaki K, Nakamura Y, Azumi R, Hirai Y, Akiyama H, Yoshida M, Norikane Y. Control of the orientation and photo-induced phase transitions of macrocyclic azobenzene. Chem Eur J. 2013;19:17391–7.

Hoshino M, Uchida E, Norikane Y, Azumi R, Nozawa S, Tomita A, Sato T, Adachi S, Koshihara S. Crystal melting by light: X-ray crystal structure analysis of an azo crystal showing photoinduced crystal-melt transition. J Am Chem Soc. 2014;136:9158–64.

Norikane Y, Uchida E, Tanaka S, Fujiwara K, Koyama E, Azumi R, Akiyama H, Kihara H, Yoshida M. Photoinduced crystal-to-liquid phase transitions of azobenzene derivatives and their application in photolithography processes through a solid-liquid patterning. Org Lett. 2014;16:5012–5.

Norikane Y, Uchida E, Tanaka S, Fujiwara K, Nagai H, Akiyama H. Photoinduced phase transitions in rod-shaped azobenzene with different alkyl chain length. J Photopolym Sci Technol. 2016;29:149–57.

Okui Y, Han MN. Rational design of light-directed dynamic spheres. Chem Commun. 2012;48:11763–5.

Baroncini M, d’Agostino S, Bergamini G, Ceroni P, Comotti A, Sozzani P, Bassanetti I, Grepioni F, Hernandez TM, Silvi S, Venturi M, Credi A. Photoinduced reversible switching of porosity in molecular crystals based on star-shaped azobenzene tetramers. Nat Chem. 2015;7:634–40.

Ishiba K, Morikawa M, Chikara C, Yamada T, Iwase K, Kawakita M, Kimizuka N. Photoliquefiable ionic crystals: a phase crossover approach for photon energy storage materials with functional multiplicity. Angew Chem Int Ed. 2015;54:1532–6.

Kikkawa Y, Tanaka S, Norikane Y. Photo-triggered enzymatic degradation of biodegradable polymers. RSC Adv. 2017;7:55720–4.

Uchida E, Azumi R, Norikane Y. Light-induced crawling of crystals on a glass surface. Nat Commun. 2015;6:7310.

Norikane Y, Tanaka S, Uchida E. Azobenzene crystals swim on water surface triggered by light. CrystEngComm. 2016;18:7225–8.

Akiyama H, Fukata T, Yamashita A, Yoshida M, Kihara H. Reworkable adhesives composed of photoresponsive azobenzene polymer for glass substrates. J Adhes. 2017;93:823–30.

Akiyama H, Kanazawa S, Okuyama Y, Yoshida M, Kihara H, Nagai H, Norikane Y, Azumi R. Photochemically reversible liquefaction and solidification of multiazobenzene sugar-alcohol derivatives and application to reworkable adhesives. ACS Appl Mater Interfaces. 2014;6:7933–41.

Akiyama H, Kanazawa S, Yoshida M, Kihara H, Nagai H, Norikane Y, Azumi R. Photochemical liquid-solid transitions in multi-dye compounds. Mol Cryst Liq Cryst. 2014;604:64–70.

Akiyama H, Yoshida M. Photochemically reversible liquefaction and solidification of single compounds based on a sugar alcohol scaffold with multi azo-arms. Adv Mater. 2012;24:2353–6.

Ichimura K. Photoalignment of liquid-crystal systems. Chem Rev. 2000;100:1847–73.

Seki T. New strategies and implications for the photoalignment of liquid crystalline polymers. Polym J. 2014;46:751–68.

Shibaev VP, Bobrovsky AY. Liquid crystalline polymers: development trends and photocontrollable materials. Russ Chem Rev. 2017;86:1024–72.

Shishido A. Rewritable holograms based on azobenzene-containing liquid-crystalline polymers. Polym J. 2010;42:525–33.

Zhou HW, Xue CG, Weis P, Suzuki Y, Huang SL, Koynov K, Auernhammer GK, Berger R, Butt HJ, Wu S. Photoswitching of glass transition temperatures of azobenzene-containing polymers induces reversible solid-to-liquid transitions. Nat Chem. 2017;9:145–51.

Zha RH, Vantomme G, Berrocal JA, Gosens R, de Waal B, Meskers S, Meijer EW. Photoswitchable nanomaterials based on hierarchically organized siloxane oligomers. Adv Funct Mater. 2018;28:1703952.

Wu YP, Wu S, Tian XJ, Wang X, Wu WX, Zou G, Zhang QJ. Photoinduced reversible gel-sol transitions of dicholesterol-linked azobenzene derivatives through breaking and reforming of van der Waals interactions. Soft Matter. 2011;7:716–21.

Suzuki M, Maruyama Y, Hanabusa K. Gel-solution phase transition of organogels with photoreversibility: l-amino acid organogelators with azobenzene. Tetrahedron Lett. 2016;57:3540–3.

Bai BL, Zhang MG, Wei J, Yan HY, Wang HT, Wu YQ, Li M. Stimuli-responsive organogels based on a gelator of hydrazide and azobenzene units connected via a flexible central spacer. Tetrahedron. 2016;72:5363–8.

Ma XF, Usui R, Kitazawa Y, Kokubo H, Watanabe M. Photo-healable ion gel with improved mechanical properties using a tetra-arm diblock copolymer containing azobenzene groups. Polymers. 2015;78:42–50.

Ueki T, Nakamura Y, Usui R, Kitazawa Y, So S, Lodge TP, Watanabe M. Photoreversible gelation of a triblock copolymer in an ionic liquid. Angew Chem Int Ed. 2015;54:3018–22.

Ma XF, Usui R, Kitazawa Y, Tamate R, Kokubo H, Watanabe M. Physicochemical characterization of a photoinduced sol-gel transition of an azobenzene-containing ABA triblock copolymer/ionic liquid system. Macromolecules. 2017;50:6788–95.

Moriyama M, Mizoshita N, Yokota T, Kishimoto K, Kato T. Photoresponsive anisotropic soft solids: liquid-crystalline physical gels based on a chiral photochromic gelator. Adv Mater. 2003;15:1335–8.

Moriyama M, Mizoshita N, Kato T. Photopatterning of discotic liquid-crystalline gels. Polym J. 2004;36:661–4.

Moriyama M, Mizoshita N, Kato T. Reversible on-off photo-switching of hydrogen bonding for self-assembled fibers comprising physical gels. Bull Chem Soc Jpn. 2006;79:962–4.

Kato T, Hirai Y, Nakaso S, Moriyama M. Liquid-crystalline physical gels. Chem Soc Rev. 2007;36:1857–67.

Yamamoto T, Yoshida M. Viscoelastic and photoresponsive properties of microparticle/liquid-crystal composite gels: tunable mechanical strength along with rapid-recovery nature and photochemical surface healing using an azobenzene dopant. Langmuir. 2012;28:8463–9.

Wang C, Hashimoto K, Tamate R, Kokubo H, Watanabe M. Controlled sol-gel transitions of a thermoresponsive polymer in a photoswitchable azobenzene ionic liquid as a molecular trigger. Angew Chem Int Ed. 2018;57:227–30.

Yamamoto T, Kawata Y, Yoshida M. Contrasting roles of layered structures in the molecular assembly of liquid crystal matrices on the viscoelastic properties of microparticle/liquid crystal composite gels leading to rigidification and destabilization. J Colloid Interf Sci. 2013;397:131–6.

Kawata Y, Yamamoto T, Kihara H, Ohno K. Dual self-healing abilities of composite gels consisting of polymer-brush-afforded particles and an azobenzene-doped liquid crystal. ACS Appl Mater Interfaces. 2015;7:4185–91.

Kawata Y, Yamamoto T, Kihara H, Yamamura Y, Saito K, Ohno K. Three gel states of colloidal composites consisting of polymer-brush-afforded silica particles and a nematic liquid crystal with distinct viscoelastic and optical properties. ACS Appl Mater Interfaces. 2016;8:29649–57.

Ahn W, Kim CY, Kim H, Kim SC. Phase-behavior of polymer liquid-crystal blends. Macromolecules. 1992;25:5002–7.

Yamamoto T, Hasegawa R, Kawata Y, Kihara H, Naga N. Photoplasticization effect of an azobenzene-doped liquid crystal depending on phase structures. Chem Lett. 2018;47:272–5.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Yamamoto, T., Norikane, Y. & Akiyama, H. Photochemical liquefaction and softening in molecular materials, polymers, and related compounds. Polym J 50, 551–562 (2018). https://doi.org/10.1038/s41428-018-0064-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0064-4

This article is cited by

-

Recent progress in photoinduced transitions between the solid, glass, and liquid states based on molecular photoswitches

Polymer Journal (2024)

-

Development of heat-responsive adhesive materials that are stable during use and quickly deteriorate during dismantling

Polymer Journal (2024)

-

Aggregation States of Poly(4-methylpentene-1) at a Solid Interface

Polymer Journal (2019)